Piezoelectric Active Sensing-Based Pipeline Corrosion Monitoring Using Singular Spectrum Analysis

Abstract

1. Introduction

2. Theoretical Fundamentals

2.1. Working Principle

2.2. Signal Analyzing and Processing

2.3. Singular Spectrum Analysis

- Step 1: Time series decomposition embedding to form a trajectory matrix

- Step 2: Singular value decomposition

- Step 3: Grouping

- Step 4: Anti-diagonal average

3. Experimental Setup and Procedure

3.1. Experimental Device and Test Specimen

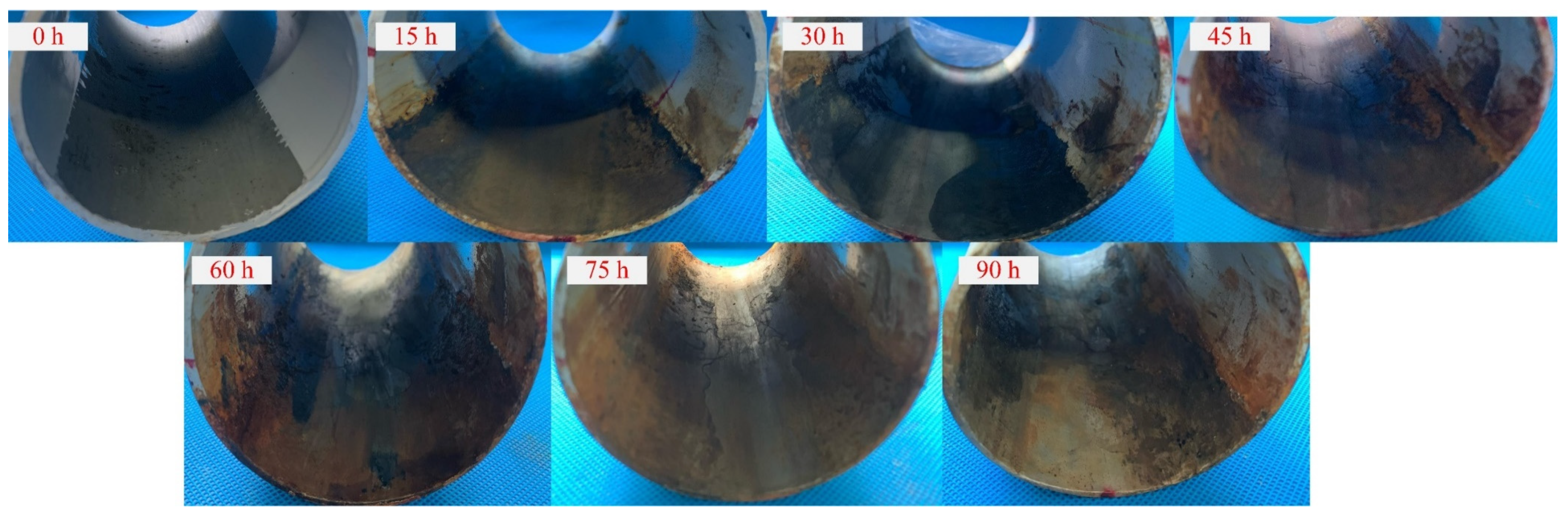

3.2. Experimental Procedure

4. Experimental Results and Discussion

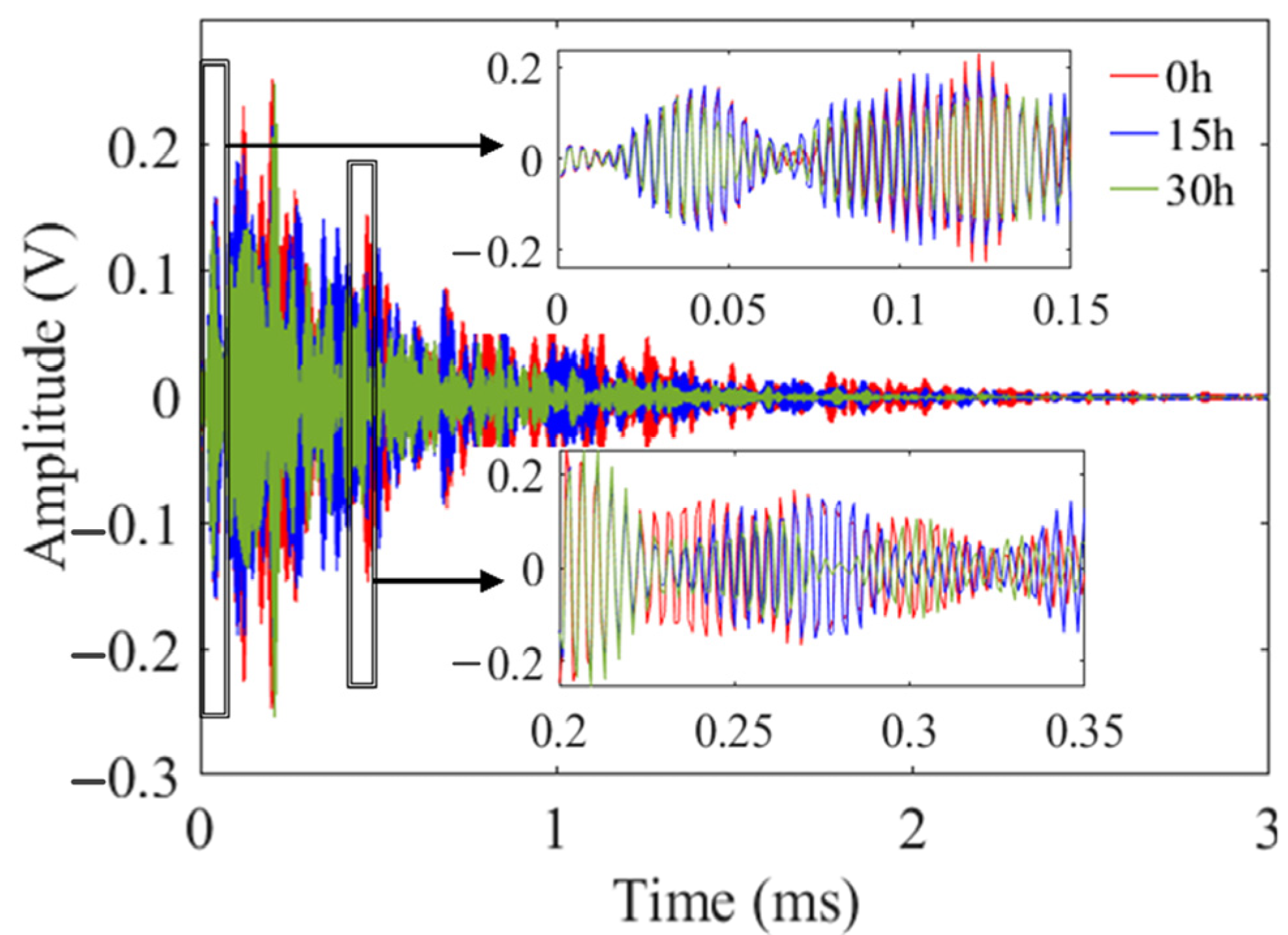

4.1. Signal Processing for Noise Reduction

4.2. Selection of Signals

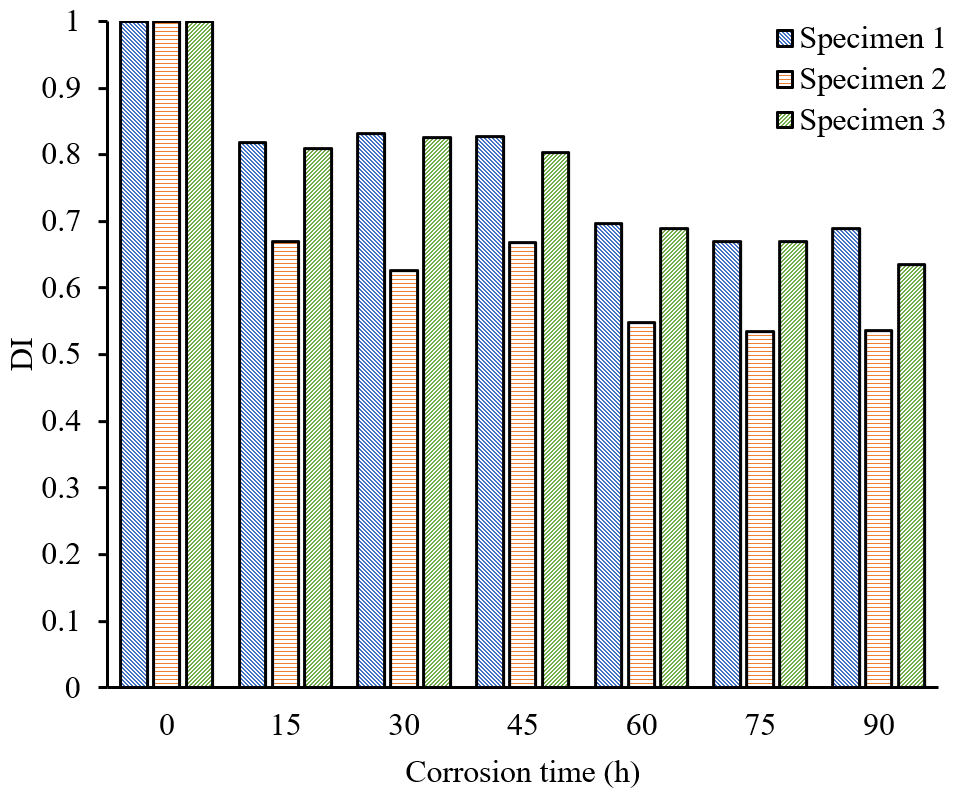

4.3. Damage Index

4.4. Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Li, K.; Feng, L. Tracing the technological trajectory of coal slurry pipeline transportation technology: An HMM-based topic modeling approach. Front. Energy Res. 2022, 10, 974747. [Google Scholar] [CrossRef]

- Ho, M.; El-Borgi, S.; Patil, D.; Song, G. Inspection and monitoring systems subsea pipelines: A review paper. Struct. Health Monit. 2020, 19, 606–645. [Google Scholar] [CrossRef]

