Design and Optimization of Intelligent High-Altitude Operation Safety System Based on Sensor Fusion

Abstract

1. Introduction

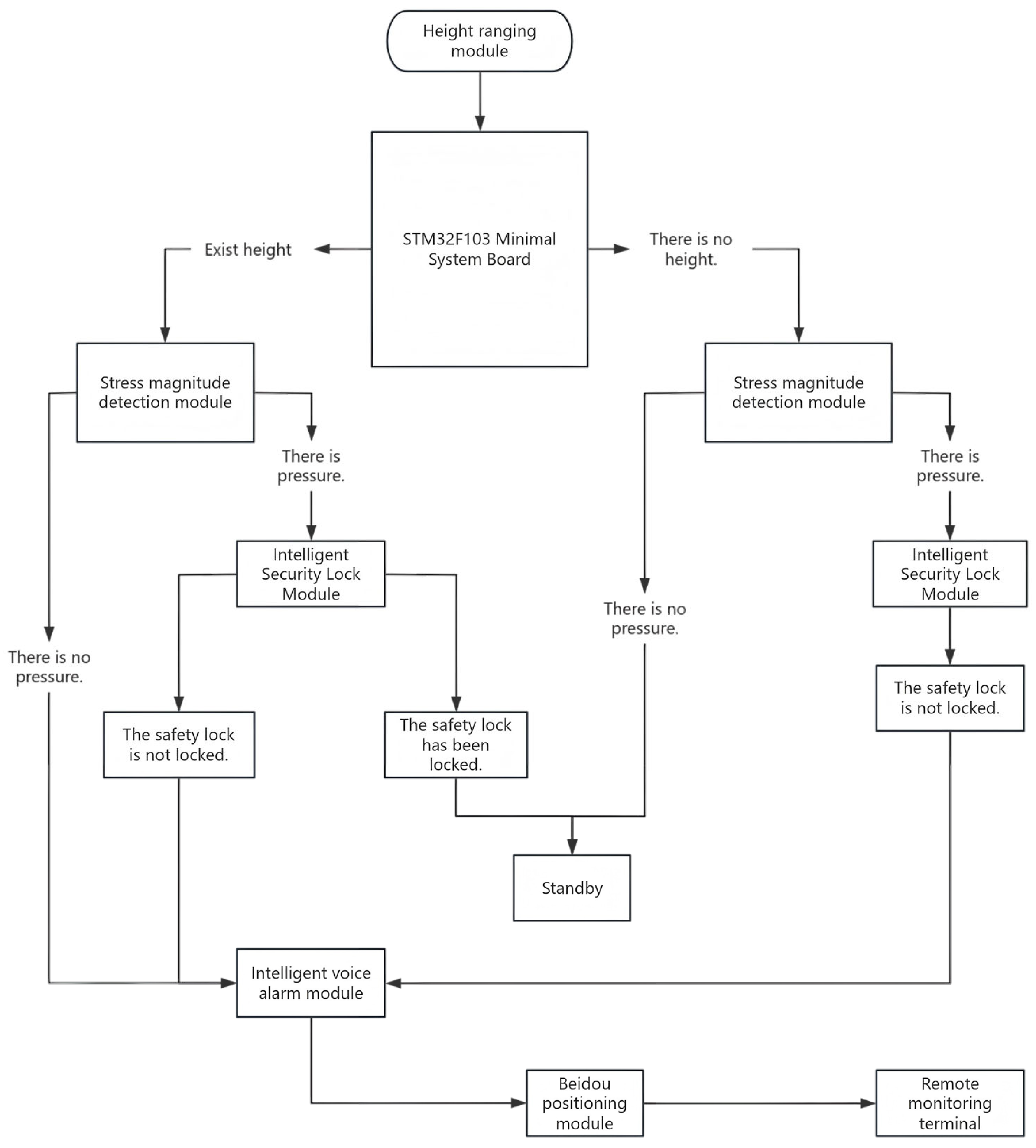

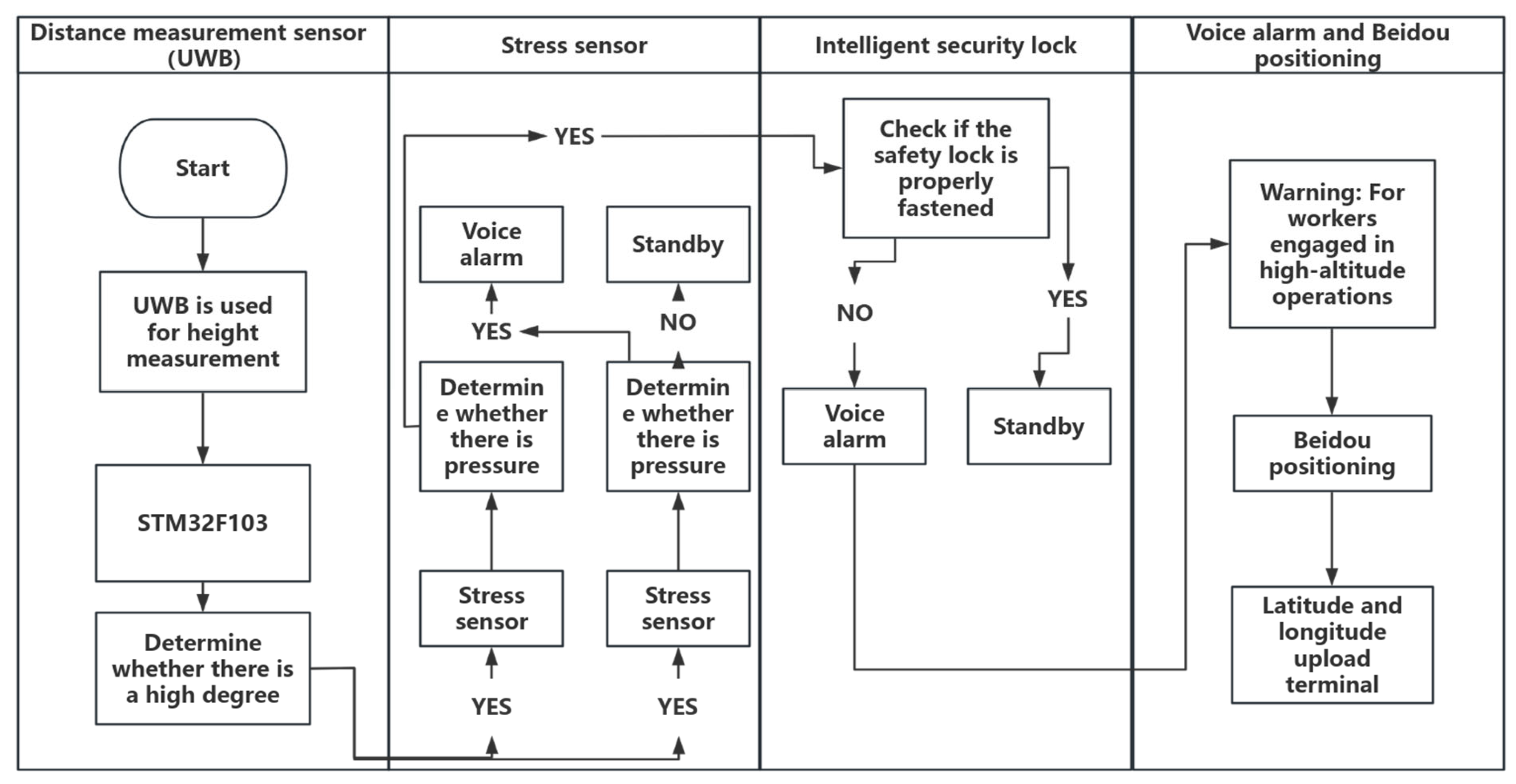

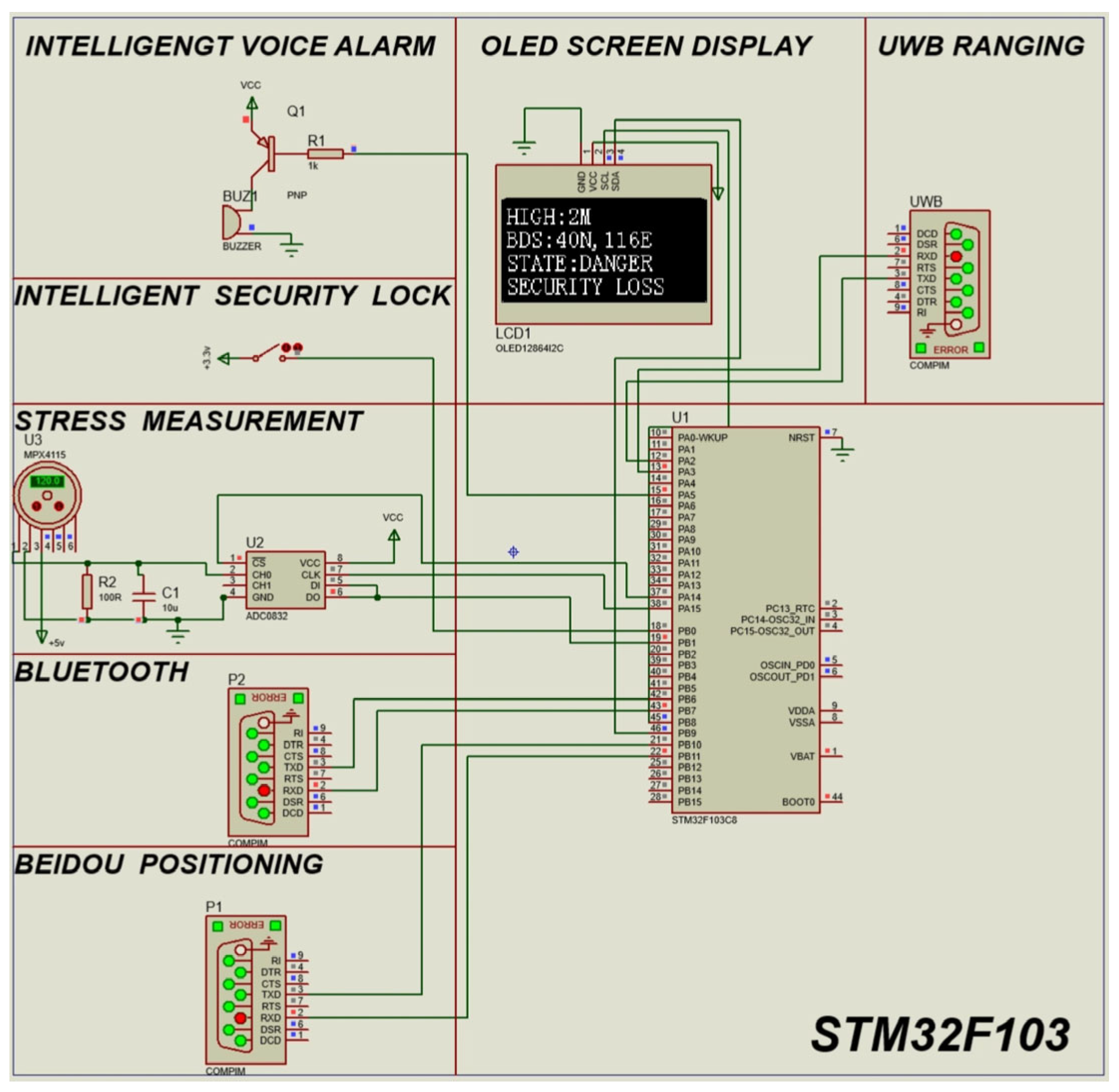

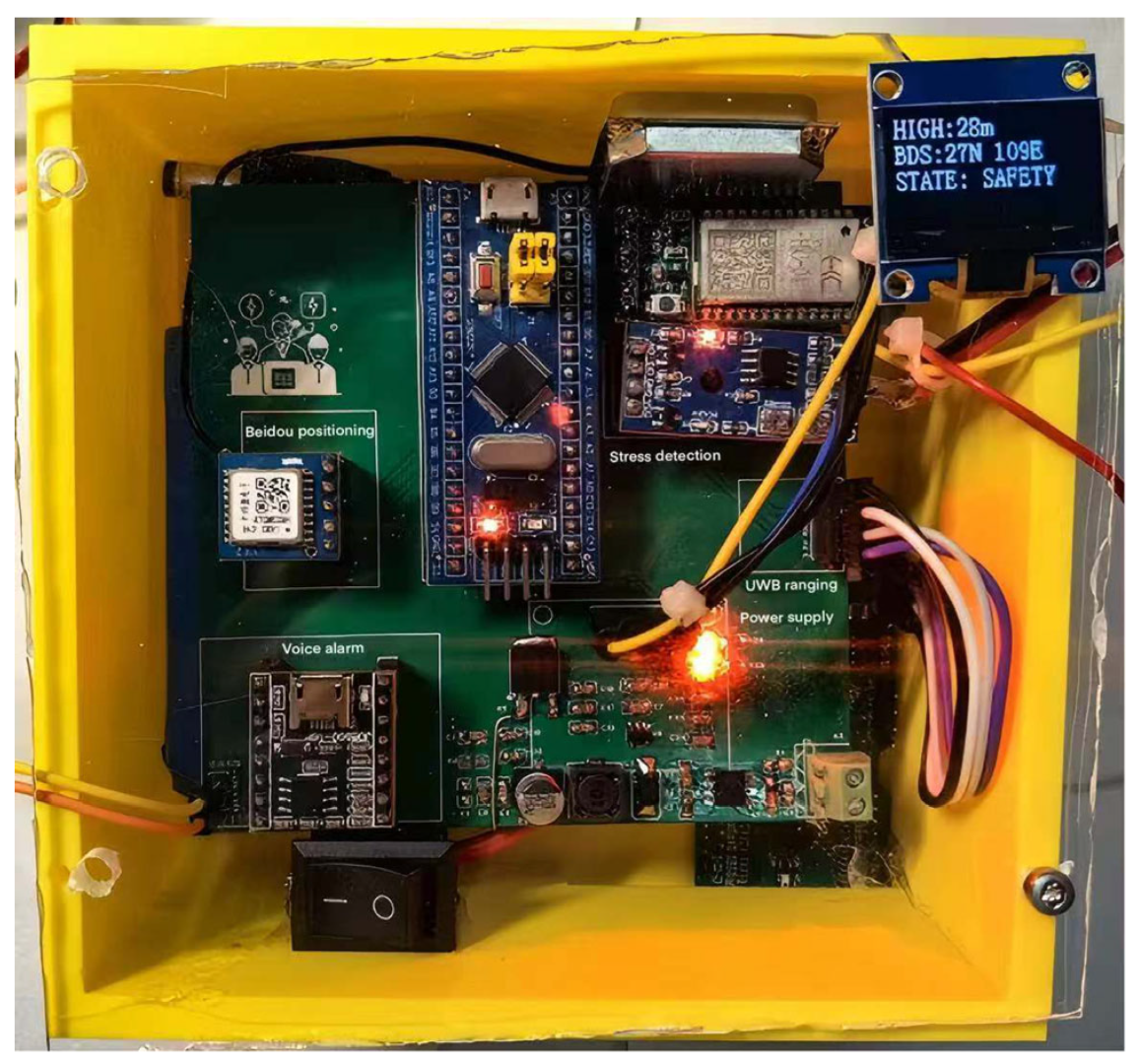

2. Key Modules and Principles of Secure Operating Systems

2.1. System Composition and Application Principles

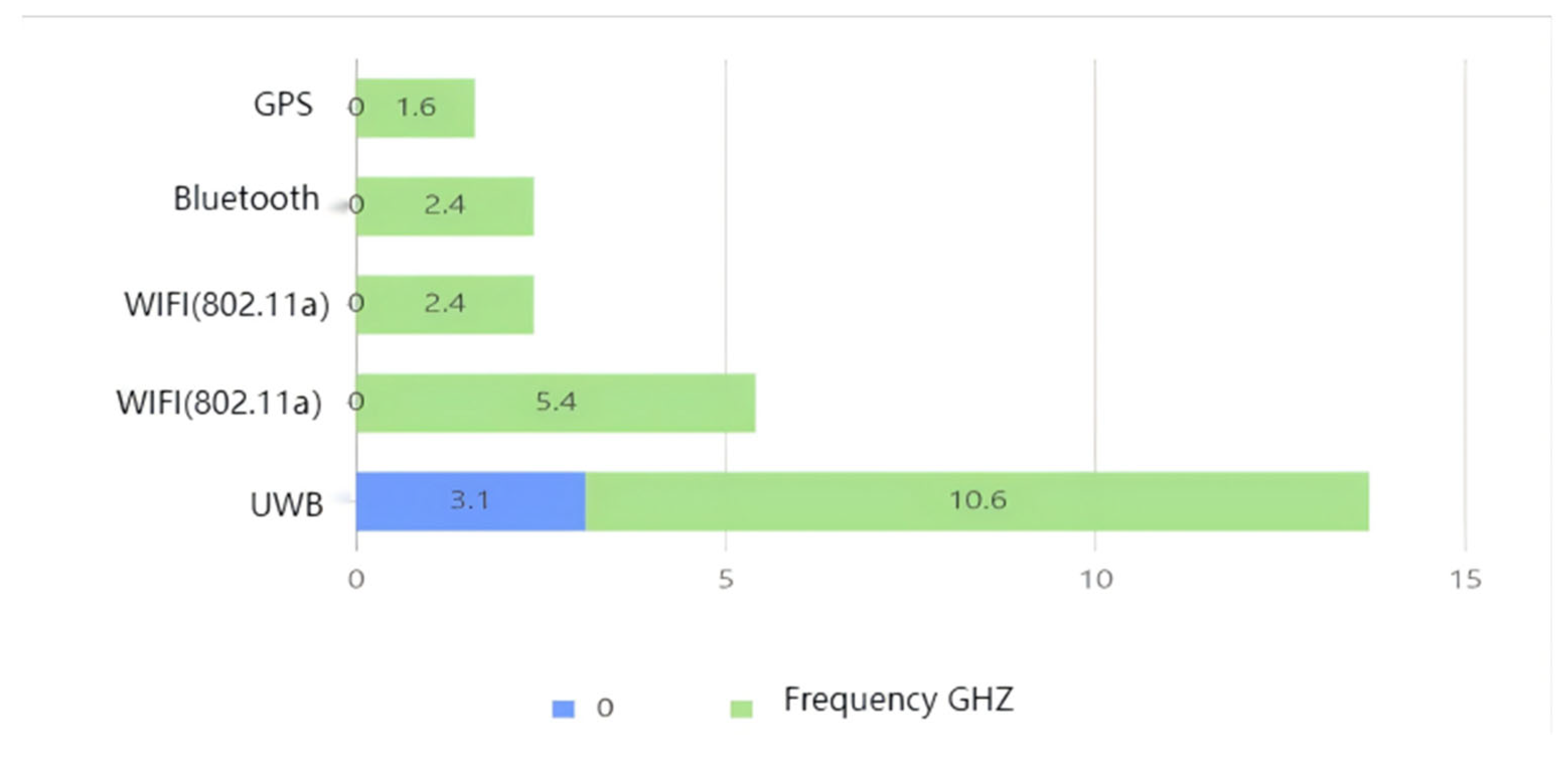

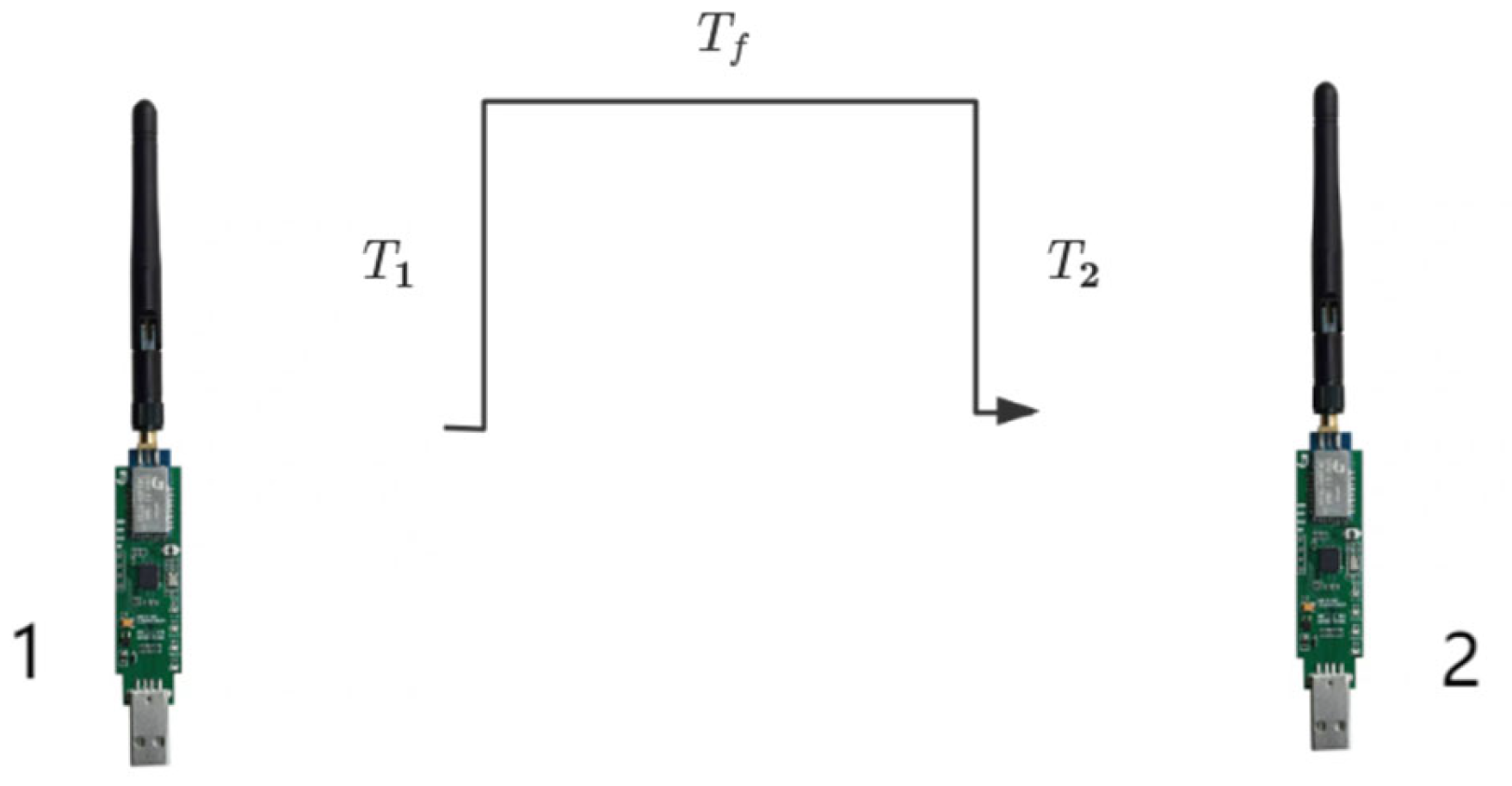

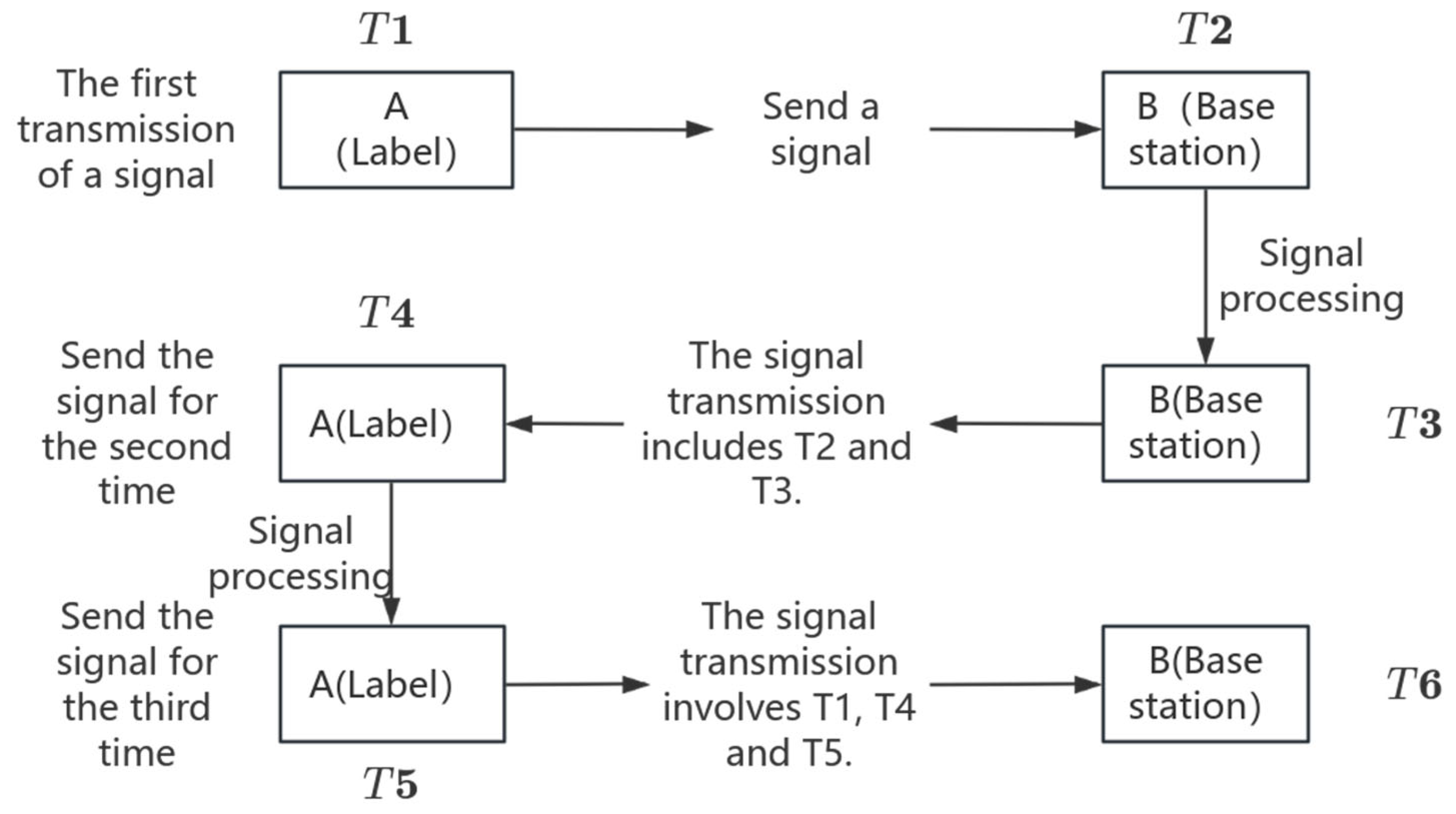

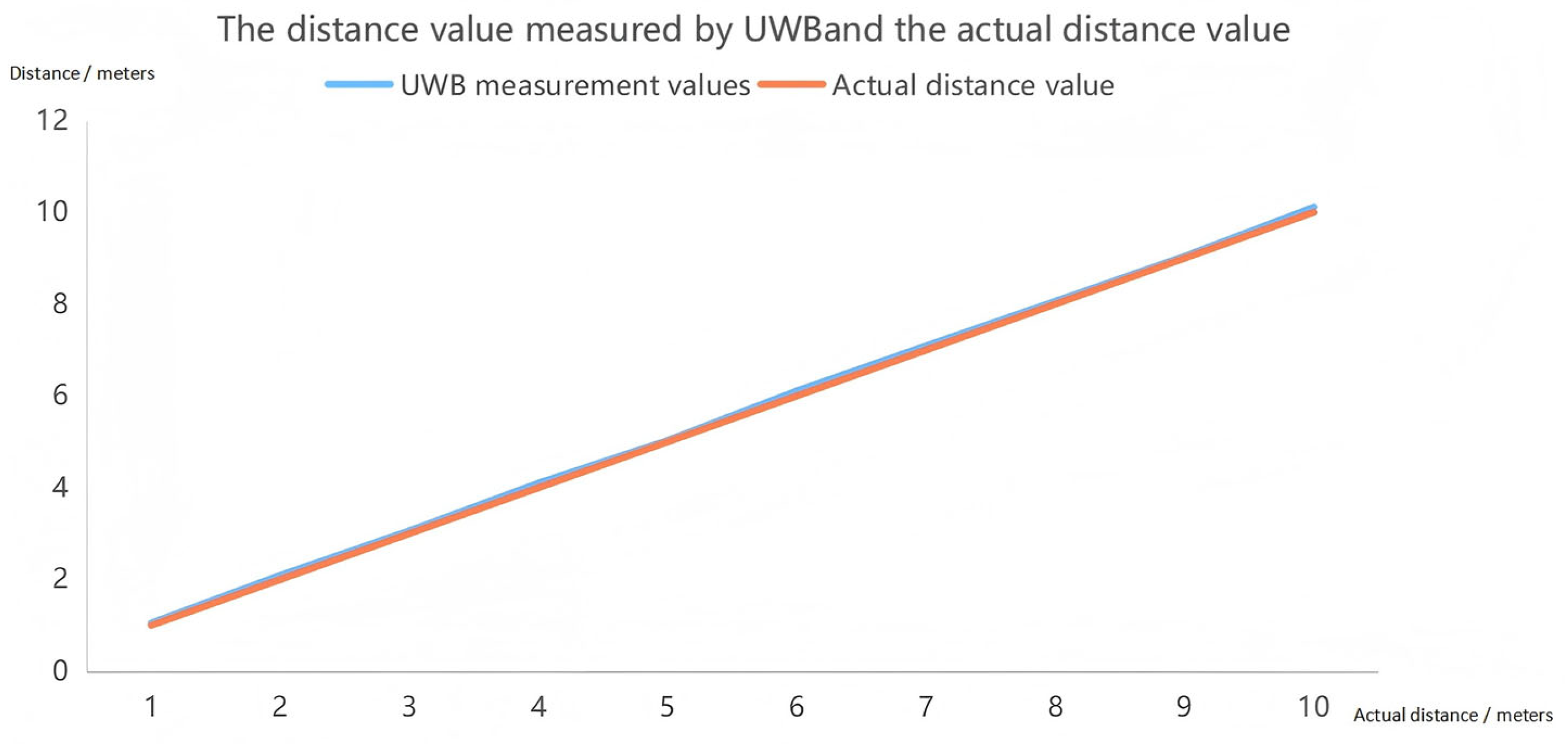

2.1.1. UWB Module

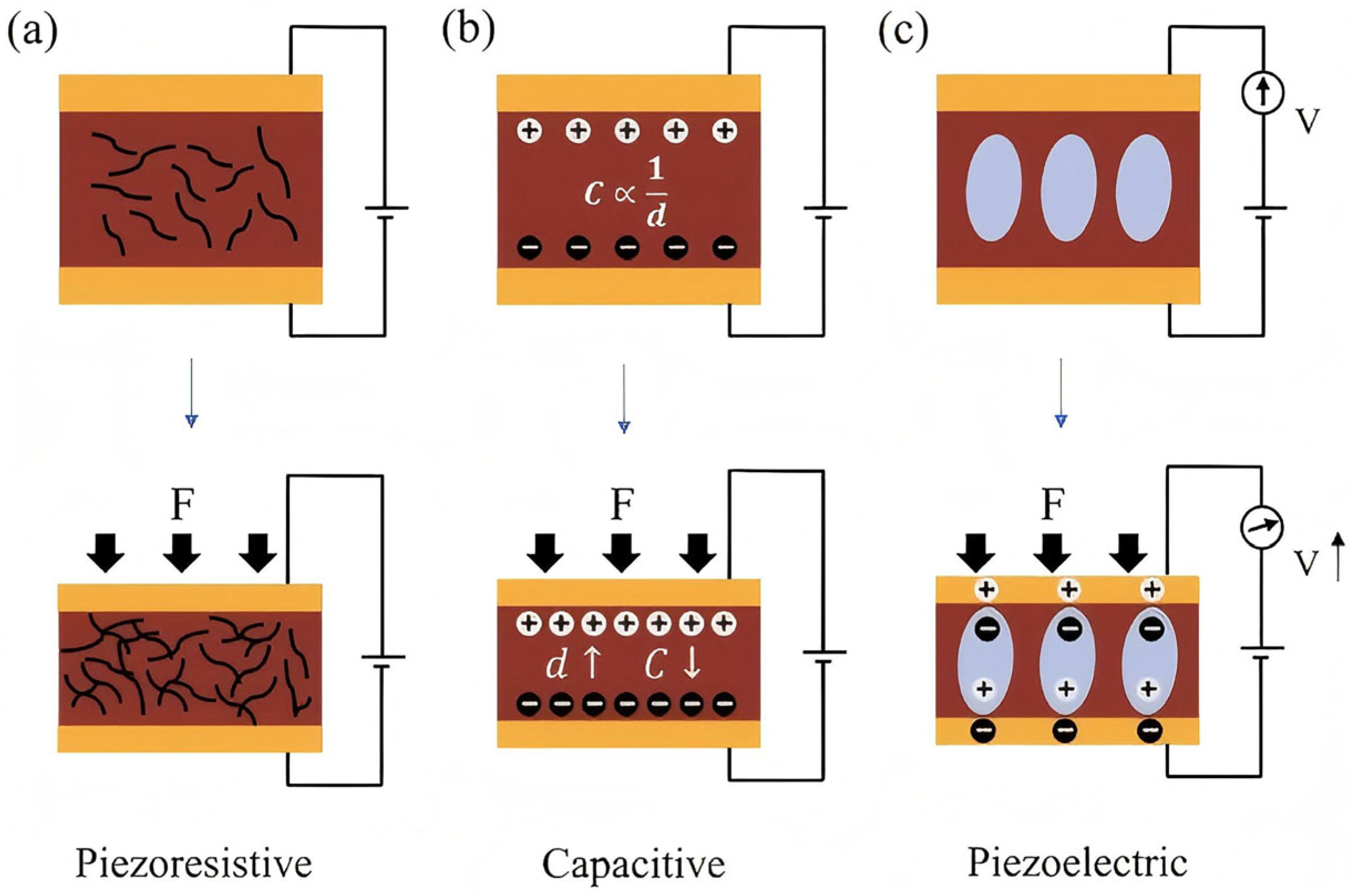

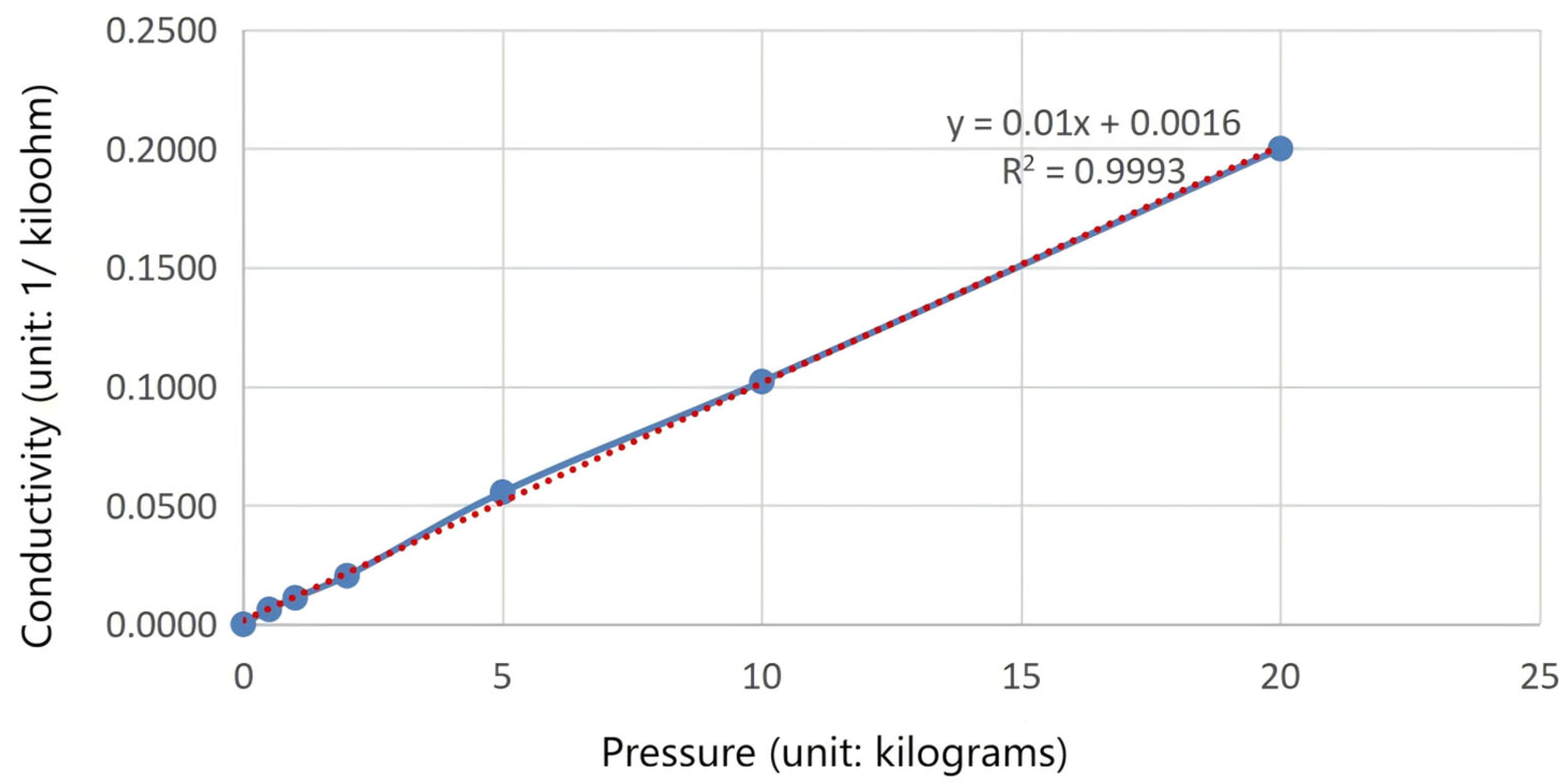

2.1.2. Stress-Sensing Module

2.1.3. Other Modules

2.1.4. Stability and Adaptability Analysis of the System in Different Environments

