IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen

Abstract

1. Introduction

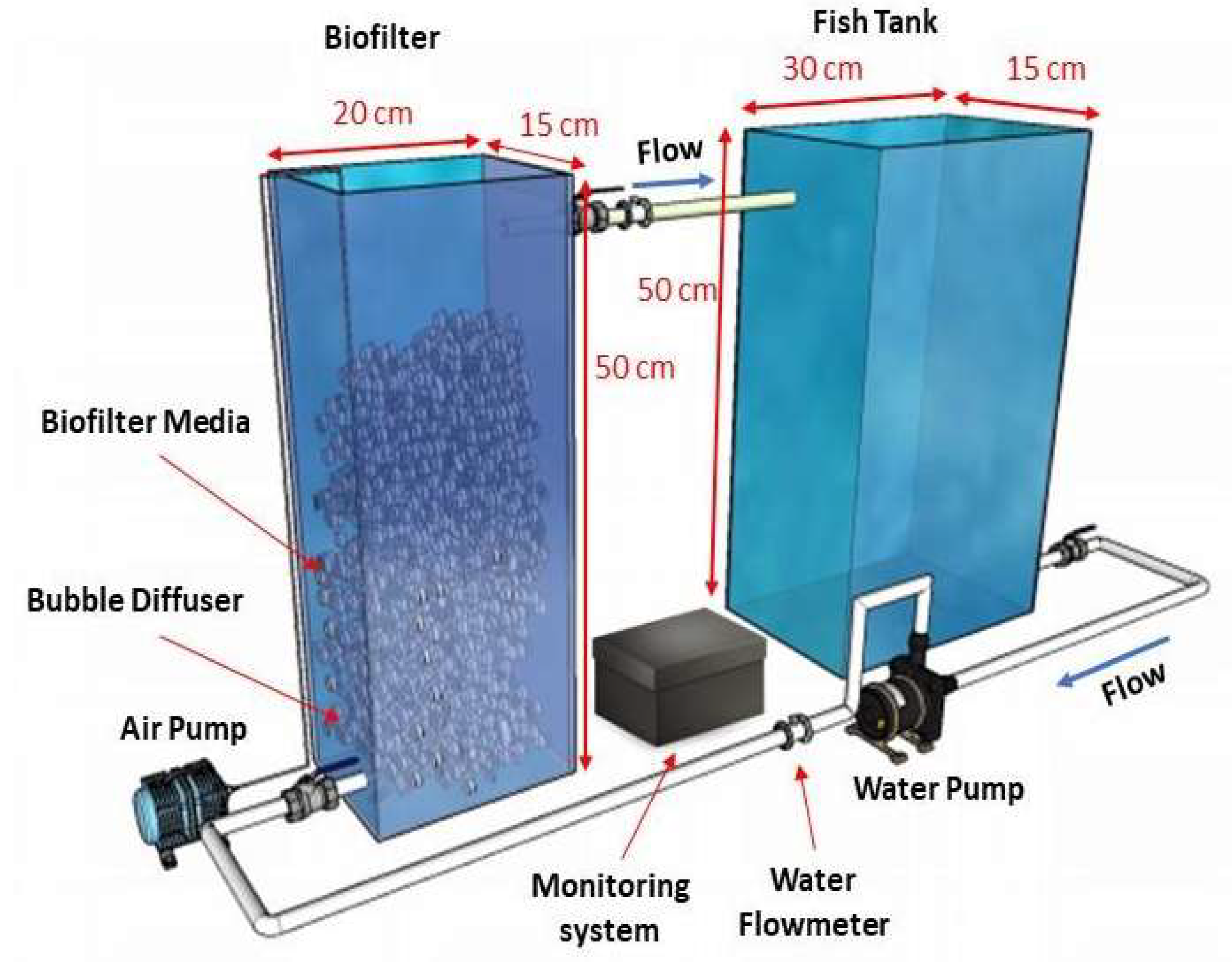

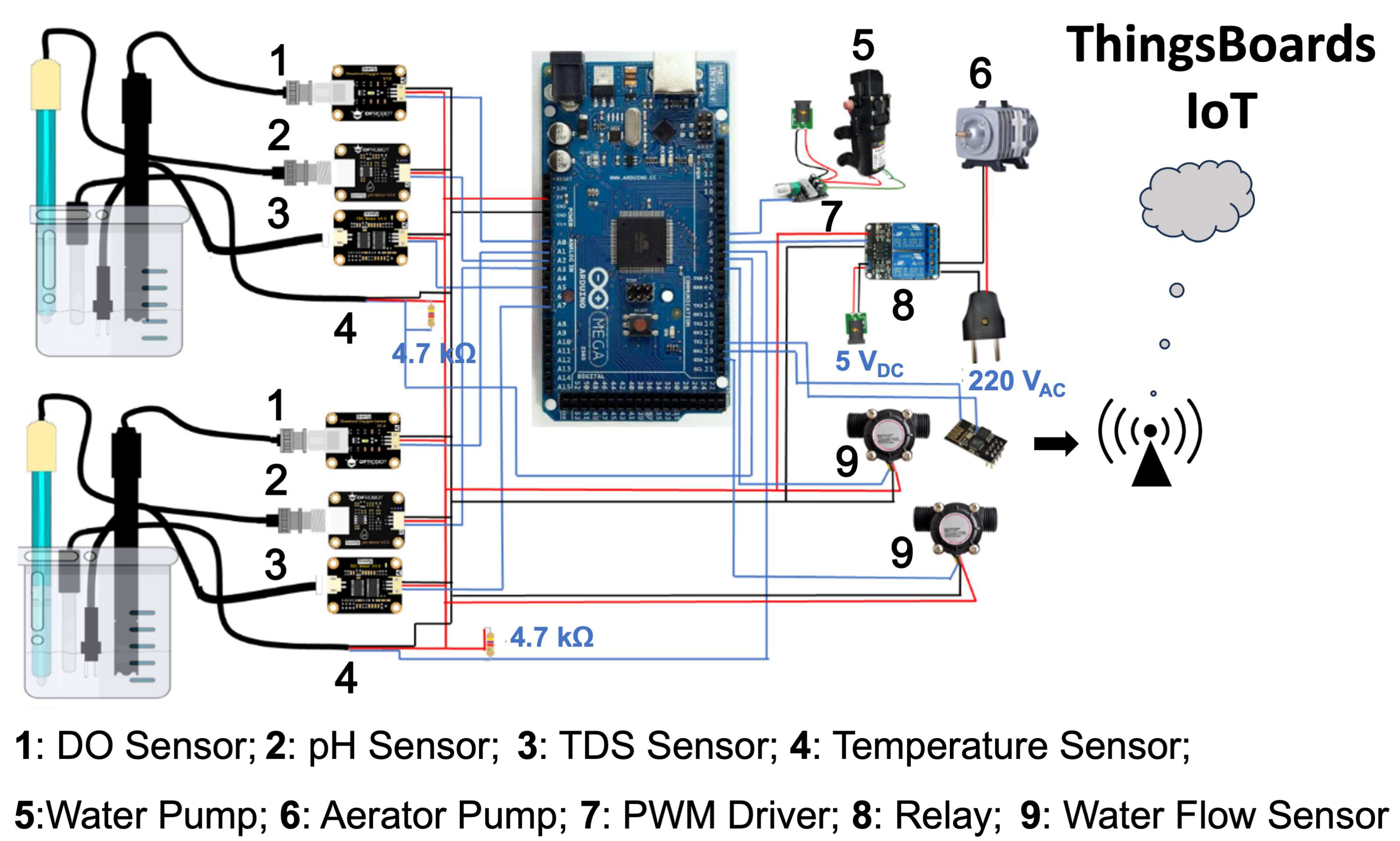

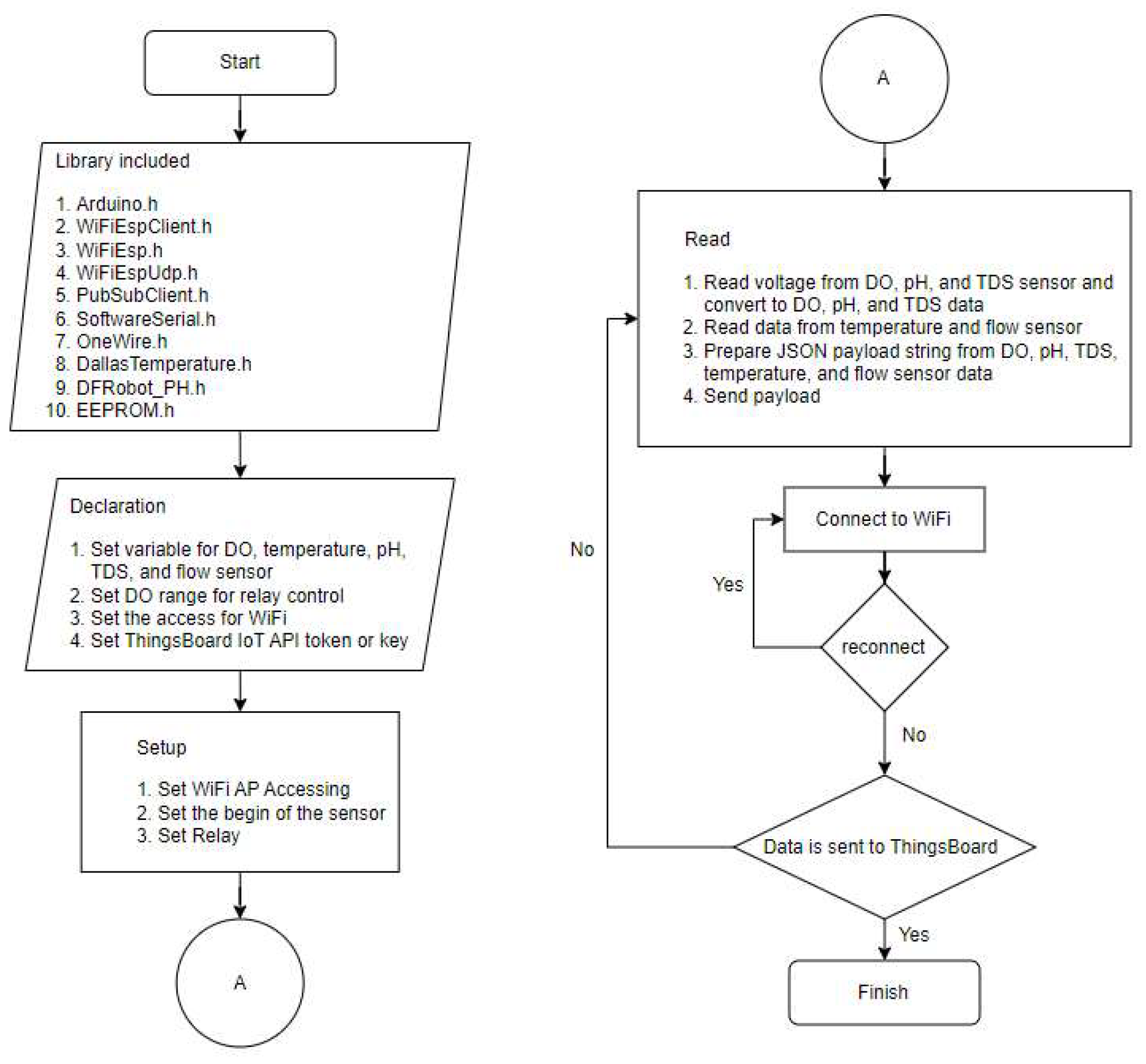

2. Design of Control and Monitoring System

2.1. Sensor Devices

2.1.1. DO Sensor

2.1.2. pH Sensor

2.1.3. Temperature Sensor

2.1.4. TDS Sensor

2.1.5. Water Flow Sensor

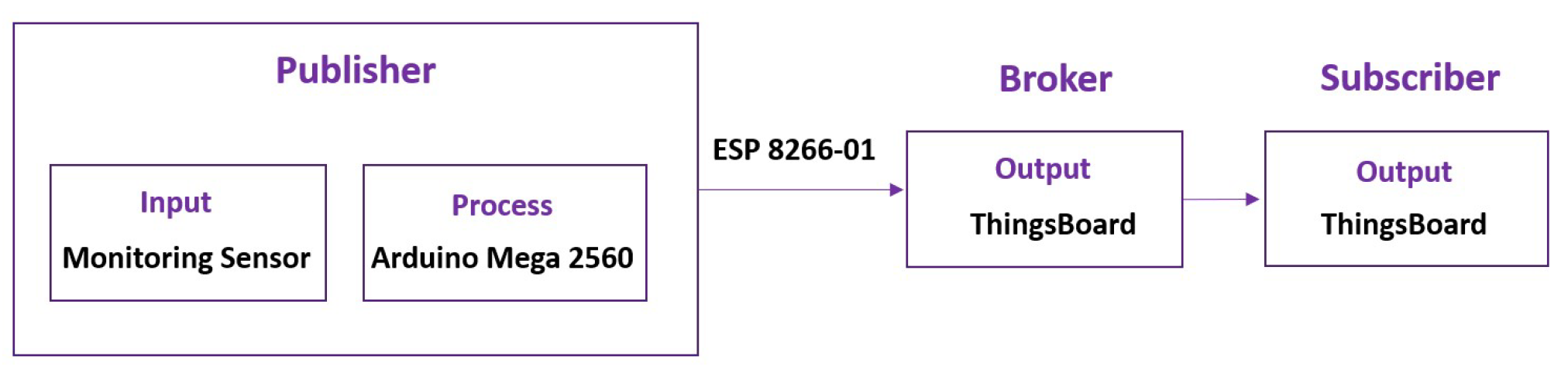

2.2. Hardware Description of Control and IoT System

