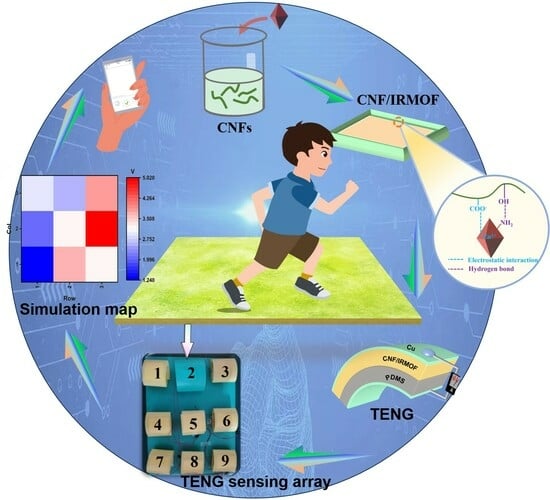

Cellulose Nanofibril-Based Triboelectric Nanogenerators Enhanced by Isoreticular Metal-Organic Frameworks for Long-Term Motion Monitoring

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of IRMOF-1 and IRMOF-3 Crystals

2.3. Preparation of Cellulose Nanofibrils (CNFs)

2.4. Preparation of CNF/IRMOF-1 and CNF/IRMOF-3 Composite Films

2.5. Characterization and Electrical Measurement

3. Results and Discussion

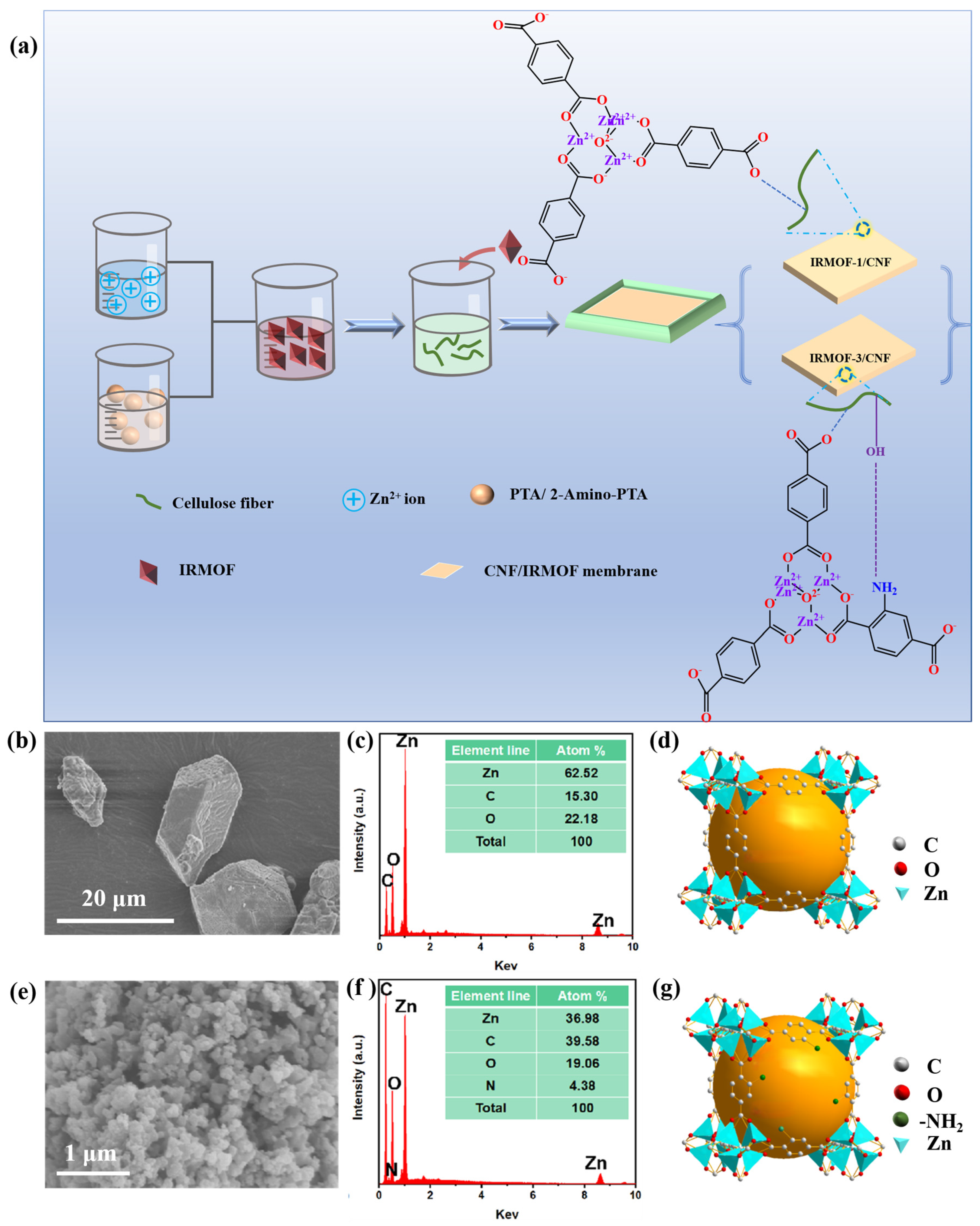

3.1. Structure and Morphology Characterizations of CNF/IRMOF Composite Films

3.2. Structure and the Working Mechanism of CNF/IRMOFs TENGs

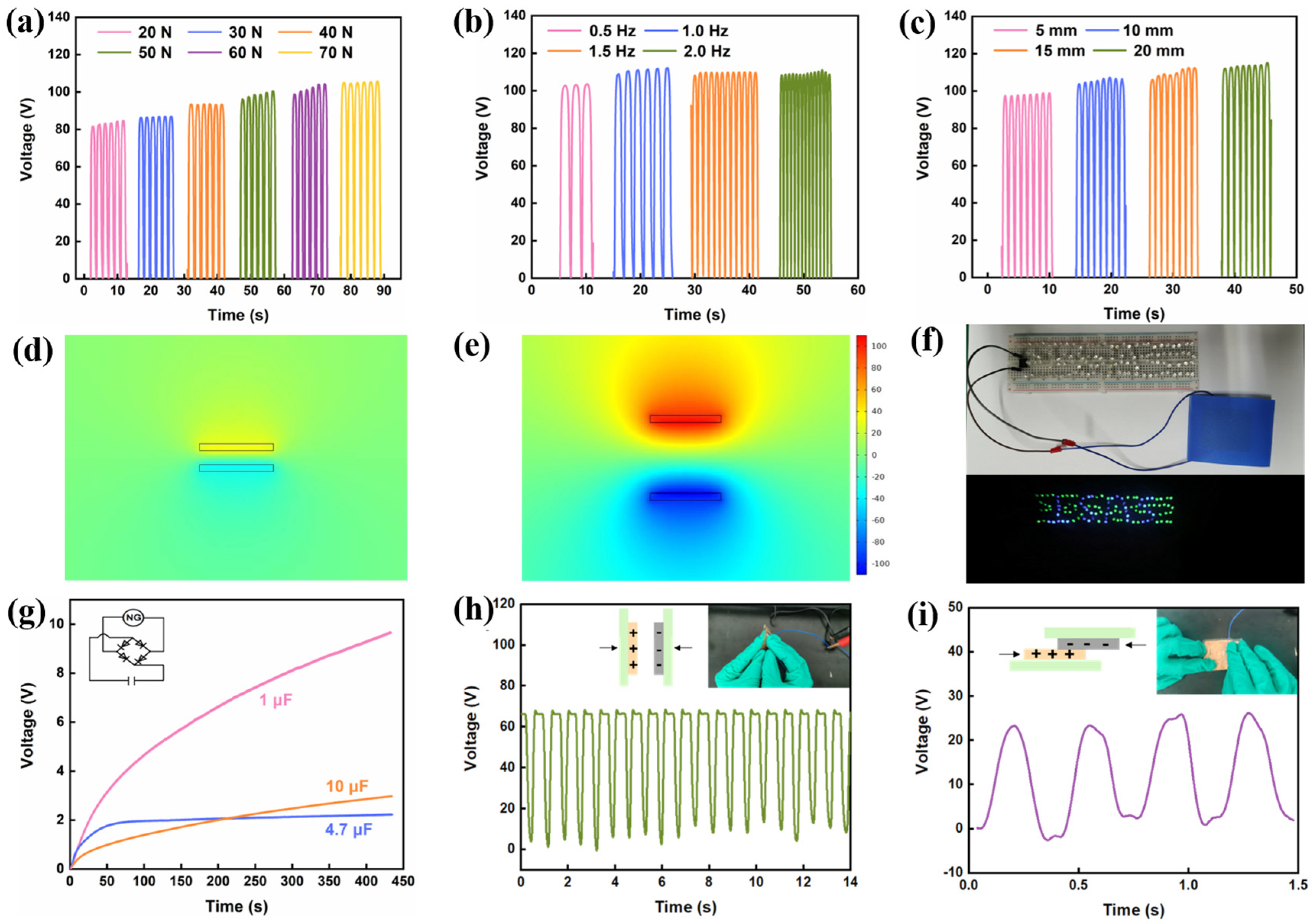

3.3. Roughness and Charge Induction Effects on TENG Performance

3.4. Applications of CNF/IRMOF TENG

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Tong, W.; Gao, C.; Liu, Y.; Li, X.; Zhang, Y. Environmentally friendly natural materials for triboelectric nanogenerators: A review. J. Mater. Chem. A 2023, 11, 9270–9299. [Google Scholar] [CrossRef]