2.2. Innovation Points of Module Application

2.2.1. UWB Real-Time Height Monitoring

2.2.2. New Type Safety Snap-On Connector

2.2.3. Precise Collaborative Positioning

2.2.4. Intelligent Voice Warning System

2.2.5. Small in Size, Low in Power Consumption, and Stable in Performance

3. Simulation Operation and Experimental Verification of High-Altitude Operation Status

3.1. State Determination Logic Simulation

3.2. Experimental Verification

4. Research on System Integration Optimization and Adaptability to Practical Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H. Abundant Energy Supply and Continuous Optimization of Consumption Structure in the First Quarter. China Reform News, 7 May 2025; p. 004. [Google Scholar]

- Wu, L.; Cai, N.; Liu, Z.; Yuan, A.; Wang, H. A One-stage deep learning framework for automatic detection of safety harnesses in high-altitude Operations. Signal Image Video Process. 2022, 17, 75–82. [Google Scholar] [CrossRef]

- Li, Y.; Chen, L.; Hui, J.; Yuan, R.; Chai, H. Detection of Safety Belt Wearing for Electric High-altitude Work Based on EPSA-YOLOv5. J. Xi’an Polytech. Univ. 2024, 38, 18–25. [Google Scholar]

- Zheng, X. Research on Safety Belt Detection for High-Altitude Work Based on the Improved YOLOv4-Tiny Algorithm; China University of Geosciences: Beijing, China, 2023. [Google Scholar]

- Li, H.; Wang, Y.M. Research and Design of Intelligent Alarm and Remote Monitoring Equipment for Safety Belts in High-Altitude Work. Mold Manuf. 2024, 24, 201–203. [Google Scholar]