2.2.1. Hardware Description of Control System

2.2.2. Hardware Description of IoT System

2.2.3. Sensor Characteristics

3. MBBR Performance Evaluation

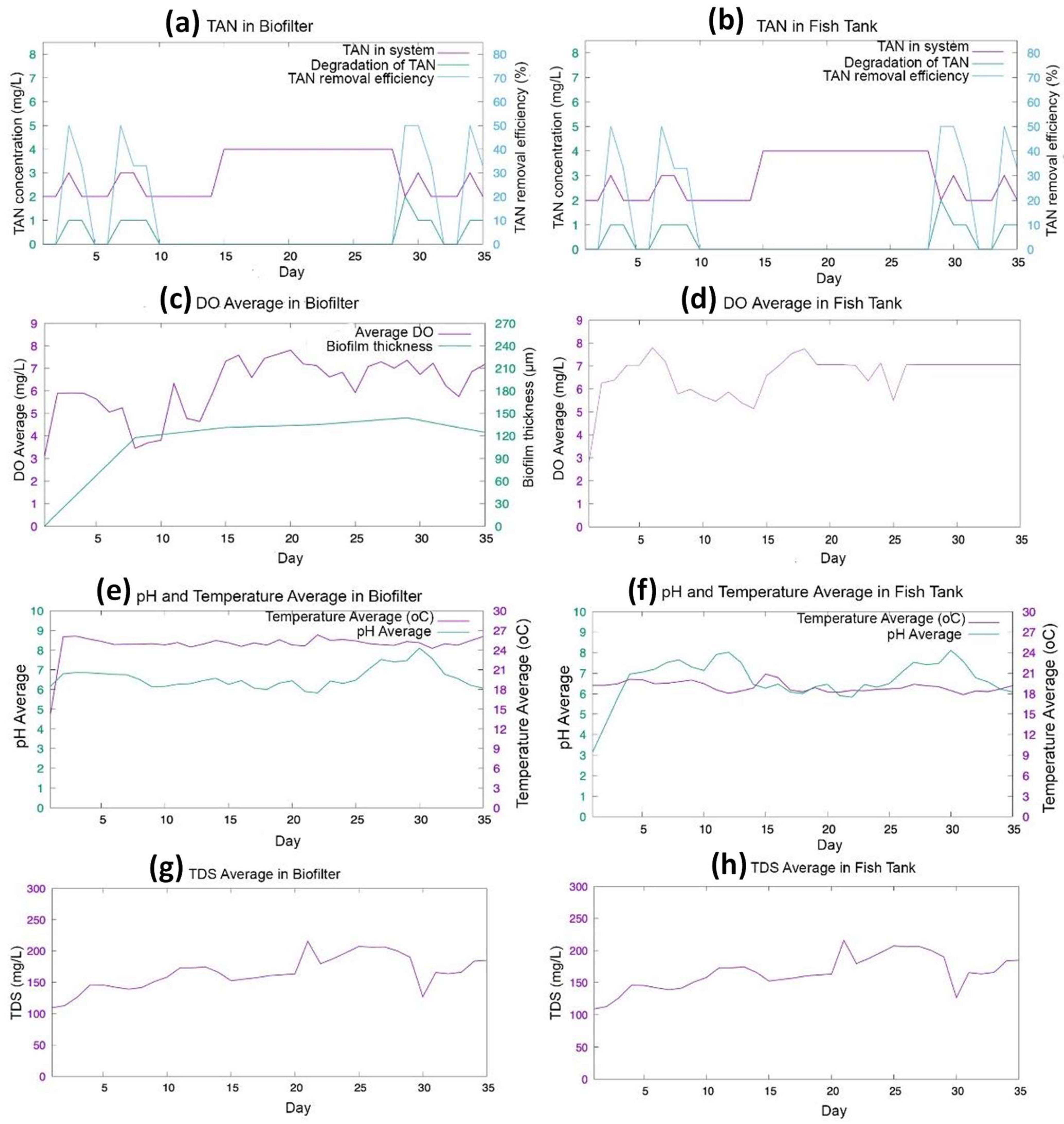

3.1. TAN Removal and Biofilm Thickness

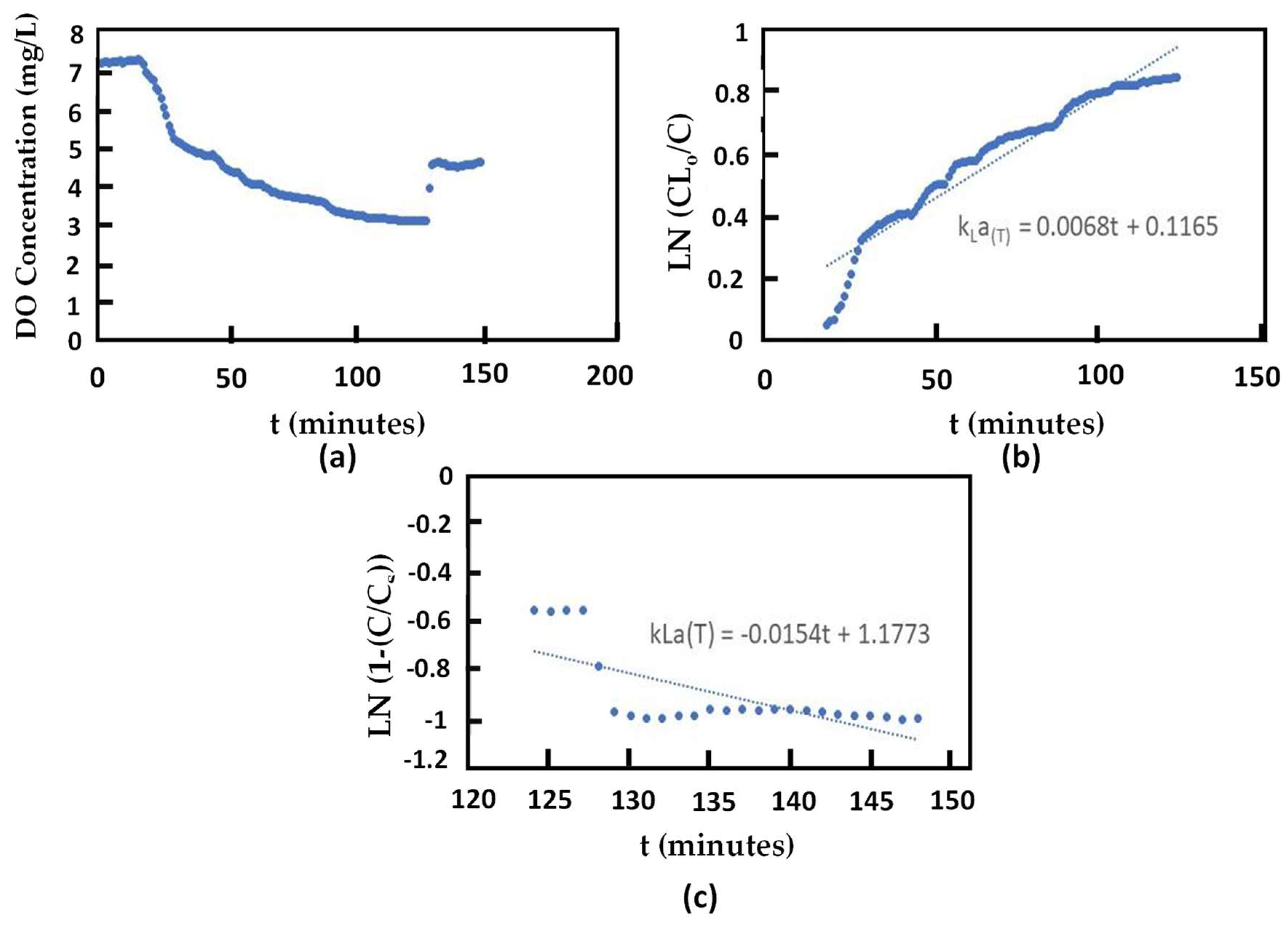

3.2. Dynamic Measurement of

4. Result and Discussion

4.1. Water Quality Sensor Characteristic

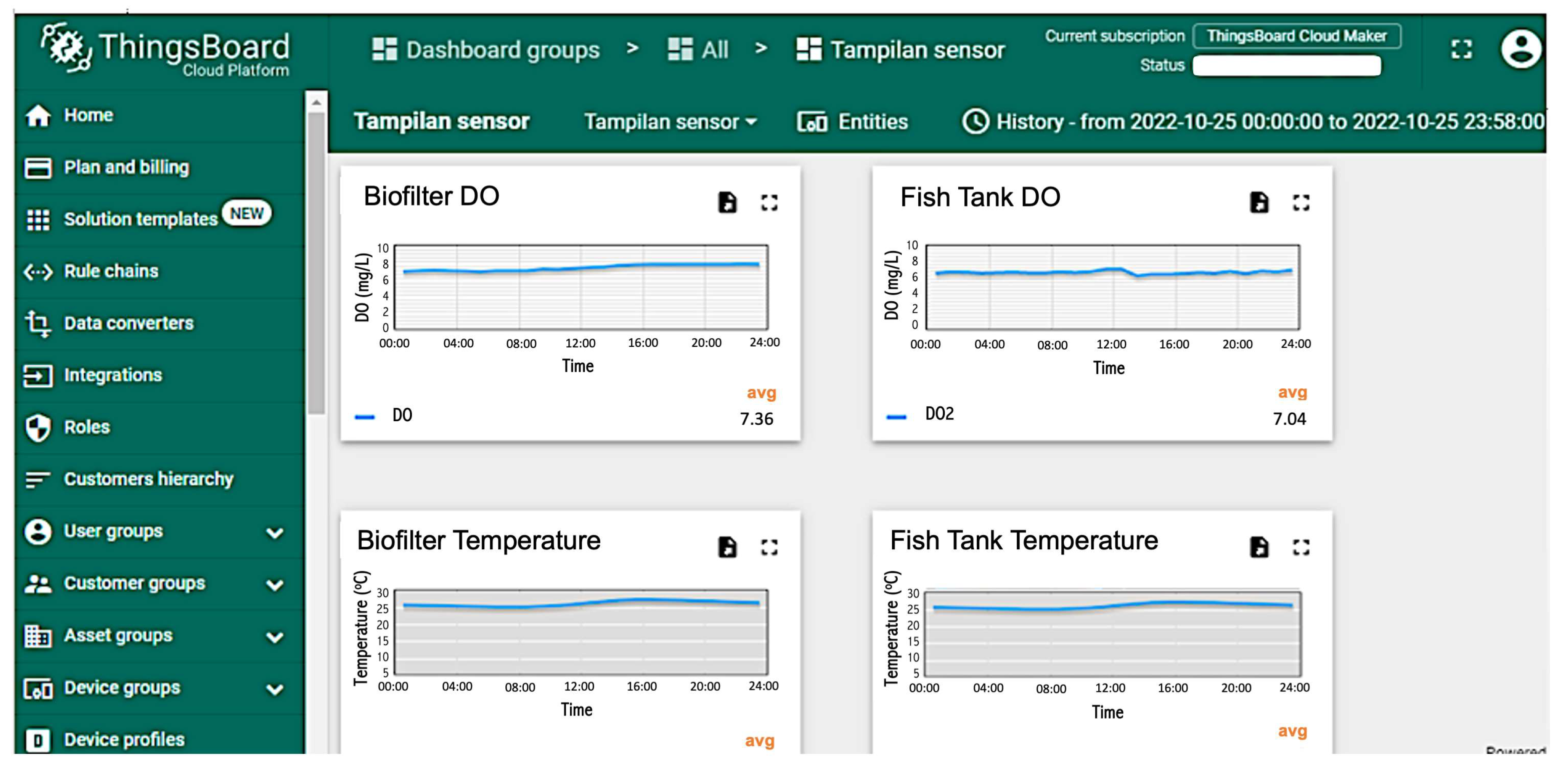

4.2. Result of the Measurement

