3.1. Micro-Strain Response Induced by Corrosion of Steel Pipes

Corrosion monitoring of steel pipes was conducted during the low-tide period over ten measurement cycles, with intervals ranging from 16 to 17 days throughout the study. Due to the high continuity requirements of distributed optical fiber sensing systems, any breakage in the sensing fiber necessitates the re-establishment of a new reference signal. Although protective measures were implemented at the fiber outlet interfaces, multiple breakages still occurred under the influence of waves and other environmental factors. As a result, some datasets were incomplete or exhibited temporal inconsistencies. To ensure the accuracy and reliability of the analysis, one representative specimen with complete and well-responding monitoring data was selected from each protective configuration for graphical presentation. The strain–time response curves for the four specimen types are shown in

Figure 7. For each processed dataset, the strain induced by temperature variations was compensated for in the corrosion-induced strain analysis, and the local temperature was recorded at the testing site during each measurement.

For the specimen in the experimental group, the strain increased steadily throughout the experimental period. In the initial stage, the strain remained at a relatively low level and gradually accumulated over time, eventually stabilizing at approximately 100 με without exhibiting any abrupt changes. This behavior indicates that the steel pipe was barely corroding, which can be attributed to the synergistic protection effect of the anti-corrosion paste layer, the anti-corrosion tape layer, and the anti-corrosion protective cover layer. The anti-corrosion paste formed a dense protective film on the surface of the steel pipe, effectively isolating corrosive media and suppressing electrochemical reactions. Meanwhile, the protective cover layer provided mechanical protection and served as an additional barrier, preventing the intrusion of particulate impurities and biofouling, thereby reducing physical damage and slowing down the rate of corrosion. One thing that needs to be mentioned is that the 15 distinct peaks exhibited in the strain curve are likely associated with localized stress concentrations caused by the periodic impact of ocean waves. The number of peaks closely matched the number of fiber coil turns, suggesting that transient dynamic loads significantly influenced the stress on the fiber’s sensitive regions.

In the early stages of the experiment, the specimen in the first control group exhibited a gradual increase in strain, similar to the trend observed in the experimental group. However, in the middle to later stages, a localized marked rise in strain was observed in the perforated regions, indicating accelerated corrosion due to a localized protective failure. Although this specimen was also equipped with a triple-layer protection system, the perforations served as direct pathways for corrosive media, substantially compromising the protective efficacy. Under frequent tidal fluctuations and wave impacts, seawater continuously penetrated the perforations, intensifying localized corrosion. The orientation of the openings toward incoming waves further elevated the local dynamic pressure, exacerbating the corrosion severity. Additionally, anti-corrosion paste may have been lost through the perforations, leading to further degradation of the protective capability. The rapid increase in strain suggests that localized corrosion had propagated into adjacent regions, demonstrating that even minor structural defects such as perforations can critically impair the overall service performance. This result underscores the crucial role of localized protective integrity in ensuring the long-term durability of structures in marine environments.

The strain observed in the specimen in the second control group remained predominantly negative throughout the experiment. Although fluctuations occurred over time, no clear trend of cumulative increase was detected, indicating the absence of significant corrosion-related structural degradation. The negative strain signals are likely attributed to non-corrosive factors such as coating detachment or redistribution. Compared with specimens in the experimental group and first control group, which employed a triple-layer protection system, the specimen in the second control group lacked the anti-corrosion tape layer and the anti-corrosion protective cover layer, relying solely on the anti-corrosion paste, thereby offering a moderate level of protection. After the experiments, the non-woven fabric was peeled off, and residual anti-corrosion paste and an absence of visible corrosion on the steel surface were observed, suggesting that the coating still provided an effective barrier. However, the absence of mechanical protection made the coating more vulnerable to environmental influences such as wave-induced impacts that could take away the anti-corrosion pate and result in negative strain in the long run. Although the current extent of corrosion was minimal, prolonged service exposure may lead to localized protective failure if anti-corrosion paste loss continues. It is therefore recommended that future engineering applications enhance the coating’s adhesion and consider incorporating a secondary protective layer to improve long-term durability.

