Electromechanical Properties of Smart Vitrimers Reinforced with Carbon Nanotubes for SHM Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis

2.3. Electrical Characterization

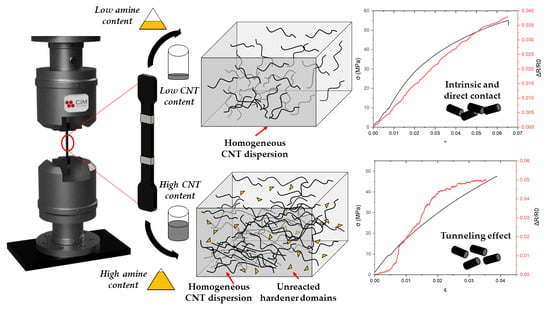

2.4. Strain Sensing Test via Electrical Measurements

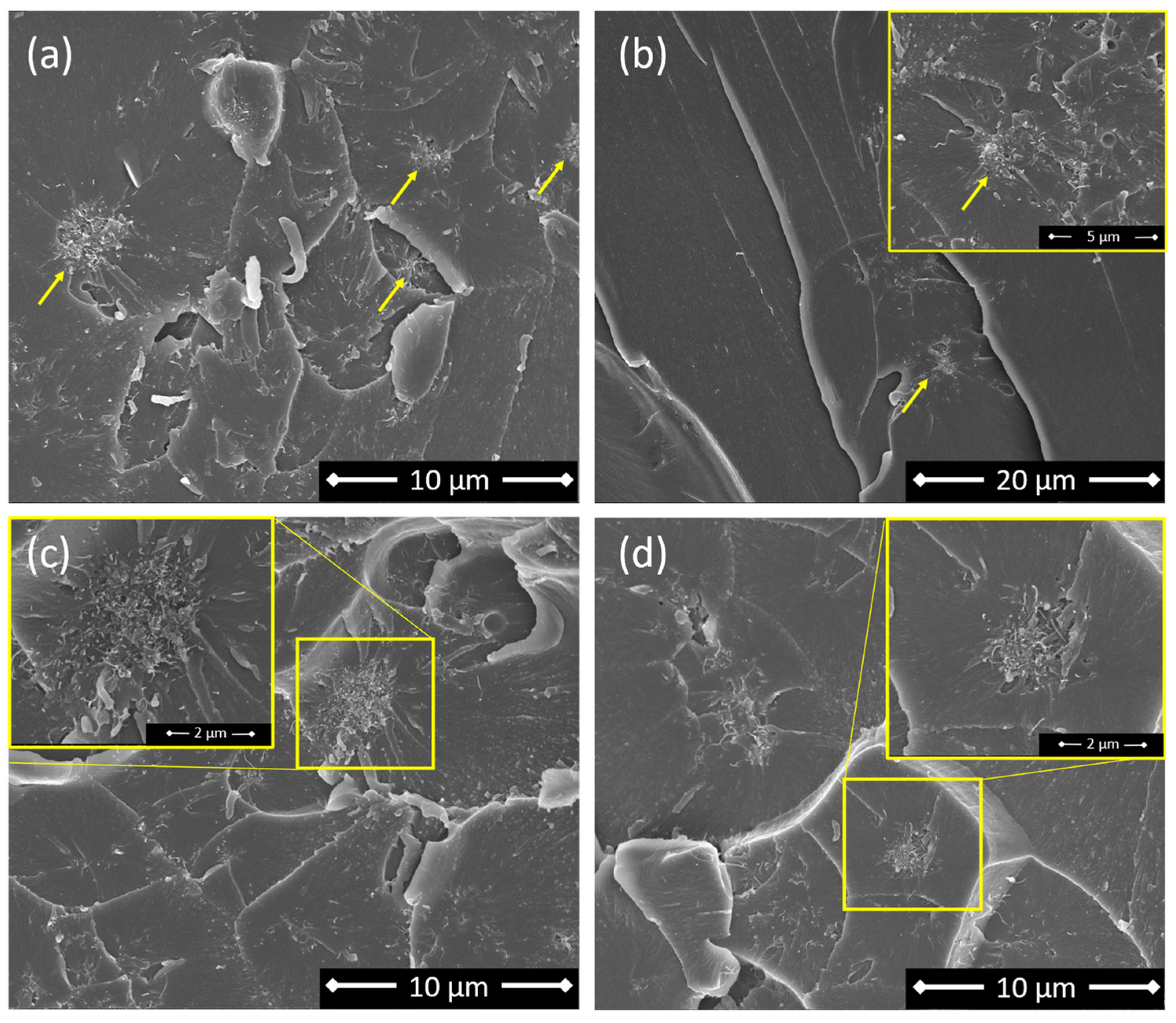

2.5. Microstructural Characterization

3. Results

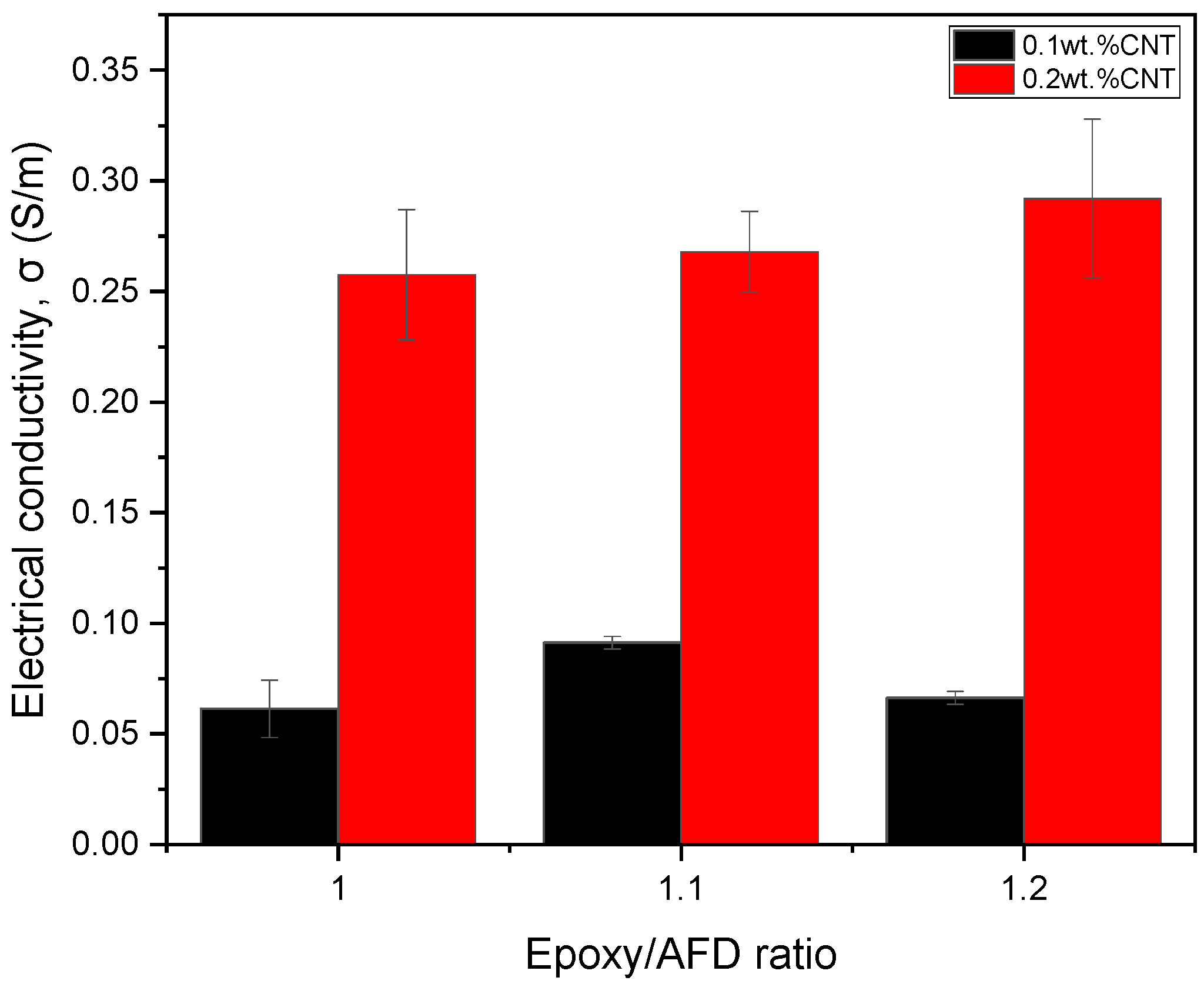

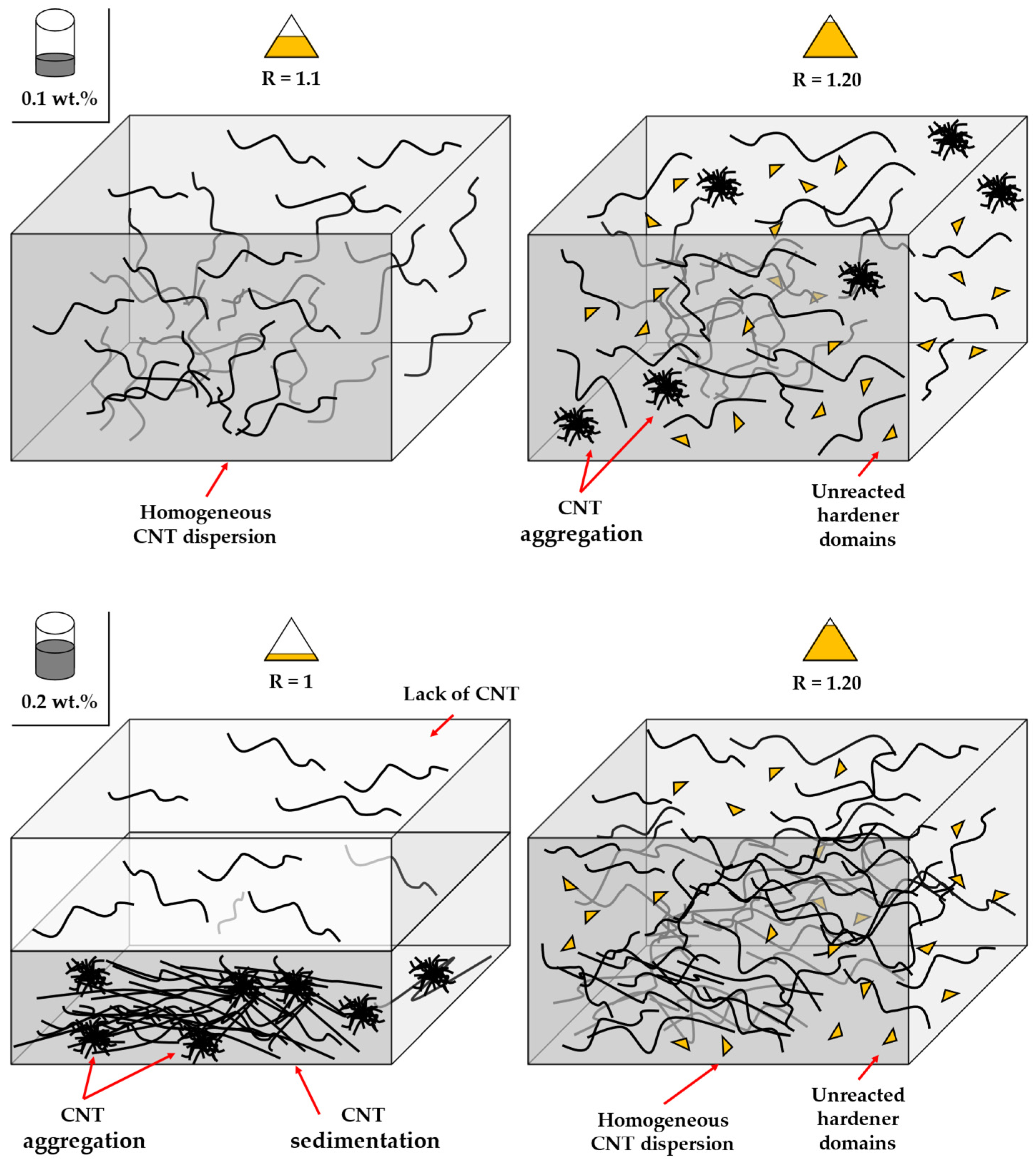

3.1. Electrical Conductivity

3.2. Mechanical and Strain-Sensing Analysis

3.2.1. Tensile Tests

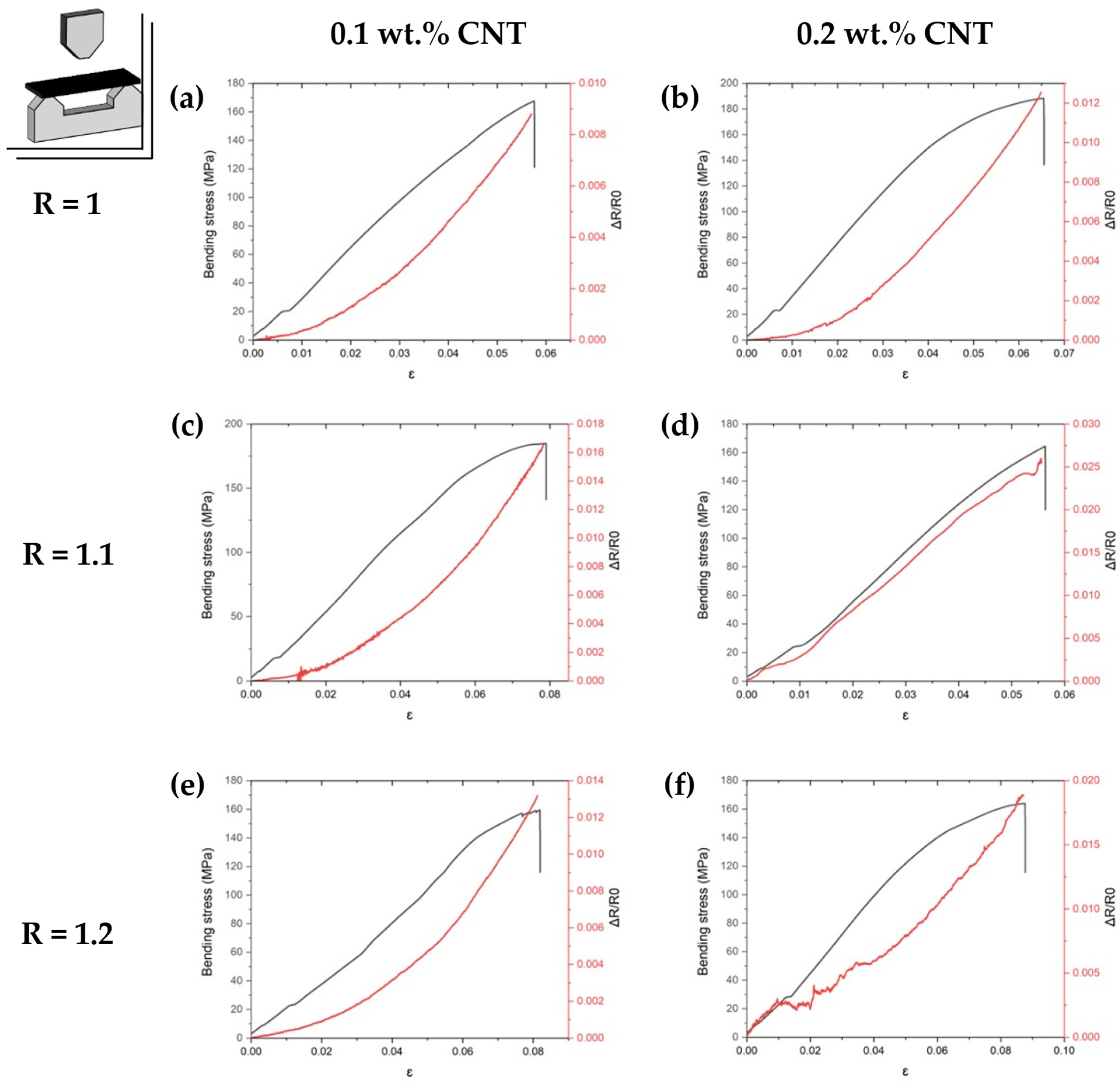

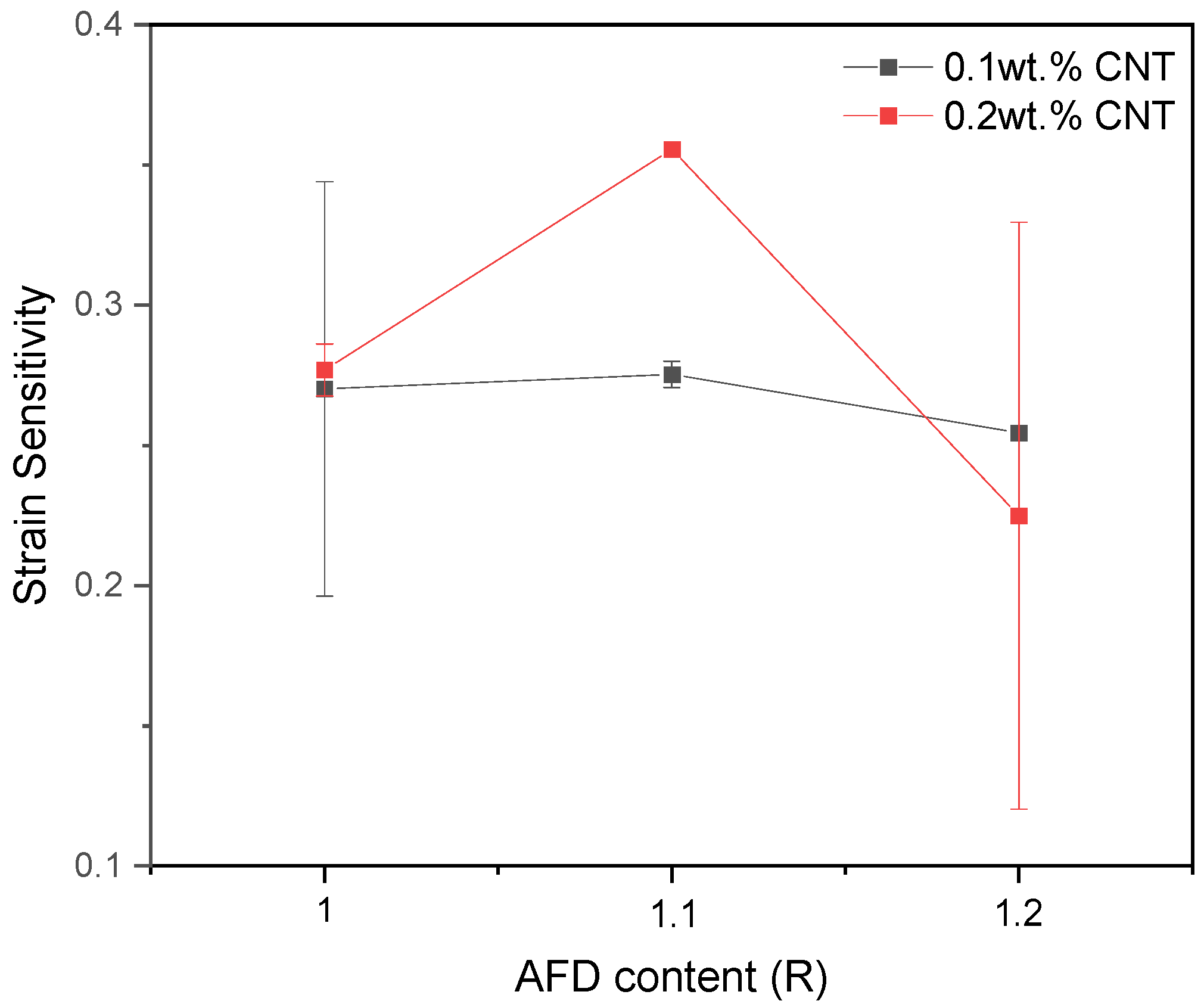

3.2.2. Bending Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soutis, C. Fibre Reinforced Composites in Aircraft Construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Dubon, J.; Seisdedos, G.; Watring, D.; Pajon, M.; Khizroev, S.; McDaniel, D.; Boesl, B. Multifunctional