Combining Infrared Thermography with Computer Vision Towards Automatic Detection and Localization of Air Leaks

Abstract

1. Introduction

2. Theoretical Background

2.1. Principles of IRT

2.2. IRT-Based Leak Detection Systems

3. Proposed Methodology

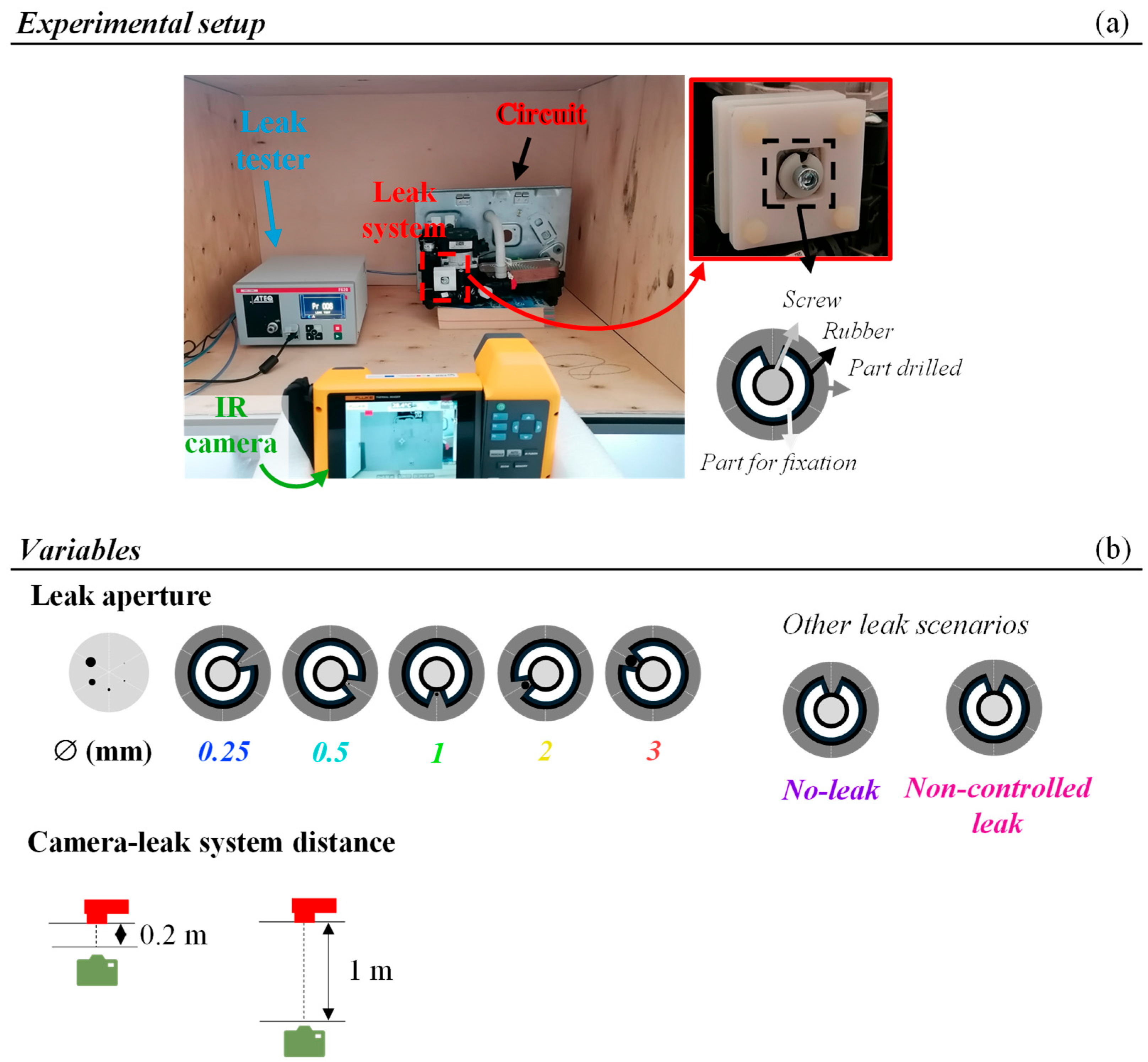

3.1. Thermal Image Acquisition Setup

3.2. Leakage Experiments

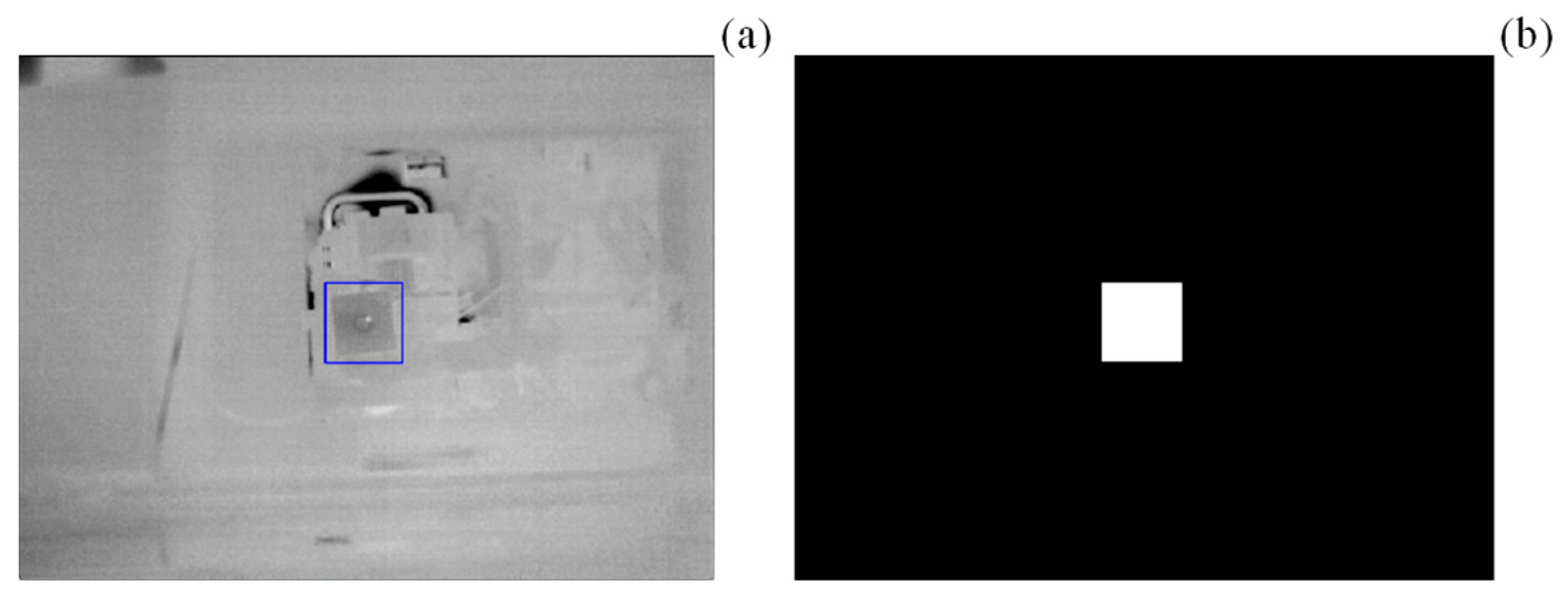

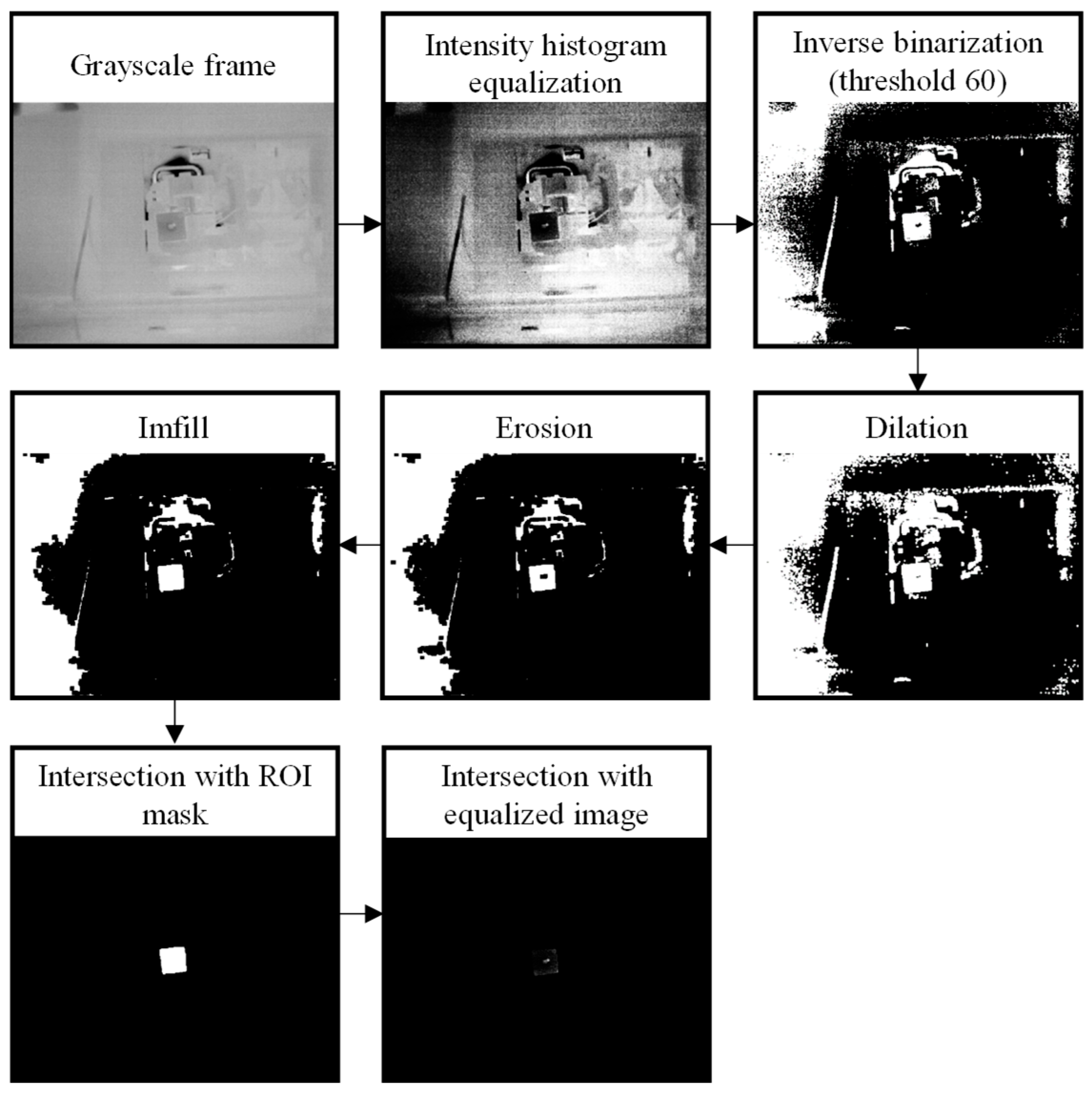

