Optical Sensing Using Hybrid Multilayer Grating Metasurfaces with Customized Spectral Response

Abstract

1. Introduction

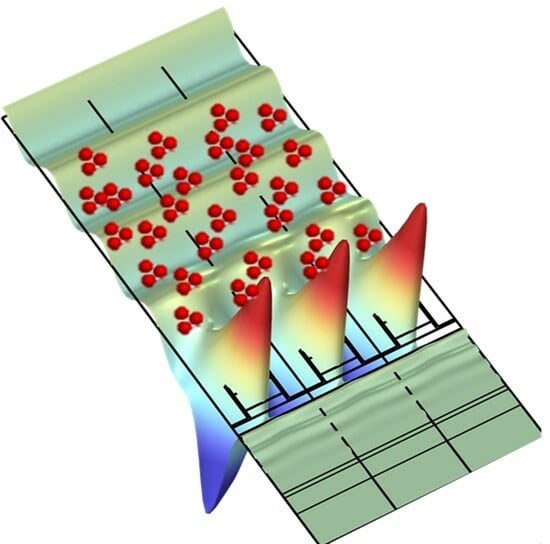

2. Design and Model

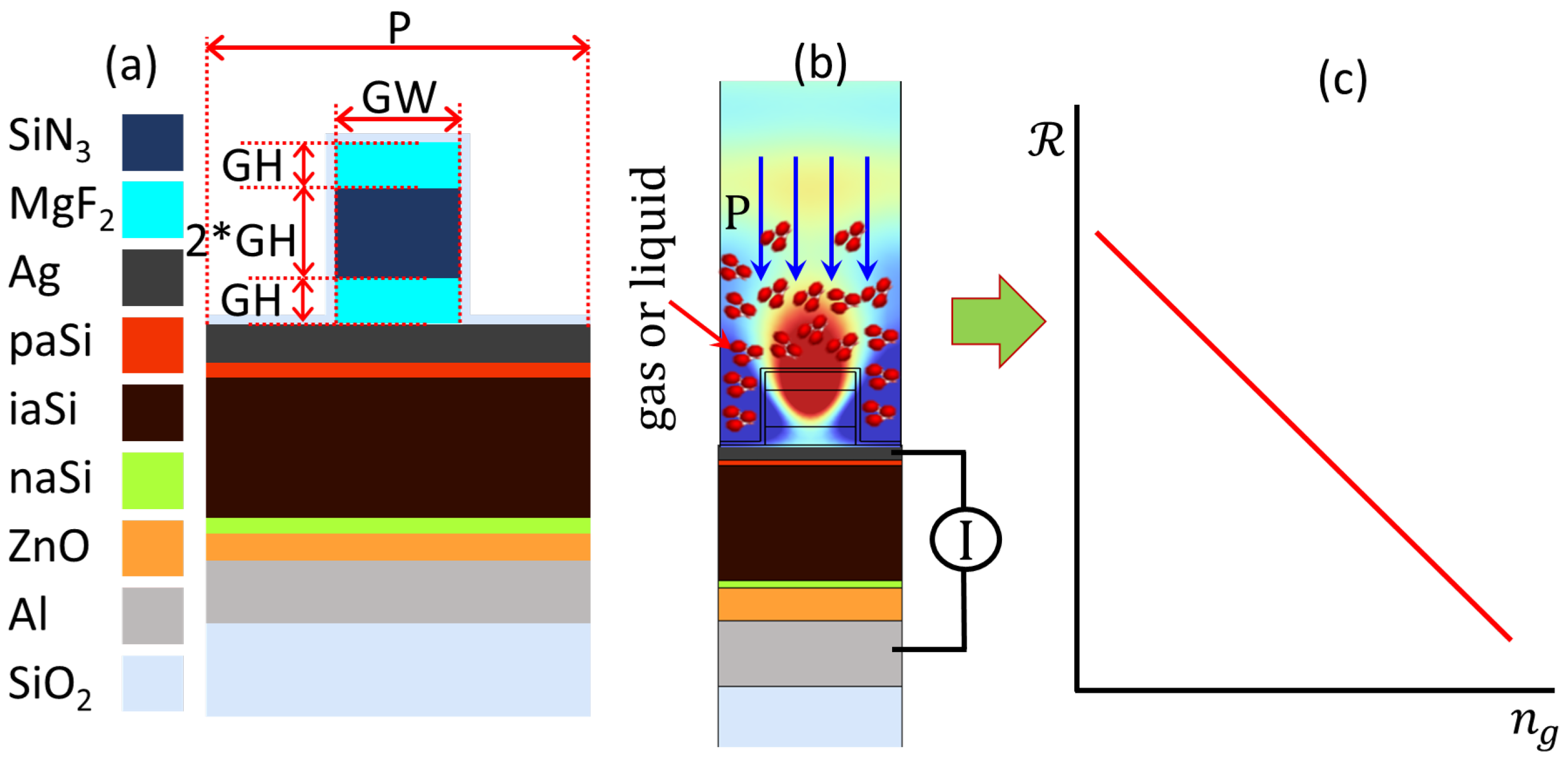

2.1. Solar Cell with Multilayer Grating

2.2. Optical Model and Merit Function

3. Results and Discussion

4. Gas Sensing with High Resolution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hossain, M.N.; Tanvir, J.; Aktar, M.N.; Ahmed, K. Design of a fuel adulteration detector sensor based on surface plasmon resonance. Opt. Quantum Electron. 2023, 55, 61. [Google Scholar] [CrossRef]

- Liu, W.; Liu, C.; Wang, J.; Lv, J.; Lv, Y.; Yang, L.; An, N.; Yi, Z.; Liu, Q.; Hu, C.; et al. Surface plasmon resonance sensor composed of microstructured optical fibers for monitoring of external and internal environments in biological and environmental sensing. Results Phys. 2023, 47, 106365. [Google Scholar] [CrossRef]

- Daniyal, W.; Fen, Y.W.; Fauzi, N.I.M.; Hashim, H.S.; Ramdzan, N.S.M.; Omar, N.A.S. Recent advances in surface plasmon resonance optical sensors for potential application in environmental monitoring. Sens. Mater 2020, 32, 4191–4200. [Google Scholar] [CrossRef]

- Chao, C.T.C.; Chau, Y.F.C.; Mahadi, A.H.; Kooh, M.R.R.; Kumara, N.T.R.N.; Chiang, H.P. Plasmonic refractive index sensor based on the combination of rectangular and circular resonators including baffles. Chin. J. Phys. 2021, 71, 286–299. [Google Scholar]

