Quantification of Size-Binned Particulate Matter in Electronic Cigarette Aerosols Using Multi-Spectral Optical Sensing and Machine Learning

Abstract

1. Introduction

2. Multi-Spectral E-Cigarette Aerosol Sensor Working Principle

3. Materials and Methods

3.1. Prototype of a Multi-Spectral E-Cigarette Aerosol Sensor

3.2. E-Cigarettes and E-Liquids

3.3. Acquisition of Data from E-Cigarettes

3.4. Sensor Signal Processing

3.5. Reference Measurement of E-Cigarette Aerosols for the Ground Truth

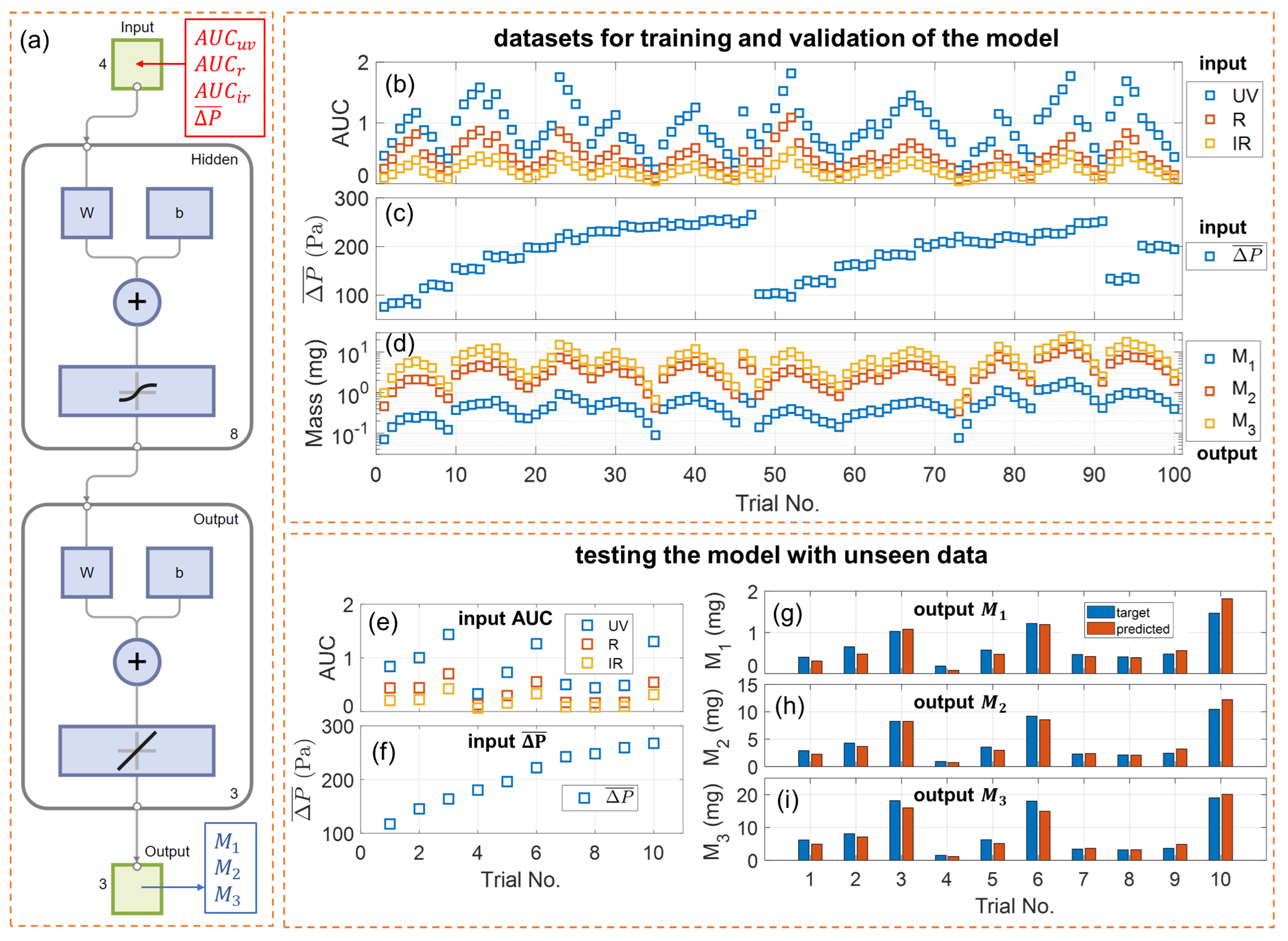

3.6. Training, Validation, and Testing of the Neural Network

4. Results and Discussion

4.1. Performance of the Default Neural Network Model

4.2. Puff Topography with Size-Binned PM Mass

4.3. Configuration of the Neural Network Models

4.4. Particle Size Bins

4.5. Performance on Unseen E-Cigarettes or E-Liquids

4.6. Machine Learning

4.7. Limitations and Future Work

4.8. Other Applications

4.9. Comparison with Other Optical Approaches

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| E-Cigarette | Electronic Cigarette |

| PM | Particulate Matter |

| UV | Ultraviolet |

| R | Red |

| IR | Infrared |

| FWHM | Full Width at Half Maximum |

| MCU | Micro-Controller Unit |

| ADC | Analog-to-Digital Conversion |

| TIA | Transimpedance Amplifier |

| LED | Light Emitting Diode |

| MSE | Mean Squared Error |

| MRE | Mean Relative Error |

| MBE | Mean Bias Error |

| NN | Neural Network |

| SMPS | Scanning Mobility Particle Sizer |

| CPC | Condensation Particle Sizer |

| EC | Electrostatic Classifier |

| DMA | Differential Mobility Analyzer |

| List of Symbols | |

| , , and | Optical intensity signal for UV, Red, and IR wavelength, respectively |

