Femtosecond Laser Inscribed Excessively Tilted Fiber Grating for Humidity Sensing

Abstract

1. Introduction

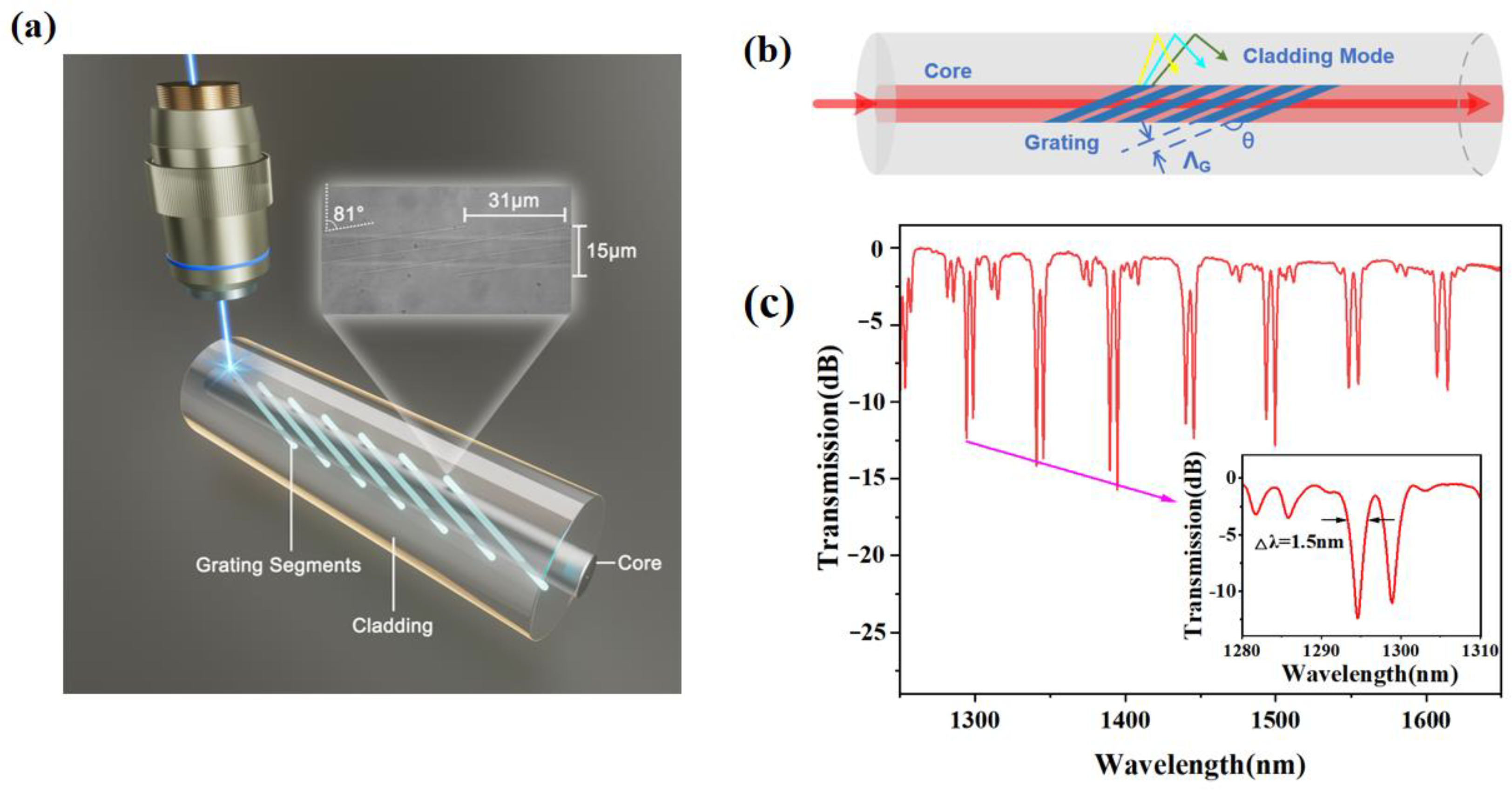

2. TFG Fabrication and Sensing Principle

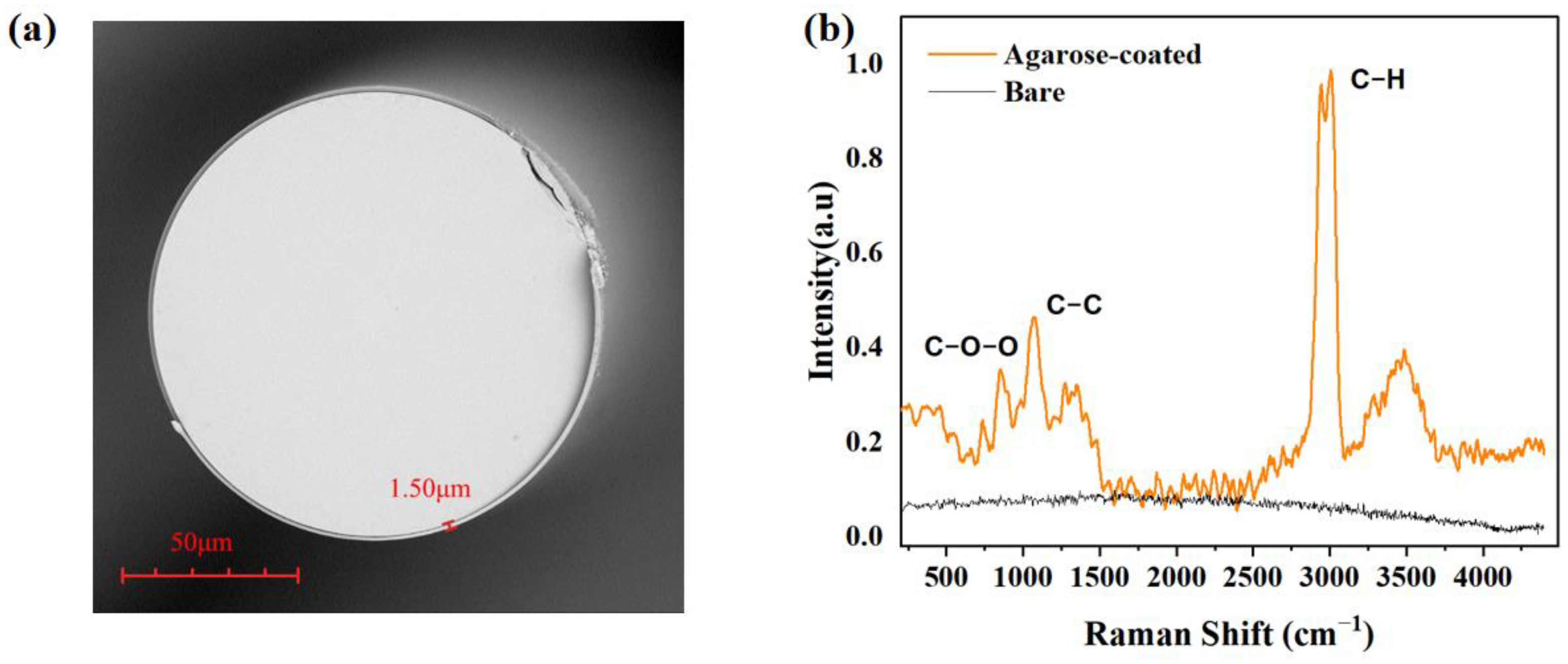

3. Surface Modification and Characterization

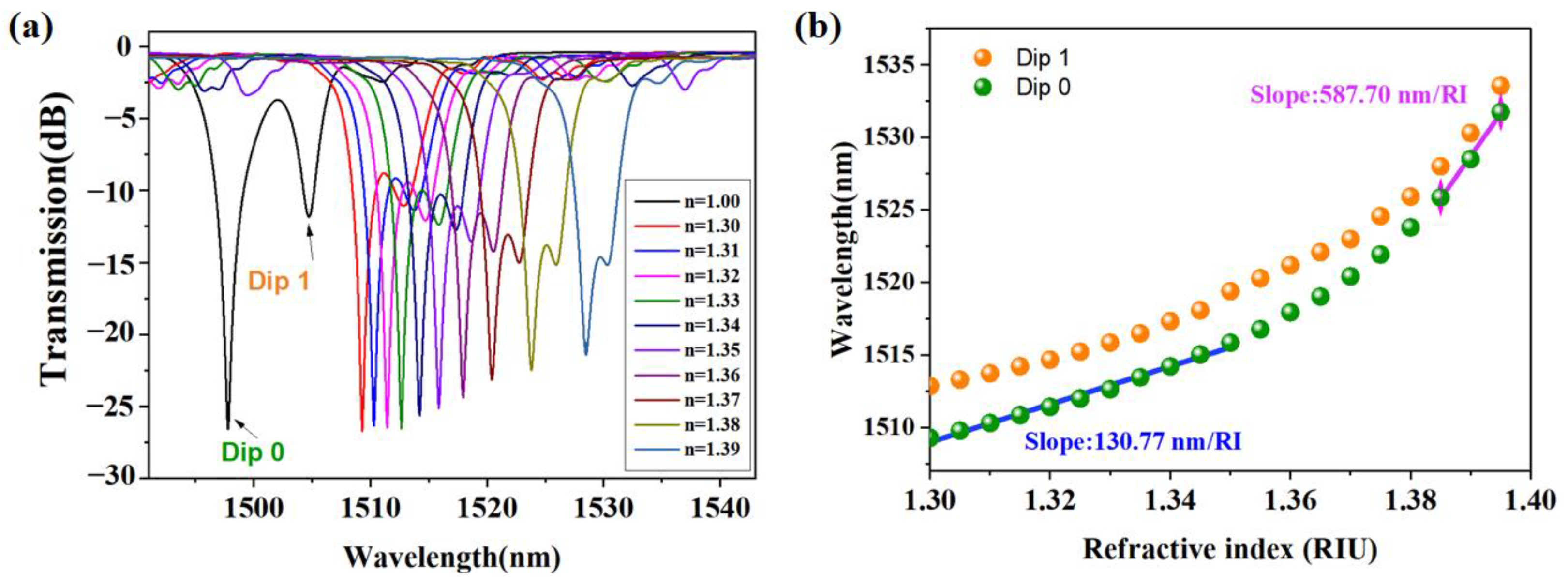

4. Results and Discussion

4.1. Sensitivity of the RH Sensor

4.2. The Response Time and Stability

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jindal, R.; Tao, S.; Singh, J.P.; Gaikwad, P.S. High dynamic range fiber optic relative humidity sensor. Opt. Eng. 2002, 41, 1093–1096. [Google Scholar] [CrossRef]

- Woyessa, G.; Fasano, A.; Stefani, A.; Markos, C.; Nielsen, K.; Rasmussen, H.K.; Bang, O. Single mode step-index polymer optical fiber for humidity insensitive high temperature fiber Bragg grating sensors. Opt. Express 2016, 24, 1253–1260. