Path Planning for a Wheel-Foot Hybrid Parallel-Leg Walking Robot

Abstract

1. Introduction

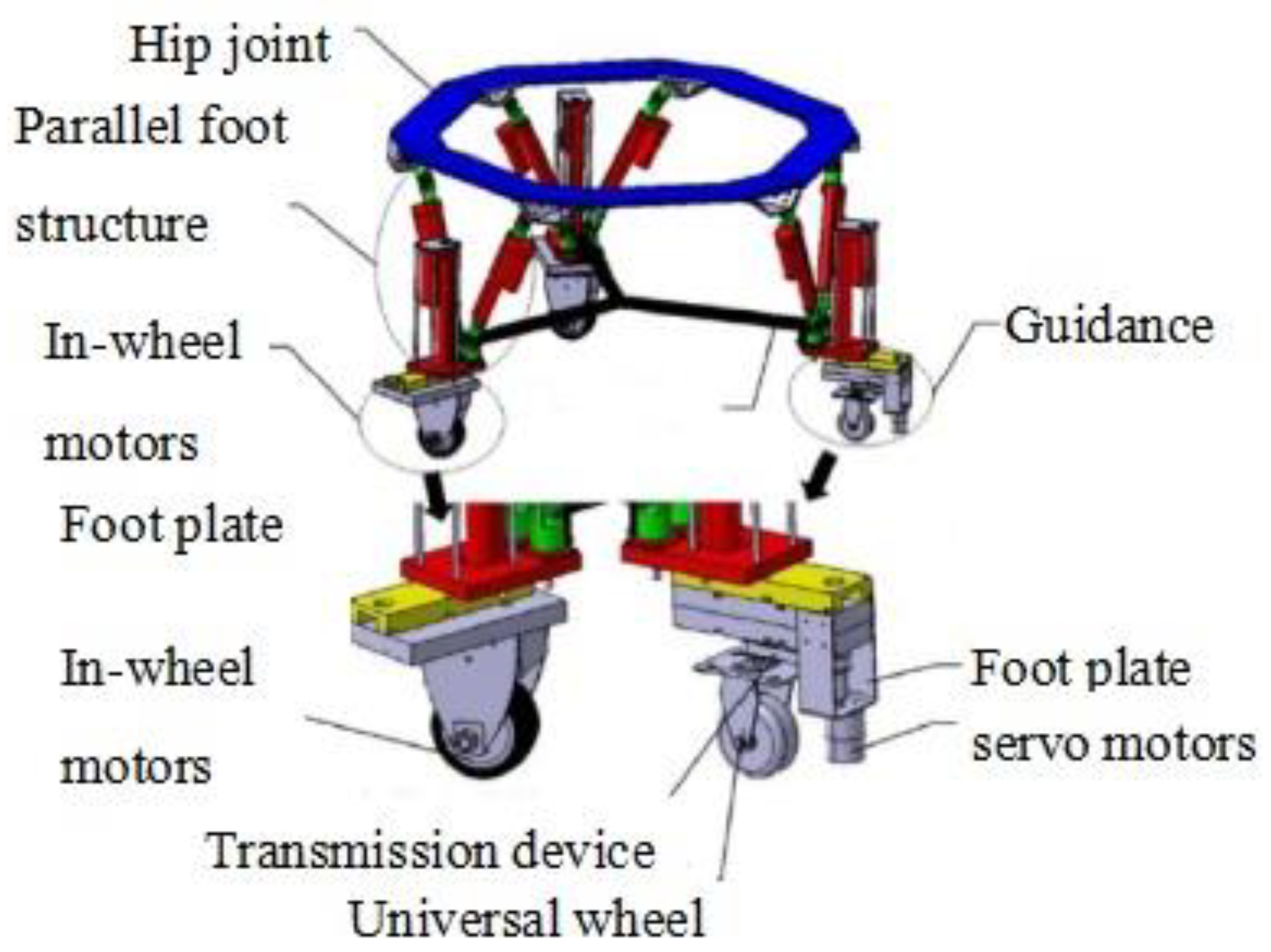

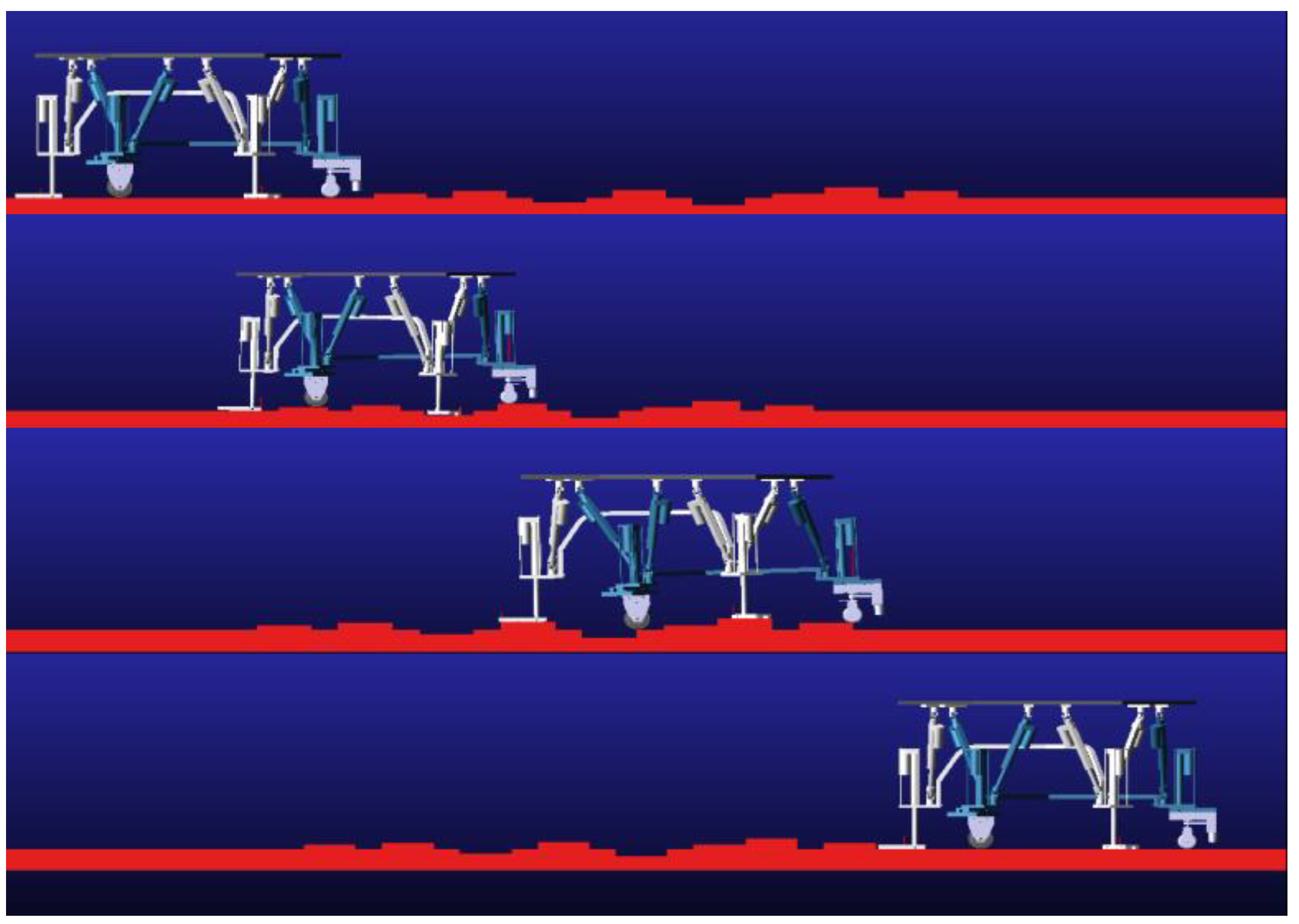

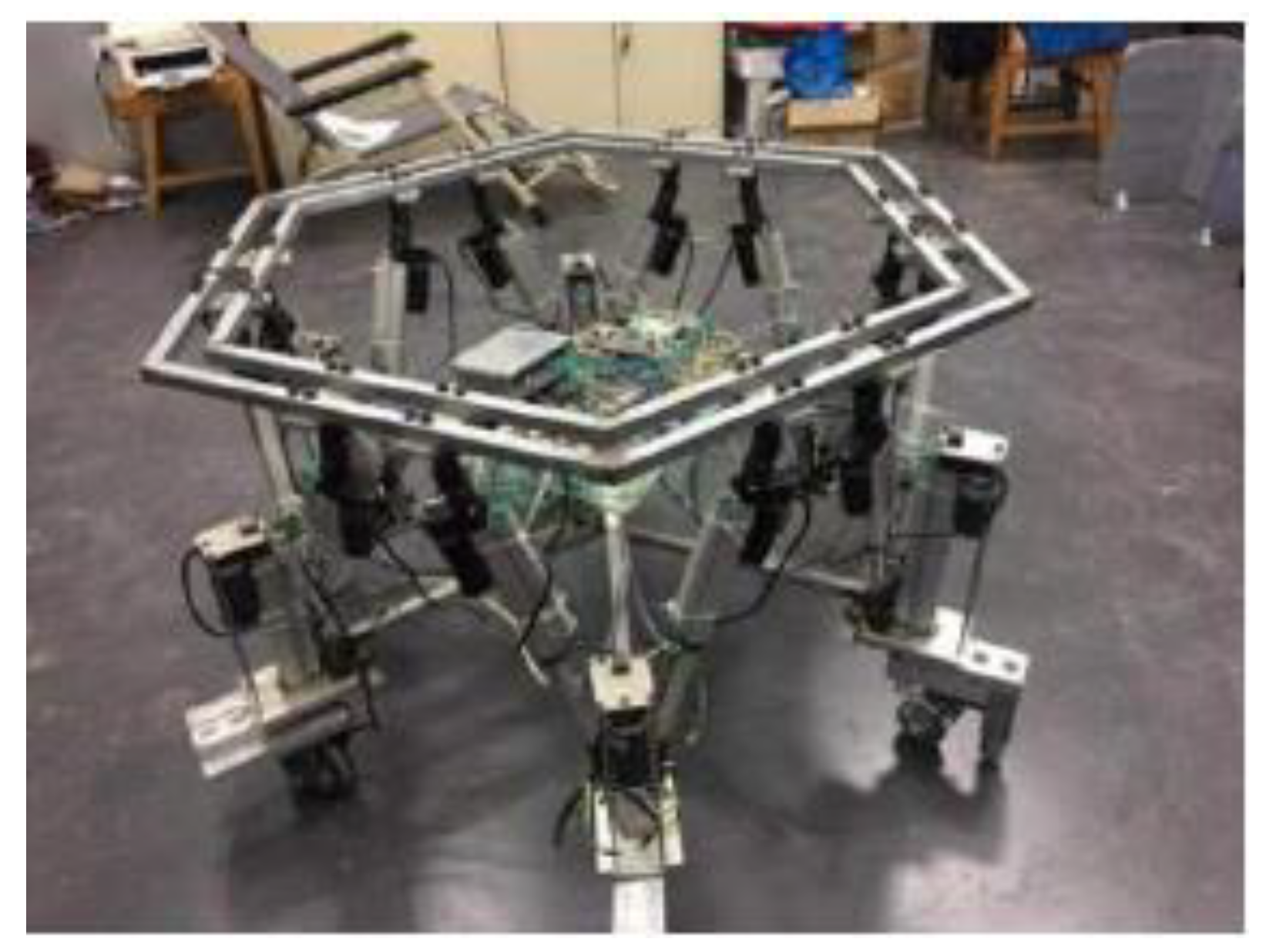

2. Structure Design of Wheel-Foot Hybrid Parallel-Leg Walking Robot

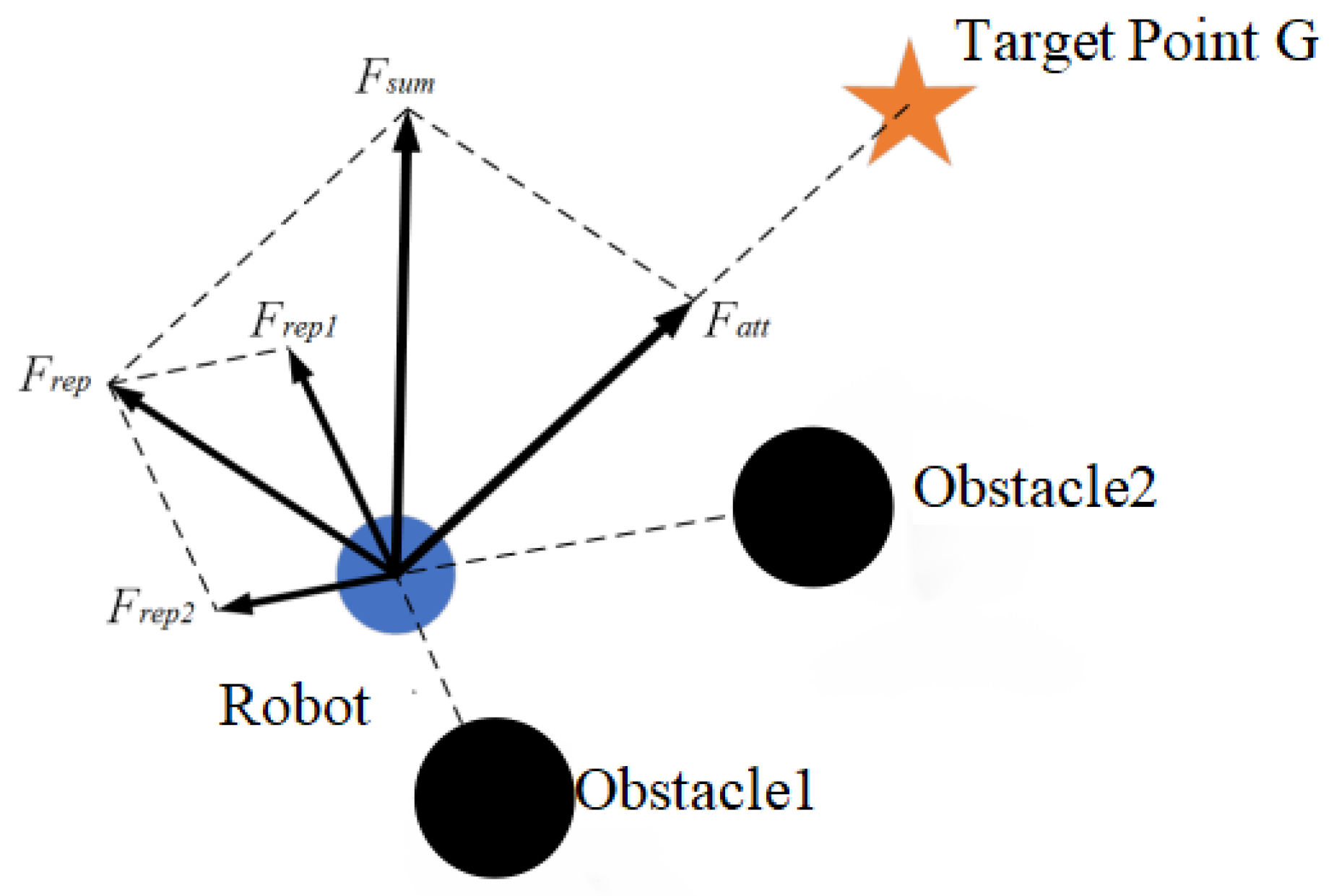

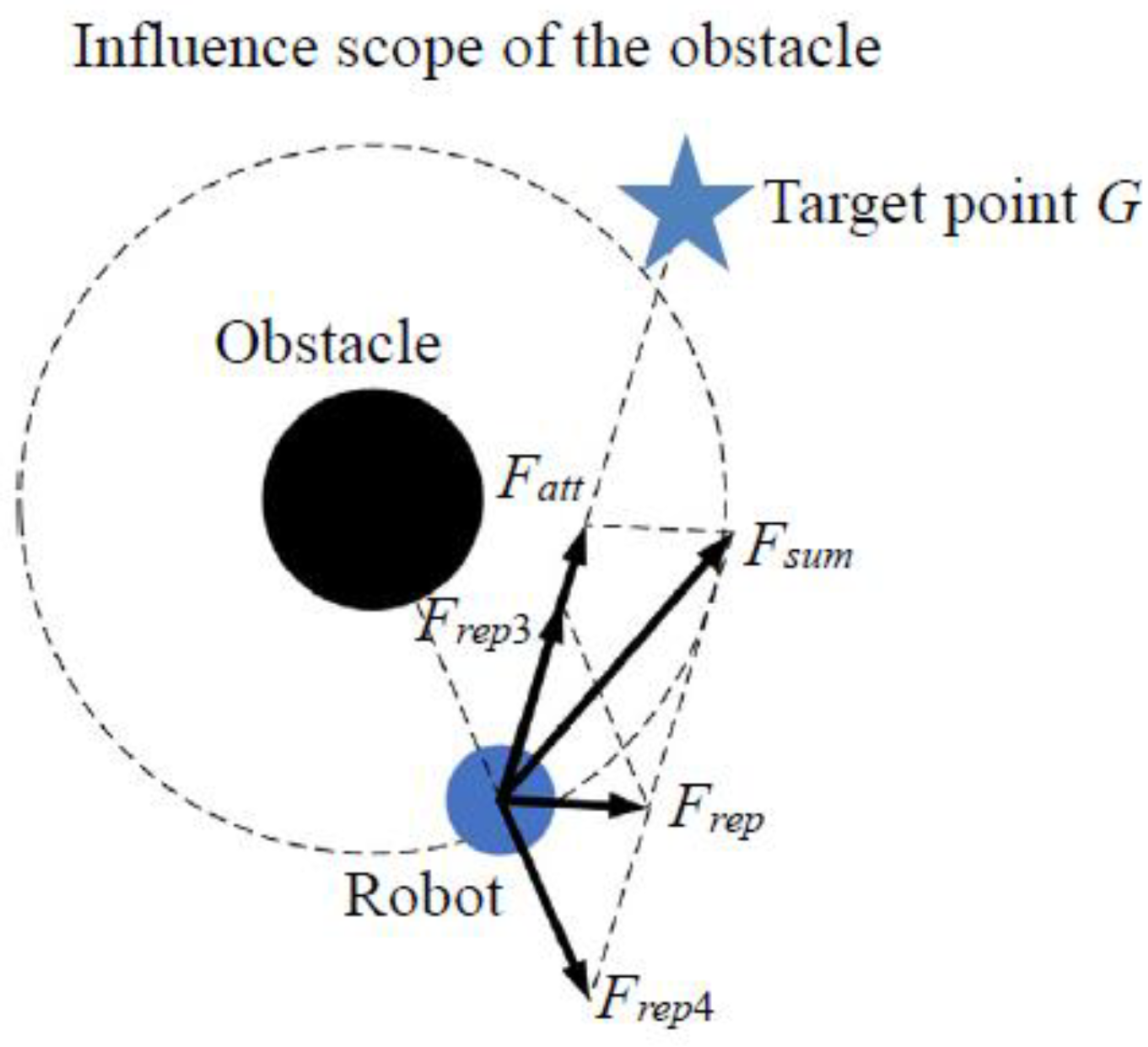

3. Classic APF Principles Method

4. The Proposed Method

4.1. Set the Thresholds to Solve the Collision Problem

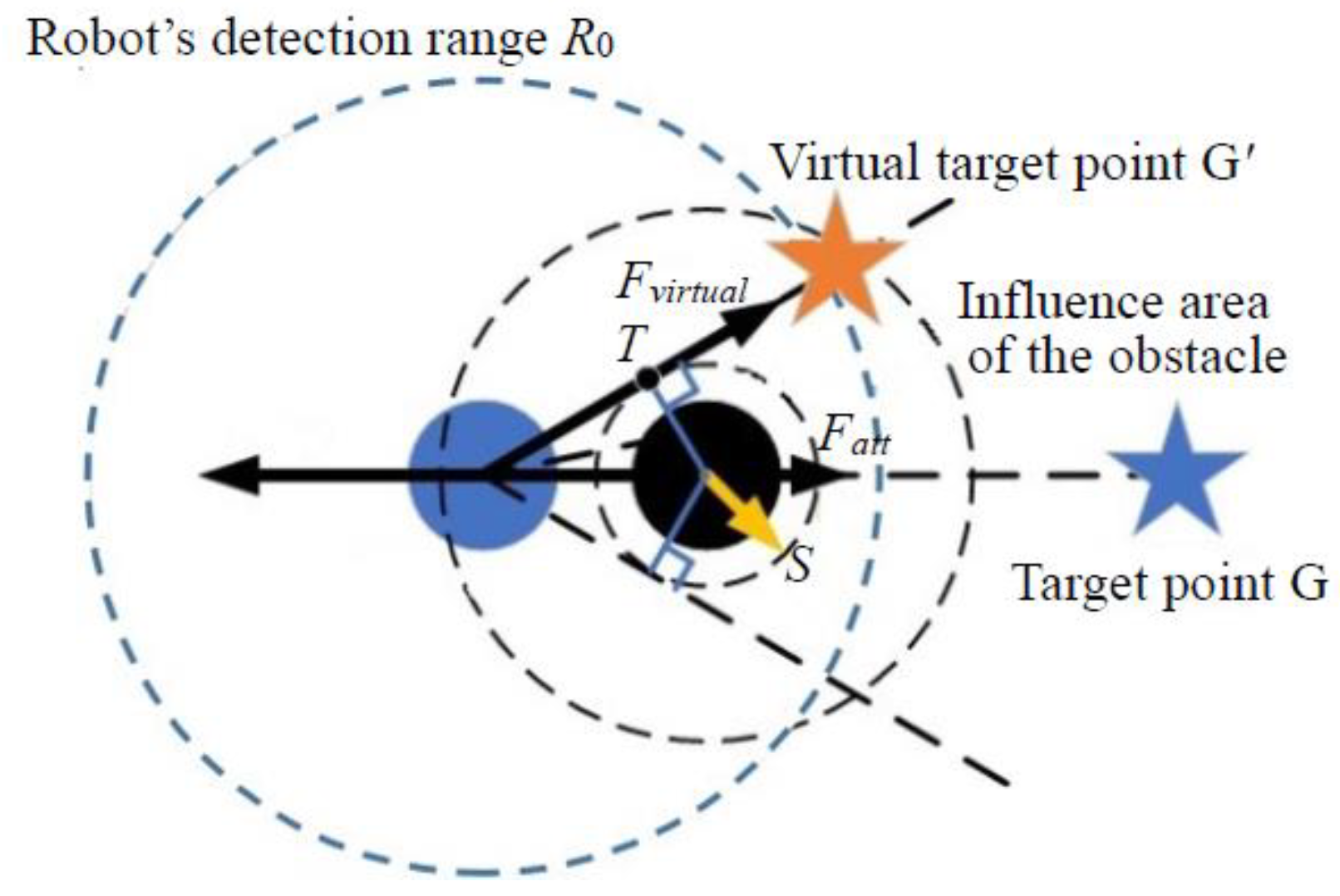

4.2. Introduce Distance Factor to Solve Goal Unreachable Problem Caused by Obstacles near the Target

