Signal Enhancement in Magnetoelastic Ribbons Through Thermal Annealing: Evaluation of Magnetic Signal Output in Different Metglas Materials

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Metglas 2826MB3

3.2. Metglas 2605SA1

3.3. Metglas 2714A

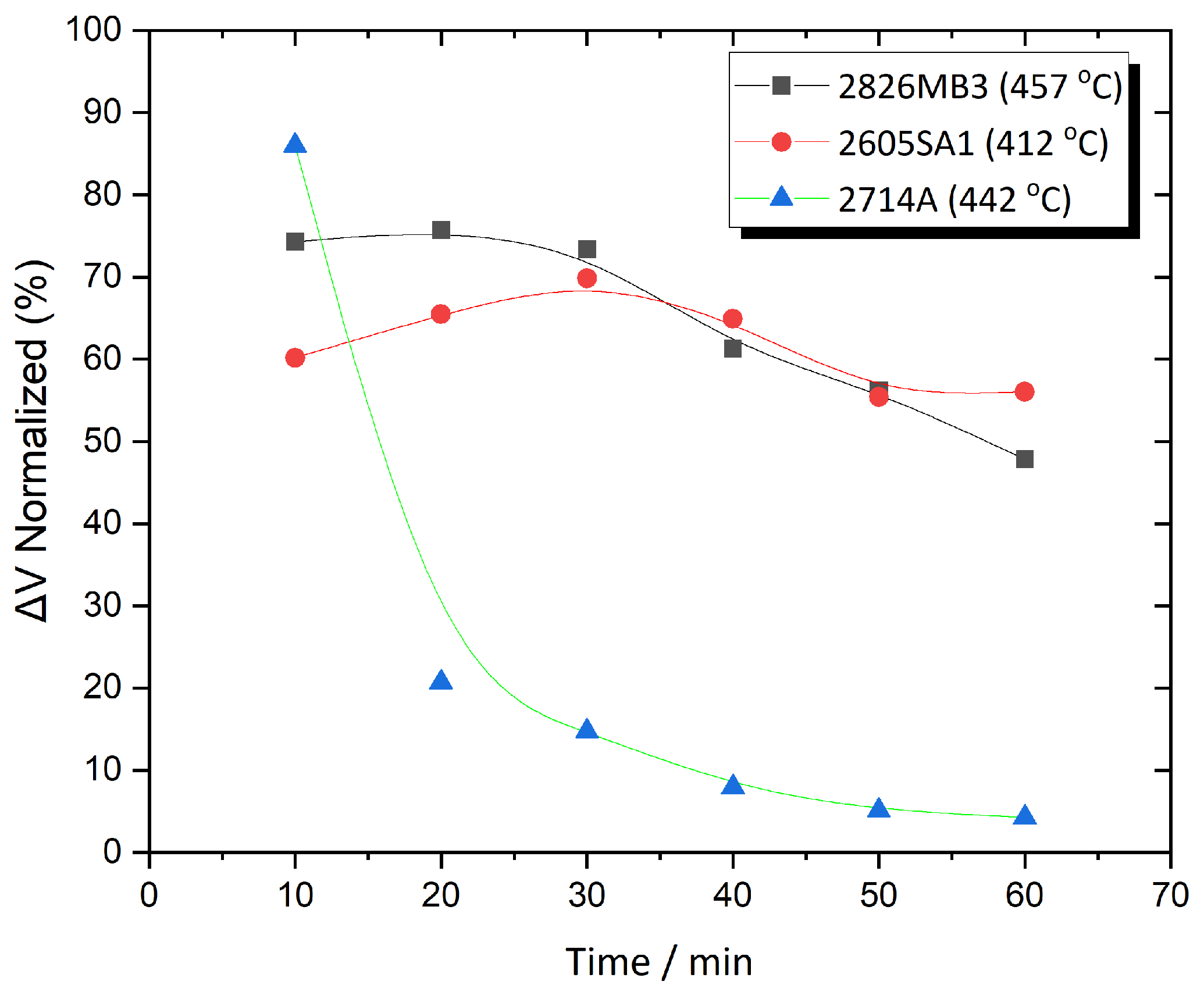

3.4. Comparison Results

3.5. Reported Benefits of Thermal Annealing in the Literature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goumiri, S.; Yahiaoui, S.; Djahel, S. Smart Mobility in Smart Cities: Emerging challenges, recent advances and future directions. J. Intell. Transp. Syst. 2025, 29, 81–117. [Google Scholar] [CrossRef]