- Chou Chau, Y.F.; Ming, T.Y.; Chou Chao, C.T.; Thotagamuge, R.; Kooh, M.R.R.; Huang, H.J.; Lim, C.M.; Chiang, H.P. Significantly enhanced coupling effect and gap plasmon resonance in a MIM-cavity based sensing structure. Sci. Rep. 2021, 11, 18515. [Google Scholar] [CrossRef] [PubMed]

- Elshorbagy, M.H.; Cuadrado, A.; González, G.; González, F.J.; Alda, J. Performance improvement of refractometric sensors through hybrid plasmonic—Fano resonances. J. Light. Technol. 2019, 37, 2905–2913. [Google Scholar] [CrossRef]

- Sang, W.; Huang, S.; Chen, J.; Dai, X.; Liu, H.; Zeng, Y.; Zhang, T.; Wang, X.; Qu, J.; Ho, H.P.; et al. Wavelength sequential selection technique for high-throughput multi-channel phase interrogation surface plasmon resonance imaging sensing. Talanta 2023, 258, 124405. [Google Scholar] [CrossRef]

- Koresawa, H.; Seki, K.; Nishimoto, K.; Hase, E.; Tokizane, Y.; Yano, T.A.; Kajisa, T.; Minamikawa, T.; Yasui, T. Real-time hybrid angular-interrogation surface plasmon resonance sensor in the near-infrared region for wide dynamic range refractive index sensing. Sci. Rep. 2023, 13, 15655. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Niu, Z.; Liu, L.; Zeng, Y.; Ma, L.; Nie, Z.; Tian, Z.; Kai, D.; Zhang, F.; Liu, G.; et al. Intensity Interrogation-Based High-Sensitivity Surface Plasmon Resonance Imaging Biosensor for Apoptosis Detection in Cancer. Biosensors 2023, 13, 946. [Google Scholar] [CrossRef]