- Zhu, J.; Ren, L.; Ho, S.-C.; Jia, Z.; Song, G. Gas pipeline leakage detection based on PZT sensors. Smart Mater. Struct. 2017, 26, 025022. [Google Scholar] [CrossRef]

- Yu, Y.; Cheng, X.; Wang, L.; Wang, C. Convolutional neural network-based quantitative evaluation for corrosion cracks in oil/gas pipeline by millimeter-wave imaging. IEEE Trans. Instrum. Meas. 2022, 71, 8006109. [Google Scholar] [CrossRef]

- Du, G.; Huo, L.; Kong, Q.; Song, G. Damage detection of pipeline multiple cracks using piezoceramic transducers. J. Vibroeng. 2016, 18, 2828–2838. [Google Scholar] [CrossRef]

- Bastian, B.T.; Jaspreeth, N.; Ranjith, S.K.; Jiji, C. Visual inspection and characterization of external corrosion in pipelines using deep neural network. NDT E Int. 2019, 107, 102134. [Google Scholar] [CrossRef]

- Shaik, N.B.; Benjapolakul, W.; Pedapati, S.R.; Bingi, K.; Le, N.T.; Asdornwised, W.; Chaitusaney, S. Recurrent neural network-based model for estimating the life condition of a dry gas pipeline. Process Saf. Environ. Prot. 2022, 164, 639–650. [Google Scholar] [CrossRef]

