Implementation and Experimental Application of Industrial IoT Architecture Using Automation and IoT Hardware/Software

Abstract

1. Introduction

- Open IoT technologies (hardware, software and communications) are integrated with traditional automation equipment.

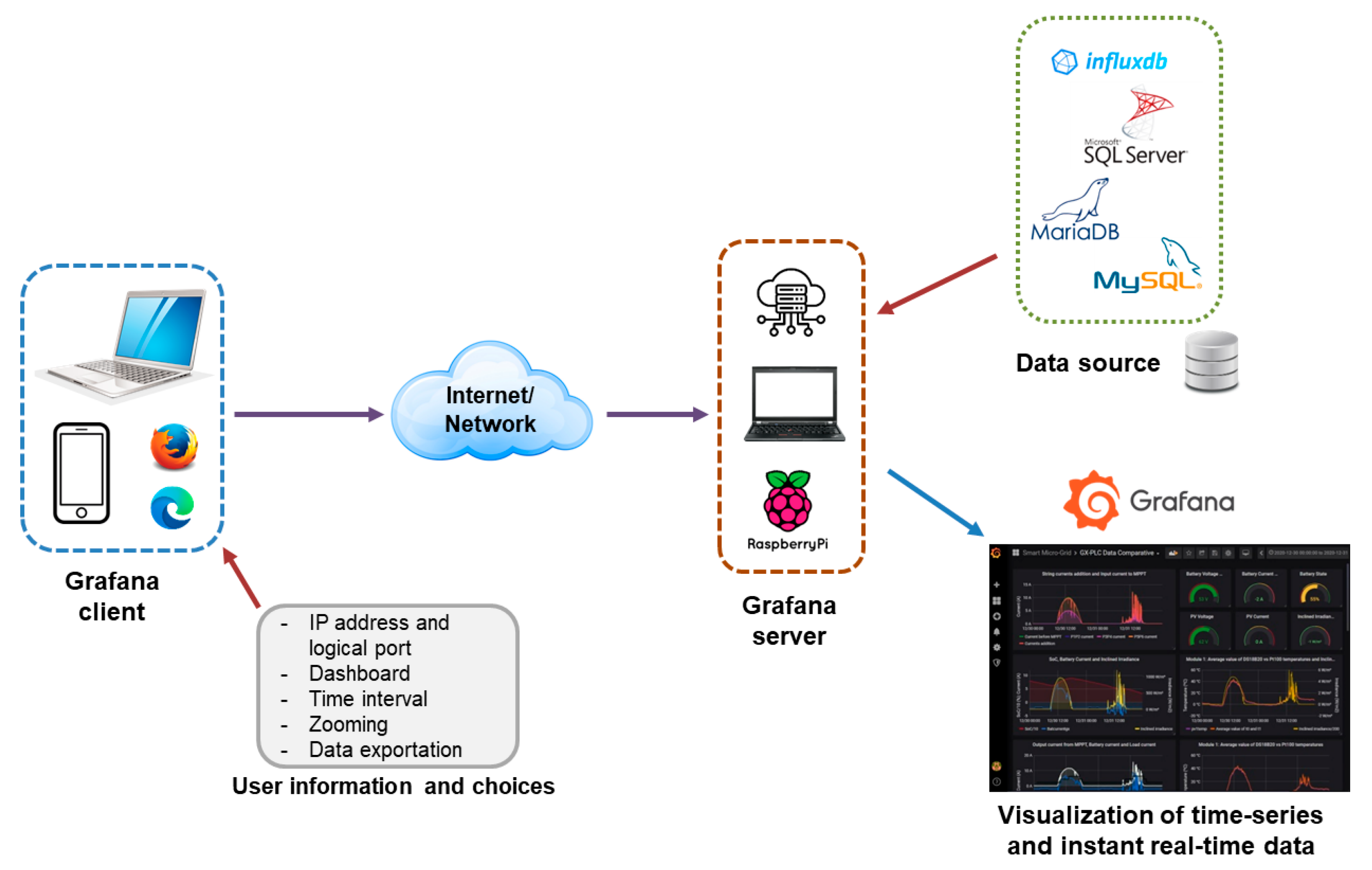

- Data are acquired, stored and visualized in a seamless manner, putting a special focus on the monitoring software environment Grafana.

- Networked remote access is allowed through a custom-tailored web user interface.

- In contrast to conceptual and/or simulation frameworks, experimental results under real operating conditions prove the validity of the architecture.