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Cai, Z.; Li, B.; Zou, M.; Zhang, L.; Hua, Y.; Mai, J.; Zhao, C.; Liao, C.; He, J. Simultaneous measurement of humidity and temperature based on fiber-tip microcantilever cascaded with fiber Bragg grating. Opt. Express 2023, 31, 8738–8747. [Google Scholar] [CrossRef] [PubMed]

- Miliou, A. In-Fiber Interferometric-Based Sensors: Overview and Recent Advances. Photonics 2021, 8, 265. [Google Scholar] [CrossRef]

- Lu, X.; Gong, H.; Lu, Y.; Liu, Y.; Shen, C.; Zhao, C. A relative humidity sensor based on open-cavity Fabry-Perot interferometer by fiber capillary splicing. Opt. Fiber Technol. 2023, 77, 103285. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.; Zhao, H.; Brambilla, G.; Fan, Y.; Wang, P. High-sensitivity humidity sensor based on microknot resonator assisted agarose-coated Mach-Zehnder interferometer. J. Light. Technol. 2021, 40, 2191–2196. [Google Scholar] [CrossRef]

- Hegde, G.; Asokan, S.; Hegde, G. Fiber Bragg grating sensors for aerospace applications: A review. ISSS J. Micro Smart Syst. 2022, 11, 257–275. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Dinia, L.; Mangini, F.; Muzi, M.; Frezza, F. FBG multifunctional pH sensor-monitoring the pH rain in cultural heritage. Acta Imeko 2018, 7, 24–30. [Google Scholar] [CrossRef]

- Lan, F.; Wang, D. Long-period fiber grating based on inner microholes in optical fiber. Opt. Lett. 2022, 47, 146–149. [Google Scholar] [CrossRef]

- Butov, O.V.; Tomyshev, K.; Nechepurenko, I.; Dorofeenko, A.V.; Nikitov, S.A. Tilted fiber Bragg gratings and their sensing applications. Uspekhi Fiz. Nauk. 2022, 192, 1385–1398. [Google Scholar] [CrossRef]

- Yuezhen, S.; Zhijun, Y.; Kaiming, Z.; Binbin, L.; Biqiang, J.; Chengbo, M.; Qizhen, S.; Lin, Z. Excessively tilted fiber grating sensors. J. Light. Technol. 2021, 39, 3761–3770. [Google Scholar] [CrossRef]