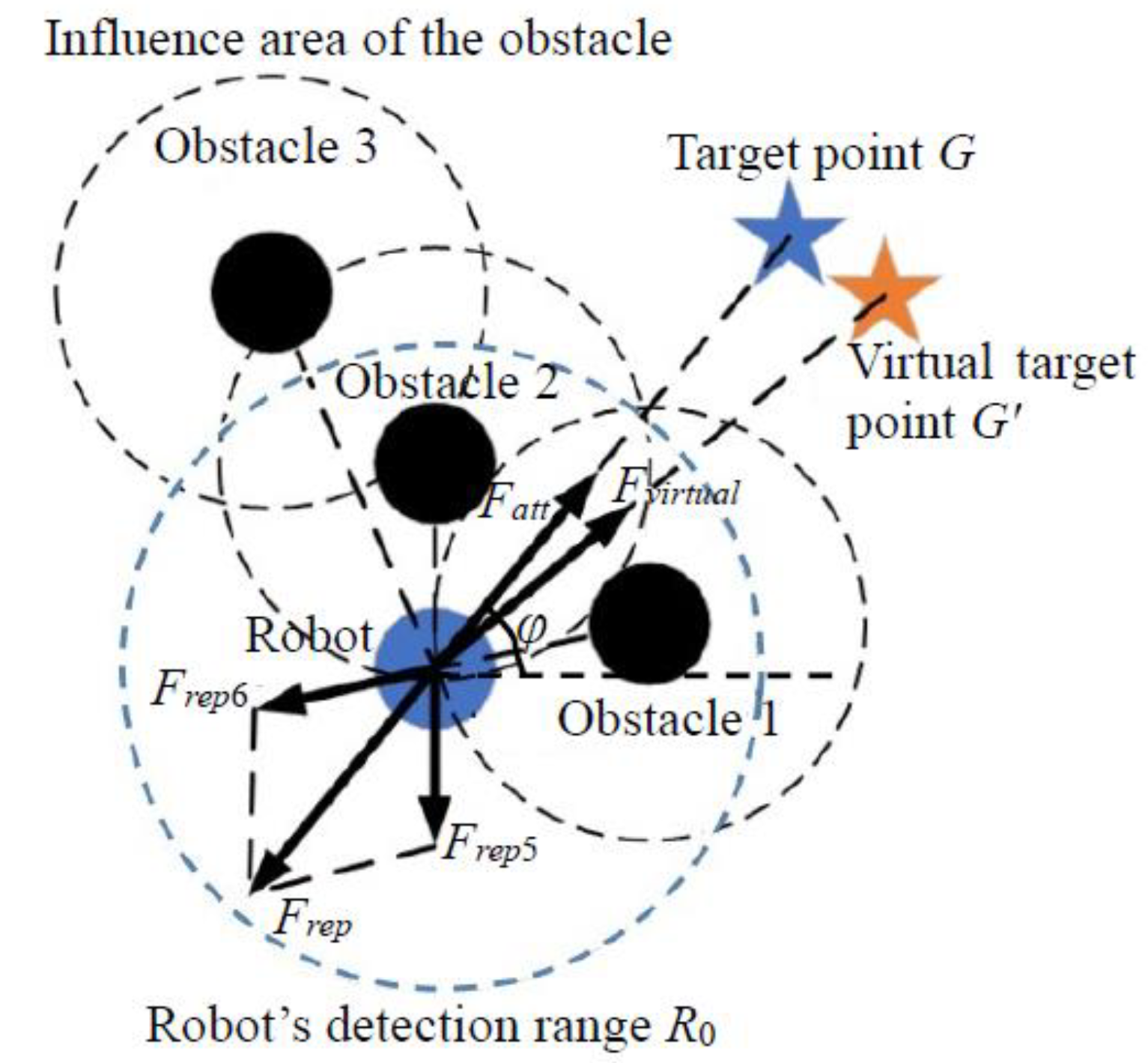

4.3. Set Virtual Target Points to Address the Local Minima Issue

4.4. Introduce Velocity Factor and Acceleration Factor

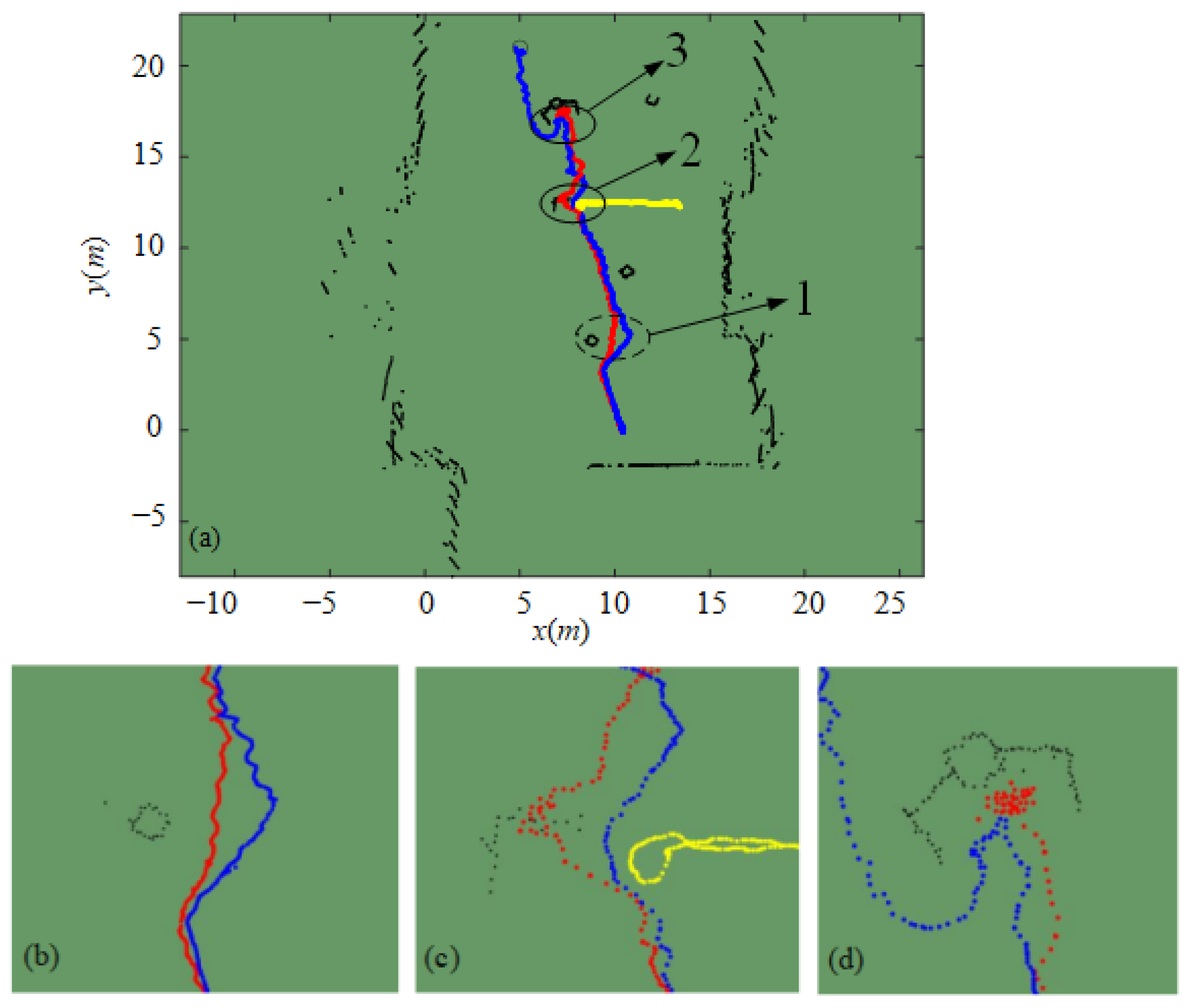

5. Simulation Analysis of the IAPF Algorithm

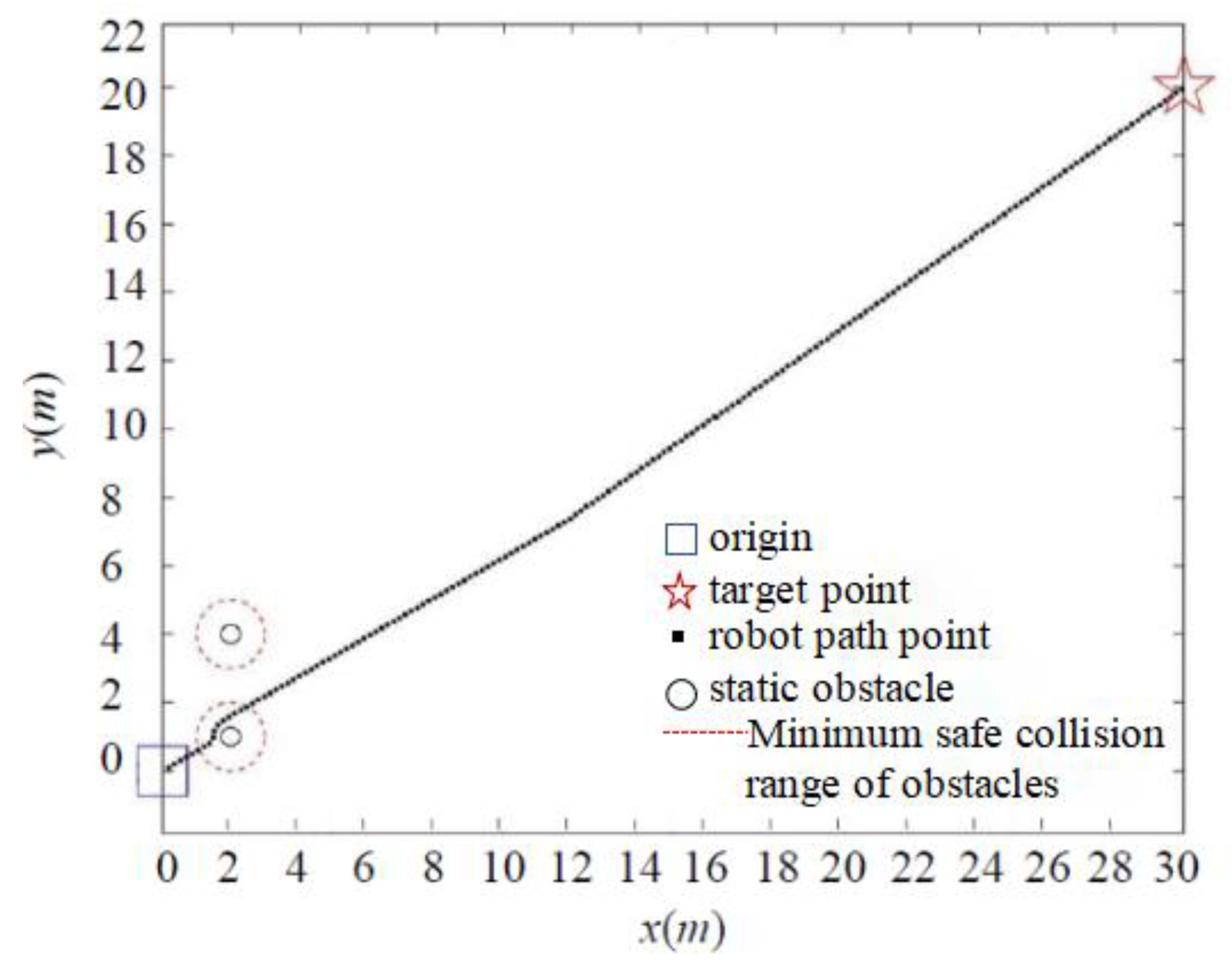

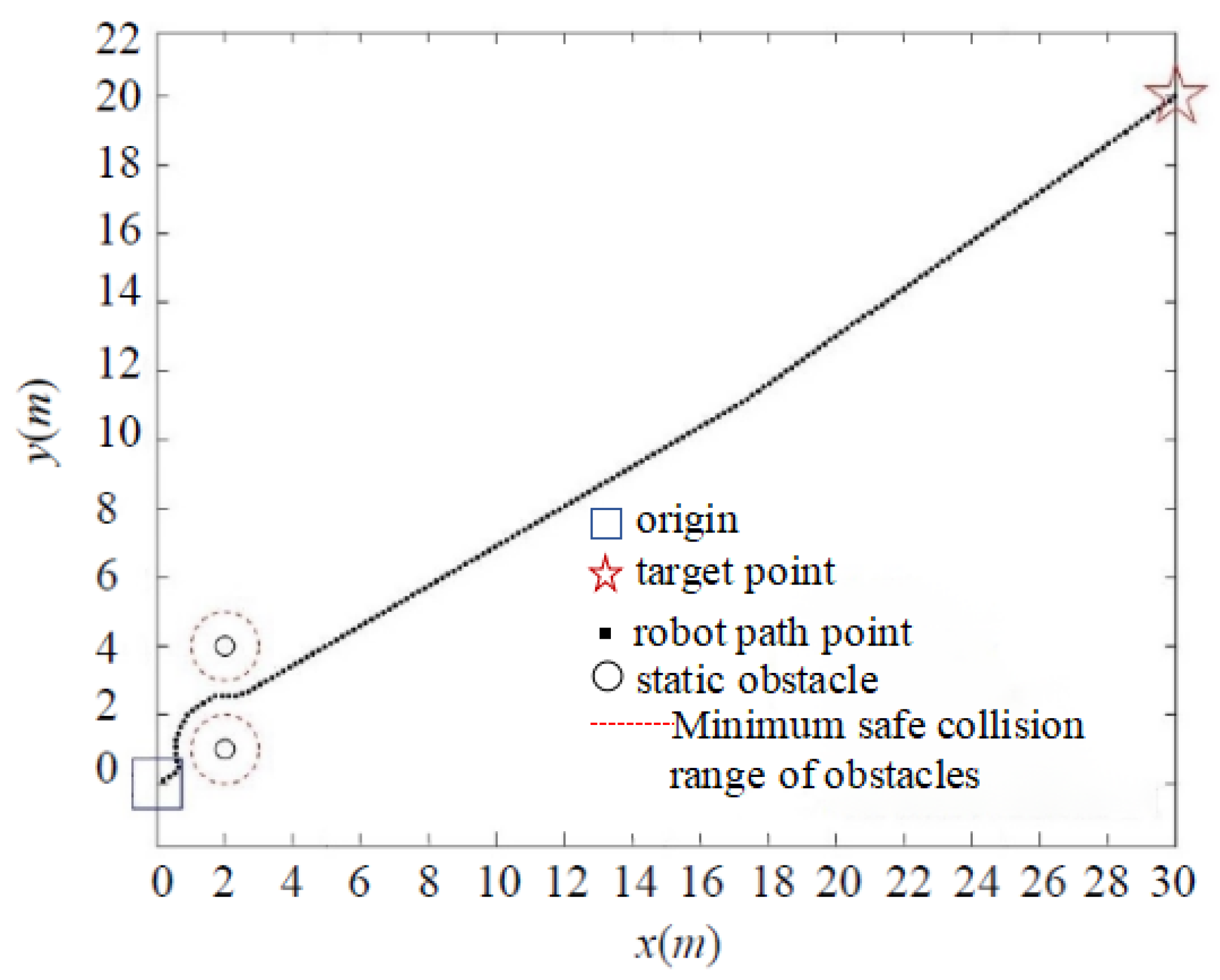

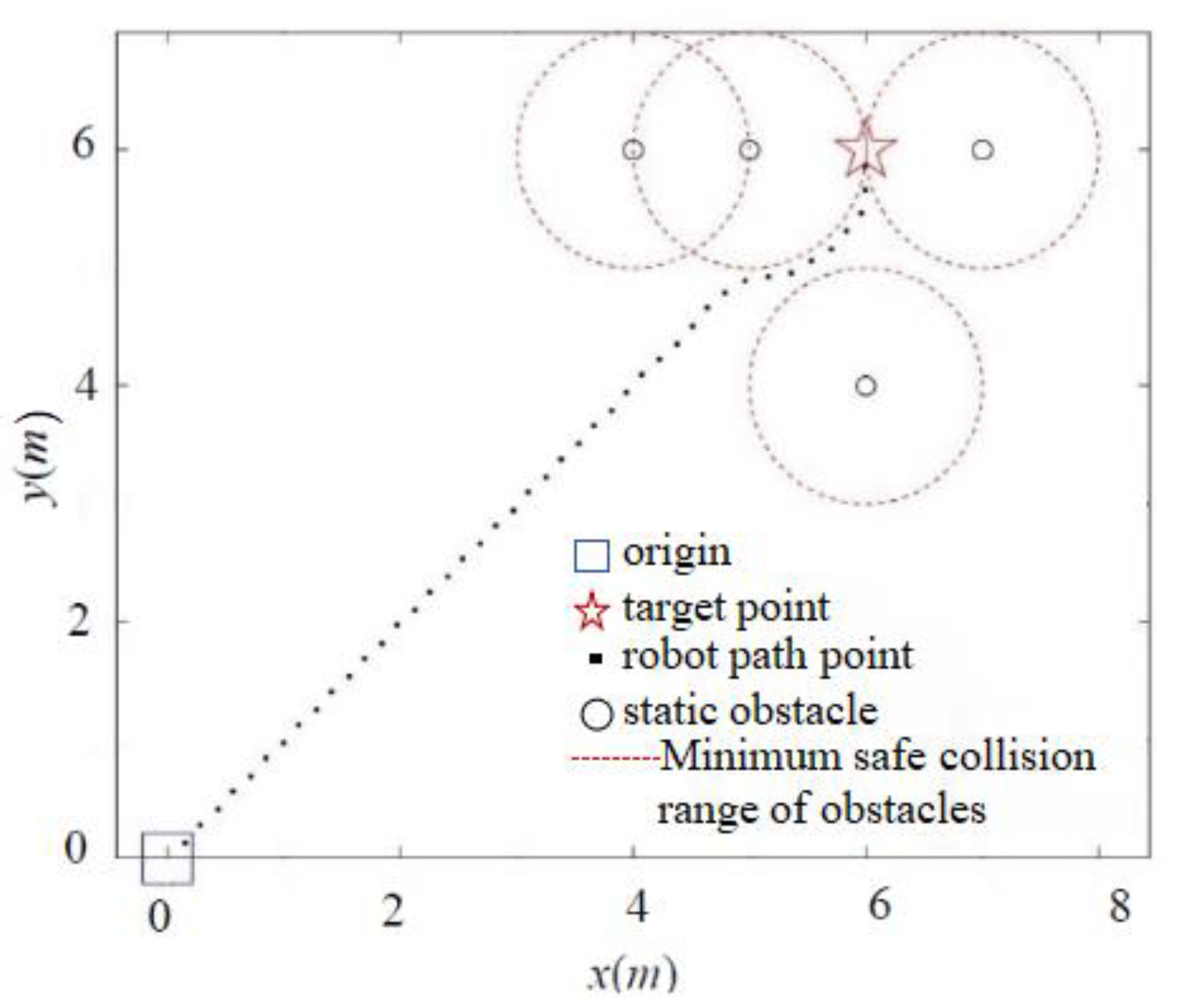

5.1. Simulation of Collision Problems

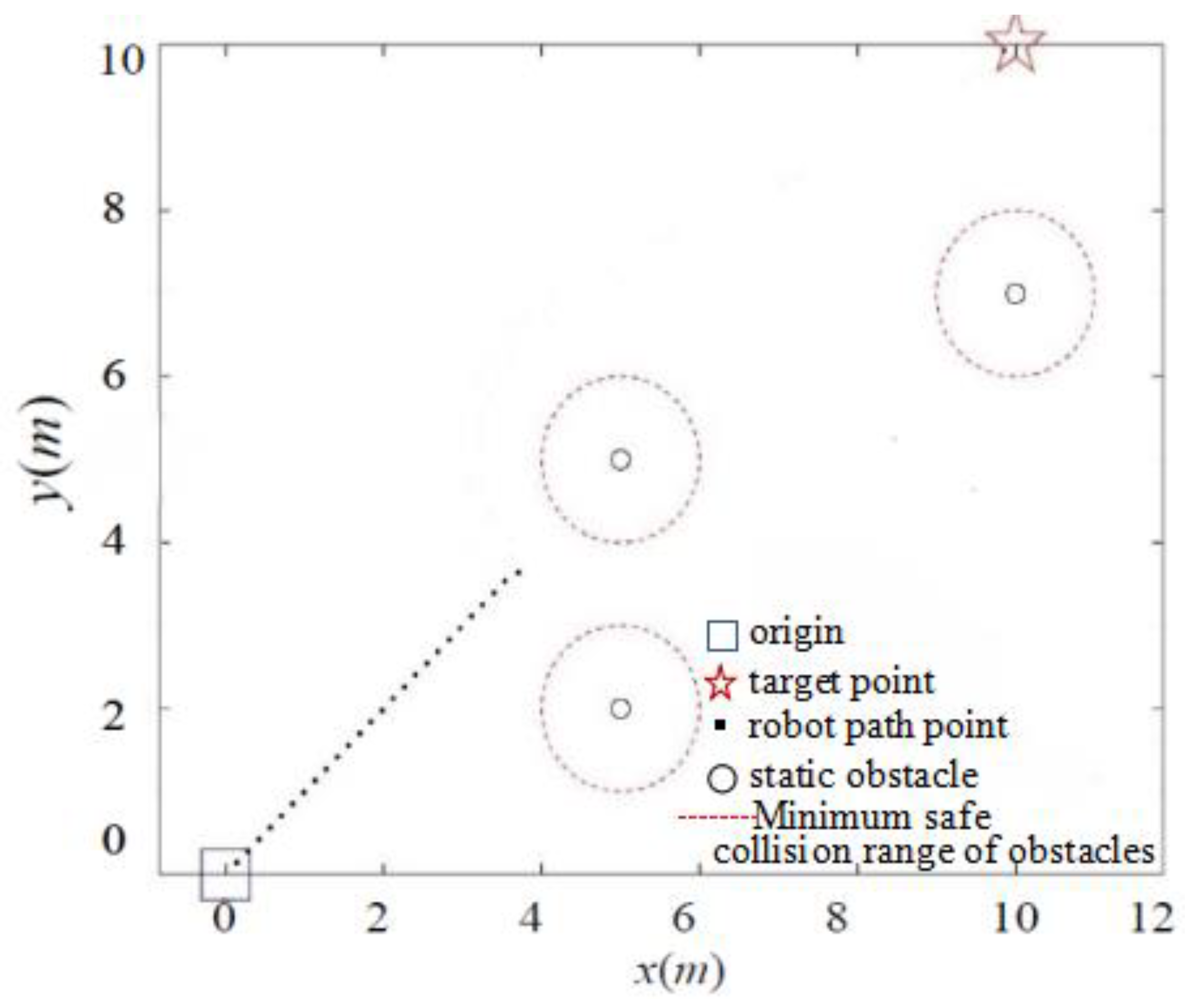

5.2. Simulation of Goal Unreachable Problem

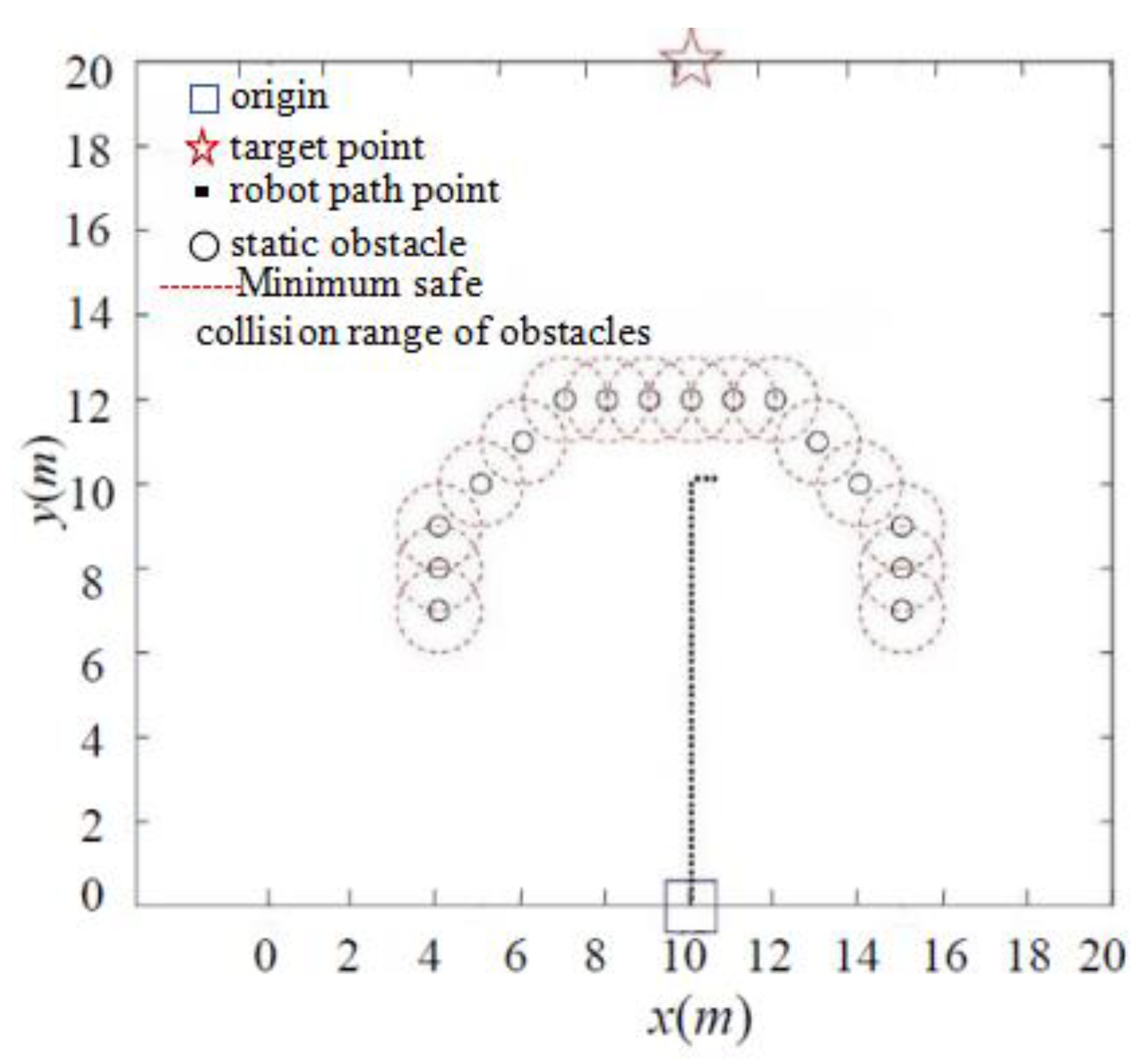

