Non-Invasive Parameter Identification of DC Arc Models for MV Circuit Breaker Diagnostics

Abstract

1. Introduction

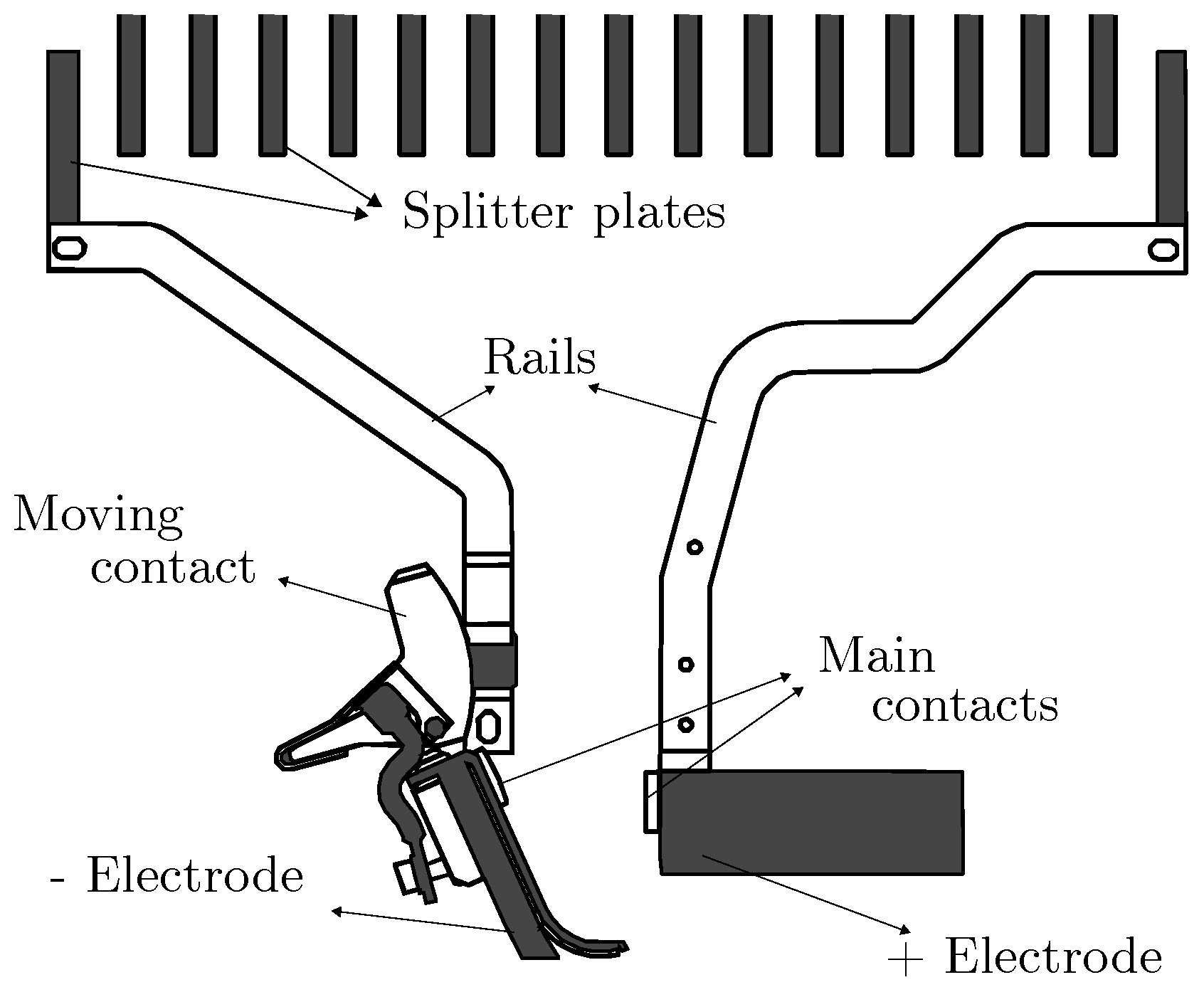

- Arc movement and elongation along the arc rails;

- Inductive effects influencing the measured voltage drop at the switch breaker terminals;

- Voltage drops at the arc roots in the splitter plates (SPs);

- Heat transfer dynamics between the arc, the surrounding insulating medium and the splitter plates.

- Contacts Closed: The circuit breaker is closed, and the circuit is energized. The current is flowing, and no arc is present.

- Contact Opening: As the contacts start to separate, an arc forms due to the breakdown of the dielectric medium. Current still flows in the circuit.

- Contacts Opened—Arc on Rails: The arc is transferred to arc runner rails, where it elongates due to electromagnetic and aerodynamic forces. Current still flows in the circuit.

- Contacts Opened—Arc Inside Splitter Plates: The arc enters the splitter plate stack, where it undergoes cooling, an increase in voltage and eventual extinction.

- The flow of electrical current imposed by the laboratory test setup according to relative product standards;

- The mechanical dynamics of the arc’s movement;

- The thermal evolution of the arc.

