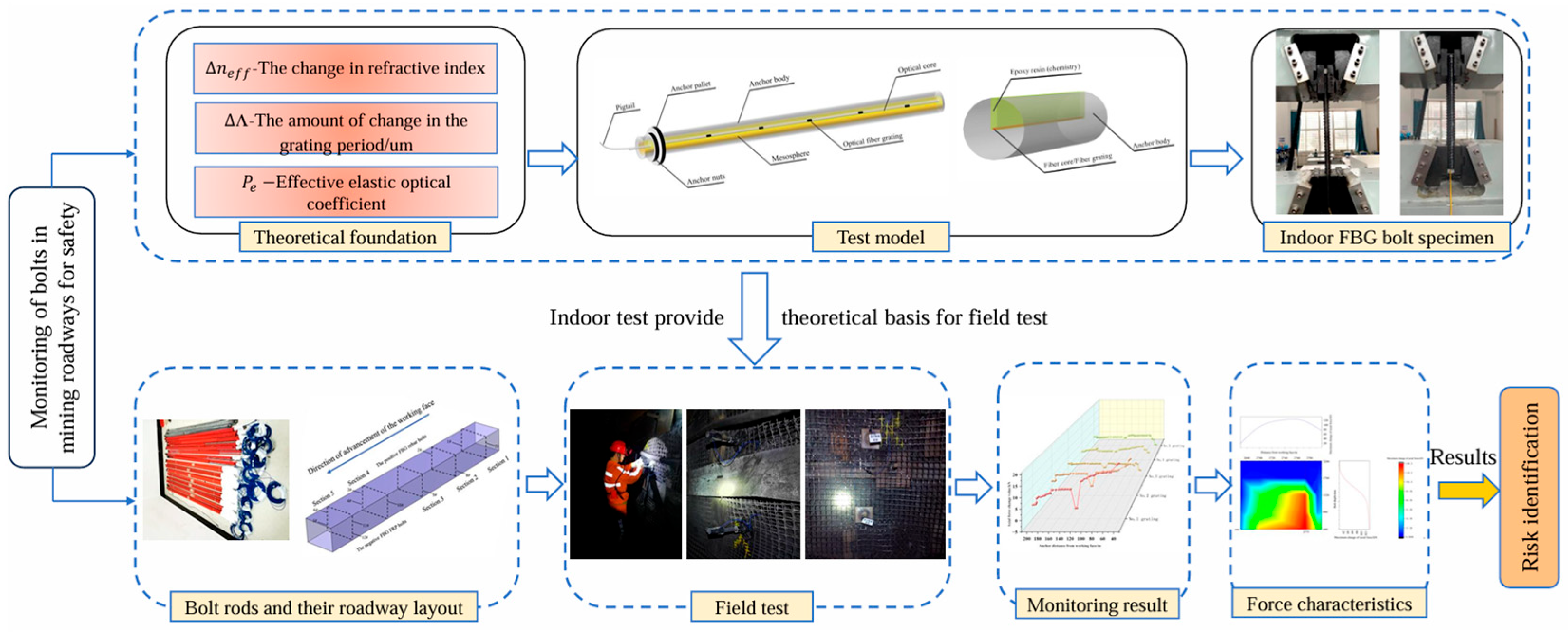

Safety Status Monitoring of Operational Rock Bolts in Mining Roadways Under Mining-Induced Effects