5.3. Simulation of Local Minima Problem

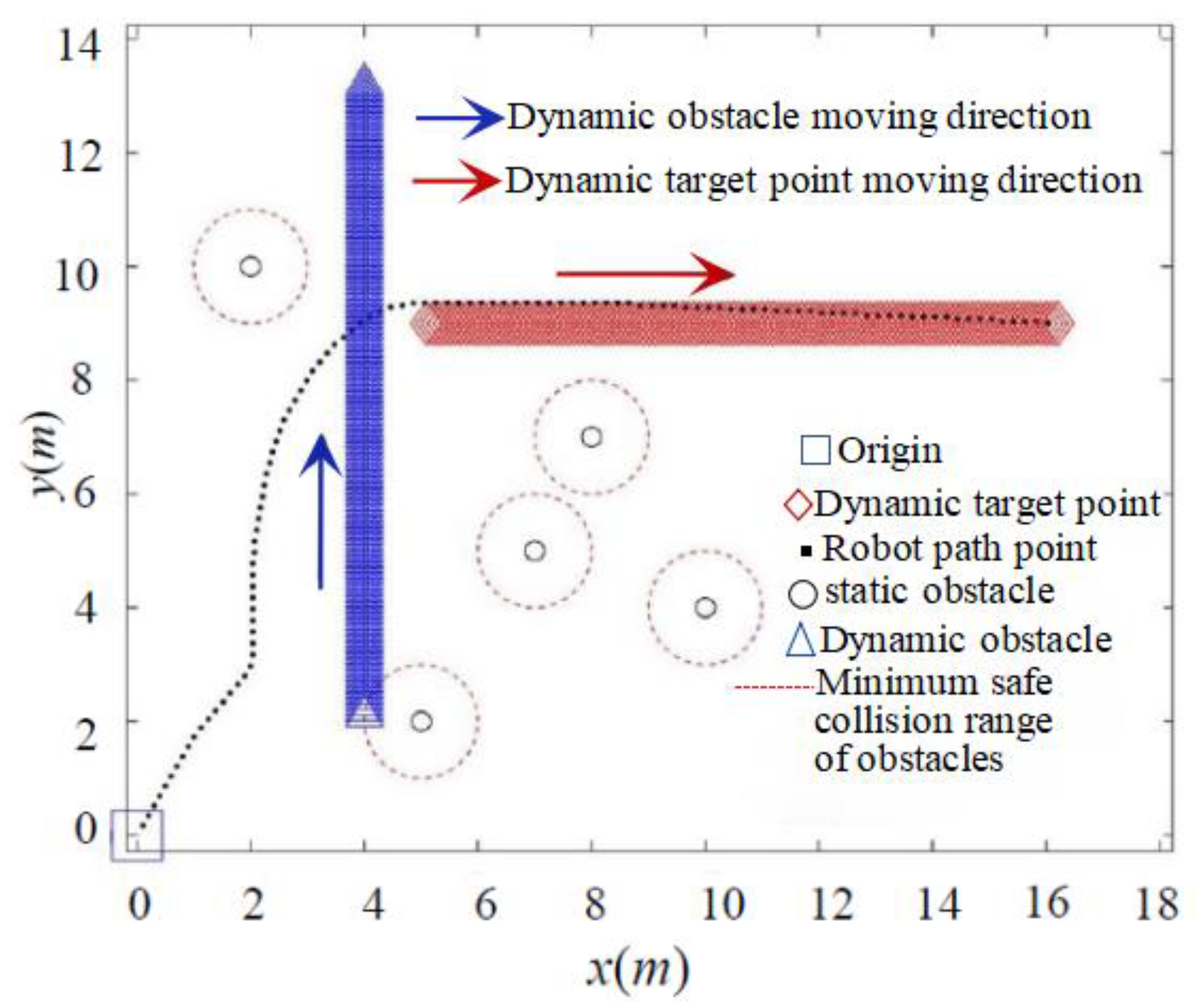

5.4. Simulation of Dynamic Planning

6. Experiment Verification

6.1. Hardware System Construction

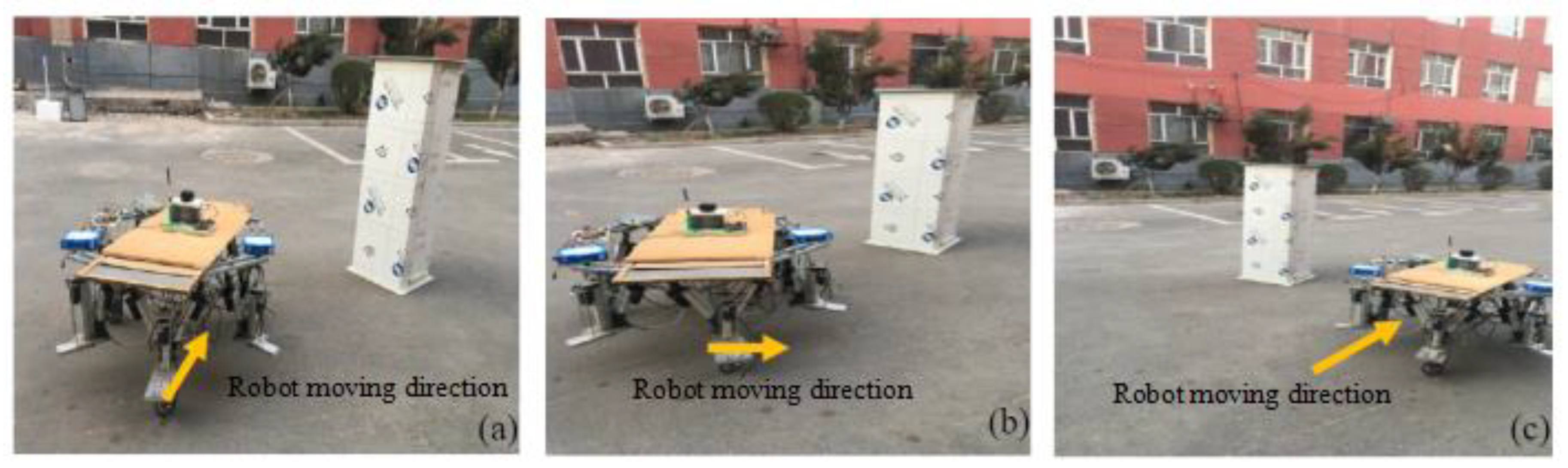

6.2. Establishment of Experimental Environment

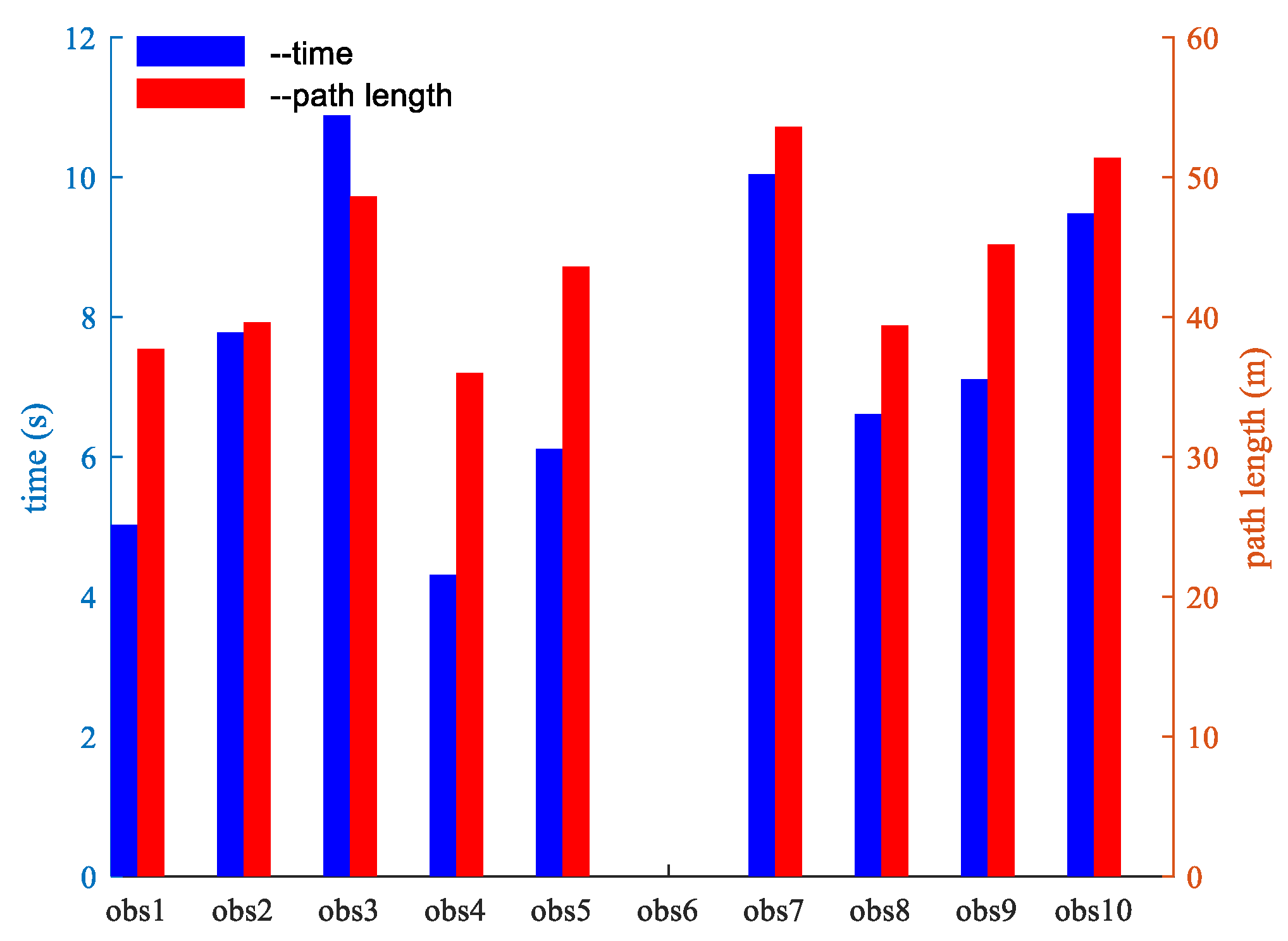

6.3. Experiment Verification Based on IAPF Algorithm

6.4. Analysis of Experiment Results

7. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, P.; Nie, J.; Xie, X.; Yan, H. Research on Design and Motion Control of Pure Rolling Wheel Mobile Robots. J. Mech. Transm. 2022, 46, 85–92. [Google Scholar]

