Design Strategies for Stack-Based Piezoelectric Energy Harvesters near Bridge Bearings

Abstract

1. Introduction

2. Materials and Methods

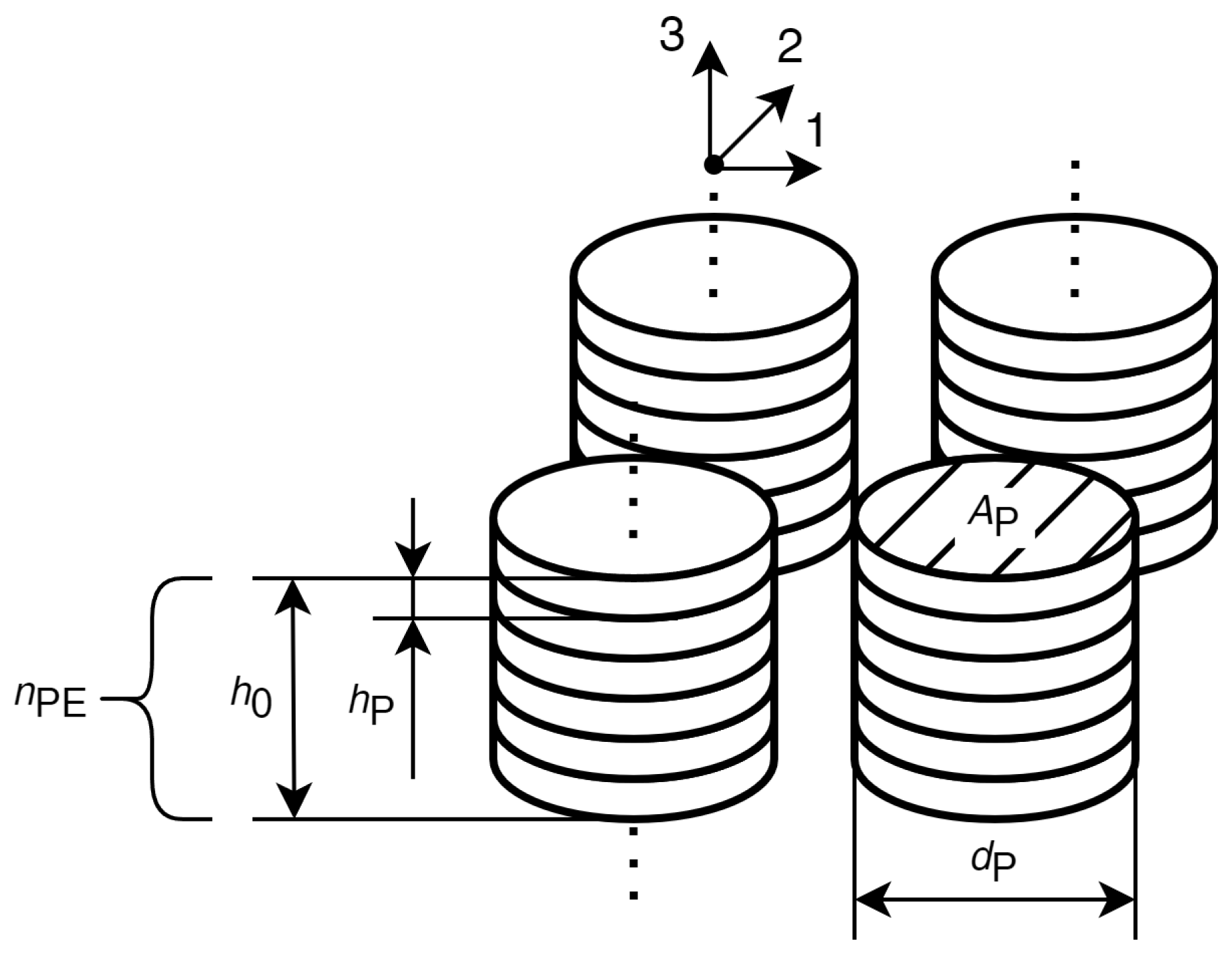

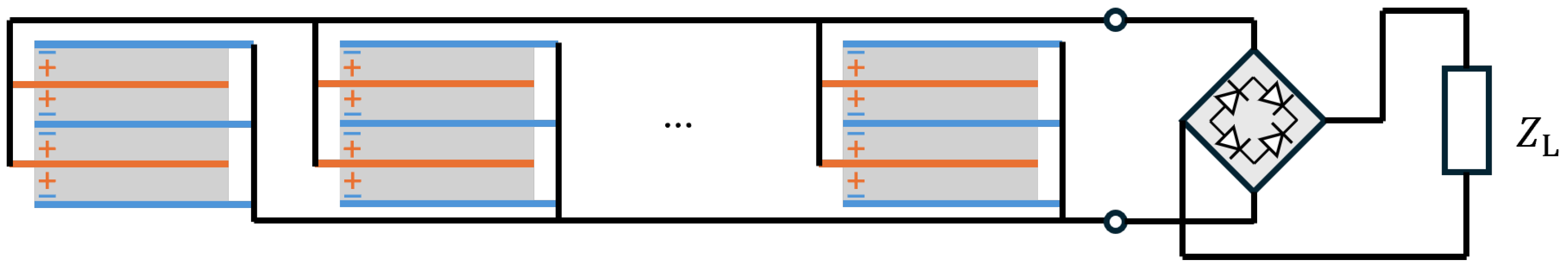

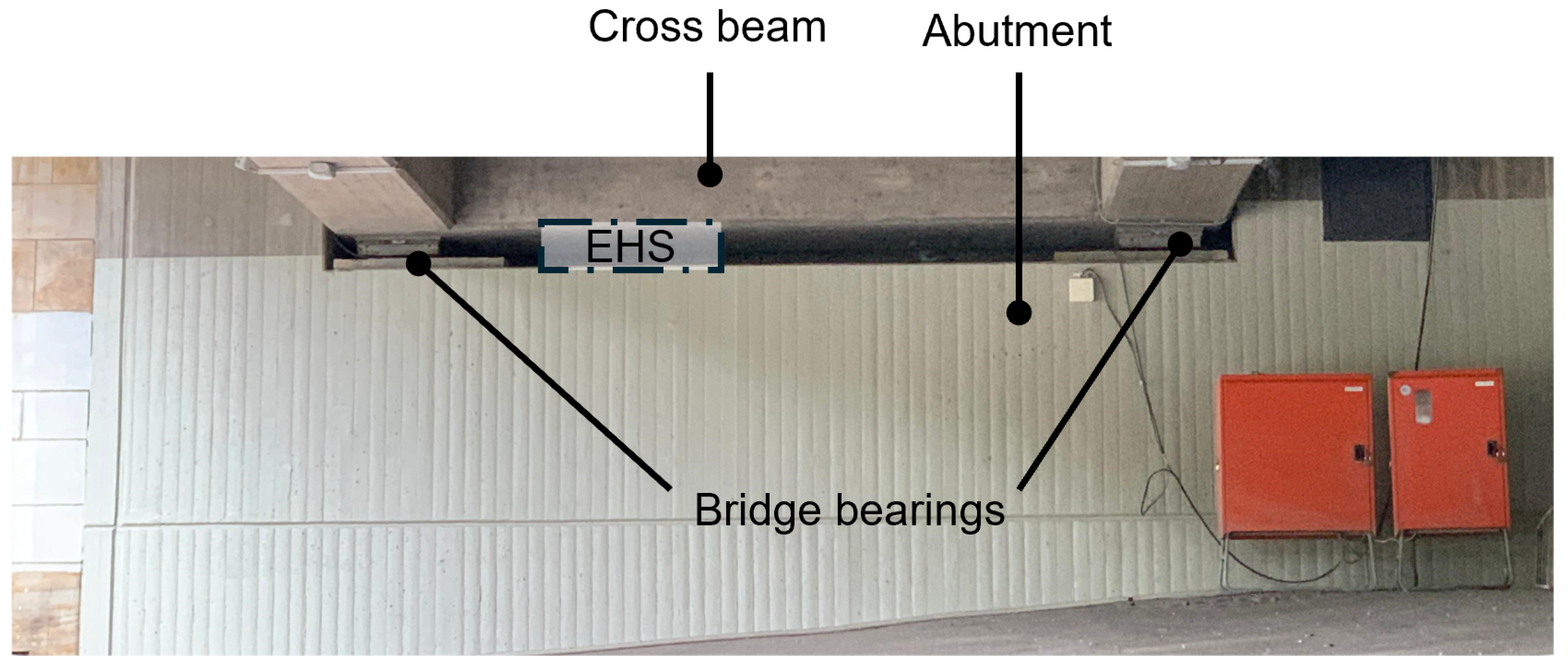

2.1. System Structure