2. DC Circuit Breaker

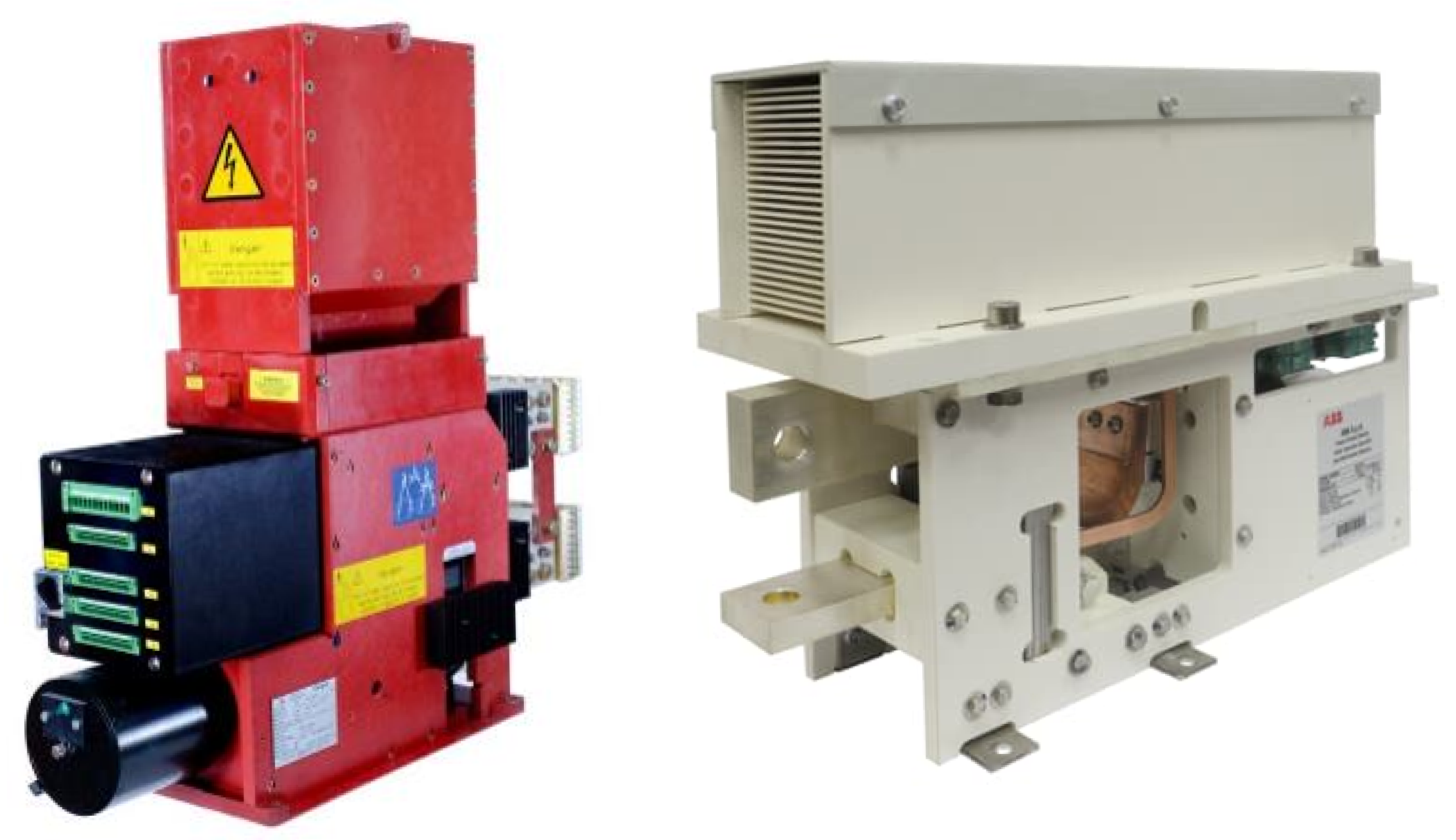

2.1. Air Arc Chute Circuit Breakers

- A contact system equipped with main and arcing contacts and a double-contact design, providing high wear-resistance under arc erosion;

- A mechanism to ensure the closing and opening of the contacts by means of manual mechanical operation or connected closing/tripping devices, designed to guarantee extended electrical and mechanical endurance;

- An arc chute consisting of arc plates to split the electric arc generated by current interruption into smaller partial arcs with a subsequent increase in arcing voltage;

- A solenoid closing drive to enable closing of the main contacts, designed to avoid repeated or premature closing operations during an existing short-circuit event, increasing the protection level;

- Additional tripping devices to enable the de-latching mechanism and subsequent contact opening. Tripping devices can be designed for “slow” opening operations (such as remotely driven actuation or actuation driven by under-voltage release) or for “quick” opening operations in the case of more severe faults such as overload and short circuits. In the prototype used for this paper, the overload tripping device consists of a ferromagnetic core able to sense the current fault level and directly trip the AACB mechanism;

- An electronic control system, including several electronic units, mainly to control the solenoid closing drive and tripping functionalities;

- Auxiliaries and accessories for additional features related to signaling, tripping and temporary blocking of the mechanism.