| , , and | Optical attenuation in response to an e-cigarette aerosol flow for UV, Red, and IR wavelength, respectively |

| , , and | Integrated optical attenuation (area under the curve) of , , and , respectively |

| Inhalation pressure measured by the pressure sensor | |

| , , and | Mass concentration of PM in size bin 1, 2, and 3, respectively, as a function of time for the aerosol flow |

| Volumetric flow rate of the e-cigarette aerosol, as a function of time | |

| , , and | Mass of PM in size bin 1, 2, and 3, respectively |

| Particle diameter | |

| PM number concentration of the diluted aerosol in the dilution box, as a function of particle diameter | |

| PM mass concentration of the diluted aerosol in the dilution box, as a function of particle diameter | |

| Volume of the dilution box |

References

- Grana, R.; Benowitz, N.; Glantz, S.A. E-cigarettes: A scientific review. Circulation 2014, 129, 1972–1986. [Google Scholar] [CrossRef] [PubMed]

- Brown, C.J.; Cheng, J.M. Electronic cigarettes: Product characterisation and design considerations. Tob. Control 2014, 23, ii4–ii10. [Google Scholar] [CrossRef] [PubMed]

- Schober, W.; Szendrei, K.; Matzen, W.; Osiander-Fuchs, H.; Heitmann, D.; Schettgen, T.; Jörres, R.A.; Fromme, H. Use of electronic cigarettes (e-cigarettes) impairs indoor air quality and increases FeNO levels of e-cigarette consumers. Int. J. Hyg. Environ. Health 2014, 217, 628–637. [Google Scholar] [CrossRef] [PubMed]

- Chapman, S.L.C.; Wu, L.T. E-cigarette prevalence and correlates of use among adolescents versus adults: A review and comparison. J. Psychiatr. Res. 2014, 54, 43–54. [Google Scholar] [CrossRef] [PubMed]