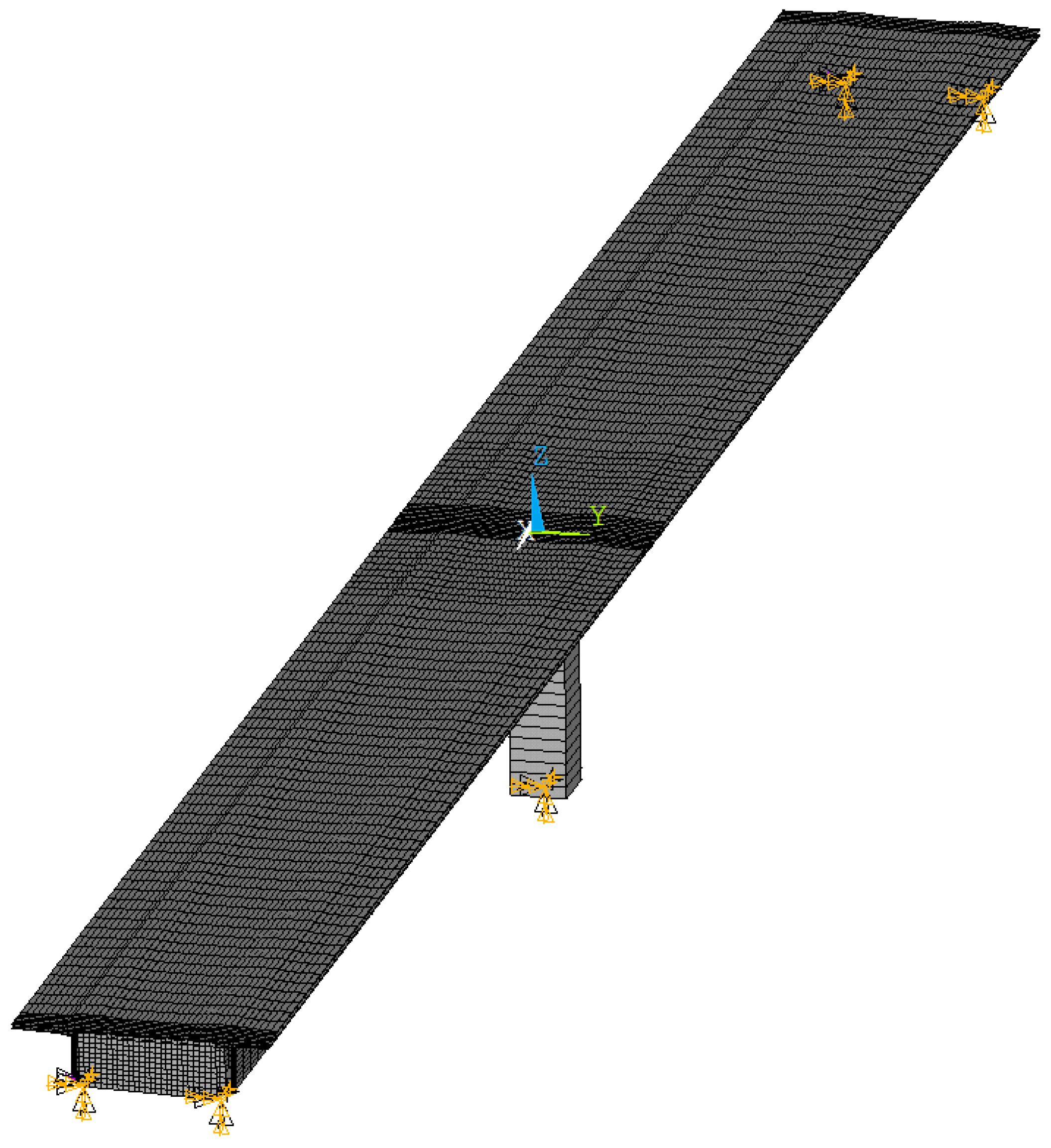

2.2. Mechanical Modelling

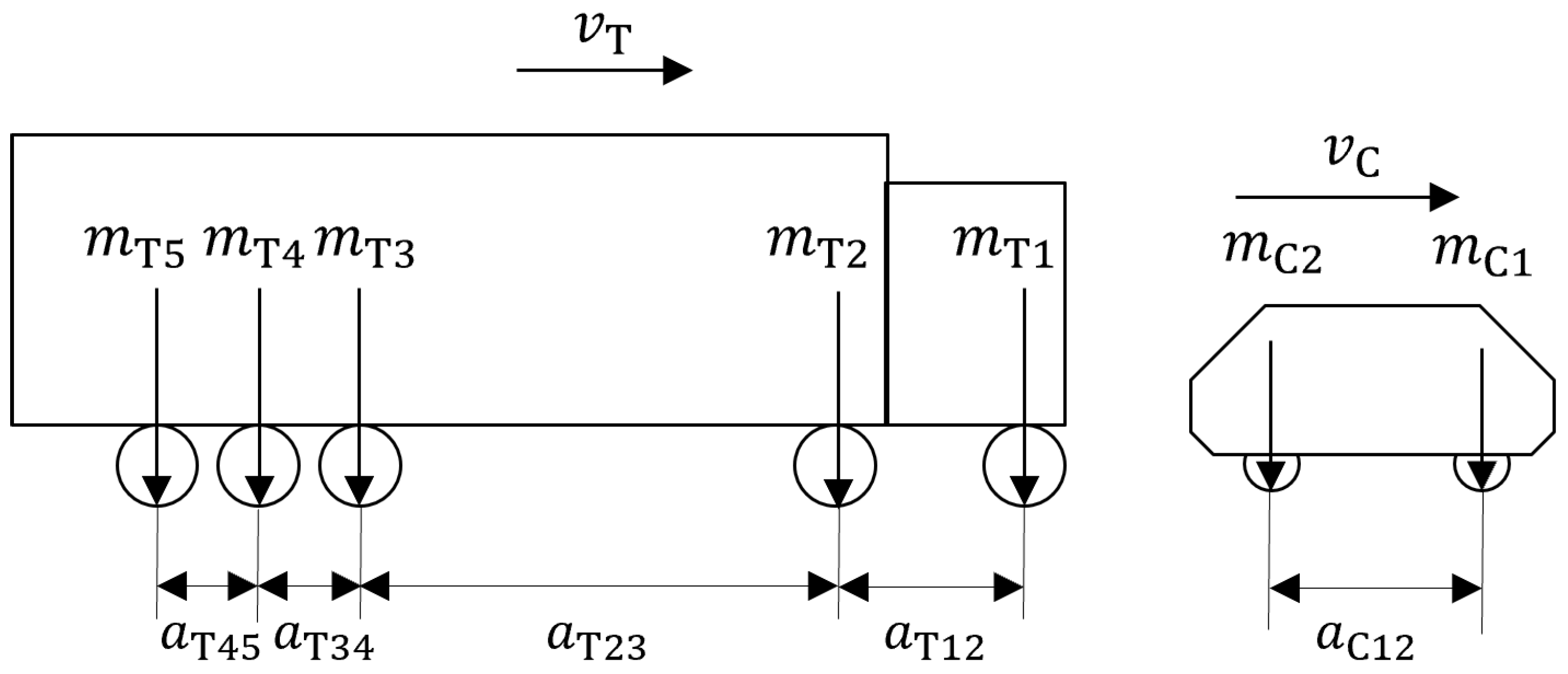

2.2.1. Excitation

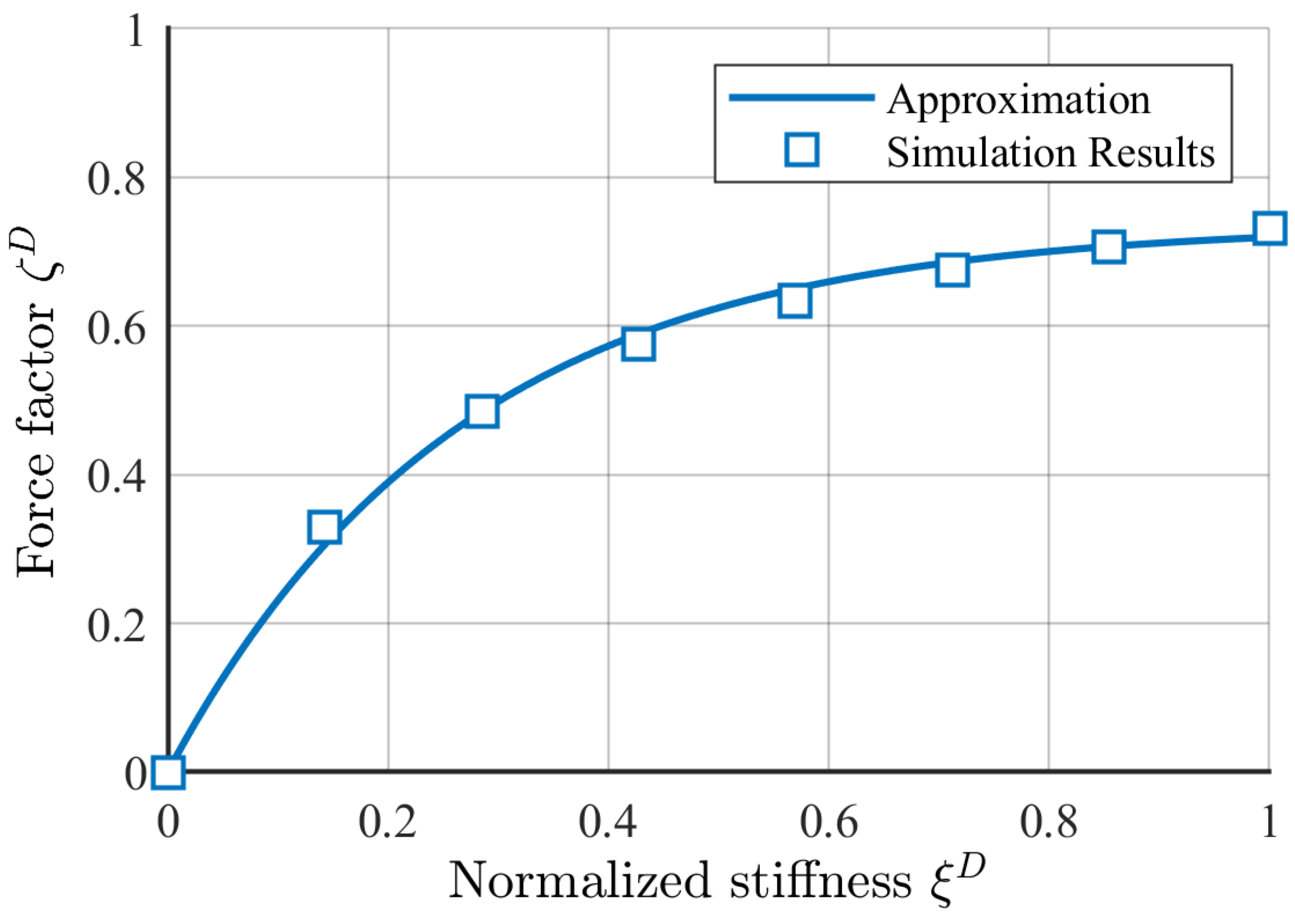

2.2.2. Interpolation Based on the Open-Circuit Stiffness

2.3. Electromechanical Modeling

2.3.1. Frequency-Dependent Stiffness

