1. Introduction

There are many problems associated with underwater vehicles, including underactuation, speed limitations, and lumped dynamics due to parameter uncertainties and external disturbances. A very attractive task for the movement of various marine vehicles is tracking control, which allows the system to achieve the desired trajectory with satisfactory performance. Since this work only deals with the implementation of trajectory tracking in horizontal motion for underactuated vehicles, only a brief review of the literature on this class of vehicles is limited.

Very often, the dynamics model assumes full symmetry of the vehicle, which means that the center of mass coincides with the geometric center. Then, a control strategy is built for the adopted model. On the one hand, the advantage of this approach is that the mathematical theory is simplified. On the other hand, if the symmetry condition is not met in practice, the implementation of the control task will be difficult or even impossible. Despite this obvious observation, many proposals have been made to solve the trajectory tracking problem.

The existing control strategies are based on different control methods or their combinations. Some examples include the use of sliding mode control (SMC) [

1], prescribed performance for trajectory tracking error [

2], contraction theory [

3], combination of backstepping and SMC [

4], backstepping and integral SMC [

5], an adaptive fixed-time terminal sliding mode control (AFiTSMC) [

6], an adaptive trajectory tracking controller with a new integral-type Lyapunov based on disturbance observer [

7], and model predictive control with SMC (theory and simulations supported by the experiment) [

8]. In many works, in addition to other control algorithms, artificial neural networks (ANNs) are used to obtain better performance of the proposed trajectory tracking strategy, e.g., ref. [

9] (with backstepping and SMC), ref. [

10] (with event-triggered control (ETC) and backstepping), ref. [

11] (with prescribed performance control (PPC), barrier Lyapunov function (BLF), and dynamic surface control (DSC)), ref. [

12] (non-singular TSMC). Additionally, it is worth pointing out some works based on fuzzy logic, e.g., ref. [

13] (with event-triggered control and dynamic surface control), ref. [

14] (with adaptive backstepping technique, command-filter, and event-triggered mechanism). Sometimes, however, the values of the forces and moments for the vehicle selected for testing do not seem realistic, e.g., in [

15,

16], and the results obtained indicate that the algorithm is effective, but not necessarily for real operating conditions.

Even based on this brief literature review, it is easy to see that control strategies focus on the use of increasingly complex methods (or rather their combinations to precisely accomplish the trajectory tracking task). However, it is difficult to know whether acceptable results will also be obtained in the case of vehicle asymmetry. Herman [

17] shows, based on simulation tests for several selected control algorithms, one vehicle model, and two trajectories, that strategies based on a fully symmetric model do not sufficiently perform the task of tracking the trajectory or are even unable to perform this task if there are shifts in the center of mass.

There are also works in which control schemes based on such a reduced model were verified experimentally. One can then somehow argue that with the adopted assumptions, the problems of lack of symmetry have been overcome. For example, ref. [

18] (adaptive single-parameter backstepping controller (SPBC) with saturation) or [

19] (the radial basis function and model reference adaptive control) may be mentioned here. It can be assumed that if the proposed control schemes were verified on a real vehicle, this work would not address this issue.

There is also a group of control strategies based on trajectory tracking using vehicle models for which the center of mass is shifted relative to the geometric center. Such models include mass couplings and hydrodynamic damping couplings. Taking this shift into account in the model brings it closer to reality than using a symmetrical vehicle model and makes the control scheme more useful. There are also some works that assume asymmetric vehicle models for control purposes. For example, the SMC method was given in [

20]. A control scheme applying backstepping and integral SMC was shown and tested in [

21]. The scheme developed in [

22] was composed of the backstepping technique, cascade analysis, and the Lyapunov approach. In [

23], a control strategy using the input–output feedback linearization method was proposed (with results obtained for a real vehicle), while in [

24], output feedback control using a state observer was considered.

It is also worth mentioning the use of ANN in control strategies, e.g., ref. [

25] (with prescribed performance and transverse function control), ref. [

26] (optimal control with adaptive dynamic programming), and [

27] (with prescribed trajectory tracking performance). Unfortunately, sometimes it happens that the performance of the control algorithms was verified by simulation, but the obtained input signal values were unrealistic, e.g., in [

28].

There are few works in which experimental results obtained for real surface vehicles with an asymmetric model can be found, e.g., refs. [

29,

30]. Thus, it can be concluded that experimental validation is difficult in the case of a shift of the center of mass, and therefore, simulation studies may indicate directions for further research in the field of trajectory tracking. It is also worth noting that there is a very limited number of papers in which the control scheme has been tested for two vehicle models. This approach proves a certain universality of the trajectory tracking algorithm. One could mention here, e.g., refs. [

21,

31].

The following thesis of the work is stated: if it is not possible, for any reason, to experimentally verify the control scheme on a real vehicle, it should be tested in simulation, taking into account the shift of the center of mass.

It can be seen that there are many control schemes for a model with a diagonal inertia matrix (i.e., assuming that the geometric center of the vehicle is located in the same place as the geometric center). Therefore, it seems interesting to check the suitability of already designed and simulation-tested control schemes for tracking the trajectories in the event of an intentional or unintentional shift of the center of mass. This work is an attempt to consider this issue because with the constantly growing number of proposed control strategies, perhaps some of them are robust to the event of center of mass shift, while others are not suitable for this purpose and require almost ideal operating conditions, which in practice may turn out to be impossible.

The slow motion of the vehicle (below 1 m/s in steady state motion phase) was chosen for two reasons. Firstly, the effect of couplings can be demonstrated when the dynamic forces resulting from vehicle movement are still small compared to movement at the permissible velocity. Secondly, if the algorithms designed for the dynamics model without taking into account the effect resulting from the shift of the center of mass were tested at high velocities, then the errors could be unacceptable.

The novelty of this work is the proposal of a combination of the backstepping and SMC methods, but additionally based on the velocity transformation method, which results in obtaining variables containing dynamic and geometric parameters of the vehicle model. Such an approach allows for including inertial couplings in the dynamic model, which leads to estimating their influence on the implementation of the trajectory tracking task in the designed controller (taking into account IQV). It is equivalent to recognizing the effect of shifting the vehicle’s center of mass on its behavior when it is in motion. It is therefore a certain extension of known control methods to the case when the vehicle dynamics model is generalized. In many works known from the literature (as mentioned earlier), the dynamics model does not take into account the couplings in the system, and the controller is designed for such a model. This simplifies the mathematical form of the controller, but the situation when the center of mass is shifted is omitted. Sometimes, of course, a model with displacement of the center of mass is assumed, but in the longitudinal direction, which also does not provide full information about the performance of the control algorithm. This work shows that the problem resulting from the simplification of the model has a significant impact on the operation and performance of the closed-loop system. Another drawback that sometimes occurs is the lack of limits on the thrust forces, which can result in the control strategy not being able to be implemented in practice. Therefore, here the real limits on the drives for the tested marine vehicles are introduced. The offered control scheme is designed under the assumption that the dynamics model has a symmetric inertia matrix, which means that couplings resulting from the fact that the center of mass is not identically located as the geometric center are taken into account. Of course, when both points are in the same place, the scheme can also be used.

Compared with the results available in the literature, the main contributions of this work can be summarized as follows.

- (1)

A new form of control algorithm (for asymmetric vehicle model) based on the IQV for a thre DOF underactuated vehicle is developed. The algorithm enables tracking the position trajectory, and it is robust to not fully known dynamics and external disturbances when inertial couplings are taken into consideration.

- (2)

Unlike [

32,

33], inaccurate knowledge of the model parameters is taken into account in the control scheme. A model with three DOF is considered instead of five DOF, but assuming the presence of inertial couplings (which was not the case in the cited works). Moreover, the proposed control method differs from the algorithms described in [

21,

34] by using a different control concept.

- (3)

The controller can be used to gain additional insight into the vehicle dynamics model, e.g., information about the kinetic energy corresponding to each variable speed deformation caused by couplings between variables is obtained.

- (4)

In additional simulation tests (other than in [

17]), two selected algorithms suitable for situations where there is no center of mass shift (for a symmetric vehicle model) are investigated to check how they perform the task of tracking the trajectory when there is a displacement of the center of mass. Two variants of moving the center of mass in the longitudinal and lateral direction are considered. Such simulation verification of the control strategies that assume no shift of the center of mass seems necessary if there is no experimental verification. It is worth noting that this type of algorithm for fully symmetric vehicles is proposed very often.

The rest of this paper is organized as follows. The mathematical model of the vehicle is shown in

Section 2.

