A Pneumatically Controlled Prosthetic Socket for Transfemoral Amputees

Abstract

:1. Introduction

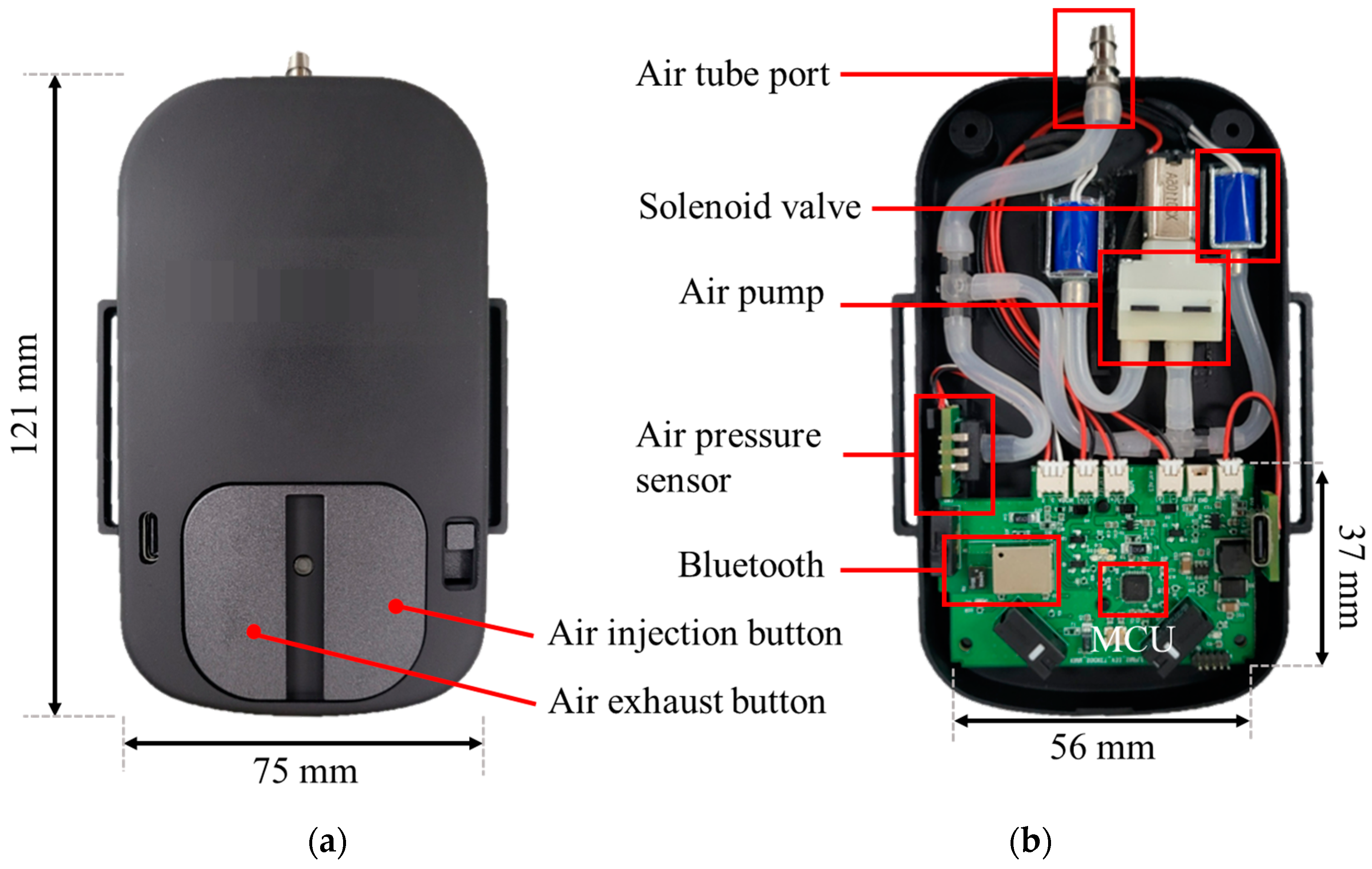

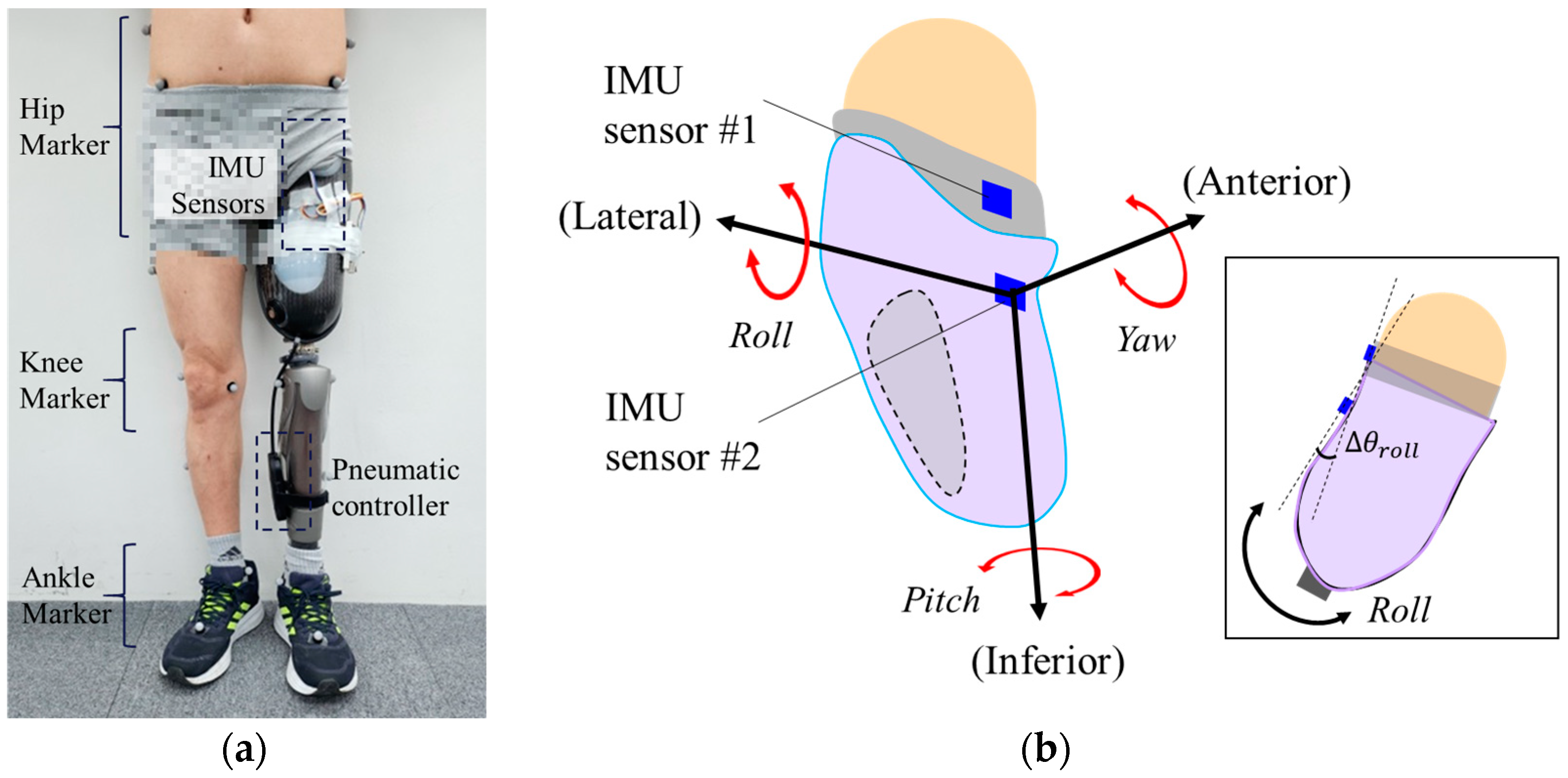

2. Materials and Methods