MEN-Doped Adhesives: Strengthening, Bond Quality Evaluation, and Variations in Magnetic Signal with Environmental Exposure. Appl. Sci. 2022, 12, 8238. [Google Scholar] [CrossRef]

- Liao, Y.; Qing, X.; Wang, Y.; Zhang, F. Damage Localization for Composite Structure Using Guided Wave Signals with Gramian Angular Field Image Coding and Convolutional Neural Networks. Compos. Struct. 2023, 312, 116871. [Google Scholar] [CrossRef]

- Balaji, R.; Sasikumar, M. Structural Health Monitoring (SHM) System for Polymer Composites: A Review. Indian. J. Sci. Technol. 2016, 9, 1–12. [Google Scholar] [CrossRef]

- Mohammadi, S.; Yousefi, M.; Khazaei, M. A Review on Composite Patch Repairs and the Most Important Parameters Affecting Its Efficiency and Durability. J. Reinf. Plast. Compos. 2020, 40, 3–15. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; de Barros, S. Bonded Repair of Composite Structures in Aerospace Application: A Review on Environmental Issues. Appl. Adhes. Sci. 2018, 6, 3. [Google Scholar] [CrossRef]

- Omairey, S.; Jayasree, N.; Kazilas, M. Defects and Uncertainties of Adhesively Bonded Composite Joints. SN Appl. Sci. 2021, 3, 769. [Google Scholar] [CrossRef]

- Azcune, I.; Odriozola, I. Aromatic Disulfide Crosslinks in Polymer Systems: Self-Healing, Reprocessability, Recyclability and More. Eur. Polym. J. 2016, 84, 147–160. [Google Scholar] [CrossRef]

- Santiago, D.; Guzmán, D.; Padilla, J.; Verdugo, P.; De la Flor, S.; Serra, À. Recyclable and Reprocessable Epoxy Vitrimer Adhesives. ACS Appl. Polym. Mater. 2023, 5, 2006–2015. [Google Scholar] [CrossRef]