- Kang, Y.; Aye, L.; Ngo, T.D.; Zhou, J. Performance evaluation of low-cost air quality sensors: A review. Sci. Total Environ. 2022, 818, 151769. [Google Scholar] [CrossRef]

- Zainurin, S.N.; Wan Ismail, W.Z.; Mahamud, S.N.I.; Ismail, I.; Jamaludin, J.; Ariffin, K.N.Z.; Wan Ahmad Kamil, W.M. Advancements in monitoring water quality based on various sensing methods: A systematic review. Int. J. Environ. Res. Public Health 2022, 19, 14080. [Google Scholar] [CrossRef]

- Alshami, A.; Ali, E.; Elsayed, M.; Eltoukhy, A.E.; Zayed, T. IoT Innovations in Sustainable Water and Wastewater Management and Water Quality Monitoring: A Comprehensive Review of Advancements, Implications, and Future Directions. IEEE Access 2024, 12, 58427–58453. [Google Scholar] [CrossRef]

- Sishodia, R.P.; Ray, R.L.; Singh, S.K. Applications of remote sensing in precision agriculture: A review. Remote Sens. 2020, 12, 3136. [Google Scholar] [CrossRef]

- Getahun, S.; Kefale, H.; Gelaye, Y. Application of precision agriculture technologies for sustainable crop production and environmental sustainability: A systematic review. Sci. World J. 2024, 2024, 2126734. [Google Scholar] [CrossRef]

- Grimes, C.A.; Mungle, C.S.; Zeng, K.; Jain, M.K.; Dreschel, W.R.; Paulose, M.; Ong, K.G. Wireless magnetoelastic resonance sensors: A critical review. Sensors 2002, 2, 294–313. [Google Scholar] [CrossRef]

- García-Arribas, A.; Gutiérrez, J.; Kurlyandskaya, G.V.; Barandiarán, J.M.; Svalov, A.; Fernández, E.; Lasheras, A.; De Cos, D.; Bravo-Imaz, I. Sensor applications of soft magnetic materials based on magneto-impedance, magneto-elastic resonance and magneto-electricity. Sensors 2014, 14, 7602–7624. [Google Scholar] [CrossRef]

- Xu, J.; Tat, T.; Zhao, X.; Zhou, Y.; Ngo, D.; Xiao, X.; Chen, J. A programmable magnetoelastic sensor array for self-powered human–machine interface. Appl. Phys. Rev. 2022, 9, 031404. [Google Scholar] [CrossRef]

- Shekhar, S.; Karipott, S.S.; Guldberg, R.E.; Ong, K.G. Magnetoelastic sensors for real-time tracking of cell growth. Biotechnol. Bioeng. 2021, 118, 2380–2385. [Google Scholar] [CrossRef]

- Sander, D. Magnetostriction and magnetoelasticity. In Handbook of Magnetism and Magnetic Materials; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–45. [Google Scholar]

- Pattipaka, S.; Jeong, J.; Choi, H.; Ryu, J.; Hwang, G.T. Magneto-mechano-electric (MME) composite devices for energy harvesting and magnetic field sensing applications. Sensors 2022, 22, 5723. [Google Scholar] [CrossRef]

- Köster, U.; Herold, U. Crystallization of metallic glasses. In Glassy Metals I: Ionic Structure, Electronic Transport, and Crystallization; Springer: Berlin/Heidelberg, Germany, 2005; pp. 225–259. [Google Scholar]

- Suryanarayana, C. In situ mechanical crystallization of amorphous alloys. J. Alloys Compd. 2023, 961, 171032. [Google Scholar] [CrossRef]

- Grishin, A.M.; Ignakhin, V.; Lugovskaya, L.; Osaulenko, R.; Sekirin, I. Crystallization kinetics and magnetostriction properties of amorphous Fe80-xCoxP14B6 metallic glasses. J. Magn. Magn. Mater. 2020, 512, 166972. [Google Scholar] [CrossRef]

- Wang, W.; Fan, J.; Li, C.; Yu, Y.; Wang, A.; Li, S.; Liu, J. Low-Loss Soft Magnetic Materials and Their Application in Power Conversion: Progress and Perspective. Energies 2025, 18, 482. [Google Scholar] [CrossRef]

- Rehalia, V.; Walia, G.; Bhalla, D. Analysing the reduction of no-load losses in distribution transformers on the usage of amorphous alloy. AIP Conf. Proc. 2024, 2900, 020012. [Google Scholar]

