A Time–Frequency-Based Data-Driven Approach for Structural Damage Identification and Its Application to a Cable-Stayed Bridge Specimen

Abstract

1. Introduction

2. Theoretical Basis of Structural Damage Identification Based on CNNs

2.1. GADF Theory

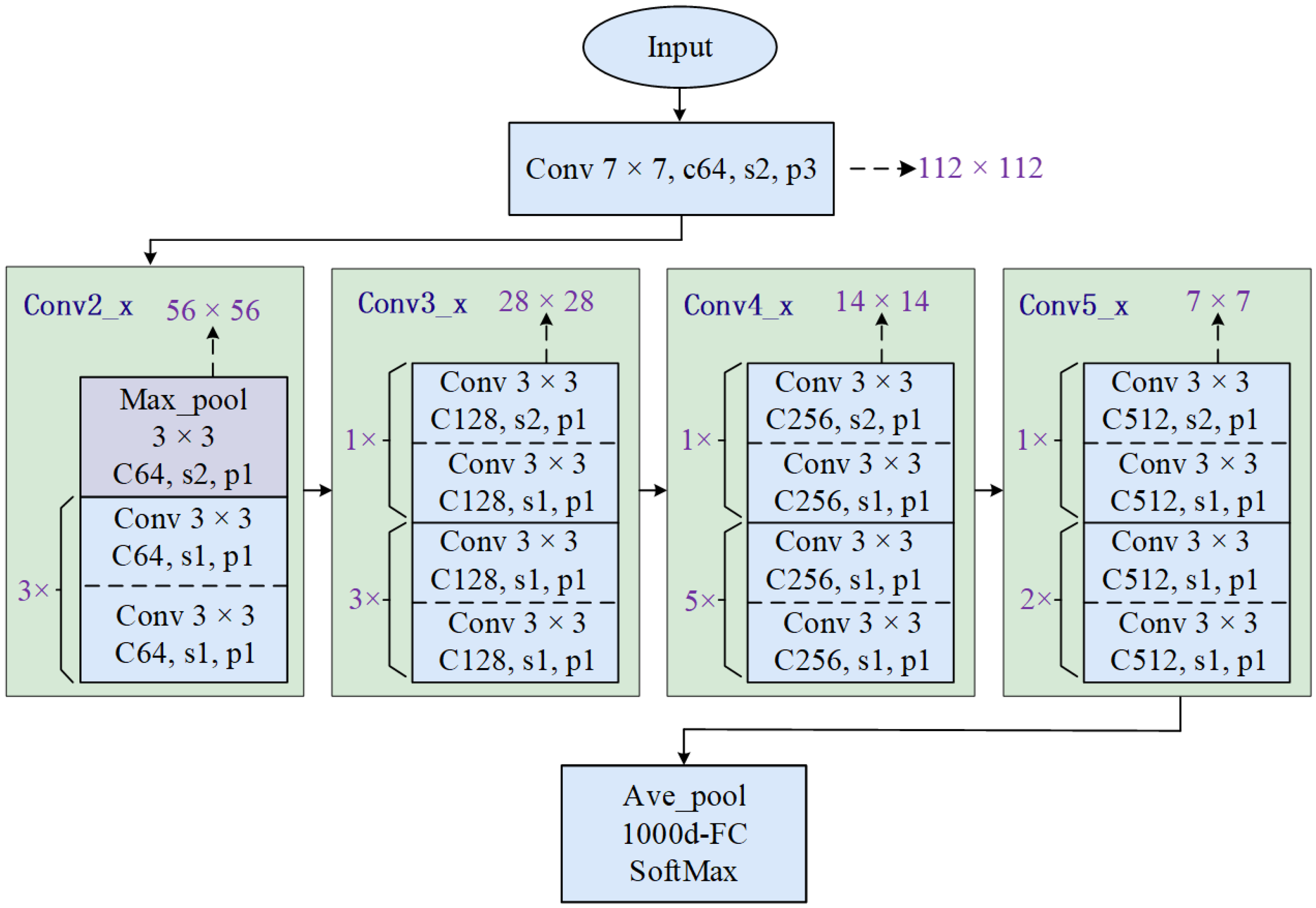

2.2. Training CNNs

3. Model Test Design

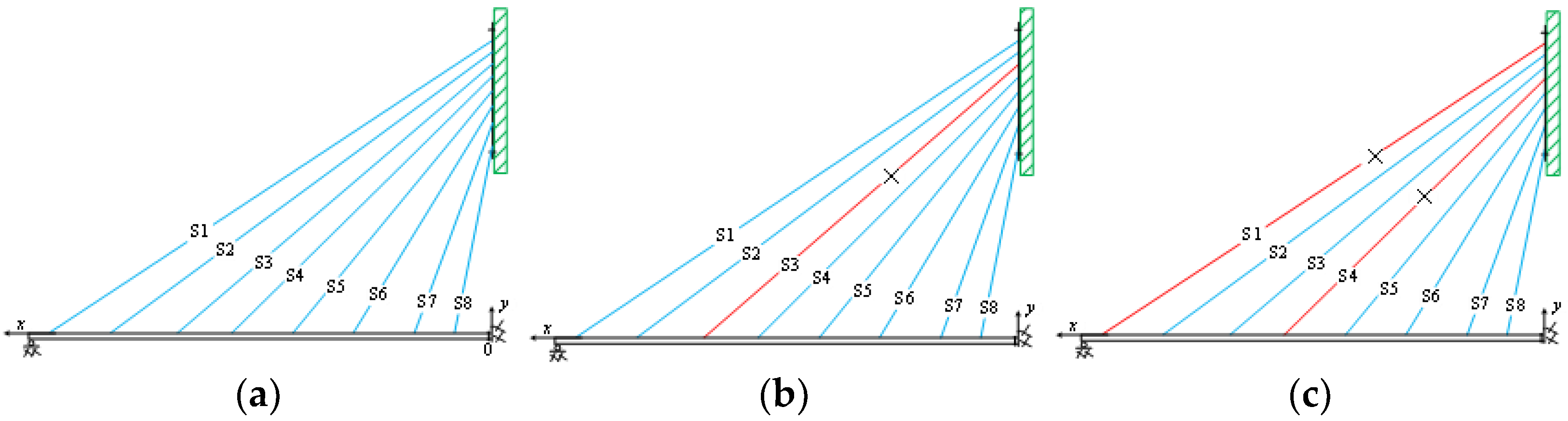

3.1. Overview of the Cable-Stayed Bridge Specimen

3.2. Probabilistic Modeling of Traffic Parameters

3.3. Damage Condition Setup

4. Results and Discussions

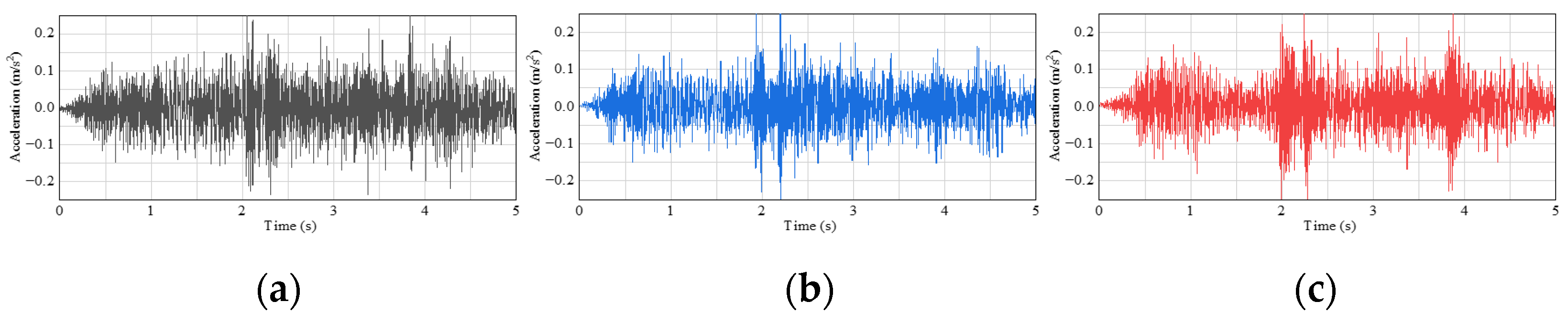

4.1. Time–Frequency Analysis Based on GADF

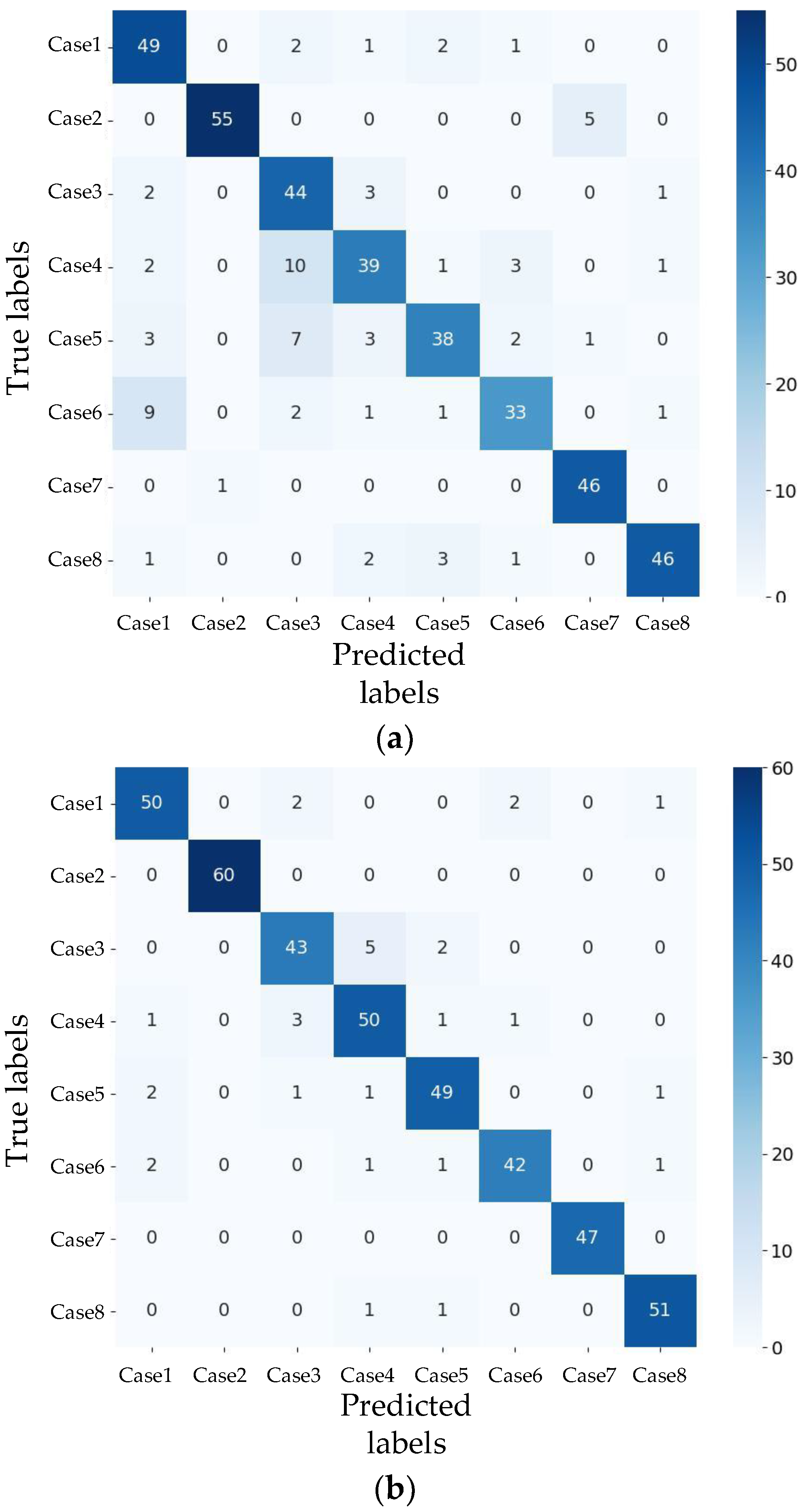

4.2. Comparison with Traditional Networks

4.3. Network Robustness Under Noise Conditions

5. Conclusions

- (1)

- The acceleration response of the vehicle–bridge interaction system was projected into the time–frequency domain using GADF, preserving the time-dependent and nonlinear characteristics of the time series in the resulting images. This process facilitates the creation