- Takahashi, A.; Ohishi, T.; Goseki, R.; Otsuka, H. Degradable Epoxy Resins Prepared from Diepoxide Monomer with Dynamic Covalent Disulfide Linkage. Polymer 2016, 82, 319–326. [Google Scholar] [CrossRef]

- Di Mauro, C.; Malburet, S.; Graillot, A.; Mija, A. Recyclable, Repairable, and Reshapable (3R) Thermoset Materials with Shape Memory Properties from Bio-Based Epoxidized Vegetable Oils. ACS Appl. Bio Mater. 2020, 3, 8094–8104. [Google Scholar] [CrossRef]

- Akhras, G. Smart Materials and Smart Systems for the Future. Can. Mil. J. 2000, 1, 25–31. [Google Scholar]

- Chen, X.; Topac, T.; Smith, W.; Ladpli, P.; Liu, C.; Chang, F.-K. Characterization of Distributed Microfabricated Strain Gauges on Stretchable Sensor Networks for Structural Applications. Sensors 2018, 18, 3260. [Google Scholar] [CrossRef]

- Seisdedos, G.; Viamontes, E.; Salazar, E.; Ontiveros, M.; Pantea, C.; Davis, E.S.; Rockward, T.; McDaniel, D.; Boesl, B. Assessment and Non-Destructive Evaluation of the Influence of Residual Solvent on a Two-Part Epoxy-Based Adhesive Using Ultrasonics. Appl. Sci. 2023, 13, 3883. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Khellil, K.; Lachat, R. On the Use of In-Situ Piezoelectric Sensors for the Manufacturing and Structural Health Monitoring of Polymer-Matrix Composites: A Literature Review. Compos. Struct. 2019, 215, 127–149. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of Fiber Optic Sensor Technologies for Strain/Temperature Sensing Applications in Composite Materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Kralovec, C.; Schagerl, M. Review of Structural Health Monitoring Methods Regarding a Multi-Sensor Approach for Damage Assessment of Metal and Composite Structures. Sensors 2020, 20, 826. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef] [PubMed]