- Sato, A.; Terada, H.; Nagata, T.; Kurita, S.; Matsuda, Y.; Fukui, K.; Azuma, D.; Hasegawa, R. Development of distribution transformer based on new amorphous metals. In Proceedings of the 20th International Conference and Exhibition on Electricity Distribution (CIRED 2009), IET, Prague, Czech Republic, 8–11 June 2009; p. 0474. [Google Scholar]

- Turutin, A.V.; Vidal, J.V.; Kubasov, I.V.; Kislyuk, A.M.; Malinkovich, M.D.; Parkhomenko, Y.N.; Kobeleva, S.P.; Kholkin, A.L.; Sobolev, N.A. Low-frequency magnetic sensing by magnetoelectric metglas/bidomain LiNbO3 long bars. J. Phys. D Appl. Phys. 2018, 51, 214001. [Google Scholar] [CrossRef]

- Bichurin, M.; Petrov, R.; Sokolov, O.; Leontiev, V.; Kuts, V.; Kiselev, D.; Wang, Y. Magnetoelectric magnetic field sensors: A review. Sensors 2021, 21, 6232. [Google Scholar] [CrossRef]

- Savage, H.; Spano, M. Theory and application of highly magnetoelastic Metglas 2605SC. J. Appl. Phys. 1982, 53, 8092–8097. [Google Scholar] [CrossRef]

- Mitchell, E.; DeMoyer, R.; Vranish, J. A new Metglas sensor. IEEE Trans. Ind. Electron. 1986, IE-33, 166–170. [Google Scholar] [CrossRef]

- Jen, S.; Liu, C.; Lin, H.; Chou, S. Frequency dependence of the magnetostrictive phenomenon in Metglas® 2605SA1 ribbon: A minor-loop case. AIP Adv. 2014, 4, 127140. [Google Scholar] [CrossRef]

- Fang, Z.; Lu, S.; Li, F.; Datta, S.; Zhang, Q.; El Tahchi, M. Enhancing the magnetoelectric response of Metglas/polyvinylidene fluoride laminates by exploiting the flux concentration effect. Appl. Phys. Lett. 2009, 95, 112903. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Lasheras, A.; Martins, P.; Pereira, N.; Barandiarán, J.M.; Lanceros-Mendez, S. Metallic glass/PVDF magnetoelectric laminates for resonant sensors and actuators: A review. Sensors 2017, 17, 1251. [Google Scholar] [CrossRef]

- Xu, X.; Wang, J.; Long, Y. Zeolite-based materials for gas sensors. Sensors 2006, 6, 1751–1764. [Google Scholar] [CrossRef]

- Wales, D.J.; Grand, J.; Ting, V.P.; Burke, R.D.; Edler, K.J.; Bowen, C.R.; Mintova, S.; Burrows, A.D. Gas sensing using porous materials for automotive applications. Chem. Soc. Rev. 2015, 44, 4290–4321. [Google Scholar] [CrossRef]

- Kouzoudis, D.; Baimpos, T.; Samourgkanidis, G. A New Method for the Measurement of the Diffusion Coefficient of Adsorbed Vapors in Thin Zeolite Films, Based on Magnetoelastic Sensors. Sensors 2020, 20, 3251. [Google Scholar] [CrossRef]

- Narita, F.; Wang, Z.; Kurita, H.; Li, Z.; Shi, Y.; Jia, Y.; Soutis, C. A review of piezoelectric and magnetostrictive biosensor materials for detection of COVID-19 and other viruses. Adv. Mater. 2021, 33, 2005448. [Google Scholar] [CrossRef]

- Meyers, K.M.; Ong, K.G. Magnetoelastic materials for monitoring and controlling cells and tissues. Sustainability 2021, 13, 13655. [Google Scholar] [CrossRef]

- Samourgkanidis, G.; Kouzoudis, D. Magnetoelastic ribbons as vibration sensors for real-time health monitoring of rotating metal beams. Sensors 2021, 21, 8122. [Google Scholar] [CrossRef]

- Kouzoudis, D.; Samourgkanidis, G.; Tapeinos, C.I. Contactless Detection of Natural Bending Frequencies using Embedded Metallic-Glass Ribbons inside Plastic Beams made of 3-D Printing. Recent Prog. Mater. 2021, 3, 1–14. [Google Scholar] [CrossRef]