Abstract

1. Introduction

2. Monitoring of Sensor Arrangement Schemes

2.1. Basic Situation of Working Surface

2.2. Monitoring Sensor Arrangement

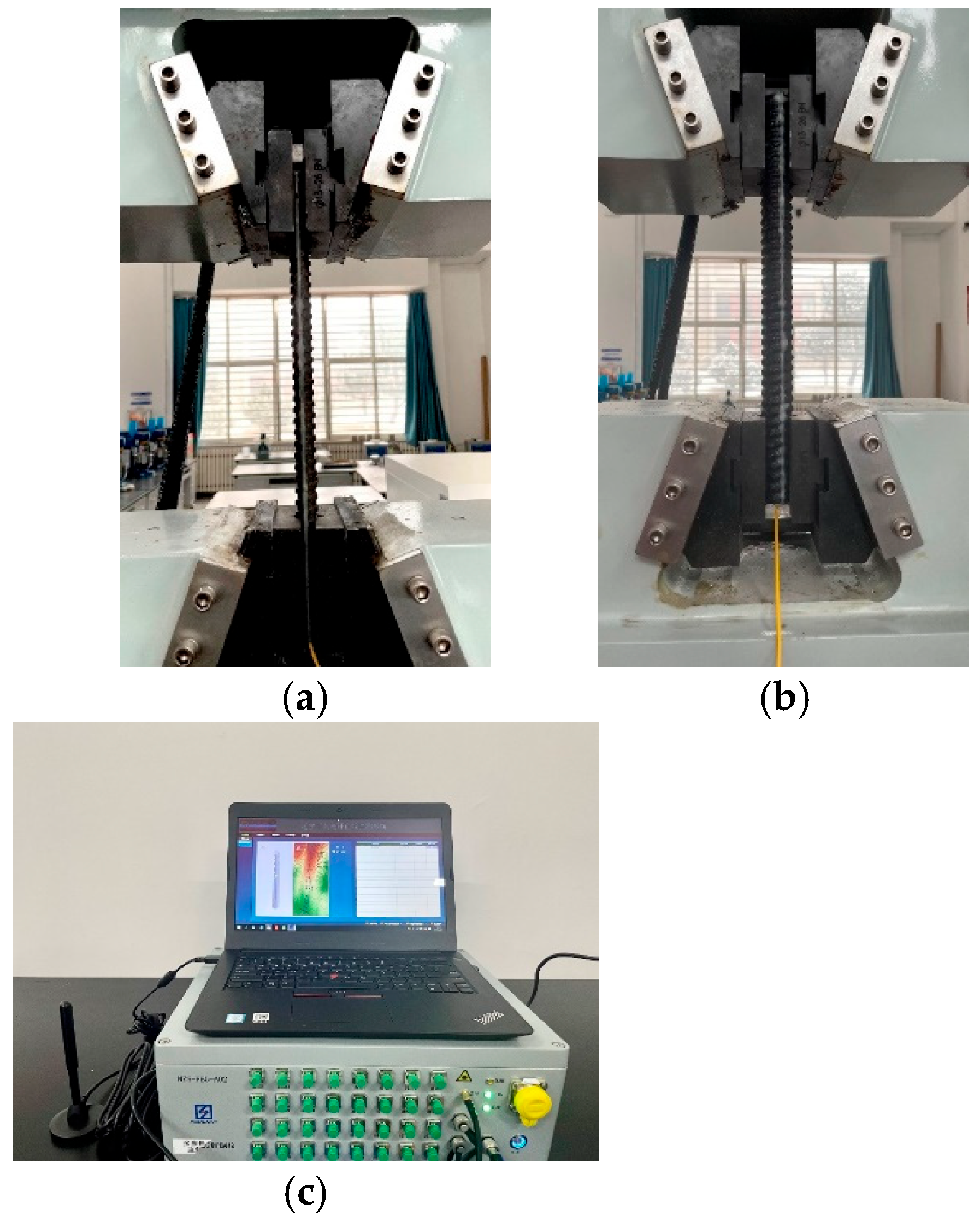

3. FBG Bolt Design and Installation

3.1. FBG Bolt Sensor Working Principle

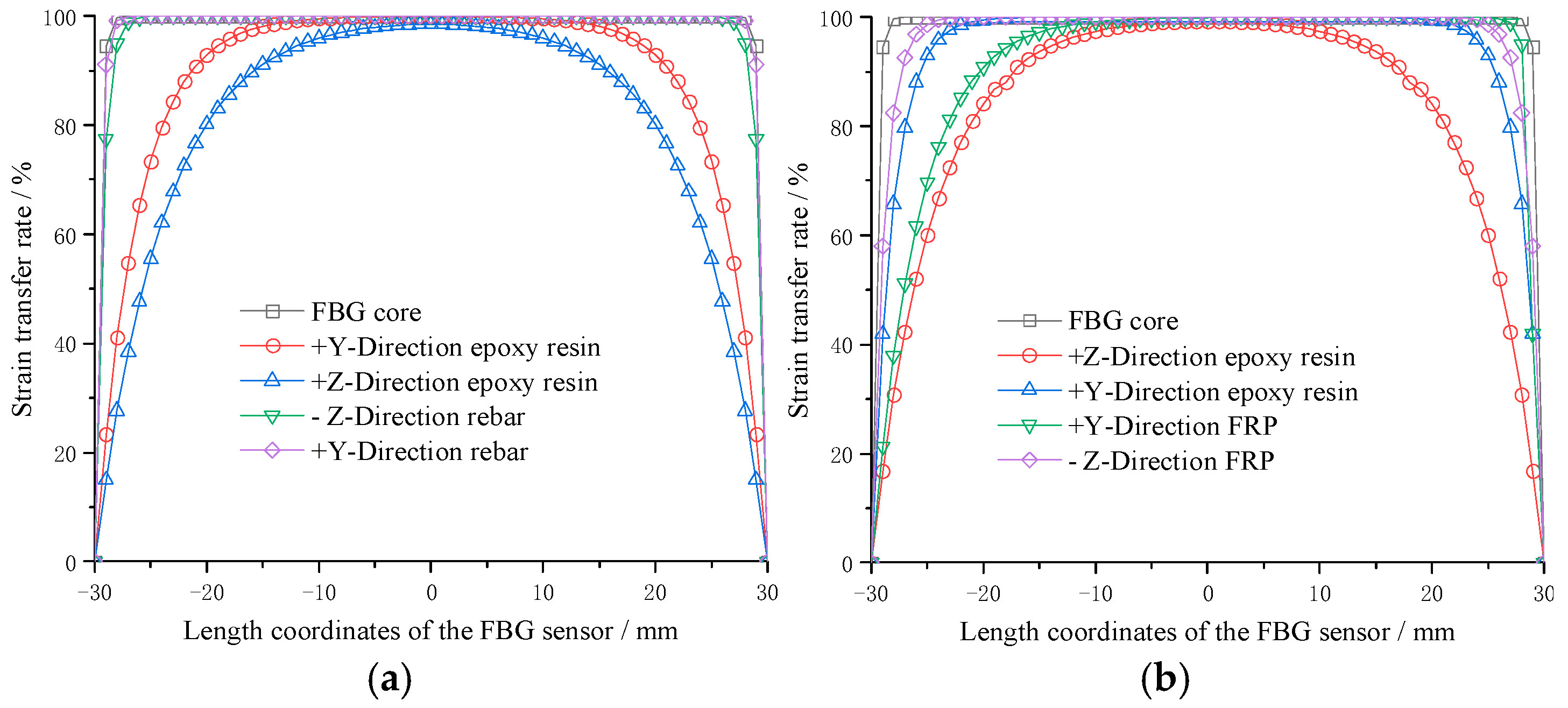

3.2. Fiber Grating Strain Measurement

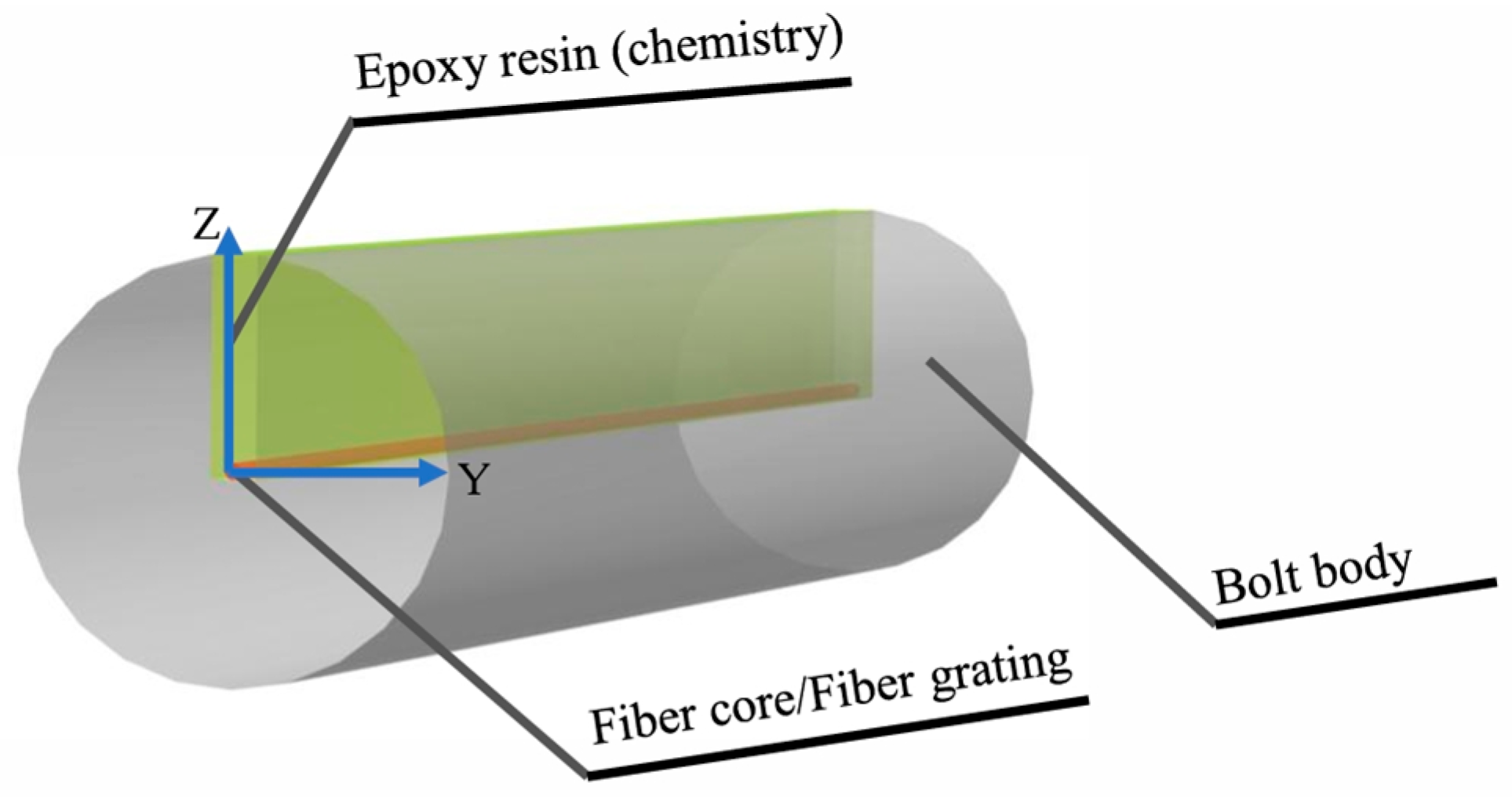

3.3. FBG Bolt Design

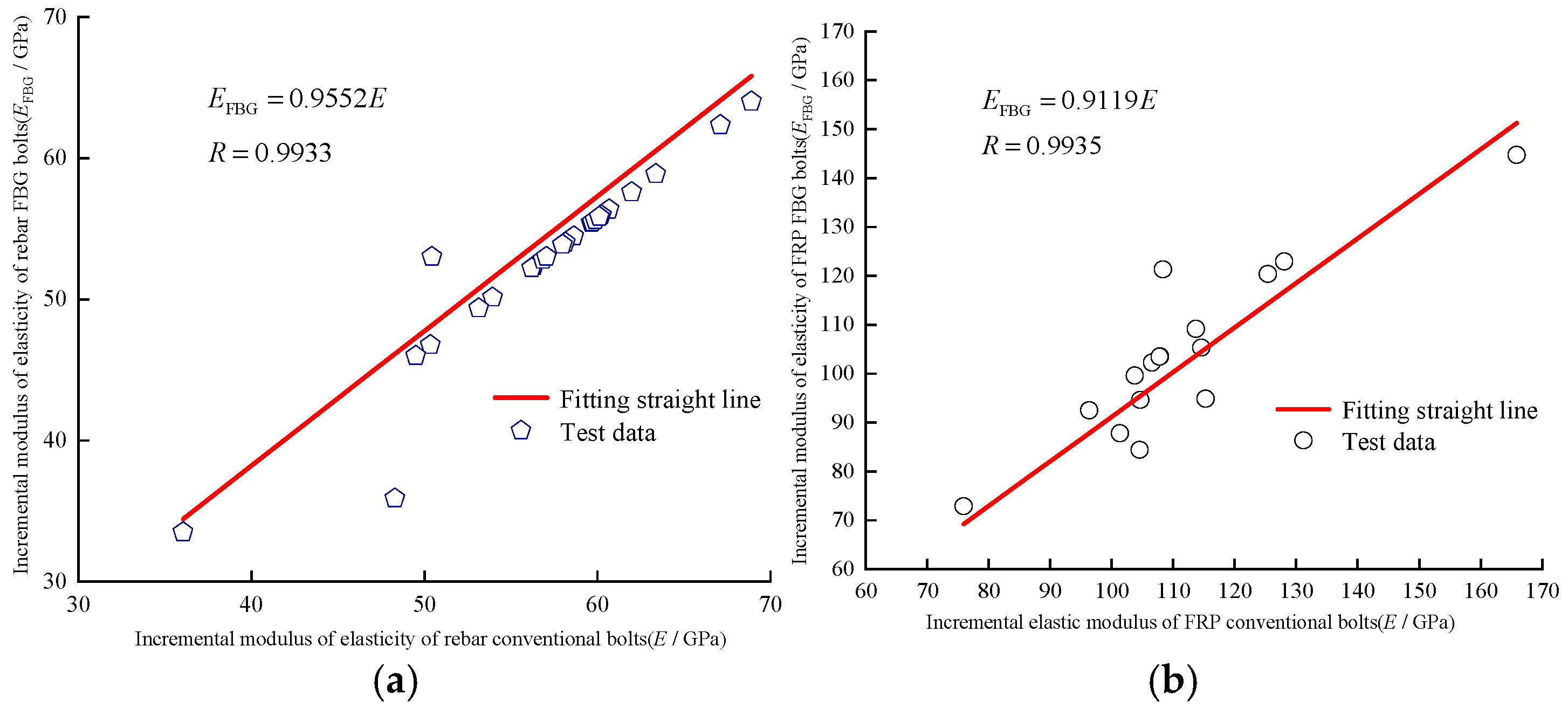

3.4. Incremental Modulus of Elasticity of Bolt

3.5. Monitoring Sensor Installation

4. Bolt Rod Body Force and Deformation Characteristics

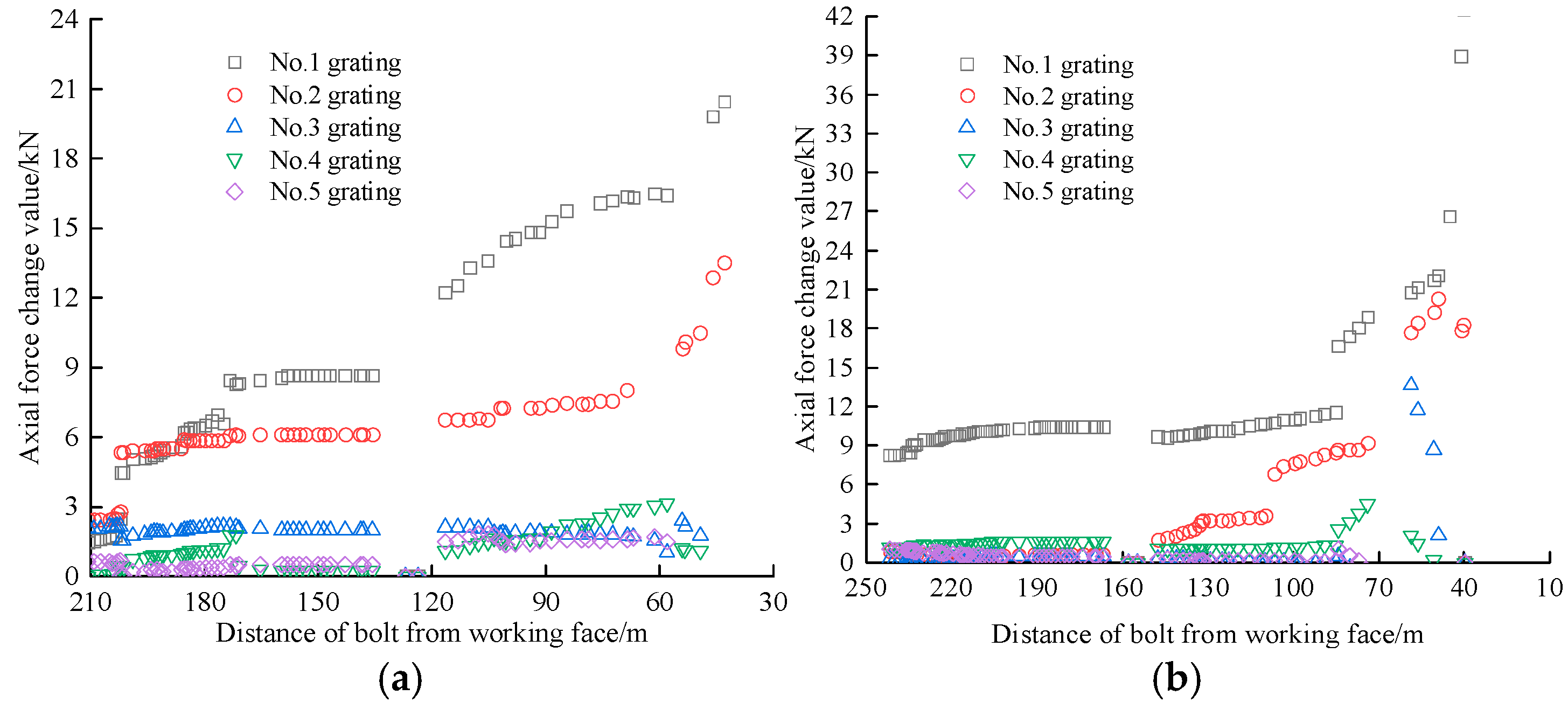

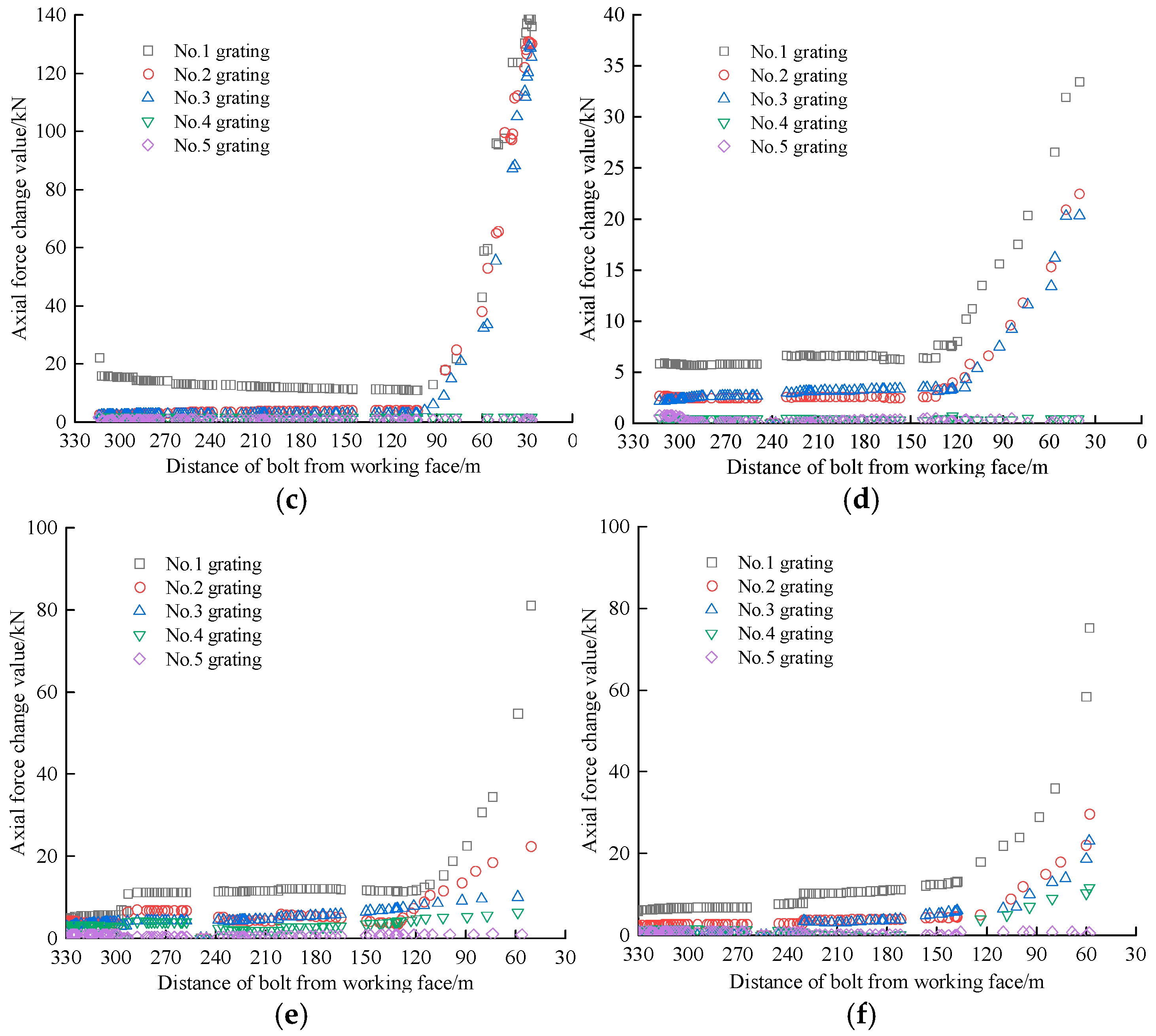

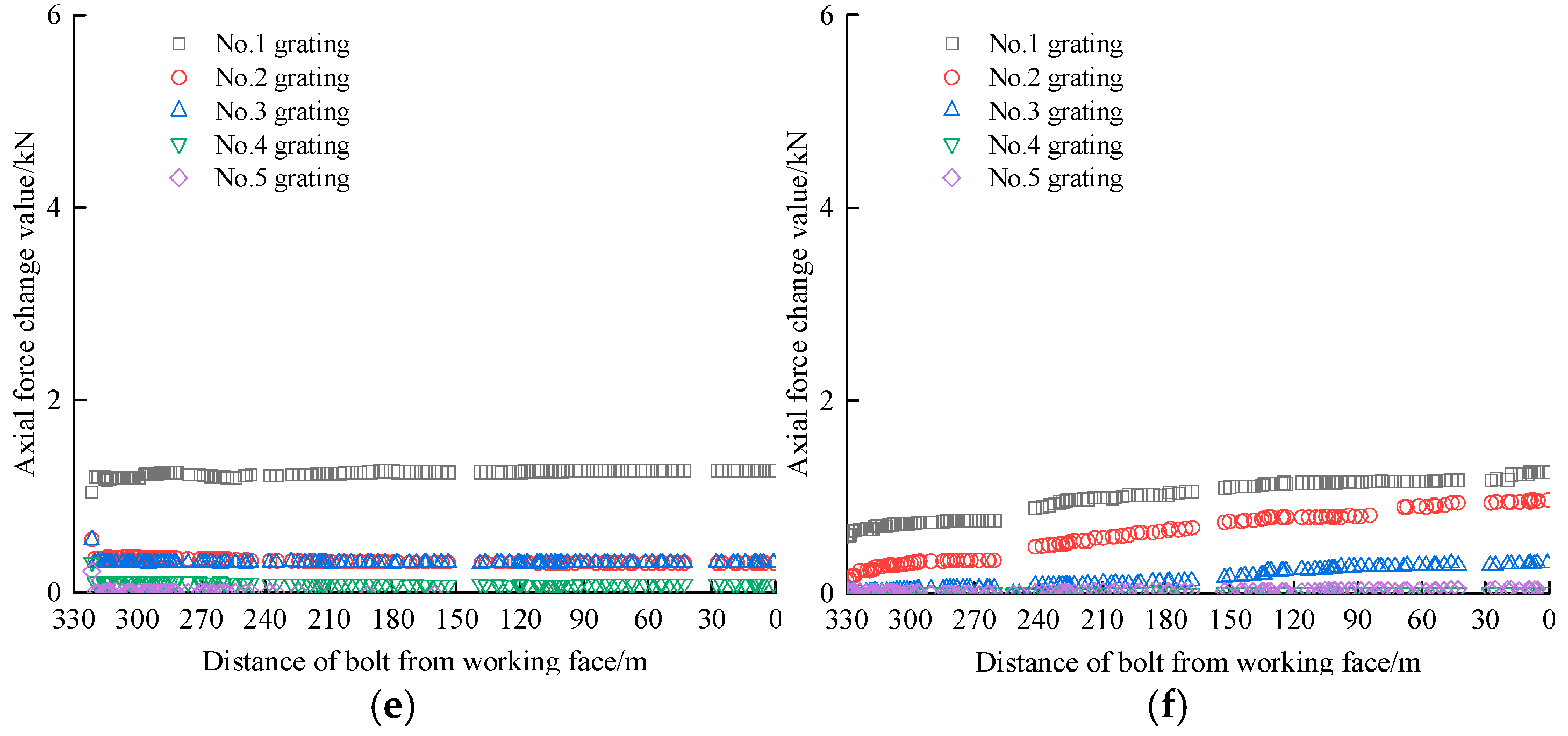

4.1. Analysis of Monitoring Results

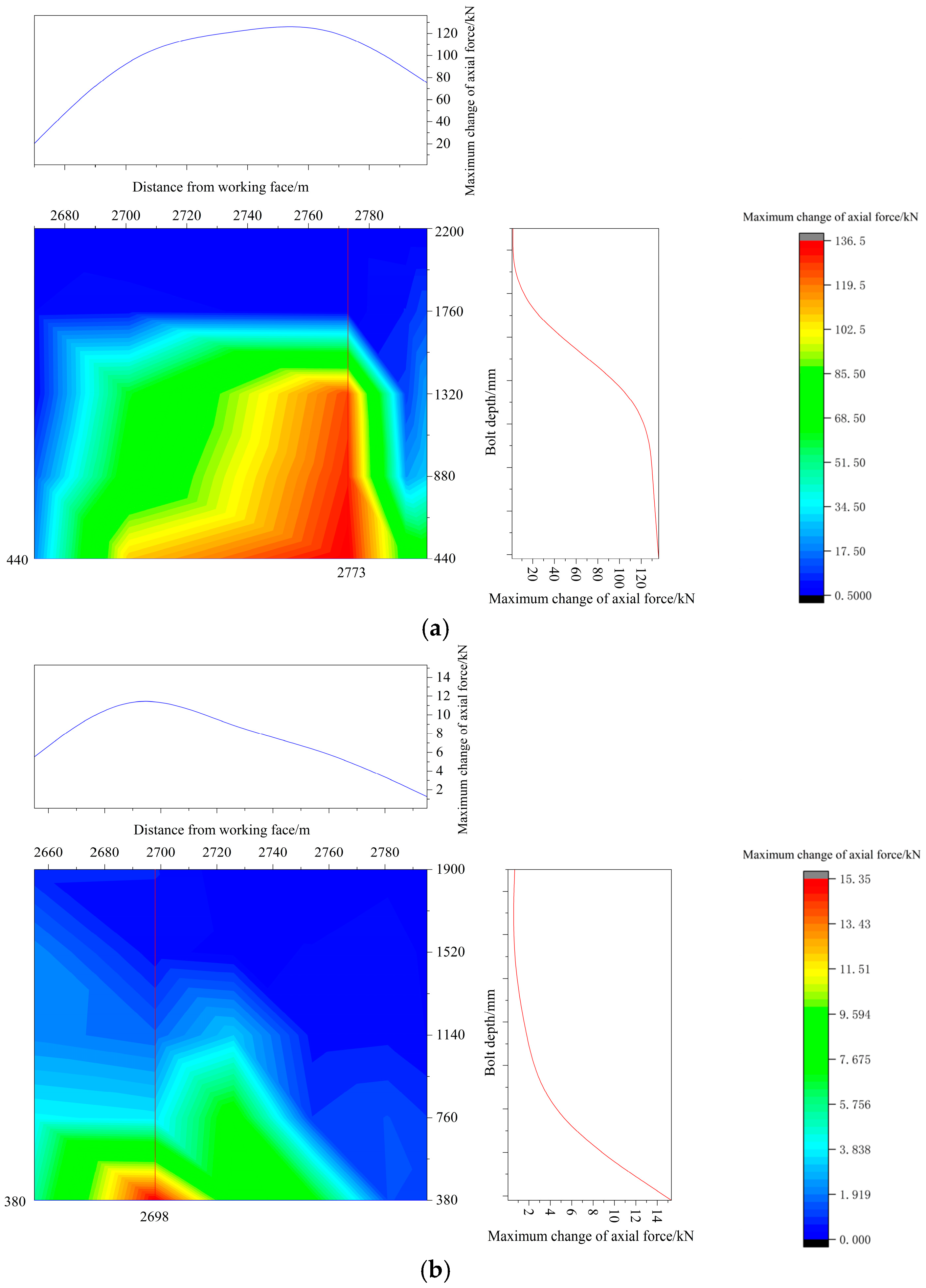

4.2. Bolt Rod Body Force Characteristics