2. Fundamentals of Grafana and a Brief Review of Grafana Applications

2.1. Grafana Main Features

2.2. Brief Review of Grafana Applications

3. Applied IoT Architecture

3.1. Overview of Architectures for I4.0 and IIoT

3.2. Description of the IIoT Architecture

3.2.1. Sensing Layer

3.2.2. Network Layer

3.2.3. Middleware Layer

3.2.4. Application Layer

4. Experimental Validation and Discussion

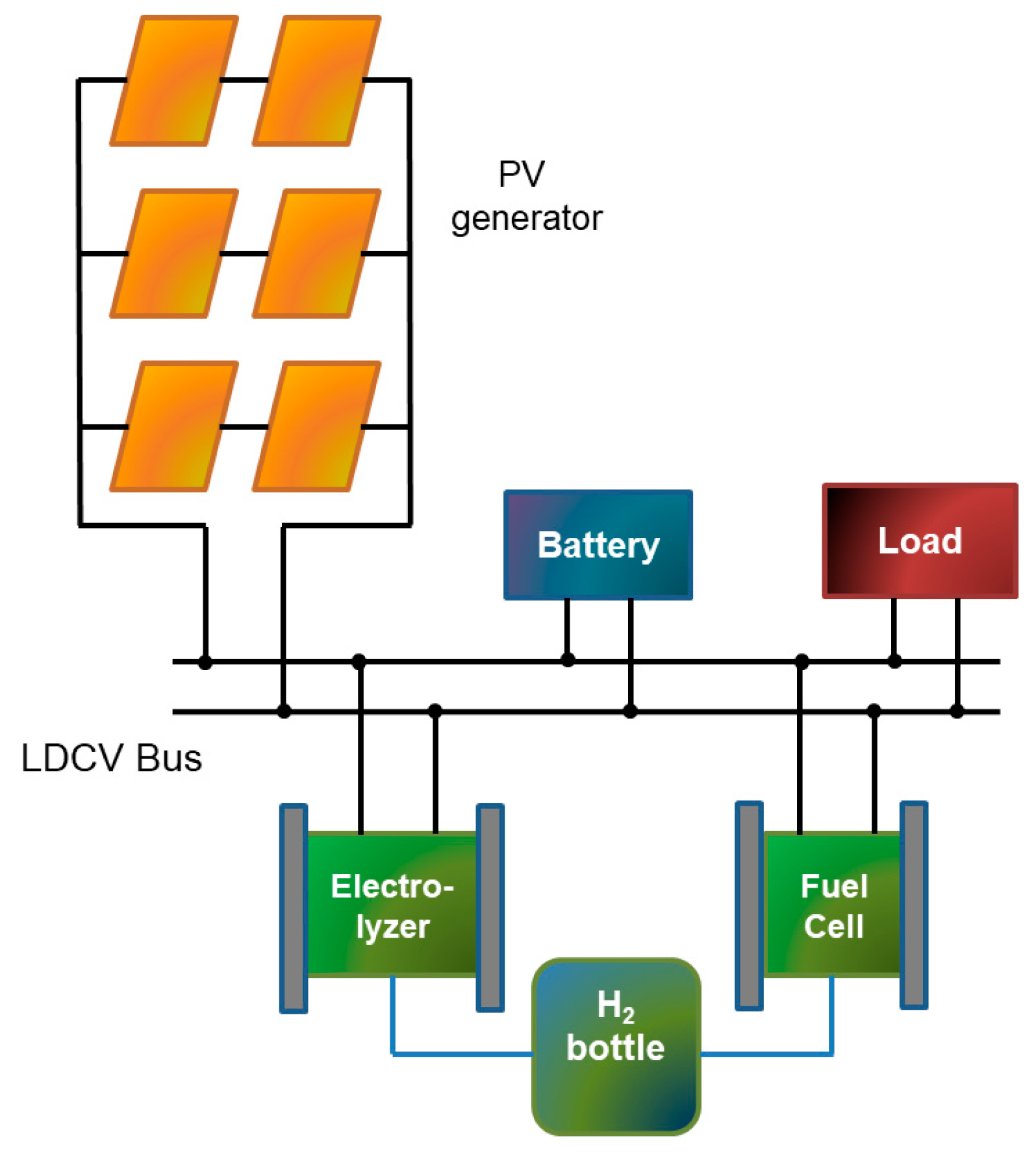

4.1. Microgrid Description

4.2. PV Generator

- Weather conditions: where incident solar irradiance, ambient temperature and wind speed are represented. These parameters are illustrated by means of instant numerical values as well as graphical time trends.

- Global parameters: where the electrical generation (in current and power) is visualized together with the solar irradiance, as well as the variation in the temperature of the PV panels.