of a labeled dataset with 2D time–frequency representations of the signals, enhancing classification and analysis through deep learning methods and improving accuracy.

- (2)

- The ResNet was demonstrated to have the best performance in terms of the damage identification accuracy and convergence speed, achieving a higher accuracy and faster convergence compared to other networks.

- (3)

- As the SNR decreases from 20 dB to 2.5 dB, ResNet’s prediction accuracy declines from 86.63% to 62.5%. Despite this, tests across eight damage conditions under different noise levels demonstrated that the ResNet model maintains strong robustness and reliability in identifying structural damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, N.; Wang, H.; Luo, Y.; Liu, X.; Liu, Y. Merging behaviour and fatigue life evaluation of multi-cracks in welds of OSDs. J. Constr. Steel Res. 2025, 225, 109189. [Google Scholar] [CrossRef]

- Ma, Y.; Peng, A.; Wang, L.; Dai, L.; Zhang, J. Structural performance degradation of cable-stayed bridges subjected to cable damage: Model test and theoretical prediction. Struct. Infrastruct. Eng. 2023, 19, 1173–1189. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, X.; Cui, J.; Wang, H.; Huang, L.; Zeng, W.; Zhang, H. Lifetime fatigue cracking behavior of weld defects in orthotropic steel bridge decks: Numerical and experimental study. Eng. Fail. Anal. 2025, 167, 108993. [Google Scholar] [CrossRef]

- Deng, F.; Wei, S.; Jin, X.; Chen, Z.; Li, H. Damage identification of long-span bridges based on the correlation of probability distribution of monitored quasi-static responses. Mech. Syst. Signal Process. 2023, 186, 109908. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Salehi, H.; Zhang, H.; Zhou, H.; Jiao, P. Integrated structural health monitoring in bridge engineering. Autom. Constr. 2022, 136, 104168. [Google Scholar] [CrossRef]

- Svendsen, B.T.; Frøseth, G.T.; Øiseth, O.; Rønnquist, A. A data-based structural health monitoring approach for damage detection in steel bridges using experimental data. J. Civ. Struct. Health Monit. 2022, 12, 101–115. [Google Scholar] [CrossRef]

- Ma, Y.; He, Y.; Wang, G.; Wang, L.; Zhang, J.; Lee, D. Corrosion fatigue crack growth prediction of bridge suspender wires using Bayesian Gaussian process. Int. J. Fatigue 2023, 168, 107377. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, P.; Floyd, R.W. Generation of optimal load paths for corroded reinforced concrete beams Part I: Automatic stiffness adjustment technique. ACI Struct. J. 2023, 120, 103–114. [Google Scholar]

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Zhang, C.; Mousavi, A.A.; Masri, S.F.; Gholipour, G.; Yan, K.; Li, X. Vibration feature extraction using signal processing techniques for structural health monitoring: A review. Mech. Syst. Signal Process. 2022, 177, 109175. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Li, X.; Fu, P.; Xu, L.; Xin, L. Assessing time-dependent damage to a cable-stayed bridge through multi-directional ground motions based on material strain measures. Eng. Struct. 2021, 227, 111417. [Google Scholar] [CrossRef]