4.3. Evaluation of the Safety Status of Bolts

5. Conclusions

- (1)

- In the axial stress monitoring test using FBG sensors at the coal mine site, the positive gang bolt bar exhibits the most significant change in axial force. The variation in axial force is generally greater than that observed in the negative gang bolt bar. The roadway gang closest to the working face is subjected to the shortest distance and the most direct impact from mining activities.

- (2)

- As the comprehensive mining face advances, the positive gang bolt rod maintains a 60 m distance from the working face. Beyond this distance, the axial force on the bolt rod starts to rise progressively. Once the working face advances 60 m past the bolt rod, its axial force experiences a significant rise. With the advancement of the working face, the axial force on the negative gang bolt rod steadily rises.

- (3)

- Based on the monitoring data of the axial force in the rock bolts within the underground tunnel, the magnitude of the change in the shaft force in the bolted section is small because the rods are relatively fit to the surrounding rock; the rods in the near-pallet area are situated in the free section, allowing them to deform freely, resulting in a significant change in axial force; in the free section, the axial force along the rock bolts is unevenly distributed, with the highest force occurring in the rods nearest to the pallet area.

- (4)

- By interpolating and smoothing the monitoring data of FBG rock bolts at the working face, a continuous contour profile curve distribution is generated. By comparing the distribution of maximum axial force values along the rock bolts at different positions, it is possible to identify the