1. Introduction

Vibration phenomena are ubiquitous in nature and are not limited to mechanical components; they can be observed in everyday structures such as bridges, roads, and buildings. As a result, vibration energy is considered a promising form of next-generation green energy. Among green energy solutions, solar panels are widely manufactured and used to collect solar energy. However, in rainy countries, the efficiency of solar panels decreases significantly. If a vibration energy harvesting system could be used to capture the energy from raindrops or be integrated with solar panels, it could not only improve the power generation efficiency of solar panels on rainy days but also enhance their applicability in rain-prone regions. For countries with abundant rainfall, the concept of utilizing raindrop impact power generation can be applied not only to solar panels but also to various structures such as rain shelters, canopies, tents, and convertible car roofs. Increasingly frequent extreme weather has made research on Rain Energy Harvesting Systems (REHs) highly practical. Additionally, using piezoelectric materials to collect vibration energy generated by rainfall has been proven to be a promising and viable approach, leading to the development of vibration energy harvesting systems (VEHs) as a practical application method. This study considers two types of nonlinear plate vibrations: one is a thin plate with all four edges hinged (hinged–hinged–hinged–hinged, H-H-H-H plate), and the other is a thin plate with one clamped edge, two hinged edges, and a free boundary on the opposite side of the fixed edge (clamped–hinged–free–hinged, C-H-F-H plate). These plates are used to capture the kinetic energy of raindrops, with multiple piezoelectric patches placed beneath the vibrating plate to achieve power generation. A nonlinear plate model is derived through theoretical analysis and numerically simulated with a function representing the random impact forces of raindrops. Commercial software simulations are also conducted to determine the best placement of multiple piezoelectric patches. Finally, the power generation efficiency and feasibility of the system are validated through a combination of software simulations and experimental verification. Additionally, this study incorporates a power management (PM) system that selectively outputs the most efficient energy generated from each vibration cycle, ensuring energy storage while enhancing power generation efficiency and reducing unnecessary energy loss. The proposed system can be applied to vibration energy harvesting in solar panels or rain shelters.

Yildirim et al. [

1] pointed out that the problem with traditional vibration energy harvesters (VEHs) is that they only operate effectively near resonance, which limits the effective working range for power collection and constrains the total extractable power. This is dependent on the design of the device as well as the amplitude and frequency of the source vibrations. Even if the environmental vibration sources are well-documented and their frequencies are known, the precise manufacturing of the devices is required since small deviations can lead to significant power reductions. Jia [

2] suggested that nonlinear vibration energy harvesting systems have a wider effective operating bandwidth and can achieve greater amplitude responses compared to traditional linear systems. Yang and Towfighian [

3] demonstrated that nonlinear vibration energy harvesters outperform linear resonators, which perform poorly when operating away from their natural frequencies. Most vibration energy harvesters are linear resonators with narrow bandwidths, leading to significant output declines when the excitation frequency differs from the resonant frequency. Yao et al. [

4] reiterated the advantages of nonlinear vibration energy harvesting systems and concluded that nonlinear system designs are essential for improving output power and broadening the frequency response range. Wu et al. [

5] summarized the requirements for new energy solutions and the piezoelectric mechanism. In addition to summarizing methods and mechanisms for enhancing piezoelectric power output, they explained the issue of most proposed piezoelectric vibration energy harvesting systems generating only small amounts of electricity. Therefore, with the aim of capturing more vibration energy, this study will focus on nonlinear vibration energy harvesting systems as its primary research direction.

Cao et al. [

6] proposed a hybrid wind and rainwater energy harvester (WEREH) system that maintains self-powered operation under various weather conditions. It was installed on the drainage pipes of piers on a cross-sea bridge. On one hand, sensors for health monitoring require substantial power; on the other hand, harsh working environments reduce battery lifespan. Bao et al. [

7] pointed out that many designs focused on harvesting energy from high-energy-density sources like mechanical vibrations are not always available for certain application scenarios. The total output power of energy harvesting methods may also be constrained by size limitations. Thus, when such energy sources are unavailable or insufficient for practical applications, alternative energy solutions must be found. Low-energy-density sources such as wind or rain are generally available over large areas and can effectively power small, remote, wireless electronic devices and self-powered sensors. Ong et al. [

8] designed a mechanism to guide water droplets into a syringe, thereby converting random raindrops into single droplets that optimally impact the piezoelectric beam. This strategy enhances energy harvesting efficiency by optimizing droplet impact positions. Chilabi et al. [

9] analyzed rotational piezoelectric energy harvesting (RPZTEH) and categorized it into four types based on external forces: fluid (air and water) motion, human motion, rotating vehicle tires, and other rotational operational principles. In addition to direct impact, using water as a mechanical input source for RPZTEH can involve an indirect method where PZT turbines or watermills are excited by magnetic forces. Wong et al. [

10] found in practical field tests that raindrop impacts form a thin water layer on the surface of piezoelectric beams. This water layer acts as artificial mass and provides resistance to the beam structure while also affecting its dynamic characteristics, such as damping coefficient and vibration mode. The study concluded that energy generation from raindrop impact on piezoelectric harvesters is highly dependent on rainfall rate. Due to the inconsistency of energy production, piezoelectric energy harvesters need to integrate suitable energy storage devices to maintain continuous operation.

Rainfall amount, in addition to rainfall rate, significantly influences the effectiveness of rainwater energy harvesting (REH). Hadidi [

11] explored three innovative REH mechanisms: (1) a piezoelectric panel collector converting raindrop kinetic energy into electricity; (2) a tower (similar to a factory chimney) amplifying collected rainwater’s potential energy for turbine-based electricity generation; and (3) a salinity gradient power generation device utilizing the difference between rainwater and saltwater. Ilyas and Swingler [

12] categorized the impact mechanisms of REH droplets on solid surfaces into three types: bouncing (complete or partial, leaving varying amounts of water residue), spreading (water adhering to the surface), and splashing (droplet fragmentation and distribution). Recognizing the limitations of single-droplet studies, Wong et al. [

13] conducted experiments simulating three rainfall patterns with multiple droplets impacting a piezoelectric beam at various locations. This approach aimed to more realistically model raindrop impacts and their effect on energy harvesting. To further enhance realism, numerical simulation using random numbers will be employed to simulate actual raindrop behavior. Miao and Jia [

14] mentioned that in regions with high rainfall, harvesting raindrop energy can be an additional alternative solution to enhance the availability of decentralized energy for sensors or small electronic devices (such as single-device-level remote and wireless communication equipment). It can also supplement traditional decentralized renewable energy generation solutions. Examples of potential candidate regions include the remote northern areas of the Amazon in Brazil and the isolated islands of eastern India and Bangladesh, where seasonal rainfall is abundant, and connecting to the national power grid is both challenging and uneconomical. These effects are further amplified by the cumulative superposition of uniformly distributed raindrops on the plate. For distributed raindrop models, the same cumulative edge strain effects were observed, yielding energy densities several orders of magnitude higher than at single direct impact points. Taiwan also experiences an average annual rainfall of 2457 mm, 2.6 times the global average, as noted by Liaw and Chiang [

15]. Rainfall distribution across Taiwan varies considerably, decreasing from northeast to southwest. This regional variation is further complicated by Taiwan’s topography, leading to significant differences even within the same rainfall range. This underscores the necessity of rainfall zoning for accurate rainfall potential assessment. El-Hebeary [

16] designed plate structures for harvesting vibration energy from two or more vibration modes. The motivation for this research was to develop resonators that respond to variable-frequency base excitation sources. Duvigneau et al. [

17] found unusual results in experimental modal analysis from the oil sump of a twin-cylinder diesel engine. Typically, such a thin oil pan base would exhibit vibration behavior similar to a plate. It was observed that in square plates, there can be positive and negative superpositions of natural modes with the same natural frequency. These superpositions were observed under free-free boundary conditions through analytical, numerical, and experimental methods. Aridogan et al. [

18] suggested that compared to harvesters based on piezoelectric cantilever beams, piezoelectric patch harvesters integrated into thin-plate structures could be a more efficient and compact choice for powering wireless structural health and condition monitoring systems. Their study introduced piezoelectric patch-based thin-plate steady-state stochastic vibration energy harvesting, along with electromechanical modeling, analysis, numerical solutions, and experimental validation. They proposed a distributed parameter modeling method for transverse point force-excited thin motherboards, presenting electromechanical models for multiple piezoelectric patches connected in series and parallel.