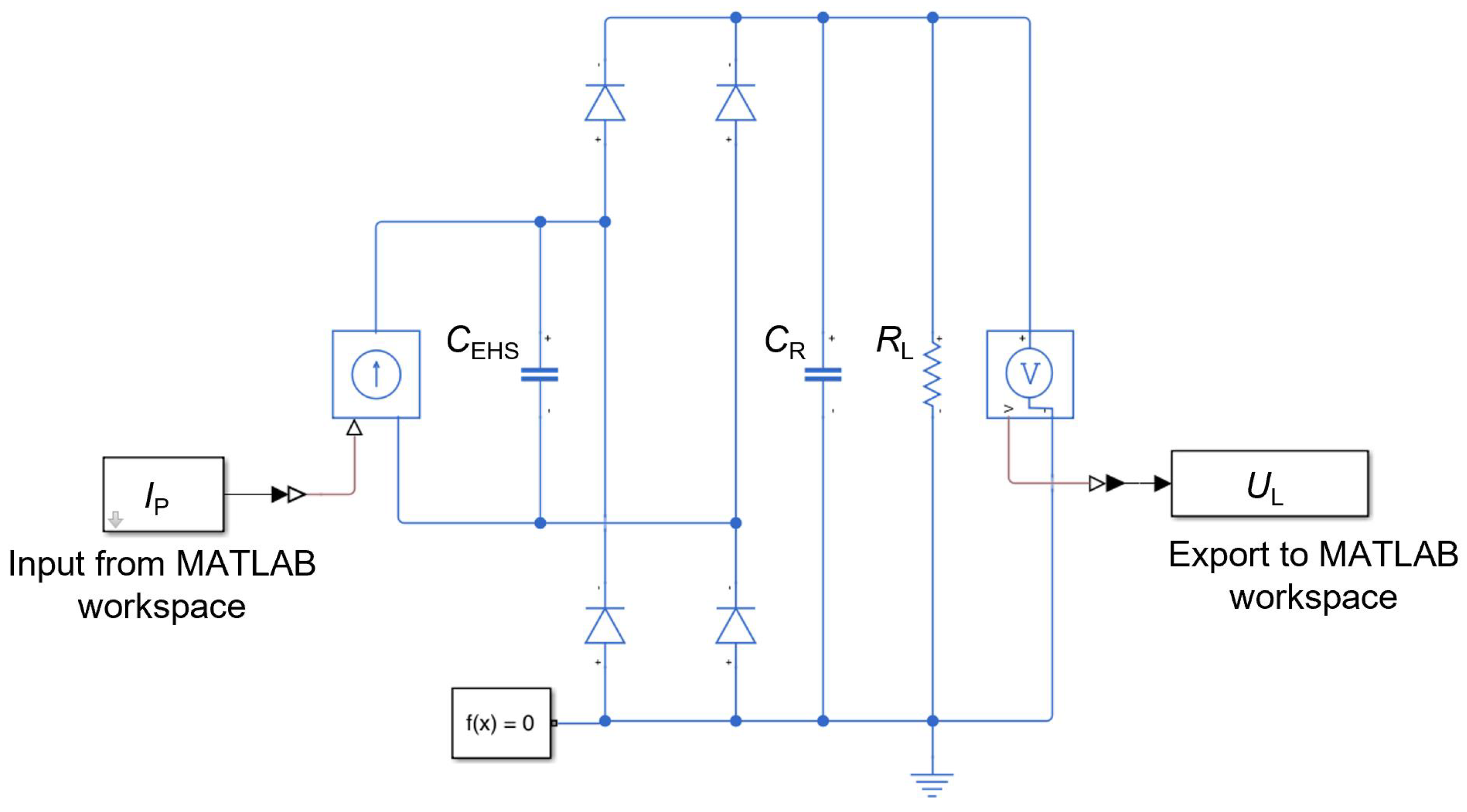

2.3.2. Resistive and Capacitive Shunting

2.3.3. Application to Non-Periodic Signals

2.3.4. Approximation of the Non-Linear Diode Characteristics

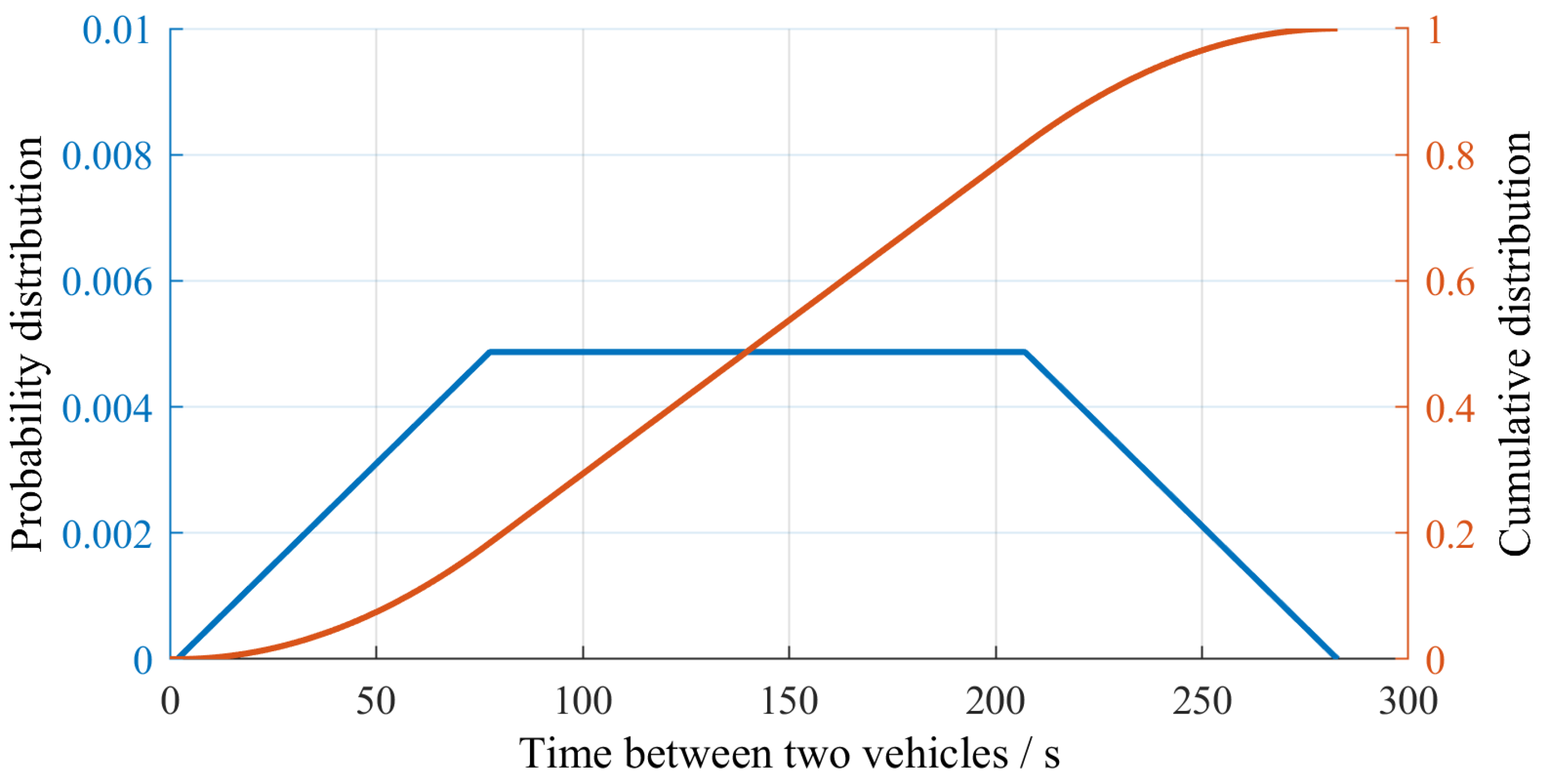

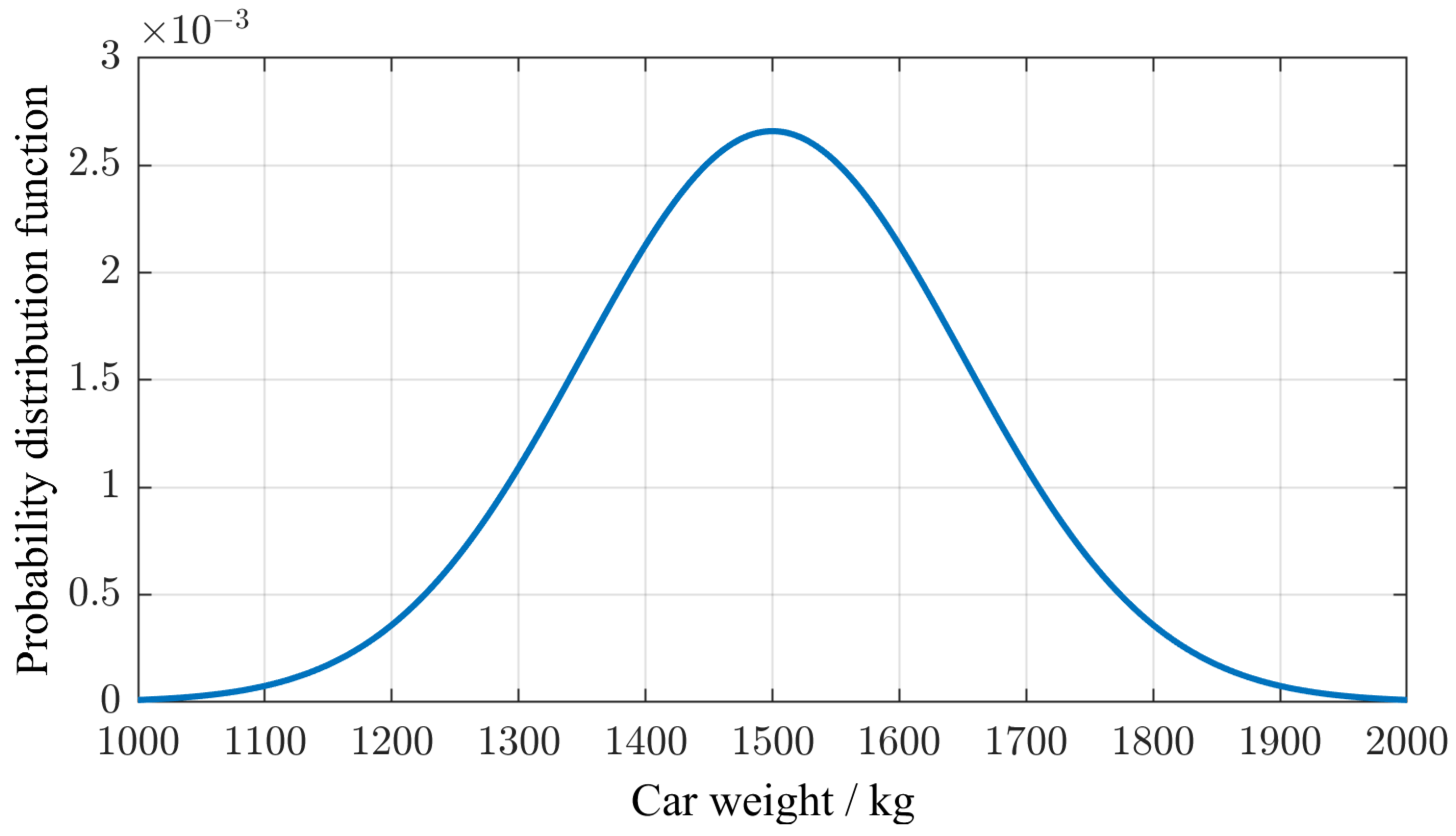

2.4. Statistical Variation