- P1–P2 panels: whose graphical elements represent the evolution of the current, voltage, generated power and temperature of the panels comprising the first string.

- P3–P4 panels: homologous to the previous row and dedicated to second string.

- P5–P6 panels: homologous to the previous row and dedicated to third string.

4.3. Battery

- Instant values: this column illustrates the instant values of the key parameters of the battery by means of numerical indicators; namely, the battery voltage, current, power, SoC, SoH and temperature are depicted.

- Global parameters and comparison: in this column there are three trend graphs representing the evolution of the battery voltage, the total current and the current of each module, as well as the total power together with the power of each module.

- Module 1: this module displays the values associated with the voltage, current and power of the first battery module using trend graphs.

- Module 2: this module is homologous to the previous column and dedicated to the second module.

4.4. Hydrogen Generator

- H2 circuit: this row illustrates the instant value and the historical trend of the working pressure and the generated hydrogen flow rate.

- Stack & DC/DC Buck Converter 1: this group is focused on the first stack and collects the evolution of current, voltage and power at the input and output of the converter. Furthermore, this group displays the efficiency of the converter as well as the working temperature of the stack.

- Stack & DC/DC Buck Converter 2: homologous to the previous row and dedicated to stack and converter 2.

- Stack & DC/DC Buck Converter 3: homologous to the previous row and dedicated to stack and converter 3.

4.5. Fuel Cell

- H2 circuit: this row illustrates the instant value and the historical trend of the pressure of H2 storage system, pressure of H2 circuit and H2 flow rate consumed.

- Fuel cell parameters: this space is dedicated to the representation of the key parameters of the fuel cell such as total voltage and current, generated power, working temperature as well as the variations of individual cells voltage.

- DC/DC Boost Converter: this last row is composed of a graph plotting the variables of the DC/DC boost converter, namely, input voltage and current, output voltage and current, and input power and output power together with efficiency are depicted.

- The hardware elements of the Sensing layer send their information correctly to the PLC.

- The elements of the Middleware layer perform the reading and storage of the installation data by means of the protocols established at the Network layer.

- The Grafana environment (Application layer) communicates correctly with the MariaDB database and allows the reading and visualization of the stored data.

4.6. Discussion

- Inherent vulnerabilities in the software version, which are solved and lead to the release of a new version of the program. Some examples include the cases associated with the MariaDB (CVE-2024-21096) and Grafana (CVE-2024-9476) environments.

- Vulnerabilities due to functions associated with packages/plugins. The use of outdated packages increases the risk of attacks due to the exploitation of vulnerabilities. The most frequent attacks in these cases are Denial of Service (DoS) attacks. As an example of this typology, a vulnerability in Node-RED associated with the Node.js “cross-spawn” package has recently been fixed (CVE-2024-21538).

- Vulnerabilities associated with SQL code injection. Environments such as MariaDB and Grafana work through requests formed in SQL code. Malicious access to these environments facilitates the attacker to execute malicious SQL code, allowing the inclusion, modification and elimination of information, thus altering the information contained in the database and the operation of the environments.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mrabet, H.; Alhomoud, A.; Jemai, A.; Trentesaux, D. A Secured Industrial Internet-of-Things Architecture Based on Blockchain Technology and Machine Learning for Sensor Access Control Systems in Smart Manufacturing. Appl. Sci. 2022, 12, 4641. [Google Scholar] [CrossRef]

- Babayigit, B.; Abubaker, M. Industrial Internet of Things: A Review of Improvements Over Traditional SCADA Systems for Industrial Automation. IEEE Syst. J. 2023, 18, 120–133. [Google Scholar] [CrossRef]

- Nakagawa, E.Y.; Antonino, P.O.; Schnicke, F.; Capilla, R.; Kuhn, T.; Liggesmeyer, P. Industry 4.0 reference architectures: State of the art and future trends. Comput. Ind. Eng. 2021, 156, 107241. [Google Scholar] [CrossRef]

- Ladegourdie, M.; Kua, J. Performance Analysis of OPC UA for Industrial Interoperability towards Industry 4.0. Internet Things 2022, 3, 507–525. [Google Scholar] [CrossRef]

- Bader, S.R.; Maleshkova, M.; Lohmann, S. Structuring reference architectures for the industrial Internet of Things. Future Internet 2019, 11, 151. [Google Scholar] [CrossRef]

- Fun, T.S.; Samsudin, A. Recent technologies, security countermeasure and ongoing challenges of industrial internet of things (IIoT): A survey. Sensors 2021, 21, 6647. [Google Scholar] [CrossRef]