- Manjakkal, L.; Szwagierczak, D.; Dahiya, R. Metal Oxides Based Electrochemical PH Sensors: Current Progress and Future Perspectives. Prog. Mater. Sci. 2020, 109, 100635. [Google Scholar] [CrossRef]

- Ju, M.; Dou, Z.; Li, J.-W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.-Z.; Gong, W.; Wang, K. Piezoelectric Materials and Sensors for Structural Health Monitoring: Fundamental Aspects, Current Status, and Future Perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef] [PubMed]

- Güemes, A.; Fernández-López, A.; Díaz-Maroto, P.F.; Lozano, A.; Sierra-Perez, J. Structural Health Monitoring in Composite Structures by Fiber-Optic Sensors. Sensors 2018, 18, 1094. [Google Scholar] [CrossRef]

- Zhu, Y.-K.; Tian, G.-Y.; Lu, R.-S.; Zhang, H. A Review of Optical NDT Technologies. Sensors 2011, 11, 7773–7798. [Google Scholar] [CrossRef]

- Luo, S.; Obitayo, W.; Liu, T. SWCNT-Thin-Film-Enabled Fiber Sensors for Lifelong Structural Health Monitoring of Polymeric Composites—From Manufacturing to Utilization to Failure. Carbon 2014, 76, 321–329. [Google Scholar] [CrossRef]

- Wang, Y.; Shu, R.; Zhang, X. Strong, Supertough and Self-Healing Biomimetic Layered Nanocomposites Enabled by Reversible Interfacial Polymer Chain Sliding. Angew. Chem. Int. Ed. 2023, 62, e202303446. [Google Scholar] [CrossRef]

- del Bosque, A.; Sánchez-Romate, X.F.; Sánchez, M.; Ureña, A. Flexible Wearable Sensors Based in Carbon Nanotubes Reinforced Poly(Ethylene Glycol) Diglycidyl Ether (PEGDGE): Analysis of Strain Sensitivity and Proof of Concept. Chemosensors 2021, 9, 158. [Google Scholar] [CrossRef]

- Payandehpeyman, J.; Mazaheri, M.; Zeraati, A.S.; Jamasb, S.; Sundararaj, U. Physics-Based Modeling and Experimental Study of Conductivity and Percolation Threshold in Carbon Black Polymer Nanocomposites. Appl. Compos. Mater. 2023. [Google Scholar] [CrossRef]

- Farhadpour, M.; Payandehpeyman, J.; Mazaheri, M.; Irandoust, N.; Pircheraghi, G.; Bagheri, R. Significance of Transcrystalline Layer Formation on Electrical Conductivity of Polyamide 6-Carbon Nanotube Nanocomposites: An Experimental and Theoretical Study. Compos. Part. A Appl. Sci. Manuf. 2024, 178, 107977. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Jiménez-Suárez, A.; Campo, M.; Ureña, A.; Prolongo, S.G. Electrical Properties and Strain Sensing Mechanisms in Hybrid Graphene Nanoplatelet/Carbon Nanotube Nanocomposites. Sensors 2021, 21, 5530. [Google Scholar] [CrossRef] [PubMed]

- 2-Aminophenyl Disulfide 98%|1141-88-4. Available online: https://www.sigmaaldrich.com/ES/es/product/aldrich/166766 (accessed on 19 December 2023).

- Gong, H.; Wu, J.; Zhao, Z.; Guo, Z.; Gao, L.; Zhang, B.; Li, M.H.; Hu, J. Recyclable High-Performance Glass-Fiber/Epoxy Composites with UV-Shielding and Intrinsic Damage Self-Reporting Properties. Chem. Eng. J. 2022, 446, 137392. [Google Scholar] [CrossRef]

- Ruiz de Luzuriaga, A.; Solera, G.; Azcarate-Ascasua, I.; Boucher, V.; Grande, H.J.; Rekondo, A. Chemical Control of the Aromatic Disulfide Exchange Kinetics for Tailor-Made Epoxy Vitrimers. Polym. 2022, 239, 124457. [Google Scholar] [CrossRef]