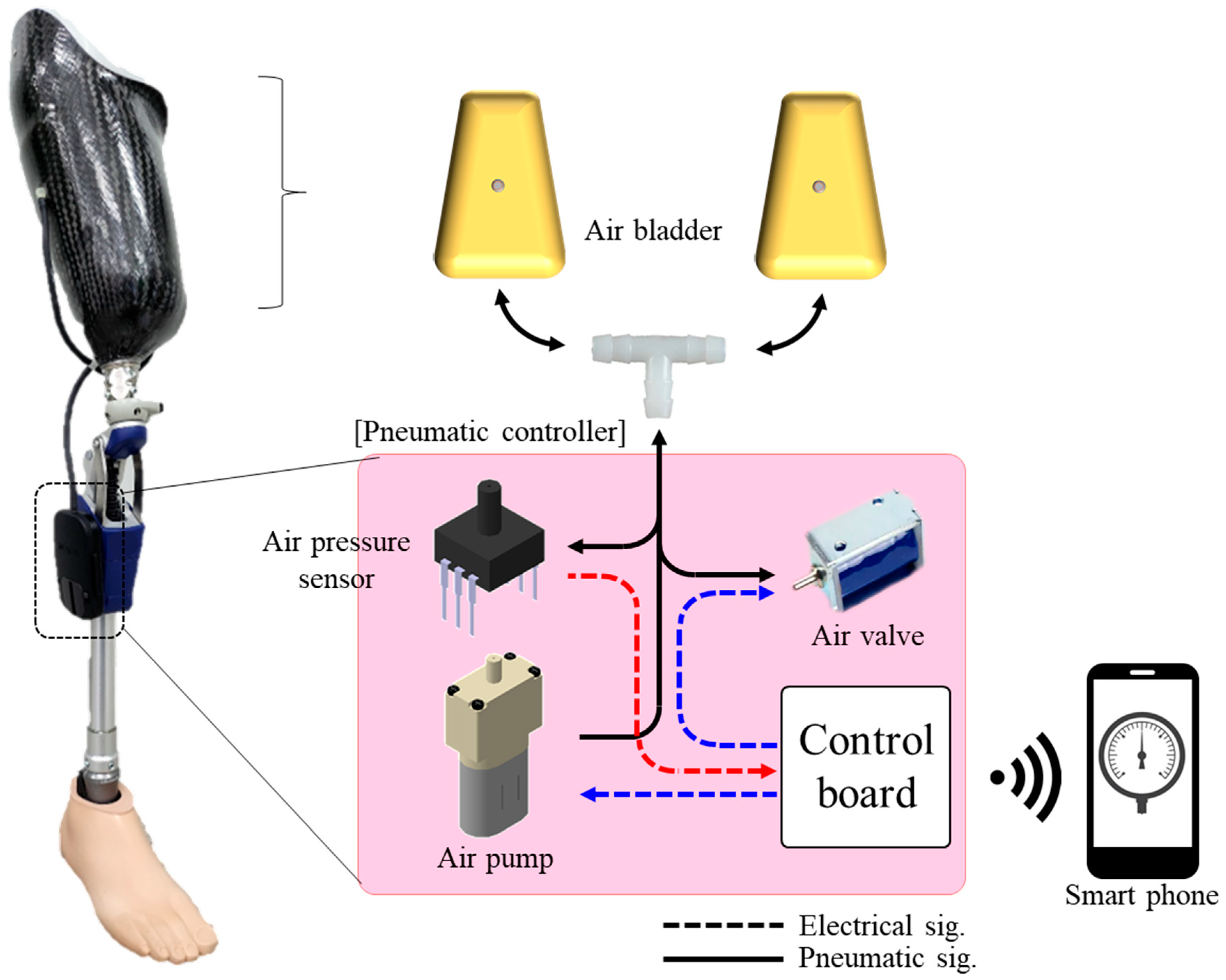

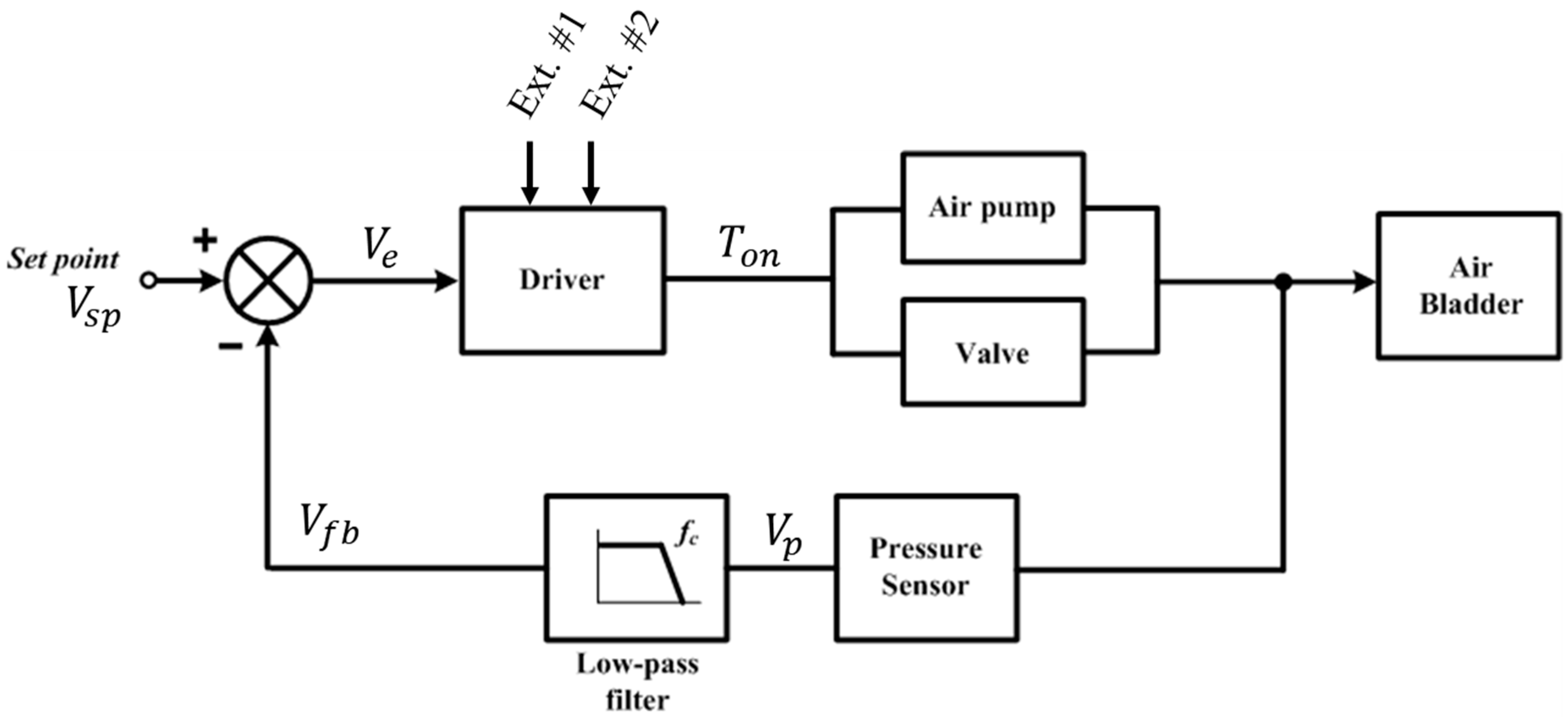

2.1. System Structure