Wang et al. [

19] designed and fabricated a type of film-based converter using polyaniline and polyaniline–graphene composite films to harvest rainwater energy. These converters generated maximum current and voltage outputs of 3.80 μA and 85.01 μV per raindrop, respectively, based on the charging and discharging processes of cations at the rain-to-film interface with the pseudocapacitor. Zhao et al. [

20] utilized graphene-rich composite films fabricated through a simple casting technique as self-powered single electrodes to harvest rainwater energy. They successfully developed single-electrode systems that generated periodic current and voltage signals when raindrops impacted the electrodes. Zhu et al. [

21] designed a self-powered cathodic protection (CP) system for metal surface protection driven by a triboelectric nanogenerator (TENG), which harvested energy from natural raindrops and wind. The corrosion mechanism on metal surfaces is an electrochemical process that accelerates in the presence of a dilute electrolyte, such as during rainfall. Ahmad et al. [

22] suggested that in piezoelectric patch designs, mechanical damping dissipates system energy and weakens vibrations. Reducing mechanical damping can thus improve output power. They found that stiffer piezoelectric patches (with higher elastic modulus) resulted in smaller deflections, leading to reduced output power. Viola [

23] conducted experimental comparisons among different rain energy harvesting structures and studied their rectification circuits. Three configurations were considered: cantilever (fixed at one side), bridge (fixed at both ends), and floating ring (a cantilever loop subject to external loading). Edla et al. [

24] proposed an improved H-bridge rectification circuit to enhance and stabilize output voltage. To evaluate the circuit’s effectiveness for human-motion energy harvesting, they conducted tests with a piezoelectric device (PD) connected to a cantilever beam and subjected it to low-frequency mechanical vibrations using a shaker. Lu and Boussaid [

25] introduced an efficient P-SSHI rectifier for piezoelectric energy harvesting. The rectifier detected the polarity change in current generated by the PD using the voltage across the PD terminals. The voltage reversal process was automatically controlled by diodes in an oscillating network. This achievement provided inspiration for integrating a power management system into rain energy harvesting (REH) systems.

The research regarding energy harvesting from other natural sources of energy is studied by Hollm et al. [

26]. They analyze a WEC design with inclined modules connected to a floating frame. Using numerical models, it examines energy harvesting performance under regular and irregular waves, highlighting the effects of design and wave parameters. Ambrożkiewicz et al. [

27] use piezoelectric energy harvesting systems to convert mechanical energy into electricity, analyzing factors such as vehicle speed and embedment depth that influence power output in pavement applications. Páez-Montoro et al. [

28] present a solar energy harvesting system using a semi-flexible solar module, flexible battery, and BLE microcontroller. Tested under daily use conditions, the device achieved up to 53% charge gain, and could operate continuously with 6 h of direct sunlight per day. Regarding intentional nonlinearities in energy harvesting, Rosso et al. [

29] experimentally investigated a magnetically frequency-upconverted piezoelectric energy harvester. Using a low-frequency shaker (3 Hz) (APS 113 Long-Stroke shaker (SPEKTRA Schwingungstechnik und Akustik GmbH Dresden, Germany)), they explored how the velocity of magnetic interaction influenced the activation of the first vibration mode, with nonlinear material effects observed as frequency shifts in the output spectrum. Additionally, Daukševičius et al. [

30] analyzed magnetic plucking dynamics for frequency up-conversion, identifying key parameters for efficient energy transfer and demonstrating that transient resonance can maximize power output. These findings provide design insights for wearable energy harvesting applications.