The strain in the specimen in the third control group increased rapidly from the onset of the experiment, with a cumulative rate significantly higher than that of the other specimens, indicating the poorest protective performance among all tested configurations. Due to the absence of an anti-corrosion paste and tape, the steel surface was directly exposed to seawater, where electrochemical corrosion processes were promptly initiated. The combined effects of oxygen concentration cell formation and chloride ion penetration further accelerated the corrosion rate. Although the non-woven fabric provided a limited physical barrier, it was insufficient to prevent the ingress of corrosive agents and could not withstand wave scouring or the cyclical wet–dry conditions that facilitate the detachment of corrosion products. Repeated dynamic pressure from wave action not only promoted the flaking of corrosion products and the continuous exposure of fresh metal surfaces but also intensified stress disturbances within the pipe surface, leading to persistent and rapid strain accumulation. Corrosion-induced damage became inevitable, severely compromising the long-term service performance of the structure.

The experimental results from

Figure 8 demonstrate that the integrity of the protective system is a critical factor in determining the strain accumulation rate and durability of steel pipes in marine environments. Specimen 1, equipped with a complete protection system comprising an anti-corrosion paste layer, an anti-corrosion tape layer, and an anti-corrosion protective cover layer, exhibited the slowest strain growth. Although Specimen 2 also featured a three-layer protection system, the presence of localized perforations compromised its sealing capability, resulting in accelerated localized corrosion and a rapid increase in strain. Specimen 3, which lacked the anti-corrosion tape layer, showed no significant corrosion, but anti-corrosion paste loss led to fluctuating strain responses, indicating uncertainty in long-term performance. Specimen 4, which only had the non-woven fabric for optical fiber sensor protection, experienced the most severe corrosion and the highest strain accumulation rate.

Furthermore, the experiment spanned the summer and autumn seasons, during which environmental temperature variations significantly influenced corrosion behavior. Elevated temperatures in June and August intensified corrosion reactions, resulting in corrosion-induced strain growth, particularly in specimens with weaker protection. High temperatures may also reduce coating adhesion, increasing the risk of a localized failure. From September to November, lower temperatures slowed corrosion progression and reduced strain accumulation rates. Overall, the period from June to November revealed the pronounced effectiveness of the mineral encapsulation coating system in preventing corrosion, highlighting its role in effectively blocking corrosive media and reducing steel degradation. In contrast, unprotected specimens experienced more severe corrosion, especially in areas subject to strong wave impacts. In engineering practice, particular attention should be paid to the integrity and weather resistance of protective systems. The monitoring and timely repair of localized defects are essential to ensure the long-term serviceability and prevent corrosion of marine infrastructure.

3.2. Verification of Experimental Results

In this experiment, a quantitative analysis of the corrosion process was achieved by monitoring strain variations on the steel pipe surface using distributed optical fiber sensors in conjunction with a non-uniform corrosion-induced mass loss model. The method for estimating mass loss via strain measurements is introduced as follows [

6].

Assume that uniform corrosion occurs at a measurement point in a distributed optical fiber system. The original radius of the steel pipe before corrosion is R0. The steel pipe reacts with environmental elements such as oxygen, water, and ions to form corresponding oxides. The insoluble corrosion products adhere to the surface of the steel pipe. The radius measured by the optical fiber, which includes the rust layer, is Rc, while the radius after removing the rust layer is Rw.

The height of the unit is related to the arrangement of the optical fiber. If the fiber is arranged in a non-uniform helical pattern, the height is half the sum of the distances from the fiber to the ones directly above and below it. If the fiber is arranged in a uniformly spaced helical pattern, the height equals the spacing between two adjacent fibers.

The angular size can be determined by the radius of the steel pipe and the arc length of its outer surface, which is related to the system’s sampling resolution. The expression is as follows:

Therefore, the volume of the corroded steel within any unit on the surface of the steel pipe (V

P1) and the volume of the rust products (V

r1) formed can be respectively expressed as:

Then, the mass loss of the steel pipe within the unit due to corrosion can be expressed as:

The increase in pipe diameter leads to an increase in the tensile strain measured by the circumferential strain fiber. If the change in strain is

, then the radius of the steel pipe after corrosion, including the rust layer R

c, is:

The mass loss due to corrosion, denoted as

m, can be calculated using the following equation:

During the calculation process, micro-strain data and their distribution along the fiber deployment path on the steel pipe surface were first extracted. These values, together with the geometric parameters of the pipe and the sensing length, were substituted into the mass loss model. The model parameters λ and β were adopted from [

6] and set to λ = 1.35 and β = 0.97, respectively. By incorporating the fiber-measured micro-strain data into the model, the calculated mass loss of the steel due to corrosion during the target period was determined to be 52.1566 g.