- Wen, H.-Y.; Huang, W.-Y.; Huang, T.-S.; Hsu, Y.-C.; Chiang, C.-C. Comparison of the sensing mechanisms and capabilities of three functional materials surface-modified TFBG sensors. AIP Adv. 2020, 10, 065319. [Google Scholar] [CrossRef]

- Thomas, P.J.; Hellevang, J.O. A high response polyimide fiber optic sensor for distributed humidity measurements. Sens. Actuators B Chem. 2018, 270, 417–423. [Google Scholar] [CrossRef]

- Wang, W.; Sun, T.; Peng, J.; Dai, J.; Yang, M. Humidity Sensor Based on Fiber BraggGratingCoated with DifferentPore-FoamingAgentDopedPolyimides. IEEE Photonics Technol. Lett. 2017, 29, 1963–1966. [Google Scholar] [CrossRef]

- Chen, N.; Zhou, X.; Li, X. Highly sensitive humidity sensor with low-temperature cross-sensitivity based on a polyvinyl alcohol coating tapered fiber. IEEE Trans. Instrum. Meas. 2020, 70, 1–8. [Google Scholar] [CrossRef]

- Fujiwara, E.; Cabral, T.D.; Sato, M.; Oku, H.; Cordeiro, C.M. Agarose-based structured optical fibre. Sci. Rep. 2020, 10, 7035. [Google Scholar] [CrossRef]

- Terdale, J.; Ghosh, A. An intensity-modulated optical fiber sensor with agarose coating for measurement of refractive index. Int. J. Syst. Assur. Eng. Manag. 2022, 1–7. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Y.; Peng, Y.; Lv, R.-q.; Zhao, Q. Review of femtosecond laser direct writing fiber-optic structures based on refractive index modification and their applications. Opt. Laser Technol. 2022, 146, 107473. [Google Scholar] [CrossRef]

- Wolf, A.; Dostovalov, A.; Bronnikov, K.; Skvortsov, M.; Wabnitz, S.; Babin, S. Advances in femtosecond laser direct writing of fiber Bragg gratings in multicore fibers: Technology, sensor and laser applications. Opto-Electron. Adv. 2022, 5, 210055. [Google Scholar] [CrossRef]

- Zhou, K.; Zhang, L.; Chen, X.; Bennion, I. Optic sensors of high refractive-index responsivity and low thermal cross sensitivity that use fiber Bragg gratings of >80 tilted structures. Opt. Lett. 2006, 31, 1193–1195. [Google Scholar] [CrossRef] [PubMed]

- Luo, B.; Yan, Z.; Sun, Z.; Li, J.; Zhang, L. Novel glucose sensor based on enzyme-immobilized 81 tilted fiber grating. Opt. Express 2014, 22, 30571–30578. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Lu, T.; Moreno, Y.; Li, L.; Wang, H.; Zhou, K.; Sun, Q.; Liu, D.; Yan, Z.; Zhang, L. Theoretical and experimental analysis of the directional RI sensing property of tilted fiber grating. J. Light. Technol. 2021, 39, 674–681. [Google Scholar] [CrossRef]

- Zhou, K.; Dubov, M.; Mou, C.; Zhang, L.; Mezentsev, V.K.; Bennion, I. Line-by-line fiber Bragg grating made by femtosecond laser. IEEE Photonics Technol. Lett. 2010, 22, 1190–1192. [Google Scholar] [CrossRef]

- He, J.; Chen, Z.; Xu, X.; He, J.; Xu, B.; Du, B.; Guo, K.; Chen, R.; Wang, Y. Femtosecond laser line-by-line inscription of apodized fiber Bragg gratings. Opt. Lett. 2021, 46, 5663–5666. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.; Jovanovic, N.; Becker, R.G.; Marshall, G.D.; Withford, M.J.; Tünnermann, A.; Nolte, S.; Steel, M. Cladding mode coupling in highly localized fiber Bragg gratings: Modal properties and transmission spectra. Opt. Express 2011, 19, 325–341. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.U.; Jovanovic, N.; Krämer, R.G.; Marshall, G.D.; Withford, M.J.; Tünnermann, A.; Nolte, S.; Steel, M.J. Cladding mode coupling in highly localized fiber Bragg gratings II: Complete vectorial analysis. Opt. Express 2012, 20, 21434–21449. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Wang, H.; Wang, C.; Sun, Z.; Yin, G.; Zhou, K.; Wang, Y.; Zhao, W.; Zhang, L. Theoretical and experimental analysis of excessively tilted fiber gratings. Opt. Express 2016, 24, 12107–12115. [Google Scholar] [CrossRef]