- Shi, Z.J.; Guo, S.L.; Li, X.; Li, Z.Q.; Meng, S.H.; Li, C.Z. Sensitivity enhancement of a wavelength interrogation-based optical fiber surface plasmon resonance sensor for hemoglobin concentration using barium titanate. Opt. Appl. 2023, 53, 167–184. [Google Scholar]

- Liu, Z.; Guo, T.; Tan, Q.; Hu, Z.; Sun, Y.; Fan, H.; Zhang, Z.; Jin, Y.; He, S. Phase Interrogation Sensor Based on All-Dielectric BIC Metasurface. Nano Lett. 2023, 23, 10441–10448. [Google Scholar] [CrossRef]

- Bang, H. Integrated Optical SPR (Surface Plasmon Resonance) Sensor Based on Optoelectronic Platform. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, 2008. [Google Scholar]

- Lotfiani, A.; Ghanaatshoar, M.; Mohseni, S. Miniaturized optoelectronic SPR sensor based on integrated planar waveguide and MIM hot-electron photodetector. IEEE Trans. Electron. Devices 2019, 66, 5215–5220. [Google Scholar] [CrossRef]

- Ai, B.; Fan, Z.; Wong, Z.J. Plasmonic—Perovskite solar cells, light emitters, and sensors. Microsyst. Nanoeng. 2022, 8, 5. [Google Scholar] [CrossRef]

- Rawat, J.; Sharma, H.; Dwivedi, C. One-Dimensional Semiconducting Hybrid Nanostructure: Gas Sensing and Optoelectronic Applications. In 1D Semiconducting Hybrid Nanostructures: Synthesis and Applications in Gas Sensing and Optoelectronics; Wiley: Hoboken, NJ, USA, 2023; pp. 1–26. [Google Scholar]

- Yi, H.; Ma, Y.; Ye, Q.; Lu, J.; Wang, W.; Zheng, Z.; Ma, C.; Yao, J.; Yang, G. Promoting 2D Material Photodetectors by Optical Antennas beyond Noble Metals. Adv. Sens. Res. 2023, 2, 2200079. [Google Scholar] [CrossRef]

- Elshorbagy, M.H.; Esteban, Ó.; Cuadrado, A.; Alda, J. Optoelectronic refractometric sensing device for gases based on dielectric bow-ties and amorphous silicon solar cells. Sci. Rep. 2022, 12, 18355. [Google Scholar] [CrossRef]

- Elshorbagy, M.H.; Cuadrado, A.; Romero, B.; Alda, J. Enabling selective absorption in perovskite solar cells for refractometric sensing of gases. Sci. Rep. 2020, 10, 7761. [Google Scholar] [CrossRef]

- Kang, J.; Yoo, Y.J.; Ko, J.H.; Mahmud, A.A.; Song, Y.M. Trilayered Gires–Tournois Resonator with Ultrasensitive Slow-Light Condition for Colorimetric Detection of Bioparticles. Nanomaterials 2023, 13, 319. [Google Scholar] [CrossRef] [PubMed]

- Maurya, S.K. Control of Light Coherence, Polarization, and Propagation Using Nanostructures. Ph.D. Thesis, Aalto University, Espoo, Finland, 2023. [Google Scholar]

- Elshorbagy, M.H.; Cuadrado, A.; Alda, J. High-sensitivity integrated devices based on surface plasmon resonance for sensing applications. Photonics Res. 2017, 5, 654–661. [Google Scholar] [CrossRef]

- Vatnik, I.D.; Gorbunov, O.A.; Churkin, D.V. Comparative Study of Ultra-Narrow-Mode Generation in Random Fiber Lasers Based on Different Fiber Types. Photonics 2023, 10, 1225. [Google Scholar] [CrossRef]

