Compound Fault Characteristic Analysis for Fault Diagnosis of a Planetary Gear Train

Abstract

1. Introduction

1.1. Literature Review

1.2. Main Work of This Paper

1.3. Contributions and Innovations

- (1)

- A carrier eccentricity error model is proposed considering the time-varying center distance, LOA, meshing angle, and contact ratio.

- (2)

- An improved TVMS model of a PGT considering both the carrier eccentricity error and compound gear faults is established.

- (3)

- The engagement characteristics and dynamic responses of a PGT are investigated to reveal the vibration responses and coupling mechanisms of compound gear faults and the carrier eccentricity error.

2. Improved TVMS Model Considering the Carrier Eccentricity Error and Gear Cracks

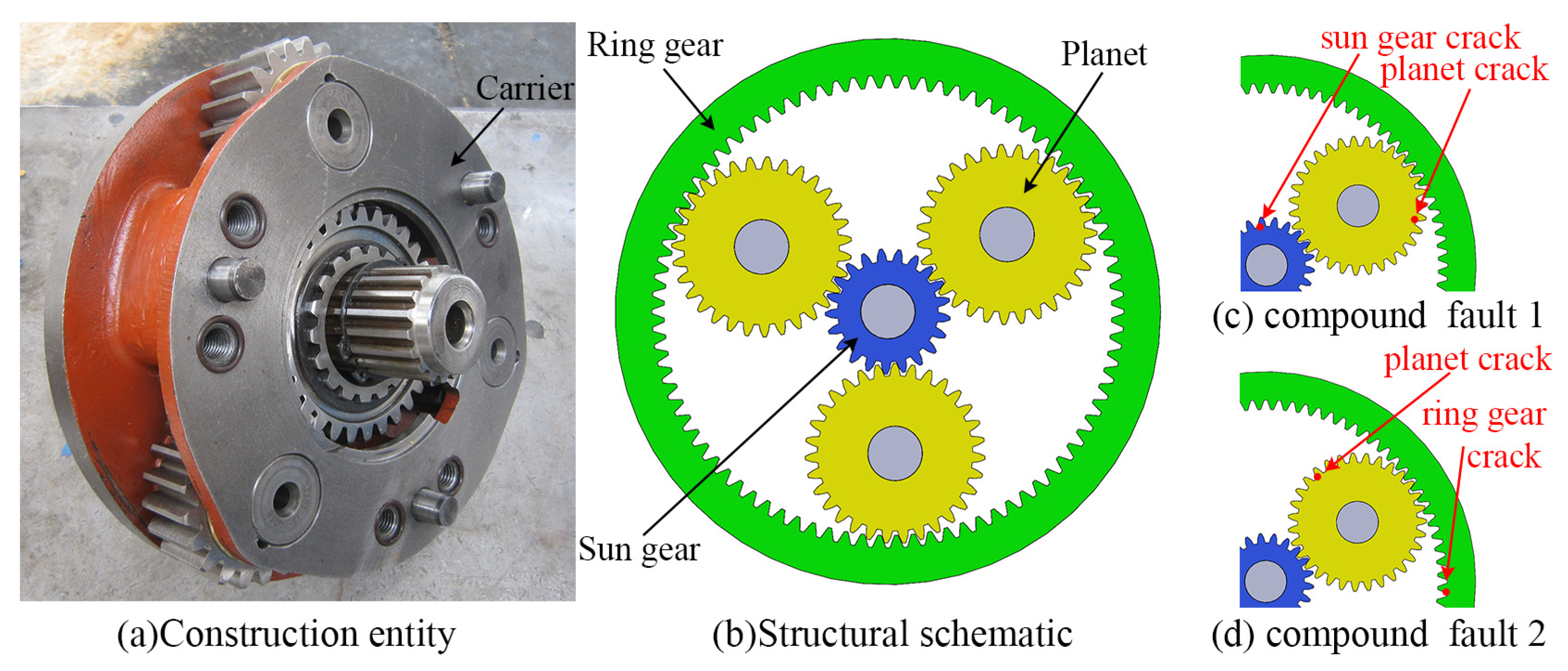

2.1. Overview of PGT

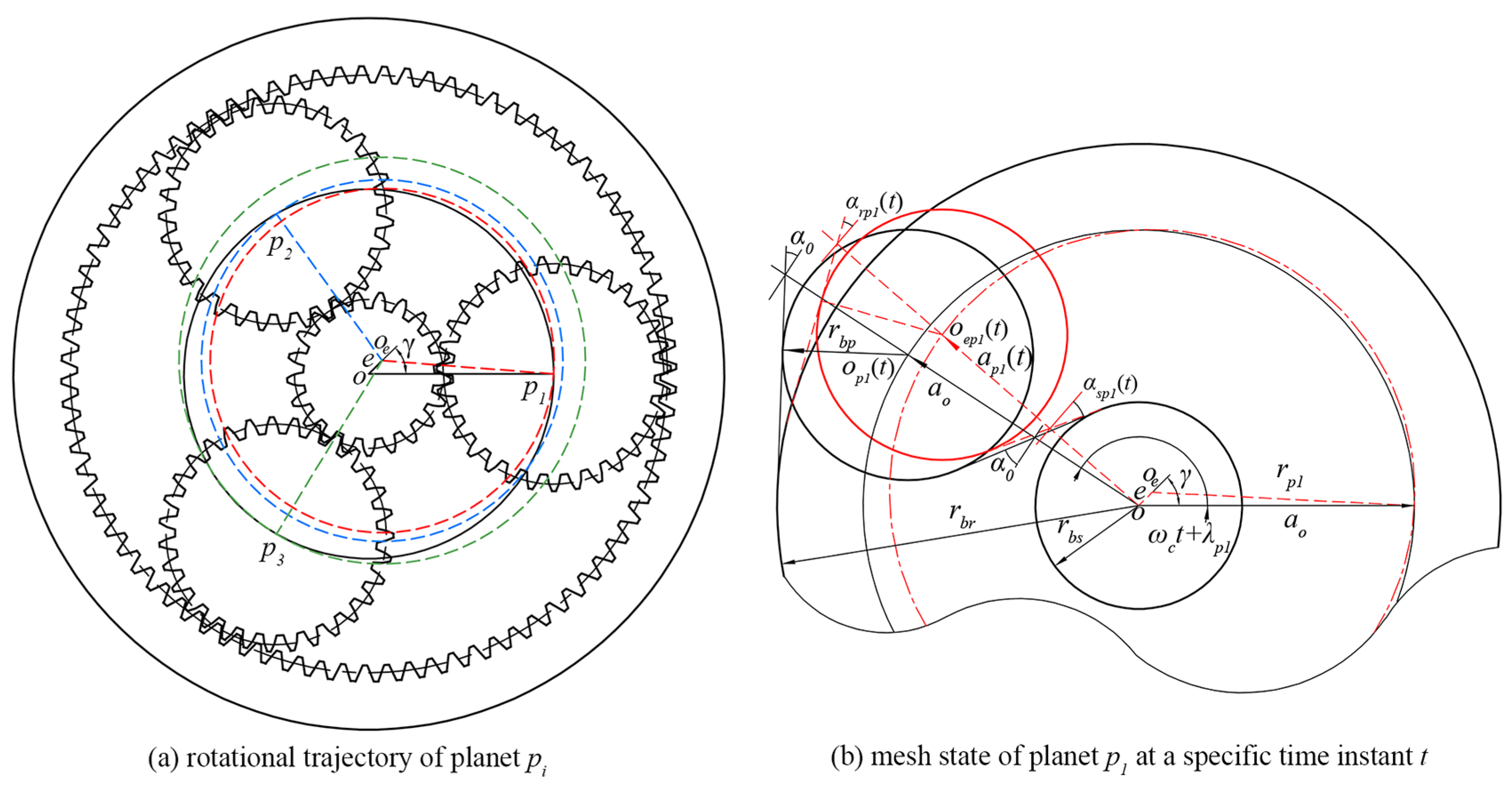

2.2. The Carrier Eccentricity Error Model

2.3. Improved TVMS Model Considering the Carrier Eccentricity Error