- Cameron, J.M.; Howell, D.N.; White, J.R.; Andrenyak, D.M.; Layton, M.E.; Roll, J.M. Variable and potentially fatal amounts of nicotine in e-cigarette nicotine solutions. Tob. Control 2014, 23, 77–78. [Google Scholar] [CrossRef]

- Breland, A.; Soule, E.; Lopez, A.; Ramôa, C.; El-Hellani, A.; Eissenberg, T. Electronic cigarettes: What are they and what do they do? Ann. N. Y. Acad. Sci. 2016, 1394, 5–30. [Google Scholar] [CrossRef]

- Sleiman, M.; Logue, J.M.; Montesinos, V.N.; Russell, M.L.; Litter, M.I.; Gundel, L.A.; Destaillats, H. Emissions from electronic cigarettes: Key parameters affecting the release of harmful chemicals. Environ. Sci. Technol. 2016, 50, 9644–9651. [Google Scholar] [CrossRef]

- Cho, J.H.; Paik, S.Y. Association between electronic cigarette use and asthma among high school students in South Korea. PLoS ONE 2016, 11, e0151022. [Google Scholar] [CrossRef]

- Hess, C.A.; Olmedo, P.; Navas-Acien, A.; Goessler, W.; Cohen, J.E.; Rule, A.M. E-cigarettes as a source of toxic and potentially carcinogenic metals. Environ. Res. 2017, 152, 221–225. [Google Scholar] [CrossRef]

- Dunbar, Z.R.; Das, A.; O’Connor, R.J.; Goniewicz, M.L.; Wei, B.; Travers, M.J. Brief report: Lead levels in selected electronic cigarettes from Canada and the United States. Int. J. Environ. Res. Public Health 2018, 15, 154. [Google Scholar] [CrossRef]

- Olmedo, P.; Goessler, W.; Tanda, S.; Grau-Perez, M.; Jarmul, S.; Aherrera, A.; Chen, R.; Hilpert, M.; Cohen, J.E.; Navas-Acien, A.; et al. Metal Concentrations in e-Cigarette Liquid and Aerosol Samples: The Contribution of Metallic Coils. Environ. Health Perspect. 2018, 126, 027010. [Google Scholar] [CrossRef] [PubMed]

- Gaur, S.; Agnihotri, R. Health effects of trace metals in electronic cigarette aerosols—a systematic review. Biol. Trace Elem. Res. 2019, 188, 295–315. [Google Scholar] [CrossRef]

- Holliday, R.; Chaffee, B.; Jakubovics, N.; Kist, R.; Preshaw, P. Electronic cigarettes and oral health. J. Dent. Res. 2021, 100, 906–913. [Google Scholar] [CrossRef] [PubMed]

- Keith, R.; Bhatnagar, A. Cardiorespiratory and Immunologic Effects of Electronic Cigarettes. Curr. Addict. Rep. 2021, 8, 336–346. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wu, D.; Ma, Y.; Ma, X.; Wang, S.; Li, F.; Li, M.; Zhang, T. Toxicity of electronic cigarettes: A general review of the origins, health hazards, and toxicity mechanisms. Sci. Total Environ. 2021, 772, 145475. [Google Scholar] [CrossRef] [PubMed]

- Ween, M.P.; Moshensky, A.; Thredgold, L.; Bastian, N.A.; Hamon, R.; Badiei, A.; Nguyen, P.T.; Herewane, K.; Jersmann, H.; Bojanowski, C.M.; et al. E-cigarettes and health risks: More to the flavor than just the name. Am. J. Physiol.-Lung Cell. Mol. Physiol. 2021, 320, L600–L614. [Google Scholar] [CrossRef]

- Williams, M.; Villarreal, A.; Bozhilov, K.; Lin, S.; Talbot, P. Metal and Silicate Particles Including Nanoparticles Are Present in Electronic Cigarette Cartomizer Fluid and Aerosol. PLoS ONE 2013, 8, e57987. [Google Scholar] [CrossRef]