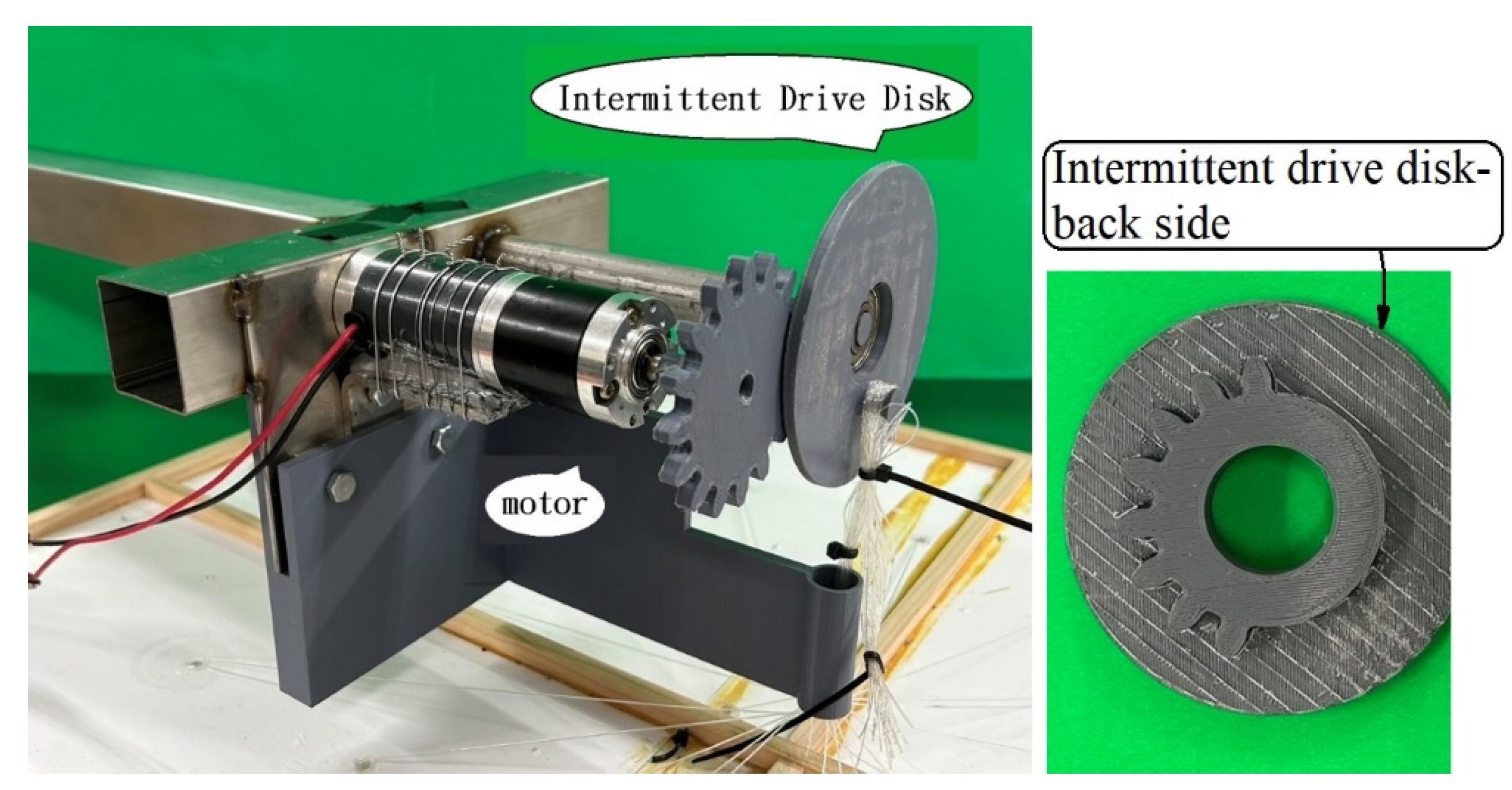

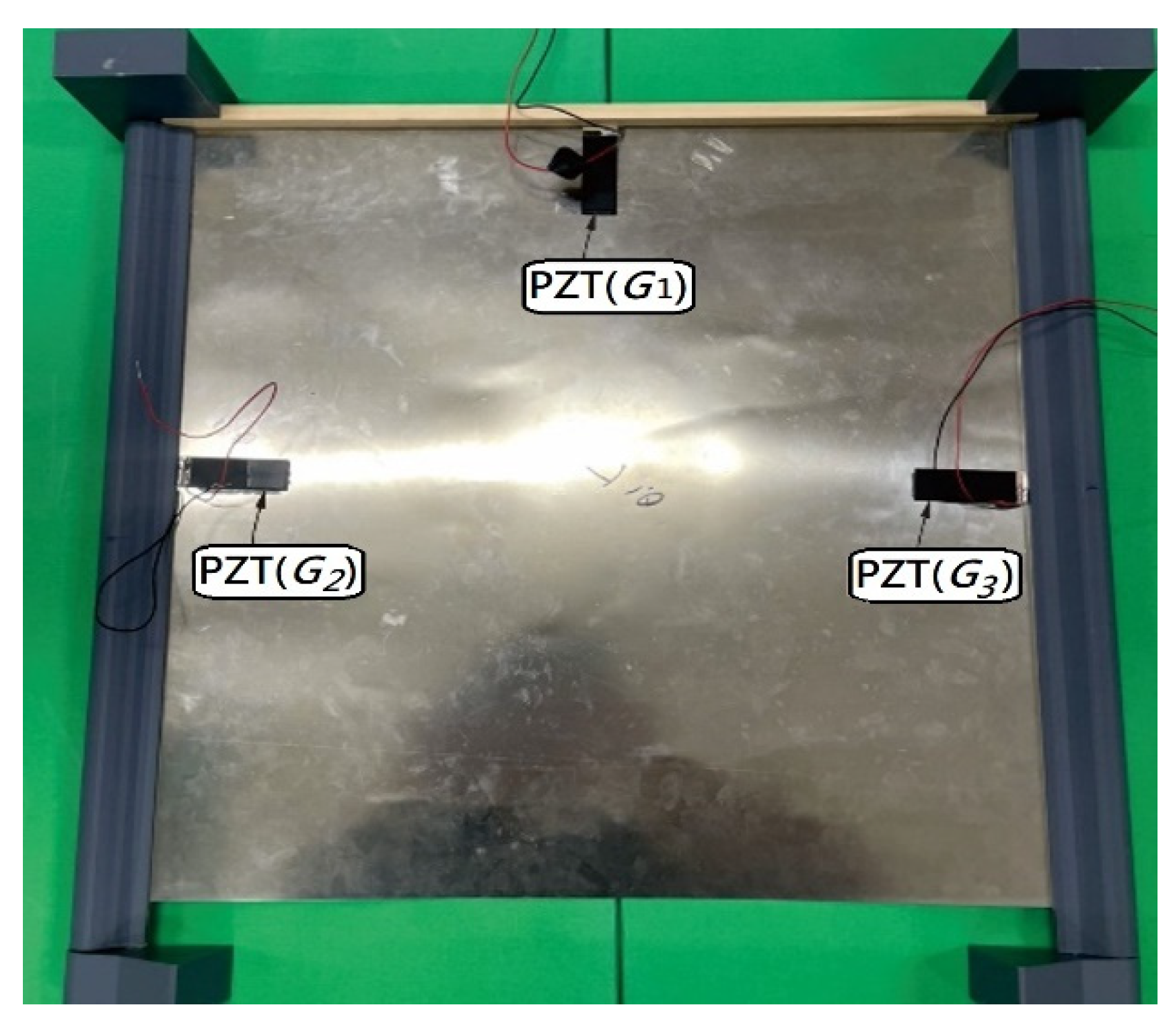

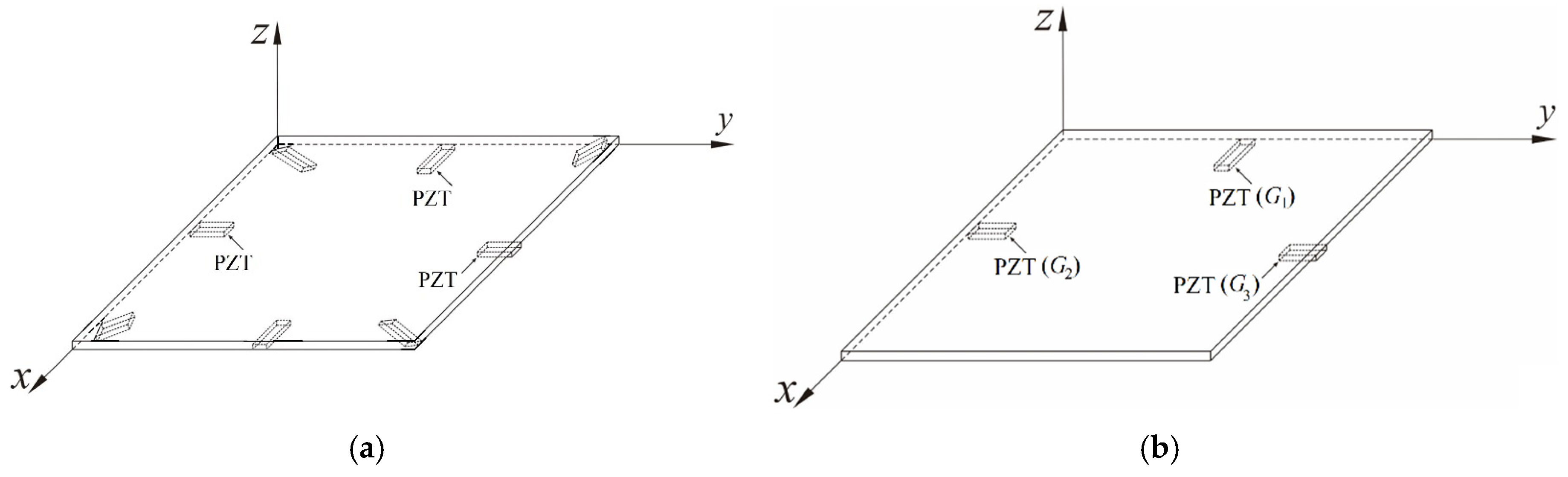

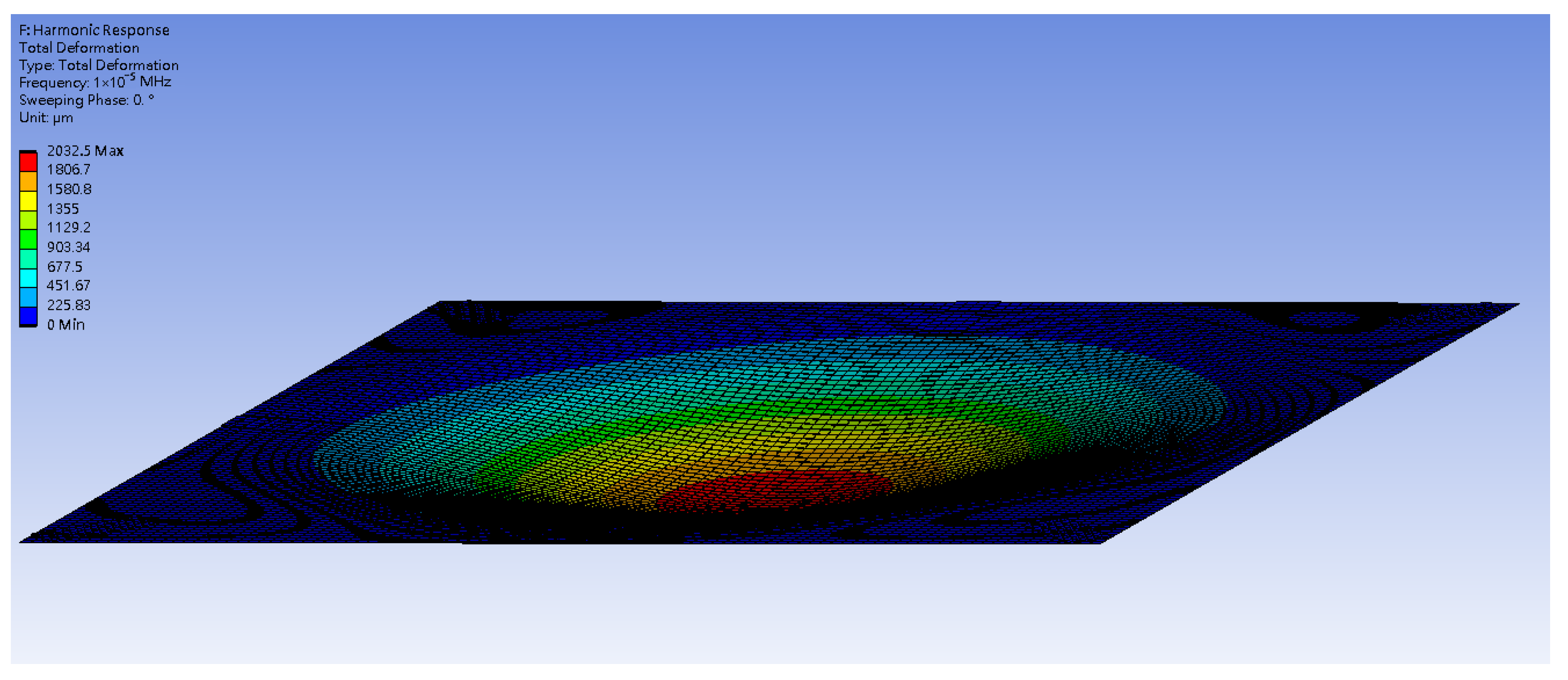

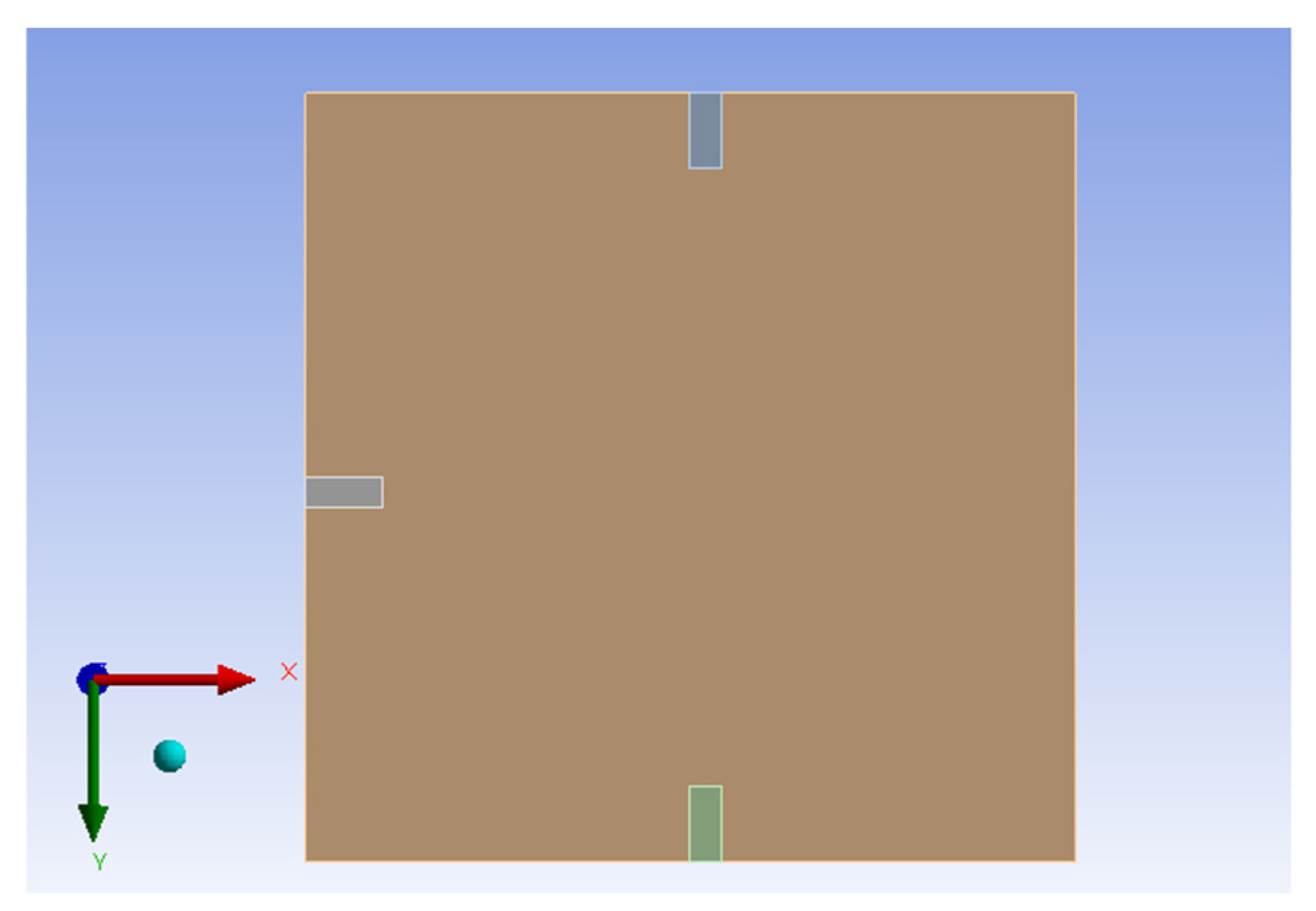

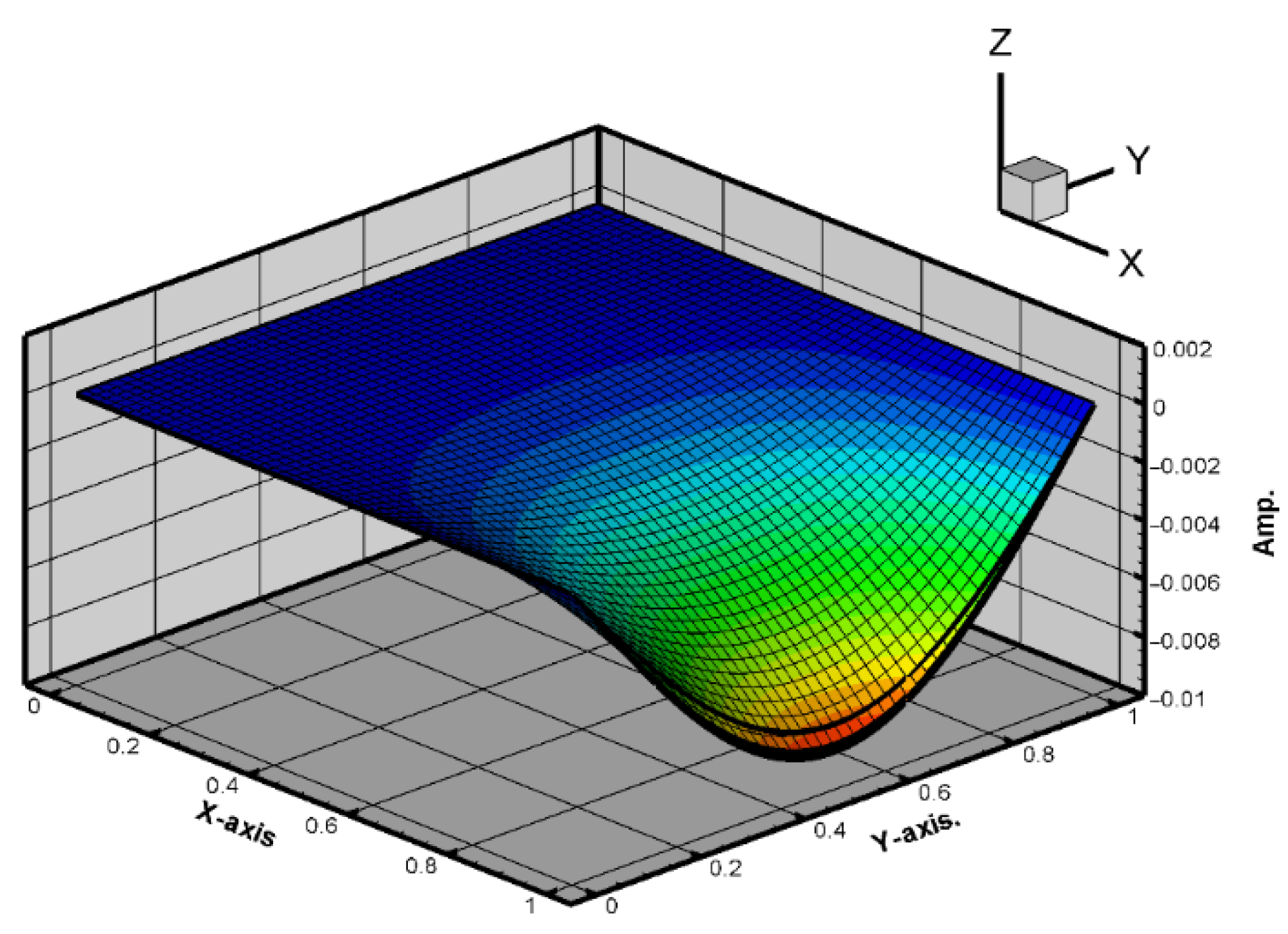

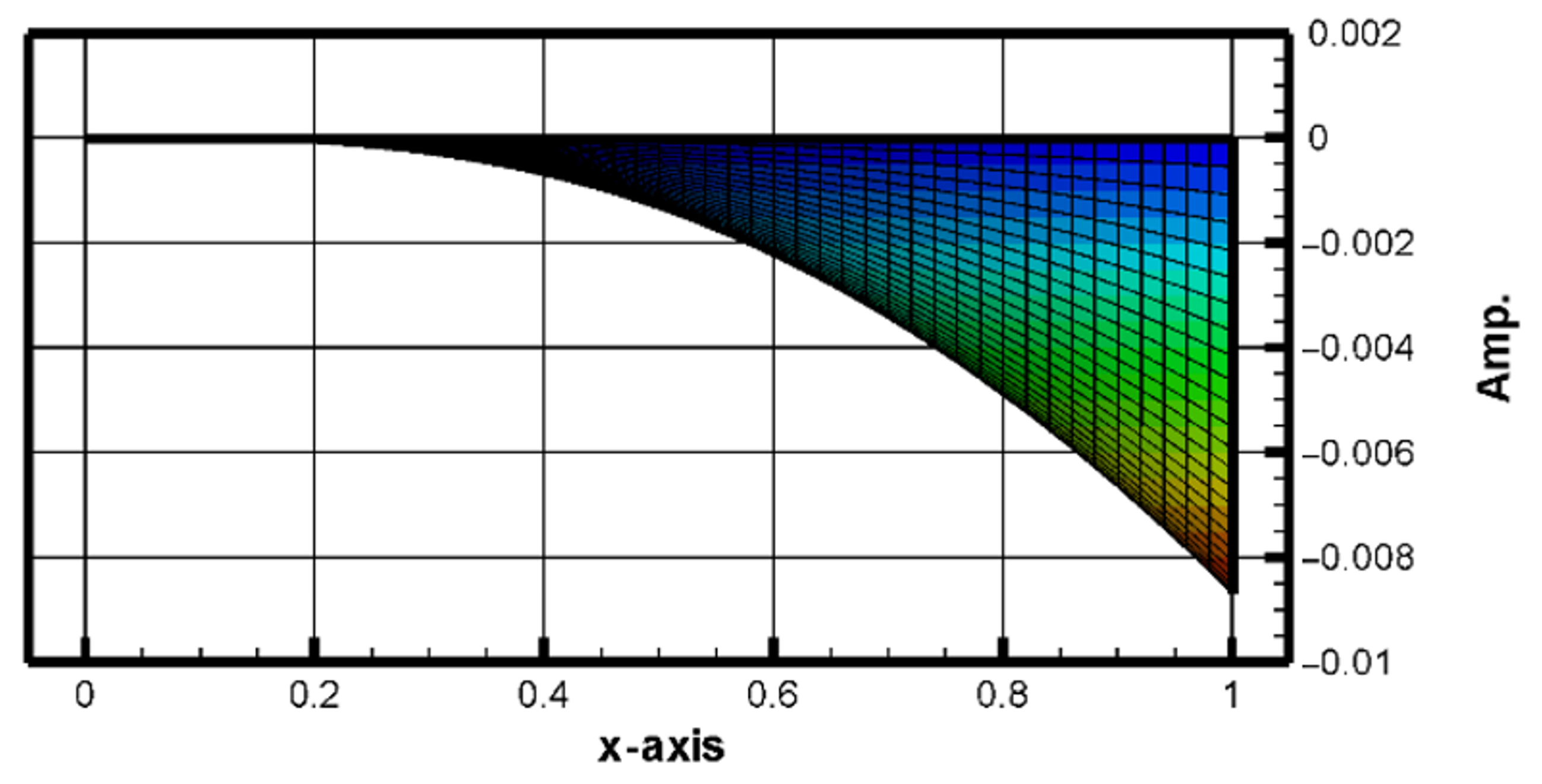

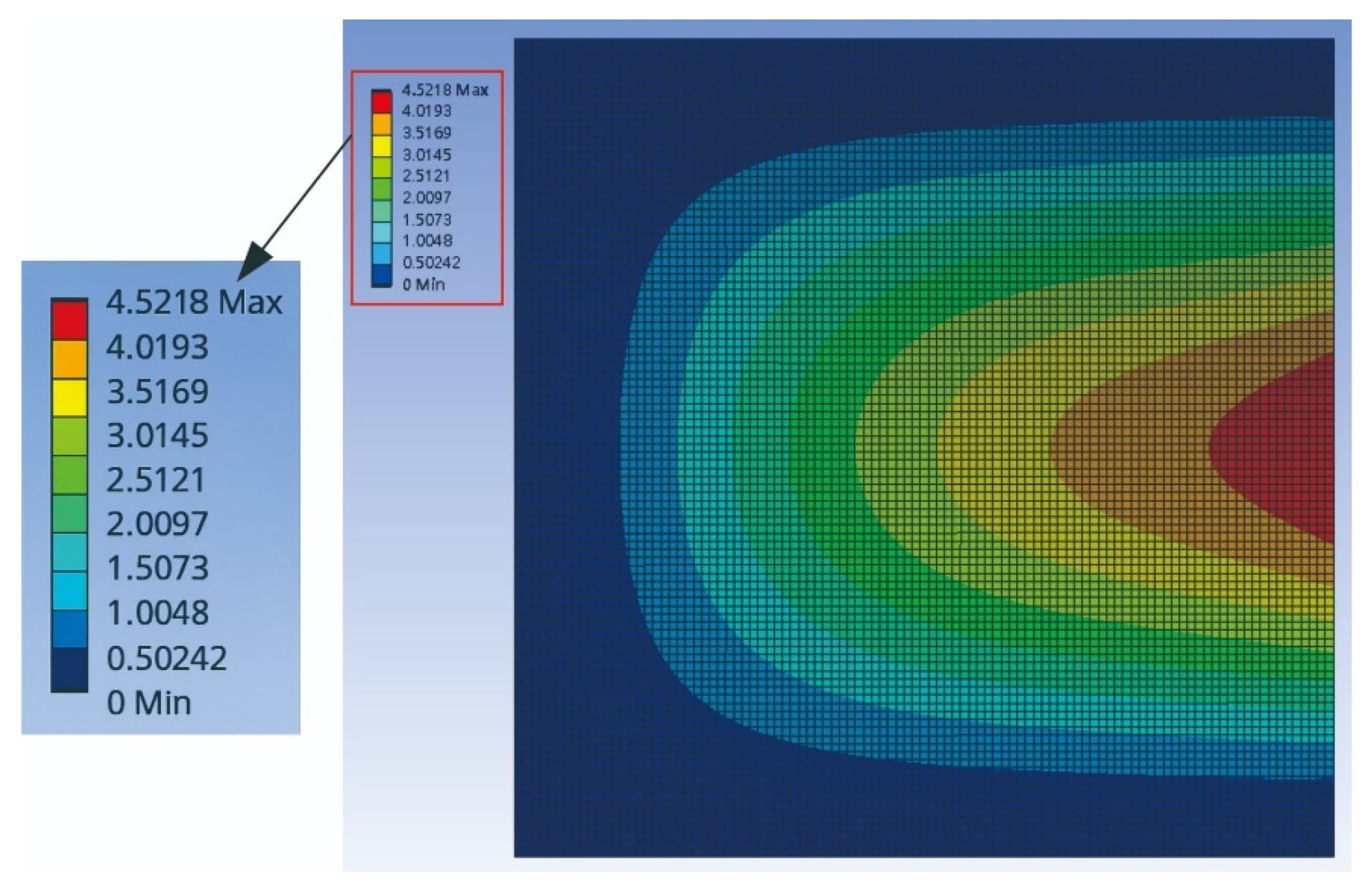

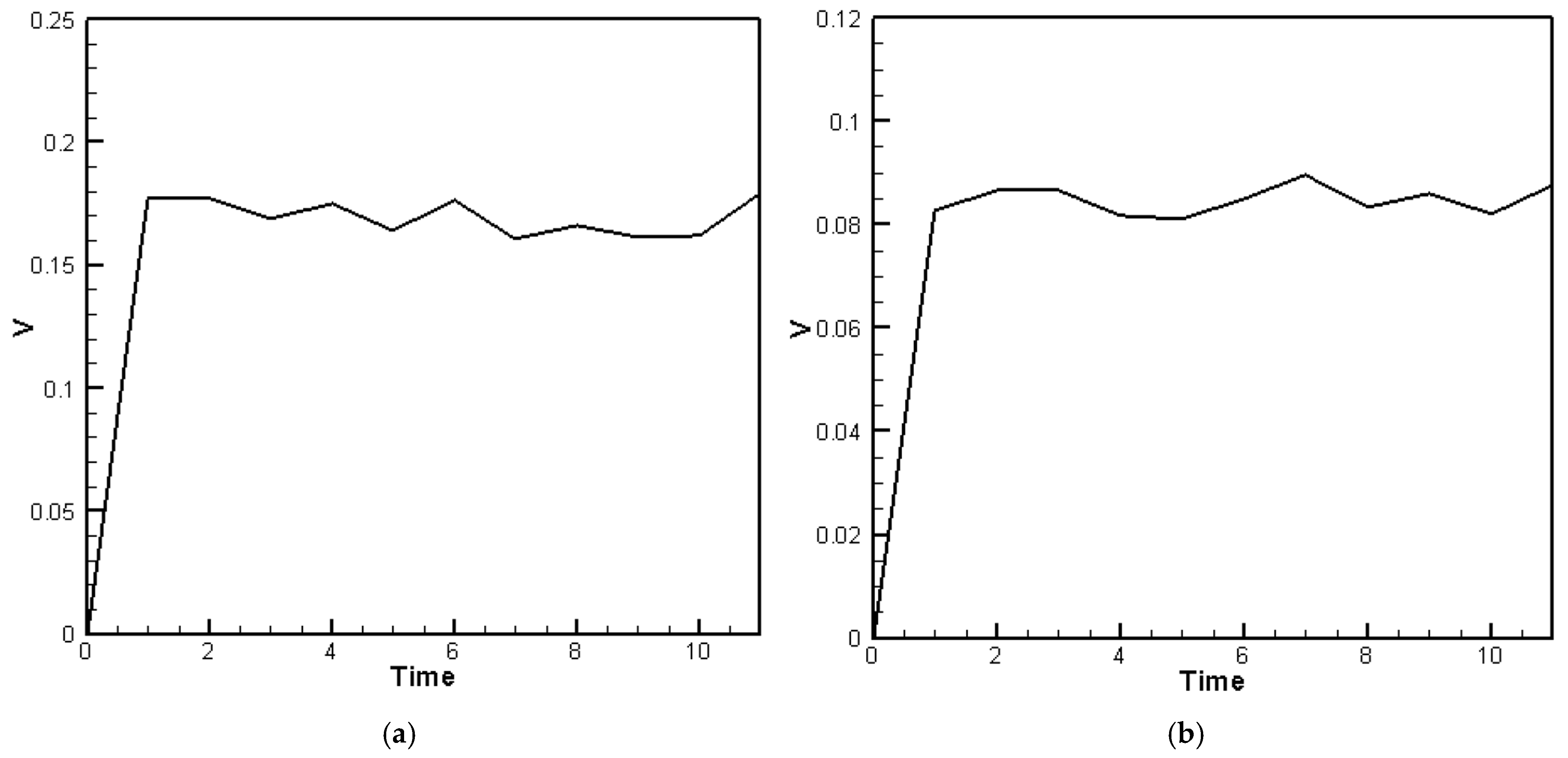

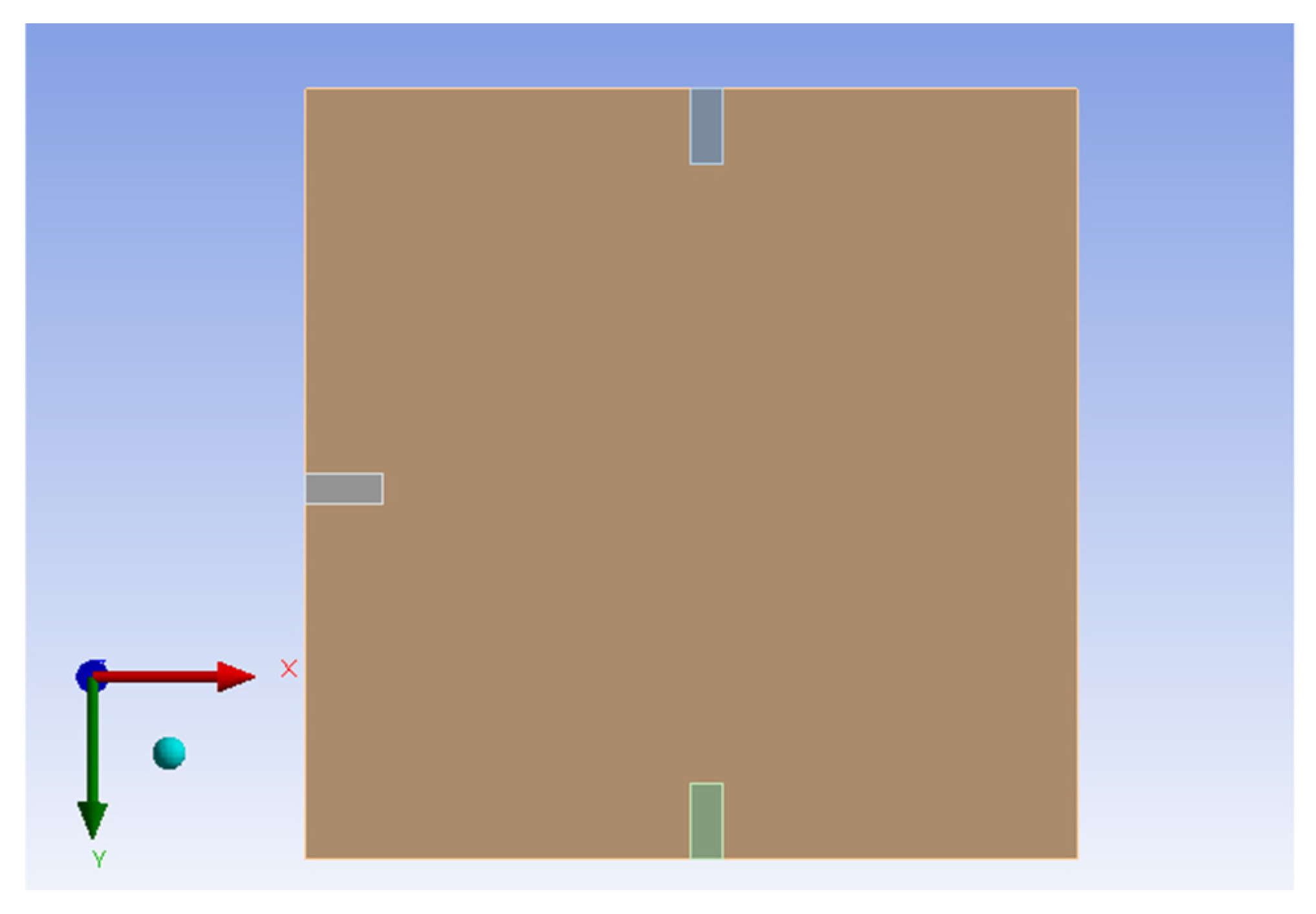

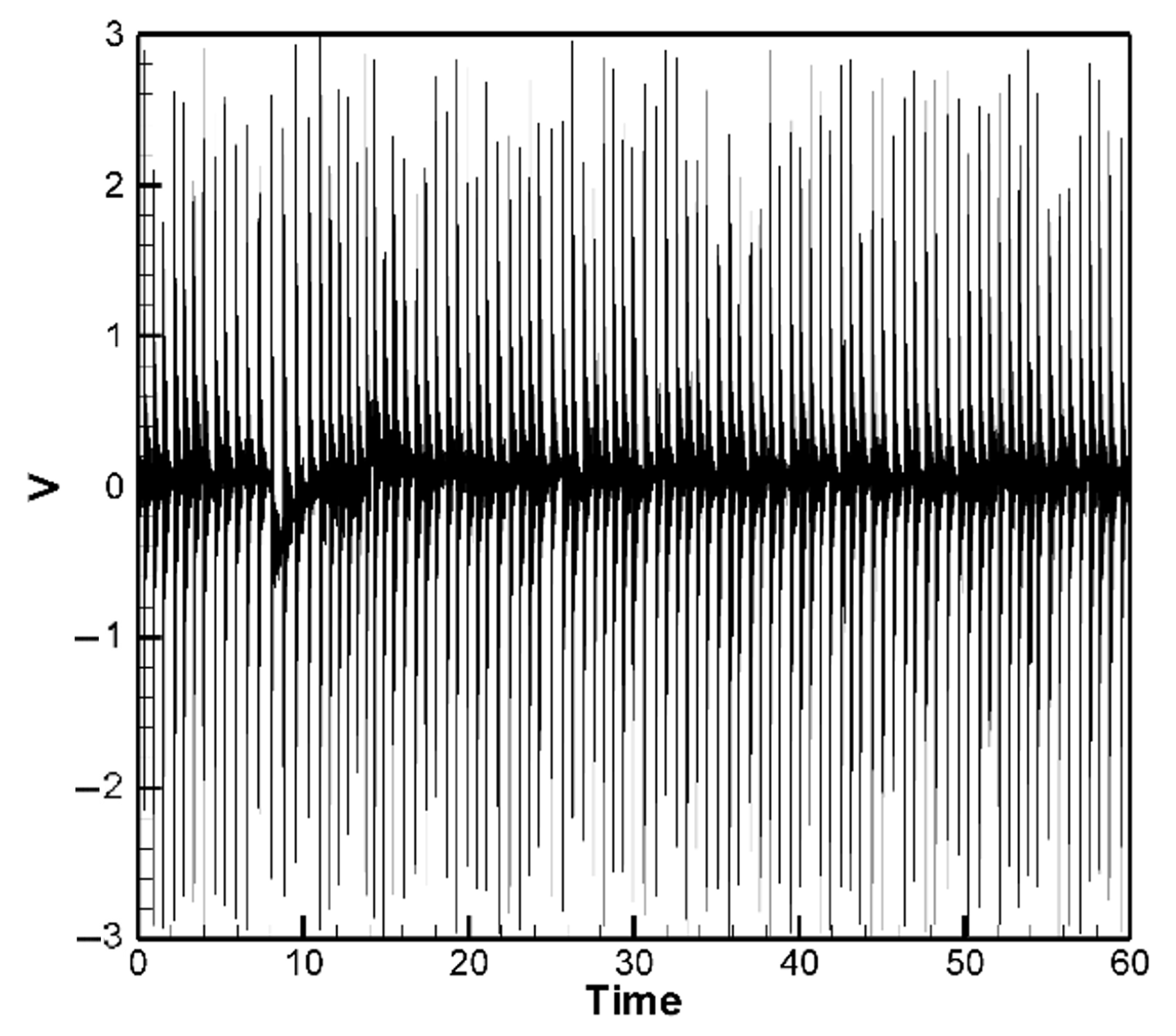

The use of rain-induced excitation is motivated by practical considerations for energy harvesting in environments where solar energy is unreliable due to frequent rainfall—such as in tropical, subtropical, or high-humidity regions. While other types of excitation (e.g., wind, vibration from human activity, or mechanical shaking) are widely studied, rainfall is an abundant and underutilized energy source that naturally produces localized, impulsive forces suitable for thin-plate vibration. Moreover, raindrops generate non-periodic, stochastic impacts, which makes this type of loading particularly challenging and novel for modeling. By successfully harvesting energy under such irregular excitation, this study