- Walker, J. In-Line Inspection of Pipelines Advanced Technologies for Economic and Safe Operation of Oil and Gas Pipelines; Verlag Moderne Industrie: Berlin, Germany, 2010; p. 327. [Google Scholar]

- Beller, M.; Barbian, A.; Strack, D. Combined in-line inspection of pipelines for metal loss and cracks. In Proceedings of the International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006; Volume 42622, pp. 857–864. [Google Scholar]

- Aron, J.; Jia, J.; Vance, B.; Chang, W.; Pohler, R.; Gore, J.; Eaton, S.; Bowles, A.; Jarman, T. Development of an EMAT In-line Inspection System for Detection, Discrimination, and Grading of Stress Corrosion Cracking in Pipelines; Tuboscope Pipeline Services: Houston, TX, USA, 2005. [Google Scholar]

- Edalati, K.; Rastkhah, N.; Kermani, A.; Seiedi, M.; Movafeghi, A. The use of radiography for thickness measurement and corrosion monitoring in pipes. Int. J. Press. Vessel. Pip. 2006, 83, 736–741. [Google Scholar] [CrossRef]

- Raude, A.; Bouchard, M.; Sirois, M. Stress Corrosion Cracking Direct Assessment of Carbon Steel Pipeline Using Advanced Eddy Current Array Technology. In Proceedings of the CORROSION 2018, Phoenix, AZ, USA, 15–19 April 2018; pp. 2018–11150. [Google Scholar]