- Goniewicz, M.L.; Knysak, J.; Gawron, M.; Kosmider, L.; Sobczak, A.; Kurek, J.; Prokopowicz, A.; Jablonska-Czapla, M.; Rosik-Dulewska, C.; Havel, C.; et al. Levels of selected carcinogens and toxicants in vapour from electronic cigarettes. Tob. Control 2014, 23, 133–139. [Google Scholar] [CrossRef]

- Talih, S.; Balhas, Z.; Eissenberg, T.; Salman, R.; Karaoghlanian, N.; El Hellani, A.; Baalbaki, R.; Saliba, N.; Shihadeh, A. Effects of User Puff Topography, Device Voltage, and Liquid Nicotine Concentration on Electronic Cigarette Nicotine Yield: Measurements and Model Predictions. Nicotine Tob. Res. 2014, 17, 150–157. [Google Scholar] [CrossRef]

- Behar, R.Z.; Hua, M.; Talbot, P. Puffing Topography and Nicotine Intake of Electronic Cigarette Users. PLoS ONE 2015, 10, e0117222. [Google Scholar] [CrossRef]

- Lerner, C.A.; Sundar, I.K.; Watson, R.M.; Elder, A.; Jones, R.; Done, D.; Kurtzman, R.; Ossip, D.J.; Robinson, R.; McIntosh, S.; et al. Environmental health hazards of e-cigarettes and their components: Oxidants and copper in e-cigarette aerosols. Environ. Pollut. 2015, 198, 100–107. [Google Scholar] [CrossRef] [PubMed]

- Williams, M.; To, A.; Bozhilov, K.; Talbot, P. Strategies to reduce tin and other metals in electronic cigarette aerosol. PLoS ONE 2015, 10, e0138933. [Google Scholar] [CrossRef] [PubMed]

- Mikheev, V.B.; Brinkman, M.C.; Granville, C.A.; Gordon, S.M.; Clark, P.I. Real-time measurement of electronic cigarette aerosol size distribution and metals content analysis. Nicotine Tob. Res. 2016, 18, 1895–1902. [Google Scholar] [CrossRef] [PubMed]

- Palazzolo, D.L.; Crow, A.P.; Nelson, J.M.; Johnson, R.A. Trace metals derived from electronic cigarette (ECIG) generated aerosol: Potential problem of ECIG devices that contain nickel. Front. Physiol. 2017, 7, 663. [Google Scholar] [CrossRef]

- Williams, M.; Li, J.; Talbot, P. Effects of model, method of collection, and topography on chemical elements and metals in the aerosol of tank-style electronic cigarettes. Sci. Rep. 2019, 9, 13969. [Google Scholar] [CrossRef]

- Mulder, H.A.; Patterson, J.L.; Halquist, M.S.; Kosmider, L.; Turner, J.B.M.; Poklis, J.L.; Poklis, A.; Peace, M.R. The effect of electronic cigarette user modifications and e-liquid adulteration on the particle size profile of an aerosolized product. Sci. Rep. 2019, 9, 10221. [Google Scholar] [CrossRef]

- Seiler-Ramadas, R.; Sandner, I.; Haider, S.; Grabovac, I.; Dorner, T.E. Health effects of electronic cigarette (e-cigarette) use on organ systems and its implications for public health. Wien. Klin. Wochenschr. 2021, 133, 1020–1027. [Google Scholar] [CrossRef]

- Fuoco, F.; Buonanno, G.; Stabile, L.; Vigo, P. Influential parameters on particle concentration and size distribution in the mainstream of e-cigarettes. Environ. Pollut. 2014, 184, 523–529. [Google Scholar] [CrossRef]

- Alderman, S.L.; Song, C.; Moldoveanu, S.C.; Cole, S.K. Particle Size Distribution of E-Cigarette Aerosols and the Relationship to Cambridge Filter Pad Collection Efficiency. Contrib. Tob. Nicotine Res. 2015, 26, 183–190. [Google Scholar] [CrossRef]