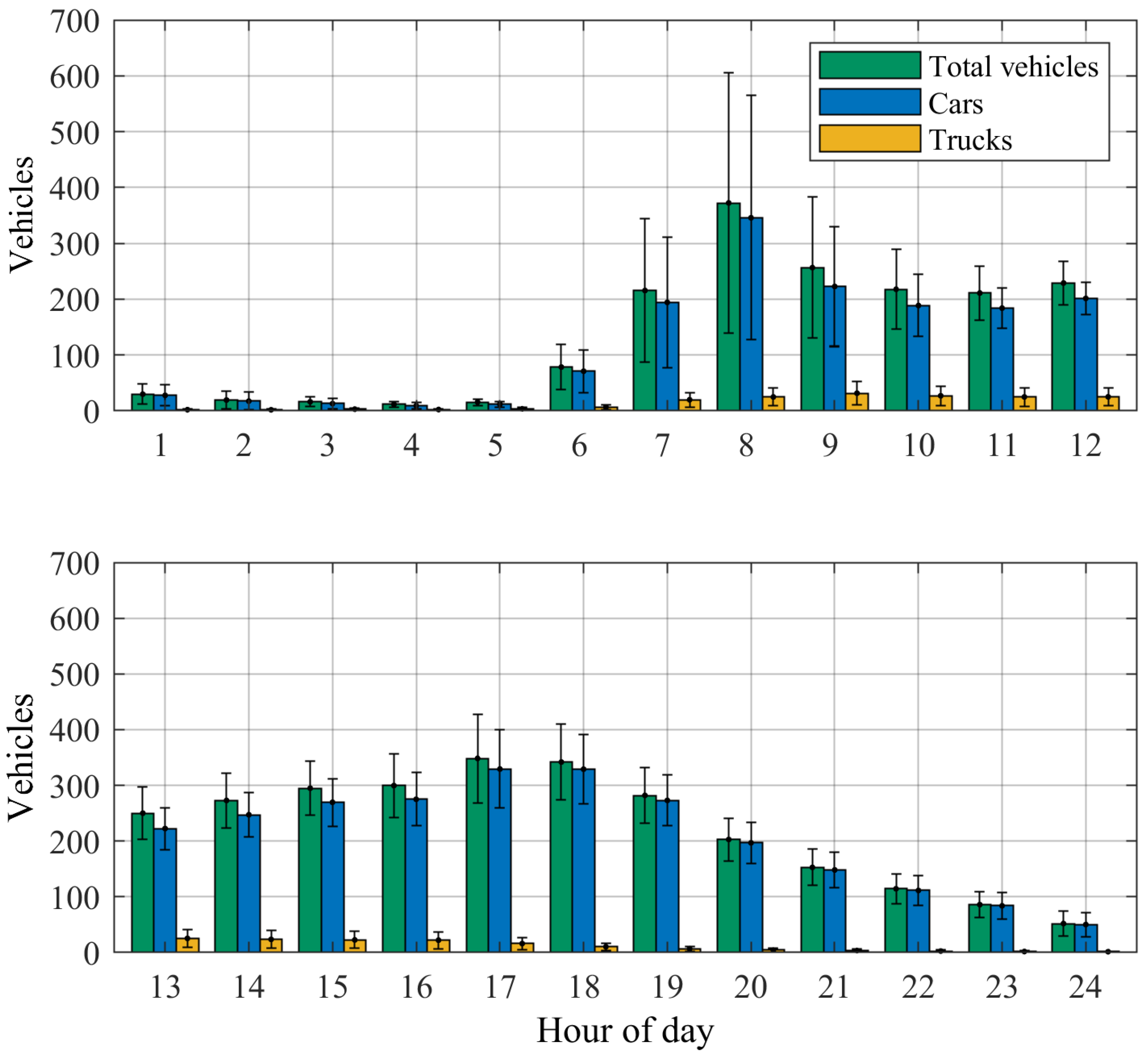

2.5. Boundary Conditions for the Case Study on the Callenberger Bridge

2.6. Optimization Algorithm

- The stack height ,

- the total piezoelectric cross-sectional area ,

- the number of elements per stack ,

- the number of stacks per pEHS ,

- the load resistance , and

- the rectifying capacitance .

- Create a new set of input parameters.

- Scale the force signal based on the new open-circuit stiffness.

- Apply the frequency-dependent stiffness scaling in the frequency domain.

- Reassemble the force signal and calculate the current from the equivalent current source.

