Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique

Abstract

1. Introduction

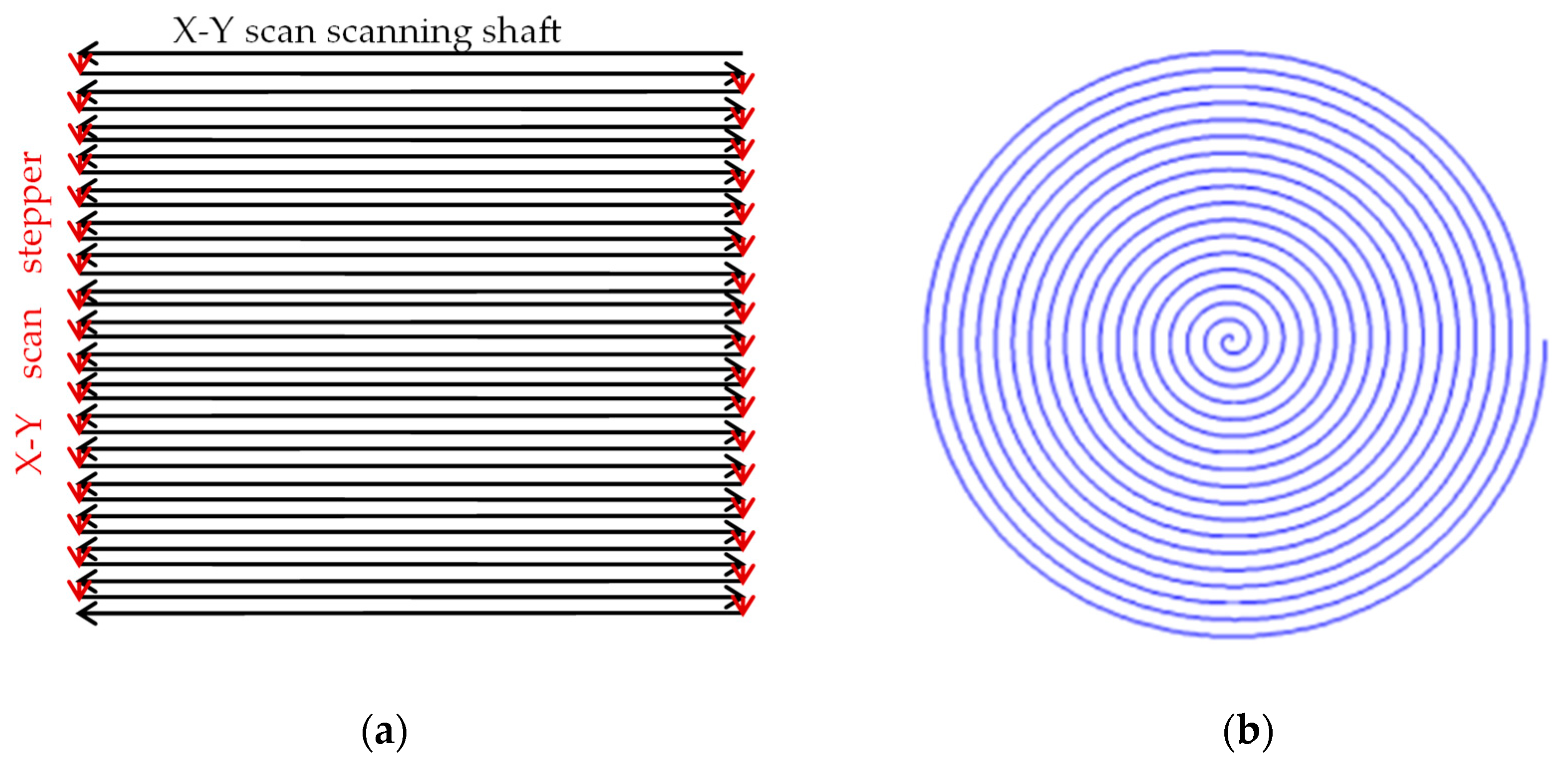

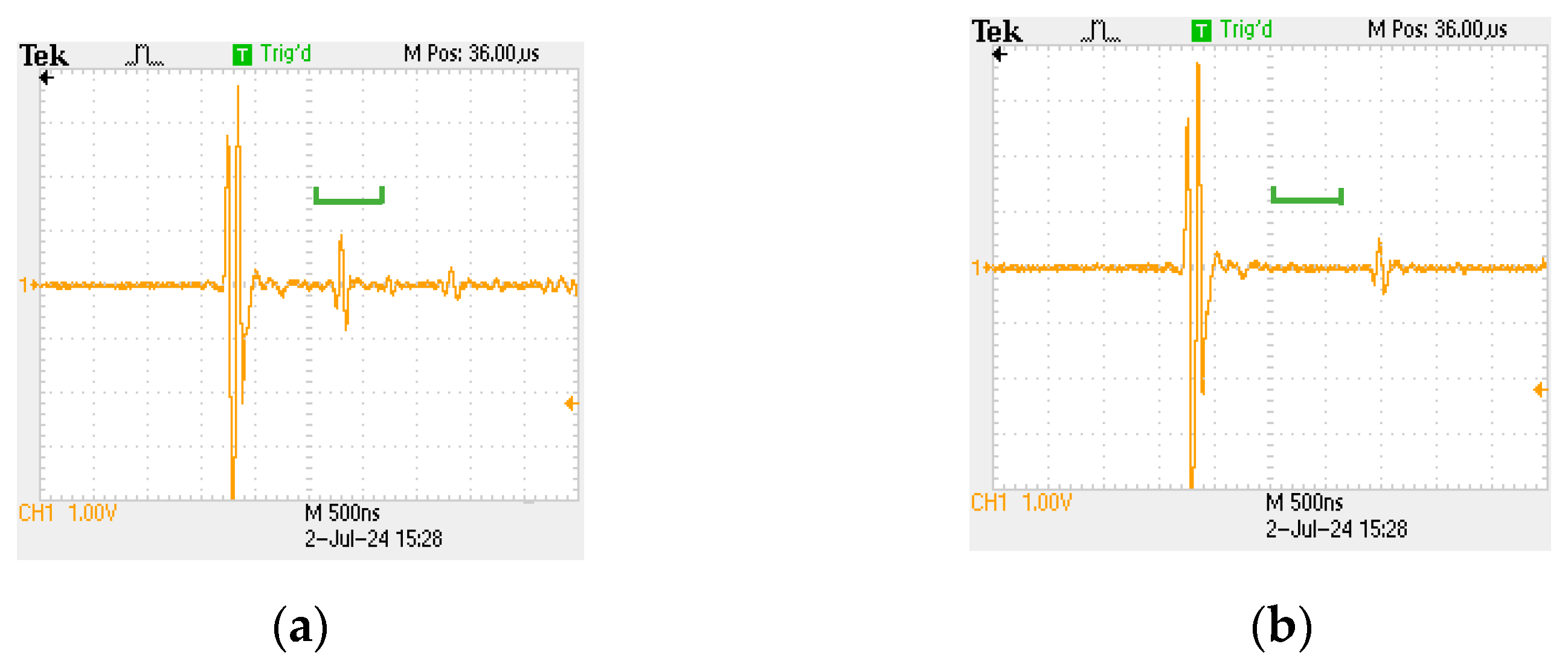

2. Principles of Ultrasonic Spiral C-Scan Test System

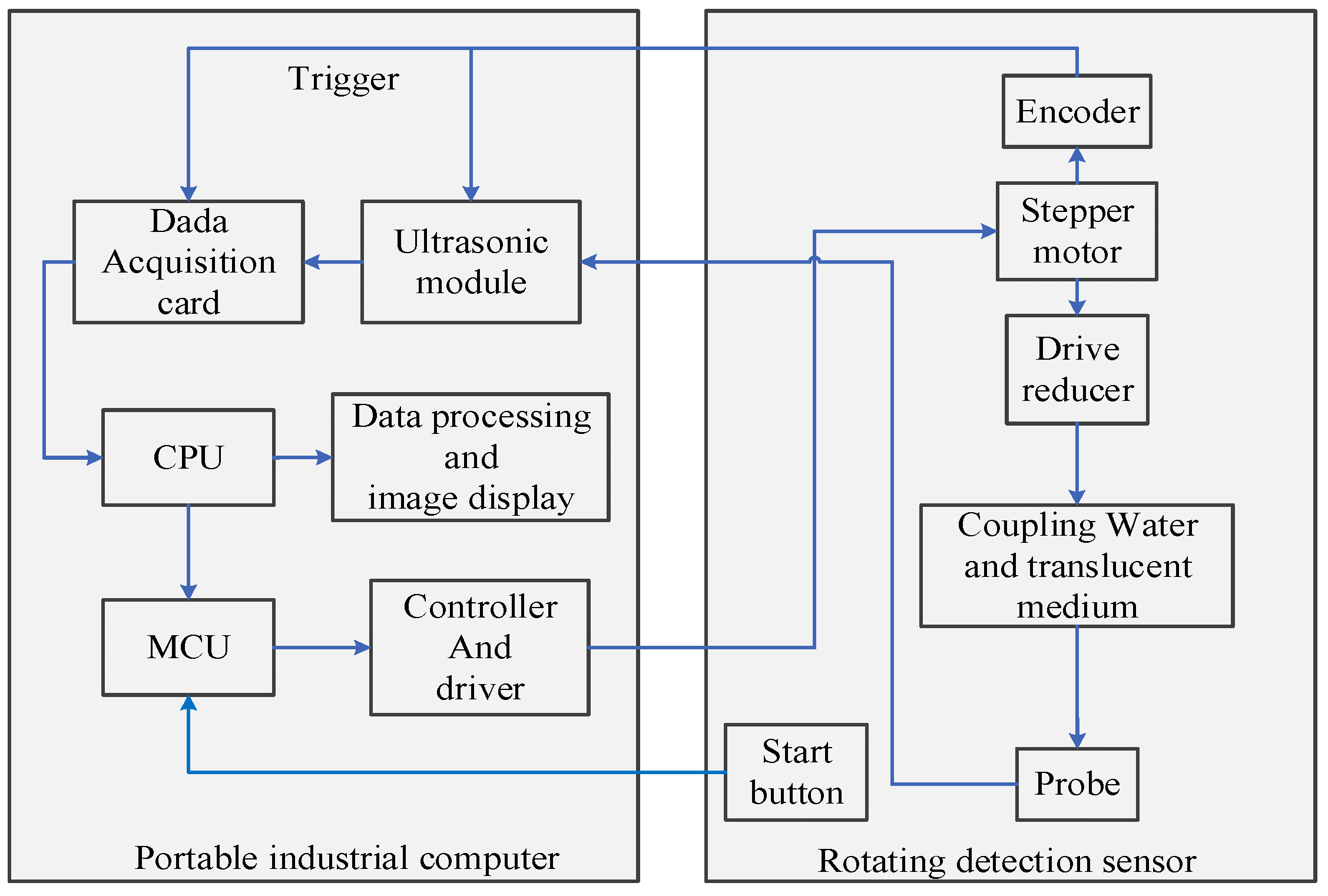

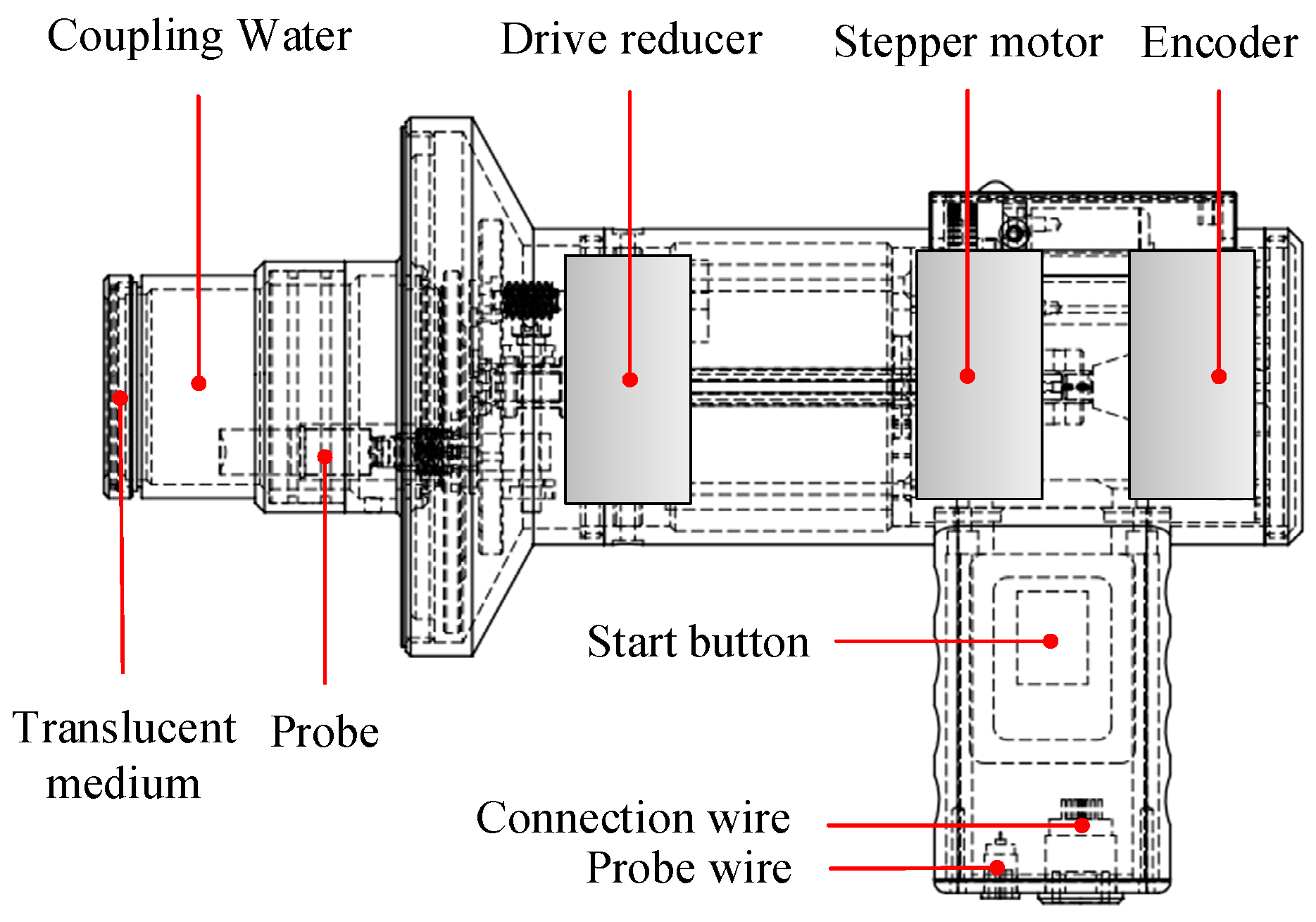

3. Structure of Ultrasonic Spiral C-Scan Test System and Data Processing of Test Results