and Operation Principle

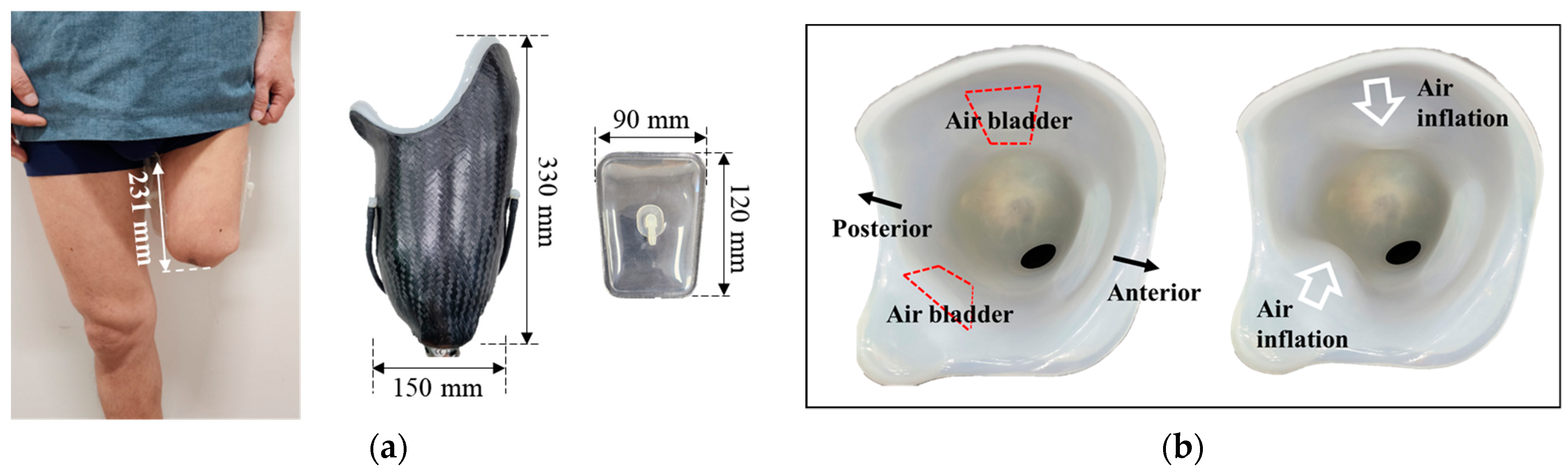

2.2. Fabrication of a Pneumatically