- Zhao, Y. Development and Application of an Automatic Alarm Device for Safety Belt Locking in High-Altitude Work. Rural. Electrif. 2024, 5, 70–72. [Google Scholar]

- Yang, K. An Online Intelligent Safety Belt Detection and Supervision Device for High-Altitude Work. CN110090372A, 6 August 2019. [Google Scholar]

- Wendou, Y.; Xiuying, W.; Shoubiao, T. YOLO-DFAN: Effective High-Altitude Safety Belt Detection Network. Future Internet 2022, 14, 349. [Google Scholar]

- Fang, W.; Ding, L.; Luo, H.; Love, P.E. Falls from heights: A computer vision based approach for safety harness detection. Autom. Constr. 2018, 91, 53–61. [Google Scholar] [CrossRef]

- Yue, J.; Cheng, G.; Deng, C. UWB indoor Positioning Method based on Tag Height difference. J. Navig. Position. 2019, 7, 44–50. [Google Scholar]

- Yang, Y.; Li, J.; Wang, A.; Xu, J.; He, H.; Guo, H.; Shen, J.; Dai, X. Preliminary Evaluation of the Basic Navigation and Positioning Performance of the Beidou Regional Satellite Navigation System. Sci. China Earth Sci. 2014, 44, 72–81. [Google Scholar]

- Sidiropoulos, A.; Bechtsis, D.; Vlachos, D. Implementing an Industry 4.0 UWB-Based Real-Time relocating System for Optimized Tracking. Appl. Sci. 2025, 15, 2689. [Google Scholar] [CrossRef]

- Prokhorov, V.A.; Kuzmin, L.V.; Krivenko, A.A.; Vladyka, P.A.; Efremova, E.V. UWB Chaotic Pulse-Based Ranging: Time-of-Flight Approach. Technologies 2024, 12, 269. [Google Scholar] [CrossRef]

- Arsan, T.; Hameez, M.M.N. A Clustering-Based Approach for Improving the Accuracy of UWB Sensor-Based Indoor Positioning System. Mob. Inf. Syst. 2019, 2019, 6372073. [Google Scholar] [CrossRef]