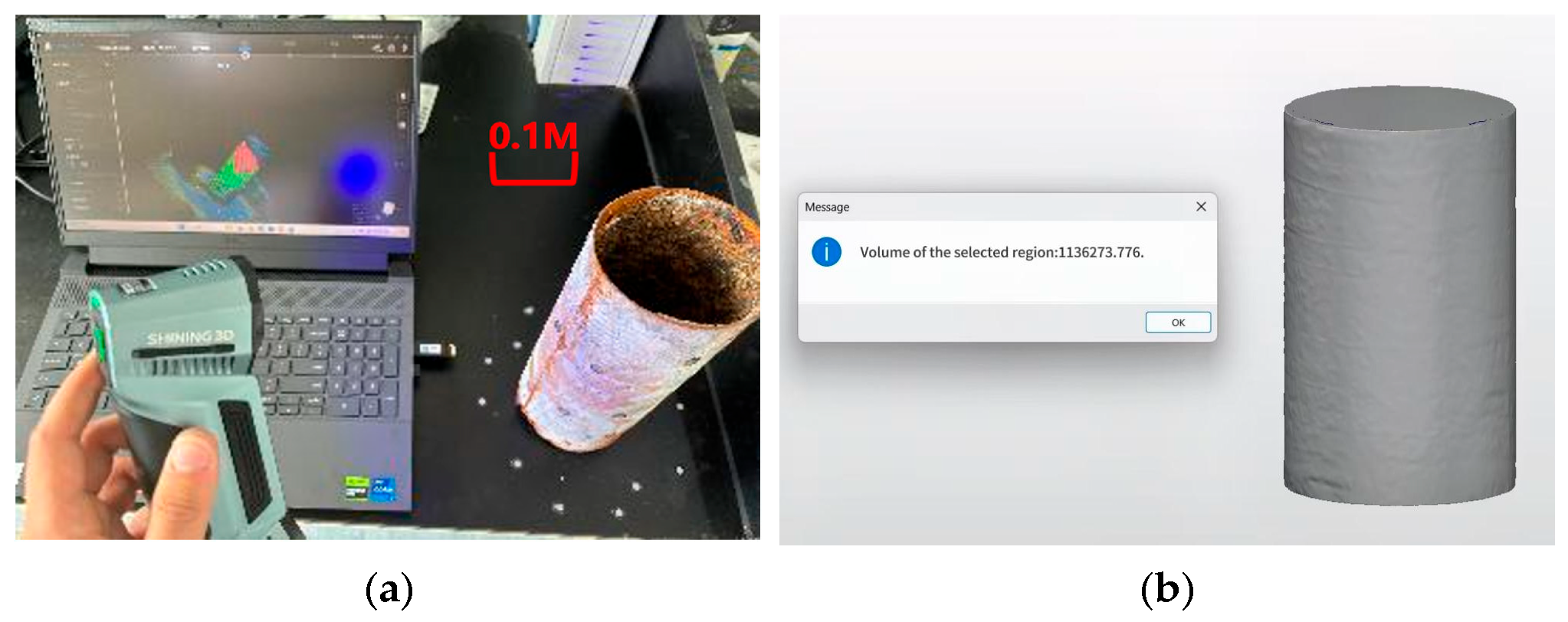

To validate the reliability of the corrosion mass estimation method based on strain data, we employed three-dimensional laser scanning technology to conduct high-precision modeling and comparative analysis of the geometric morphology of the steel pipes before and after corrosion as shown in

Figure 9a. The three-dimensional scanner used in the experiment had a scanning accuracy of 0.02 mm, a volumetric accuracy of 0.015 + 0.035 mm/m, and a spatial point distance of 0.05 mm. The scanning speed was no less than 5,370,000 points per second, with a maximum static scanning area of at least 650 mm × 550 mm and a scanning depth of field of 550 mm. Considering that internal wall corrosion and biofouling may influence the measurement results, the external cylindrical volume method was consistently used in this study to assess the material loss caused by corrosion.