- Tapeinos, C.I.; Kamitsou, M.D.; Dassios, K.G.; Kouzoudis, D.; Christogerou, A.; Samourgkanidis, G. Contactless and Vibration-Based Damage Detection in Rectangular Cement Beams Using Magnetoelastic Ribbon Sensors. Sensors 2023, 23, 5453. [Google Scholar] [CrossRef]

- Samourgkanidis, G.; Kouzoudis, D. A pattern matching identification method of cracks on cantilever beams through their bending modes measured by magnetoelastic sensors. Theor. Appl. Fract. Mech. 2019, 103, 102266. [Google Scholar] [CrossRef]

- Samourgkanidis, G.; Kouzoudis, D. Experimental detection by magnetoelastic sensors and computational analysis with finite elements, of the bending modes of a cantilever beam with minor damage. Sens. Actuators A Phys. 2018, 276, 155–164. [Google Scholar] [CrossRef]

- Sagasti, A.; Palomares, V.; Porro, J.M.; Orúe, I.; Sánchez-Ilárduya, M.B.; Lopes, A.C.; Gutiérrez, J. Magnetic, magnetoelastic and corrosion resistant properties of (Fe–Ni)-based metallic glasses for structural health monitoring applications. Materials 2019, 13, 57. [Google Scholar] [CrossRef]

- Samourgkanidis, G.; Kouzoudis, D. Characterization of magnetoelastic ribbons as vibration sensors based on the measured natural frequencies of a cantilever beam. Sens. Actuators A Phys. 2020, 301, 111711. [Google Scholar] [CrossRef]

- Sarker, P.C.; Islam, M.R.; Guo, Y.; Zhu, J.; Lu, H.Y. State-of-the-art technologies for development of high frequency transformers with advanced magnetic materials. IEEE Trans. Appl. Supercond. 2018, 29, 7000111. [Google Scholar] [CrossRef]

- Mouhamad, M.; Elleau, C.; Mazaleyrat, F.; Guillaume, C.; Jarry, B. Short-circuit withstand tests of metglas 2605SA1-based amorphous distribution transformers. IEEE Trans. Magn. 2011, 47, 4489–4492. [Google Scholar] [CrossRef]

- Fang, Z. Ultra Sensitive Magnetic Sensors Integrating the Giant Magnetoelectric Effect with Advanced Microelectronics; The Pennsylvania State University: University Park, PA, USA, 2011. [Google Scholar]

- Kolano, R.; Kolano-Burian, A.; Krykowski, K.; Hetmańczyk, J.; Hreczka, M.; Polak, M.; Szynowski, J. Amorphous soft magnetic core for the stator of the high-speed PMBLDC motor with half-open slots. IEEE Trans. Magn. 2016, 52, 1–5. [Google Scholar] [CrossRef]

- Austrin, L.; Figueroa-Karlstrom, E.; Engdahl, G. Evaluation of switching losses in magnetic amplifiers as an alternative to IGBT switching technologies. In Proceedings of the 2008 4th IET Conference on Power Electronics, Machines and Drives, York, UK, 2–4 April 2008; pp. 250–254. [Google Scholar]

- Quach, H.P.; Chui, T.C. Low temperature magnetic properties of Metglas 2714A and its potential use as core material for EMI filters. Cryogenics 2004, 44, 445–449. [Google Scholar] [CrossRef]

- Luong, V.S.; Le, M.; Quang, V.P. Fluxgate-based displacement sensor design. J. Supercond. Nov. Magn. 2023, 36, 1767–1775. [Google Scholar] [CrossRef]

- Cadogan, J.; Campbell, S.; Jing, J.; Foley, C.; Kater, P.; Mai, Y. Annealing embrittlement of Fe78Si9B13 (METGLAS-2605S2). Hyperfine Interact. 2014, 226, 7–14. [Google Scholar] [CrossRef]

- Deng, T.; Chen, Z.; Di, W.; Fang, B.; Luo, H. Enhancement magnetoelectric effect in Metglas-Fe by annealing. Appl. Phys. A 2021, 127, 1–11. [Google Scholar] [CrossRef]

- Lee, D.Y.; Yim, S.H.; Son, D. Effects of Annealing Temperature on Amorphous CoFeCrBSi Alloys for Flux-gate Magnetometers. J. Magn. 2021, 26, 67–70. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Wu, S.; Zhuang, X.; Yan, B.; Zhu, W.; Dolabdjian, C.; Fang, G. Magnetomechanical properties of Fe-Si-B and Fe-Co-Si-B metallic glasses by various annealing temperatures for actuation applications. Sensors 2022, 23, 299. [Google Scholar] [CrossRef]