- Li, N.; Qiao, L.; He, J.; Wang, S.; Yu, L.; Murto, P.; Li, X.; Xu, X. Solar-Driven Interfacial Evaporation and Self-Powered Water Wave Detection Based on an All-Cellulose Monolithic Design. Adv. Funct. Mater. 2021, 31, 2008681. [Google Scholar] [CrossRef]

- Wu, J.; Li, X.; Xue, N.; Wang, J.; Xu, G.; Chen, S.; Cui, H.; Zi, Y.; Wang, Z.L. Managing the two mode outputs of triboelectric nanogenerators to reach a pulsed peak power density of 31 MW m−2. Energy Environ. Sci. 2025, 18, 2381–2394. [Google Scholar] [CrossRef]

- Wang, F.; Wang, S.; Liu, Y.; Hou, T.; Wu, Z.; Qian, J.; Zhao, Z.; Wang, L.; Jia, C.; Ma, S. Improved Electrical Output Performance of Cellulose-Based Triboelectric Nanogenerators Enabled by Negative Triboelectric Materials. Small 2024, 20, 2308195. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Wang, M.; Wu, J.; Zhu, C.; Shi, J.; Morikawa, H. Stretchable, Adhesive, Self-Healable, and Conductive Hydrogel-Based Deformable Triboelectric Nanogenerator for Energy Harvesting and Human Motion Sensing. ACS Appl. Mater. Interfaces 2022, 14, 9126–9137. [Google Scholar] [CrossRef]

- Lin, C.; Zhao, H.; Huang, H.; Ma, X.; Cao, S. PEO/cellulose composite paper based triboelectric nanogenerator and its application in human-health detection. Int. J. Biol. Macromol. 2023, 228, 251–260. [Google Scholar] [CrossRef]

- Graham, S.A.; Patnam, H.; Manchi, P.; Paranjape, M.V.; Kurakula, A.; Yu, J.S. Biocompatible electrospun fibers-based triboelectric nanogenerators for energy harvesting and healthcare monitoring. Nano Energy 2022, 100, 107455. [Google Scholar] [CrossRef]

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A Hierarchically Nanostructured Cellulose Fiber-Based Triboelectric Nanogenerator for Self-Powered Healthcare Products. Adv. Funct. Mater. 2018, 28, 1805540. [Google Scholar] [CrossRef]

- Ding, Z.; Tian, Z.; Ji, X.; Yang, G.; Sameer, M.; Lu, Y.; Rojas, O.J. Hybrid Cellulose-Based Systems for Triboelectrification in Aerosol Filtration, Ammonia Abatement and Respiration Monitoring. Adv. Funct. Mater. 2024, 34, 2313790. [Google Scholar] [CrossRef]