3.3. Algorithm for Automatic Leak Localization

Performance Evaluation

3.4. Statistical Analysis

4. Results and Discussion

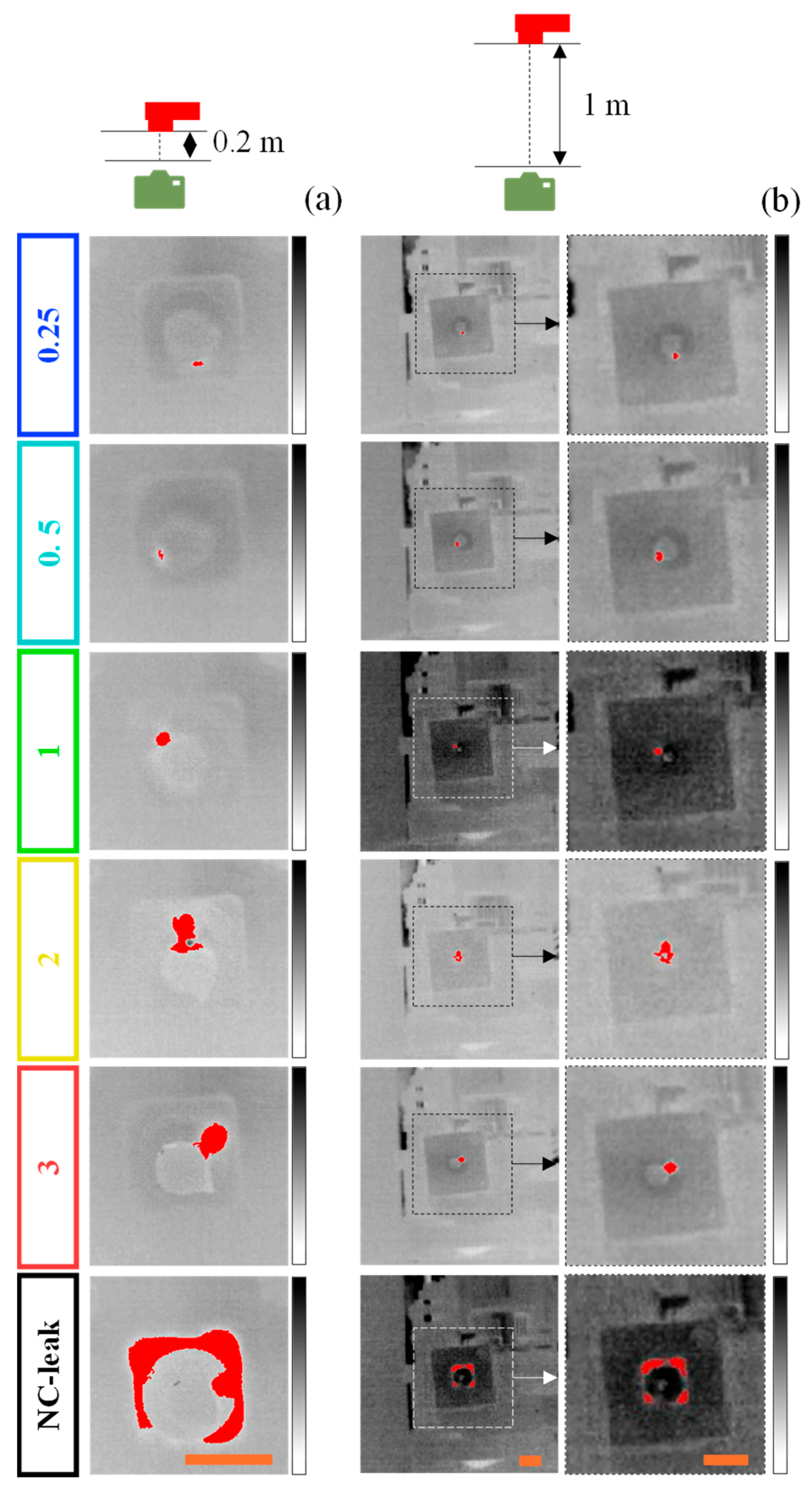

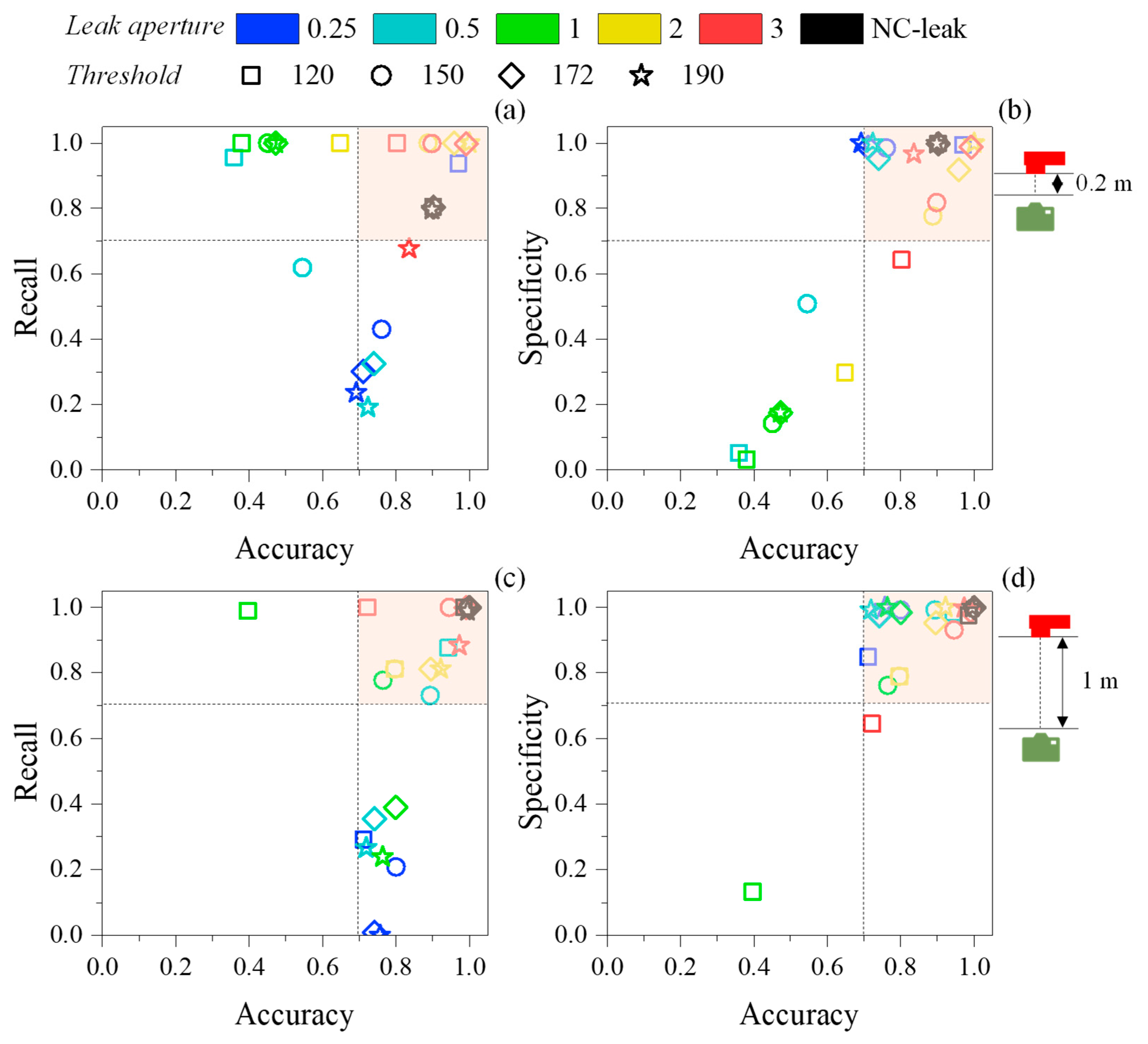

4.1. Leak Detection

4.2. Leak Localization

5. Conclusions

- The universal leak tester successfully detected and quantified all air leaks, regardless of the leak aperture. However, its size significantly affected the air pressure retained within the hydraulic circuit, overall airtightness test time, and the resulting leak rate. In this instance, an increasing trend was observed in leak rates with increasing leak aperture.