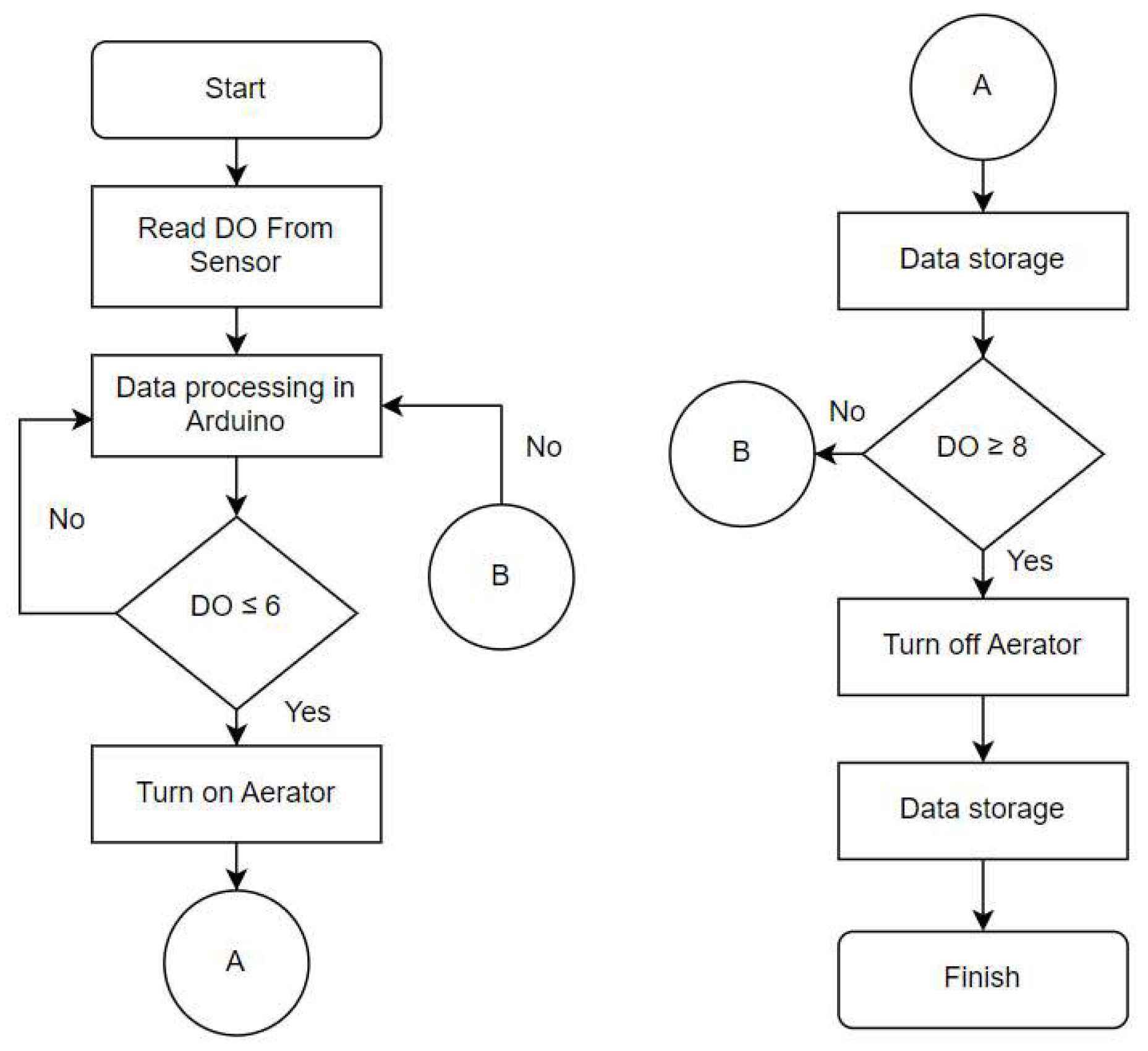

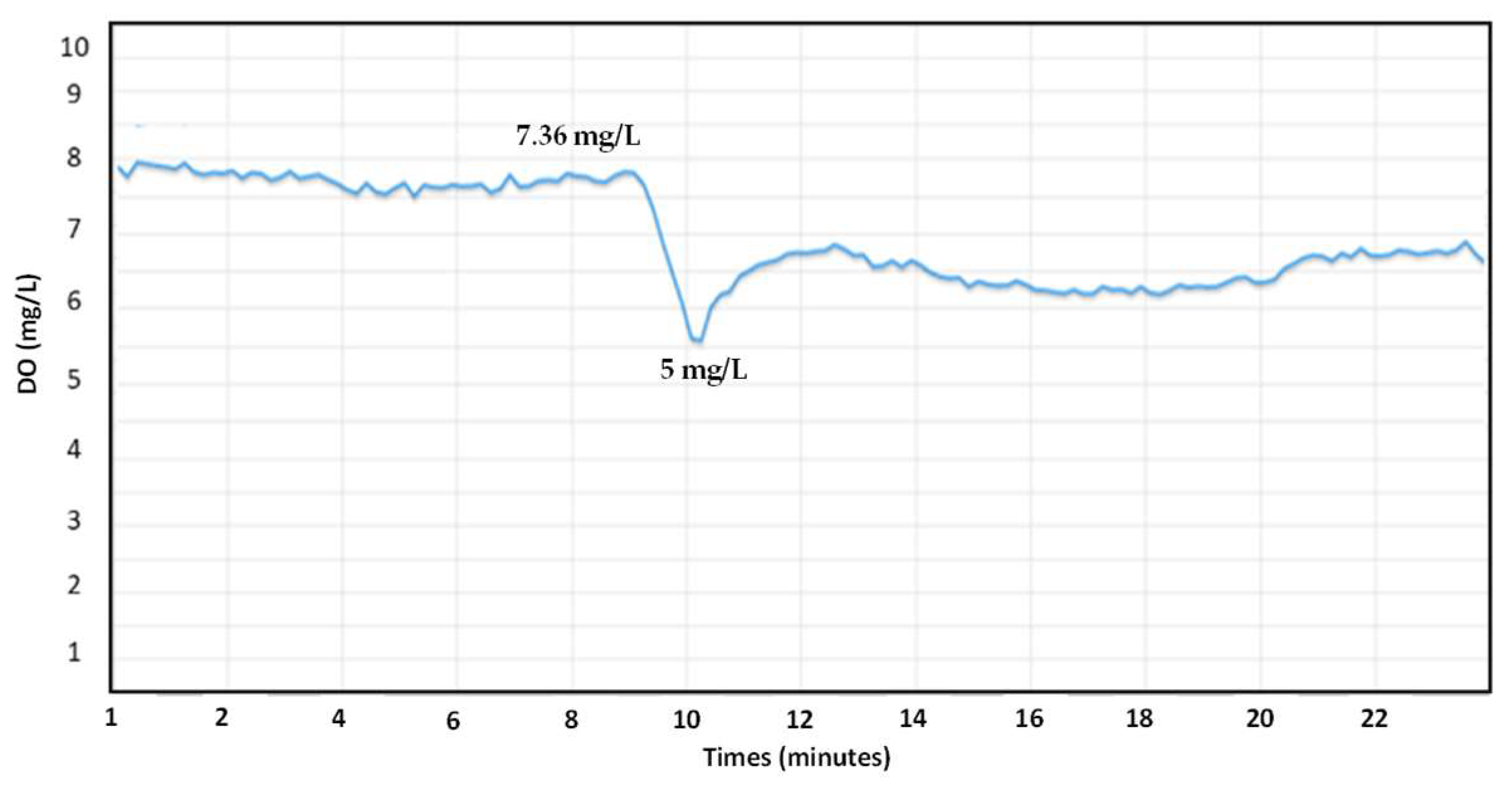

4.3. Control System

4.4. Water Quality vs. Film Thickness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- FAO. The State of World Fisheries and Aquaculture 2022 towards Blue Transformation; FAO: Rome, Italy, 2022. [Google Scholar]

- Hutchinson, W.; Jeffrey, M.; O’Sullivan, D.; Casement, D.; Clarke, S. Recirculating Aquaculture Systems Minimum Standards for Design, Construction