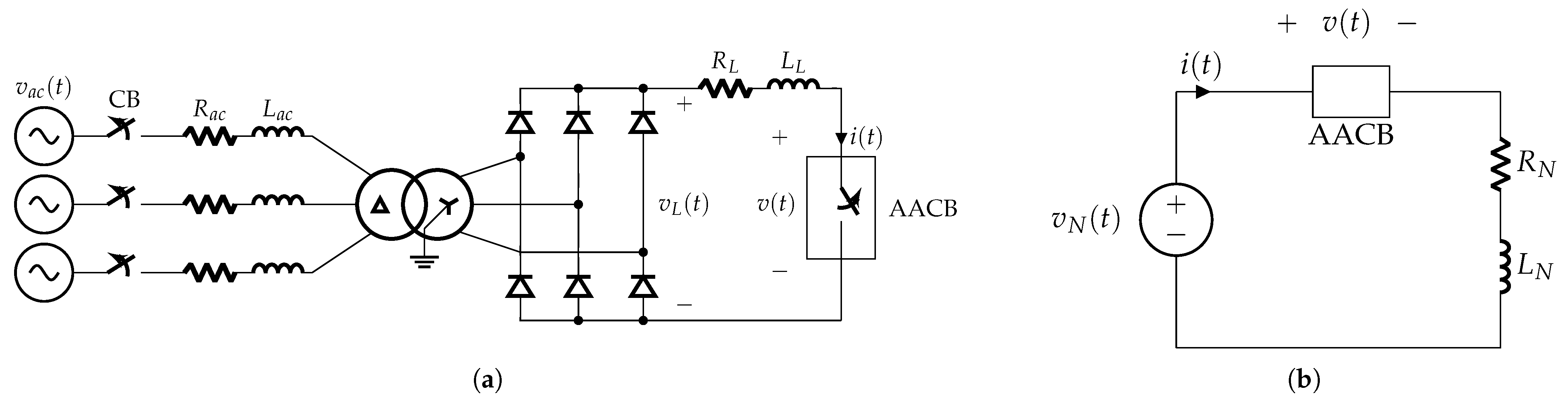

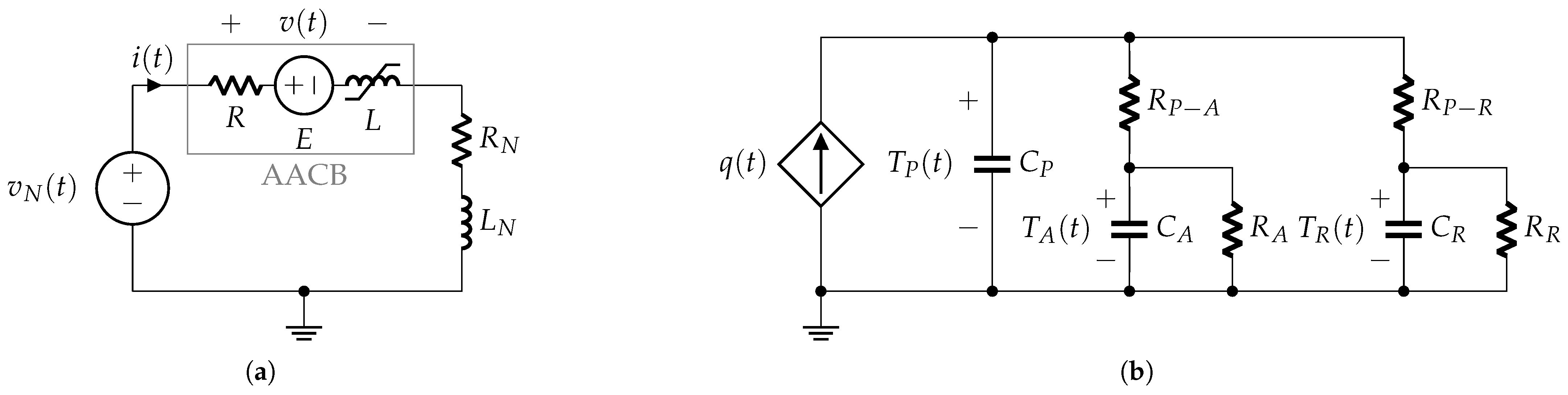

2.2. Short-Circuit Test Setup

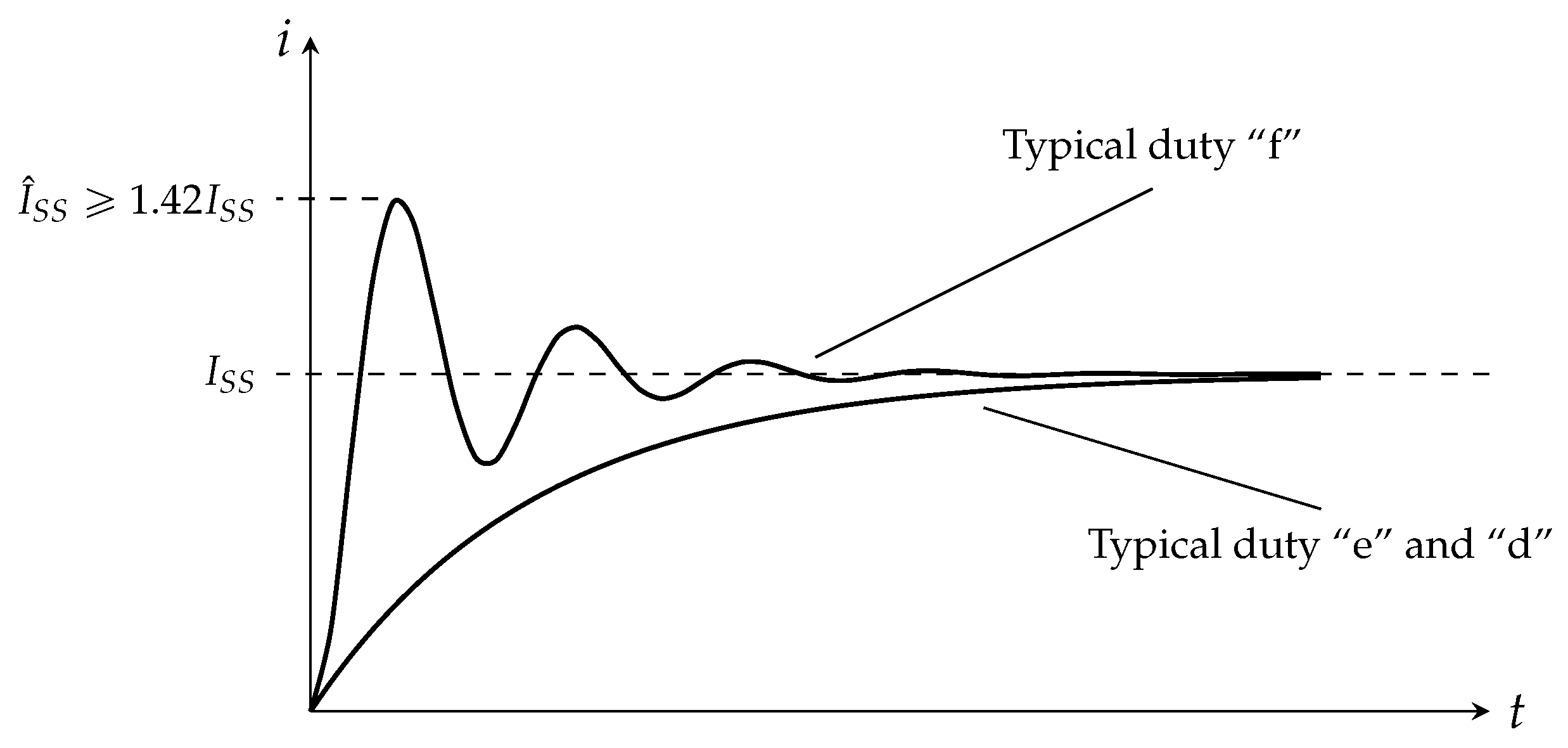

- Duty “f” represents the case of a fault occurring close to a substation where impedance is negligible. The prospective short-circuit current reaches the maximum fault level with a peak of .

- Duty “e” is the maximum circuit energy fault: as the short-circuit occurs at a longer distance from the substation, the circuit time constant () gradually moves from the value at the source to the value of the track. When the circuit time constant is approximately in the middle of these two extreme values, the maximum-energy fault occurs. According to the rated track time constant declared for the circuit breaker, the standard prescribes the test circuit parameters.

- Duty “d” represents a distant short-circuit fault. Test parameters include a current value typically twice the nominal-load current of the breaker and a circuit time constant equal to the rated track-time constant of the AACB.