Section 3 presents the equations of motion after velocity transformation, which include inertial quasi-velocities (IQVs). The proposed trajectory tracking controller is presented in

Section 4. The numerical test conditions are discussed in

Section 5. The simulation results of the performance of the proposed controller are given in

Section 6.

Section 7 describes the performance of two other selected control strategies.

Section 8 gives additional analysis and discussion of the results. The conclusions of this paper and possible further research are offered in

Section 9.

3. Inertial Quasi-Velocities Based Equations

In order to decompose the inertial matrix

M and to obtain the dynamics equation containing IQV, the inertial matrix must be symmetric. There are various decomposition methods, but the method from [

41] is used here as it has been successfully implemented for marine vehicles, e.g., in [

21,

34].

Remark 1. Decomposing the matrix M, one has a positive definite diagonal matrix (it has the properties of the M matrix). So this means that . The matrix contains nominal parameters, while any inaccuracies of Φ are shifted to the vector defined as . However, the decomposition of the matrix into nominal parameters leads to the matrix . Therefore, the term represents the inertial forces resulting from the use of two different matrices N and .

The following additional assumptions are valid.

Assumption 6. Taking into account Assumption 3, , where also applies.

Assumption 7. Due to the fact that parameter disturbances are taken into account in the control scheme (this is the essence of the method), it is allowed to use the vector instead of the vector , that is .

Assumption 8. Recalling Assumption 4 is also , where is a constants concerning an unknown bound.

With these assumptions, the new equations, instead of (

2), have the form:

Considering the elements defined in

Appendix A, the vector of the inertial quasi-velocities can be written as

. The quantities

,

,

,

,

result from the decomposition of the matrix

M.

New equations of motion replacing (

4) and (

5) are as follows:

with

,

and:

For simplicity, the symbols , , and are introduced.

4. Trajectory Tracking Controller Design

In this section, the desired trajectory tracking control algorithm, including IQV, will be designed. The control scheme is inspired by the results of [

33] (this concept was also developed in [

32]). However, in the mentioned work, as well as in [

32], only a model with a diagonal inertia matrix was considered.

When an asymmetric vehicle model is taken into account, the inertia matrix is symmetrical, and solving the task of tracking the desired trajectory is more difficult and not so obvious. Moreover, the proposed algorithm takes into account the dynamic components of the vehicle model in the form representing the percentage of inaccurate knowledge of the parameters of this model.

Using (

9) and (

11), the accelerations

and

can be obtained in the form:

where:

Since the objective of the algorithm is to track a desired trajectory

, then two errors of the form are defined:

The calculation of the second derivative of these position errors allows the use of available control signals

from (

15) and (

16), applying

:

Denoting now:

it can be written in the matrix form

, i.e.,

where

, and

which represents the actuated input signals. However, from (

23), it can be seen that the matrix

is singular because its determinant is equal to zero. Therefore, it is not possible to directly control with

and

. Instead, kinematic relationships can be used as in [

42] and later in [

33].

Defining:

one has

and the time derivative of the function

can be determined in the form:

Assuming that the actual position is

and the desired position is

, one obtains the tracking position error

. Now, the new position error is defined as follows:

where

means the position error in the body-fixed frame and

is the constant error margin. Taking the above quantities into account, one can calculate the derivative of the variable

:

Consequently, one obtains:

However, due to the fact that the controller should include quasi-velocities (

6) and (

8), the following relationship should be used instead

,

:

Considering the above equation, the second component on the right will be of the form:

Therefore, (

29) can be written as follows:

The desired quasi-velocities are determined from the relationship:

where

,

,

. Inserting (

33) into (

32), one obtains:

The trajectory tracking according the relationship (

27) can be applied if (1) the matrix

is uniformly exponential stable, and (2)

is uniformly exponentially convergent to zero. Consider then the following equation:

In the paper [

42] (Theorem 1, Corollary 1), it is proved that condition (1) is satisfied for

. In order to satisfy condition (2), that is, to ensure that the signal vector

converges to zero, the SMC method was used. The sliding surfaces were proposed as follows:

where

are some constants. Calculating the time derivative of

and recalling Assumption 7, one obtains:

Next, the sliding mode control vector is introduced

, where

(

). It consists of two components, i.e., first

enables dynamics compensation whereas the second

allows to reach the sliding surface rate:

The control signals can be applied in case of accurate knowledge of the model parameters. However, here, the model is not known exactly and, in addition, there are external disturbances (Assumption 4).

If the dynamic model is not known exactly, then instead of (

38) and (

39), one obtains:

For the model under consideration, one obtains:

The estimates of these values can be determined from:

where

mean some adaptive gains. Thus, the adaptive errors can be defined as:

Taking into account the above considerations, the control signals should be modified to the form:

where the gain functions

are:

The constants must be selected in the process of designing the controller.

Theorem 1. For the vehicle described by (1) and (4)–(14), if Assumptions 1 ÷ 8 are fulfilled, the vector uniformly converges to neighborhood of zero. Proof of Theorem 1. The Lyapunov function candidate is assumed in the following form:

Calculating the time derivatives of the functions

and

and using (

42)–(

51) leads to the following:

where

are some constants arising from the approximation of the model. From the above calculations, it follows that the sum of the derivatives

. Assuming

, one can write:

which means that vector

is uniformly bounded. Considering the fulfillment of conditions (1) and (2), it can be concluded that the proposed scheme provides tracking of the desired trajectory. □

Remark 2. From the fact that , it follows that and . If , then . Therefore, both variables result in . Moreover, .

This result means that all tracking errors in the closed system converge to a small neighborhood of zero, and are therefore uniformly ultimately bounded. Taken together, the results conclude the proof.

Control signal calculation algorithm.

- 1.

Calculation of accelerations from (15) and (16).

- 2.

Defining the position errors from (19) and determination of their second derivative with respect to time from (20) and (21), and next the vector (23).

- 3.

Defining the new position error from (27), calculation of from (32), the desired quasi-velocities vector from (33), and next inserting the results into (34).

- 4.

Defining the sliding surfaces (36) and (37), and calculation of their time derivatives from (38) and (39) for exactly known model or from (42) and (43) if the model contains inaccuracies.

- 5.

Defining from (40) and from (41), and determination of their components from (44) and (45).

- 6.

Calculation of control signals from (48) and (49) using from (50) and (51).

5. Conditions for Numerical Tests

5.1. Models and Limitations

Three problems are considered in simulation studies, namely the following:

- 1.

Test on two underwater vehicle models;

- 2.

Limitation thrust forces;

- 3.

Shifting the center of mass (asymmetry of the vehicle model).

Examination of the control scheme for two models should answer the question of whether the control algorithm can be used for vehicles with different dynamics. The vehicles taken for testing are applied in real marine research.

Limiting the thrust force causes the algorithm’s operating conditions to be close to real ones (of course, bearing in mind that these are simulation studies). In some works known from the literature, this condition is not met and therefore only information about the correct operation of the controller can be obtained, but without reference to real operating conditions.

Shifting the center of mass makes control difficult, so this issue is considered here. The inertia matrix is then symmetric. The proposed algorithm, from a theoretical point of view, is suitable to achieve this goal. Nevertheless, two other schemes for the dynamics model with a diagonal inertia matrix were tested in simulation studies. This is intended to answer the question whether such control strategies can be useful under the assumed operating conditions.

5.2. C-Ranger Vehicle

The C-Ranger AUV underwater vehicle was selected for testing. Its parameters, shown in

Table 1, are taken from [

43,

44]. Because the matrix

M should contain off-diagonal elements, then it is assumed that

kg·m and

kg·m (in source works, these values are absent, but they are needed for this test). These data correspond to

m,

m, and

kg·m,

kg·m. From the parameters set elements of the diagonal matrix

are as follows:

kg, and

kg,

kg·m

2. Other non-zero linear and quadratic coefficients used are:

,

,

,

.

Based on the vehicle specifications [

43,

44], it was assumed that the force and torque, as well as the surge velocity, were limited. The forward force can be calculated as

(because maximum values of forces from engines are

N) and torques

, where

m. In the tests, the maximum values of propulsion force and torque were as follows:

N and

N·m. The maximum value of surge speed is

m/s (close to 3 knots). In continuous mode, the vehicle can travel for eight hours at a speed of 1 knot.