- Liu, M.; Li, Y.; Huo, Q.; Li, A.; Zhu, M.; Qu, N.; Chen, L.; Xia, M. A Two-Way Parallel Slime Mold Algorithm by Flow and Distance for the Travelling Salesman Problem. Appl. Sci. 2020, 10, 6180. [Google Scholar] [CrossRef]

- Chang, L.; Piao, S.; Leng, X.; He, Z.; Zhu, Z. Inverted pendulum model for turn-planning for biped robot. Phys. Commun. 2020, 42, 101168. [Google Scholar] [CrossRef]

- Du, X.; Zhu, H. Research on terrain classification of tracked robot based on time-frequency characteristics and PCA-SVM. J. Henan Polytech. Univ. (Nat. Sci.) 2019, 38, 84–90. [Google Scholar]

- Dobrokvashina, A.; Lavrenov, R.; Bai, Y.; Svinin, M.; Meshcheryakov, R.; Magid, E. Servosila Engineer Crawler Robot Modelling in Webots Simulator. Int. J. Mech. Eng. Robot. Res. 2022, 11, 417–421. [Google Scholar] [CrossRef]

- Sugahara, Y.; Carbone, G.; Hashimoto, K.; Ceccarelli, M.; Lim, H.O.; Takanishi, A. Experimental Stiffness Measurement of WL-16RII Biped Walking Vehicle during Walking Operation. J. Robot. Mechatron. 2007, 19, 272–280. [Google Scholar] [CrossRef]

- Sun, Q.; Gao, F.; Qi, C.K.; Chen, X.B. A simplified control method to achieve stable and robust