- Benazzo, F.; Rigamonti, D.; Bettini, P.; Sala, G.; Grande, A.M. Interlaminar Fracture of Structural Fibre/Epoxy Composites Integrating Damage Sensing and Healing. Compos. B Eng. 2022, 244, 110137. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Artigas, J.; Jiménez-Suárez, A.; Sánchez, M.; Güemes, A.; Ureña, A. Critical Parameters of Carbon Nanotube Reinforced Composites for Structural Health Monitoring Applications: Empirical Results versus Theoretical Predictions. Compos. Sci. Technol. 2019, 171, 44–53. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Jiménez-Suárez, A.; Sánchez, M.; Güemes, A.; Ureña, A. Novel Approach to Percolation Threshold on Electrical Conductivity of Carbon Nanotube Reinforced Nanocomposites. RSC Adv. 2016, 6, 43418–43428. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Cortés, A.; Jiménez-Suárez, A.; Prolongo, S.G. Hardener Isomerism and Content of Dynamic Disulfide Bond Effect on Chemical Recycling of Epoxy Networks. ACS Appl. Polym. Mater. 2022, 4, 5068–5076. [Google Scholar] [CrossRef]

- ASTM D257-14; Standard Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastic. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Isarn, I.; Bonnaud, L.; Massagués, L.; Serra, À.; Ferrando, F. Study of the Synergistic Effect of Boron Nitride and Carbon Nanotubes in the Improvement of Thermal Conductivity of Epoxy Composites. Polym. Int. 2020, 69, 280–290. [Google Scholar] [CrossRef]

- Fernandez-Nograro, F.; Valea, A.; Llano-Ponte, R.; Mondragon, I. Dynamic and Mechanical Properties of DGEBA/Poly(Propylene Oxide) Amine Based Epoxy Resins as a Function of Stoichiometry. Eur. Polym. J. 1996, 32, 257–266. [Google Scholar] [CrossRef]

- Backes, E.H.; Sene, T.S.; Passador, F.R.; Pessan, L.A.; Pessan, L.A. Electrical, Thermal and Mechanical Properties of Epoxy/CNT/Calcium Carbonate Nanocomposites. Mater. Res. 2018, 21, e20170801. [Google Scholar] [CrossRef]

- Yang, Q.; He, X.; Liu, X.; Leng, F.; Mai, Y.-W. The Effective Properties and Local Aggregation Effect of CNT/SMP Composites. Compos. B Eng. 2012, 43, 33–38. [Google Scholar] [CrossRef]

- Garcia, F.G.; Soares, B.G.; Pita, V.J.R.R.; Sánchez, R.; Rieumont, J. Mechanical Properties of Epoxy Networks Based on DGEBA and Aliphatic Amines. J. Appl. Polym. Sci. 2007, 106, 2047–2055. [Google Scholar] [CrossRef]

- Galy, J.; Sabra, A.; Pascault, J.-P. Characterization of Epoxy Thermosetting Systems by Differential Scanning Calorimetry. Polym. Eng. Sci. 1986, 26, 1514–1523. [Google Scholar] [CrossRef]

- Li, B.; Zhu, G.; Hao, Y.; Ren, T. An Investigation on the Performance of Epoxy Vitrimers Based on Disulfide Bond. J. Appl. Polym. Sci. 2022, 139, 51589. [Google Scholar] [CrossRef]

- Esmaeili, A.; Sbarufatti, C.; Youssef, K.; Jiménez-Suárez, A.; Ureña, A.; Hamouda, A.M.S. Enhanced Tensile Strength, Fracture Toughness and Piezoresistive Performances of CNT Based Epoxy Nanocomposites Using Toroidal Stirring Assisted Ultra-Sonication. Mech. Adv. Mater. Struct. 2022, 29, 5557–5566. [Google Scholar] [CrossRef]

- Cortés, A.; Sánchez-Romate, X.F.; Jiménez-Suárez, A.; Campo, M.; Ureña, A.; Prolongo, S.G. Mechanical and Strain-Sensing Capabilities of Carbon Nanotube Reinforced Composites by Digital Light Processing 3D Printing Technology. Polymers 2020, 12, 975. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.R.; Estaji, S.; Kiaei, H.; Mansourian-Tabaei, M.; Nouranian, S.; Jafari, S.H.; Ruckdäschel, H.; Arjmand, M.; Khonakdar, H.A. A Review of Electrical and Thermal Conductivities of Epoxy Resin Systems Reinforced with Carbon Nanotubes and Graphene-Based Nanoparticles. Polym. Test. 2022, 112, 107645. [Google Scholar] [CrossRef]

- Li, J.; Ma, P.C.; Chow, W.S.; To, C.K.; Tang, B.Z.; Kim, J.-K. Correlations between Percolation Threshold, Dispersion State, and Aspect Ratio of Carbon Nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- del Bosque, A.; Fernández Sánchez-Romate, X.X.; De La Llana Calvo, Á.; Fernández, P.R.; Borromeo, S.; Sánchez, M.; Ureña, A. Highly Flexible Strain Sensors Based on CNT-Reinforced Ecoflex Silicone Rubber for Wireless Facemask Breathing Monitoring via Bluetooth. ACS Appl. Polym. Mater. 2023, 5, 8589–8599. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Vertuccio, L.; Guadagno, L. Experimental and Theoretical Study on Piezoresistive Properties of a Structural Resin Reinforced with Carbon Nanotubes for Strain Sensing and Damage Monitoring. Compos. B Eng. 2018, 145, 90–99. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Tucci, V.; Russo, S. Piezoresistive Properties of Resin Reinforced with Carbon Nanotubes for Health-Monitoring of Aircraft Primary Structures. Compos. B Eng. 2016, 107, 192–202. [Google Scholar] [CrossRef]