- Yi, Y.; Yi, Y.; Long, M.; Yi, Z.; Bian, L.; Li, G.; Zeng, L.; Li, H. Highly tunable and ultrasensitive hybrid plasmonic platform for multi-spectral sensing: Non-invasive diabetes surveillance and global warming directives. Opt. Commun. 2023, 545, 129697. [Google Scholar] [CrossRef]

- Saravanapavanantham, M.; Mwaura, J.; Bulović, V. Printed Organic Photovoltaic Modules on Transferable Ultra-thin Substrates as Additive Power Sources. Small Methods 2023, 7, 2200940. [Google Scholar] [CrossRef] [PubMed]

- Amrillah, T.; Prasetio, A.; Supandi, A.R.; Sidiq, D.H.; Putra, F.S.; Nugroho, M.A.; Salsabilla, Z.; Azmi, R. Environment-friendly copper-based chalcogenide thin film solar cells: Status and perspectives. Mater. Horizons 2023, 10, 313–339. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Zeng, Q.; Li, J.; Hao, X.; Ho-Baillie, A.; Tang, J.; Green, M.A. Emerging inorganic compound thin film photovoltaic materials: Progress, challenges and strategies. Mater. Today 2020, 41, 120–142. [Google Scholar] [CrossRef]

- Buonomenna, M.G. Inorganic Thin-Film Solar Cells: Challenges at the Terawatt-Scale. Symmetry 2023, 15, 1718. [Google Scholar] [CrossRef]

- Stuckelberger, M.; Biron, R.; Wyrsch, N.; Haug, F.J.; Ballif, C. Progress in solar cells from hydrogenated amorphous silicon. Renew. Sustain. Energy Rev. 2017, 76, 1497–1523. [Google Scholar] [CrossRef]

- Grimani, C.; Fabi, M.; Sabbatini, F.; Villani, M.; Antognini, L.; Bashiri, A.; Calcagnile, L.; Caricato, A.P.; Catalano, R.; Chilà, D.; et al. A Hydrogenated amorphous silicon detector for Space Weather Applications. Astrophys. Space Sci. 2023, 368, 78. [Google Scholar] [CrossRef]

- Lopez-Garcia, A.J.; Voz, C.; Asensi, J.M.; Puigdollers, J.; Izquierdo-Roca, V.; Pérez-Rodríguez, A. Ultrathin a-Si: H/Oxide Transparent Solar Cells Exhibiting UV-Blue Selective-Like Absorption. Sol. RRL 2023, 7, 2200928. [Google Scholar] [CrossRef]

- Riesen, Y.; Stuckelberger, M.; Haug, F.J.; Ballif, C.; Wyrsch, N. Temperature dependence of hydrogenated amorphous silicon solar cell performances. J. Appl. Phys. 2016, 119, 044505. [Google Scholar] [CrossRef]

- Pathak, M.; Girotra, K.; Harrison, S.; Pearce, J.M. The effect of hybrid photovoltaic thermal device operating conditions on intrinsic layer thickness optimization of hydrogenated amorphous silicon solar cells. Sol. Energy 2012, 86, 2673–2677. [Google Scholar] [CrossRef]

- Elshorbagy, M.H.; Sánchez, P.A.; Cuadrado, A.; Alda, J.; Esteban, Ó. Resonant nano-dimer metasurface for ultra-thin a-Si: H solar cells. Sci. Rep. 2021, 11, 7179. [Google Scholar] [CrossRef]

- Shah, A.V.; Schade, H.; Vanecek, M.; Meier, J.; Vallat-Sauvain, E.; Wyrsch, N.; Kroll, U.; Droz, C.; Bailat, J. Thin-film silicon solar cell technology. Prog. Photovoltaics Res. Appl. 2004, 12, 113–142. [Google Scholar] [CrossRef]

- Rakić, A.D. Algorithm for the determination of intrinsic optical constants of metal films: Application to aluminum. Appl. Opt. 1995, 34, 4755–4767. [Google Scholar] [CrossRef]

- Treharne, R.; Seymour-Pierce, A.; Durose, K.; Hutchings, K.; Roncallo, S.; Lane, D. Optical design and fabrication of fully sputtered CdTe/CdS solar cells. J. Phys. Conf. Ser. 2011, 286, 012038. [Google Scholar] [CrossRef]