and Management, 1st ed.; Inland Aquaculture Association of South Australia: Kent Town, SA, Australia, 2004; pp. 1–70. [Google Scholar]

- Mook, W.; Chakrabarti, M.; Aroua, M.; Khan, G.; Ali, B.; Islam, M.; Hassan, M.A. Removal of total ammonia nitrogen (TAN), nitrate and total organic carbon (TOC) from aquaculture wastewater using electrochemical technology: A review. Desalination 2012, 285, 1–13. [Google Scholar] [CrossRef]

- Bernet, N.; Dangcong, P.; Delgenès, J.-P.; Moletta, R. Nitrification at Low Oxygen Concentration. J. Environ. Eng. 2001, 127, 266–271. [Google Scholar] [CrossRef]

- Havlíček, K.; Nechanická, M.; Lederer, T.; Sirková, B.K. Analysis of nitrifying bacteria growth on two new types of biomass carrier using respirometry and molecular genetic methods. Ecotoxicol. Environ. Saf. 2021, 225, 112795. [Google Scholar] [CrossRef] [PubMed]

- Piculell, M.; Welander, P.; Jönsson, J.; Welander, T. Evaluating the Effect of Biofilm Thickness on Nitrification in Moving Bed Biofilm Reactors. Environ. Technol. 2016, 37, 732–743. [Google Scholar] [CrossRef] [PubMed]

- Tsitouras, A.; Al-Ghussain, N.; Butcher, J.; Stintzi, A.; Delatolla, R. The microbiome of two strategies for ammonia removal with the sequencing batch moving bed biofilm reactor treating cheese production wastewater. Appl. Environ. Microbiol. 2023, 27, e0150723. [Google Scholar] [CrossRef] [PubMed]