3.1. Structure of Ultrasonic Spiral C-Scan Test System

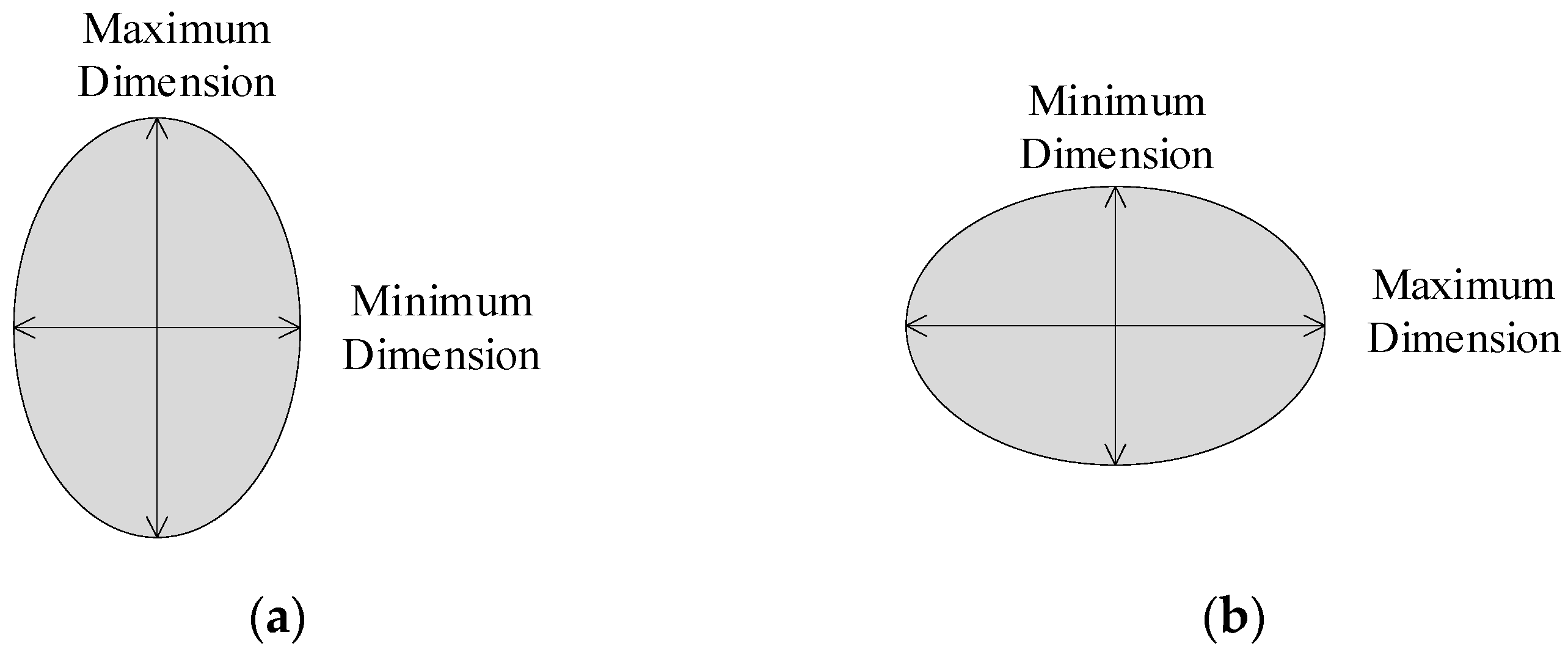

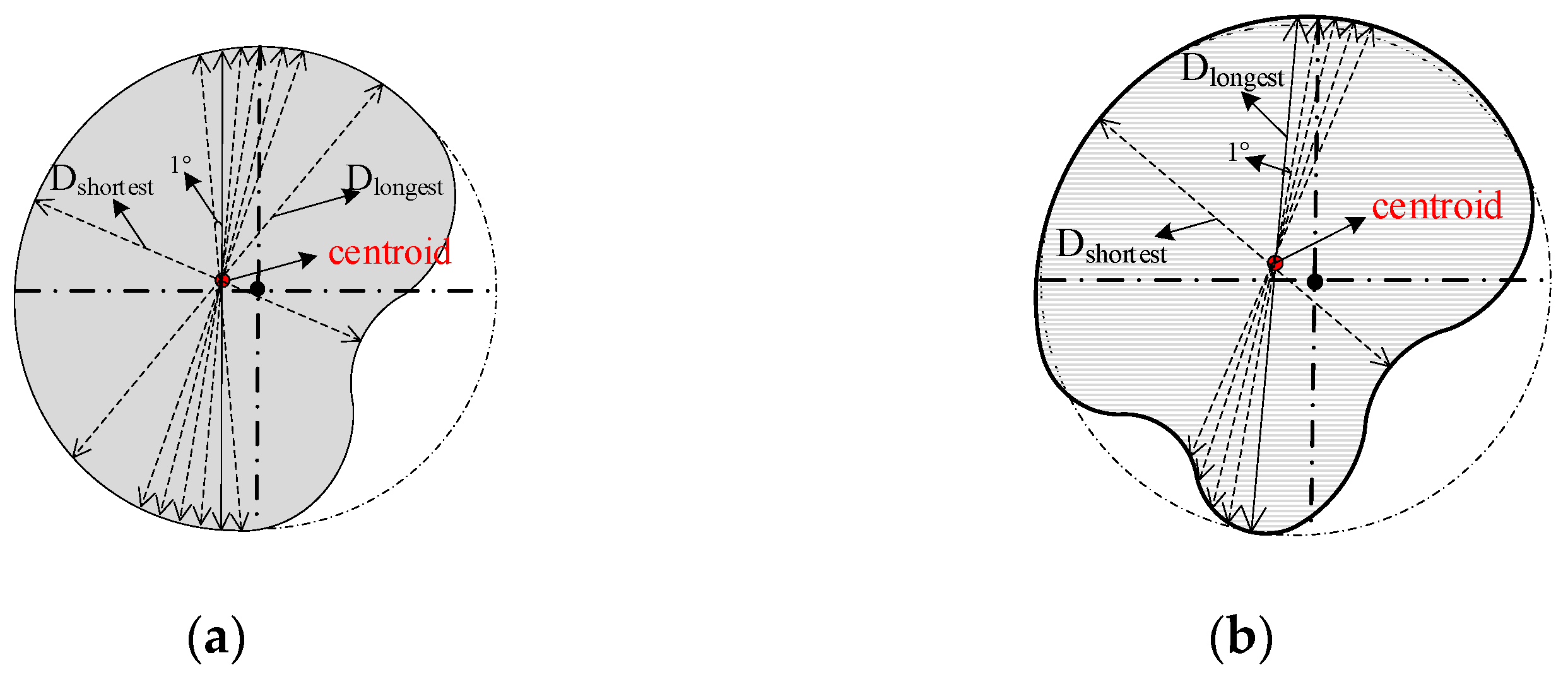

3.2. Data Processing of Test Results

4. Experiments of Ultrasonic Spiral C-Scan Tests and Tensile Shear Tests

4.1. Specimen Preparation

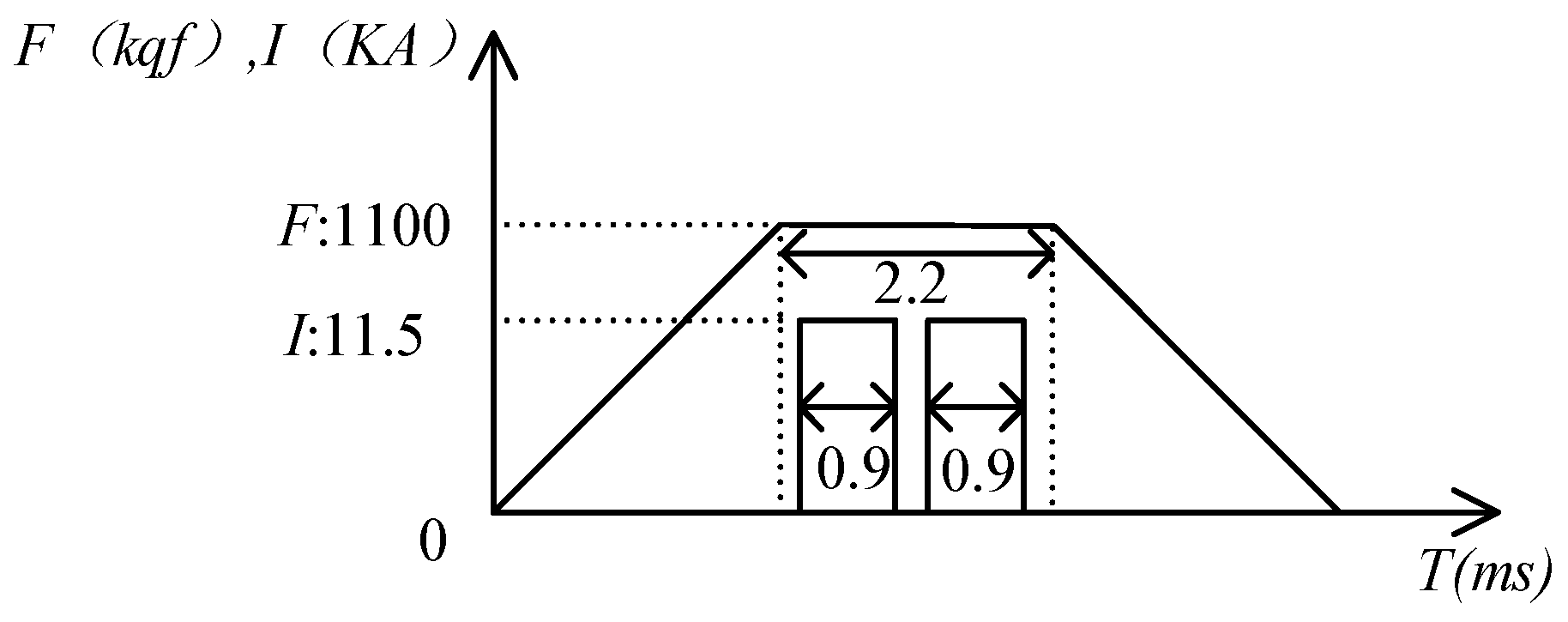

4.2. Experimental Ultrasonic Spiral C-Scan Tests and Tensile Shear Tests

4.3. Result Analysis

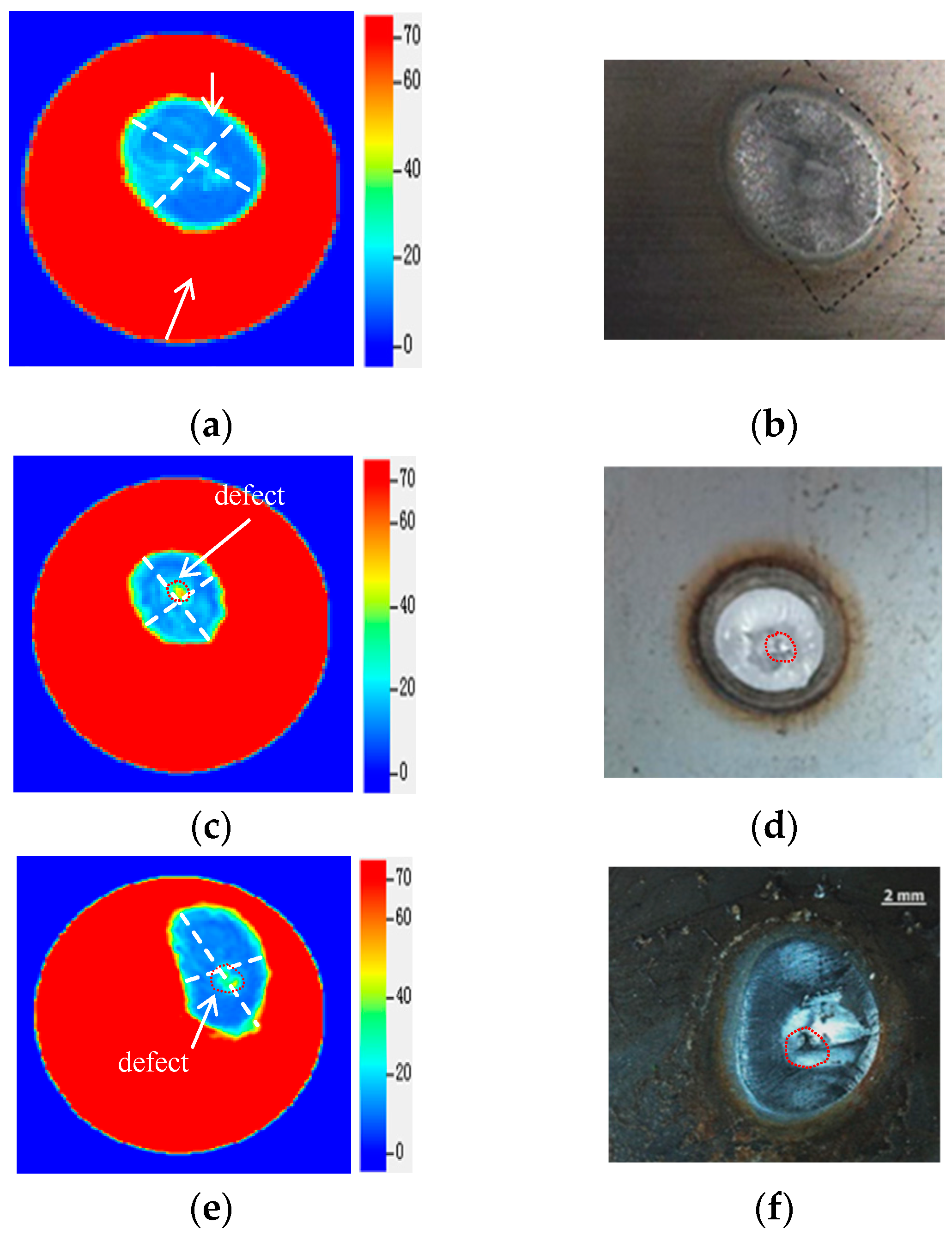