- Zheng, T.; Li, G.; Zhang, L.; Sun, W.; Pan, X.; Chen, T.; Wang, Y.; Zhou, Y.; Tian, J.; Yang, Y. A waterproof, breathable nitrocellulose-based triboelectric nanogenerator for human-machine interaction. Nano Energy 2023, 114, 108649. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, Y.; Chen, H.; Zhang, Y.; Liu, H.; Qu, C.; Shao, H.; Xu, Y. Flexible Triboelectric Tactile Sensor Based on a Robust MXene/Leather Film for Human–Machine Interaction. ACS Appl. Mater. Interfaces 2023, 15, 13802–13812. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Ji, X.; Wang, H.; Jiang, H.; Gao, M.; Liu, H.; Liu, Y.; Cheng, B. Cellulose-based green triboelectric nanogenerators: Materials, form designs, and applications. J. Mater. Chem. A 2024, 12, 9322–9344. [Google Scholar] [CrossRef]

- Saito, T.; Nishiyama, Y.; Putaux, J.-L.; Vignon, M.; Isogai, A. Homogeneous Suspensions of Individualized Microfibrils from TEMPO-Catalyzed Oxidation of Native Cellulose. Biomacromolecules 2006, 7, 1687–1691. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Cai, C.; Luo, B.; Liu, T.; Shao, Y.; Wang, S.; Nie, S. Rational Design of Cellulosic Triboelectric Materials for Self-Powered Wearable Electronics. Nano-Micro Lett. 2023, 15, 124. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, Q.; Mo, J.; Lu, Y.; Cai, C.; Luo, B.; Nie, S. Chemically tailored molecular surface modification of cellulose nanofibrils for manipulating the charge density of triboelectric nanogenerators. Nano Energy 2021, 89, 106369. [Google Scholar] [CrossRef]

- Yao, C.; Yin, X.; Yu, Y.; Cai, Z.; Wang, X. Chemically Functionalized Natural Cellulose Materials for Effective Triboelectric Nanogenerator Development. Adv. Funct. Mater. 2017, 27, 1700794. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced performance of a cellulose nanofibrils-based triboelectric nanogenerator by tuning the surface polarizability and hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Du, G.; Wang, J.; Liu, Y.; Yuan, J.; Liu, T.; Cai, C.; Luo, B.; Zhu, S.; Wei, Z.; Wang, S.; et al. Fabrication of Advanced Cellulosic Triboelectric Materials via Dielectric Modulation. Adv. Sci. 2023, 10, 2206243. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Xu, Y.; Ling, Z.; Nawaz, H.; Chen, S.; Xu, F. Surface-microstructured cellulose films toward sensitive pressure sensors and efficient triboelectric nanogenerators. Int. J. Biol. Macromol. 2022, 208, 324–332. [Google Scholar] [CrossRef]

- Shao, Y.; Feng, C.-P.; Deng, B.-W.; Yin, B.; Yang, M.-B. Facile method to enhance output performance of bacterial cellulose nanofiber based triboelectric nanogenerator by controlling micro-nano structure and dielectric constant. Nano Energy 2019, 62, 620–627. [Google Scholar] [CrossRef]

- Kirchon, A.; Feng, L.; Drake, H.F.; Joseph, E.A.; Zhou, H.-C. From fundamentals to applications: A toolbox for robust and multifunctional MOF materials. Chem. Soc. Rev. 2018, 47, 8611–8638. [Google Scholar] [CrossRef]

- Khandelwal, G.; Chandrasekhar, A.; Raj, N.P.M.J.; Kim, S.-J. Metal–Organic Framework: A Novel Material for Triboelectric Nanogenerator–Based Self-Powered Sensors and Systems. Adv. Energy Mater. 2019, 9, 1803581. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Saqib, Q.M.; Kim, J.; Song, H.; Khan, M.U.; Chougale, M.Y.; Bae, J.; Choi, M.J. Ultra-robust tribo- and piezo-electric nanogenerator based on metal organic frameworks (MOF-5) with high environmental stability. Nano Energy 2022, 96, 107128. [Google Scholar] [CrossRef]

- Hajra, S.; Sahu, M.; Padhan, A.M.; Lee, I.S.; Yi, D.K.; Alagarsamy, P.; Nanda, S.S.; Kim, H.J. A Green Metal–Organic Framework-Cyclodextrin MOF: A Novel Multifunctional Material Based Triboelectric Nanogenerator for Highly Efficient Mechanical Energy Harvesting. Adv. Funct. Mater. 2021, 31, 2101829. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Q.; Zhu, Q.; Yang, Q.; Wang, S.; Luo, L. A highly stable bimetallic organic framework for enhanced electrical performance of cellulose nanofiber-based triboelectric nanogenerators. Nanoscale Adv. 2022, 4, 4314–4320. [Google Scholar] [CrossRef] [PubMed]