3. Modeling the DC Apparatus: The Thermo-Electrical Approach

- represents the state vector of the j-th model;

- dNefines the system dynamics;

- is the supply voltage, serving as the input to every model;

- consists of the measured quantities, which, for each model, include the measured voltage and current of the AACB;

- represents the vector measurands, expressed as a function of the j-th model state and input;

- and denote stochastic processes modeling system and measurement errors, with covariance matrices and , respectively.

3.1. Phase 1: Contacts Closed

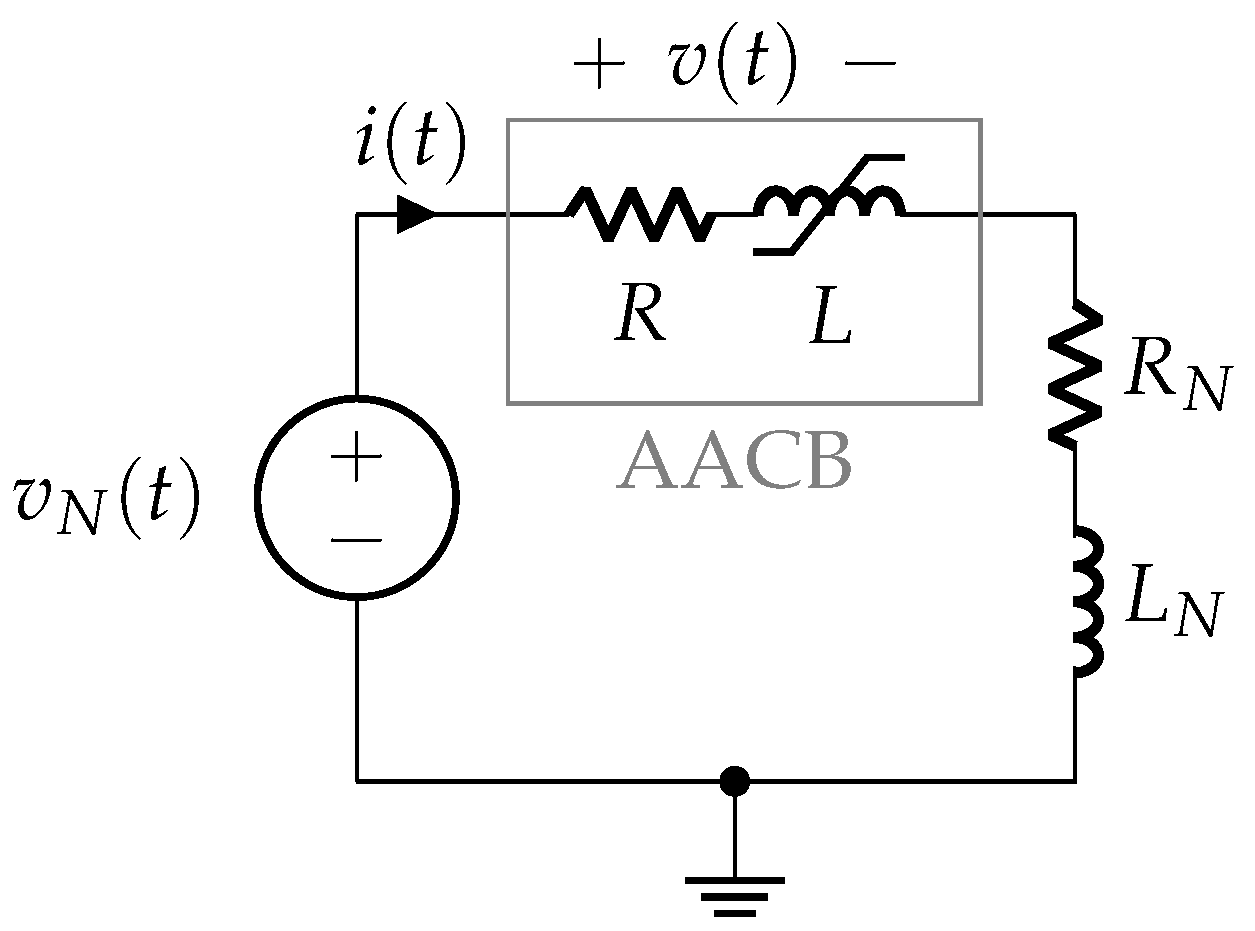

- The electrical parameters of the laboratory set-up: resistance () and inductance (), as well as the supplying voltage ();

- The inductance (L) as a function of the current ().

3.2. Phase 2: Contact Opening

- The values of the external resistance () and inductance (), as well as the supplying voltage () (as in any phase model);

- The inductance (L) as a function of the current () (as in the phase 1 model);

- The electromotive force (E);

- The thermal capacities of plasma, air and electrodes ( and , respectively).