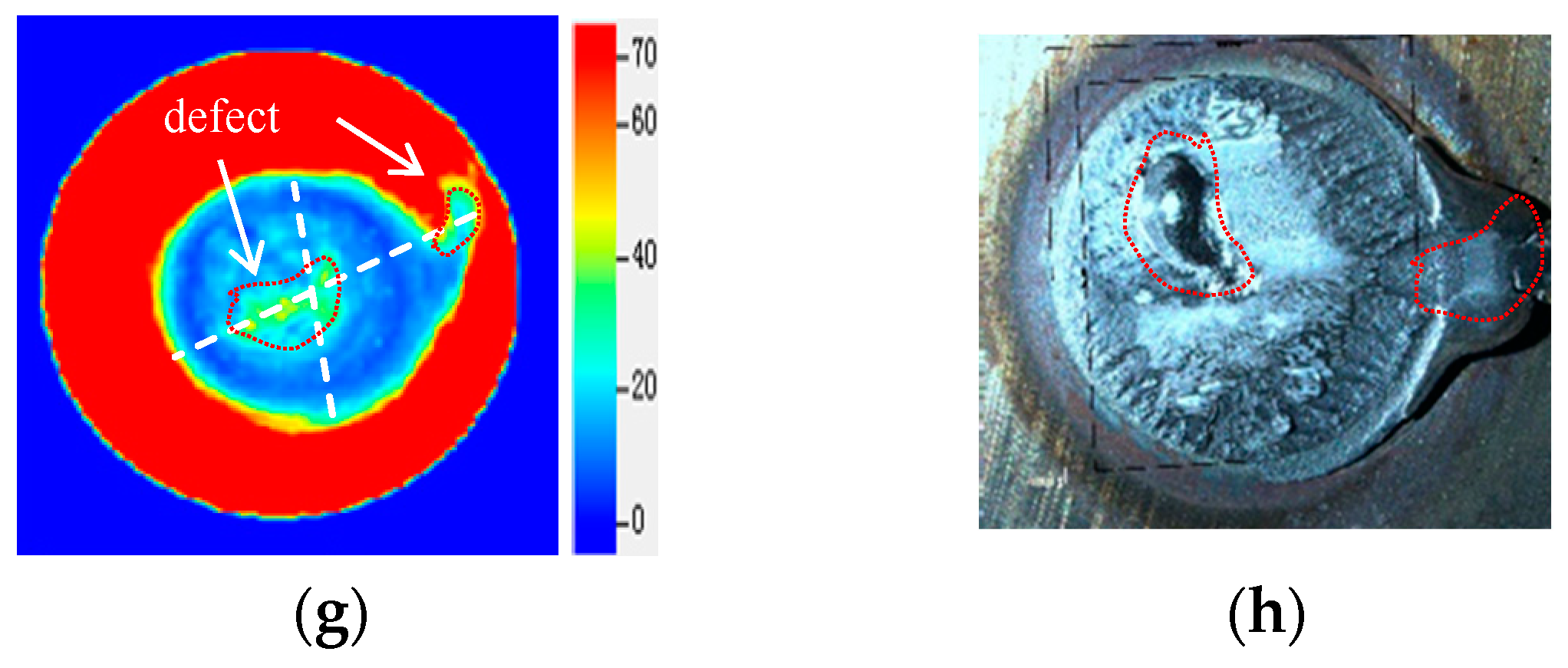

4.3.1. Verification of RSW Nugget Morphologies Obtained by Ultrasonic Spiral C-Scan

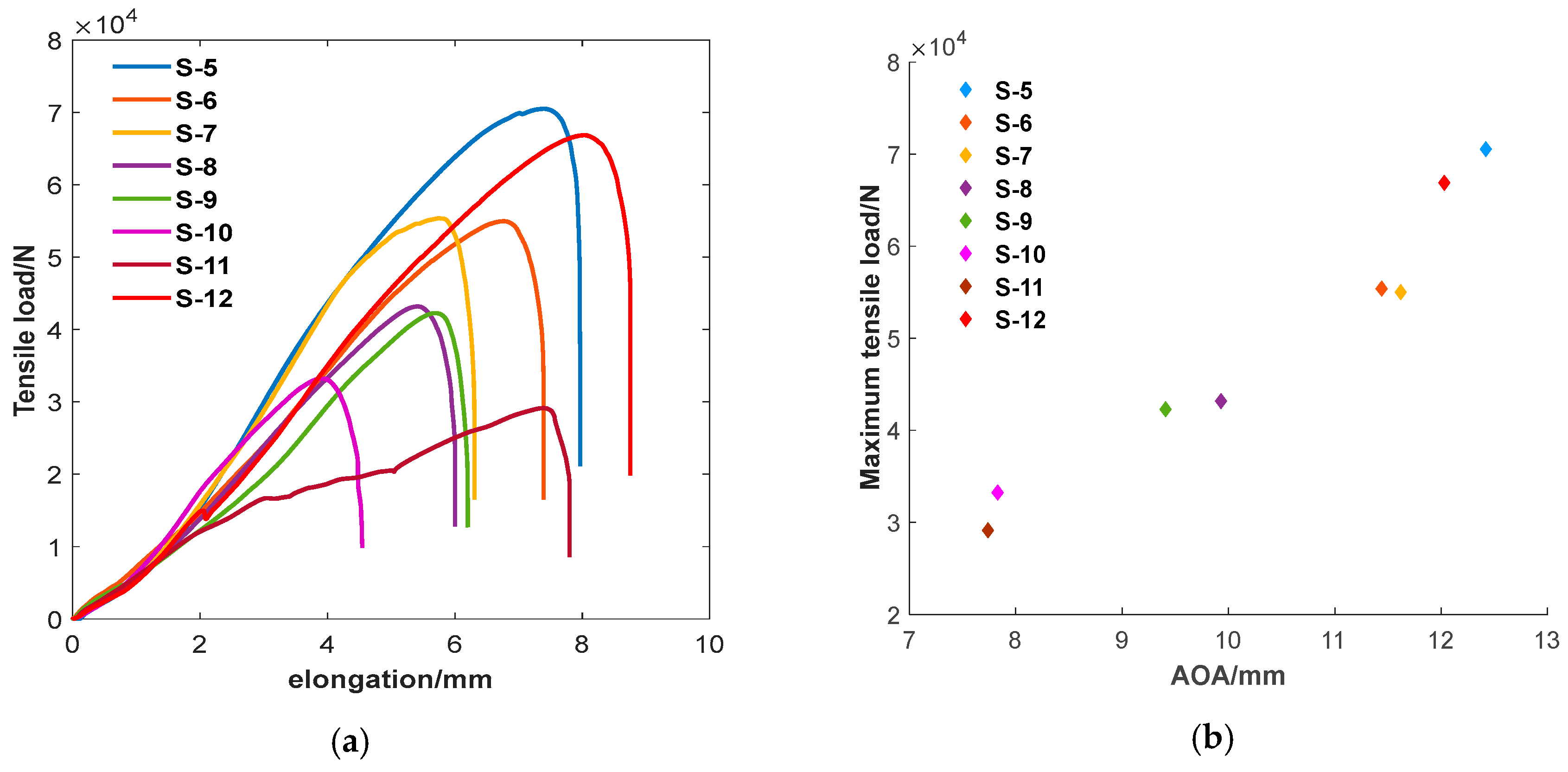

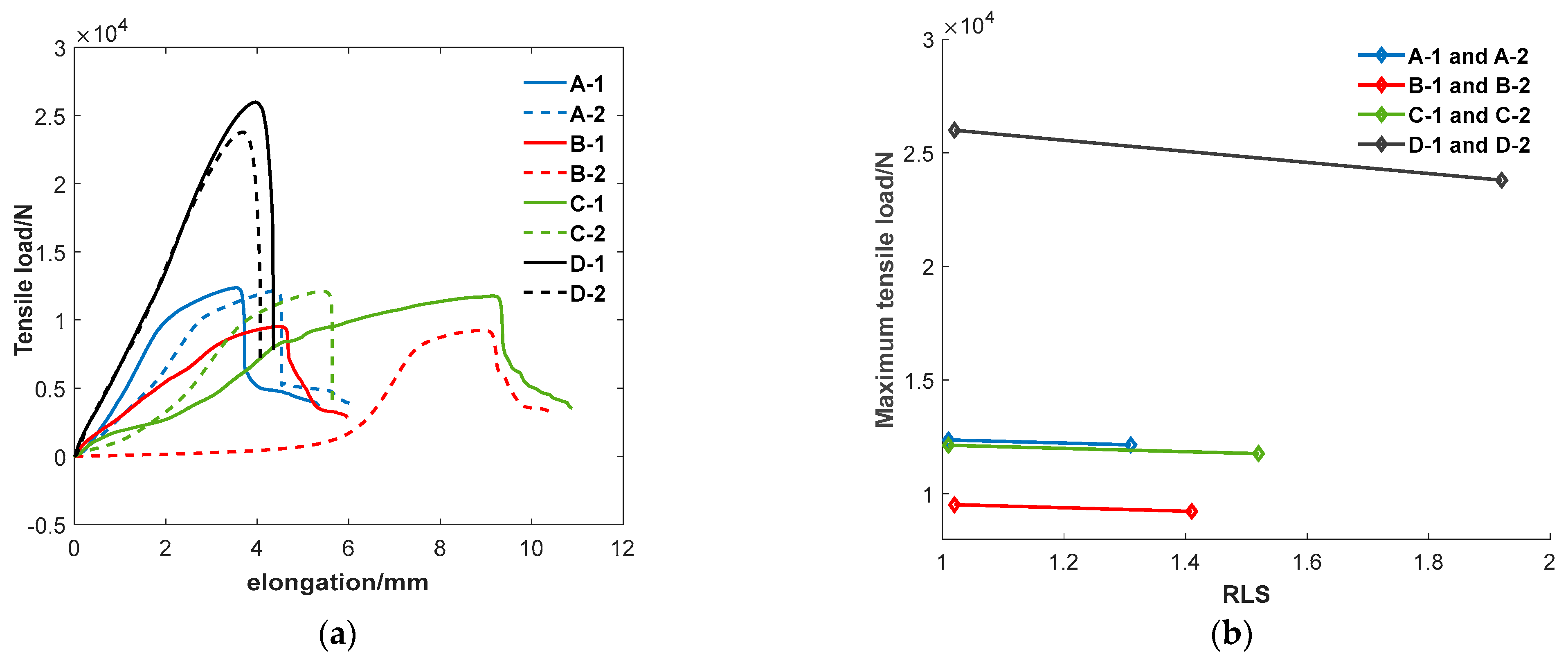

4.3.2. The Influence of Evaluation Factors on Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jagadeesha, T. Experimental studies in weld nugget strength of resistance spot-welded 316L austenitic stainless steel sheet. Int. J. Adv. Manuf. Technol. 