- Da, Y.; Dong, G.; Shang, Y.; Wang, B.; Liu, D.; Qian, Z. Circumferential defect detection using ultrasonic guided waves: An efficient quantitative technique for pipeline inspection. Eng. Comput. 2020, 37, 1923–1943. [Google Scholar] [CrossRef]

- Lyu, F.; Zhou, X.; Ding, Z.; Qiao, X.; Song, D. Application Research of Ultrasonic-Guided Wave Technology in Pipeline Corrosion Defect Detection: A Review. Coatings 2024, 14, 358. [Google Scholar] [CrossRef]

- Rodgers, E.C.; Mariani, S.; Cawley, P. The use of circumferential guided waves to monitor axial cracks in pipes. Struct. Health Monit. 2023, 22, 2609–2625. [Google Scholar] [CrossRef]

- Shi, W.; Chen, W.; Lu, C.; Chen, Y. Interaction of circumferential SH0 guided wave with circumferential cracks in pipelines. Nondestruct. Test. Eval. 2021, 36, 571–596. [Google Scholar] [CrossRef]

- Chen, J.; Cao, L.; Song, G. Detection of the pipeline elbow erosion by percussion and deep learning. Mech. Syst. Signal Process. 2023, 200, 110546. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.H.; Silva, P.; Mo, Y.L. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Wang, F.; Huo, L.; Song, G. A piezoelectric active sensing method for quantitative monitoring of bolt loosening using energy dissipation caused by tangential damping based on the fractal contact theory. Smart Mater. Struct. 2017, 27, 015023. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Z.; Song, G. Smart crawfish: A concept of underwater multi-bolt looseness identification using entropy-enhanced active sensing and ensemble learning. Mech. Syst. Signal Process. 2021, 149, 107186. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Zhou, T.; Wang, T.; Li, J. A Novel Pipeline Corrosion Monitoring Method Based on Piezoelectric Active Sensing and CNN. Sensors 2023, 23, 855. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Pollock, P. A multi-mode sensing system for corrosion detection using piezoelectric wafer active sensors. Sens. Smart Struct. Technol. Civ. Mech. Aerosp. Syst. 2008, 6932, 734–745. [Google Scholar]

- Li, T.; Li, G.; Zhang, X.; Xu, S.; Ghougassian, H. Study on the Electrochemical Anticorrosion Effect of Piezoelectric Materials in the Internal Environment of Water Supply Pipeline. Nat. Environ. Pollut. Technol. 2021, 20, 941–953. [Google Scholar] [CrossRef]

- Siswantoro, N.; Doğan, A.; Priyanta, D.; Zaman, M.B.; Semin, S. Possibility of piezoelectric sensor to monitor onshore pipeline in real time monitoring. Int. J. Mar. Eng. Innov. Res. 2019, 3, 4. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V.; Chao, Y.; Pollock, P. In-situ multi-mode sensing with embedded piezoelectric wafer active sensors for critical pipeline health monitoring. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2007; Volume 43041, pp. 687–696. [Google Scholar]

- Lu, P.; Oetjen, K.A.; Bender, D.E.; Ruzinova, M.B.; Fisher, D.A.C.; Shim, K.G.; Pachynski, R.K.; Brennen, W.N.; Oh, S.T.; Link, D.C.; et al. IMC-Denoise: A content aware denoising pipeline to enhance Imaging Mass Cytometry. Nat. Commun. 2023, 14, 1601. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Liu, Y.; Zheng, L.; Ma, C.; Wang, H. Leak detection of water pipeline using wavelet transform method. In Proceedings of the 2009 International Conference on Environmental Science and Information Application Technology, Wuhan, China, 4–5 July 2009; Volume 2, pp. 217–220. [Google Scholar]

- Xu, Z.D.; Zhu, C.; Shao, L.W. Damage identification of pipeline based on ultrasonic guided wave and wavelet denoising. J. Pipeline Syst. Eng. Pract. 2021, 12, 04021051. [Google Scholar] [CrossRef]

- Jin, Y.; Xiao, H.; Fu, C. Power load forecasting based on SSA non-noise reduction processing. In Proceedings of the 5th International Conference on Computer Science and Software Engineering, Guilin, China, 21–23 October 2022; pp. 103–107. [Google Scholar]