2.3.1. Single-Tooth Meshing Stiffness Derivation

2.3.2. Influence of the Time-Varying Contact Ratio on the Meshing Stiffness

2.3.3. Influence of Time-Varying Meshing Angle on the Meshing Stiffness

2.4. TVMS Model of Cracked Gear Teeth

3. Dynamic Modeling

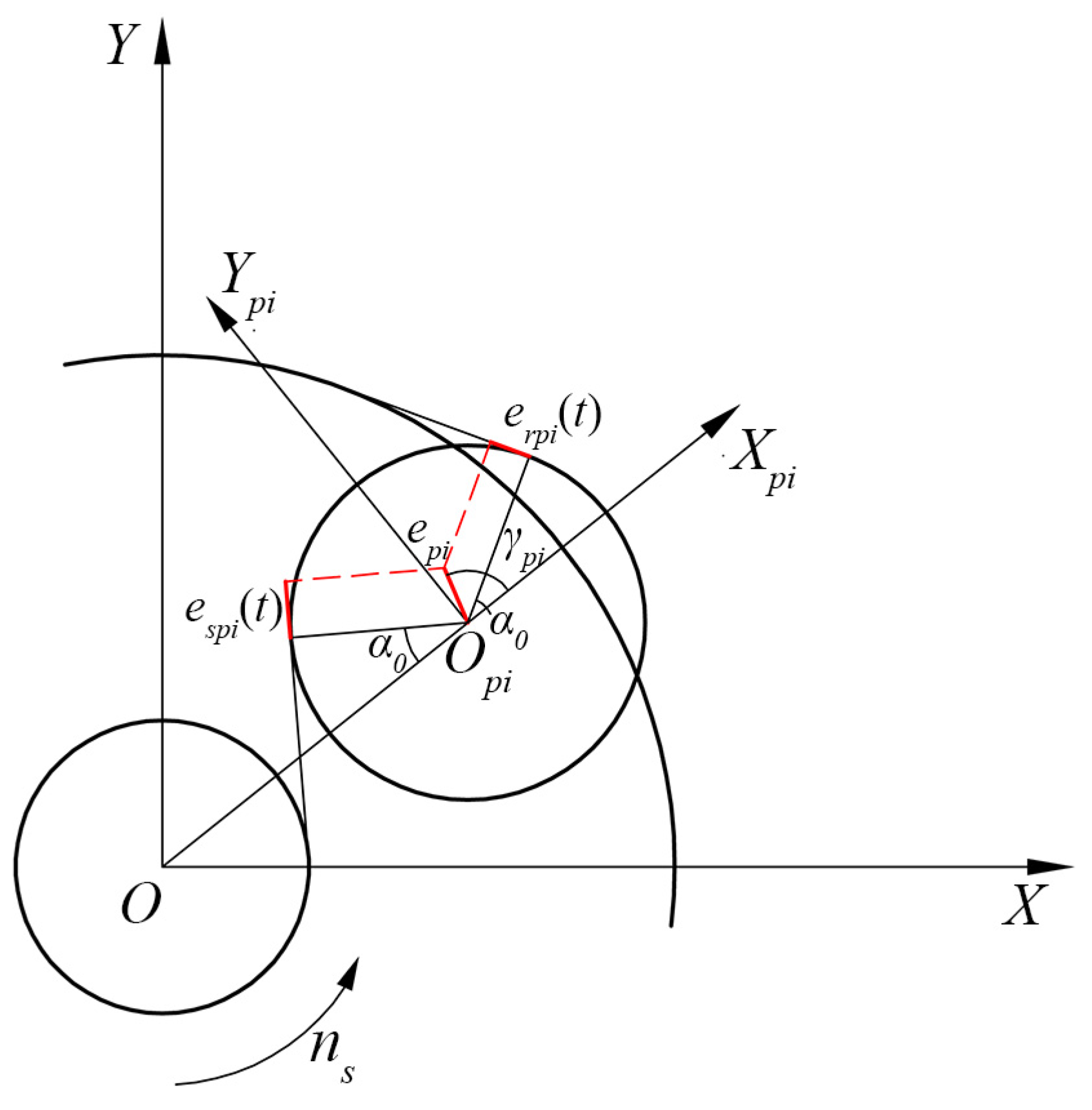

3.1. Relative Displacement of a Meshing Pair with the Carrier Eccentricity Error

3.2. Dynamic Equations of Motion

4. Meshing Characteristic Analysis

4.1. Influence of the Carrier Eccentricity Error on Meshing Parameters

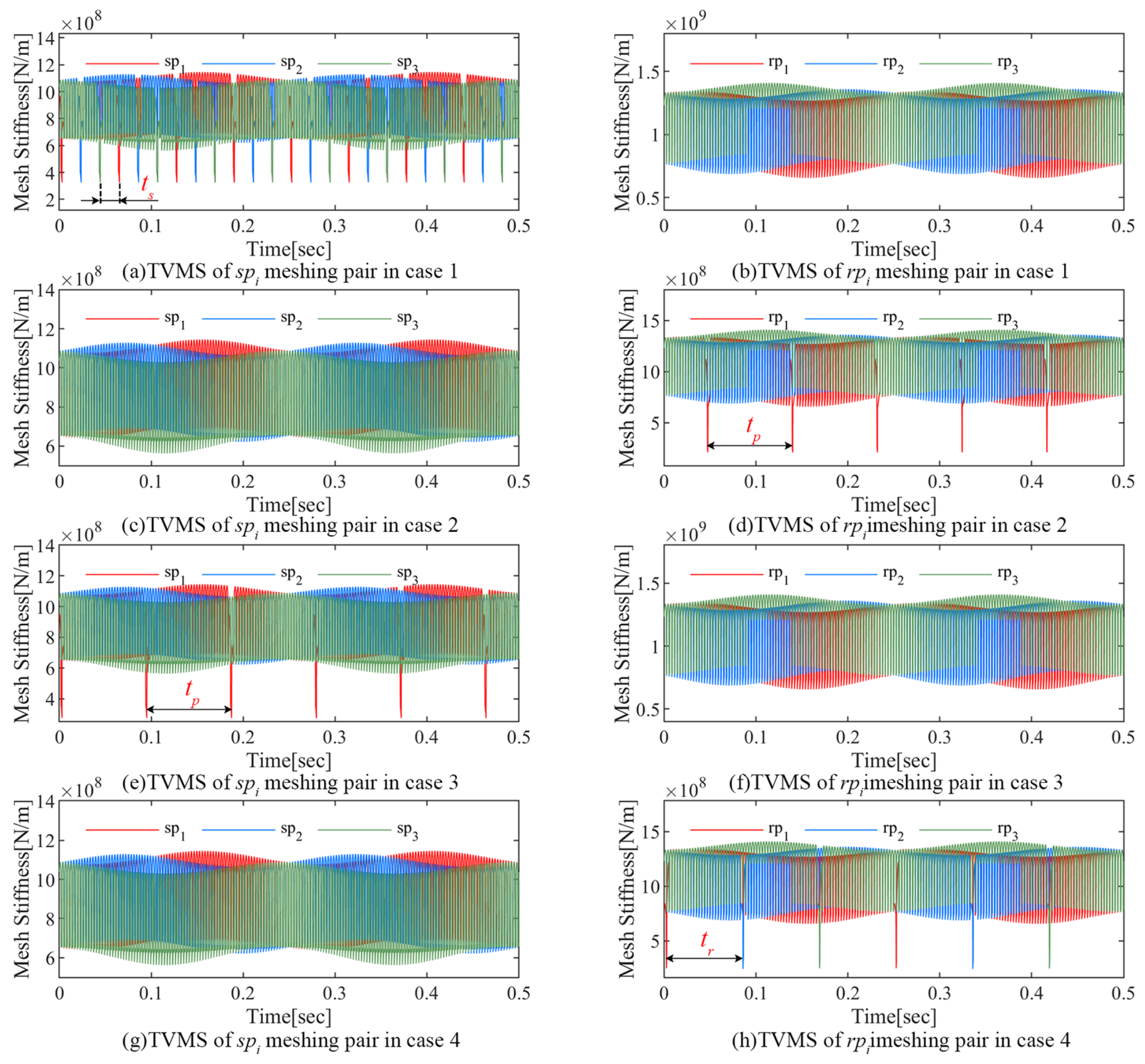

4.2. Influence of the Carrier Eccentricity Error on TVMS

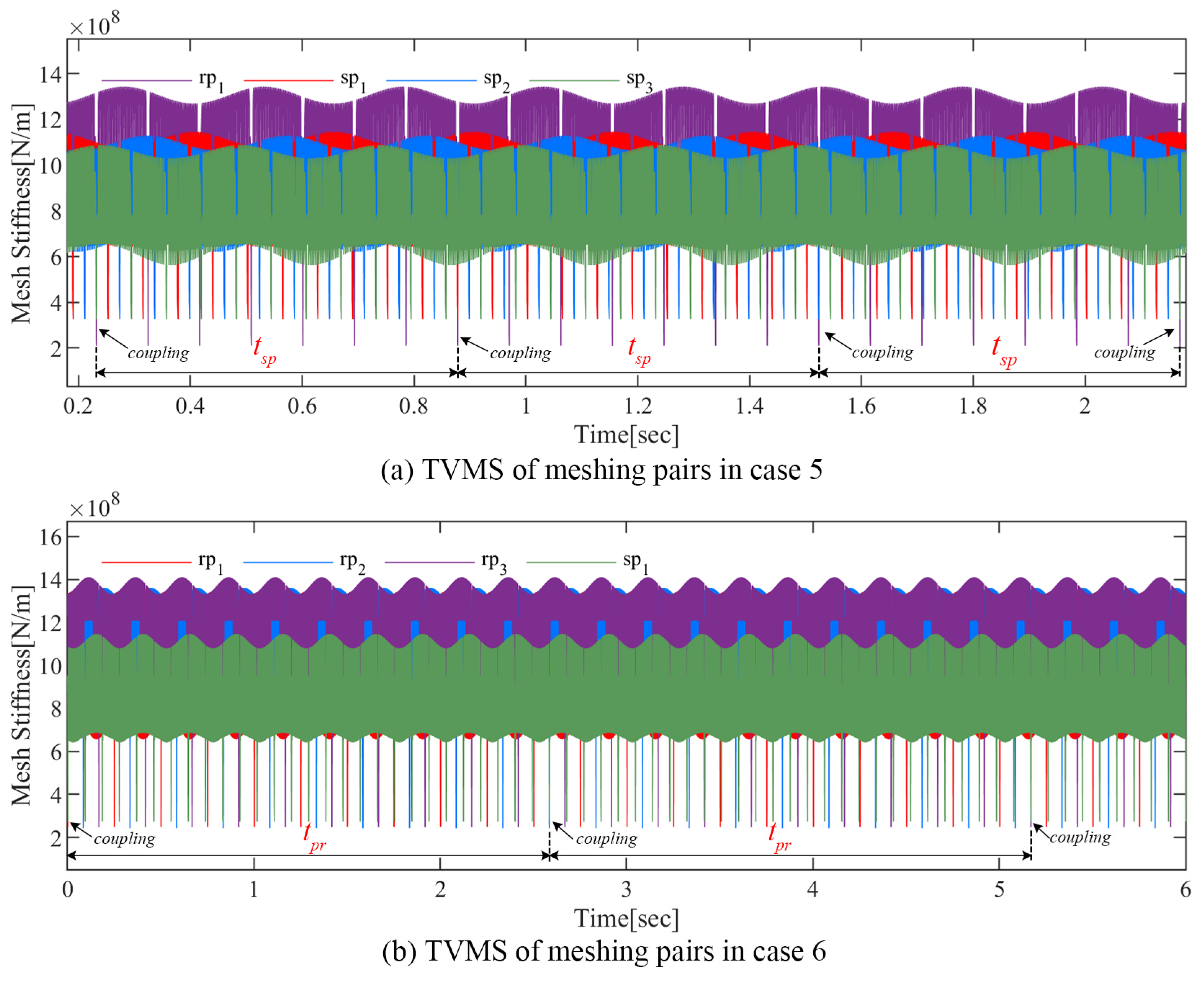

4.3. TVMS Variation with Different Fault Combinations

5. Dynamic Simulation and Results Discussion

5.1. Analysis of Characteristic Frequencies

5.2. Dynamic Characteristics of a PGT with the Carrier Eccentricity Error

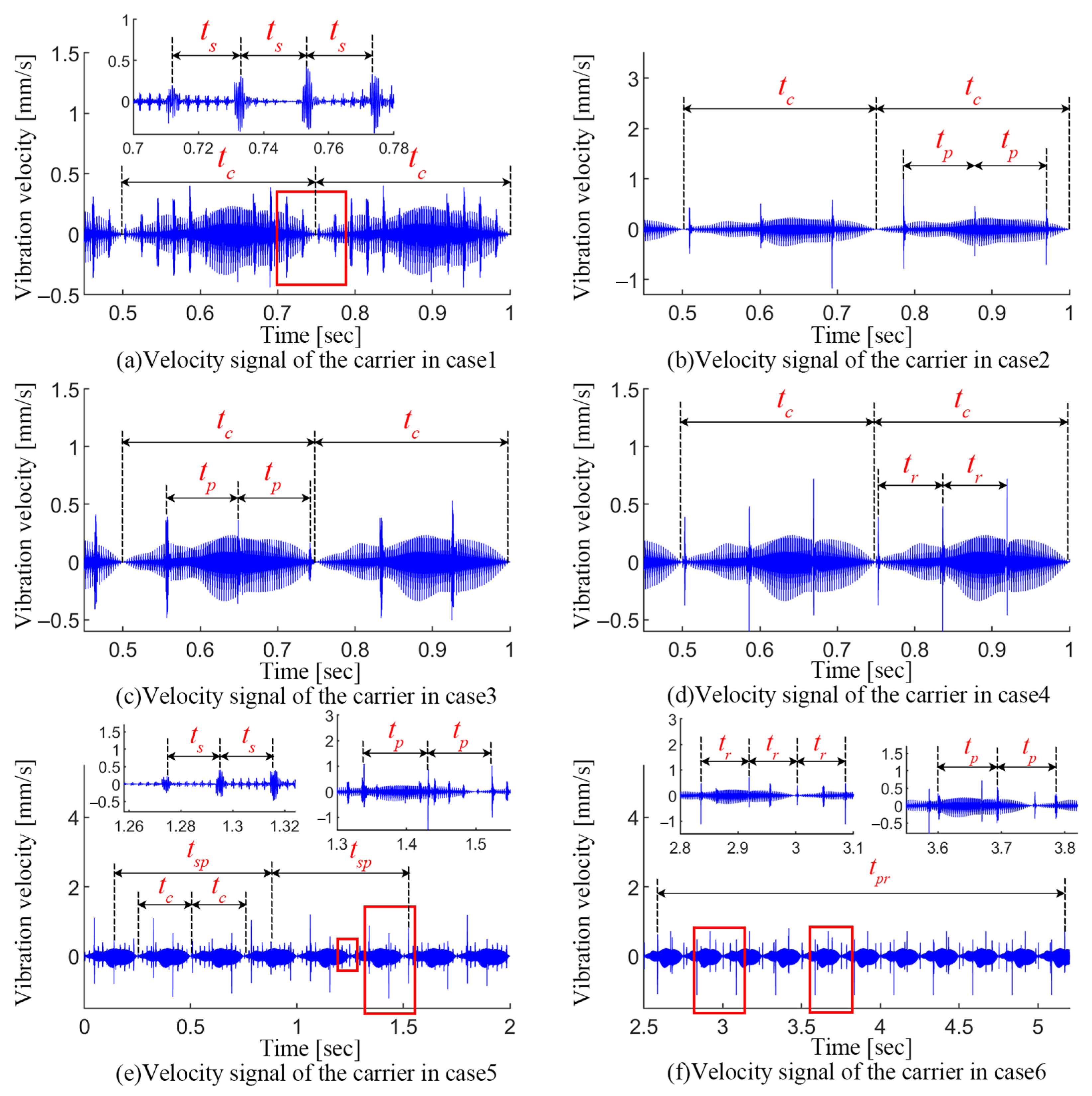

5.3. Dynamic Responses of PGT in Different Faulty Cases

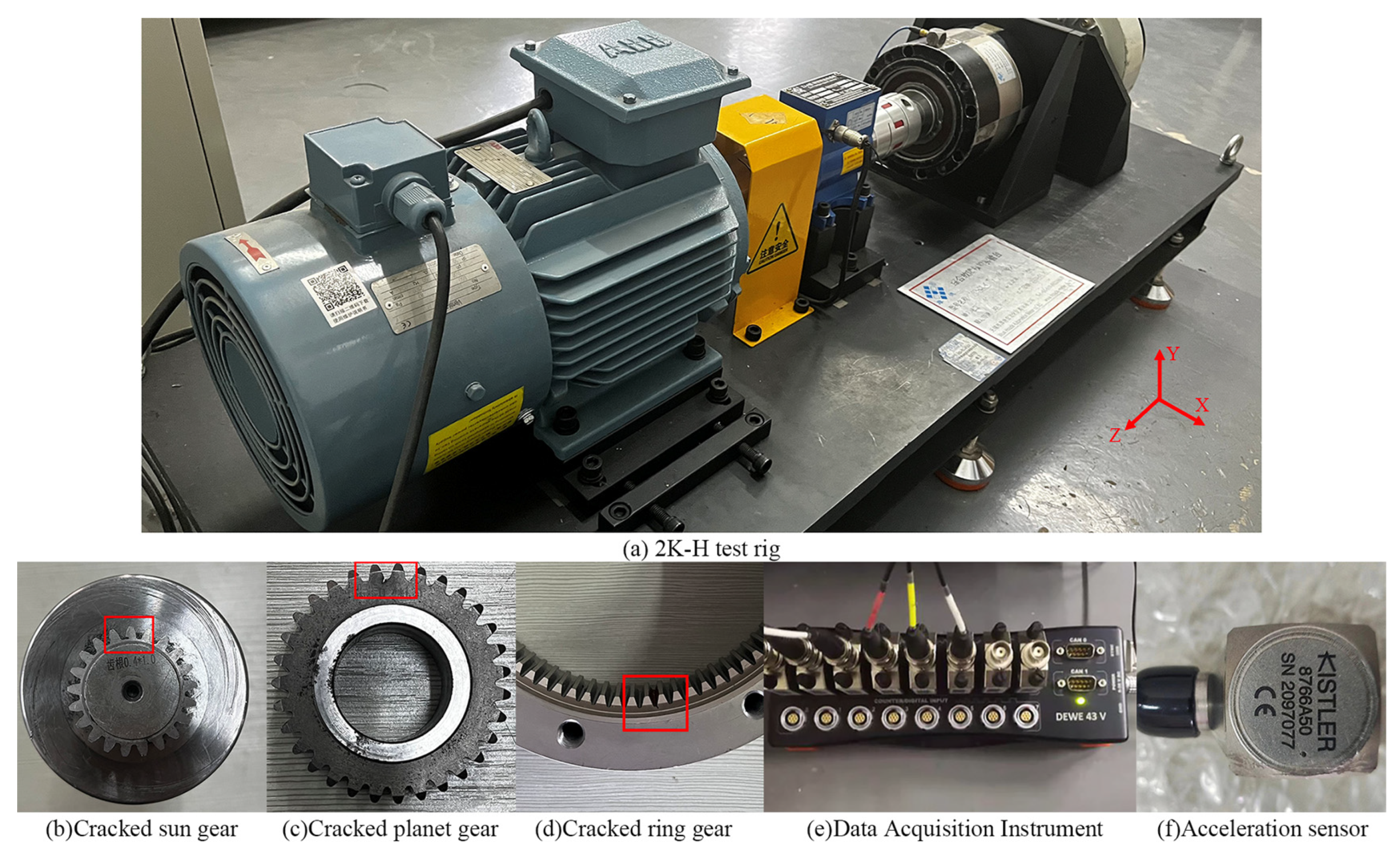