- Meng, J.; Zeng, Y.; Chen, P.; Zhang, J.; Yao, C.; Fang, Z.; Ouyang, P.; Guo, K. Flame Retardancy and Mechanical Properties of Bio-Based Furan Epoxy Resins with High Crosslink Density. Macromol. Mater. Eng. 2020, 305, 1900587. [Google Scholar] [CrossRef]

| Cycle | Gap 1 (μm) | Gap 2 (μm) | Rotating Speed of the Last Roll (rpm) |

|---|---|---|---|

| 1 | 120 | 40 | 250 |

| 2 | 75 | 25 | 250 |

| 3 | 45 | 15 | 250 |

| 4–7 | 15 | 5 | 250 |

| CNT Content | Epoxy/AFD Ratio | Tensile Modulus (GPa) | Tensile Strength (MPa) | Failure Strain (%) | Gauge Factor |

|---|---|---|---|---|---|

| 0.1 wt.% | R = 1 | 1.68 ± 0.13 | 55.15 ± 0.72 | 7.54 ± 0.89 | 2.05 ± 0.63 |

| R = 1.1 | 1.7 ± 0.21 | 80.18 ± 3.19 | 8.6 ± 2.14 | 1.55 ± 0.02 | |

| R = 1.2 | 1.44 ± 0.46 | 47.37 ± 13.41 | 11.71 ± 3 | 2.61 ± 0.17 | |

| 0.2 wt.% | R = 1 | 1.81 ± 0.09 | 60.46 ± 7.01 | 7.12 ± 1.88 | 0.69 ± 0.23 |

| R = 1.1 | 1.78 ± 0.36 | 73.3 ± 7.35 | 7.03 ± 1.08 | 0.63 ± 0.15 | |

| R = 1.2 | 1.81 ± 0.18 | 51.44 ± 8.27 | 5.5 ± 2.45 | 2.22 ± 0.01 * |

| CNT Content | Epoxy/AFD Ratio | Flexural Modulus (GPa) | Flexural Strength (MPa) | Failure Strain (%) | Gauge Factor |

|---|---|---|---|---|---|

| 0.1 wt.% | R = 1 | 2.51 ± 0.76 | 177.26 ± 14.32 | 7.09 ± 1.41 | 0.27 ± 0.07 |

| R = 1.1 | 2.36 ± 0.2 | 185.63 ± 18.26 | 8.16 ± 1.13 | 0.28 ± 0.01 | |

| R = 1.2 | 1.50 ± 0.51 | 142.17 ± 16.87 | 8.61 ± 3.09 | 0.26 | |

| 0.2 wt.% | R = 1 | 2.96 ± 0.57 | 191.97 ± 5.2 | 6.73 ± 0.36 | 0.26 |

| R = 1.1 | 2.45 ± 0.28 | 194.81 ± 28.91 | 7.97 ± 2.02 | 0.28 | |

| R = 1.2 | 2.52 ± 0.43 | 183.91 ± 25.13 | 7.25 ± 1.85 | 0.24 ± 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Sánchez, J.; Sánchez-Romate, X.F.; Espadas, F.J.; Prolongo, S.G.; Jiménez-Suárez, A. Electromechanical Properties of Smart Vitrimers Reinforced with Carbon Nanotubes for SHM Applications. Sensors 2024, 24, 806. https://doi.org/10.3390/s24030806

Gómez-Sánchez J, Sánchez-Romate XF, Espadas FJ, Prolongo SG, Jiménez-Suárez A. Electromechanical Properties of Smart Vitrimers Reinforced with Carbon Nanotubes for SHM Applications. Sensors. 2024; 24(3):806. https://doi.org/10.3390/s24030806

Chicago/Turabian StyleGómez-Sánchez, Javier, Xoan F. Sánchez-Romate, Francisco Javier Espadas, Silvia G. Prolongo, and Alberto Jiménez-Suárez. 2024. "Electromechanical Properties of Smart Vitrimers Reinforced with Carbon Nanotubes for SHM Applications" Sensors 24, no. 3: 806. https://doi.org/10.3390/s24030806

APA StyleGómez-Sánchez, J., Sánchez-Romate, X. F., Espadas, F. J., Prolongo, S. G., & Jiménez-Suárez, A. (2024). Electromechanical Properties of Smart Vitrimers Reinforced with Carbon Nanotubes for SHM Applications. Sensors, 24(3), 806. https://doi.org/10.3390/s24030806