- Ni, J.; Arndt, D.; Ngo, P.; Phan, C.; Dekome, K.; Dusl, J. Ultra-wideband Time-Difference-Of-Arrival High Resolution 3D Proximity Tracking System. In Proceedings of the IEEE/ION Position, Location and Navigation Symposium, Indian Wells, CA, USA, 4–6 May 2010; pp. 37–43. [Google Scholar]

- Zhang, Z.; Li, S.; Lu, Z. Analysis of the precision influence factors of SDS-TWR method based on UWB. In Automotive, Mechanical and Electrical Engineering; CRC Press: Boca Raton, FL, USA, 2017; pp. 127–132. [Google Scholar]

- Bagus Muliawan, N.; Sulistijono, I.A. Sistem Lokalisasi Mobile-Robot Pertanian Otonom Berbasis Ultra-Wideband (UWB) dan Sensor Inersia. Indones. J. Comput. Sci. 2023, 12, 284–301. [Google Scholar] [CrossRef]

- Yuan, M.; Gu, Y.; Li, Z.; Li, G. Research on Vehicle Combination Positioning Method Based on Neural Network Ranging Error Prediction and Compensation. Technol. Mark. 2025, 32, 13–18. [Google Scholar]

- Liu, S.L.; Cai, H.; Liu, C. Soft Body Belt-Type Touch Sensor With Impact Resistance: A Study of Dynamic Behavior. IEEE Access 2021, 9, 128460–128466. [Google Scholar] [CrossRef]

- Singh, R.; Ngo, L.L.; Seng, H.S.; Mok, F.N.C. A silicon piezoresistive pressure sensor. In Proceedings of the First IEEE International Workshop on Electronic Design, Test and Applications ‘2002, Christchurch, New Zealand, 29–31 January 2002; pp. 181–184. [Google Scholar]

- Kanekal, D.; Jindal, S.K. Investigation of MEMS Piezoresistive Pressure Sensor with a Freely Supported Rectangular Silicon Carbide Diaphragm as a Primary Sensing Element for Altitudinal Applications. Silicon 2022, 15, 1947–1959. [Google Scholar] [CrossRef]