demonstrates a potentially valuable alternative energy source for low-power devices (e.g., environmental sensors, IoT systems) in outdoor, rain-prone environments. The ability to integrate this system with existing structures (such as tents, canopies, or solar panels) further supports its practical appeal. This present study first establishes a theoretical plate motion model to verify the feasibility of the proposed “Rain Energy Harvester (REH)” system through numerical calculations, commercial software simulations, and experimental validation. Given that the plate thickness is much smaller than its length and width, the Kirchhoff–Love Plate Theory was selected as the primary framework. Random functions simulating raindrops were incorporated into the numerical simulations to develop a model that describes plate deformation caused by the kinetic energy of raindrops. This study analyzes two plate configurations: a fully hinged plate (H-H-H-H plate) and a plate with one fixed edge, two hinged edges, and one free edge (C-H-F-H plate) to simulate the vibration behavior of solar panels and/or rain covers. Using ANSYS Workbench (ANSYS 2021 R1) for simulation, the study identifies the best piezoelectric patch placements and evaluates their piezoelectric outputs. Numerical simulations incorporating piezoelectric equations further validate these findings. In the experimental setup, elastic steel was used as the plate material. Multiple small steel balls were dropped at various locations on the plate to simulate random raindrop impacts. A power management (PM) system was integrated, involving a full-bridge rectifier to convert the alternating current from the piezoelectric patches into direct current. The rectified current was filtered using an Arduino Uno R3 (Mouser electronics, Inc., Taipei, Taiwan), which selected the highest energy-generating vibration events. These signals were then fed into a buck-boost converter to provide a stable voltage for circuit loads or battery storage. The PM system ensures efficient vibration energy capture, stable conversion, and storage, providing a reliable voltage output. This study conducts mutual validation through numerical calculations, software simulations, and experimental results. This research will offer practical applications for rain-rich regions. Potential applications include integrating the system with solar panels to enhance energy efficiency on rainy days or using it for power generation in structures like tents and rain shelters. The system is also suitable for remote areas without access to the power grid or emergency power supply scenarios after disasters, providing decentralized and sustainable energy solutions. Moreover, this study can drive industrial applications in piezoelectric materials and energy management technologies, fostering the design and production of green energy equipment and stimulating related industrial developments. For smart sensor and IoT applications, a miniaturized rain energy harvesting system can power small sensors and IoT devices, such as those for bridge health monitoring, agricultural sensing, and environmental monitoring, enhancing the devices’ autonomy and practicality. Given the study’s methodological and theoretical extensibility, the proposed approach can be adapted to other vibration energy harvesting scenarios, such as wind energy and structural vibrations, offering foundational models and methodologies for future research in emerging energy technologies.

The remainder of this paper is organized as follows.