- Mallik, A.K.; Liu, D.; Kavungal, V.; Wu, Q.; Farrell, G.; Semenova, Y. Agarose coated spherical micro resonator for humidity measurements. Opt. Express 2016, 24, 21216–21227. [Google Scholar] [CrossRef]

- Batumalay, M.; Harun, S.; Ahmad, F.; Nor, R.; Zulkepely, N.; Ahmad, H. Study of a fiber optic humidity sensor based on agarose gel. J. Mod. Opt. 2014, 61, 244–248. [Google Scholar] [CrossRef]

- David, N.A.; Wild, P.M.; Djilali, N. Parametric study of a polymer-coated fibre-optic humidity sensor. Meas. Sci. Technol. 2012, 23, 035103. [Google Scholar] [CrossRef]

- Dong, X.; Li, T.; Liu, Y.; Li, Y.; Zhao, C.-L.; Chan, C.C. Polyvinyl alcohol–coated hybrid fiber grating for relative humidity sensing. J. Biomed. Opt. 2011, 16, 077001. [Google Scholar] [CrossRef] [PubMed]

- Chiu, Y.-D.; Wu, C.-W.; Chiang, C.-C. Tilted fiber Bragg grating sensor with graphene oxide coating for humidity sensing. Sensors 2017, 17, 2129. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Gong, Y.; Wu, Y.; Wu, H. Polyimide-coated fiber Bragg grating for relative humidity sensing. Photonic Sens. 2015, 5, 60–66. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; Webb, D.J.; Peng, G.-D. Optical fibre temperature and humidity sensor. Electron. Lett. 2010, 46, 643–644. [Google Scholar] [CrossRef]

- Xu, W.; Shi, J.; Yang, X.; Xu, D.; Rong, F.; Zhao, J.; Yao, J. Relative humidity sensor based on no-core fiber coated by agarose-gel film. Sensors 2017, 17, 2353. [Google Scholar] [CrossRef]

| Sensor Type | RH Range (% RH) | Sensitivity (pm/%RH) | Response | Recovery | Ref |

|---|---|---|---|---|---|

| Pyralin-coated-FBG | 15−95 | 1.28 | 5 s | 20 s | [31] |

| PVA-coated hybrid fiber grating | 30–95 | Nonlinear, ~0.737 nW/%RH | ~2 s | NA | [32] |

| GO-coated etched TFBG | 20–80 | 10 | 12.25 min | 21.75 min | [33] |

| Polyimide-coated FBG | 12–97 | 13.6 | 22 min | NA | [34] |

| Polyimide-coated FBG | 20−90 | 1.71 | >33 s | NA | [15] |

| Polymer FBG | 50–95 | 35 | 30 min | NA | [35] |

| AGAROSEG-coated No-Core | 30–75 | 149 | 4.8 s | 7.1 s | [36] |

| AGAROSEG-coated TFBG | 30–95 | 18.5 | 4 s | 2 s | Our work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, L.; Liu, B.; Liu, D.; Liu, D.; Wang, F.; Guan, C.; Wang, Y.; Liao, C. Femtosecond Laser Inscribed Excessively Tilted Fiber Grating for Humidity Sensing. Sensors 2024, 24, 342. https://doi.org/10.3390/s24020342

Jing L, Liu B, Liu D, Liu D, Wang F, Guan C, Wang Y, Liao C. Femtosecond Laser Inscribed Excessively Tilted Fiber Grating for Humidity Sensing. Sensors. 2024; 24(2):342. https://doi.org/10.3390/s24020342

Chicago/Turabian StyleJing, Liqing, Bonan Liu, Dejun Liu, Dan Liu, Famei Wang, Chunying Guan, Yiping Wang, and Changrui Liao. 2024. "Femtosecond Laser Inscribed Excessively Tilted Fiber Grating for Humidity Sensing" Sensors 24, no. 2: 342. https://doi.org/10.3390/s24020342

APA StyleJing, L., Liu, B., Liu, D., Liu, D., Wang, F., Guan, C., Wang, Y., & Liao, C. (2024). Femtosecond Laser Inscribed Excessively Tilted Fiber Grating for Humidity Sensing. Sensors, 24(2), 342. https://doi.org/10.3390/s24020342