Equipment. The C-Ranger vehicle is used as a platform for testing algorithms and verifying them in marine research [

43,

44]. The control hardware system is composed of a decision-making and navigation subsystem, a CAN bus, a perception subsystem, and an actuator subsystem. Each of these subsystems has a significant impact on the vehicle’s operation. In particular, the perception subsystem contains both fundamental sensors and additional so-called new ones. The following variables can be measured: polar coordinate (Super SeaKing DST imaging sonar, Gemini 720i multibeam imaging sonar), XYZ position (XW-GPS1000 GPS), velocity (NavQuest 600 DVL-Doppler Velocity Log), attitude (Honeywell HMR3000 digital compass, Innalabs

® AHRS M2), angular velocity (VG951D Gyroscope), depth (Desert-star SSP-1 300PSIG Digital Pressure Sensor), communication (UWM3000 Acoustic Modems), and colour image (Kongsberg Maritime OE14-376 (PAL) Colour Camera).

5.3. ROPOS Vehicle

The parameters of the ROPOS vehicle can be found, e.g., [

45,

46]. The ROPOS vehicle dimensions, namely length, width, and height, are

,

, and

m [

45]. Recalling [

45], the signal constraints were assumed as

N,

N·m (although values

N and

N·m are possible). According to [

46], the allowable velocities are

m/s,

m/s. The working conditions were adopted in accordance with the technical data to be realistic.

The proposed control algorithm is intended in general for vehicle models with a symmetric inertia matrix; therefore, the tests take into account the occurrence of a situation in which the center of mass has been shifted (e.g., additional mass has been added). Thus, it was assumed that kg·m, kg·m (Case 1) and kg·m (Case 2). This corresponds (Case 1) to m, m, and kg·m, kg·m. Elements of the diagonal matrix were as follows: kg, and kg, kg·m2. For Case 2, it was m and kg·m. Elements of the diagonal matrix were as follows: kg, and 11,786 kg, kg·m2. Moreover, nonzero drag coefficients were as follows: = = 50, = = 100, = = = 10, = = = 10, = = = = = = = = 10.

Equipment. Information about ROPOS (Remotely Operated Platform for Ocean Sciences), which is a remotely operated vehicle (ROV), can be found on the Canadian Scientific Submersible Facility website [

47,

48]. The vehicle, whose design has been developed since 1986, has three generations. The third generation of the vehicle is equipped with various research instruments. ROPOS has, among other things, two manipulators to perform tasks underwater. In order to perform the navigation task, ROPOS is equipped with navigation sensors that are combined using a LOKI Kalman filter. With this accurate and repeatable underwater positioning, ROPOS can safely and quickly perform difficult surveys and dives. The EIVA NaviPac Pro software package is used to share, manage, and control data from sensors and systems. Telemetry is realized by Greensea Systems, whereas imaging is carried out by two HD Cameras, six pilot and tooling cameras, a 36.3 megapixel digital still camera, and over 3700 watts of lighting. The sensors subsystem is composed of an inertial navigation system (ROVINS Nano), heading primary (ROVINS Nano (Primary) IMPACT SUBSEA ISM2D COMPASS), pitch and roll (ROVINS Nano), depth (Digiquartz 8B7000-I), altimeter (Kongsberg Simrad 1007-200 kHz), sonar (Simrad MS1171 dual-frequency 330/675 kHz Digital), a Doppler Velocity Log (Nortek Compact DVL 500), USBL (iXblue GAPS, Sonardyne Ranger, Sonardyne Fusion or Kongsberg HiPAP), sound velocity (AML-1RT with an SVT), CTD (SBE 19plusV2 CTD profiler), an RF beacon (MetOcean RF-7000A1), and a strobe beacon (MetOcean ST-400A). ROPOS also has other systems used for cable laying, data management, communications, and multibeam sonar.

The second-generation ROPOS vehicle was used for the simulation tests, the parameters of which are well known from the literature, e.g., ref. [

45].

The original parameters of the vehicles C-Ranger [

43] and ROPOS [

45] are summarized in

Table 1.

5.4. Assumed Work Conditions

Simulation tests were performed using Matlab/Simulink in

s (linear trajectory) and

s (complex trajectory), with an integration step of

s and the ode14x method (only for C-Ranger, complex trajectory, and the ADSMC algorithm, the ode3 method was used for numerical reasons). For testing purposes, the software was written in Matlab/Simulink from [

49,

50,

51], and the author’s own software was used.

The desired trajectory position profiles

were selected as follows:

with

.

The disturbance functions considered for both vehicles were of the form:

Inaccuracy of the model parameters was assumed as W = 0.2 (20%).

The set of metrics used to evaluate controller performance was as follows:

- (1)

Time history of important variables and position tracking errors;

- (2)

Mean integrated absolute error where (the variables , were the position errors in the body-fixed frame);

- (3)

Mean integrated absolute control ;

- (4)

Root mean square of the tracking error , where .

The time history of the selected variables was necessary to determine whether the control algorithm is working properly. The indexes were used to compare the performance of various control schemes.

Additional information based on IQV. If the description of dynamics includes IQV, then based on the determined variables (after velocity transformation), it is possible to gain some insight into the dynamics of the system when the control algorithm is running.

In this work, two graphs and one index were used in the simulation tests, namely, known, e.g., from [

21]:

- (1)

Time history of kinetic energy K;

- (2)

Mean kinetic energy , ();

- (3)

Time history of errors between IQV and vehicle velocity, i.e., .

Remark 3. On the basis of IQV, it is also possible to determine the kinetic energy reduced by each quasi-velocity, i.e., . The errors between each IQV and its corresponding velocity represent the deformation of that velocity due to the action of dynamic couplings. In this way, it is possible to estimate how the dynamic parameters of the system affect the velocity history.

Additionally, the

index was introduced, representing the share of couplings in the tested model to the maximum values of couplings for this vehicle (explained in

Appendix B).

Simulation test conditions. The operating conditions, as well as the desired trajectories, were chosen according to Assumptions 1 ÷ 8.

Comment. To select controller parameters, one can apply the heuristic method described in [

52], which allows us to tune these parameters to improve controller quality measured by the time history of selected signals and the assumed evaluation criteria. The advantage of this method is that it is suitable for various types of control schemes (also for underactuated vehicle models). Therefore, it is useful for comparing the performance of different control algorithms. This method was used for simulation studies.

6. Simulation Results for Proposed Control Scheme

The proposed IQV control scheme is called here the BS-IQV (Basic Scheme using Inertial Quasi Velocities). This subsection presents the results of simulation studies performed for two vehicle models, namely C-Ranger and ROPOS. The task was to track two trajectories: linear (

56) and complex (

57), discussed in

Section 5.

For the ROPOS vehicle, weaker and stronger couplings were considered. Based on the

index (

Appendix B), the couplings present in each model were calculated. For the C-Ranger vehicle,

, which means couplings greater than 28 percent; for ROPOS (weaker couplings),

(less than 3 percent), and for stronger couplings,

(over 4 percent). Such values indicate that for C-Ranger, the couplings are strong, while for ROPOS, they are weak (regardless of the case considered). However, the goal is to show the effectiveness of the control schemes when increasing the distance of the center of mass from the geometric center (for ROPOS).

The BS-IQV control algorithm proposed in this paper aims to track the trajectory when the vehicle’s center of mass is shifted.

C-Ranger. The following sets of control parameters have been selected:

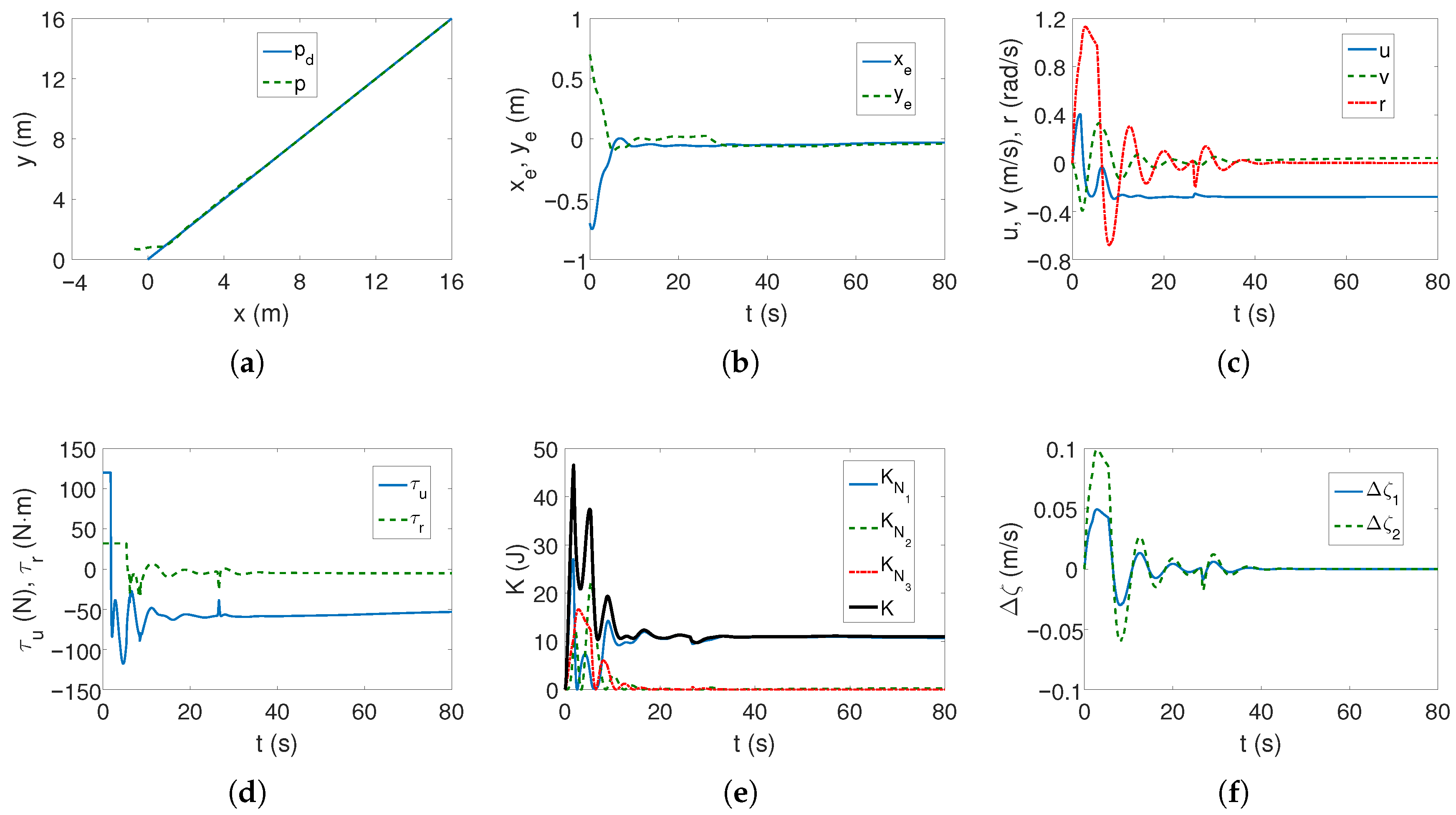

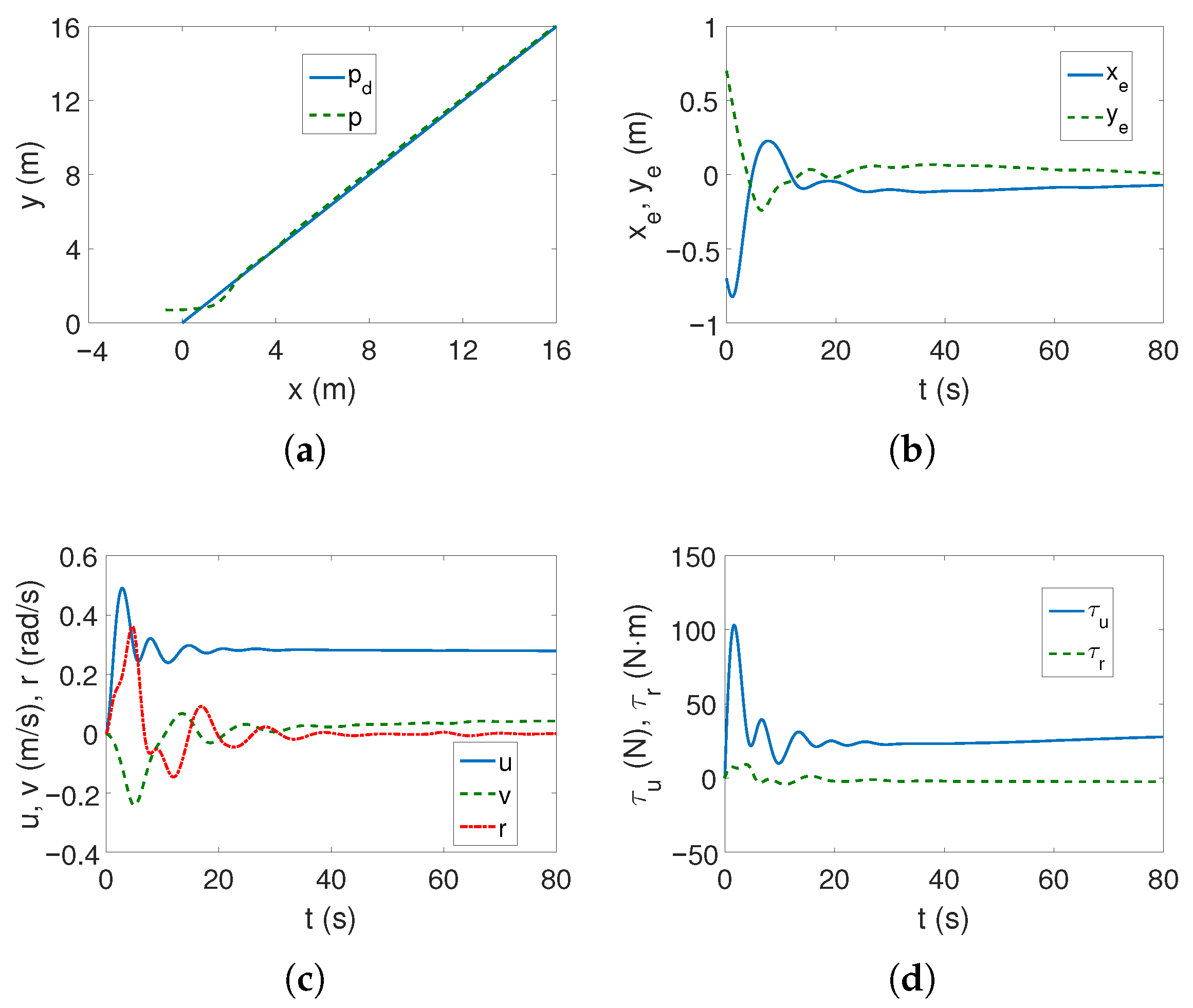

As can be seen in

Figure 2a,b, the desired linear trajectory is tracked, and the signal settling time is approximately 30 s. Linear velocities have small values and only the angular velocity value is higher (

Figure 2c), which is caused by the inclusion of dynamics in the control algorithm. The values of the force and torque only at the beginning of the movement are maximum and then significantly decrease, as is observed in

Figure 2d. The results from

Figure 2e indicate that the vehicle’s movement is mainly due to surge speed, because this direction has the highest kinetic energy value. Comparing

Figure 2c and

Figure 2f, it can be seen that at the beginning of the vehicle’s motion, the couplings deform the speed

u by about 1/8 of the value, and the speed

v by even 1/4, which can be considered a significant impact (maximum error/velocity). The following mean kinetic energy values were obtained:

J,

J,

J,

J.