- Zhao, T.; Shu, S.; Guo, Q.; Zhu, Y. Effects of design parameters and puff topography on heating coil temperature and mainstream aerosols in electronic cigarettes. Atmos. Environ. 2016, 134, 61–69. [Google Scholar] [CrossRef]

- Floyd, E.L.; Queimado, L.; Wang, J.; Regens, J.L.; Johnson, D.L. Electronic cigarette power affects count concentration and particle size distribution of vaping aerosol. PLoS ONE 2018, 13, e0210147. [Google Scholar] [CrossRef] [PubMed]

- Dunkhorst, W.; Lipowicz, P.; Li, W.; Hux, C.; Wang, Q.; Koch, W. In-situ characterization of e-cigarette aerosols by 90°-light scattering of polarized light. Aerosol Sci. Technol. 2018, 52, 717–724. [Google Scholar] [CrossRef]

- Lechasseur, A.; Altmejd, S.; Turgeon, N.; Buonanno, G.; Morawska, L.; Brunet, D.; Duchaine, C.; Morissette, M.C. Variations in coil temperature/power and e-liquid constituents change size and lung deposition of particles emitted by an electronic cigarette. Physiol. Rep. 2019, 7, e14093. [Google Scholar] [CrossRef] [PubMed]

- CORESTA. Cooperation Centre for Scientific Research Relative to Tobacco (CORESTA). Available online: https://www.coresta.org (accessed on 1 May 2023).

- Cunningham, A.; Slayford, S.; Vas, C.; Gee, J.; Costigan, S.; Prasad, K. Development, validation and application of a device to measure e-cigarette users’ puffing topography. Sci. Rep. 2016, 6, 35071. [Google Scholar] [CrossRef] [PubMed]

- Williams, M.; Bozhilov, K.; Ghai, S.; Talbot, P. Elements including metals in the atomizer and aerosol of disposable electronic cigarettes and electronic hookahs. PLoS ONE 2017, 12, e0175430. [Google Scholar] [CrossRef]

- Farsalinos, K.; Poulas, K.; Voudris, V. Changes in Puffing Topography and Nicotine Consumption Depending on the Power Setting of Electronic Cigarettes. Nicotine Tob. Res. 2017, 20, 993–997. [Google Scholar] [CrossRef]

- Floyd, E.; Greenlee, S.; Oni, T.; Sadhasivam, B.; Queimado, L. The Effect of Flow Rate on a Third-Generation Sub-Ohm Tank Electronic Nicotine Delivery System—Comparison of CORESTA Flow Rates to More Realistic Flow Rates. Int. J. Environ. Res. Public Health 2021, 18, 7535. [Google Scholar] [CrossRef]

- Floyd, E.; Oni, T.; Cai, C.; Rehman, B.; Hwang, J.; Watson, T. Validation of a High Flow Rate Puff Topography System Designed for Measurement of Sub-Ohm, Third Generation Electronic Nicotine Delivery Systems. Int. J. Environ. Res. Public Health 2022, 19, 7989. [Google Scholar] [CrossRef]

- Kolaczyk, K.; Jiang, H. Photometric monitoring of electronic cigarette puff topography. Sensors 2023, 23, 8220. [Google Scholar] [CrossRef]

- Dunkhorst, W.; Lipowicz, P.; Koch, W. Characterization of highly concentrated organic aerosols by optical extinction in the mid infrared regime: Application to e-cigarettes. J. Aerosol Sci. 2016, 94, 33–42. [Google Scholar] [CrossRef]