2017, 93, 505–513. [Google Scholar] [CrossRef]

- Qian, C.; Ghassemi-Armaki, H.; Shi, L.; Kang, J.; Haselhuhn, A.S.; Carlson, B.E. Competing fracture modes in Al-steel resistance spot welded structures: Experimental evaluation and numerical prediction. Int. J. Impact Eng. 2024, 185, 104838. [Google Scholar] [CrossRef]

- Pal, T.K.; Chattopadhyay, K. Resistance spot weldability and high cycle fatigue behaviour of martensitic (M190) steel sheet. Fatigue Fract. Eng. Mater. Struct. 2010, 34, 46–52. [Google Scholar]

- Mathiszik, C.; Zschetzsche, E.; Reinke, A.; Koal, J.; Zschetzsche, J.; Füssel, U.J.C. Magnetic characterization of the nugget microstructure at resistance spot welding. Crystals 2022, 12, 1512. [Google Scholar] [CrossRef]

- Forejtová, L.; Zavadil, T.; Kolařík, L.; Kolaříková, M.; Sova, J.; Vávra, P. Non-destructive inspection by infrared thermography of resistance spot welds used in automotive industry. Acta Polytech. 2019, 59, 238–247. [Google Scholar]

- Thornton, M.; Han, L.; Shergold, M. Progress in NDT of resistance spot welding of aluminium using ultrasonic C-scan. NDT E Int. 2012, 48, 30–38. [Google Scholar]

- Mezher, M.T.; Pereira, A.; Trzepieciński, T.; Acevedo, J. Artificial Neural Networks and Experimental Analysis of the Resistance Spot Welding Parameters Effect on the Welded Joint Quality of AISI 304. Materials 2024, 17, 2167. [Google Scholar] [CrossRef]

- Martin, O.; Tiedra, P.; Lopez, M. Artificial neural networks for pitting potential prediction of resistance spot welding joints of AISI 304 austenitic stainless steel. Corros. Sci. 2010, 52, 2397–2402. [Google Scholar]