- Mai, Z.; Liu, D. Synthesis and Applications of Isoreticular Metal–Organic Frameworks IRMOFs-n (n = 1, 3, 6, 8). Cryst. Growth Des. 2019, 19, 7439–7462. [Google Scholar] [CrossRef]

- Eddaoudi, M.; Kim, J.; Rosi, N.; Vodak, D.; Wachter, J.; O’Keeffe, M.; Yaghi, O.M. Systematic Design of Pore Size and Functionality in Isoreticular MOFs and Their Application in Methane Storage. Science 2002, 295, 469–472. [Google Scholar] [CrossRef]

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.M.S.; Park, J.Y. High-performance triboelectric nanogenerator based on MXene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy 2021, 81, 105670. [Google Scholar] [CrossRef]

- Wang, H.; Shi, M.; Zhu, K.; Su, Z.; Cheng, X.; Song, Y.; Chen, X.; Liao, Z.; Zhang, M.; Zhang, H. High performance triboelectric nanogenerators with aligned carbon nanotubes. Nanoscale 2016, 8, 18489–18494. [Google Scholar] [CrossRef]

- Saito, T.; Isogai, A. TEMPO-Mediated Oxidation of Native Cellulose. The Effect of Oxidation Conditions on Chemical and Crystal Structures of the Water-Insoluble Fractions. Biomacromolecules 2004, 5, 1983–1989. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhang, Y.; Yang, X.; Zhao, L.; Wang, G. Functionalized IRMOF-3 as efficient heterogeneous catalyst for the synthesis of cyclic carbonates. J. Mol. Catal. A Chem. 2012, 361–362, 12–16. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, C.; Han, C.B.; Wang, Z.L. Enhancing Output Power of Cylindrical Triboelectric Nanogenerators by Segmentation Design and Multilayer Integration. Adv. Funct. Mater. 2014, 24, 6684–6690. [Google Scholar] [CrossRef]

- Zong, Y.; Wang, R.; Xu, S.; Zhang, R.; Zhang, Z. Flexible Piezoelectric Nanogenerator Based on Cellulose Nanofibril/MXene Composite Aerogels for Low-Frequency Energy Harvesting. ACS Appl. Nano Mater. 2023, 6, 9021–9031. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Y.; Deng, H.; Shi, S.; Tian, S.; Wu, H.; Tang, J.; Zhang, C.; Zhang, X.; Zha, J.-W.; et al. Advanced Dielectric Materials for Triboelectric Nanogenerators: Principles, Methods, and Applications. Adv. Mater. 2024, 36, 2314380. [Google Scholar] [CrossRef]

- Yu, Y.; Gao, Q.; Zhao, D.; Li, X.; Wang, Z.L.; Cheng, T. Influence of mechanical motions on the output characteristics of triboelectric nanogenerators. Mater. Today Phys. 2022, 25, 100701. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, M.; Zong, Y.; Zhang, X. Cellulose Nanofibril-Based Triboelectric Nanogenerators Enhanced by Isoreticular Metal-Organic Frameworks for Long-Term Motion Monitoring. Sensors 2025, 25, 3232. https://doi.org/10.3390/s25103232

Shang M, Zong Y, Zhang X. Cellulose Nanofibril-Based Triboelectric Nanogenerators Enhanced by Isoreticular Metal-Organic Frameworks for Long-Term Motion Monitoring. Sensors. 2025; 25(10):3232. https://doi.org/10.3390/s25103232

Chicago/Turabian StyleShang, Mingli, Yan Zong, and Xiujun Zhang. 2025. "Cellulose Nanofibril-Based Triboelectric Nanogenerators Enhanced by Isoreticular Metal-Organic Frameworks for Long-Term Motion Monitoring" Sensors 25, no. 10: 3232. https://doi.org/10.3390/s25103232

APA StyleShang, M., Zong, Y., & Zhang, X. (2025). Cellulose Nanofibril-Based Triboelectric Nanogenerators Enhanced by Isoreticular Metal-Organic Frameworks for Long-Term Motion Monitoring. Sensors, 25(10), 3232. https://doi.org/10.3390/s25103232