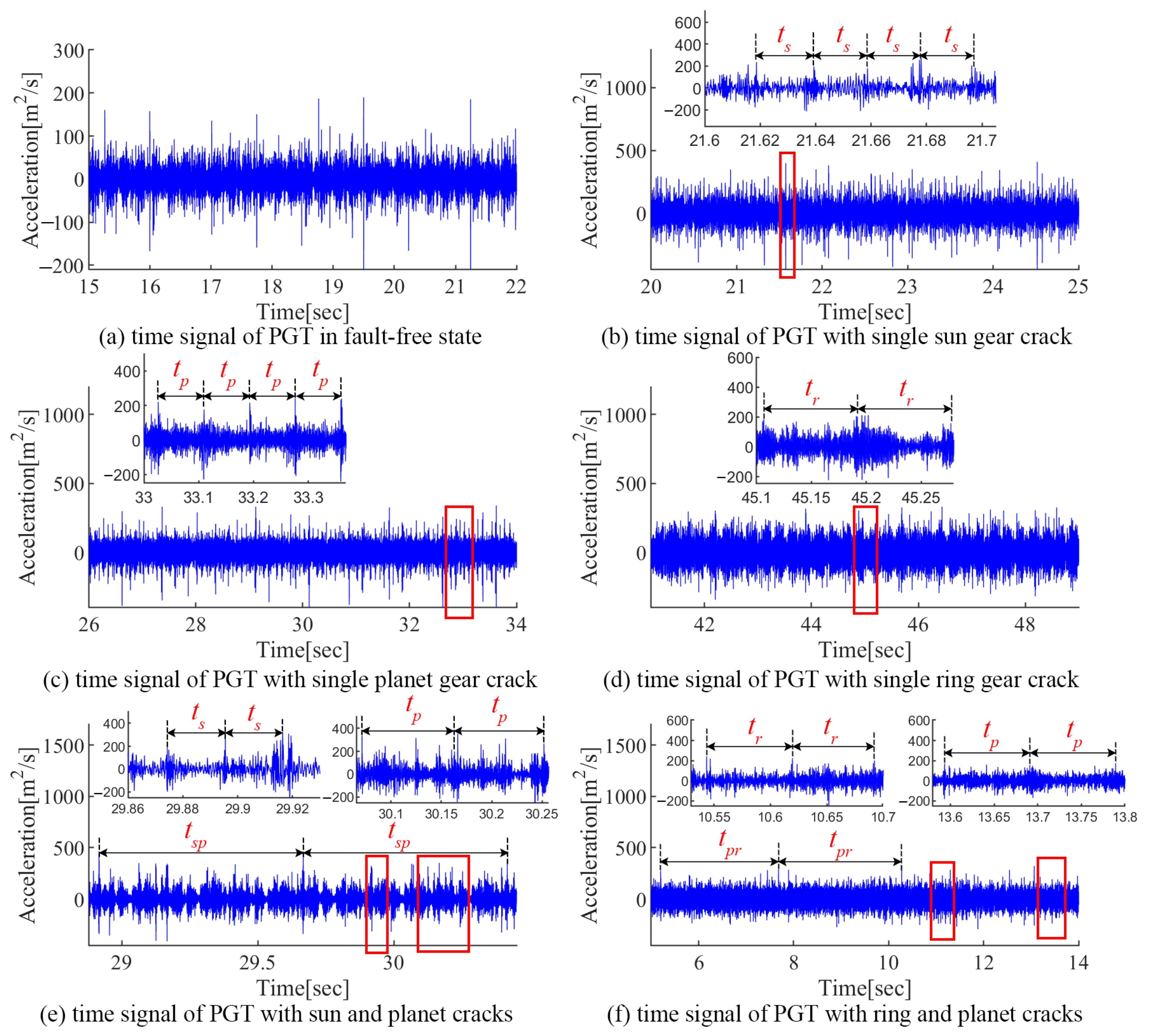

6. Experimental Verification

7. Conclusions

- (1)

- The carrier eccentricity error comprehensively changes multiple meshing parameters, which will lead to the amplitude fluctuation and variation of single- and double-tooth meshing ranges of the TVMS.

- (2)

- The single gear crack can cause periodic TVMS reductions. Furthermore, the overlap of TVMS reductions occurs when multiple cracked teeth enter engagement simultaneously, which will cause new fault characteristics and have a greater influence on the dynamic response of the system.

- (3)

- The amplitude modulation caused by the carrier eccentricity error can generate sidebands around meshing harmonics with an interval of rotation frequency of the carrier in the spectrum. The gear cracks induce a series of periodic impacts in the time-domain signal, and the joint effect of the carrier eccentricity error and gear cracks makes the sidebands more complex. The coupling of this effect with gear