- Sun, W.; Chang, W. Blood Pressure Monitoring Based on Flexible Encapsulated Sensors. Appl. Sci. 2023, 13, 7473. [Google Scholar] [CrossRef]

- Aparna, J.; Philip, S.; Topkar, A. Thermal energy harvester powered piezoresistive pressure sensor system with wireless operation for nuclear reactor Application. Rev. Sci. Instrum. 2019, 90, 044705. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, Y.; Li, Y.; Wang, P.; Hu, D. Recent development of flexible force sensors with multiple environmental Adaptations. Nano Energy 2024, 124, 109443. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, P.; Wang, Z.; Wu, Y.; Yu, X.; Ai, Z.; Dong, X. Experimental and Finite Element Study on the Force Distribution of the Thoracolumbar Spine during Posterior Falls. Chin. J. Spinal Cord Spinal Column 2020, 30, 827–832. [Google Scholar]

- Huang, P.; Huang, X. Design of Intelligent Lock and Supervision Device for Enhancing Safety in High-Altitude Operations. Electr. Technol. Econ. 2024, 3, 193–195. [Google Scholar]

- Luo, H.; Wang, L.; Zuo, H.; Zhao, H.; Shi, R. Indoor and outdoor collaborative localization system based on beidou and bluetooth. J. Integr. Circuits Embed. Syst. 2025, 25, 73–79. [Google Scholar]

- GB/T 3608-2008; National Safety Production Standardization Technical Committee (SAC/TC 288). Classification of High Altitude Operations. China Standard Press: Beijing, China, 2008.

- Li, B.; Zhao, K.; Sandoval, E.B. A UWB-Based Indoor Positioning System Employing Neural Networks. J. Geovis. Spat. Anal. 2020, 4, 18. [Google Scholar] [CrossRef]

- Chen, R.; Xiao, Y.; Chen, Y.; Xu, H.; Yu, P.; Peng, Q.; Li, X.; Guo, X.; Huang, J.; Li, N.; et al. A 6.5-to-10 GHZ IEEE 802.15.4/4z-Compliant 1T3R UWB Transceiver. In Proceedings of the 2022 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 20–26 February 2022; pp. 396–398. [Google Scholar]

- Malajner, M.; Planinsic, P.; Gleich, D. UWB ranging accuracy. In Proceedings of the 2015 International Conference on Systems, Signals and Image Processing (IWSSIP), London, UK, 10–12 September 2015. [Google Scholar]

- Akahori, S.; Higashi, Y.; Masuda, A. Position estimation system with UWB, IMU and a distance sensor for quad-rotors. In Proceedings of the TENCON 2017—2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 1992–1996. [Google Scholar]

- Al-Kadi, R.; Zorn, C. Ultra-Wideband—Marktpotenziale und Funktionsweise. ATZelektronik 2020, 15, 44–49. [Google Scholar] [CrossRef]

- EN 361:2002: DIN EN 361-2002; Protective Equipment to Prevent Personnel from Falling from Heights Full Body Protective Seat Belt. iTeh: Newark, DE, USA, 2002.

- GB 6095-2021; Ministry of Emergency Management of the People’s Republic of China Fall Protection Safety Belts. China Standard Press: Beijing, China, 2021.

- ANSI/ASSE Z359.1; Fall Protection Code 2016 Revision. ISHN: Birmingham, MI, USA, 2017.

- GB/T 6096-2020; Performance Testing Methods for Fall Protection Seat Belt Systems. China Standard Press: Beijing, China, 2021.

| Standard Type | International Standard | Chinese Standard | Test Focus | Determine Whether It Is Qualified |

|---|---|---|---|---|

| Static load | EN 361 [34] | GB 6095-2021 [35] | The load-bearing capacity of the webbing and metal fasteners | Yes |

| Dynamic impact | ANSI Z359.1 [36] | GB/T 6096-2020 [37] | Peak impact force and energy absorption | Yes |

| Intelligent Security Lock | Stress Measurement Value | Stress Detection Sensor | Voice Alarm | Number of Incorrect Executions | Detection Probability | |

|---|---|---|---|---|---|---|

| Located at ground level (with a height of less than 2 m) | Lock it up | >20 N | There is stress. | Do not call the alarm | 2 | 99.6% |

| Lock it up | <5 N | No stress | Alarm | 1 | 99.8% | |

| Do not lock | >20 N | There is stress. | Alarm | 1 | 99.8% | |

| Do not lock | <5 N | No stress | Alarm | 1 | 99.8% |

| Intelligent Security Lock | Stress Measurement Value | Stress Detection Sensor | Voice Alarm | Number of Incorrect Executions | Detection Probability | |

|---|---|---|---|---|---|---|

| Located at ground level (with a height greater than 2 m) | Lock it up | >20 N | There is stress. | Do not call the alarm | 3 | 99.4% |

| Lock it up | <5 N | No stress | Alarm | 2 | 99.6% | |

| Do not lock | >20 N | There is stress. | Alarm | 1 | 99.8% | |

| Do not lock | <5 N | No stress | Alarm | 2 | 99.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Gong, T.; Lei, T.; Zhu, Y.; Huang, Y.; Tang, K.; Zhou, Q. Design and Optimization of Intelligent High-Altitude Operation Safety System Based on Sensor Fusion. Sensors 2025, 25, 4626. https://doi.org/10.3390/s25154626

Liu B, Gong T, Lei T, Zhu Y, Huang Y, Tang K, Zhou Q. Design and Optimization of Intelligent High-Altitude Operation Safety System Based on Sensor Fusion. Sensors. 2025; 25(15):4626. https://doi.org/10.3390/s25154626

Chicago/Turabian StyleLiu, Bohan, Tao Gong, Tianhua Lei, Yuxin Zhu, Yijun Huang, Kai Tang, and Qingsong Zhou. 2025. "Design and Optimization of Intelligent High-Altitude Operation Safety System Based on Sensor Fusion" Sensors 25, no. 15: 4626. https://doi.org/10.3390/s25154626

APA StyleLiu, B., Gong, T., Lei, T., Zhu, Y., Huang, Y., Tang, K., & Zhou, Q. (2025). Design and Optimization of Intelligent High-Altitude Operation Safety System Based on Sensor Fusion. Sensors, 25(15), 4626. https://doi.org/10.3390/s25154626