- Li, Z.; Lan, Y.; Lin, W. Indirect damage detection for bridges using sensing and temporarily parked vehicles. Eng. Struct. 2023, 291, 116459. [Google Scholar] [CrossRef]

- Alampalli, S.; Frangopol, D.M.; Grimson, J.; Halling, M.W.; Kosnik, D.E.; Lantsoght, E.O.; Zhou, Y.E. Bridge load testing: State-of-the-practice. J. Bridge Eng. 2021, 26, 03120002. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Heidarrezaei, M.; Rahimian Koloor, S.S.; Petrů, M. Vehicle-assisted techniques for health monitoring of bridges. Sensors 2020, 20, 3460. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Huang, Z.; Liu, Y. Bridge damage identification under the moving vehicle loads based on the method of physics-guided deep neural networks. Mech. Syst. Signal Process. 2023, 190, 110123. [Google Scholar] [CrossRef]

- Zhu, X.Q.; Law, S.S. Structural health monitoring based on vehicle-bridge interaction: Accomplishments and challenges. Adv. Struct. Eng. 2015, 18, 1999–2015. [Google Scholar] [CrossRef]

- Li, J.; Law, S.S.; Hao, H. Improved damage identification in bridge structures subject to moving loads: Numerical and experimental studies. Int. J. Mech. Sci. 2013, 74, 99–111. [Google Scholar] [CrossRef]

- Fallahian, M.; Khoshnoudian, F.; Talaei, S. Application of couple sparse coding ensemble on structural damage detection. Smart Struct. Syst. 2018, 21, 1–14. [Google Scholar]

- Pathirage, C.S.N.; Li, J.; Li, L.; Hao, H.; Liu, W.; Ni, P. Structural damage identification based on autoencoder neural networks and deep learning. Eng. Struct. 2018, 172, 13–28. [Google Scholar] [CrossRef]

- YiFei, L.; Minh, H.L.; Khatir, S.; Sang-To, T.; Cuong-Le, T.; MaoSen, C.; Wahab, M.A. Structure damage identification in dams using sparse polynomial chaos expansion combined with hybrid K-means clustering optimizer and genetic algorithm. Eng. Struct. 2023, 283, 115891. [Google Scholar] [CrossRef]

- Lin, Y.Z.; Nie, Z.H.; Ma, H.W. Structural damage detection with automatic feature-extraction through deep learning. Comput.-Aided Civil Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Albayati, A.Q.; Altaie, S.A.J.; Al-Obaydy, W.N.I.; Alkhalid, F.F. Performance analysis of optimization algorithms for convolutional neural network-based handwritten digit recognition. IAES Int. J. Artif. Intell. 2024, 13, 563–571. [Google Scholar] [CrossRef]

- Shin, H.C.; Roth, H.R.; Gao, M.; Lu, L.; Xu, Z.; Nogues, I.; Summers, R.M. Deep convolutional neural networks for computer-aided detection: CNN architectures, dataset characteristics and transfer learning. IEEE Trans. Med. Imaging 2016, 35, 1285–1298. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Singh, P.; Sadhu, A. Limited sensor-based bridge condition assessment using vehicle-induced nonstationary measurements. Structures 2021, 32, 1207–1220. [Google Scholar] [CrossRef]

- Pan, H.; Azimi, M.; Yan, F.; Lin, Z. Time-frequency-based data-driven structural diagnosis and damage detection for cable-stayed bridges. J. Bridge Eng. 2018, 23, 04018033. [Google Scholar] [CrossRef]

- Wang, F.; Huang, H.; Liu, J. Variational-based mixed noise removal with CNN deep learning regularization. IEEE Trans. Image Process. 2019, 29, 1246–1258. [Google Scholar] [CrossRef]