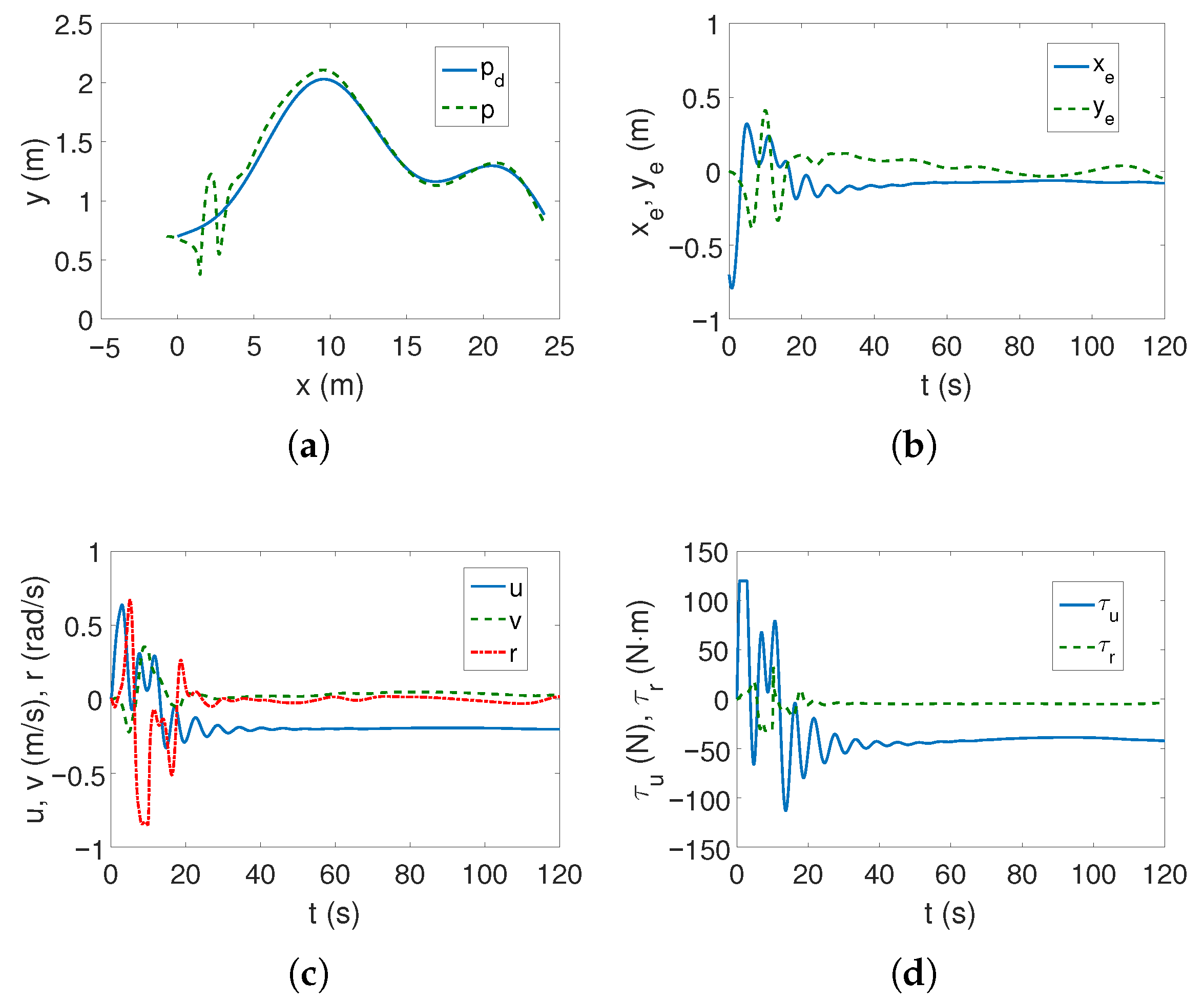

The results of tracking a complex trajectory are shown in

Figure 3. At the beginning, the vehicle changes position to reach the trajectory (

Figure 3a,b), but as can be seen from

Figure 3b, the errors in the direction of motion are slightly larger than for the linear trajectory. Also, regarding velocities, force, and torque, analogous observations can be made as before (

Figure 3c,d). From

Figure 3e, it can be seen that the highest kinetic energy concerns the motion at the speed

u, and the other directions of movement do not change their values much. Similarly,

Figure 3f shows that the couplings have the greatest impact on the vehicle’s movement in the transverse direction and with similar values as for the linear trajectory. Therefore, it can be concluded that the maximum coupling values existing in the vehicle model may be independent of the trajectory. The following mean kinetic energy values were obtained:

J,

J,

J, and

J.

On the basis of the obtained results, it can therefore be concluded that the proposed controller operates correctly when the center of mass is shifted by the assumed values.

ROPOS. The following sets of control parameters have been selected:

Two cases were considered for this vehicle, namely weaker couplings and stronger couplings resulting from the shift of the center of mass on the longitudinal axis (x-axis). During the tests, it turned out that a set of parameters that was selected to provide acceptable results could be used for both linear and complex trajectories in both cases. Therefore, this proves a certain universality of the set of control parameters if it is selected correctly. Stronger couplings are understood here as larger shifts in the longitudinal axis of the x axis.

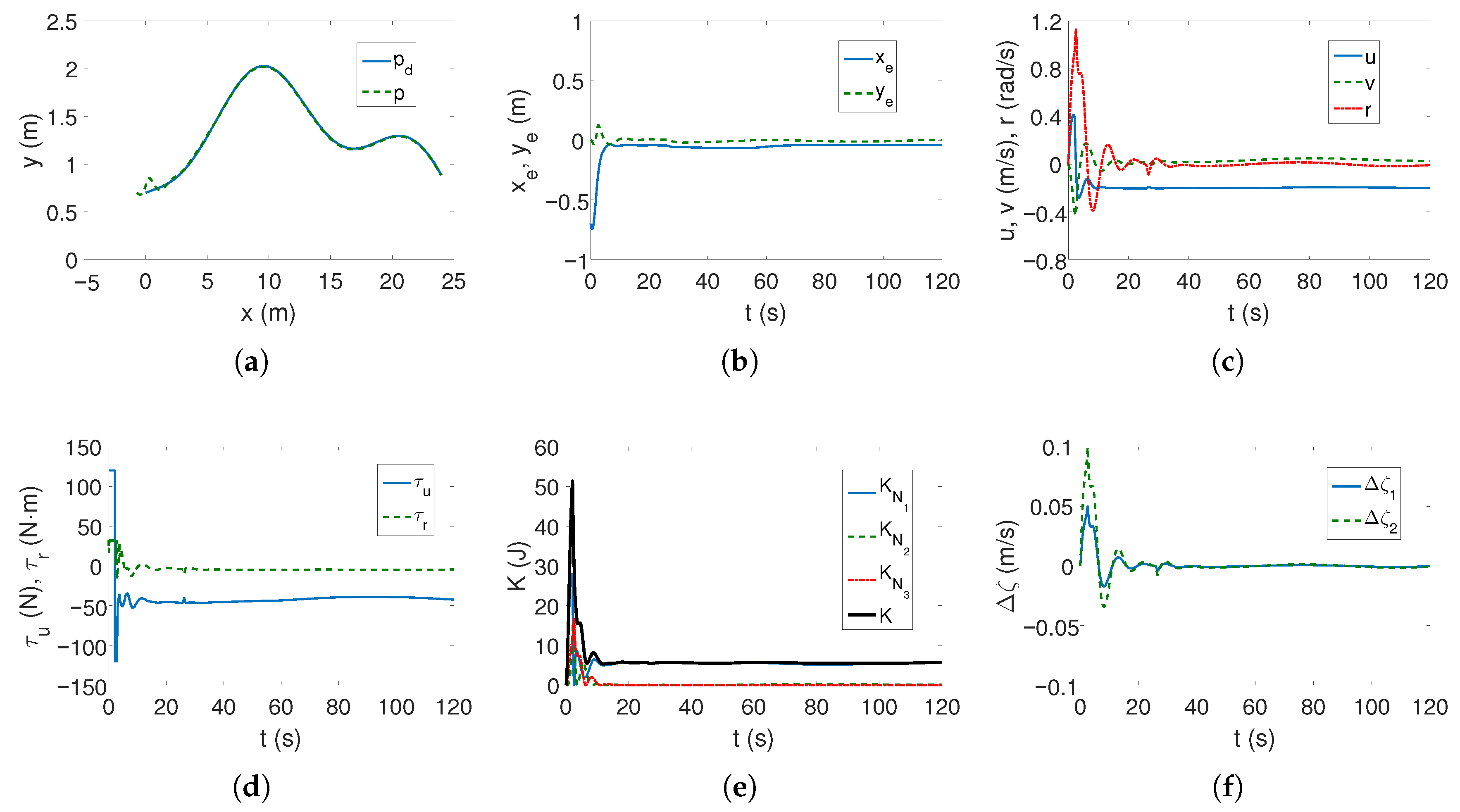

Case 1—weaker couplings. The linear trajectory is tracked correctly as shown in

Figure 4a,b. The position errors stabilize after approximately 15 s, which is a short time considering the vehicle’s mass. These errors, however, do not tend to zero but to certain values in their neighborhood, which is consistent with the control scheme. The yaw velocity has lower values than for the C-Ranger vehicle, which can also be explained by the ROPOS vehicle mass (cf.

Figure 2c and

Figure 4c). The torque

has its maximum value for about 10 s, as can be seen from

Figure 4d (the dynamic parameters of the model are taken into account in the control algorithm). From

Figure 4e, it is noticeable that the kinetic energy is much higher than for the C-Ranger, but this is due to the mass of the vehicle. But here, in the first phase of motion, the kinetic energy for the angular velocity

r has the greatest value, and therefore, the vehicle rotates. Then the main part of the energy is consumed in linear motion (velocity

u). The quasi-velocity errors shown in

Figure 4f indicate that the velocity deformation is much smaller than for C-Ranger (maximum for velocity

u about 0.04 and

v about 0.07). This means that the dynamic couplings are also much weaker. The following mean kinetic energy values were obtained:

J,

J,

J,

J.