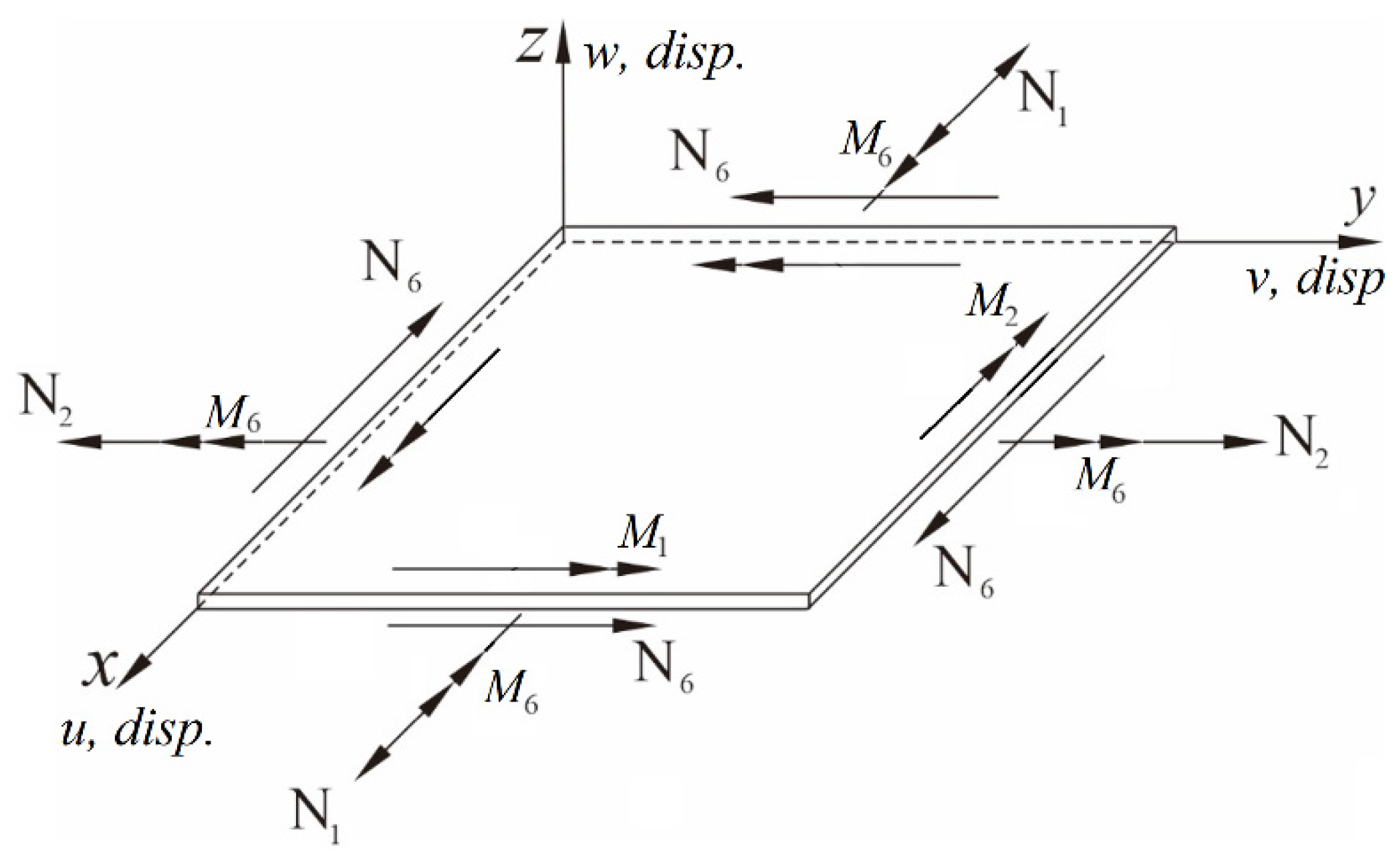

Section 2 presents the theoretical modeling of the nonlinear plate using Hamilton’s principle, including geometric assumptions, governing equations, and piezoelectric coupling.

Section 3 describes the numerical methods used to solve the system, including the application of random excitation forces and the Runge–Kutta algorithm.

Section 4 describes the experimental setup, including the vibration energy harvester, piezoelectric patch placement, and measurement procedures. It also compares theoretical, simulation, and experimental results, focusing on the effects of slapping forces and boundary conditions.

Section 5 introduces the power management system design, including rectification and NMOS control for voltage stabilization and efficient energy handling. Finally,

Section 6 provides conclusions and discusses implications for future development.

5. Power Management System Design

Having validated the proposed rain energy harvesting system through theoretical modeling, numerical simulation, and experimental verification, it is essential to explore its potential deployment in real-world environments. The following section outlines practical applications, scalability considerations, and integration strategies, particularly in rain-prone and energy-deficient regions. These insights directly reflect on the system’s practical viability and long-term relevance.

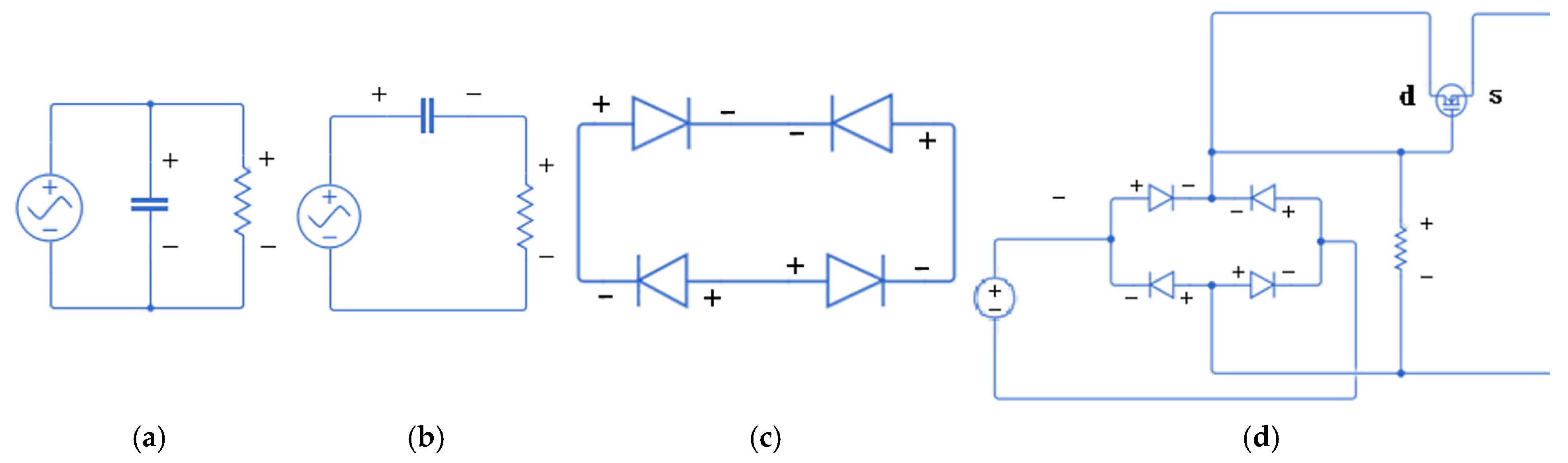

According to the general principle of battery charging, the charging voltage must exceed a certain threshold to allow continuous energy flow into the battery. If the charging voltage is too low, it may instead cause the battery to discharge. To achieve effective energy storage, this study designs a power management system with the goal of enabling the proposed design to function effectively and fulfill the purpose of energy storage. In the power management system, the circuit simulation is carried out using Simulink (

Figure 17a–d). The equivalent circuits for current and voltage behavior of the piezoelectric patches are shown in

Figure 17a,b. Since the output of piezoelectric patches is alternating current (AC), it must be rectified into direct current (DC) for practical use. This is achieved using a full-bridge rectifier composed of diodes (

Figure 17c). An N-channel MOSFET (NMOS) is then integrated to conduct the current more effectively, especially under higher output voltages, forming the basic unit of the circuit (

Figure 17d).

For the H-H-H-H plate, four such units (each consisting of a piezoelectric patch, rectifier, and NMOS circuit) are connected in parallel. For the C-H-F-H plate, three units are connected in parallel. Parallel connection is chosen over series due to its higher energy harvesting efficiency and its ability to mitigate mismatched voltages across different patches. To ensure the MOSFET operates correctly, a resistor is included to maintain the gate-source voltage above the threshold level. A boost (step-up) converter is added after the parallel circuits to stabilize the output voltage for powering external loads. This configuration ensures consistent voltage during vibrations and prevents energy loss when connecting piezoelectric patches of varying output voltages.

The complete circuit—consisting of four parallel-connected rectifier-NMOS units followed by a boost converter—is illustrated in

Figure 18. The switching element in the boost converter is controlled using an Arduino UNO (

Figure 19). In this study, the vibration frequency (representing rainfall) is set at approximately 2 Hz, with a moderate rain intensity. The relation between input voltage (U

in), output voltage (U

out), and duty cycle (

q) is expressed as U

out(1 −

q) = U

in, where

q represents the duty cycle. This formula is used to calculate the duty cycle and set the switching timing. The Arduino’s pin 7 controls the NMOS switch, while pin A0 monitors the output voltage of the piezoelectric array. Based on the voltage readings, the Arduino adjusts the switching frequency to optimize converter performance. The Arduino UNO sends a signal to the NMOS to control the switch. When the NMOS is turned on, the circuit becomes conductive, and the NMOS acts like a ground wire. The circuit then forms a loop, with current flowing clockwise through the inductor. The inductor converts electrical energy into a magnetic field to store energy. The left side of the inductor is positive. When the NMOS is turned off, the inductor current cannot change abruptly, so the current continues to flow to the right. This allows the voltage from the power source, which is the piezoelectric patch, to be in series with the inductor voltage.