- Vora, A.; Gwamuri, J.; Pearce, J.M.; Bergstrom, P.L.; Güney, D.Ö. Multi-resonant silver nano-disk patterned thin film hydrogenated amorphous silicon solar cells for Staebler-Wronski effect compensation. J. Appl. Phys. 2014, 116, 093103. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical constants of the noble metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Li, H. Refractive index of alkaline earth halides and its wavelength and temperature derivatives. J. Phys. Chem. Ref. Data 1980, 9, 161–290. [Google Scholar] [CrossRef]

- Philipp, H.R. Optical properties of silicon nitride. J. Electrochem. Soc. 1973, 120, 295. [Google Scholar] [CrossRef]

- Sharma, S.C. Surface plasmon resonance sensors: Fundamental concepts, selected techniques, materials and applications. In Advances in Sensors; Yurish, S., Ed.; IFSA Publishing: Barcelona, Spain, 2018; Volume 5, pp. 25–77. [Google Scholar]

- Mehta, V.; Conkel, C.; Cochran, A.; Ravindra, N. Materials for Antireflection Coatings in Photovoltaics—An Overview. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2022; pp. 350–365. [Google Scholar]

- Boroumand, J.; Das, S.; Vázquez-Guardado, A.; Franklin, D.; Chanda, D. Unified electromagnetic-electronic design of light trapping silicon solar cells. Sci. Rep. 2016, 6, 31013. [Google Scholar] [CrossRef] [PubMed]

- Gan, X.; Shiue, R.J.; Gao, Y.; Meric, I.; Heinz, T.F.; Shepard, K.; Hone, J.; Assefa, S.; Englund, D. Chip-integrated ultrafast graphene photodetector with high responsivity. Nat. Photonics 2013, 7, 883–887. [Google Scholar] [CrossRef]

- Hu, S.; Shi, W.; Chen, Y.; Yuan, J.; Xiong, X.; Liu, T.; Ding, S.; Xiao, W.; Chen, Y.; Liu, G.S.; et al. Universal and flexible design for high-sensitivity and wide-ranging surface plasmon resonance sensors based on a three-dimensional tuning hypersurface. Sens. Actuators Chem. 2023, 380, 133284. [Google Scholar] [CrossRef]

- Aharoni, R.; Sinvani, M.; Tischler, Y.R.; Zalevsky, Z. Basic model of absorption depth and injection levels in silicon under intermediate illumination levels. Opt. Commun. 2013, 291, 1–6. [Google Scholar] [CrossRef]

- Biswas, R.; Xu, C. Nano-crystalline silicon solar cell architecture with absorption at the classical 4n 2 limit. Opt. Express 2011, 19, A664–A672. [Google Scholar] [CrossRef]

- Camarillo Abad, E.; Joyce, H.J.; Hirst, L.C. Light management for ever-thinner photovoltaics: A tutorial review. APL Photonics 2024, 9, 011101. [Google Scholar] [CrossRef]

- Lee, K.L.; Chang, C.C.; You, M.L.; Pan, M.Y.; Wei, P.K. Enhancing surface sensing sensitivity of metallic nanostructures using blue-shifted surface plasmon mode and fano resonance. Sci. Rep. 2018, 8, 9762. [Google Scholar] [CrossRef]

- Zheng, G.; Cong, J.; Xu, L.; Wang, J. High-resolution surface plasmon resonance sensor with Fano resonance in waveguide-coupled multilayer structures. Appl. Phys. Express 2017, 10, 042202. [Google Scholar] [CrossRef]

- Nesterenko, D.V.; Sekkat, Z. Resolution estimation of the Au, Ag, Cu, and Al single-and double-layer surface plasmon sensors in the ultraviolet, visible, and infrared regions. Plasmonics 2013, 8, 1585–1595. [Google Scholar] [CrossRef]

- Kumar, R.; Agarwal, S.; Pal, S.; Verma, A.; Prajapati, Y.K. Refractive index sensing using MXene mediated surface plasmon resonance sensor in visible to near infrared regime. Measurement 2024, 224, 113682. [Google Scholar] [CrossRef]