cracks generates more complex sidebands, while the coupling of different gear cracks generates a new set of impact components and causes severe degradation of the system performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Nomenclature | Specification |

| Three degrees of freedom: x, y represent translational degrees of freedom, θ represents torsional degree of freedom | |

| Carrier, ring gear, sun gear, and planet | |

| Number of planets | |

| Teeth number of the ring gear, sun gear, and planet | |

| The radius of the indexing circle, base circle, and root circle of component j | |

| Distance from the planet geometric center to the carrier geometric center | |

| Theoretical and actual rotation center of the carrier | |

| Magnitude and phase angle of the carrier eccentricity error | |

| Theoretical and actual rotation radius of planet | |

| Initial position angle of planet | |

| Theoretical and actual meshing position of planet at time t | |

| Theoretical meshing angle | |

| Theoretical and actual center distance about planet at time t | |

| Actual meshing angle of the or meshing pair at time t | |

| Actual contact ratio of the or meshing pair at time t | |

| Variation of the actual meshing angle of the or meshing pair at time t | |

| Number of teeth and addendum meshing angle of the driving gear | |

| Number of teeth and addendum meshing angle of the driven gear | |

| Rotating speed of the sun gear and carrier | |

| Meshing force | |

| Effective calculated length of the cantilever beam | |

| Half-tooth angle of calculation point | |

| Range from the base circle to the root circle | |

| Bending stiffness, shear stiffness, axial compression stiffness and Hertzian contact stiffness of gears, and comprehensive meshing stiffness | |

| d | Distance from the contact point to the root circle |

| l | Distance from the section area to the root circle |

| Angle between the vertical line of the action line and the tooth center line | |

| h | Distance from the contact point to the tooth centerline |

| Length from the fillet to the dedendum | |

| Section area and area moment of inertia of tooth | |

| E, G, v | Young’s modulus, shear modulus, and Poisson’s ratio |

| Distance from the section area to the tooth centerline | |

| w | Tooth width |

| The half-tooth angle on the base circle and root circle | |

| Base pitch | |

| Angular displacement of the or meshing pair | |

| Meshing angle of the driving and driven gear in the j-th tooth pair | |

| Angular displacement of the driving gear | |

| Addendum meshing angle | |

| Length of the crack before and after the tooth centerline | |

| β | Angle between the crack extension line and the tooth centerline |

| Distance from the crack tip to the tooth centerline | |

| Distance from the end of the crack extending to the base circle and root circle | |

| Length of the crack tip stress boundary line | |

| Half tooth angle of the crack tip and stress boundary point on the tooth crack | |