- Gapes, D.; Keller, J. Impact of oxygen mass transfer on nitrification reactions in suspended carrier reactor biofilms. Process Biochem. 2009, 44, 43–53. [Google Scholar] [CrossRef]

- Islam, M.M.; Kashem, M.A.; Alyami, S.A.; Moni, M.A. Monitoring water quality metrics of ponds with IoT sensors and machine learning to predict fish species survival. Microprocess. Microsyst. 2023, 102, 104930. [Google Scholar] [CrossRef]

- Zulkifli, C.Z.; Garfan, S.; Talal, M.; Alamoodi, A.H.; Alamleh, A.; Ahmaro, I.Y.Y.; Sulaiman, S.; Ibrahim, A.B.; Zaidan, B.B.; Ismail, A.R.; et al. IoT-Based Water Monitoring Systems: A Systematic Review. Water 2022, 14, 3621. [Google Scholar] [CrossRef]

- Hemdan, E.E.D.; Essa, Y.M.; Shouman, M.; El-Sayed, A.; Moustafa, A.N. An efficient IoT based smart water quality monitoring system. Multimed Tools Appl. 2023, 82, 28827–28851. [Google Scholar] [CrossRef]

- Mustafa, H.M.; Mustapha, A.; Hayder, G.; Salisu, A. Applications of IoT and Artificial Intelligence in Water Quality Monitoring and Prediction: A Review. In Proceedings of the 6th International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 20–22 January 2021; pp. 968–975. [Google Scholar] [CrossRef]

- Hashemi, H.; Mirnasab, M.A. “Internet of Things”: An Emerging Real-Time Technology for Environmental Health Monitoring. J. Environ. Health Sustain. Dev. 2018, 3, 432–435. [Google Scholar]

- Kumar, M.; Singh, T.; Maurya, M.K.; Shivhare, A.; Raut, A.; Singh, P.K. Quality Assessment and Monitoring of River Water Using IoT Infrastructure. IEEE Internet Things J. 2023, 10, 10280–10290. [Google Scholar] [CrossRef]

- Jan, F.; Min-Allah, N.; Düştegör, D. IoT Based Smart Water Quality Monitoring: Recent Techniques, Trends and Challenges for Domestic Applications. Water 2021, 13, 1729. [Google Scholar] [CrossRef]

- Odobašić, A.; Šestan, I.; Begić, S. Biosensors For Monitoring Heavy Metals Contamination. In The Wastewater Recent Advances in Biosensor Technology; Bentham Science Publisher: Rome, Italy, 2023; pp. 203–211. [Google Scholar] [CrossRef]

- Shafique, K.; Khawaja, B.A.; Sabir, F.; Qazi, S.; Mustaqim, M. Internet of Things (IoT) for Next-Generation Smart Systems: A Review of Current Challenges, Future Trends and Prospects for Emerging 5G-IoT Scenarios. IEEE Access 2020, 8, 23022–23040. [Google Scholar] [CrossRef]

- Lin, J.-Y.; Tsai, H.-L.; Lyu, W.-H. An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture. Sensors 2021, 21, 8179. [Google Scholar] [CrossRef]

- Billah, M.M.; Yusof, Z.M.; Kadir, K.; Ali, A.M.M.; Ahmad, I. Quality Maintenance of Fish Farm: Development of Real-time Water Quality Monitoring System. In Proceedings of the 2019 IEEE 6th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA 2019), Kuala Lumpur, Malaysia, 27–29 August 2019. [Google Scholar]

- Naj, N.; Sanzgiri, A. An IoT based Real-Time Monitoring of Water Quality System. Asian J. Converg. Technol. 2021, 7, 44–51. [Google Scholar] [CrossRef]

- Danh, L.V.Q.; Dung, D.V.M.; Danh, T.H.; Ngon, N.C. Design and Deployment of an IoT-Based Water Quality Monitoring System for Aquaculture in Mekong Delta. Int. J. Mech. Eng. Robot. Res. 2020, 9, 1170–1175. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, W.; Wang, Z.; Tan, X.; Wu, F.; Wang, D.; Fang, X. Development of remote monitoring system for aquaculture water quality based on Internet of Things. IOP Conf. Ser. Mater. Sci. Eng. 2020, 768, 052033. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, G.; Chen, Y.; Zhao, L. Effect of dissolved oxygen on the sulfidization flotation of smithsonite. Miner. Eng. 2022, 186, 107741. [Google Scholar] [CrossRef]

- Devi, P.A.; Padmavathy, P.; Aanand, S.; Aruljothi, K. Review on water quality parameters in freshwater cage fish culture. Int. J. Appl. Res. 2017, 3, 114–120. [Google Scholar]

- Stenstrom, M.K.; Poduska, R.A. The effect of dissolved oxygen concentration on nitrification. Water Res. 1980, 14, 643–649. [Google Scholar] [CrossRef]

- Lee, Y.H.; Tsao, G.T. Dissolved oxygen electrodes. In Advances in Biochemical Engineering, 1st ed.; Ghose, T.K., Blakebrough, N., Fiechter, A., Eds.; Springer: Berlin/Heidelberg, Germany, 1979; Volume 13, pp. 35–86. [Google Scholar] [CrossRef]

- Boyd, C.E.; Tucker, C.S.; Viriyatum, R. Interpretation of pH, Acidity, and Alkalinity in Aquaculture and Fisheries. Aquaculture 2011, 73, 403–408. [Google Scholar] [CrossRef]

- Sajuni, N.; Ahmad, A.; Vadivelu, V. Effect of Filter Media Characteristics, pH and Temperature on the Ammonia Removal in the Wastewater. J. Appli. Sci. 2010, 10, 1146–1150. [Google Scholar] [CrossRef][Green Version]

- Justnes, H.; Escudero-Oñate, C.; Garmo, Ø.A.; Mengede, M. Transformation Kinetics of Burnt Lime in Freshwater and Sea Water. Materials 2020, 13, 4926. [Google Scholar] [CrossRef] [PubMed]