- Wu, J.; Yang, M.; Huang, J.; Gao, Y.; Li, D.; Gao, N. Vaporization characteristics and aerosol optical properties of electronic cigarettes. Environ. Pollut. 2021, 275, 116670. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Wu, Y.; Li, L.; Guo, Y.; Çetintaş, E.; Zhu, Y.; Ozcan, A. Dynamic imaging and characterization of volatile aerosols in e-cigarette emissions using deep learning-based holographic microscopy. ACS Sens. 2021, 6, 2403–2410. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Wang, S.; Liu, Y.; Yan, S.; Zeng, J.; Deng, T. Light scattering intensity field imaging sensor for in situ aerosol analysis. ACS Sens. 2020, 5, 2061–2066. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Xia, J. Light scattering method for aerosol sizing based on machine learning. ACS Sens. 2024, 9, 1208–1217. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Bian, A.; Wang, S.; Yan, S.; Cheng, W.; Deng, T. An optical soot sizing method without prior morphology parameters. Combust. Flame 2024, 261, 113295. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, S.; Zhu, M.; Deng, T.; Chen, A.; Zeng, J. Three-wavelength optical sensor for measuring distributed mass concentrations of aerosols from stationary sources. Opt. Express 2021, 29, 6407–6423. [Google Scholar] [CrossRef]

- Jiang, H. Smart Electronic Cigarettes with Built-in Aerosol Sensors. In Proceedings of the 2022 IEEE Sensors, Dallas, TX, USA, 30 October–2 November 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Jiang, H. Aerosol Delivery Device with Aerosol Sensor Assembly for Detecting Physical and Chemical Properties of the Generated Aerosol. U.S. Patent Application 20220280732A1, 8 September 2022. [Google Scholar]

- Boiger, R.; Modini, R.L.; Moallemi, A.; Degen, D.; Adelmann, A.; Gysel-Beer, M. Retrieval of aerosol properties from in situ, multi-angle light scattering measurements using invertible neural networks. J. Aerosol Sci. 2022, 163, 105977. [Google Scholar] [CrossRef]

- Ruske, S.; Topping, D.O.; Foot, V.E.; Kaye, P.H.; Stanley, W.R.; Crawford, I.; Morse, A.P.; Gallagher, M.W. Evaluation of machine learning algorithms for classification of primary biological aerosol using a new UV-LIF spectrometer. Atmos. Meas. Tech. 2017, 10, 695–708. [Google Scholar] [CrossRef]

- Siomos, N.; Fountoulakis, I.; Natsis, A.; Drosoglou, T.; Bais, A. Automated aerosol classification from spectral UV measurements using machine learning clustering. Remote Sens. 2020, 12, 965. [Google Scholar] [CrossRef]

- Anjilvel, S.; Asgharian, B. A multiple-path model of particle deposition in the rat lung. Fundam. Appl. Toxicol. 1995, 28, 41–50. [Google Scholar] [CrossRef]

- James, S.; Brown, W.E.W.; Grant, L.D. Dosimetric comparisons of particle deposition and retention in rats and humans. Inhal. Toxicol. 2005, 17, 355–385. [Google Scholar] [CrossRef]

- Miller, F.J.; Asgharian, B.; Schroeter, J.D.; Price, O. Improvements and additions to the multiple path particle dosimetry model. J. Aerosol Sci. 2016, 99, 14–26. [Google Scholar] [CrossRef]

- Manojkumar, N.; Srimuruganandam, B.; Shiva Nagendra, S. Application of multiple-path particle dosimetry model for quantifying age specified deposition of particulate matter in human airway. Ecotoxicol. Environ. Saf. 2019, 168, 241–248. [Google Scholar] [CrossRef] [PubMed]

- MiePlot: A Computer Program for Scattering of Light from a Sphere Using Mie Theory & the Debye Series. Available online: http://www.philiplaven.com/mieplot.htm (accessed on 10 June 2022).