- Mirani, A.A.; Velasco-Hernandez, G.; Awasthi, A.; Walsh, J. Key Challenges and Emerging Technologies in Industrial IoT Architectures: A Review. Sensors 2022, 22, 5836. [Google Scholar] [CrossRef]

- Fraile, F.; Sanchis, R.; Poler, R.; Ortiz, A. Reference models for digital manufacturing platforms. Appl. Sci. 2019, 9, 4433. [Google Scholar] [CrossRef]

- Serôdio, C.; Mestre, P.; Cabral, J.; Gomes, M.; Branco, F. Software and Architecture Orchestration for Process Control in Industry 4.0 Enabled by Cyber-Physical Systems Technologies. Appl. Sci. 2024, 14, 2160. [Google Scholar] [CrossRef]

- Ungurean, I.; Gaitan, N.C. A software architecture for the industrial internet of things—A conceptual model. Sensors 2020, 20, 5603. [Google Scholar] [CrossRef]

- Trunzer, E.; Calà, A.; Leitão, P.; Gepp, M.; Kinghorst, J.; Lüder, A.; Schauerte, H.; Reifferscheid, M.; Vogel-Heuser, B. System architectures for Industrie 4.0 applications: Derivation of a generic architecture proposal. Prod. Eng. 2019, 13, 247–257. [Google Scholar] [CrossRef]

- Lombardi, M.; Pascale, F.; Santaniello, D. Internet of things: A general overview between architectures, protocols and applications. Information 2021, 12, 87. [Google Scholar] [CrossRef]

- Oñate, W.; Sanz, R. Analysis of architectures implemented for IIoT. Heliyon 2023, 9, e12868. [Google Scholar] [CrossRef] [PubMed]

- Hsiao, C.H.; Lee, W.P. OPIIoT: Design and Implementation of an Open Communication Protocol Platform for Industrial Internet of Things. Internet Things 2021, 16, 100441. [Google Scholar] [CrossRef]

- Domínguez-Bolaño, T.; Campos, O.; Barral, V.; Escudero, C.J.; García-Naya, J.A. An overview of IoT architectures, technologies, and existing open-source projects. Internet Things 2022, 20, 100626. [Google Scholar] [CrossRef]

- Sasiain, J.; Sanz, A.; Astorga, J.; Jacob, E. Towards flexible integration of 5G and IIoT technologies in industry 4.0: A practical use case. Appl. Sci. 2020, 10, 7670. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F.; Poler, R. A conceptual framework for smart production planning and control in Industry 4.0. Comput. Ind. Eng. 2022, 173, 108659. [Google Scholar] [CrossRef]

- Cabrini, F.H.; Filho, F.V.; Rito, P.; Filho, A.B.; Sargento, S.; Neto, A.V.; Kofuji, S.T. Enabling the industrial internet of things to cloud continuum in a real city environment. Sensors 2021, 21, 7707. [Google Scholar] [CrossRef]

- Gabriel, M.F.; Marques, G.; Filipe, D.; Felgueiras, F.; Cardoso, J.P.; Azeredo, J.; Kazdaridis, G.; Symeonidis, P.; Keranidis, S.; Conradie, P.; et al. Implementation of an IoT architecture for promoting healthy air quality in 84 homes of families with children. Build. Environ. 2024, 266, 112040. [Google Scholar] [CrossRef]

- Costa, F.S.; Nassar, S.M.; Gusmeroli, S.; Schultz, R.; Conceição, A.G.S.; Xavier, M.; Hessel, F.; Dantas, M.A.R. Fasten iiot: An open real-time platform for vertical, horizontal and end-to-end integration. Sensors 2020, 20, 5499. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, S.I.; da Cruz, A.M.R.; Curado, A. Towards a smart & sustainable campus: An application-oriented architecture to streamline digitization and strengthen sustainability in academia. Sustainability 2021, 13, 3189. [Google Scholar] [CrossRef]

- Moens, P.; Bracke, V.; Soete, C.; Hautte, S.V.; Avendano, D.N.; Ooijevaar, T.; Devos, S.; Volckaert, B.; Van Hoecke, S. Scalable fleet monitoring and visualization for smart machine maintenance and industrial iot applications. Sensors 2020, 20, 4308. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Mukherjee, A.; Misra, S. SEGA: Secured Edge Gateway Microservices Architecture for IIoT-Based Machine Monitoring. IEEE Trans. Ind. Inform. 2022, 18, 1949–1956. [Google Scholar] [CrossRef]

- Villa, V.; Naticchia, B.; Bruno, G.; Aliev, K.; Piantanida, P.; Antonelli, D. Iot open-source architecture for the maintenance of building facilities. Appl. Sci. 2021, 11, 5374. [Google Scholar] [CrossRef]