3.3. Phase 3: Contacts Opened—Arc on Rails

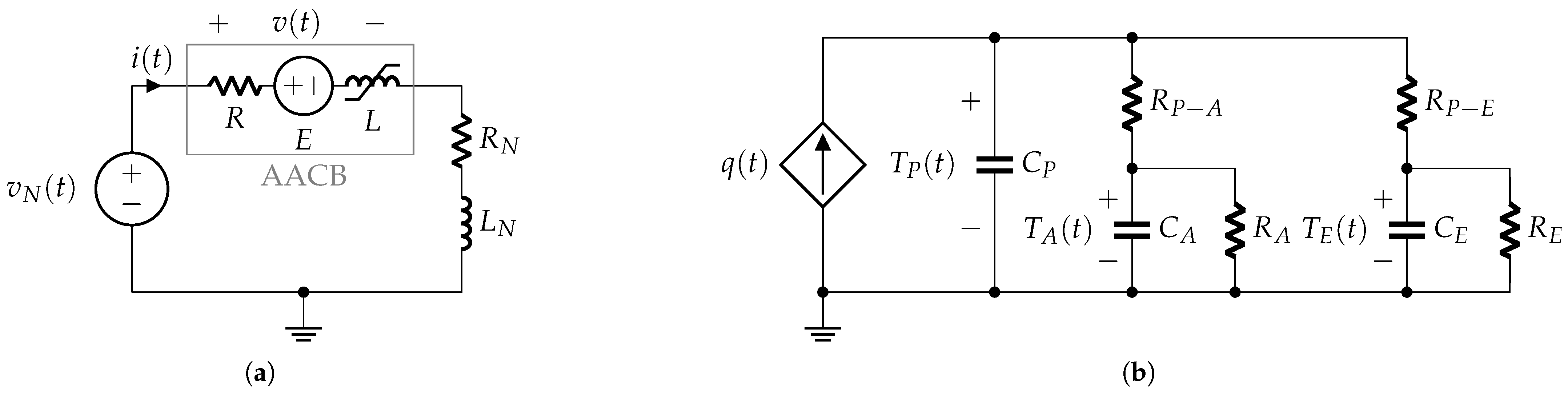

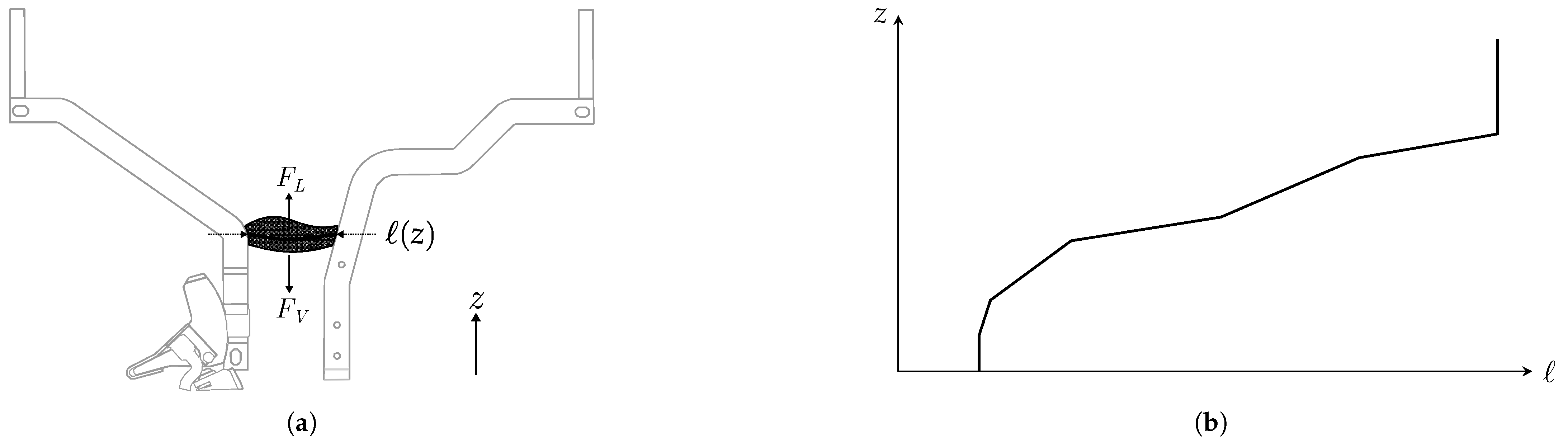

- The values of the external resistance () and inductance (), as well as the supplying voltage () (as in any phase model);

- The inductance () and its derivatives ( and );

- The electromotive force (E) and the arc-length mapping ();

- The thermal capacities of plasma, air and rails ( and , respectively).

3.4. Phase 4: Contacts Opened—Arc Inside Splitter Plates

- The values of the external resistance () and inductance (), as well as the supplying voltage ();

- The inductance (L) when the arc is inside the splitter plates;

- The thermal capacities of plasma, air and splitter plates ( and , respectively);

4. Extended Kalman Filter for State Estimation

5. Experimental Results

- AC side: A 50 Hz, kV three-phase generator supplies power to a 10.2/0.65 Yy transformer through a resistance and 3 mH inductance line.

- DC side: An uncontrolled full-bridge rectifier feeds the test object via rectangular busbars, which introduce unintentional parasitic impedance.

- Test object: The tested device is a prototype DC circuit breaker. It has a nominal voltage of 900 V, a kA service current and a 178/125 kA rated short-circuit and breaking capacity.

- Current sensor: A coaxial shunt with an kA/V scale factor, 10 kHz bandwidth and maximum current rating of 200 kA for a 100 ms duration. The shunt was calibrated in accordance with IEC 62475 standard [26].

- Voltage sensor: An RC voltage divider rated at kV, with an input impedance of 20 M and 25 pF and a bandwidth of 300 kHz. Calibration was performed following IEC 60060-2:2025 standard [27].