- Zarei, M.; Hamidi, S.M.; Chee, K.W.A. Colorimetric Plasmonic Hydrogen Gas Sensor Based on One-Dimensional Nano-Gratings. Crystals 2023, 13, 363. [Google Scholar] [CrossRef]

- Kalvoda, L.; Jakoubková, J.; Burda, M.; Kwiecien, P.; Richter, I.; Kopeček, J. Fiber Optic Sensor of Ammonia Gas Using Plasmonic Extraordinary Optical Transmission. Sensors 2023, 23, 4065. [Google Scholar] [CrossRef] [PubMed]

- Chylek, J.; Ciprian, D.; Hlubina, P. Optimized film thicknesses for maximum refractive index sensitivity and figure of merit of a bimetallic film surface plasmon resonance sensor. Eur. Phys. J. Plus 2024, 139, 11. [Google Scholar] [CrossRef]

- Sinha, R.; Jana, B.; Mukherjee, R.; Maji, P.S. Porous Tamm Plasmon based refractive index gas sensor using four different Plasmon active metals. Opt. Quantum Electron. 2023, 55, 183. [Google Scholar] [CrossRef]

- Moeinimaleki, B.; Kaatuzian, H.; Mallah Livani, A. Design and Simulation of a Resonance-Based Plasmonic Sensor for Mass Density Sensing of Methane and Carbon Dioxide Gases. Plasmonics 2023, 18, 225–240. [Google Scholar] [CrossRef]

- Irfan, M.; Khan, Y.; Rehman, A.U.; Ullah, N.; Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A. Plasmonic Perfect Absorber Utilizing Polyhexamethylene Biguanide Polymer for Carbon Dioxide Gas Sensing Application. Materials 2023, 16, 2629. [Google Scholar] [CrossRef] [PubMed]

- Sherif, S.M.; Swillam, M.A. Silicon-based mid infrared on-chip gas sensor using Fano resonance of coupled plasmonic microcavities. Sci. Rep. 2023, 13, 12311. [Google Scholar] [CrossRef] [PubMed]