- Mantravadi, S.; Møller, C.; LI, C.; Schnyder, R. Design choices for next-generation IIoT-connected MES/MOM: An empirical study on smart factories. Robot. Comput. Integr. Manuf. 2022, 73, 102225. [Google Scholar] [CrossRef]

- Fortoul-Diaz, J.A.; Carrillo-Martinez, L.A.; Centeno-Tellez, A.; Cortes-Santacruz, F.; Olmos-Pineda, I.; Flores-Quintero, R.R. A Smart Factory Architecture Based on Industry 4.0 Technologies: Open-Source Software Implementation. IEEE Access 2023, 11, 101727–101749. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a Smart Factory Based on Cyber-Physical Systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Hussain, Z.; Akhunzada, A.; Iqbal, J.; Bibi, I.; Gani, A. Secure IIoT-enabled industry 4.0. Sustainability 2021, 13, 12384. [Google Scholar] [CrossRef]

- Ramzey, H.; Badawy, M.; Elhosseini, M.; Elbaset, A.A. I2OT-EC: A Framework for Smart Real-Time Monitoring and Controlling Crude Oil Production Exploiting IIOT and Edge Computing. Energies 2023, 16, 2023. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J. Integration of open source hardware Arduino platform in automation systems applied to Smart Grids/Micro-Grids. Sustain. Energy Technol. Assess. 2019, 36, 100557. [Google Scholar] [CrossRef]

- Aceto, G.; Persico, V.; Pescapé, A. A Survey on Information and Communication Technologies for Industry 4.0: State-of-the-Art, Taxonomies, Perspectives, and Challenges. IEEE Commun. Surv. Tutor. 2019, 21, 3467–3501. [Google Scholar] [CrossRef]

- Minchala, L.I.; Peralta, J.; Mata-Quevedo, P.; Rojas, J. An approach to industrial automation based on low-cost embedded platforms and open software. Appl. Sci. 2020, 10, 4696. [Google Scholar] [CrossRef]

- Nițulescu, I.V.; Korodi, A. Supervisory Control and Data Acquisition Approach in Node-RED: Application and Discussions. Internet Things 2020, 1, 76–91. [Google Scholar] [CrossRef]

- Folgado, F.J.; González, I.; Calderón, A.J. Data acquisition and monitoring system framed in Industrial Internet of Things for PEM hydrogen generators. Internet Things 2023, 22, 100795. [Google Scholar] [CrossRef]

- Ayele, E.D.; Gavriel, S.; Gonzalez, J.F.; Teeuw, W.B.; Philimis, P.; Gillani, G. Emerging Industrial Internet of Things Open-Source Platforms and Applications in Diverse Sectors. Telecom 2024, 5, 369–399. [Google Scholar] [CrossRef]

- Martinez, B.; Vilajosana, X.; Kim, I.H.; Zhou, J.; Tuset-Peiró, P.; Xhafa, A.; Poissonnier, D.; Lu, X. I3mote: An open development platform for the intelligent industrial internet. Sensors 2017, 17, 986. [Google Scholar] [CrossRef] [PubMed]

- Klimt, J.; Eiling, N.; Wege, F.; Baude, J.; Monti, A. The Role of Open-Source Software in the Energy Sector. Energies 2023, 16, 5855. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Figueiredo, J.; Sousa, J.M.C. A literature survey on open platform communications (OPC) applied to advanced industrial environments. Electronics 2019, 8, 510. [Google Scholar] [CrossRef]

- Oberloier, S.; Whisman, N.G.; Hafting, F.; Pearce, J.M. Open source framework for a Broadly Expandable and Reconfigurable data acquisition and automation device (BREAD). HardwareX 2023, 15, e00467. [Google Scholar] [CrossRef] [PubMed]

- Vuković, M.; Jorg, O.; Hosseinifard, M.; Fantoni, G. Low-Cost Digitalization Solution through Scalable IIoT Prototypes. Appl. Sci. 2022, 12, 8571. [Google Scholar] [CrossRef]

- Mellado, J.; Núñez, F. Design of an IoT-PLC: A containerized programmable logical controller for the industry 4.0. J. Ind. Inf. Integr. 2022, 25, 100250. [Google Scholar] [CrossRef]

- Langmann, R.; Stiller, M. The PLC as a smart service in industry 4.0 production systems. Appl. Sci. 2019, 9, 3815. [Google Scholar] [CrossRef]