- Hajializadeh, D. Deep learning-based indirect bridge damage identification system. Struct. Health Monit. 2023, 22, 897–912. [Google Scholar] [CrossRef]

- Fernandez-Navamuel, A.; Pardo, D.; Magalhães, F.; Zamora-Sánchez, D.; Omella, Á.J.; Garcia-Sanchez, D. Bridge damage identification under varying environmental and operational conditions combining Deep Learning and numerical simulations. Mech. Syst. Signal Process. 2023, 200, 110471. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, C.; Guo, B. Transfer-learning guided Bayesian model updating for damage identification considering modeling uncertainty. Mech. Syst. Signal Process. 2022, 166, 108426. [Google Scholar] [CrossRef]

- Yang, D.S.; Wang, C.M. Bridge damage detection using reconstructed mode shape by improved vehicle scanning method. Eng. Struct. 2022, 263, 114373. [Google Scholar] [CrossRef]

- Silik, A.; Noori, M.; Altabey, W.A.; Ghiasi, R.; Wu, Z. Comparative analysis of wavelet transform for time-frequency analysis and transient localization in structural health monitoring. Struct. Durabil. Health Monit. 2021, 15, 1–22. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, H.; Zhang, Y.; Qi, Z.; Wang, D. GAF-MAE: A self-supervised automatic modulation classification method based on Gramian angular field and masked autoencoder. IEEE Trans. Cogn. Commun. Netw. 2023, 10, 94–106. [Google Scholar] [CrossRef]

- Wang, Z.; Oates, T. Imaging time-series to improve classification and imputation. arXiv 2015, arXiv:1506.00327. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

| Cable Number | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|---|---|---|---|---|---|---|---|---|

| Cable force/N | 12.3 | 17 | 20.7 | 37.1 | 29.5 | 24.8 | 15.3 | 13.4 |

| Scenario | Damage Location | Damage Levels |

|---|---|---|

| Case 1 | Intact | / |

| Case 2 | S1 | 30% |

| Case 3 | S3 | 30% |

| Case 4 | S5 | 30% |

| Case 5 | S1, S4 | 30% |

| Case 6 | S2, S5 | 30% |

| Case 7 | N2, N4 | 30% |

| Case 8 | N5, N6 | 30% |

| SNR | 0 dB | 20 dB | 10 dB | 5 dB | 2.5 dB |

|---|---|---|---|---|---|

| Accuracy | 92.75% | 86.63% | 82.50% | 73.75% | 62.5% |

| Loss | 0.26 | 0.41 | 0.55 | 0.77 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, N.; Liu, Y.; Cui, J.; Xiao, X.; Luo, Y.; Noori, M. A Time–Frequency-Based Data-Driven Approach for Structural Damage Identification and Its Application to a Cable-Stayed Bridge Specimen. Sensors 2024, 24, 8007. https://doi.org/10.3390/s24248007

Lu N, Liu Y, Cui J, Xiao X, Luo Y, Noori M. A Time–Frequency-Based Data-Driven Approach for Structural Damage Identification and Its Application to a Cable-Stayed Bridge Specimen. Sensors. 2024; 24(24):8007. https://doi.org/10.3390/s24248007

Chicago/Turabian StyleLu, Naiwei, Yiru Liu, Jian Cui, Xiangyuan Xiao, Yuan Luo, and Mohammad Noori. 2024. "A Time–Frequency-Based Data-Driven Approach for Structural Damage Identification and Its Application to a Cable-Stayed Bridge Specimen" Sensors 24, no. 24: 8007. https://doi.org/10.3390/s24248007

APA StyleLu, N., Liu, Y., Cui, J., Xiao, X., Luo, Y., & Noori, M. (2024). A Time–Frequency-Based Data-Driven Approach for Structural Damage Identification and Its Application to a Cable-Stayed Bridge Specimen. Sensors, 24(24), 8007. https://doi.org/10.3390/s24248007