roadway areas most influenced by mining activities. This enables the implementation of timely bolt support and preventive measures to avoid accidents such as broken rock bolts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, H. Sixty years development and prospects of rock bolting technology for underground coal mine roadways in China. J. China Univ. Min. Technol. 2016, 45, 1071–1081. [Google Scholar]

- Chen, C.; Cui, Q. Study on characteristics of bolt support of roadway in typical shallow coal seam. Coal Sci. Technol. 2018, 46, 12–17. [Google Scholar]

- Li, Y.; Liu, L.; Sun, J.; Li, Y.; Yan, X. Research on support of deformation of mining side gob along high-stress mining roadway. Geotech. Geol. Eng. 2019, 37, 5543–5553. [Google Scholar] [CrossRef]

- Cui, F.; Dong, S.; Lai, X.; Chen, J.; Jia, C.; Zhang, T. Study the fracture law of inclined hard roof and surrounding rock control of mining roadway in longwall mining face. Energies 2020, 13, 5344. [Google Scholar] [CrossRef]

- Jia, H.; Pan, K.; Liu, S.; Peng, B.; Fan, K. Evaluation of the mechanical instability of mining roadway overburden: Research and applications. Energies 2019, 12, 4265. [Google Scholar] [CrossRef]

- Li, G.; Cao, S.; Luo, F.; Li, Y.; Wei, Y. Research on mining-induced deformation and stress, insights from physical modeling and theoretical analysis. Arab. J. Geosci. 2018, 11, 1–9. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Y.; Liu, G.; Meng, X. Mechanism analysis and control technology of surrounding rock failure in deep soft rock roadway. Eng. Fail. Anal. 2020, 115, 104611. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, N.; Wang, S.; Qian, D.; Xie, Z. Physical model test study on support of super pre-stressed anchor in the mining engineering. Eng. Fail. Anal. 2020, 118, 104833. [Google Scholar] [CrossRef]

- He, Z.; Xie, Z.; Zhang, N.; Han, C.; Xiang, Z.; Yan, G.; Qiao, H.; Shao, C. Research on spatiotemporal evolution law of surrounding rock fractures and hierarchical collaborative control technology in high-stress soft rock roadway: A case study. Eng. Fail. Anal. 2023, 150, 107366. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; He, M.; Tian, H.; Gong, W. Mechanical behavior of a deep soft rock large deformation roadway supported by NPR bolts: A case study. Rock Mech. Rock Eng. 2023, 56, 8851–8867. [Google Scholar] [CrossRef]

- Li, A.; Ji, B.; Zhou, H.; Wang, F.; Liu, Y.; Mu, P.; Yang, J.; Xu, G.; Zhao, C. Research on reinforcement mechanism of soft coal pillar anchor cable. Geomech. Eng. 2022, 29, 697–706. [Google Scholar]