- Hinojosa-Palafox, E.A.; Rodríguez-Elías, O.M.; Hoyo-Montaño, J.A.; Pacheco-Ramírez, J.H.; Nieto-Jalil, J.M. An analytics environment architecture for industrial cyber-physical systems big data solutions. Sensors 2021, 21, 4282. [Google Scholar] [CrossRef]

- Meira, J.; Matos, G.; Perdigão, A.; Cação, J.; Resende, C.; Moreira, W.; Antunes, M.; Quevedo, J.; Moutinho, R.; Oliveira, J.; et al. Industrial Internet of Things over 5G: A Practical Implementation. Sensors 2023, 23, 5199. [Google Scholar] [CrossRef]

- Portalo, J.M.; González, I.; Calderón, A.J. Monitoring system for tracking a pv generator in an experimental smart microgrid: An open-source solution. Sustainability 2021, 13, 8182. [Google Scholar] [CrossRef]

- Cruz, M.; Mafra, S.; Teixeira, E.; Figueiredo, F. Smart Strawberry Farming Using Edge Computing and IoT. Sensors 2022, 22, 5866. [Google Scholar] [CrossRef] [PubMed]

- Hashmani, R.K.; Konyushikhin, M.; Shan, B.; Cai, X.; Demirköz, M.B. New monitoring interface for the AMS experiment. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2023, 1046, 167704. [Google Scholar] [CrossRef]

- Gimeno-Sales, F.J.; Orts-Grau, S.; Escribá-Aparisi, A.; González-Altozano, P.; Balbastre-Peralta, I.; Martínez-Márquez, C.I.; Gasque, M.; Seguí-Chilet, S. Pv monitoring system for a water pumping scheme with a lithium-ion battery using free open-source software and iot technologies. Sustainability 2020, 12, 10651. [Google Scholar] [CrossRef]

- Díaz, A.F.; Prieto, B.; Escobar, J.J.; Lampert, T. Vampire: A smart energy meter for synchronous monitoring in a distributed computer system. J. Parallel Distrib. Comput. 2024, 184, 104794. [Google Scholar] [CrossRef]

- Catalan, L.; Araiz, M.; Aranguren, P.; Padilla, G.D.; Hernandez, P.A.; Perez, N.M.; de la Noceda, C.G.; Albert, J.F.; Astrain, D. Prospects of autonomous volcanic monitoring stations: Experimental investigation on thermoelectric generation from fumaroles. Sensors 2020, 20, 3547. [Google Scholar] [CrossRef]

- Orts-Grau, S.; Gonzalez-Altozano, P.; Gimeno-Sales, F.J.; Balbastre-Peralta, I.; Martinez Marquez, C.I.; Gasque, M.; Segui-Chilet, S. Photovoltaic Water Pumping: Comparison between Direct and Lithium Battery Solutions. IEEE Access 2021, 9, 101147–101163. [Google Scholar] [CrossRef]

- De Arquer Fernández, P.; Fernández, M.A.F.; Luis, J.; Candás, C.; Arboleya, P.A. An IoT open source platform for photovoltaic plants supervision. Electr. Power Energy Syst. 2021, 125, 106540. [Google Scholar] [CrossRef]

- Alvear-Puertas, V.E.; Burbano-Prado, Y.A.; Rosero-Montalvo, P.D.; Tözün, P.; Marcillo, F.; Hernandez, W. Smart and Portable Air-Quality Monitoring IoT Low-Cost Devices in Ibarra City, Ecuador. Sensors 2022, 22, 7015. [Google Scholar] [CrossRef] [PubMed]

- Filip, I.D.; Iliescu, C.M.; Pop, F. Assertive, Selective, Scalable IoT-Based Warning System. Sensors 2022, 22, 1015. [Google Scholar] [CrossRef]

- Benomar, Z.; Campobello, G.; Segreto, A.; Battaglia, F.; Longo, F.; Merlino, G.; Puliafito, A. A Fog-Based Architecture for Latency-Sensitive Monitoring Applications in Industrial Internet of Things. IEEE Internet Things J. 2023, 10, 1908–1918. [Google Scholar] [CrossRef]

- Grafana Labs. Available online: https://grafana.com/ (accessed on 23 February 2024).