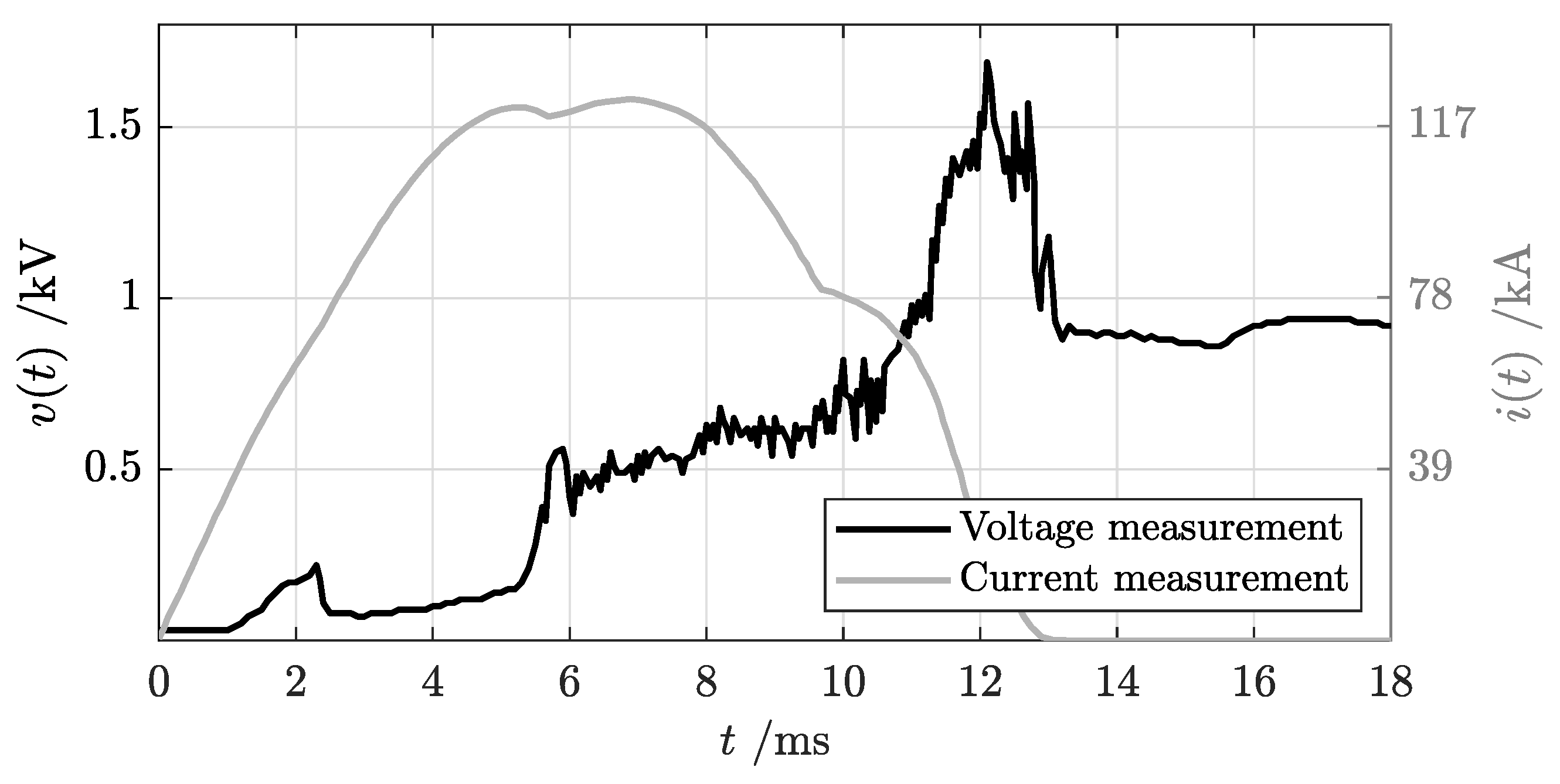

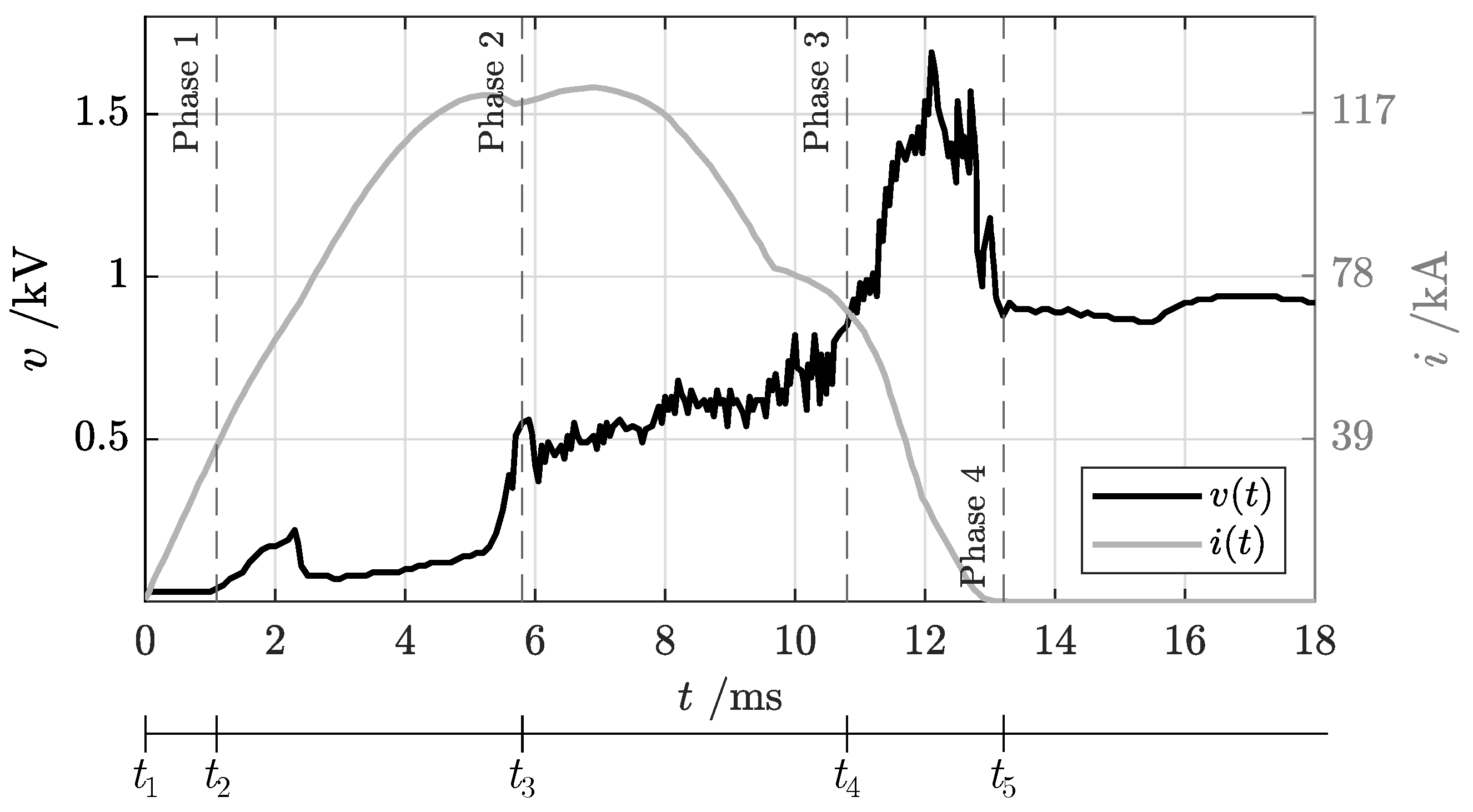

5.1. Identification of Short-Circuit Oscillogram Phases

- Phase 1 is characterized by zero voltage across the AACB terminals and an increasing current flow in the breaker conductive path, following the prospective current profile. During this phase, the contacts are closed with the nominal contact pressure. When the current value overcomes the threshold trip level set for the overcurrent device, the tripping mechanism starts to react to short-circuit fault and to drive contact opening. This action requires some time, typically in the order of a maximum of a few for an high-speed ACCB, during which time the contacts remain in closed position.