Controlled Prosthetic Socket

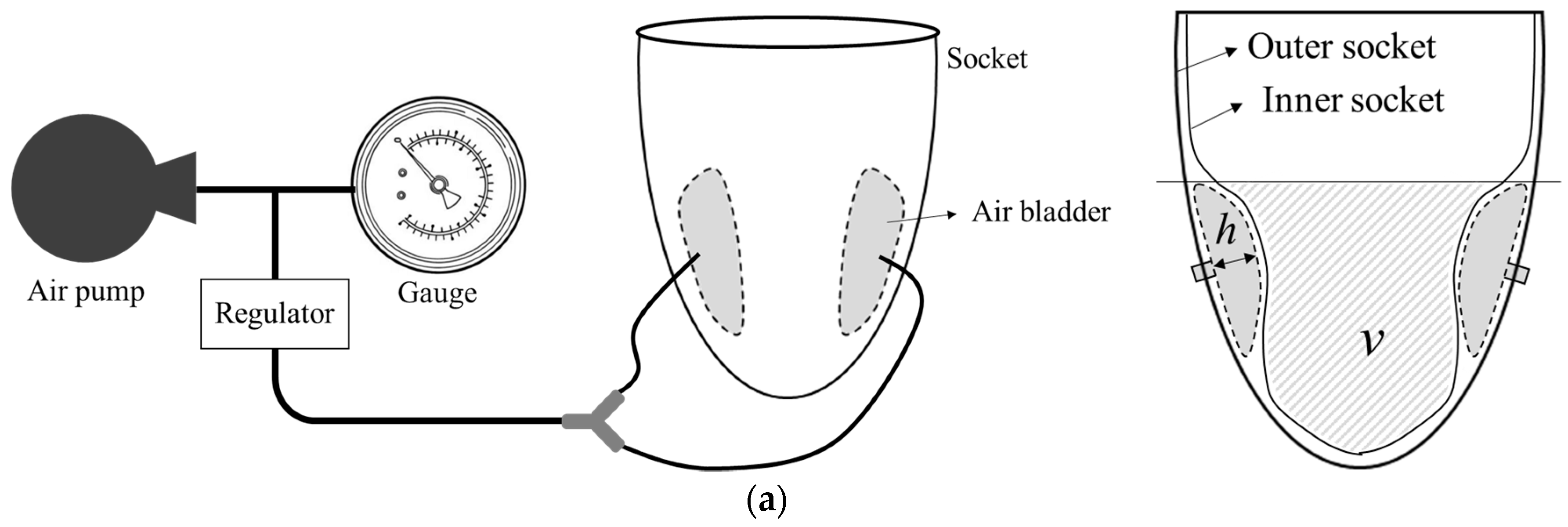

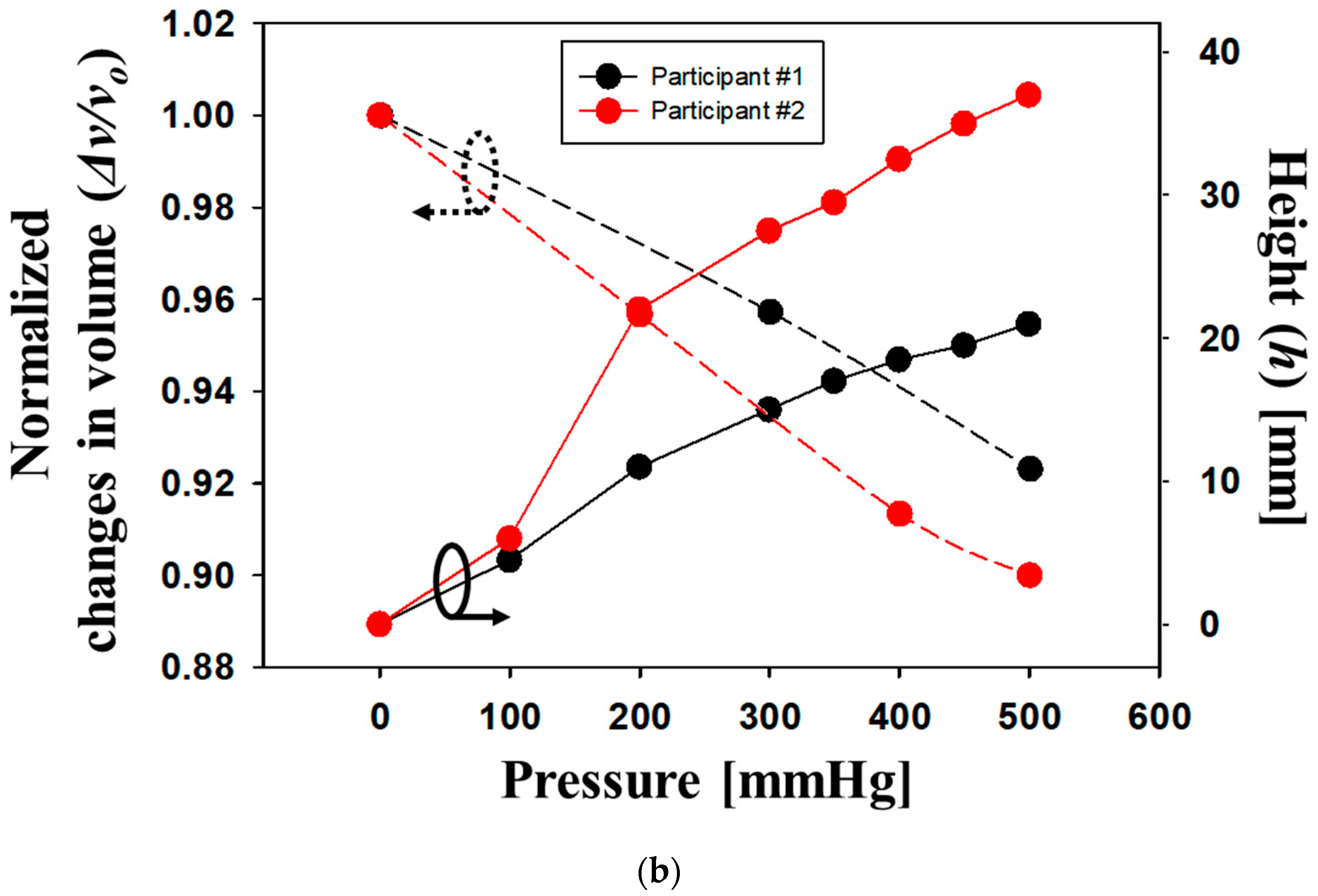