- González, I.; Folgado, F.J.; Orellana, D.; Calderón, D.; Calderón, A.J. PV panel monitoring system for cell temperature analysis and comparison by embedded models. In Proceedings of the XVII Simposio CEA de Control Inteligente, León, Spain, 27–29 June 2022. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Folgado, F.J. IoT real time system for monitoring lithium-ion battery long-term operation in microgrids. J. Energy Storage 2022, 51, 104596. [Google Scholar] [CrossRef]

- Ali, A.S.; Coté, C.; Heidarinejad, M.; Stephens, B. Elemental: An open-source wireless hardware and software platform for building energy and indoor environmental monitoring and control. Sensors 2019, 19, 4017. [Google Scholar] [CrossRef]

- González, I.; Folgado, F.J.; Calderón, A.J. Visualisation and Analysis of Digital and Analog Temperature Sensors in PV Generator through IoT Software. Eng. Proc. 2022, 27, 59. [Google Scholar] [CrossRef]

- Ferlito, S.; Ippolito, S.; Santagata, C.; Schiattarella, P.; Di Francia, G. A Study on an IoT-Based SCADA System for Photovoltaic Utility Plants. Electronics 2024, 13, 2065. [Google Scholar] [CrossRef]

- Mudaliar, M.D.; Sivakumar, N. IoT based real time energy monitoring system using Raspberry Pi. Internet Things 2020, 12, 100292. [Google Scholar] [CrossRef]

- Yasin, A.; Pang, T.Y.; Cheng, C.T.; Miletic, M. A roadmap to integrate digital twins for small and medium-sized enterprises. Appl. Sci. 2021, 11, 9479. [Google Scholar] [CrossRef]

- Liu, C.; Su, Z.; Xu, X.; Lu, Y. Service-oriented industrial internet of things gateway for cloud manufacturing. Robot. Comput.-Integr. Manuf. 2022, 73, 102217. [Google Scholar] [CrossRef]

- Zhu, Y.; Al-Ahmed, S.A.; Shakir, M.Z.; Olszewska, J.I. LSTM-Based IoT-Enabled CO2 Steady-State Forecasting for Indoor Air Quality Monitoring. Electronics 2023, 12, 107. [Google Scholar] [CrossRef]

- Broniewski, A.; Tirmizi, M.I.; Zimányi, E.; Sakr, M. Using MobilityDB and Grafana for Aviation Trajectory Analysis. Eng. Proc. 2023, 28, 17. [Google Scholar] [CrossRef]

- Vasile, M.E.; Avolio, G.; Soloviev, I. Performance Evaluation of Modern Time-Series Database Technologies for the ATLAS Operational Monitoring Data Archiving Service. IEEE Trans. Nucl. Sci. 2023, 70, 1131–1135. [Google Scholar] [CrossRef]

- Åkerberg, J.; Åkesson, J.F.; Gade, J.; Vahabi, M.; Björkman, M.; Lavassani, M.; Gore, R.N.; Lindh, T.; Jiang, X. Future industrial networks in process automation: Goals, challenges, and future directions. Appl. Sci. 2021, 11, 3345. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Plattform Industrie 4.0: RAMI 4.0. Available online: https://www.plattform-i40.de/IP/Redaktion/EN/Downloads/Publikation/rami40-an-introduction.pdf?__blob=publicationFile&v=7 (accessed on 18 January 2024).

- Latif, S.; Driss, M.; Boulila, W.; Huma, Z.E.; Jamal, S.S.; Idrees, Z.; Ahmad, J. Deep learning for the industrial internet of things (IIoT): A comprehensive survey of techniques, implementation frameworks, potential applications, and future directions. Sensors 2021, 21, 7518. [Google Scholar] [CrossRef]

- Yavari, A.; Harrison, C.J.; Gorji, S.A.; Shafiei, M. Hydrogen 4.0: A Cyber–Physical System for Renewable Hydrogen Energy Plants. Sensors 2024, 24, 3239. [Google Scholar] [CrossRef]

- Tidrea, A.; Korodi, A.; Silea, I. Elliptic Curve Cryptography Considerations for Securing Automation and SCADA Systems. Sensors 2023, 23, 2686. [Google Scholar] [CrossRef] [PubMed]

- da Rocha, H.; Abrishambaf, R.; Pereira, J.; Santo, A.E. Integrating the IEEE 1451 and IEC 61499 Standards with the Industrial Internet Reference Architecture. Sensors 2022, 22, 1495. [Google Scholar] [CrossRef] [PubMed]

- Ali, Z.; Mahmood, A.; Khatoon, S.; Alhakami, W.; Ullah, S.S.; Iqbal, J.; Hussain, S. A Generic Internet of Things (IoT) Middleware for Smart City Applications. Sustainability 2023, 15, 743. [Google Scholar] [CrossRef]

- Bellini, P.; Nesi, P.; Pantaleo, G. IoT-Enabled Smart Cities: A Review of Concepts, Frameworks and Key Technologies. Appl. Sci. 2022, 12, 1607. [Google Scholar] [CrossRef]