- Luong, V.S.; Le, M.; Nguyen, K.D.; Le, D.-K.; Lee, J. Electromagnetic Testing of Moisture Separation Reheater Tube based on Multivariate Singular Spectral Analysis. Appl. Sci. 2020, 10, 3954. [Google Scholar] [CrossRef]

- Li, X.; Guo, M.; Zhang, R.; Chen, G. A data-driven prediction model for maximum pitting corrosion depth of subsea oil pipelines using SSA-LSTM approach. Ocean Eng. 2022, 261, 112062. [Google Scholar] [CrossRef]

- Wang, J.; Lu, G.; Song, H.; Wang, T.; Yang, D. Damage identification of thin plate-like structures combining improved singular spectrum analysis and multiscale cross-sample entropy (ISSA-MCSEn). Smart Mater. Struct. 2023, 32, 034001. [Google Scholar] [CrossRef]

- Golyandina, N.; Korobeynikov, A.; Zhigljavsky, A. Singular Spectrum Analysis with R; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Muruganatham, B.; Sanjith, M.; Krishnakumar, B.; Murty, S.S. Roller element bearing fault diagnosis using singular spectrum analysis. Mech. Syst. Signal Process. 2013, 35, 150–166. [Google Scholar] [CrossRef]

- Jeong-Tae, K.; Park, J.-H.; Lee, B.-J. Vibration-based damage monitoring in model plate-girder bridges under uncertain temperature conditions. Eng. Struct. 2006, 29, 1354–1365. [Google Scholar]

- Yang, D.; Xiong, M.; Wang, T.; Lu, G. Percussion-based pipeline ponding detection using a convolutional neural network. Appl. Sci. 2022, 12, 2127. [Google Scholar] [CrossRef]

- Cui, E.; Zuo, C.; Fan, M.; Jiang, S. Monitoring of corrosion-induced damage to bolted joints using an active sensing method with piezoceramic transducers. J. Civ. Struct. Health Monit. 2021, 11, 411–420. [Google Scholar] [CrossRef]

- Pourbaix, M. Lectures on Electrochemical Corrosion; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Liang, Y.; Li, D.; Kong, Q.; Song, G. Load monitoring of the pin-connected structure using time reversal technique and piezoceramic transducers-A feasibility study. IEEE Sens. J. 2016, 16, 7958–7966. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J. A novel decomposition ensemble model for forecasting short term load time series with multiple seasonal patterns. Appl. Soft Comput. J. 2018, 65, 478–494. [Google Scholar] [CrossRef]

- Qin, S.R.; Zhong, Y.M. A new envelope algorithm of Hilbert–Huang transform. Mech. Syst. Signal Process. 2006, 20, 1941–1952. [Google Scholar] [CrossRef]

- Ulrich, T. Envelope Calculation from the Hilbert Transform; Technical Report; Los Alamos National Laboratory: Los Alamos, NM, USA, 2006. [Google Scholar]

| Parameter | Values | Unit |

|---|---|---|

| Density | 7.85 | g/cm3 |

| Elasticity modulus | 200~210 | GPa |

| Strength of extension | 370~500 | MPa |

| Linear expansion | 1.2 × 10−5 | 1/°C |

| Parameter | Values | Unit |

|---|---|---|

| Amplitude | 10 | V |

| Center frequency | 150 | kHz |

| Normalized bandwidth | 0.8 | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Wang, H.; Wang, T.; Lu, G. Piezoelectric Active Sensing-Based Pipeline Corrosion Monitoring Using Singular Spectrum Analysis. Sensors 2024, 24, 4192. https://doi.org/10.3390/s24134192

Yang D, Wang H, Wang T, Lu G. Piezoelectric Active Sensing-Based Pipeline Corrosion Monitoring Using Singular Spectrum Analysis. Sensors. 2024; 24(13):4192. https://doi.org/10.3390/s24134192

Chicago/Turabian StyleYang, Dan, Hu Wang, Tao Wang, and Guangtao Lu. 2024. "Piezoelectric Active Sensing-Based Pipeline Corrosion Monitoring Using Singular Spectrum Analysis" Sensors 24, no. 13: 4192. https://doi.org/10.3390/s24134192

APA StyleYang, D., Wang, H., Wang, T., & Lu, G. (2024). Piezoelectric Active Sensing-Based Pipeline Corrosion Monitoring Using Singular Spectrum Analysis. Sensors, 24(13), 4192. https://doi.org/10.3390/s24134192