2.3. Characterization of Air Bladder

2.4. An Alternating Mechanism for Closed- and Open-Loop Control

3. Results and Discussion

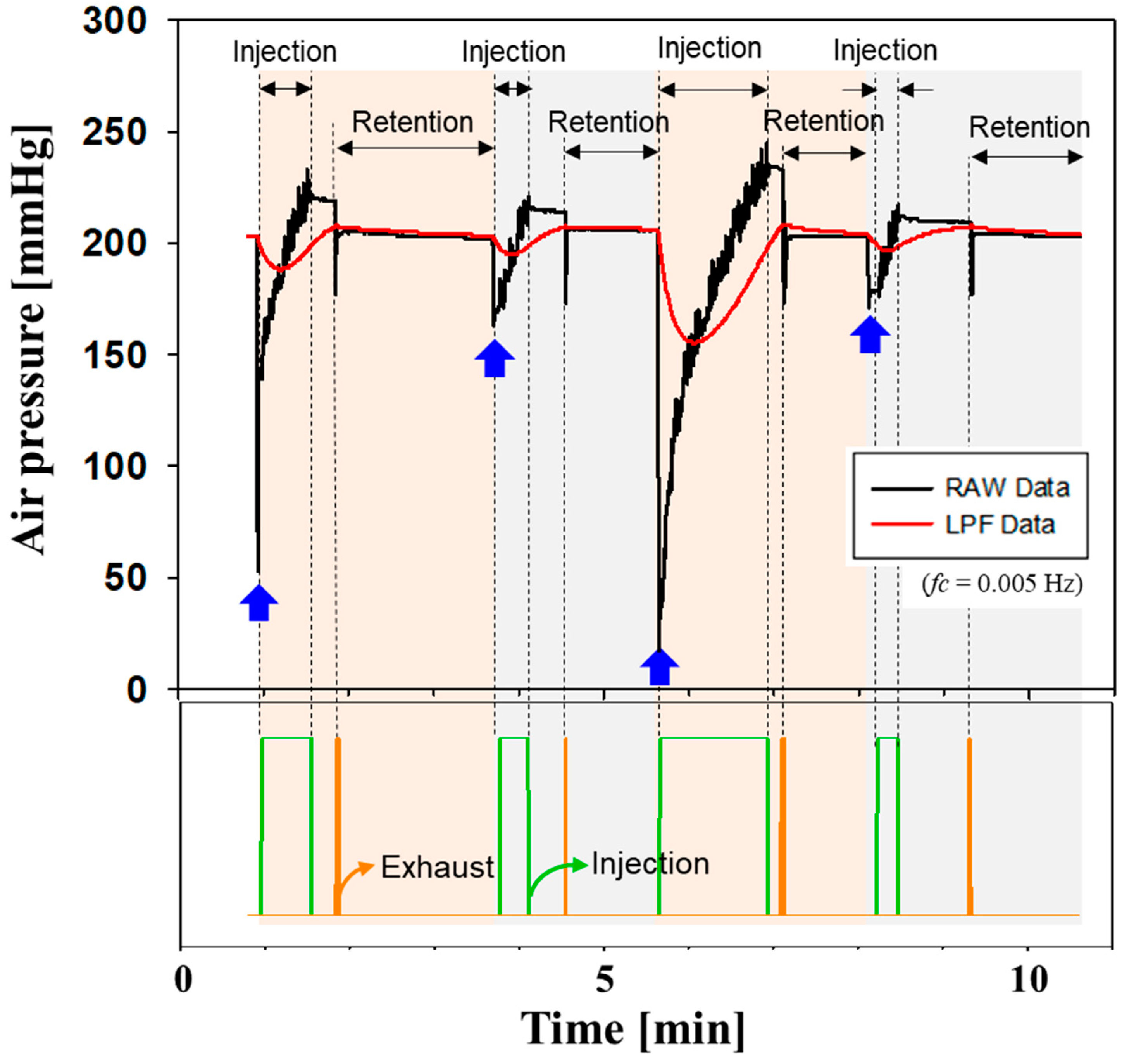

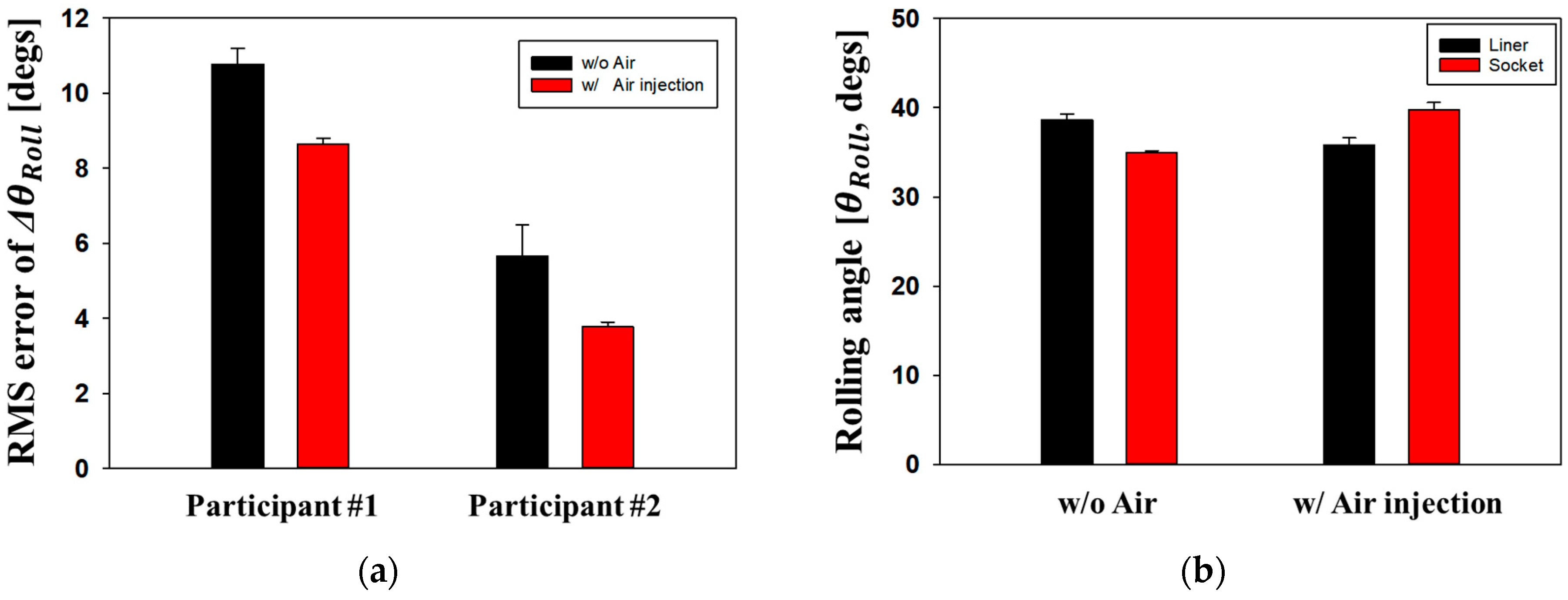