- Solve the Simulink model for the rectified voltage.

- Compute the total converted energy at the load resistor for the chosen traffic scenario.

3. Results and Discussion

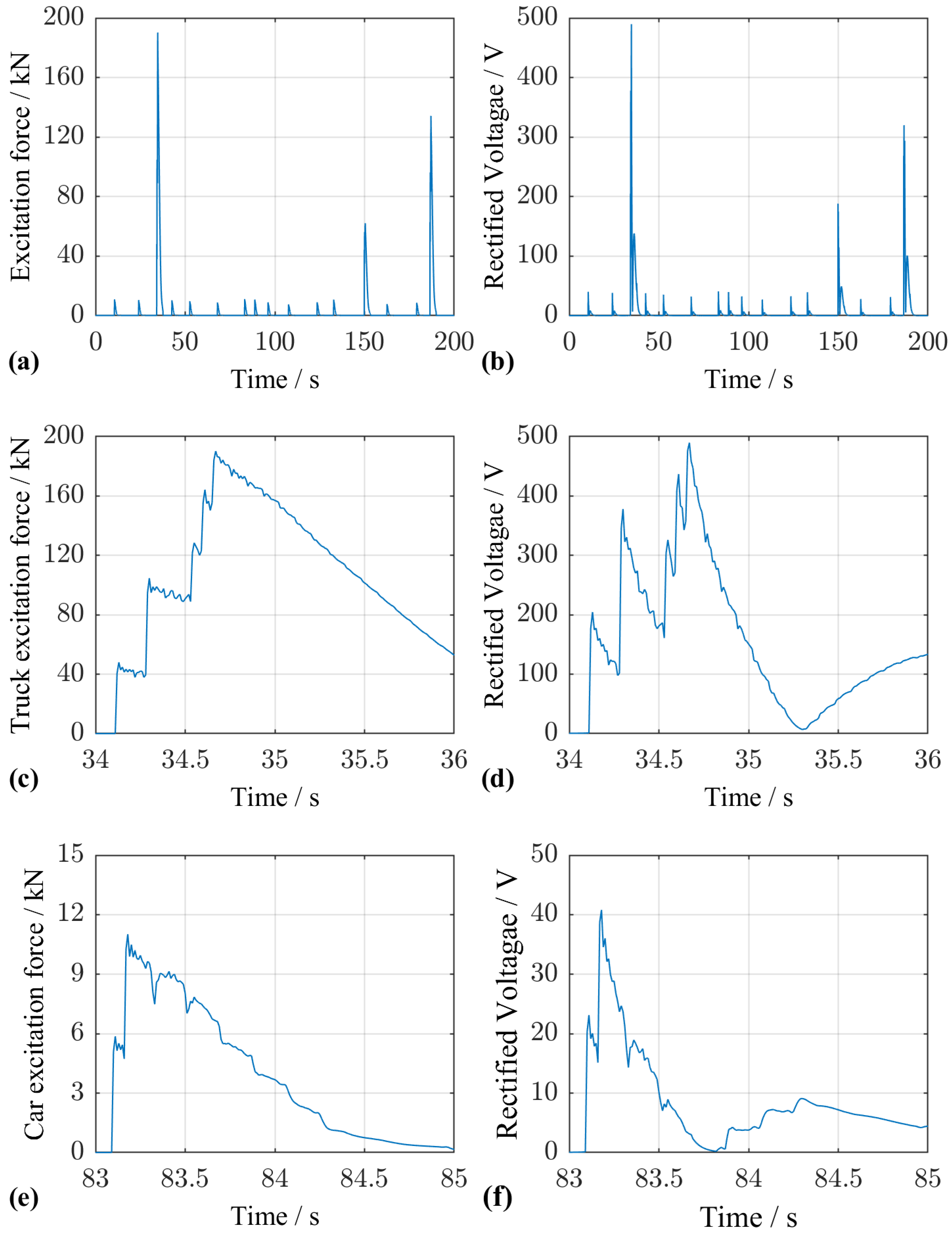

3.1. Time-Series Evaluation of the Optimized Configuration

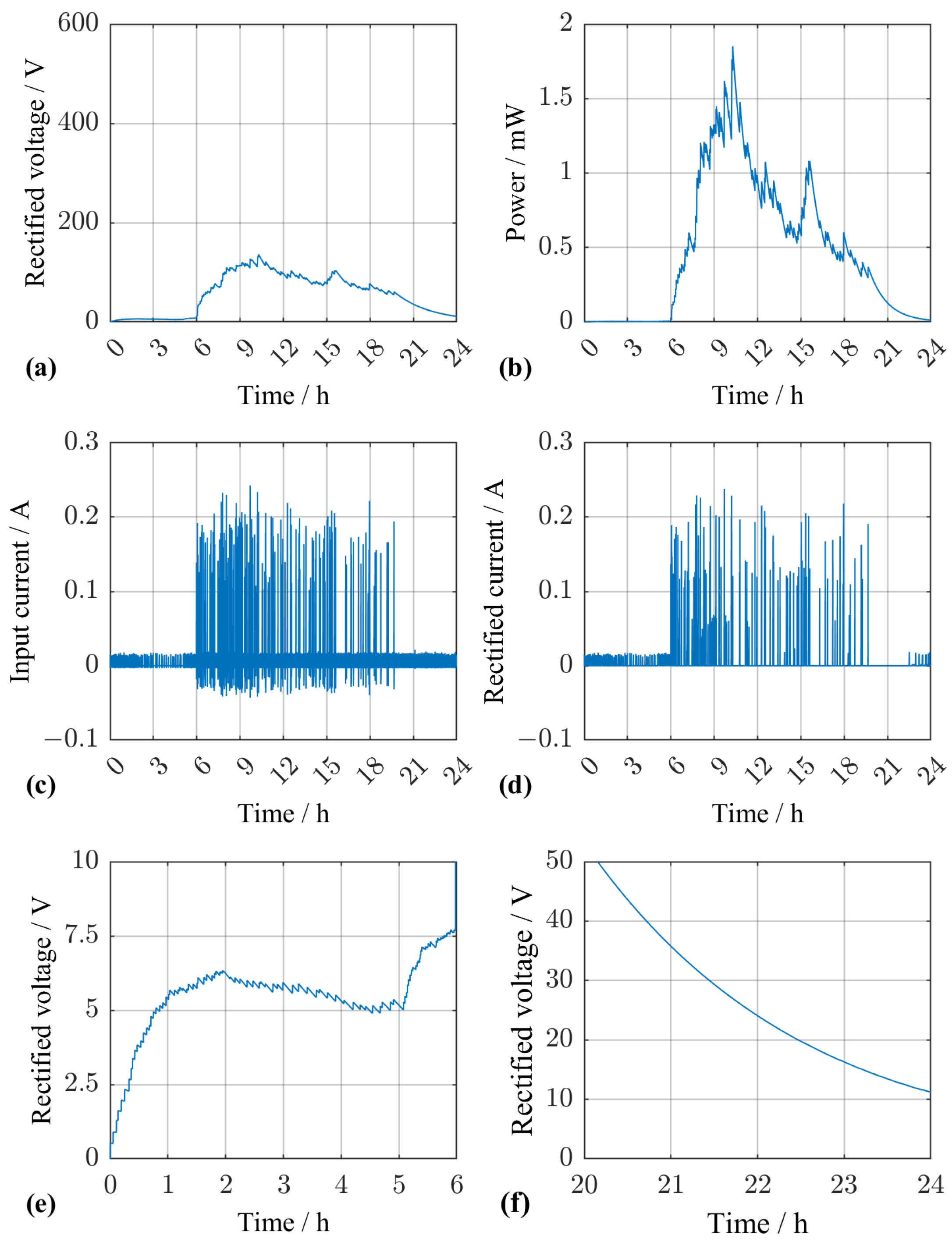

3.2. Measure to Reduce the Time Variation of the EHS Output Voltage

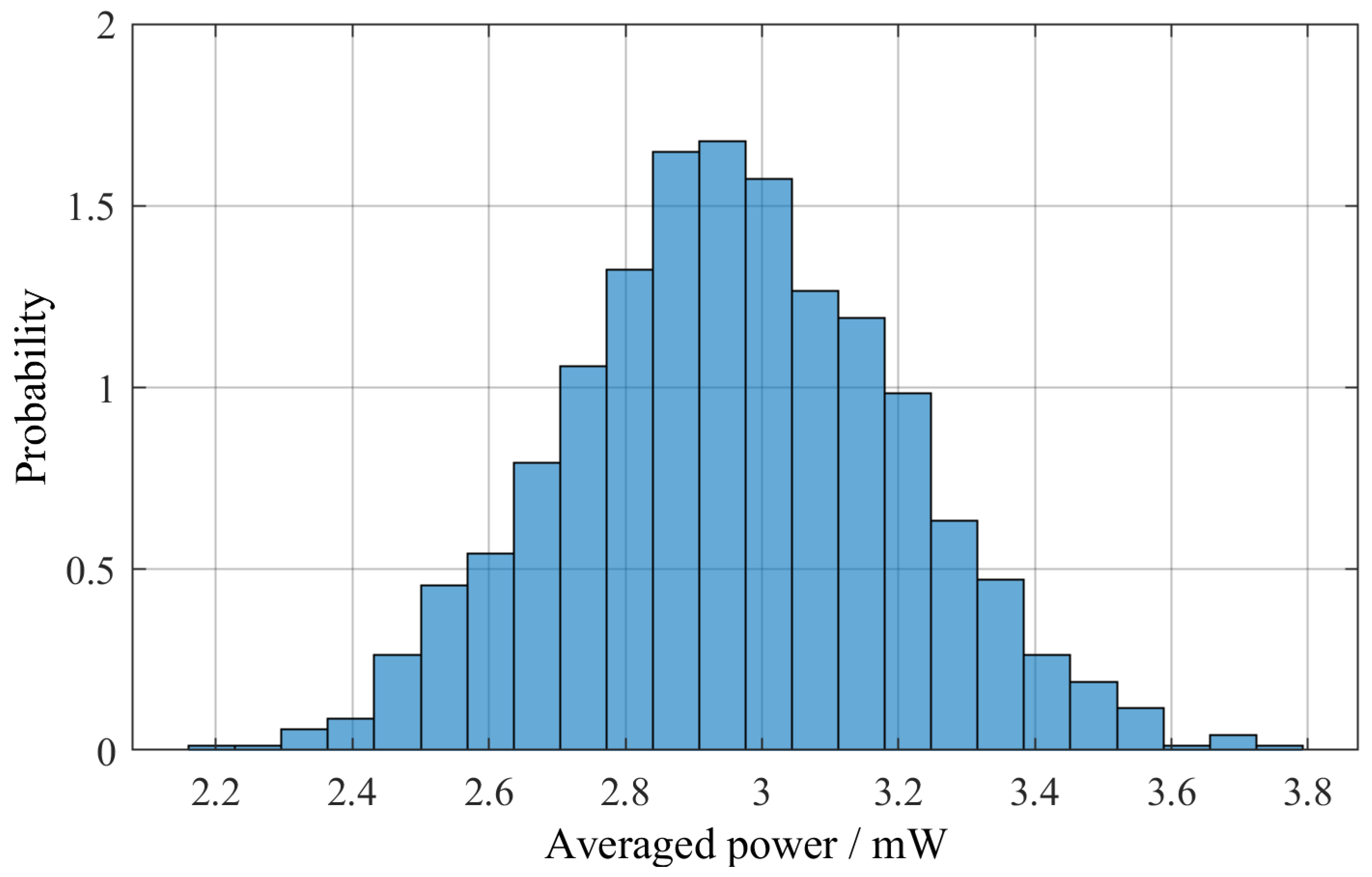

3.3. Statistical Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Engström, R. The Roads’ Role in the Freight Transport System. Transp. Res. Procedia 2016, 14, 1443–1452. [Google Scholar] [CrossRef]

- Beförderungsmenge und Beförderungsleistung nach Verkehrsträgern (Transport Volume and Transport Performance by Mode of Transport). Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Transport-Verkehr/Gueterverkehr/Tabellen/gueterbefoerderung-lr.html (accessed on 5 May 2025). (In German).

- Zustand der Brücken an Bundesfernstraßen in Deutschland in den Jahren 2019 bis 2024 (Condition of Bridges on Federal Highways in Germany in the Years 2019 to 2024). Available online: https://www.bast.de/DE/Statistik/Bruecken/Brueckenstatistik (accessed on 5 May 2025). (In German).

- Wang, H.; Abbas, J.; Chen, X. Energy harvesting technologies in roadway and bridge for different applications—A comprehensive review. Appl. Energy 2018, 212, 1083–1094. [Google Scholar] [CrossRef]