quadrupedal quasi-passive walking with compliant legs. J. Bionic Eng. 2016, 13, 585–599. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, J.; Shang, J.; Wang, Z. Energy Efficient Fluid Power in Autonomous Legged Robotics Based on Bionic Multi-Stage Energy Supply. Adv. Robot. 2014, 28, 1445–1457. [Google Scholar] [CrossRef]

- Wang, L.Q.; Wang, H.L.; Wang, G.; Chen, X.; Khan, A.; Jin, L.X. Investigation of the hydrodynamic performance of crablike robot swimming leg. J. Hydrodyn. 2018, 30, 605–617. [Google Scholar] [CrossRef]

- Misyurin, S.Y.; Kreinin, G.V.; Nosova, N.Y.; Nelubin, A.P. Six-Legged Walking Robot (Hexabot), Kinematics, Dynamics and Motion Optimization. Procedia Comput. Sci. 2021, 190, 604–610. [Google Scholar] [CrossRef]

- Roy, S.; Pratihar, D. Effects of turning gait parameters on energy consumption and stability of a six-legged walking robot. Robot. Auton. Syst. 2012, 60, 72–82. [Google Scholar] [CrossRef]

- Tang, X.; Fan, D.; Han, F.; Cui, Y. Simulation and experiment of legs-stride forward and overcoming obstacle gait of walking robot based on double 6-UPU parallel mechanism. Trans. Chin. Soc. Agric. Eng. 2019, 35, 83–91. [Google Scholar]