- Hiraoka, M.; Firbank, M.; Essenpreis, M.; Cope, M.; Arridge, S.R.; van der Zee, P.; Delpy, D.T. A Monte Carlo investigation of optical pathlength in inhomogeneous tissue and its application to near-infrared spectroscopy. Phys. Med. Biol. 1993, 38, 1859. [Google Scholar] [CrossRef]

- Delpy, D.T.; Cope, M.; van der Zee, P.; Arridge, S.; Wray, S.; Wyatt, J. Estimation of optical pathlength through tissue from direct time of flight measurement. Phys. Med. Biol. 1988, 33, 1433–1442. [Google Scholar] [CrossRef]

- Kyriacou, P.A.; Chatterjee, S. The origin of photoplethysmography. In Photoplethysmography; Academic Press: Cambridge, MA, USA, 2022; pp. 17–43. [Google Scholar] [CrossRef]

- Obrig, H.; Villringer, A. Beyond the visible—Imaging the human brain with light. J. Cereb. Blood Flow Metab. 2003, 23, 1–18. [Google Scholar] [CrossRef]

- Sassaroli, A.; Fantini, S. Comment on the modified Beer–Lambert law for scattering media. Phys. Med. Biol. 2004, 49, N255. [Google Scholar] [CrossRef]

- Pourchez, J.; Parisse, S.; Sarry, G.; Perinel-Ragey, S.; Vergnon, J.M.; Clotagatide, A.; Prévôt, N. Impact of power level and refill liquid composition on the aerosol output and particle size distribution generated by a new-generation e-cigarette device. Aerosol Sci. Technol. 2018, 52, 359–369. [Google Scholar] [CrossRef]

- Judge, S.; Jaramillo, J.; Jiang, H. Numerical study of metal nano-orifices for optical sizing of ultrafine particles in aerosols. Plasmonics 2024, 19, 145–158. [Google Scholar] [CrossRef]

- Jiang, H.; Judge, S. An optofluidic nanoplasmonic sensor for aerosols. In Proceedings of the 2023 IEEE Photonics Conference (IPC), Orlando, FL, USA, 12–16 November 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Judge, S.; Jiang, H. Rational selection of metal subwavelength apertures for sensing aerosol nanoparticles. In Proceedings of the 2023 IEEE Photonics Conference (IPC), Orlando, FL, USA, 12–16 November 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Setiono, A.; Bertke, M.; Nyang’au, W.O.; Xu, J.; Fahrbach, M.; Kirsch, I.; Uhde, E.; Deutschinger, A.; Fantner, E.J.; Schwalb, C.H.; et al. In-plane and out-of-plane MEMS piezoresistive cantilever sensors for nanoparticle mass detection. Sensors 2020, 20, 618. [Google Scholar] [CrossRef]

- Pachkawade, V.; Tse, Z. MEMS sensor for detection and measurement of ultra-fine particles. Eng. Res. Express 2022, 4, 022002. [Google Scholar] [CrossRef]

- Kwon, H.S.; Ryu, M.H.; Carlsten, C. Ultrafine particles: Unique physicochemical properties relevant to health and disease. Exp. Mol. Med. 2020, 52, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Schraufnagel, D.E. The health effects of ultrafine particles. Exp. Mol. Med. 2020, 52, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Jung, H.T.; Ferrell, A.; Woo, S.; Haddad, L. Machine learning-based nicotine addiction prediction models for youth e-cigarette and waterpipe (hookah) users. J. Clin. Med. 2021, 10, 972. [Google Scholar] [CrossRef]

- Shi, J.; Fu, R.; Hamilton, H.; Chaiton, M. A machine learning approach to predict e-cigarette use and dependence among Ontario youth. Health Promot. Chronic Dis. Prev. Can. Res. Policy Pract. 2022, 42, 21. [Google Scholar] [CrossRef]

| Model Ref. No. | Input | Layer Size | Epoch | Performance for Model Training and Validation | Performance for Testing the Model with Unseen Data | ||||

|---|---|---|---|---|---|---|---|---|---|

| MSE for M1 | MSE for M2 | MSE for M3 | MSE for M1 | MSE for M2 | MSE for M3 | ||||