The tracking of the complex trajectory also works correctly (

Figure 5a,b), but at the beginning of the movement, there is a deviation of the current trajectory resulting from taking into account the vehicle parameters in the controller. The velocities, as can be seen from

Figure 5c, are low, and the thrust force and torque are maximum only when the vehicle starts moving (

Figure 5d). The changes in kinetic energy compared to those calculated for the linear trajectory (

Figure 5e) are not large, nor are the quasi-velocity errors (

Figure 5f). This is not an unexpected result because the velocity deformation depends on the model parameters, and these have not changed. The observed differences result from the shape of the trajectory. The following mean kinetic energy values were obtained:

J,

J,

J,

J.

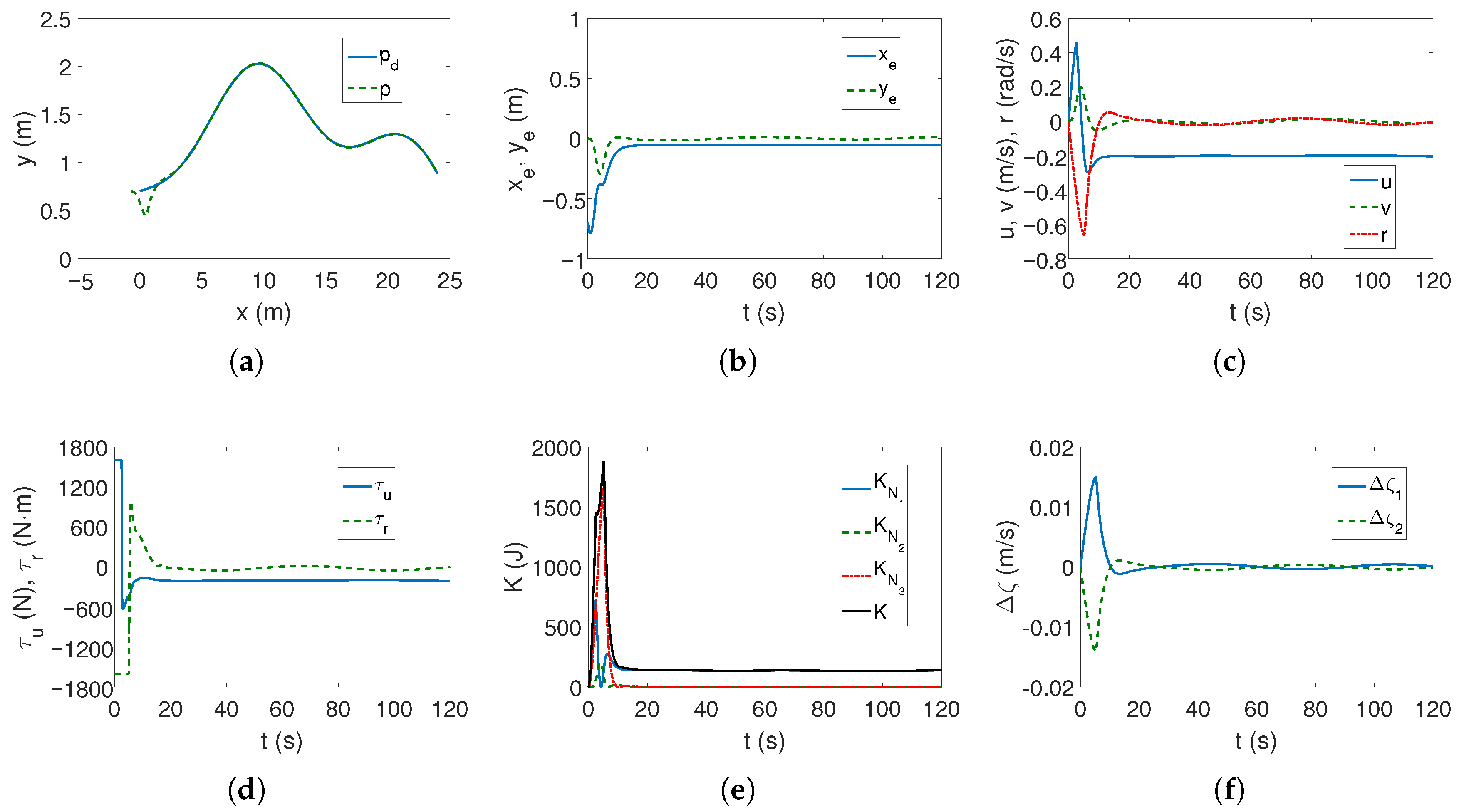

Case 2—stronger couplings. For the linear trajectory, when the couplings are stronger, the realized trajectory is similar to

Case 1, and the velocities have similar values (

Figure 6a,c). The differences are that the stabilization of the lateral position errors

is several seconds shorter, which can be seen in

Figure 6b, and the maximum torque values also operate for a shorter time (

Figure 6d). It can therefore be concluded that the increase in dynamic couplings (in

x direction) not only did not worsen the controller’s performance, but actually improved it.

It is worth noting that the maximum values of kinetic energy decreased slightly (

Figure 6e) despite the increase in coupling in the longitudinal direction, with a similar time history of this energy. But

Figure 6f shows that in the transverse direction the maximum couplings have doubled (at the beginning of the movement, the velocity

v is deformed almost twice as much—about 0.12). Hence, the increase in the distance along the vehicle axis also changed the velocity deformation. The following mean kinetic energy values were obtained:

J,

J,

J,

J.

For the complex trajectory, the results shown in

Figure 7a–e resemble those in

Case 1 (

Figure 5a–e). There are no significant differences in the operation of the control algorithm. However, there have been changes in the time history of quasi-velocity errors because when the vehicle takes off, the couplings deform the velocity

v by approximately 0.14 (cf.

Figure 7f with

Figure 5f), but this is not such a large deformation of this velocity as for C-Ranger (cf.

Figure 7f with

Figure 3f). The following mean kinetic energy values were obtained:

J,

J,

J,

J.

7. Comparison with Selected Other Control Schemes

The proposed IQV control scheme, called BS-IQV here, has been compared with two other control strategies, namely the adaptive dynamical sliding mode control (ADSMC) [

4] and the global integral sliding mode control (GISMC) [

5] (extended and modified in [

36]). The appropriate stability proof for a three DOF vehicle moving horizontally can be found in [

34]. Both control tracking algorithms were initially investigated in [

17], in which better performance was obtained for them than for other tested controllers. The justification for such a comparison is also that the components of each method are backstepping and SMC. The following software was used for simulation tests: BS-IQV (modification of software [

49] for three DOF and adaptation to the considered vehicles), ADSMC (software according to [

50] adapted to the vehicles), and GISMC (software according to [

51] adapted to the vehicles).

7.1. ADSMC Algorithm

The tested ADSMC control algorithm is intended, according to [

4], to track the trajectory in the ideal case, or without any shift of the vehicle’s center of mass. However, here, the test concerned a situation in which the above condition is not met, and therefore, the task was to check the controller’s robustness to such a shift.

C-Ranger. The following set of controller parameters was selected:

It is worth noting that the controller parameters depend on the shape of the desired trajectory and are different for both trajectories. However, it also turned out that , and had the greatest impact on the performance of the control algorithm.

For the linear trajectory, from

Figure 8a,b, it can be seen that the controller is trying to cope with an unknown motion disturbance (the impact of dynamic couplings is not included in the control scheme) but the position errors do not reach a steady state within 80 s. The velocity values in

Figure 8c are small, as are the force and torque values in

Figure 8d, but they change for about 30 s as a result of trying to achieve the trajectory.

In the case of the complex trajectory, the results are worse because at the beginning of the movement, the vehicle essentially changes its position (

Figure 9a), whereas

Figure 9b shows that the position errors are variable. In addition, as can be observed in

Figure 9c, the speed values oscillate as the vehicle moves, which also applies to the force and torque shown in

Figure 9d.

Based on the presented tests, it can be concluded that for the C-Ranger vehicle and the given operating conditions, the ADSMC algorithm does not provide fully acceptable results, although it tries to deal with the unexpected disturbance.