- The performance of the passive IRT was highly affected by the leak aperture and the camera–leak system distance. Indeed, for smaller camera–leak system distances (0.2 m), IRT allowed for effective air leak localization in closed circuits, with the size and intensity of the thermal images correlating positively with the size of the leak aperture, given the larger temperature differences triggered by the larger volumes of leaked air. However, larger camera–leak system distances (1 m) significantly impacted the performance of the IRT, particularly for smaller leak apertures.

- The developed algorithm successfully located all air leaks in laboratorial and industrial settings, regardless of the leak aperture and the camera–leak system distance, but its performance in terms of accuracy, recall, and specificity fluctuated slightly with modifications of both these variables and the intensity threshold employed for leak localization.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klippel, W. End-Of-Line Testing. In Assembly Line—Theory and Practice; Grzechca, W., Ed.; InTech: Rikeja, Croatia, 2011; pp. 181–206. [Google Scholar] [CrossRef]

- Tao, W.; Qin, M.; Wei, F.; Junzheng, W. Study of Differential Pressure Method for Air Leak Detection Based on Temperature. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011. [Google Scholar] [CrossRef]

- Shi, Y.; Chang, J.; Wang, Y.; Yang, L. Analysis on Influence Factors of Differential Pressure Detection of Gas Leakage. J. Sens. 2022, 2022, 973299. [Google Scholar] [CrossRef]

- Bunian, S.; Al-Ebrahim, M.A.; Nour, A.A. Role and Applications of Artificial Intelligence and Machine Learning in Manufacturing Engineering: A Review. Eng. Sci. 2024, 29, 1088. [Google Scholar] [CrossRef]

- Costa, V.A.F. Liquid Leakage Assessment from Gas Leakage Tests. Measurement 2020, 151, 107135. [Google Scholar] [CrossRef]

- Hirsch, V.; Reimann, P.; Mitschang, B. Data-Driven Fault Diagnosis in End-of-Line Testing of Complex Products. In Proceedings of the 2019 IEEE International Conference on Data Science and Advanced Analytics (DSAA 2019), Washington, DC, USA, 1 October 2019. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Murvay, P.-S.; Silea, I. A Survey on Gas Leak Detection and Localization Techniques. J. Loss Prev. Process Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Yuan, J.; Mao, W.; Hu, C.; Zheng, J.; Zheng, D.; Yang, Y. Leak Detection and Localization Techniques in Oil and Gas Pipeline: A Bibliometric and Systematic Review. Eng. Fail. Anal. 2023, 146, 107060. [Google Scholar] [CrossRef]

- Adefila, K.; Yan, Y.; Wang, T. Leakage Detection of Gaseous CO2 through Thermal Imaging. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Pisa, Italy, 11–14 May 2015. [Google Scholar] [CrossRef]

- Zimmerle, D.; Vaughn, T.; Bell, C.; Bennett, K.; Deshmukh, P.; Thoma, E. Detection Limits of Optical Gas Imaging for Natural Gas Leak Detection in Realistic Controlled Conditions. Environ. Sci. Technol. 2020, 54, 11506–11514. [Google Scholar] [CrossRef]

- De Ketelaere, B.; Wouters, N.; Kalfas, I.; Van Belleghem, R.; Saeys, W. A Fresh Look at Computer Vision for Industrial Quality Control. Qual. Eng. 2022, 34, 152–158. [Google Scholar] [CrossRef]

- Ettalibi, A.; Elouadi, A.; Mansour, A. AI and Computer Vision-Based Real-Time Quality Control: A Review of Industrial Applications. Procedia Comput. Sci. 2024, 231, 212–220. [Google Scholar] [CrossRef]

- Semitela, Â.; Ferreira, A.; Completo, A.; Lau, N.; Santos, J.P. Detecting and Classifying Defects on the Surface of Water Heaters: Development of an Automated System. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2024. [Google Scholar] [CrossRef]