- Wang, T.; Chen, J.; Wei, R.; Chen, C.; Li, F. Improving the B s and soft magnetic properties of Fe-based amorphous ribbons by manipulating the surface crystallization behavior. J. Mater. Sci. Mater. Electron. 2021, 32, 21206–21212. [Google Scholar] [CrossRef]

- Palneedi, H.; Patil, D.R.; Priya, S.; Woo, K.; Ye, J.; Woo, Y.M.; Hwang, Y.S.; Hwang, G.T.; Park, J.H.; Ryu, J. Intense Pulsed Light Thermal Treatment of Pb (Zr, Ti)O3/Metglas Heterostructured Films Resulting in Extreme Magnetoelectric Coupling of over 20 V cm−1 Oe−1. Adv. Mater. 2023, 35, 2303553. [Google Scholar] [CrossRef]

- Samourgkanidis, G.; Varvatsoulis, K.; Kouzoudis, D. The Effect of the Thermal Annealing Process to the Sensing Performance of Magnetoelastic Ribbon Materials. Sustainability 2021, 13, 13947. [Google Scholar] [CrossRef]

- Metglas, Inc. Magnetic Materials—Metglas. 2025. Available online: https://metglas.com/magnetic-materials/ (accessed on 11 June 2025).

- Livingston, J.D. Magnetomechanical properties of amorphous metals. Phys. Status Solidi 1982, 70, 591–596. [Google Scholar] [CrossRef]

| Properties | 2628MB3 | 2605SA1 | 2714A |

|---|---|---|---|

| Base Material | Fe-Ni | Fe | Co |

| Density () | 7.90 | 7.18 | 7.59 |

| Saturation Induction (T) | 0.88 | 1.56 | 0.57 |

| Saturation Magnetostriction (ppm) | 12 | 27 | <0.5 |

| Curie Temperature (C) | 353 | 395 | 225 |

| Crystallization Temperature (C) | 410 | 510 | 550 |

| Ref. | Alloy | OAS (C-min) | Property | Improvement |

|---|---|---|---|---|

| [45] | (Metglas 2605S2) | 360-5 | In-plane magnetic texture | 27.2% |

| [46] | Mn-PMNT/FeBSiC | 360-5 | Piezomagnetic coefficient | 36.8% |

| [47] | 350-60 | Noise level | 108.3% | |

| [48] | FeCoSiB (Vitrovac 7600) | 390-20 | Coupling factor | 23% |

| FeSiB (Metglas 2605SA1) | 440-20 | // | 73% | |

| [49] | 523-10 | Magnetic permeability | 136.8% | |

| 521-10 | Core losses | 50% | ||

| [50] | Pb(Zr,Ti)/FeSiB (PZT/Metglas 2605SA1) | 300-2 | Magnetoelectric coupling | ≈1000% |

| CW | (Metglas 2826MB3) | 457-22 | Magnetic signal | 75.8% |

| FeSiB (Metglas 2605SA1) | 412-31 | // | 70% | |

| (Metglas 2714A) | 442-9 | // | 86.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samourgkanidis, G.; Kouzoudis, D.; Charalampous, P.; Adnan, E. Signal Enhancement in Magnetoelastic Ribbons Through Thermal Annealing: Evaluation of Magnetic Signal Output in Different Metglas Materials. Sensors 2025, 25, 3722. https://doi.org/10.3390/s25123722

Samourgkanidis G, Kouzoudis D, Charalampous P, Adnan E. Signal Enhancement in Magnetoelastic Ribbons Through Thermal Annealing: Evaluation of Magnetic Signal Output in Different Metglas Materials. Sensors. 2025; 25(12):3722. https://doi.org/10.3390/s25123722

Chicago/Turabian StyleSamourgkanidis, Georgios, Dimitris Kouzoudis, Panagiotis Charalampous, and Eyad Adnan. 2025. "Signal Enhancement in Magnetoelastic Ribbons Through Thermal Annealing: Evaluation of Magnetic Signal Output in Different Metglas Materials" Sensors 25, no. 12: 3722. https://doi.org/10.3390/s25123722

APA StyleSamourgkanidis, G., Kouzoudis, D., Charalampous, P., & Adnan, E. (2025). Signal Enhancement in Magnetoelastic Ribbons Through Thermal Annealing: Evaluation of Magnetic Signal Output in Different Metglas Materials. Sensors, 25(12), 3722. https://doi.org/10.3390/s25123722