- Walczyńska, A.; Sobczyk, Ł. The underestimated role of temperature–oxygen relationship in large-scale studies on size-to-temperature response. Ecol. Evol. 2017, 7, 7434–7441. [Google Scholar] [CrossRef]

- Paredes, D.; Kuschk, P.; Mbwette, T.S.A.; Stange, F.; Müller, R.A.; Köser, H. New Aspects of Microbial Nitrogen Transformations in the Context of Wastewater Treatment—A Review. Eng. Life Sci. 2007, 7, 13–25. [Google Scholar] [CrossRef]

- Garg, R.; Rao, R.; Uchchariya, D.; Shukla, G.; Saksena, D. Seasonal variations in water quality and major threats to Ramsagar reservoir, India. Afr. J. Environ. Sci. Technol. 2010, 4, 061–076. [Google Scholar]

- Azzola, F. Android Things Projects, 1st ed.; Packt Publishing Ltd.: Birmingham, UK, 2017; pp. 1–232. [Google Scholar]

- He, Y.; He, J.; Wen, N. The challenges of IoT-based applications in high-risk environments, health and safety industries in the Industry 4.0 era using decision-making approach. J. Innov. Knowl. 2023, 8, 100347. [Google Scholar] [CrossRef]

- Tsagkari, E.; Sloan, W. The Role of Chlorine in the Formation and Development of Tap Water Biofilms under Different Flow Regimes. Microorganisms 2023, 11, 2680. [Google Scholar] [CrossRef]

- Tribe, L.A.; Briens, C.L.; Margaritis, A. Determination of the Volumetric Mass Transfer Coefficient (k,a) Using the Dynamic “Gas Out-Gas In” Method: Analysis of Errors Caused by Dissolved Oxygen Probes. Biotechnol. Bioeng. 1995, 46, 388–392. [Google Scholar] [CrossRef]

- Suriasni, P.A.; Faizal, F.; Panatarani, C.; Hermawan, W.; Joni, I.M. A Review of Bubble Aeration in Biofilter to Reduce Total Ammonia Nitrogen of Recirculating Aquaculture System. Water 2023, 15, 808. [Google Scholar] [CrossRef]

- Raghavendra, N.; Krishnamurthy, L. Engineering Metrology and Measurement, 1st ed.; Oxford University Press: New Delhi, India, 2013; pp. 1–520. [Google Scholar]

- Terasaka, K.; Hirabayashi, A.; Nishino, T.; Fujioka, S.; Kobayashi, D. Development of microbubble aerator for waste water treatment using aerobic activated sludge. Chem. Eng. Sci. 2011, 66, 3172–3179. [Google Scholar] [CrossRef]

- Doran, P.M. Bioprocess Engineering Principles, 2nd ed.; Academic Press: London, UK, 2013; pp. 379–444. [Google Scholar]

- Karaguler, T.; Kahraman, H.; Tuter, M. Analyzing effects of ELF electromagnetic fields on removing bacterial biofilm. Biocybern. Biomed. Eng. 2017, 37, 336–340. [Google Scholar] [CrossRef]

- Stoodley, P.; Sauer, K.; Davies, D.G.; Costerton, J.W. Biofilm as Complex Differentiated Communities. Annu. Rev. Microbiol. 2022, 56, 187–209. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, P.; Allison, D.G.; Evans, D.J.; Handley, P.S.; Brown, M.R. Growth rate control of adherent bacterial populations. Appl. Environ. Microbiol. 1989, 55, 1308–1311. [Google Scholar] [CrossRef]

- Morita, R.Y. Bioavailability of Energy and the Starvation State. In Starvation in Bacteria, 1st ed.; Kjelleberg, S., Ed.; Springer: Boston, MA, USA, 1993; pp. 1–23. [Google Scholar] [CrossRef]

| Sensor | Place | Accuracy (%) | Precision (%) | Error (%) |

|---|---|---|---|---|

| DO | Biofilter | 98.97 | 98.31 | ±1.03 |

| Fish tank | 95.53 | 94.50 | ±4.47 | |

| pH | Biofilter | 99.16 | 99.84 | ±0.84 |

| Fish tank | 93.61 | 98.79 | ±6.39 | |

| Temperature | Biofilter | 97.92 | 99.75 | ±2.08 |

| Fish tank | 96.56 | 95.16 | ±3.44 | |

| TDS | Biofilter | 92.83 | 98.81 | ±7.17 |

| Fish tank | 93.26 | 98.74 | ±6.74 |

| Week | Coarse Bubble (min−1) | |

|---|---|---|

| Desorption | Absorption | |

| 0 (without bacteria) | 0.0042 | 0.0005 |

| 1 | 0.0099 | 0.0293 |

| 2 | 0.0261 | 0.0472 |

| 3 | 0.0099 | 0.0293 |

| 4 | 0.0143 | 0.0011 |

| 5 | 0.0144 | 0.0082 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suriasni, P.A.; Faizal, F.; Hermawan, W.; Subhan, U.; Panatarani, C.; Joni, I.M. IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen. Sensors 2024, 24, 494. https://doi.org/10.3390/s24020494

Suriasni PA, Faizal F, Hermawan W, Subhan U, Panatarani C, Joni IM. IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen. Sensors. 2024; 24(2):494. https://doi.org/10.3390/s24020494

Chicago/Turabian StyleSuriasni, Putu A., Ferry Faizal, Wawan Hermawan, Ujang Subhan, Camellia Panatarani, and I Made Joni. 2024. "IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen" Sensors 24, no. 2: 494. https://doi.org/10.3390/s24020494

APA StyleSuriasni, P. A., Faizal, F., Hermawan, W., Subhan, U., Panatarani, C., & Joni, I. M. (2024). IoT Water Quality Monitoring and Control System in Moving Bed Biofilm Reactor to Reduce Total Ammonia Nitrogen. Sensors, 24(2), 494. https://doi.org/10.3390/s24020494