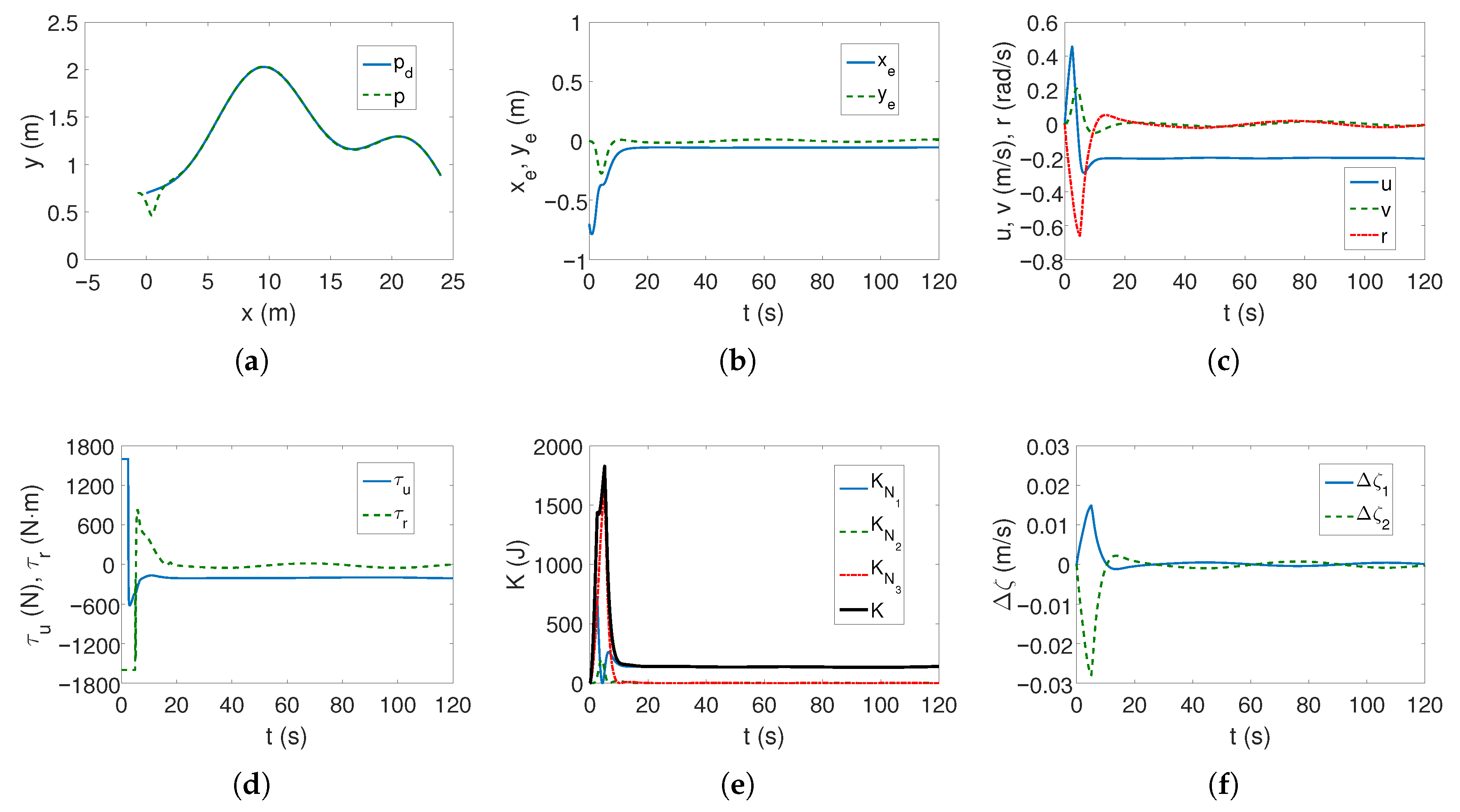

ROPOS. The same two cases of shifting the vehicle’s center of mass were also assumed for this algorithm.

Case 1—weaker couplings. The following set of controller parameters was selected:

When changing the vehicle, it turned out that it is worth noting that the controller parameter values should be different depending on both the model and the shape of the trajectory. Here, the change also concerned , and .

Figure 10a,b show that the algorithm fulfills its task of tracking the linear trajectory. The convergence of position errors stabilizes, which is a better result than for the C-Ranger vehicle. The speeds are low and therefore the motion is slow (well below the permissible values), as it can be noticed from

Figure 10c. The force and torque have high values only when the vehicle starts to move (

Figure 10d).

For the complex trajectory, however, the results are significantly different. The realized trajectory is not very close to the set one, which can be observed in

Figure 11a, but the lateral errors

change during the motion as shown in

Figure 11b. Although the speeds are low (

Figure 11c), the torque values oscillate, especially in the first phase of movement, as can be seen from

Figure 11d.

Case 2—stronger couplings. The following set of controller parameters was selected:

After moving the center of mass further relative to the geometric center, the same control parameters as Case 1 could be used to track the linear trajectory. But using a complex trajectory required changing to improve controller performance. After applying these sets of gains, the results obtained were not noticeably different from those for Case 1.

The plots for

Case 2 were omitted because when comparing

Figure 10 with the results for

Case 2, it was difficult to notice any significant differences. It can be concluded that the shift, even by a double amount in the longitudinal direction (in the

x axis), did not affect the system time response of the examined quantities. This is important information that will be commented on in the discussion of the results.

Figure 12a shows that when approaching the desired trajectory, its tracking deteriorates, and

Figure 12b shows that it is clear that this error occurs in the lateral direction (

y). The vehicle velocities are low (

Figure 12c), as are the force and torque values (

Figure 12d), but compared to

Case 1 (

Figure 11c,d), the oscillations are smaller.

7.2. GISMC Algorithm

This control scheme is also intended, according to [

5,

36], to track the trajectory in the ideal case, or without any shift of the vehicle’s center of mass.

C-Ranger. The following set of controller parameters was assumed:

As can be seen, the controller parameter values differ depending on the desired trajectory. The changes concerned .

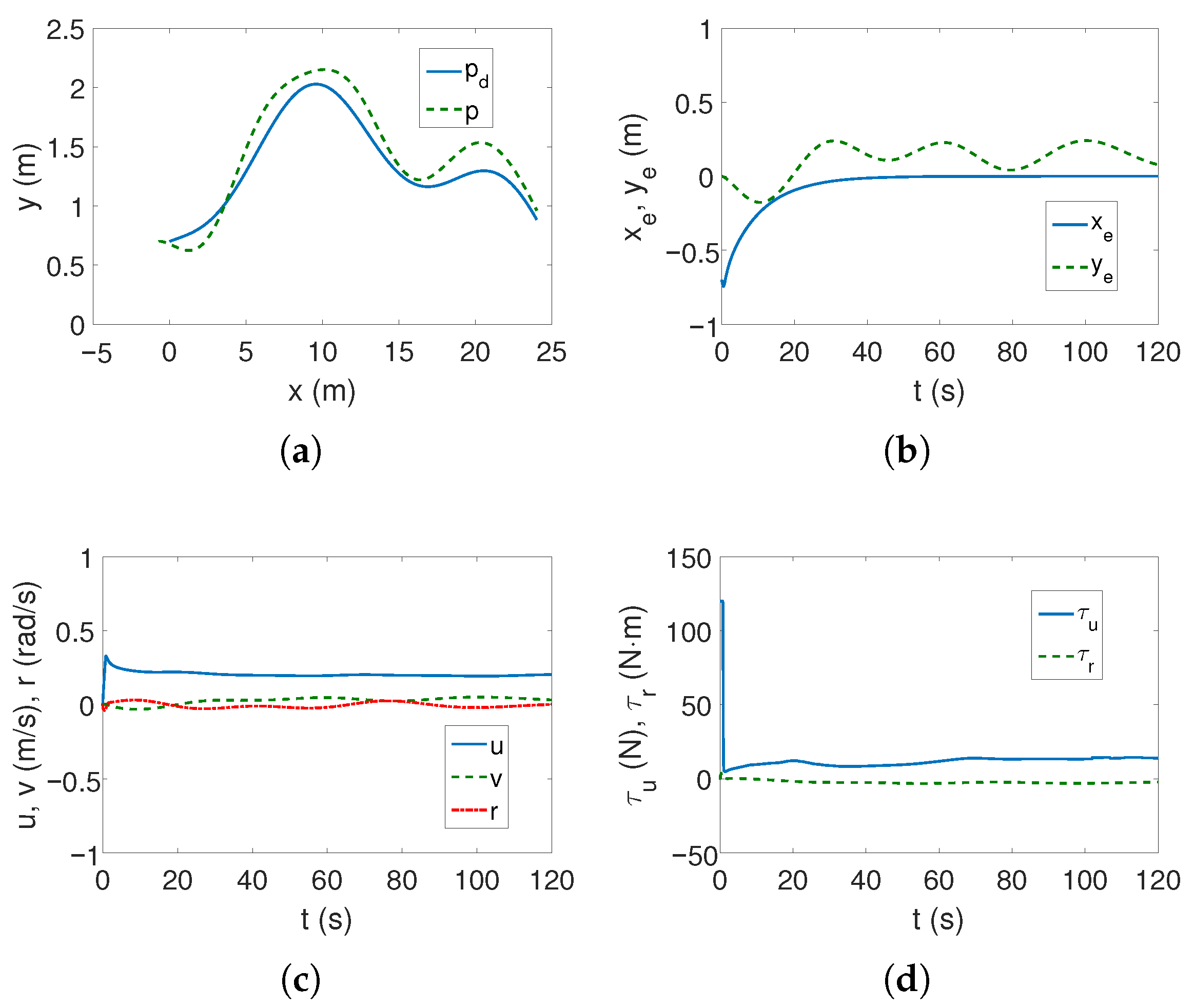

In the case of the linear trajectory, it turned out that it was not possible to ensure accurate tracking of the lateral variable

y and, moreover, its value changed during the movement. This is shown in

Figure 13a,b. However, the velocities are small (

Figure 13c), and the force and torque are also small (

Figure 13d). The lack of more accurate trajectory tracking is due to the fact that the controller is not robust to shifting the center of mass in the transverse direction.