| Layer | Shape and Geometry [nm] | Materials and Ref. |

|---|---|---|

| Substrate | Infinite layer | Glass |

| Back contact | Thin film [200] | Aluminum [35] |

| Buffer layer | Thin film [100] | Aluminum-doped zinc oxide [36] |

| Buffer layer | Thin film [22] | n-type hydrogenated amorphous silicon [37] |

| Active layer | Thin film [350] | i-type hydrogenated amorphous silicon [37] |

| Buffer layer | Thin film [17] | p-type hydrogenated amorphous silicon [37] |

| Top contact | Thin film [50] | Silver [38] |

| Metasurface | Three-layer grating, GW, GH, P | MgF2/Si3N4/MgF2 [39,40] |

| Protecting layer | Thin film [10] | SiO2 |

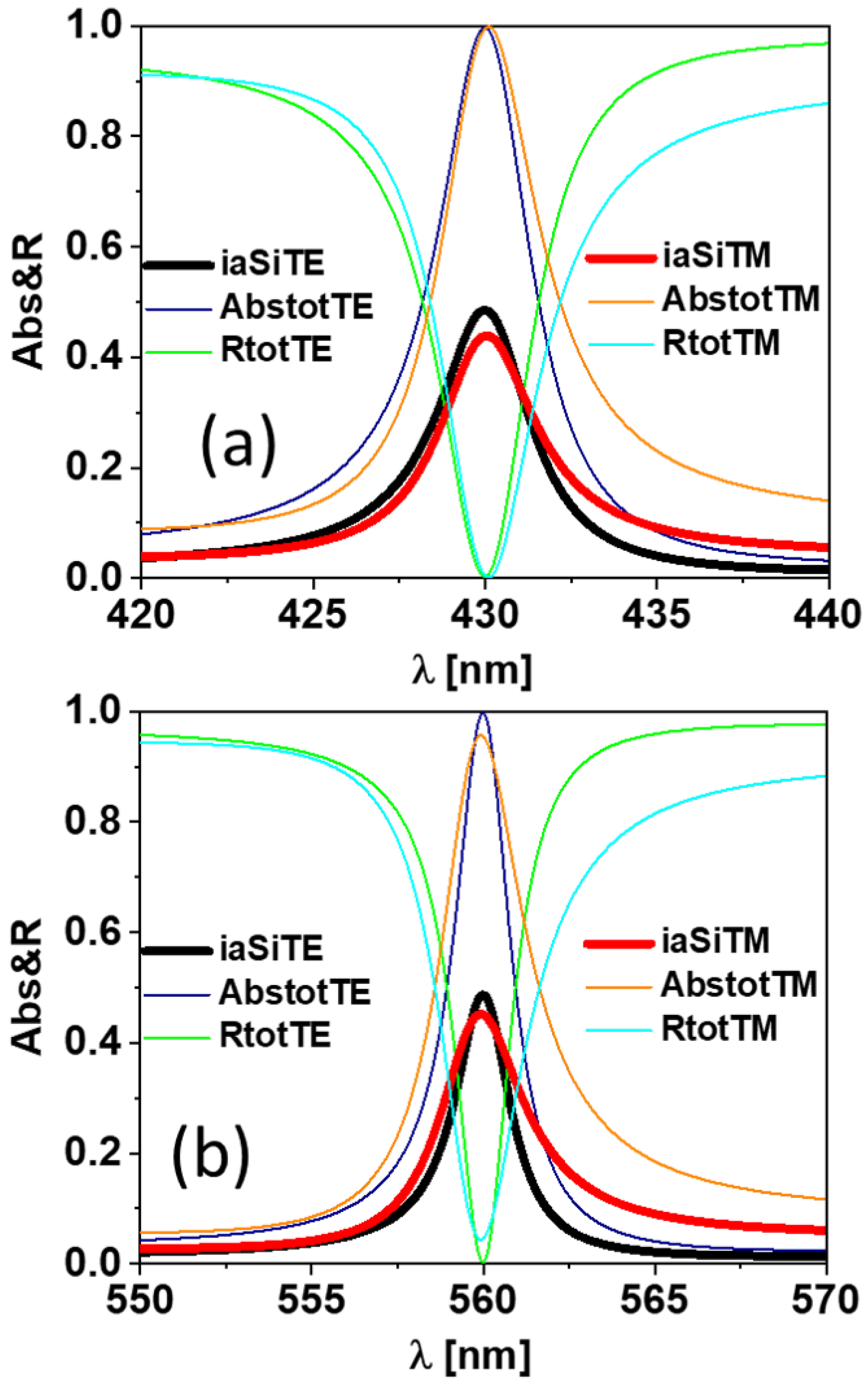

| Maximum Number- Wavelength (nm) | Polarization | GW, GH [nm] | Maximum Absorption |

|---|---|---|---|

| 1–430 | TE | 88, 58 | 0.485 |

| 2–430 | TM | 124, 92 | 0.438 |

| 3–560 | TE | 224, 70 | 0.486 |

| 4–560 | TM | 248, 100 | 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elshorbagy, M.H.; Cuadrado, A.; Alda, J. Optical Sensing Using Hybrid Multilayer Grating Metasurfaces with Customized Spectral Response. Sensors 2024, 24, 1043. https://doi.org/10.3390/s24031043

Elshorbagy MH, Cuadrado A, Alda J. Optical Sensing Using Hybrid Multilayer Grating Metasurfaces with Customized Spectral Response. Sensors. 2024; 24(3):1043. https://doi.org/10.3390/s24031043

Chicago/Turabian StyleElshorbagy, Mahmoud H., Alexander Cuadrado, and Javier Alda. 2024. "Optical Sensing Using Hybrid Multilayer Grating Metasurfaces with Customized Spectral Response" Sensors 24, no. 3: 1043. https://doi.org/10.3390/s24031043

APA StyleElshorbagy, M. H., Cuadrado, A., & Alda, J. (2024). Optical Sensing Using Hybrid Multilayer Grating Metasurfaces with Customized Spectral Response. Sensors, 24(3), 1043. https://doi.org/10.3390/s24031043