- Ghafarallahi, E.; Farrahi, G.H.; Amiri, N. Acoustic simulation of ultrasonic testing and neural network used for diameter prediction of three-sheet spot welded joints. J. Manuf. Process. 2021, 64, 1507–1516. [Google Scholar]

- Wan, X.; Wang, Y.; Zhao, D.; Huang, Y. A comparison of two types of neural network for weld quality prediction in small scale resistance spot welding. Mech. Syst. Signal Process. 2017, 93, 634–644. [Google Scholar] [CrossRef]

- Wen, J.; Jia, H. Real-time monitoring system for resistance spot welding quality. Eng. Res. Express 2023, 5, 015006. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, S.; Fan, L. Flexible differential pick-up Koch fractal eddy current sensor for internal crack detection. Chin. J. Sci. Instrum. 2023, 44, 234–242. [Google Scholar]

- Pasadas, D.J.; Ramos, H.G.; Baskaran, P.; Ribeiro, A.L. ECT in composite materials using double excitation coils and resonant excitation sensing circuits. Measurement 2020, 161, 107859. [Google Scholar]

- Taram, A.; Roquelet, C.; Meilland, P.; Le Noc, G.; Bodnar, J.; Duvaut, T.; Kaczynski, C.; Dupuy, T. Assessment of nugget diameter of resistance spot welds using pulse eddy current thermography. In Thermosense: Thermal Infrared Applications XL; Hindustan Aeronautics Limited: Bengaluru, India, 2018; Volume 10661, pp. 236–243. [Google Scholar]

- Taram, A.; Roquelet, C.; Meilland, P.; Dupuy, T.; Kaczynski, C.; Bodnar, J.-L.; Duvaut, T. Nondestructive testing of resistance spot welds using eddy current thermography. Appl. Opt. 2018, 57, D63–D68. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xu, G.; Ren, L.; Qian, Z.; Ren, L. Defect intelligent identification in resistance spot welding ultrasonic detection based on wavelet packet and neural network. Int. J. Adv. Manuf. Technol. 2017, 90, 2581–2588. [Google Scholar]

- Liu, J.; Xu, G.; Ren, L.; Qian, Z.; Ren, L. Simulation analysis of ultrasonic detection for resistance spot welding based on COMSOL Multiphysics. Int. J. Adv. Manuf. Technol. 2017, 93, 2089–2096. [Google Scholar] [CrossRef]

- Chen, H.; Hu, X.; Xiang, B. Research on phased array theory for non-destructive testing of welds. Weld. Technol. 2017, 46, 89–93. [Google Scholar]

- Wang, B.; Gan, W. Phased array ultrasonic testing method of nugget diameter for resistance spot welding. J. Nondestruct. Eval. 2022, 44, 31–35. [Google Scholar]

- Li, Z.; Cai, G.; Zhang, B.; Li, J.; Li, J. Synthetic Aperture Imaging Technology for Ultrasonic Spiral Scanning Detection of Metal Bars. Acta Met. Sin. 2024, 60, 559–568. [Google Scholar]

- Ma, P.; Xu, C.; Xiao, D. Robotic Ultrasonic Testing Technology for Aero-Engine Blades. Sensors 2016, 23, 3729. [Google Scholar] [CrossRef]

- AWS D8.7M-2005; Recommended Practices for Automotive Weld Quality Resistance SpotWelding. American Welding Society: Doral, FL, USA, 2005.

- EN15085-3-2007; Railwayapplications-Weldingofrailwayvehiclesandcomponents-Part3Design Requirement. BSI: London, UK, 2007.

- Zhang, B.; Zhang, B.; Cai, W.; Wang, L.; Zhang, Y. A novel method to eliminate the corona bond effect in detecting resistance spot welding joints based on ultrasonic vortex C-Scan technique. Int. J. Adv. Manuf. Technol. 2021, 117, 3241–3252. [Google Scholar] [CrossRef]

- JIS Z3136-1999; Specimen Dimensions and Procedure for Shear Testing Resistance Spot and Embossed Projection Welded Joints. Japanese Standards Association: Tokyo, Japan, 1999.

- He, Y.; Yang, K.; Wang, X.; Huang, H.; Chen, J. Quality prediction and parameter optimisation of resistance spot welding using machine learning. Appl. Sci. 2022, 12, 9625. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni | Cr | N | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 7.10 | 17.70 | 0.2 | Bal |

| Sample Number | S-1 | S-2 | S-3 | S-4 |

|---|---|---|---|---|

| Detected defect size | 0 | 1.18 | 1.36 | 2.05 |

| Actual defect size | 0 | 1.25 | 1.40 | 1.94 |

| Error (Unit in mm) | 0 | −0.07 | −0.04 | 0.09 |

| Error (Unit in %) | 0% | −5.9% | 2.9% | 4.3% |

| Sample Number | A-1 | A-2 | B-1 | B-2 | C-1 | C-2 | D-1 | D-2 |

|---|---|---|---|---|---|---|---|---|

| RLS value | 1.01 | 1.31 | 1.02 | 1.41 | 1.01 | 1.52 | 1.02 | 1.92 |

| Maximum tensile load (kN) | 12.37 | 12.15 | 9.52 | 9.23 | 12.14 | 11.77 | 26.00 | 23.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Chuai, R.; Cai, G.; Xue, D.; Li, J.; Liu, K.; Liu, C. Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique. Sensors 2024, 24, 4771. https://doi.org/10.3390/s24154771

Yang L, Chuai R, Cai G, Xue D, Li J, Liu K, Liu C. Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique. Sensors. 2024; 24(15):4771. https://doi.org/10.3390/s24154771

Chicago/Turabian StyleYang, Liang, Rongyan Chuai, Guixi Cai, Dan Xue, Jingming Li, Kunlin Liu, and Chang Liu. 2024. "Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique" Sensors 24, no. 15: 4771. https://doi.org/10.3390/s24154771

APA StyleYang, L., Chuai, R., Cai, G., Xue, D., Li, J., Liu, K., & Liu, C. (2024). Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique. Sensors, 24(15), 4771. https://doi.org/10.3390/s24154771