For a complex trajectory, the controller’s performance is also not acceptable.

Figure 14a,b show that the complex trajectory is not tracked because the position errors in the lateral direction are large. This is the result of a missing component in the control scheme that would enable the task to be performed effectively. Importantly, the results from

Figure 14c,d (velocities, force, and torque time responses) indicate that the algorithm is working properly.

ROPOS. Two cases, as previously, were considered.

Case 1—weaker couplings. The following set of controller parameters was assumed:

The controller parameter sets are almost the same for linear and complex trajectories except for constant.

Figure 15a,b show that the linear trajectory is tracked, although the time needed to establish the position errors is approximately 50 s. The vehicle moves at low speeds (

Figure 15c) and the force and torque decrease quickly after it starts (

Figure 15d).

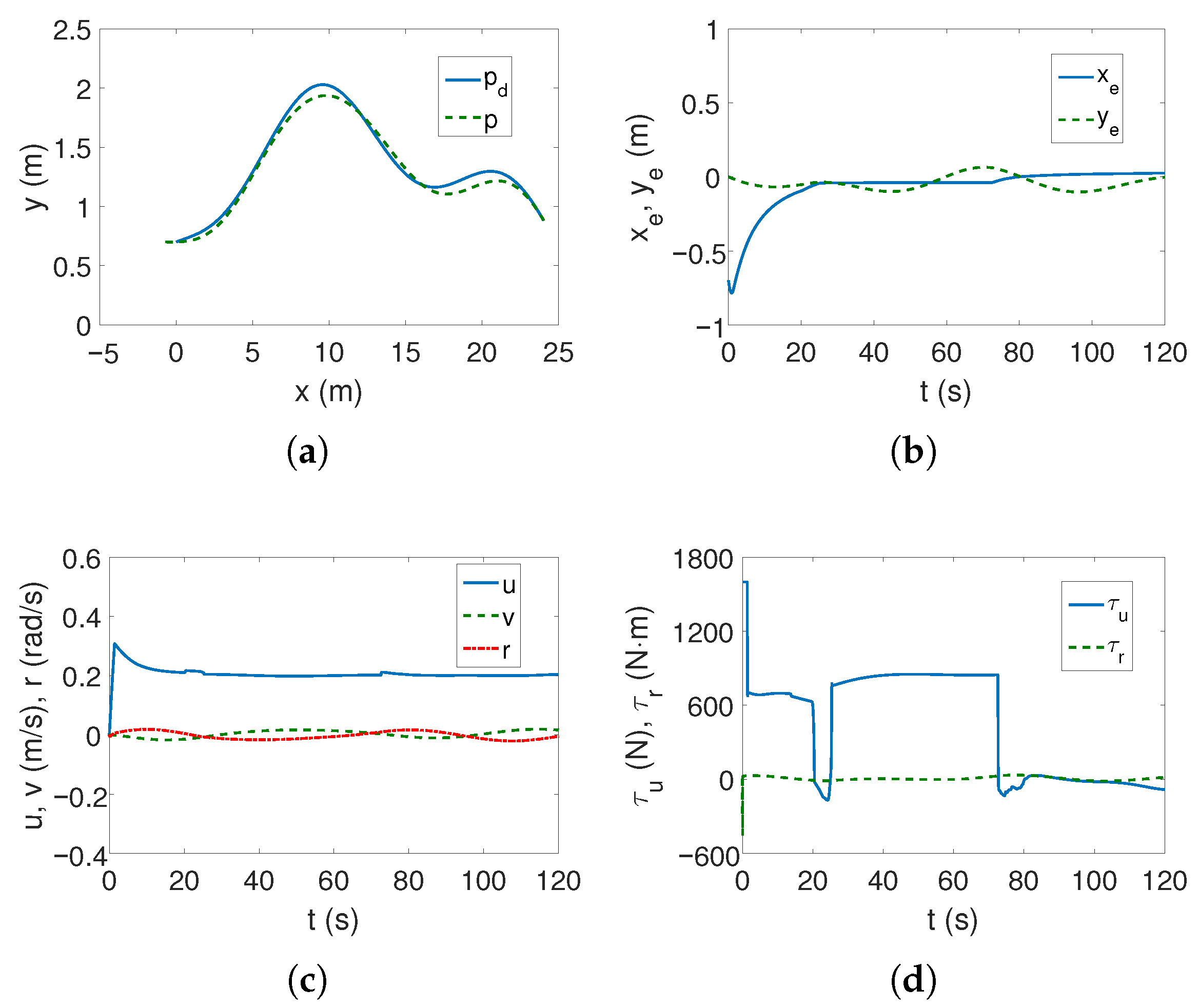

For the complex trajectory, tracking the

y variable is insufficient and the corresponding position error changes during vehicle movement but does not stabilize (

Figure 16a,b). In turn, the velocity, force, and torque graphs indicate that the controller is working properly (

Figure 16c,d), although it is not.

Case 2—stronger couplings. The same set of controller parameters, i.e., (

70) and (

71) was assumed.

The plots for

Case 2 were omitted because when comparing

Figure 15 with the results for

Case 2 (for linear trajectory), it was difficult to notice any clear changes, which suggests that moving the center of mass even twice did not result in a loss of controller performance.

A similar observation can be made when comparing

Case 2 and

Figure 16 relating to complex trajectory tracking. For the same reason, the graphs for

Case 2 were omitted. Therefore, the conclusion regarding the control algorithm is the same as before for linear trajectory tracking.

9. Conclusions

This work proposes a motion control scheme for a vehicle moving horizontally, taking into account robustness to imperfectly known model parameters, environmental disturbances and shifts of its center of mass. The focus was on the issue of shifting the center of mass in relation to the geometric center of the vehicle. It has been shown (in simulation) that the control method developed for the model containing such a shift ensures acceptable performance regarding position errors under the assumed operating conditions, including realistic limits on the driving forces and the vehicle speed. The performance of the designed controller was compared with the results obtained for other algorithms that were dedicated to controlling vehicles with a diagonal inertia matrix model (omitting dynamic couplings). For two such control schemes, the work conditions for which trajectory tracking can be achieved with acceptable accuracy regarding position errors are indicated.

Despite the fact that the most accurate tracking of the trajectory position, taking into account the mass displacement, was obtained for the control scheme intended for this purpose, it cannot be said that the existing strategies proposed for the model without couplings are useless. On the contrary, there are operating conditions that allow the successful implementation of the trajectory tracking task. This is also where they should focus on finding solutions to this problem.

Since control schemes for models with a diagonal inertia matrix are very often proposed in the literature, it seems necessary to check the robustness of these schemes to the possibility of displacing the center of mass. It is essential to define under what conditions they will operate effectively. Checking operation in ideal conditions obviously makes sense—it will not be an experimental verification, for which the operating conditions of the controller are also given, but it gives some insight into the behavior of the model-controller system. However, verification of the algorithm only through simulation, without information about the vehicle’s motion when the center of mass is moved, is insufficient because it may be impractical, and the controller itself may not be very robust to disturbances resulting from such a situation.

From the presented simulation results, it can be concluded that the control algorithms are robust to shift changes in the longitudinal direction (such a test was performed for the ROPOS vehicle). It is worth noting that the control schemes designed for models with couplings concern shifts in this direction.

Future research should focus on identifying such operating conditions for models with a diagonal matrix of inertia that will allow the practical application of these algorithms based on simulation studies. Currently, this problem is often ignored or solved to a narrow extent.