- Phase 2: The transition to this phase can be recognized by a constant build-up in the voltage level. During this phase, contacts are opening, and the distance between moving and fixed contacts increases. An electric arc starts to form and to gradually elongate, leading the voltage drop across the ACCB to progressively increase. The voltage rise rate depends on the final opening velocity of the ACCB mechanism as a result of the opening force provided by the mechanical actuators and the electro-dynamic repulsive forces generated by the fault current. The first part of this phase (between approximately 1 and 5 ms) is characterized by a lower slope of voltage increase because the arc is still rooted on the main contacts and the arc length is limited to the contact stroke. The last part of this stage presents an abrupt change in current rise, corresponding to arc commutation from contacts to arc rails, which is the transition point to the following stage.

- Phase 3: During this phase, the arc remains on arc rails. Their duty is to further elongate the electric arc and to guide it towards the arc chute. The duration of this phase strongly depends on the AACB geometry—in particular, the geometries of the contacts and rails. The AACB breaking capability is already visible at this stage: the current rise is limited, and therefore, its gradient starts to decrease, deviating from the peak prospective current profile. Due to the complex balance between electro-dynamic, magnetic and aerodynamic forces, the arc is increasingly stretched along the rails, but this process is highly unstable as can be observed from the numerous fluctuations in voltage signal. During this stage, it is critical to support the continuous “build-up” of a counter voltage in the ACCB and “push” the current towards the zero crossing and successful current interruption. The duration of this phase strongly contributes to total arc break time.

- Phase 4: Once the electric arc definitely enters the arc chute, a more rapid voltage increase can be observed until the maximum voltage level is reached. In this phase, the splitter plates act to divide the original energetic arc into smaller arcs. It is crucial that the rails and arc chute are properly designed to avoid any arc re-ignition towards the contact region, which would result in an evident voltage drop to levels close to those of phase 1 and phase 2, an increase in the real fault current and a severe increase in total breaking time. Once the fault is permanently interrupted, the current goes to zero and the supply voltage level is fully restored.

5.2. Measurement and Model Uncertainties

5.2.1. Phase 1: Contacts Closed

5.2.2. Phase 2: Contact Opening

5.2.3. Phase 3: Contacts Opened—Arc on Rails

5.2.4. Phase 4: Contacts Opened—Arc Inside Splitter Plates

5.3. Estimation Results

6. Conclusions

- Enhanced arc model description, including improved representation of arc behavior, the incorporation of mechanical contact separation dynamics, the possibility of the arc returning to the rails and a more detailed modeling of heat transfer, including radiation effects;

- Implementation of Bayesian automatic model selection to define arc model phases, replacing manual voltage signal analysis by an expert;

- Analysis of the full O-CO-CO-CO sequence instead of analyzing individual CO events one at a time, which would allow the cumulative effects of previous tests on subsequent tests to be considered;

- Improvement of the accuracy of the lumped-parameter model through a calibration phase tailored to specific AACB types or even individual devices, which can be achieved using distributed parameter simulations for AACB-type calibration and/or simple experimental tests on specific units (for example, thermal constants can be determined through low-current heating experiments followed by cooling-phase observations);

- Incorporation of additional external measurements during standard short-circuit tests, such as the power supply voltage () and the external case temperature. These additional measurands can help refine the accuracy of extended Kalman filter estimates and reduce uncertainty.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AACB | Air Arc-chute Circuit Breaker |

| SP | Splitter Plate |

| MHD | Magneto-Hydro-Dynamic |

| FEM | Finite-Element Method |

References

- Gordon, L.B. Modeling DC Arc Physics and Applications for DC Arc Flash Risk Assessment. In Proceedings of the 2023 IEEE IAS Electrical Safety Workshop (ESW), Reno, NV USA, 13–17 March 2023; pp. 1–10. [Google Scholar] [CrossRef]

- Schwarz, J. Dynamisches verhalten eines gasbeblasenen, turbulenzbestimmten schaltlichtbogens. ETZ Arch. 1971, 92, 389–391. [Google Scholar]

- Smeets, R.; Kertesz, V. Evaluation of high-voltage circuit breaker performance with a validated arc model. IEE Proc. Gener. Transm. Distrib. 2000, 147, 121–125. [Google Scholar] [CrossRef]

- Rieder, W.; Urbanek, J. New Aspects of Current-Zero Research on Circuit-Breaker Reignition: A Theory of Thermal Non-Equilibrium Arc Conditions; Report; CIGRE: Paris, France, 1966. [Google Scholar]

- Ghezzi, L.; Balestrero, A. Modeling and Simulation of Low Voltage Arcs. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Lim, S.W.; Khan, U.A.; Lee, J.G.; Lee, B.W.; Kim, K.S.; Gu, C.W. Simulation analysis of DC arc in circuit breaker applying with conventional black box arc model. In Proceedings of the 2015 3rd International Conference on Electric Power Equipment-Switching Technology (ICEPE-ST), Busan, Republic of Korea, 25–28 October 2015; pp. 332–336. [Google Scholar] [CrossRef]

- Park, K.H.; Lee, H.Y.; Asif, M.; Lee, B.W.; Shin, T.Y.; Gu, C.W. Assessment of various kinds of AC black-box arc models for DC circuit breaker. In Proceedings of the 2017 4th International Conference on Electric Power Equipment—Switching Technology (ICEPE-ST), Xi’an, China, 22–25 October 2017; pp. 465–469. [Google Scholar] [CrossRef]

- Pessoa, F.P.; Acosta, J.S.; Tavares, M.C. Parameter Estimation of DC Black-Box Arc Models Using System Identification Theory. J. Control. Autom. Electr. Syst. 2022, 33, 1229–1236. [Google Scholar] [CrossRef]

- EN 50123-2:2003; Railway Applications—Fixed Installations—D.C. Switchgear—Part 2: D.C. Circuit Breakers. CENELEC—European Committee for Electrotechnical Standardization: Brussels, Belgium, 2003.

- IEC 61992-2:2006+AMD1:2014 CSV; Railway Applications—Fixed Installations—DC Switchgear—Part 2: DC Circuit-Breakers. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- IEEE C37.14:2015; IEEE Standard for DC (3200 V and Below)—Power Circuit Breakers Used in Enclosures. IEEE Power and Energy Society: Piscataway, NJ, USA, 2015.