- Li, G.; Yamashita, A.; Asama, H.; Tamura, Y. An efficient improved artificial potential field based regression search method for robot path planning. In Proceedings of the 2012 IEEE International Conference on Mechatronics and Automation, Chengdu, China, 5–8 August 2012; pp. 1227–1232. [Google Scholar]

- Koubaa, A.; Bennaceur, H.; Chaari, I.; Trigui, S.; Ammar, A.; Sriti, M.-F.; Alajlan, M.; Cheikhrouhou, O.; Javed, Y. Robot Path Planning and Cooperation: Foundations, Algorithms and Experimentations; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Khatib, O. Real-Time Obstacle Avoidance for Manipulators and Mobile Robots. Int. J. Rob. Res. 1986, 5, 90–98. [Google Scholar] [CrossRef]

- Zhu, D.; Yang, S.X. Path planning method for unmanned underwater vehicles eliminating effect of currents based on artificial potential field. J. Navig. 2021, 74, 955–967. [Google Scholar] [CrossRef]

- Chen, J.; Tan, C.; Mo, R.; Zhang, H.; Cai, G.; Li, H. Research on path planning of three-neighbor search A* algorithm combined with artificial potential field. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211026449. [Google Scholar] [CrossRef]

- Orozco-Rosas, U.; Picos, K.; Montiel, O. Hybrid Path Planning Algorithm Based on Membrane Pseudo-Bacterial Potential Field for Autonomous Mobile Robots. IEEE Access 2019, 7, 156787–156803. [Google Scholar] [CrossRef]

- Cong, Y.; Zhao, Z.; Xing, C.; Wang, Z. Dynamic Obstacle Avoidance Path Planning of UAV Based on Improved Artificial Potential Field. J. Ordnance Equip. Eng. 2021, 42, 170–176. [Google Scholar]

- Zhijiu, H.; Wenjiang, W.; Xiaowei, L.; Dan, Z.; Chunxin, L. An improved artificial potential field method constrained by a dynamic model. J. Shanghai Univ. (Nat. Sci.) 2019, 25, 879–887. [Google Scholar]

- Zhang, L. Virtual target point-based obstacle-avoidance method for manipulator systems in a cluttered environment. Eng. Optim. 2019, 52, 1–17. [Google Scholar]

- Zhang, T.; Xu, J.; Wu, B. Hybrid Path Planning Model for Multiple Robots Considering Obstacle Avoidance. IEEE Access 2022, 10, 71914–71935. [Google Scholar] [CrossRef]

- Pan, Z.; Zhang, C.; Xia, Y.; Xiong, H.; Shao, X. An Improved Artificial Potential Field Method for Path Planning and Formation Control of the Multi-UAV Systems. IEEE Trans. Circuits Syst. II Express Briefs 2022, 63, 1129–1133. [Google Scholar] [CrossRef]

- Weerakoon, T.; Ishii, K.; Nassiraei, A.A.F. An artificial potential field based mobile robot navigation method to prevent from deadlock. J. Artif. Intell. Soft Comput. Res. 2015, 5, 189–203. [Google Scholar] [CrossRef]

- Matoui, F.; Boussaid, B.; Abdelkrim, M.N. Distributed path planning of a multi-robot system based on the neighborhood artificial potential field approach. Simulation 2019, 95, 637–657. [Google Scholar] [CrossRef]

- Yang, X.; Yang, W.; Zhang, H.; Chang, H.; Chen, C.Y.; Zhang, S. A new method for robot path planning based artificial potential field. In Proceedings of the IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 5–7 June 2016. [Google Scholar]

- Montiel, O.; Sepulveda, R.; Orozco-Rosas, U. Optimal path planning generation for mobile robots using parallel evolutionary artifificial potential Field. J. Intell. Robot. Syst. 2015, 79, 237–257. [Google Scholar] [CrossRef]

- Zhu, D.Q.; Cheng, C.L.; Sun, B. An integrated AUV path planning algorithm with ocean current and dynamic obstacles. Int. J. Robot. Autom. 2016, 31, 382–389. [Google Scholar] [CrossRef]

- Jing, X.; Ji, F.; Mei, B.; Xia, H. Research on the design technology of six degrees of freedom parallel mechanism based on large component assembly. Manuf. Technol. Mach. Tool 2018, 59–63. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, W.; Zheng, M.; Chen, J.; Piao, M. Parametric Modeling and Optimization of Six-DOF Stewart Platform. J. Harbin Univ. Sci. Technol. 2021, 26, 66–76. [Google Scholar]

- Rostami, S.M.H.; Sangaiah, A.K.; Wang, J.; Liu, X. Obstacle avoidance of mobile robots using modified artificial potential field algorithm. EURASIP J. Wirel. Commun. Netw. 2019, 2019, 70. [Google Scholar] [CrossRef]

- Orozco-Rosas, U.; Montiel, O.; Sepúlveda, R. Mobile robot path planning using membrane evolutionary artificial potential field. Appl. Soft Comput. 2019, 77, 236–251. [Google Scholar] [CrossRef]

- Zheng, L.; Yu, W.; Li, G.; Qin, G.; Luo, Y. Particle Swarm Algorithm Path-planning Method for Mobile Robots Based on Artificial Potential Fields. Sensors 2023, 23, 6082. [Google Scholar] [CrossRef]

- Liu, G.; He, H.; Tian, G.; Zhang, J.; Ji, Z. Online collision avoidance for human-robot collaborative interaction concerning safety and efficiency. In Proceedings of the 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 6–9 July 2020; pp. 1667–1672. [Google Scholar]

- Tong, X.; Yu, S.; Liu, G.; Niu, X.; Xia, C.; Chen, J.; Yang, Z.; Sun, Y. A hybrid formation path planning based on A* and multi-target improved artificial potential field algorithm in the 2D random environments. Adv. Eng. Inform. 2022, 54, 101755. [Google Scholar] [CrossRef]

- Liang, X.; Liu, C.; Song, X.; Hao, C. Research on mobile robot path planning in dynamic environment. In Proceedings of the 2017 Chinese Automation Congress, Jinan, China, 20–22 October 2017; pp. 3890–3894. [Google Scholar]

- Li, Y.; Chen, C.; Ma, T.; Wei, H.; Yang, Q.; Li, L. A multiple constraints modified artificial potential field algorithm for complex dynamic environment. In Proceedings of the 2019 Chinese Automation Congress, Hangzhou, China, 22–24 November 2019; pp. 1277–1282. [Google Scholar]

- Xiao, B.X.; Yu, L.; Li, S.S.; Chen, R.B. Research of Escaping Local Minima Strategy for Artificial Potential Field. J. Syst. Simul. 2007, 19, 4495–4503. [Google Scholar]

- Zhang, F.; Gao, X.; Xie, Z.; Liu, Y. Multi-robot Rounding Strategy Based on Artificial Potential Field Method in Dynamic Environment. In Proceedings of the 2019 Chinese Automation Congress, Hangzhou, China, 22–24 November 2019; pp. 2294–2299. [Google Scholar]

- He, N.; Su, Y.; Fan, X.; Liu, Z.; Wang, B. Dynamic path planning of mobile robot based on artificial potential field. In Proceedings of the 2020 International Conference on Intelligent Computing and Human-Computer Interaction, Sanya, China, 4–6 December 2020; pp. 259–264. [Google Scholar]

| Main Parameters | Value |

|---|---|

| Influence area of obstacle ρ0 (m) | 2 |

| Coefficient kax, kav, kaa | 200 |

| Coefficient krx, krv, kra | 1000 |

| Distance threshold d0 (m) | 2 |

| positive exponent n | 2 |

| Robot detection range R0 (m) | 2.5 |

| Minimum safe collision distance S (m) | 1 |

| Robot body radius r (m) | 0.5 |

| Robot velocity Vrob (m/s) | 0.2 |

| Dynamic goal velocity Vgd (m/s) | 0.1 |

| Dynamic obstacle velocity Vod (m/s) | 0.1 |

| Δf | 0.02 |

| ΔP | 0.01 |

| Pursuing Dynamic Goal and Avoiding Dynamic Obstacles | ||

|---|---|---|

| Classic APF Method | IAPF Method | |

| time (s) | 3.49 | 2.47 |

| path length (m) | 22.40 | 15.40 |

| path length reduction rate (%) | 31.25 | |

| Run time reduction rate (%) | 29.22 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Pei, H.; Zhang, D. Path Planning for a Wheel-Foot Hybrid Parallel-Leg Walking Robot. Sensors 2024, 24, 2178. https://doi.org/10.3390/s24072178

Tang X, Pei H, Zhang D. Path Planning for a Wheel-Foot Hybrid Parallel-Leg Walking Robot. Sensors. 2024; 24(7):2178. https://doi.org/10.3390/s24072178

Chicago/Turabian StyleTang, Xinxing, Hongxin Pei, and Deyong Zhang. 2024. "Path Planning for a Wheel-Foot Hybrid Parallel-Leg Walking Robot" Sensors 24, no. 7: 2178. https://doi.org/10.3390/s24072178

APA StyleTang, X., Pei, H., & Zhang, D. (2024). Path Planning for a Wheel-Foot Hybrid Parallel-Leg Walking Robot. Sensors, 24(7), 2178. https://doi.org/10.3390/s24072178