Based on the scanning data, the external cylindrical volume of the steel pipe after corrosion was determined to be approximately 1136.27 cm

3 in

Figure 9b. By estimating the volume loss through comparison with the theoretical volume before corrosion and multiplying by the steel density, the corrosion mass loss was calculated to be 56.06 g, which is about 7.48% higher than the result obtained using the optical fiber strain-based method. This discrepancy may arise from the different sensitivities of the two methods to corrosion. The three-dimensional scanning technique is more sensitive to localized geometric changes such as small pits and surface roughness, making it more responsive to early-stage, minor corrosion. In contrast, distributed optical fiber strain monitoring primarily exhibits a weaker response to minor surface corrosion-induced morphological changes. Despite the relative error, the numerical trends and magnitudes of the corrosion mass loss estimated by both methods are highly consistent, providing strong evidence that the strain inversion method possesses good accuracy and practical applicability in engineering contexts.

Through cross-validation with the three-dimensional scanning results, the credibility of the corrosion mass estimation method based on strain data was significantly enhanced. This also provides a practical basis for integrating optical fiber sensing and geometric measurement technologies, thus paving the way for the development of a multidimensional corrosion monitoring system. In summary, the experiment validated the effectiveness of the corrosion mass loss assessment method based on distributed optical fiber micro-strain inversion. This provides a theoretical foundation and technical support for accurate corrosion state identification and early warning systems.

3.3. Spatial Characteristics of the Corrosion Distribution

We employed distributed optical fiber sensing technology to achieve high-resolution, full-coverage, and dynamic monitoring of the corrosion process of steel pipes in a tidal marine zone environment. Quantitative analysis focused on Specimen 4, which exhibited most significant corrosion. Four sequential mass loss heatmaps (

Figure 10) captured the spatiotemporal evolution of corrosion, demonstrating progressive localized degradation. The heatmap was generated by processing strain data collected from distributed optical fiber sensors helically wrapped around the steel pipe’s outer surface. Each helical loop of the fiber contains approximately 500 sensing points, with the spatial distribution allowing each loop’s data to correspond to a row in the heatmap. Micro-strain values from these sensing points were input into the corrosion mass loss model (Equations (8) and (9)) to calculate the localized corrosion-induced mass loss at each position, thereby constructing a two-dimensional distribution of non-uniform corrosion across the pipe surface. The computed mass loss data in matrix format were visualized using a contour map in Origin software, where the color scale explicitly represents corrosion mass loss values in grams (g).

In the initial stage (

Figure 10a), the heatmap predominantly appears deep blue, indicating that corrosion has not yet occurred extensively. Only slight strain fluctuations can be observed in isolated regions, which may correspond to the emergence of early micro-corrosion points. As time progresses (

Figure 10b), these initial corrosion points gradually expand and propagate along the axial direction of the fiber, forming continuous light-blue band-like areas. Some regions show orange high-strain zones, suggesting the intensification of local corrosion and the initial stages of corrosion spreading. In the middle to later stages (

Figure 10c), the corrosion area further extends toward the upper half of the steel pipe, with increased light-green and orange regions, indicating that environmental factors are impacting a broader area and the corrosion severity is deepening. During this phase, the periodic immersion and exposure caused by tidal effects likely enhanced the accumulation of corrosive agents in seawater, accelerating corrosion development. In the final stage (

Figure 10d), the heatmap shows several originally discrete high-strain corrosion zones merging, forming a continuous distribution of green to orange-red corrosion bands. Some areas appear red, with significant mass loss peaks, reflecting severe localized corrosion. These high-corrosion zones are concentrated in regions with substantial material loss, indicating that these areas, long exposed to the cyclic “dry–wet–oxygen–salt” conditions, are high-sensitivity zones for corrosion development.