- He, Y.; Deng, B.; Wang, H.; Cheng, L.; Zhou, K.; Cai, S.; Ciampa, F. Infrared Machine Vision and Infrared Thermography with Deep Learning: A Review. Infrared Phys. Technol. 2021, 116, 103754. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared Thermography for Condition Monitoring—A Review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Vavilov, V.; Burleigh, D. Infrared Systems. In Infrared Thermography and Thermal Nondestructive Testing; Springer Nature: Cham, Switzerland, 2020; pp. 341–396. [Google Scholar] [CrossRef]

- Gade, R.; Moeslund, T.B. Thermal Cameras and Applications: A Survey. Mach. Vis. Appl. 2014, 25, 245–262. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and Application of Infrared Thermography Non-Destructive Testing Techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef]

- Sivathanu, Y. Natural Gas Leak Detection in Pipelines; Report of U.S. Department of Energy National Energy Technology Laboratory, DE-FC26-03NT41857; U.S. Department of Energy National Energy Technology Laboratory: Morgantown, WV, USA, 2003.

- Kasai, N.; Tsuchiya, C.; Fukuda, T.; Sekine, K.; Sano, T.; Takehana, T. Propane Gas Leak Detection by Infrared Absorption Using Carbon Infrared Emitter and Infrared Camera. NDT E Int. 2011, 44, 57–60. [Google Scholar] [CrossRef]

- Barber, R.; Rodriguez-Conejo, M.A.; Melendez, J.; Garrido, S. Design of an Infrared Imaging System for Robotic Inspection of Gas Leaks in Industrial Environments. Int. J. Adv. Robot. Syst. 2015, 12, 23. [Google Scholar] [CrossRef]

- Bach, P.M.; Kodikara, J.K. Reliability of Infrared Thermography in Detecting Leaks in Buried Water Reticulation Pipes. IEEE J Sel. Top. Appl. Earth. Obs. Remote Sens. 2017, 10, 4210–4224. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Y.; He, Z.; Liu, P.; Qin, Y.; Wang, Z.; Xu, C. Automated Leakage Detection Method of Pipeline Networks under Complicated Backgrounds by Combining Infrared Thermography and Faster R-CNN Technique. Process Saf. Environ. Prot. 2023, 174, 39–52. [Google Scholar] [CrossRef]

- Xu, S.; Wang, X.; Sun, Q.; Dong, K. MWIRGas-YOLO: Gas Leakage Detection Based on Mid-Wave Infrared Imaging. Sensors 2024, 24, 4345. [Google Scholar] [CrossRef]

- Ma, D.; Liu, A.; Fan, Z.; Wu, R.; Gao, J.; Zhao, H.; Zhang, Z.; Zuo, X. Gas Leakage Recognition Based on Wide-Band Infrared Imaging with the Auxiliary Excitation Method and Machine Learning Model. ACS Chem. Health Safe. 2022, 29, 455–466. [Google Scholar] [CrossRef]

- Jadin, M.S.; Ghazali, K.H. Gas Leakage Detection Using Thermal Imaging Technique. In Proceedings of the 2014 UKSim-AMSS 16th International Conference on Computer Modelling and Simulation (UKSim 2014), Cambridge, UK, 26–28 March 2014. [Google Scholar] [CrossRef]

- Zhao, Q.; Nie, X.; Luo, D.; Wang, J.; Li, Q.; Chen, W. An Effective Method for Gas-Leak Area Detection and Gas Identification with Mid-Infrared Image. Photonics 2022, 9, 992. [Google Scholar] [CrossRef]

- Hassan, M.; Ebrahimi, A.; Woo Jeon, H.; Wang, C. Compressed Air Leakage Detection and Quantification through Infrared Thermography. In Proceedings of the 2020 Institute of Industrial and Systems Engineers Annual Conference (IISE 2020), New Orleans, LA, USA, 30 May–2 June 2020. [Google Scholar]

- Yang, H.; Yao, X.-F.; Wang, S.; Yuan, L.; Ke, Y.-C.; Liu, Y.-H. Simultaneous Determination of Gas Leakage Location and Leakage Rate Based on Local Temperature Gradient. Measurement 2019, 133, 233–240. [Google Scholar] [CrossRef]