- Yu, W.; Wu, G.; Pan, B.; Wang, C.; Li, K.; Liao, Z. Laboratory and field investigations of different bolting configurations for coal mine roadways in weak coal strata. Bull. Eng. Geol. Environ. 2021, 80, 8995–9013. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, H.; Jiang, B.; Li, S.; He, M.; Wang, D.; Lu, W.; Qin, Q.; Gao, S.; Yu, H. Bolt fracture mechanism of roadway driven along gob in high street area caused by mining. J. China Univ. Min. Technol. 2017, 46, 769–775. [Google Scholar]

- Yu, W.; Li, K.; Zhang, J.; Han, S.; Liao, Z.; Zhang, Z. Deformation characteristics and control factors of the surrounding rock in the deep buried soft rock roadway under the influence of mining. Coal Sci. Technol. 2020, 48, 125–135. [Google Scholar]

- Li, C.; Zhang, W.; Wang, N.; Hao, C. Roof stability control based on plastic zone evolution during mining. J. Min. Saf. Eng. 2019, 36, 753–761. [Google Scholar]

- WWang, P.; Jiang, L.; Ma, C.; Yuan, A. Evolution laws of floor stress and stability of floor roadway affected by overhead mining. Earth Sci. Res. J. 2020, 24, 45–54. [Google Scholar] [CrossRef]

- Wang, W.; Gao, M.; Wang, M.; Xie, J.; Liu, Q.; Li, A.; Chen, H. Study on characteristics of deformation and stress distribution of gob-side entry retaining in the ultra-deep mine. J. Rock Mech. Eng. 2019, 38, 2955–2963. [Google Scholar]

- Kan, J.G.; Zhang, N.; Zhang, H.W.; Zhang, Z.Y.; Si, G.Y. Stress Evolution and Deformation Control Technology for Deep Mining Influenced Roadway. Appl. Mech. Mater. 2011, 90–93, 137–145. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Wu, Y.; Zhang, G.; Zhang, L. Field measurement study of the relation between mining pressure and axial boltload. J. Coal 2016, 41, 1106–1110. [Google Scholar]

- Liu, X.; Yao, Z.; Cheng, H.; Zha, W. Experimental study and mechanism analysis of bolt anchorage interface failure under temperature and pressure coupling. Int. J. Adhes. Adhes. 2023, 126, 103488. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, X.; Tan, Y.; Wang, W.; Li, X.; Wang, X. Mechanism of bolt breakage in deep mining roadway under dynamic load and advanced strengthening support technology. Eng. Fail. Anal. 2024, 161, 108255. [Google Scholar] [CrossRef]

- Sun, L.; Li, C.; Zhang, C.; Liang, T.; Zhao, Z. The Strain Transfer Mechanism of Fiber Bragg Grating Sensor for Extra Large Strain Monitoring. Sensors 2019, 19, 1851. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Yao, Z.; Wu, Y.; Xu, Y.; Wang, X.; Wang, C. Application of FBG Sensor to Safety Monitoring of Mine Shat Lining Structure. Sensors 2022, 22, 4838. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Guo, J.; Tan, Y.; Zhou, Z. Recent advances and tendency in fiber Bragg grating-based vibration sensor: A review. IEEE Sens. J. 2020, 20, 12074–12087. [Google Scholar] [CrossRef]

| Bolt Number | Maximum Value of Change in Bolt Axial Force/kN | Ratio of Bolt Axial Force to Design Anchorage Force/% |

|---|---|---|

| Bolt 1 | 20.44 | 76.04 |

| Bolt 2 | 108.11 | >100 |

| Bolt 3 | 136.15 | >100 |

| Bolt 4 | 33.42 | 90.47 |

| Bolt 5 | 81.13 | >100 |

| Bolt 6 | 75.29 | >100 |

| Bolt 7 | 5.52 | 59.47 |

| Bolt 8 | 15.32 | 70.36 |

| Bolt 9 | 8.09 | 61.32 |

| Bolt 10 | 7.27 | 59.41 |

| Bolt 11 | 1.27 | 54.74 |

| Bolt 12 | 1.25 | 54.72 |

| Bolt Status | Condition | Bolt Number |

|---|---|---|

| Normal | Bolt axial force less than 60% of design anchorage force | Bolt 7, Bolt 10, Bolt 11, Bolt 12 |

| Abnormal | Bolt axial force is 60–100% of design anchorage force | Bolt 1, Bolt 4, Bolt 8, Bolt 9 |

| Destroyed | Bolt axial force greater than design anchorage force | Bolt 2, Bolt 3, Bolt 5, Bolt 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, J.; Ding, W.; Qin, Y.; Gao, K. Safety Status Monitoring of Operational Rock Bolts in Mining Roadways Under Mining-Induced Effects. Sensors 2025, 25, 3486. https://doi.org/10.3390/s25113486

Dong J, Ding W, Qin Y, Gao K. Safety Status Monitoring of Operational Rock Bolts in Mining Roadways Under Mining-Induced Effects. Sensors. 2025; 25(11):3486. https://doi.org/10.3390/s25113486

Chicago/Turabian StyleDong, Jianjun, Wenduo Ding, Yu Qin, and Ke Gao. 2025. "Safety Status Monitoring of Operational Rock Bolts in Mining Roadways Under Mining-Induced Effects" Sensors 25, no. 11: 3486. https://doi.org/10.3390/s25113486

APA StyleDong, J., Ding, W., Qin, Y., & Gao, K. (2025). Safety Status Monitoring of Operational Rock Bolts in Mining Roadways Under Mining-Induced Effects. Sensors, 25(11), 3486. https://doi.org/10.3390/s25113486