| Maximum length of the crack across the whole tooth | |

| XOY | Absolute coordinate of the system |

| Planetary gear coordinate system keeping relative static with the carrier | |

| Theoretical and actual meshing positions of planet in XOY | |

| Magnitude and phase angle of the deviation vector of planet pi in | |

| Equivalent displacement mapping of the planet deviation vector onto the acting line of or meshing pair | |

| Relative meshing angle and relative displacement of or meshing pair | |

| Mapping of linear displacement of planet in x and y directions | |

| Displacement of component j in x and y directions | |

| Rotation angle of component j and its linear displacement in the rotational direction | |

| Meshing force of the or meshing pair | |

| Mesh damping coefficient and scale constant of the or meshing pair | |

| Average mesh damping coefficient, average meshing stiffness, and equivalent mass of the or meshing pair | |

| Mesh damping ratio | |

| Supporting force of component j in x, y, and directions | |

| Component of the supporting force on planet in x and y directions | |

| Radial support stiffness and support damping coefficient of component j | |

| Torsional support stiffness and support damping coefficient of component j | |

| Radial support stiffness and support damping coefficient of planet | |

| Mass and mass moment of inertia of component j | |

| Input Torque and Output Torque | |

| Mass matrix, mesh damping matrix, support damping matrix, meshing stiffness matrix, support stiffness matrix, displacement matrix, and load matrix | |

| Meshing frequency and meshing period | |

| Rotation frequency of the carrier and its corresponding period | |

| Characteristic frequency of the planet local fault and corresponding period | |

| Characteristic frequency of the ring gear local fault and corresponding period | |

| Rotation frequency of the sun gear | |

| Characteristic frequency of the sun gear local fault and corresponding period | |

| Characteristic frequency and corresponding period of the sun gear and the planet gear compound fault | |

| Characteristic frequency and corresponding period of the planet and ring gear compound fault |

Appendix B

References

- Shen, Z.X.; Qiao, B.J.; Yang, L.H.; Luo, W.; Yang, Z.B.; Chen, X.F. Fault mechanism and dynamic modeling of planetary gear with gear wear. Mech. Mach. Theory 2021, 155, 104098. [Google Scholar] [CrossRef]

- Dong, H.M.; Zhang, C.; Bai, S.P.; Wang, D.L. Modeling, analysis and testing of load distribution for planetary gear trains with 3D carrier pinhole position errors. Int. J. Precis. Eng. Man. 2019, 20, 1381–1394. [Google Scholar] [CrossRef]

- Wang, C.G.; Li, H.K.; Ou, J.Y.; Hu, R.J.; Hu, S.L.; Liu, A.Q. Identification of planetary gearbox weak compound fault based on parallel dual-parameter optimized resonance sparse decomposition and improved MOMEDA. Measurement 2020, 165, 108079. [Google Scholar] [CrossRef]

- Lyu, X.; Hu, Z.Q.; Zhou, H.L.; Wang, Q. Application of improved MCKD method based on QGA in planetary gear compound fault diagnosis. Measurement 2019, 139, 236–248. [Google Scholar] [CrossRef]

- Zhao, D.Z.; Cheng, W.D.; Gao, R.X.; Yan, R.Q.; Wang, P. Generalized Vold–Kalman filtering for nonstationary compound faults feature extraction of bearing and gear. IEEE Trans. Instrum. Meas. 2019, 69, 401–410. [Google Scholar] [CrossRef]

- Chen, Y.J.; Rao, M.; Feng, K.; Zuo, M.J. Physics-Informed LSTM hyperparameters selection for gearbox fault detection. Mech. Syst. Signal Process. 2022, 171, 108907. [Google Scholar] [CrossRef]

- He, G.L.; Li, J.L.; Ding, K.; Zhang, Z.G. Feature extraction of gear and bearing compound faults based on vibration signal sparse decomposition. Appl. Acoust. 2022, 189, 108604. [Google Scholar] [CrossRef]

- Moshrefzadeh, A.; Fasana, A. Planetary gearbox with localised bearings and gears faults: Simulation and time/frequency analysis. Meccanica 2017, 52, 3759–3779. [Google Scholar] [CrossRef]

- Ma, R.; Chen, Y.S. Research on the dynamic mechanism of the gear system with local crack and spalling failure. Eng. Fail. Anal. 2012, 26, 12–20. [Google Scholar] [CrossRef]

- Wang, X. A study on coupling faults’ characteristics of fixed-axis gear crack and planetary gear wear. Shock Vib. 2018, 2018, 4692796. [Google Scholar] [CrossRef]

- Ouyang, T.C.; Wang, G.; Cheng, L.; Wang, J.X.; Yang, R. Comprehensive diagnosis and analysis of spur gears with pitting-crack coupling faults. Mech. Mach. Theory 2022, 176, 104968. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.F.; Wang, L.Z. Research on Root Strain Response Characteristics of Inner Ring of Planetary Gear Transmission System with Crack Fault. Sensors 2023, 23, 253. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.K.; Huangfu, Y.F.; Zhao, Z.F.; Ma, H.; Dong, X.J. Dynamic modeling of the gear-rotor systems with spatial propagation crack and complicated foundation structure. Mech. Mach. Theory 2022, 172, 104827. [Google Scholar] [CrossRef]

- Yuan, B.; Chang, L.H.; Liu, G.; Chang, S.; Liu, L.; Shen, Y.B. An efficient three-dimensional dynamic contact model for cylindrical gear pairs with distributed tooth flank errors. Mech. Mach. Theory 2020, 152, 103930. [Google Scholar] [CrossRef]

- Cao, Z.; Rao, M. Coupling effects of manufacturing error and flexible ring gear rim on dynamic features of planetary gear. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 5234–5246. [Google Scholar] [CrossRef]

- Ren, F.; Li, A.S.; Shi, G.Q.; Wu, X.L.; Wang, N. The effects of the planet–gear manufacturing eccentric errors on the dynamic properties for herringbone planetary gears. Appl. Acoust. 2020, 10, 1060. [Google Scholar] [CrossRef]