- Kroll, A.; Baetz, W.; Peretzki, D. On Autonomous Detection of Pressured Air and Gas Leaks Using Passive IR-Thermography for Mobile Robot Application. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, K.; Liu, Y.; Zhao, Y. Effect of Surface Oxidation on Emissivity Properties of Pure Aluminum in the near Infrared Region. Mater. Res. Express 2017, 4, 086501. [Google Scholar] [CrossRef]

| Leak Aperture (mm) | Airtightness Total Time (s) | Leak Rate (Pa·m3/s) |

|---|---|---|

| 0 (No-leak) | 15.9 ± 0.12 | 0.02 ± 0.001 |

| 0 (Leak) | 15.2 ± 0.21 | 0.08 ± 0.001 |

| 0.25 | 10.95 ± 0.10 | 0.98 ± 0.01 |

| 0.5 | 10.5 ± 0.18 | 2.76 ± 0.05 |

| 1 | 7.15 ± 0.10 | 6.05 ± 0.09 |

| 2 | 5.38 ± 0.15 | 9.29 ± 0.25 |

| 3 | 5.18 ± 0.05 | 10.55 ± 0.10 |

| Distance (m) | Threshold | Recall | Precision | Specificity | Accuracy |

|---|---|---|---|---|---|

| 0.2 | 120 | 0.95 ± 0.08 | 0.66 ± 0.29 | 0.50 ± 0.44 | 0.68 ± 0.26 |

| 150 | 0.81 ± 0.24 | 0.73 ± 0.27 | 0.71 ± 0.33 | 0.74 ± 0.20 | |

| 172 | 0.74 ± 0.34 | 0.84 ± 0.23 | 0.84 ± 0.33 | 0.80 ± 0.20 | |

| 190 | 0.65 ± 0.36 | 0.89 ± 0.24 | 0.86 ± 0.33 | 0.77 ± 0.19 | |

| 1 | 120 | 0.83 ± 0.27 | 0.64 ± 0.29 | 0.73 ± 0.32 | 0.76 ± 0.21 |

| 150 | 0.75 ± 0.29 | 0.83 ± 0.16 | 0.91 ± 0.11 | 0.87 ± 0.09 | |

| 172 | 0.59 ± 0.40 | 0.80 ± 0.34 | 0.98 ± 0.02 | 0.86 ± 0.11 | |

| 190 | 0.53 ± 0.41 | 0.82 ± 0.40 | 0.99 ± 0.01 | 0.85 ± 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semitela, Â.; Silva, J.; Girão, A.F.; Verdasca, S.; Futre, R.; Lau, N.; Santos, J.P.; Completo, A. Combining Infrared Thermography with Computer Vision Towards Automatic Detection and Localization of Air Leaks. Sensors 2025, 25, 3272. https://doi.org/10.3390/s25113272

Semitela Â, Silva J, Girão AF, Verdasca S, Futre R, Lau N, Santos JP, Completo A. Combining Infrared Thermography with Computer Vision Towards Automatic Detection and Localization of Air Leaks. Sensors. 2025; 25(11):3272. https://doi.org/10.3390/s25113272

Chicago/Turabian StyleSemitela, Ângela, João Silva, André F. Girão, Samuel Verdasca, Rita Futre, Nuno Lau, José P. Santos, and António Completo. 2025. "Combining Infrared Thermography with Computer Vision Towards Automatic Detection and Localization of Air Leaks" Sensors 25, no. 11: 3272. https://doi.org/10.3390/s25113272

APA StyleSemitela, Â., Silva, J., Girão, A. F., Verdasca, S., Futre, R., Lau, N., Santos, J. P., & Completo, A. (2025). Combining Infrared Thermography with Computer Vision Towards Automatic Detection and Localization of Air Leaks. Sensors, 25(11), 3272. https://doi.org/10.3390/s25113272