- Kassakian, J.; Schlecht, M.; Verghese, G. Principles of Power Electronics; Addison-Wesley Series in Electrical Engineering; Addison-Wesley: Reading, MA, USA, 1991. [Google Scholar]

- D’Antona, G.; Ferrero, A. Digital Signal Processing for Measurement Systems: Theory and Applications; Springer: New York, NY, USA, 2006. [Google Scholar]

- Lindmayer, M.; Marzahn, E.; Mutzke, A.; Ruther, T.; Springstubbe, M. The process of arc-splitting between metal plates in low voltage arc chutes. IEEE Trans. Compon. Packag. Technol. 2016, 29, 310–317. [Google Scholar] [CrossRef]

- Bergman, T. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Huang, K.; Niu, C.; Wu, Y.; Rong, M.; Yang, F.; Sun, H. Arc Plasma Simulation Method in DC Relay with Contact Opening Process. In Proceedings of the 2019 5th International Conference on Electric Power Equipment - Switching Technology (ICEPE-ST), Kitakyushu, Japan, 13–16 October 2019; pp. 226–229. [Google Scholar] [CrossRef]

- Yang, F.; Rong, M.; Sun, Z.; Wu, Y.; Wang, W. A numerical study of arc-splitting processes with eddy-current effects. In Proceedings of the 2008 17th International Conference on Gas Discharges and Their Applications, Cardiff, UK, 7–12 September 2008; pp. 197–200. [Google Scholar]

- Lisnyak, M. Theoretical, Numerical and Experimental Study of DC and AC Electric Arcs. Ph.D. Thesis, Université Orléans, Orléans, France, 2018. [Google Scholar]

- Li, J.; Yuan, H.; Xu, M.; Tian, F.; Wang, Z.; Ren, J. Research on Improved Schwarz Arc Model Considering Dynamic Arc Length. J. Electr. Eng. Technol. 2023, 18, 1625–1636. [Google Scholar] [CrossRef]

- Khakpour, A.; Franke, S.; Uhrlandt, D.; Gorchakov, S.; Methling, R.P. Electrical Arc Model Based on Physical Parameters and Power Calculation. IEEE Trans. Plasma Sci. 2015, 43, 2721–2729. [Google Scholar] [CrossRef]

- Cohen, R.S.; Spitzer, L.; Routly, P.M. The Electrical Conductivity of an Ionized Gas. Phys. Rev. 1950, 80, 230–238. [Google Scholar] [CrossRef]

- Stengel, R. Optimal Control and Estimation; Dover Books on Advanced Mathematics; Dover Publications: Mineola, NY, USA, 1994. [Google Scholar]

- Maybeck, P. Stochastic Models: Estimation and Control: V. 1; Mathematics in Science and Engineering; Academic Press: Cambridge, MA, USA, 1979. [Google Scholar]

- Evensen, G.; Vossepoel, F.; van Leeuwen, P. Data Assimilation Fundamentals: A Unified Formulation of the State and Parameter Estimation Problem; Springer Textbooks in Earth Sciences, Geography and Environment; Springer International Publishing: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- IEC 61992-1:2006+AMD1:2014 CSV; Railway Applications—Fixed Installations—DC Switchgear—Part 1: General. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- IEC 62475:2010; High-Current Test Techniques—Definitions and Requirements for Test Currents and Measuring Systems. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- IEC 60060-2:2025; High-Voltage Test Techniques—Part 2: Measuring Systems. International Electrotechnical Commission: Geneva, Switzerland, 2025.

- ISO 80000-1:2022; Quantities and Units—Part 1: General. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO/IEC Guide 99:2007; International Vocabulary of Metrology—Basic and General Concepts and Associated Terms (VIM). International Organization for Standardization: Geneva, Switzerland, 2007.

- Ohtaka, T.; Kertész, V.; Paul Smeets, R.P. Novel Black-Box Arc Model Validated by High-Voltage Circuit Breaker Testing. IEEE Trans. Power Deliv. 2018, 33, 1835–1844. [Google Scholar] [CrossRef]

- van der Sluis, L. Transient in Power Systems; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Yang, F.; Wu, Y.; Rong, M.; Sun, H.; Murphy, A.B.; Ren, Z.; Niu, C. Low-voltage circuit breaker arcs—Simulation and measurements. J. Phys. Appl. Phys. 2013, 46, 273001. [Google Scholar] [CrossRef]

- Ren, Z.; Ma, R.; Sun, H.; Ning, J.; Chen, Z.; Niu, C. Experimental investigation of arc characteristics in medium-voltage DC circuit breaker. In Proceedings of the 2013 IEEE International Conference of IEEE Region 10 (TENCON 2013), Xi’an, China, 22–25 October 2013; pp. 1–4. [Google Scholar] [CrossRef]

| Quantity | Magnitude | Standard Deviation Symbol |

|---|---|---|

| kV | ||

| Quantity | Magnitude | Standard Deviation Symbol |

|---|---|---|

| L | ||

| E | V | |

| J/K | ||

| J/K | ||

| kJ/K |

| Quantity | Magnitude | Standard Deviation Symbol |

|---|---|---|

| L | 0.41(8) H–0.71(8) H | |

| 0.5(1) nH/kA–0.9(2) nH/kA | ||

| E | V | |

| J/K | ||

| kJ/K | ||

| kJ/K | ||

| ℓ | 5(4) cm to 40(4) cm |

| Quantity | Magnitude | Standard Deviation Symbol |

|---|---|---|

| J/K | ||

| kJ/K | ||

| kJ/K | ||

| L | H |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Antona, G.; Trujillo-Arboleda, C.; Amato, M.; Riva, M. Non-Invasive Parameter Identification of DC Arc Models for MV Circuit Breaker Diagnostics. Sensors 2025, 25, 3161. https://doi.org/10.3390/s25103161

D’Antona G, Trujillo-Arboleda C, Amato M, Riva M. Non-Invasive Parameter Identification of DC Arc Models for MV Circuit Breaker Diagnostics. Sensors. 2025; 25(10):3161. https://doi.org/10.3390/s25103161

Chicago/Turabian StyleD’Antona, Gabriele, Camilo Trujillo-Arboleda, Massimiliano Amato, and Marco Riva. 2025. "Non-Invasive Parameter Identification of DC Arc Models for MV Circuit Breaker Diagnostics" Sensors 25, no. 10: 3161. https://doi.org/10.3390/s25103161

APA StyleD’Antona, G., Trujillo-Arboleda, C., Amato, M., & Riva, M. (2025). Non-Invasive Parameter Identification of DC Arc Models for MV Circuit Breaker Diagnostics. Sensors, 25(10), 3161. https://doi.org/10.3390/s25103161