- Sanchez-Espiga, J.; Fernandez-del-Rincon, A.; Iglesias, M.; Viadero, F. Use of sun gear orbits to obtain the load sharing in planetary transmissions and its impact in the tooth load. Mech. Mach. Theory 2023, 181, 105216. [Google Scholar] [CrossRef]

- Zhao, B.S.; Huangfu, Y.F.; Ma, H.; Zhao, Z.F.; Wang, K. The influence of the geometric eccentricity on the dynamic behaviors of helical gear systems. Eng. Fail. Anal. 2020, 118, 104907. [Google Scholar] [CrossRef]

- Mo, S.; Wang, D.D.; Hu, X.S.; Bao, H.Y.; Cen, G.J.; Huang, Y.S. Dynamic characteristics of helical gear with root crack and friction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 3163–3180. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, N.Q.; Tang, J.Y.; Hu, J.; Zhang, L.; Cheng, Z. Dynamic analysis for a spur geared rotor system with tooth tip chipping based on an improved time-varying mesh stiffness model. Mech. Mach. Theory 2021, 165, 104435. [Google Scholar] [CrossRef]

- Doğan, O.; Kalay, O.C.; Karpat, F. Influence of tooth root cracks on the mesh stiffness of asymmetric spur gear pair with different backup ratios. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 717–731. [Google Scholar] [CrossRef]

- Meng, F.S.; Xia, H.; Zhang, X.; Wang, J.X. A new tooth pitting modeling method based on matrix equation for evaluating time-varying mesh stiffness. Eng. Fail. Anal. 2022, 142, 106799. [Google Scholar] [CrossRef]

- Tian, H.X.; Han, H.Z.; Zhao, Z.F.; Han, C.Y.; Ma, H. Wear prediction and meshing characteristics for the planetary gear set considering angular misalignment and rotating carrier. Eng. Fail. Anal. 2022, 140, 106583. [Google Scholar] [CrossRef]

- Shen, Z.X.; Qiao, B.J.; Yang, L.H.; Luo, W.; Chen, X.F. Evaluating the influence of tooth surface wear on TVMS of planetary gear set. Mech. Mach. Theory 2019, 136, 206–223. [Google Scholar] [CrossRef]

- Liang, X.H.; Zuo, M.J.; Pandey, M. Analytically evaluating the influence of crack on the mesh stiffness of a planetary gear set. Mech. Mach. Theory 2014, 76, 20–38. [Google Scholar] [CrossRef]

- Liang, X.H.; Zuo, M.J.; Hoseini, M.R. Vibration signal modeling of a planetary gear set for tooth crack detection. Eng. Fail. Anal. 2015, 48, 185–200. [Google Scholar] [CrossRef]

- Feng, Z.P.; Zhao, L.L.; Chu, F.L. Vibration Spectral Characteristics of Localized Gear Fault of Planetary Gearboxes. Proc. Chin. Soc. Elect. Eng. 2013, 33, 119–127. [Google Scholar]

- Li, X.; Feng, Z.P. Vibration spectral features of planetary gearbox combined faults. Shock Vib. 2020, 39, 15–23. [Google Scholar]

| Parameter | Sun Gear | Planet | Ring Gear | Carrier |

|---|---|---|---|---|

| Number of teeth | 21 | 31 | 84 | / |

| Mass (kg) | 0.208 | 0.471 | 1.133 | 1.543 |

| Base circle radius (mm) | 19.7 | 29.1 | 78.9 | / |

| Mass moment of inertia (kg/m2) | 5.183 × 10−5 | 1.733 × 10−4 | 4.235 × 10−3 | 1.167 |

| Module (mm) | 2 | |||

| Tooth width (mm) | 22 | |||

| Theoretical meshing angle (deg.) | 20 | |||

| Theoretical contact ratio (deg.) | ||||

| Theoretical center distance (mm) | 52 | |||

| Support stiffness (N/m) | ||||

| Young’s modulus (GPa) | 206 | |||

| Poisson’s ratio | 0.3 | |||

| Case | Carrier Eccentricity Error | Types of Tooth Damage |

|---|---|---|

| 1 | e = 0.2 mm, γ = 45° | sun gear crack (20%) |

| 2 | e = 0.2 mm, γ = 45° | crack (40%, mesh with ring) |

| 3 | e = 0.2 mm, γ = 45° | crack (40%, mesh with sun gear) |

| 4 | e = 0.2 mm, γ = 45° | ring gear crack (20%) |

| 5 | e = 0.2 mm, γ = 45° | sun gear crack (20%) + crack (40%, mesh with ring) |

| 6 | e = 0.2 mm, γ = 45° | ring gear crack (35%) + crack (25%, mesh with sun gear) |

| fm/Hz | fc | fs | fp | fr | fsp | fpr | |

|---|---|---|---|---|---|---|---|

| 336 | 4 | 20 | 48 | 10.8387 | 12 | 1.5483 | 0.387 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Li, G.; Li, X.; Zhang, J.; Liu, R.; Shi, S. Compound Fault Characteristic Analysis for Fault Diagnosis of a Planetary Gear Train. Sensors 2024, 24, 927. https://doi.org/10.3390/s24030927

Ren Y, Li G, Li X, Zhang J, Liu R, Shi S. Compound Fault Characteristic Analysis for Fault Diagnosis of a Planetary Gear Train. Sensors. 2024; 24(3):927. https://doi.org/10.3390/s24030927

Chicago/Turabian StyleRen, Yulin, Guoyan Li, Xiong Li, Jingbin Zhang, Runjun Liu, and Sifan Shi. 2024. "Compound Fault Characteristic Analysis for Fault Diagnosis of a Planetary Gear Train" Sensors 24, no. 3: 927. https://doi.org/10.3390/s24030927

APA StyleRen, Y., Li, G., Li, X., Zhang, J., Liu, R., & Shi, S. (2024). Compound Fault Characteristic Analysis for Fault Diagnosis of a Planetary Gear Train. Sensors, 24(3), 927. https://doi.org/10.3390/s24030927