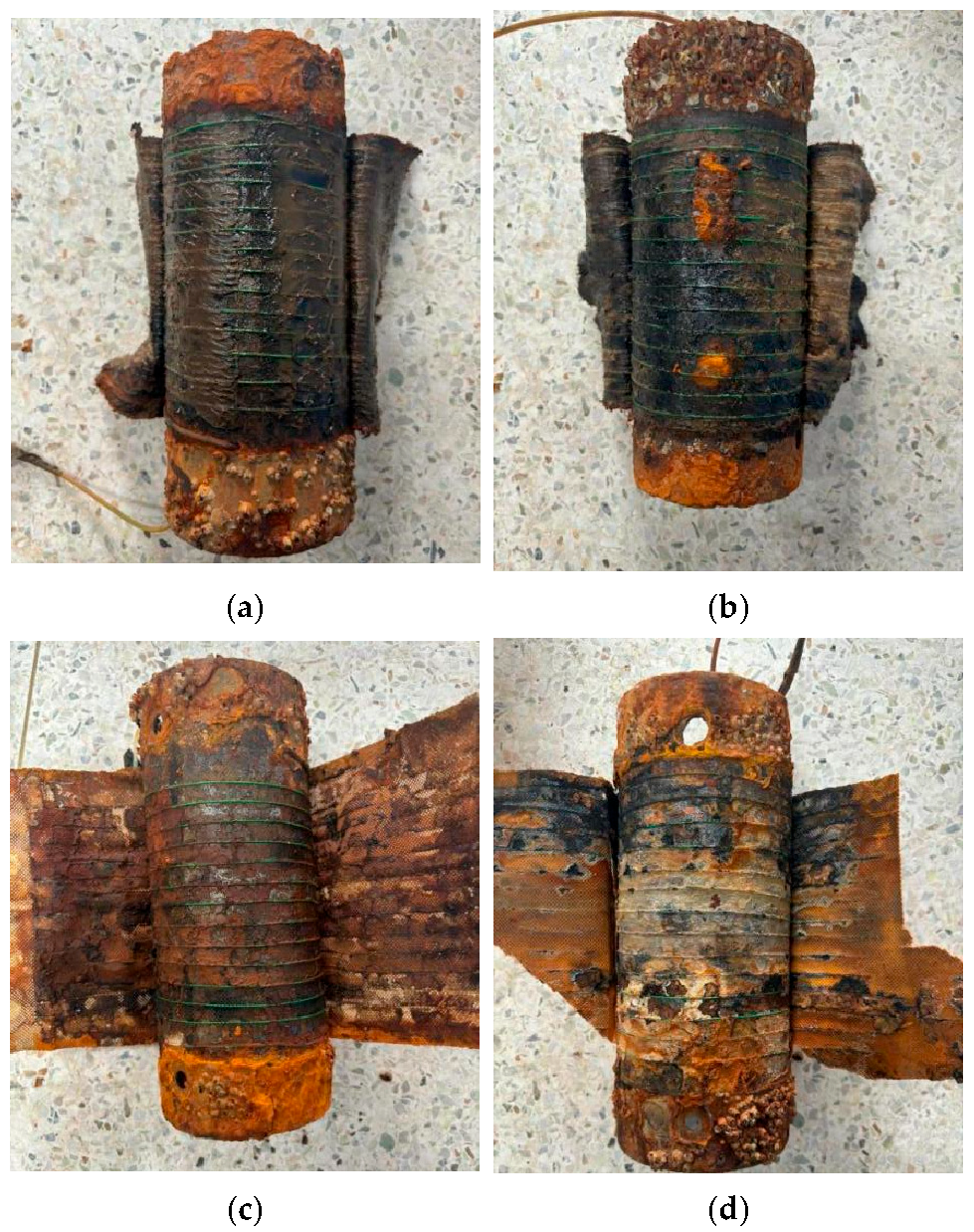

Figure 11 shows the appearance of the steel pipe after removing the anti-corrosion protective cover layer and peeling off the anti-corrosion tape layer. Anti-corrosion paste was visible on the steel pipe surfaces in the first and second specimens except at the damaged location in the second specimen. The thickness of the anti-corrosion paste was nearly identical in the first and second specimens but reduced significantly in the third specimen. Severe corrosion was observed across the surface of the fourth specimen. These observations align with the strain measurement results obtained from the optical fiber sensors.