- Sezer, N.; Koc, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Wang, H.; Abbas, J. Piezoelectric energy harvesting from pavement. In Eco-Efficient Pavement Construction Materials; Pacheco-Torgal, F., Amirkhanian, S., Schlangen, E., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 367–382. [Google Scholar]

- Huang, K.; Zhang, H.; Jiang, J.; Zhang, Y.; Zhou, Y.; Sun, L.; Zhang, Y. The optimal design of a piezoelectric energy harvester for smart pavements. Appl. Energy 2022, 232, 107609. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, Q.; Wang, J.; Lv, C. Piezoelectric Energy Harvesting from Roadways under Open-Traffic Conditions: Analysis and Optimization with Scaling Law Method. Energies 2022, 15, 3395. [Google Scholar] [CrossRef]

- Erturk, A. Piezoelectric energy harvesting for civil infrastructure system applications: Moving loads and surface strain fluctuations. J. Intell. Mater. Syst. Struct. 2011, 22, 1959–1973. [Google Scholar] [CrossRef]

- Cahill, P.; Nuallain, N.; Jackson, N.; Mathewson, A.; Karoumi, R.; Pakrashi, V. Energy Harvesting from Train-Induced Response in Bridges. J. Bridge Eng. 2014, 19, 04014034. [Google Scholar] [CrossRef]

- Peralta-Braz, P.; Alamdari, M.; Ruiz, R.; Atroshchenko, E.; Hassan, M. Design optimisation of piezoelectric energy harvesters for bridge infrastructure. Mech. Syst. Signal Process. 2023, 205, 110823. [Google Scholar] [CrossRef]