- Jaskó, S.; Skrop, A.; Holczinger, T.; Chován, T.; Abonyi, J. Development of manufacturing execution systems in accordance with Industry 4.0 requirements: A review of standard- and ontology-based methodologies and tools. Comput. Ind. 2020, 123, 103300. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. The Future of the Human–Machine Interface (HMI) in Society 5.0. Future Internet 2023, 15, 162. [Google Scholar] [CrossRef]

- Folgado, F.J.; González, I.; Calderón, A.J. PEM Electrolyzer Digital Replica based on internal resistance determination applied to hydrogen energy storage. J. Energy Storage 2024, 75, 109694. [Google Scholar] [CrossRef]

- Jaloudi, S. Communication protocols of an industrial internet of things environment: A comparative study. Future Internet 2019, 11, 66. [Google Scholar] [CrossRef]

- Hasır, M.; Cekli, S.; Uzunoğlu, C.P. Simultaneous remote monitoring of transformers’ ambient parameters by using IoT. Internet Things 2021, 14, 100390. [Google Scholar] [CrossRef]

- Hajda, J.; Jakuszewski, R.; Ogonowski, S. Security challenges in industry 4.0 plc systems. Appl. Sci. 2021, 11, 9785. [Google Scholar] [CrossRef]

| Signal | Sensor |

|---|---|

| Temperature | Pt-100 |

| Voltage | Potentiometric voltage divider |

| Current | Hall effect sensor |

| Irradiance | Pyranometer |

| Signal | Sensor |

|---|---|

| Current | Hall effect sensor |

| Voltage | Potentiometric voltage divider |

| SoC | Gateway |

| SoH | Gateway |

| Temperature | Gateway |

| Signal | Sensor |

|---|---|

| Current | Hall effect sensor |

| Voltage | Potentiometric voltage divider |

| Temperature | Pt-100 |

| Pressure | Pressure transmitter |

| Hydrogen flow | Thermal mass flow meter |

| Signal | Sensor |

|---|---|

| Current | Hall effect sensor |

| Voltage | Potentiometric voltage divider |

| Temperature | Pt-100 |

| Pressure | Pressure transmitter |

| Hydrogen flow | Thermal mass flow meter |

| Hardware | Variables | Sample Period | Total Number of Records |

|---|---|---|---|

| PV generator | 16 | 1 min | 1.625.319 |

| Battery | 12 | 1 min | 1.625.319 |

| Hydrogen generator | 26 | 1 min | 347.329 |

| Fuel cell | 19 | 1 min | 521.674 |

| Layer | PV Generator | Battery | Hydrogen Generator | Fuel Cell |

|---|---|---|---|---|

| Application layer | Grafana | Grafana | Grafana | Grafana |

| Raspberry Pi | Raspberry Pi | PC | IoT2050 | |

| Middleware layer | Python, MariaDB | Python, MariaDB | Node-RED, MariaDB | Python, MariaDB |

| Raspberry Pi | Raspberry Pi, Gateway | PC, IoT2050 | IoT2050 | |

| Network layer | Modbus TCP, HTTP, PROFINET | Modbus TCP, HTTP, CAN | Modbus TCP, HTTP | Modbus TCP, HTTP |

| Sensing layer | PLC, RIOS | PLC, BMU | PLC | PLC |

| Temperature, irradiance, voltage, current | Temperature, voltage, current, SoC | Temperature, hydrogen flow, voltage, current | Temperature, hydrogen flow, voltage, current |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calderón, D.; Folgado, F.J.; González, I.; Calderón, A.J. Implementation and Experimental Application of Industrial IoT Architecture Using Automation and IoT Hardware/Software. Sensors 2024, 24, 8074. https://doi.org/10.3390/s24248074

Calderón D, Folgado FJ, González I, Calderón AJ. Implementation and Experimental Application of Industrial IoT Architecture Using Automation and IoT Hardware/Software. Sensors. 2024; 24(24):8074. https://doi.org/10.3390/s24248074

Chicago/Turabian StyleCalderón, David, Francisco Javier Folgado, Isaías González, and Antonio José Calderón. 2024. "Implementation and Experimental Application of Industrial IoT Architecture Using Automation and IoT Hardware/Software" Sensors 24, no. 24: 8074. https://doi.org/10.3390/s24248074

APA StyleCalderón, D., Folgado, F. J., González, I., & Calderón, A. J. (2024). Implementation and Experimental Application of Industrial IoT Architecture Using Automation and IoT Hardware/Software. Sensors, 24(24), 8074. https://doi.org/10.3390/s24248074