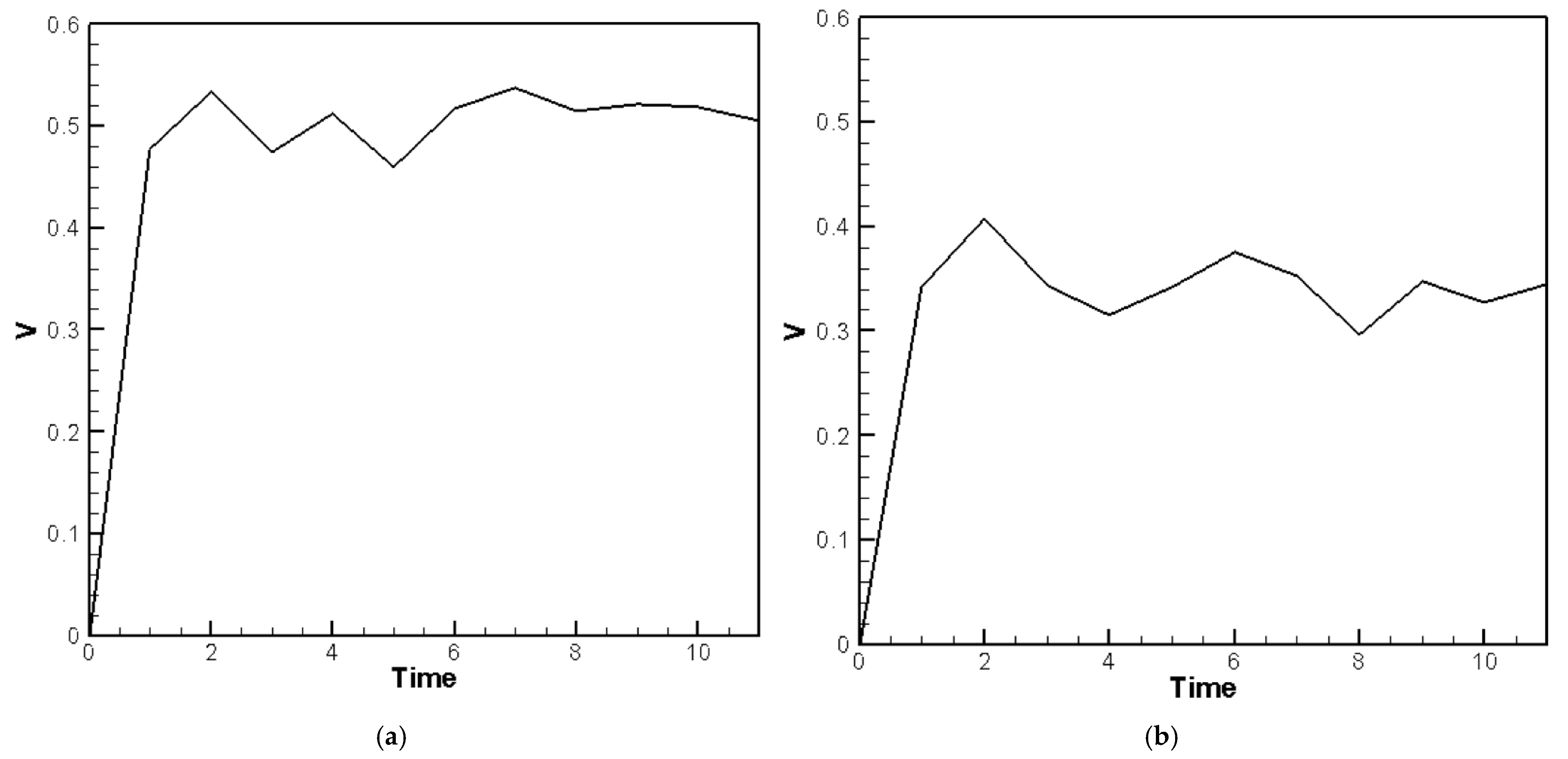

For the case of H-H-H-H plate, the piezoelectric patch used in the experiment outputs an AC signal with an average voltage of approximately 0.53 V and an average current of 0.01 mA. After passing through a full-wave bridge rectifier composed of Schottky diodes, due to the typical voltage drop of about 0.12 V across the Schottky full-wave bridge, the resulting DC output has an average voltage of approximately 0.41 V (

Figure 20a). Two piezoelectric patches (corner and edge) are connected in parallel using an NMOS. After rectification, the positive terminal is connected to both the “Gate” and “Drain” of the NMOS, while the negative terminal is grounded. When the gate voltage exceeds the threshold voltage of 0.2 V, the NMOS turns on, and the output voltage equals the input voltage. When the gate voltage is below the threshold, the NMOS turns off and the output voltage drops to zero. As shown in

Figure 20b, the vertical axis represents voltage and the horizontal axis represents time. The average output voltage after NMOS switching is approximately 0.38 V.

Figure 20c is a zoomed-in view of a portion of

Figure 20b, showing that voltages below 0.2 V are blocked. Since this design blocks voltage flow below 0.2 V, it may reduce the average voltage, but it helps prevent excessive voltage differences between parallel-connected piezoelectric patches, thereby reducing current loss, improving efficiency, and providing a more stable output voltage.

For the case of C-H-F-H plate, the same as H-H-H-H plate, piezoelectric patch used in the experiment outputs an AC signal with an average voltage of approximately 0.50 V and an average current of 0.01 mA. After passing through a full-wave bridge rectifier composed of Schottky diodes, due to the typical voltage drop, the resulting DC output has an average voltage of approximately 0.38 V (

Figure 21a). Three piezoelectric patches (

G1,

G2 and

G3) are connected in parallel via an NMOS transistor. After rectification, when the gate voltage exceeds the threshold of 0.2 V, the NMOS turns on, allowing the output voltage to follow the input voltage. As shown in

Figure 21b, the average output voltage after NMOS activation is approximately 0.34 V.

Figure 21c presents a zoomed-in view of a selected portion of

Figure 21b, clearly illustrating that input voltages below 0.2 V are effectively blocked.

This power management system actively monitors the energy output from each piezoelectric unit and dynamically adjusts to select the most efficient energy source. It enables effective vibration energy harvesting, stable DC conversion, and reliable power delivery for downstream loads. Although the measured average current output from the proposed system is relatively low (approximately 0.01 mA), the ability to achieve a stable voltage output through the implemented power management circuit represents a significant milestone in validating the theoretical framework. This outcome confirms that the rain-induced impact model, including the slapping force correction, is both feasible and functionally effective. The system’s capability to stabilize voltage under randomly distributed raindrop excitations serves as a critical proof-of-concept for real-world energy harvesting scenarios. While the harvested current may not yet be sufficient for direct battery charging, it is already suitable for powering ultra-low-power devices, such as environmental sensors or wireless communication modules operating on intermittent duty cycles. Future enhancements—such as increasing the number of piezoelectric elements, optimizing plate geometry and material, or incorporating energy storage components like supercapacitors—can further improve the energy output and broaden the application scope. Therefore, the success of voltage regulation under stochastic excitation provides a solid foundation for the continued advancement of rain-based vibration energy harvesting systems.

6. Conclusions

This study presents a rain-induced vibration energy harvesting system (REH) using nonlinear thin plates with integrated piezoelectric elements. Two structural configurations were investigated: a fully hinged plate (H-H-H-H) and a clamped–hinged–free–hinged plate (C-H-F-H). The nonlinear plate behavior was modeled using Hamilton’s principle combined with classical Kirchhoff plate theory and von Kármán-type geometric nonlinearity. The governing equations were solved using the fourth-order Runge–Kutta method under random impact forces simulating raindrop excitation.

A key contribution of this study is the inclusion of slapping forces, representing localized raindrop impacts. Theoretical results that incorporate slapping forces show significantly improved agreement with experimental measurements, reducing the voltage prediction error from 67.7% to 3.88% for corner-mounted piezoelectric patches. In contrast, edge-mounted patches remain affected by dual boundary interactions, resulting in a residual error of approximately 32%, which is acknowledged as a modeling limitation beyond the current study’s scope.

Comparative analysis between theoretical simulations and ANSYS results further validates the nonlinear plate model under deterministic loading. While ANSYS effectively simulates structural deformation, its standard framework does not account for transient, stochastic slapping forces, highlighting the necessity of a customized theoretical approach.

Additionally, a power management circuit was integrated to achieve stable voltage output from the harvested vibration energy. Although the current output remains relatively low (~0.01 mA), the successful rectification and voltage stabilization confirm the system’s functional feasibility and lay the groundwork for future energy storage enhancements.

Overall, the proposed REH system demonstrates promising potential for deployment in rain-prone environments, with applications in self-powered sensors, canopies, tents, and hybrid solar–rain energy systems. Future work will focus on extending excitation duration, increasing piezoelectric density, and optimizing structural design to improve energy output and broaden practical applications.

Future research will aim to improve the realism and effectiveness of the proposed energy harvesting system. First, the excitation model will be extended to cover longer durations and more frequent raindrop events to better simulate continuous rainfall conditions. Second, the refinement of the theoretical model—particularly in capturing the complex interactions at clamped–hinged boundaries—will be undertaken to improve accuracy. Lastly, integration with energy storage components, such as supercapacitors or low-power storage modules, will be explored to develop a fully functional and autonomous rain energy harvesting system for practical applications.