- Yao, S.; Peralta-Braz, P.; Alamdari, M.; Atroshchenko, E. Optimal design of piezoelectric energy harvesters for bridge infrastructure: Effects of location and traffic intensity on energy production. Appl. Energy 2024, 355, 122285. [Google Scholar] [CrossRef]

- Xiong, T.; Zhang, Y. Feasibility Study for Using Piezoelectric-Based Weigh-In-Motion (WIM) System on Public Roadway. Appl. Sci. 2019, 9, 3098. [Google Scholar] [CrossRef]

- Xiang, T.; Huang, K.; Zhang, H.; Zhang, Y.; Zhang, Y.; Zhou, Y. Detection of Moving Load on Pavement Using Piezoelectric Sensors. Sensors 2020, 20, 2366. [Google Scholar] [CrossRef] [PubMed]

- Khalili, M.; Vishwakarma, G.; Ahmed, S.; Papagiannakis, A. Development of a low-power weigh-in-motion system using cylindrical piezoelectric elements. Int. J. Transp. Sci. Technol. 2022, 11, 496–508. [Google Scholar] [CrossRef]

- Hagood, N.; von Flotow, A. Damping of structural vibrations with piezoelectric materials and passive electrical networks. J. Sound Vib. 1991, 146, 243–268. [Google Scholar] [CrossRef]

- DIN 1045-2; Tragwerke aus Beton, Stahlbeton und Spannbeton—Teil 2: Beton (Concrete, Reinforced and Prestressed Concrete Structures—Part 2: Concrete). DIN Media: Berlin, Germany, 2023; (In German). [CrossRef]

- Li, G.; Zhao, Y.; Peng, S.; Li, Y. Effective Young’s modulus estimation of concrete. Cem. Concr. Res. 1999, 29, 1455–1462. [Google Scholar] [CrossRef]

- Council Directive 96/53/EC of 25 July 1996 Laying Down for Certain Road Vehicles Circulating Within the Community the Maximum Authorized Dimensions in National and International Traffic and the Maximum Authorized Weights in International Traffic. Available online: http://data.europa.eu/eli/dir/1996/53/2019-08-14 (accessed on 10 July 2025).

- Rupitsch, S.J. Piezoelectric Sensors and Actuators; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Erturk, A.; Inman, D. Piezoelectric Energy Harvesting; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- ANSI/IEEE Std 176-1987; IEEE Standard on Piezoelectricity. IEEE: New York, NY, USA, 1988. [CrossRef]

- Ergebnisse der automatischen Verkehrszählung an der Dauerzählstelle 9237 Untersiemenau (Results of the Automatic Traffic Count at the Permanent Counting Station 9237 Untersiemenau). Available online: https://www.bast.de/DE/Verkehrstechnik/Fachthemen/v2-verkehrszaehlung/Aktuell/zaehl_aktuell_node.html?cms_detail=9237&cms_map=0 (accessed on 5 May 2025). (In German).

- Richtlinie zur Nachrechnung von Straßenbrücken im Bestand (Guideline for the Recalculation of Existing Road Bridges). Available online: https://www.bast.de/DE/Publikationen/Regelwerke/Ingenieurbau/Entwurf/Nachrechnungsrichtlinie-Ausgabe-5_2011.html (accessed on 10 July 2025). (In German).

- Abramovich, H.; Tsikchotsky, E.; Klein, G. Allowable Stresses for High-Power Piezoelectric Generators: Effects of location and traffic intensity on energy production. J. Ceram. Sci. Technol. 2013, 4, 131–136. [Google Scholar]

- CeramTec GmbH. Piezoceramic—Soft Materials. Available online: https://www.ceramtec-group.com/de/download-bereich (accessed on 14 July 2025).

- The MathWorks Inc. MATLAB Version: 24.2.0.2740171 (R2024b) Update 1; The MathWorks Inc.: Natick, MA, USA, 2025; Available online: https://www.mathworks.com (accessed on 6 June 2025).

- Tronci, E.; Nagabuko, S.; Hieda, H.; Feng, M. Long-Range Low-Power Multi-Hop Wireless Sensor Network for Monitoring the Vibration Response of Long-Span Bridges. Sensors 2022, 22, 3916. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liao, T.; Huang, K.; Chen, H. A low-power design of a bridge scour monitoring system. In Proceedings of the 2014 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Montevideo, Uruguay, 12–15 May 2014; pp. 30–34. [Google Scholar]

- Philip, M.; Singh, P. Energy Consumption Evaluation of LoRa Sensor Nodes in Wireless Sensor Network. In Proceedings of the 2021 Advanced Communication Technologies and Signal Processing (ACTS), Rourkela, India, 15–17 December 2021; p. 4. [Google Scholar]

- Bouguera, T.; Diouris, J.; Chaillout, J.; Jaouadi, R.; Andrieux, G. Energy Consumption Model for Sensor Nodes Based on LoRa and LoRaWAN. Sensors 2018, 18, 2104. [Google Scholar] [CrossRef] [PubMed]

| Model Parameter | Symbol | Value |

|---|---|---|

| Young’s modulus | ||

| Shear modulus | ||

| Poisson’s ratio | ||

| Mass density |

| Model Parameter | Symbol | Value |

|---|---|---|

| Car velocity | ||

| Distance axle 1–axle 2 | ||

| Axle load 1 | ||

| Axle load 2 |

| Model Parameter | Symbol | Value | ||

|---|---|---|---|---|

| Velocity | ||||

| Distance axle 1–axle 2 | ||||

| Distance axle 2–axle 3 | ||||

| Distance axle 3–axle 4 | ||||

| Distance axle 4–axle 5 | ||||

| Loading case | Empty | Medium | Full | |

| Load axle 1 | ||||

| Load axle 2 | ||||

| Load axle 3 | ||||

| Load axle 4 | ||||

| Load axle 5 | ||||

| Model Parameter | Symbol | Value |

|---|---|---|

| Minimum element length | ||

| Time Step | ||

| Search Radius | r |

| Parameter | Symbol | Value |

|---|---|---|

| Relevant piezoelectric charge coefficient | ||

| Relevant mechanical compliance tensor component | ||

| Relevant permittivity tensor component | 1800 |

| Parameter | Symbol | Value |

|---|---|---|

| Cross-sectional area | ||

| Stack height | ||

| Number of stacks | ||

| Elements per stack | ||

| Smoothing capacitance | ||

| Load resistance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mattauch, P.; Schneider, O.; Fischerauer, G. Design Strategies for Stack-Based Piezoelectric Energy Harvesters near Bridge Bearings. Sensors 2025, 25, 4692. https://doi.org/10.3390/s25154692

Mattauch P, Schneider O, Fischerauer G. Design Strategies for Stack-Based Piezoelectric Energy Harvesters near Bridge Bearings. Sensors. 2025; 25(15):4692. https://doi.org/10.3390/s25154692

Chicago/Turabian StyleMattauch, Philipp, Oliver Schneider, and Gerhard Fischerauer. 2025. "Design Strategies for Stack-Based Piezoelectric Energy Harvesters near Bridge Bearings" Sensors 25, no. 15: 4692. https://doi.org/10.3390/s25154692

APA StyleMattauch, P., Schneider, O., & Fischerauer, G. (2025). Design Strategies for Stack-Based Piezoelectric Energy Harvesters near Bridge Bearings. Sensors, 25(15), 4692. https://doi.org/10.3390/s25154692