| NN01 (Default) | and for UV, Red & IR | 8 | 8 | 0.009939 | 0.2416 | 0.5393 | 0.01935 | 0.5296 | 2.1065 |

| NN02 | and for IR only | 8 | 4 | 0.03886 | 1.1561 | 2.5582 | 0.05941 | 2.4227 | 9.7990 |

| NN03 | and for Red only | 8 | 9 | 0.05745 | 1.8651 | 4.7808 | 0.06869 | 2.5469 | 11.3641 |

| NN04 | and for UV only | 8 | 4 | 0.03943 | 1.4460 | 3.7362 | 0.05638 | 2.3871 | 9.4459 |

| NN05 | and for UV & IR | 8 | 5 | 0.03525 | 1.0848 | 2.0966 | 0.04068 | 2.0939 | 6.9357 |

| NN06 | and for IR only | 5 | 57 | 0.02878 | 0.9960 | 2.0654 | 0.04487 | 2.0051 | 7.1812 |

| NN07 | and for Red only | 5 | 10 | 0.04971 | 1.8346 | 4.8166 | 0.06208 | 3.2874 | 14.0912 |

| NN08 | and for UV only | 5 | 24 | 0.03350 | 1.0728 | 2.4257 | 0.05101 | 2.4485 | 12.1907 |

| NN09 | and for UV & IR | 5 | 7 | 0.03948 | 1.2161 | 2.6419 | 0.03799 | 1.1729 | 5.0783 |

| NN10 | and for UV, Red & IR | 12 | 17 | 0.008897 | 0.1321 | 0.3017 | 0.01626 | 1.6694 | 5.4919 |

| Config. No. | Electronic Cigarette Device | E-Liquid | Performance for Testing the Model with Unseen Data | E-Liquid Color | * Device Pressure Testing (Pa) | Notes | ||

|---|---|---|---|---|---|---|---|---|

| MSE for M1 | MSE for M2 | MSE for M3 | ||||||

| 01 | Nautilus PrimeX | KSPR | 0.01935 | 0.5296 | 2.1065 | light yellow | 898.5 | Default configuration |

| 02 | Nautilus PrimeX | ENVY | 0.1042 | 4.1486 | 8.5527 | brown | 898.5 | E-liquid more opaque than KSPR |

| 03 | Nautilus PrimeX | DewBerry | 0.1150 | 3.7665 | 5.4013 | clear | 898.5 | E-liquid more transparent than KSPR |

| 04 | SUORIN | KSPR | 0.07011 | 2.1045 | 5.2330 | light yellow | 1601.0 | The e-cigarette has higher flow resistance than default |

| 05 | SMOK S-PRIV | KSPR | 0.2673 | 11.5140 | 25.7882 | light yellow | 2518.3 | The e-cigarette has the highest flow resistance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Kolaczyk, K. Quantification of Size-Binned Particulate Matter in Electronic Cigarette Aerosols Using Multi-Spectral Optical Sensing and Machine Learning. Sensors 2024, 24, 7082. https://doi.org/10.3390/s24217082

Jiang H, Kolaczyk K. Quantification of Size-Binned Particulate Matter in Electronic Cigarette Aerosols Using Multi-Spectral Optical Sensing and Machine Learning. Sensors. 2024; 24(21):7082. https://doi.org/10.3390/s24217082

Chicago/Turabian StyleJiang, Hao, and Keith Kolaczyk. 2024. "Quantification of Size-Binned Particulate Matter in Electronic Cigarette Aerosols Using Multi-Spectral Optical Sensing and Machine Learning" Sensors 24, no. 21: 7082. https://doi.org/10.3390/s24217082

APA StyleJiang, H., & Kolaczyk, K. (2024). Quantification of Size-Binned Particulate Matter in Electronic Cigarette Aerosols Using Multi-Spectral Optical Sensing and Machine Learning. Sensors, 24(21), 7082. https://doi.org/10.3390/s24217082