3.1. Verification of a Closed-Loop Control

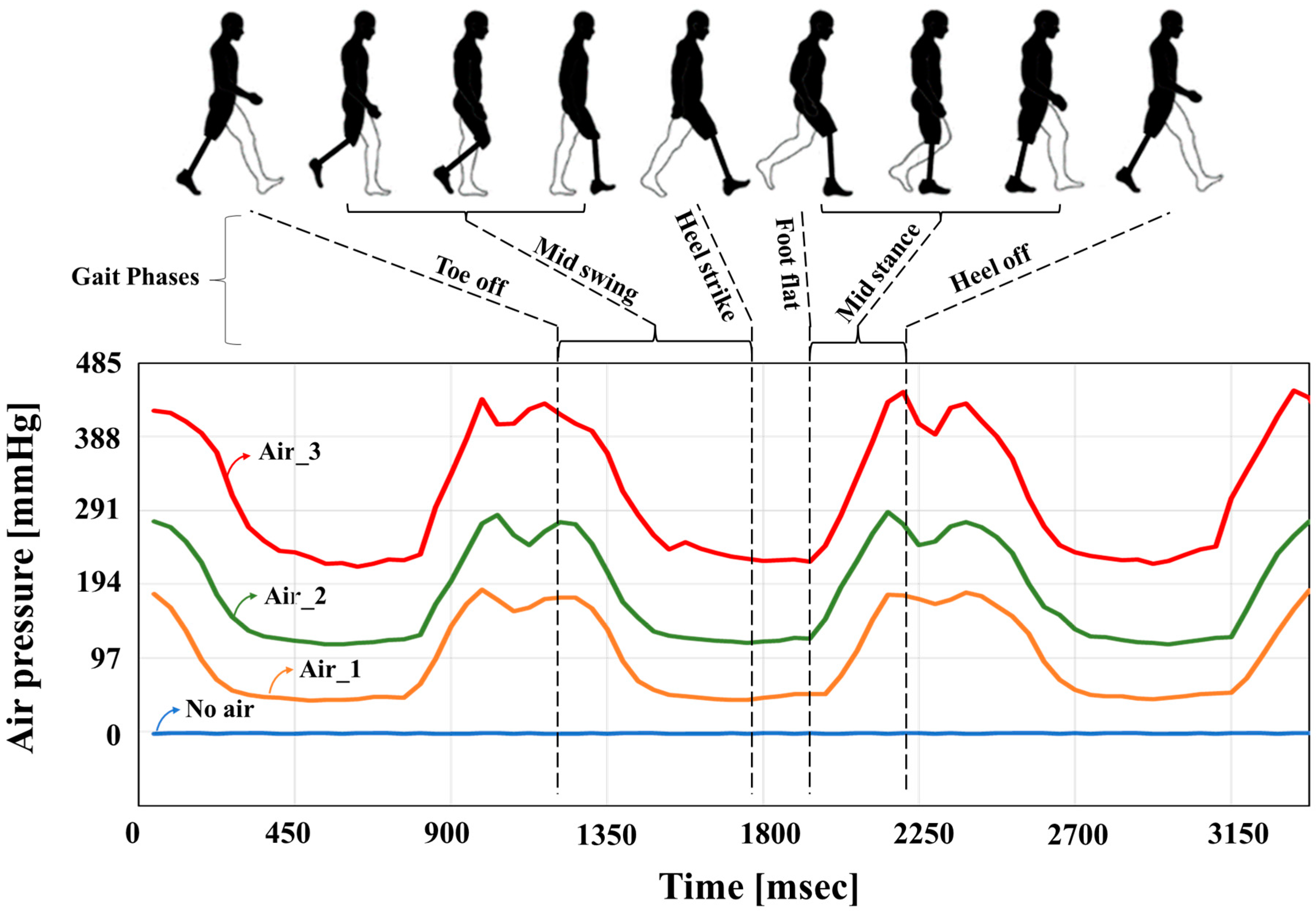

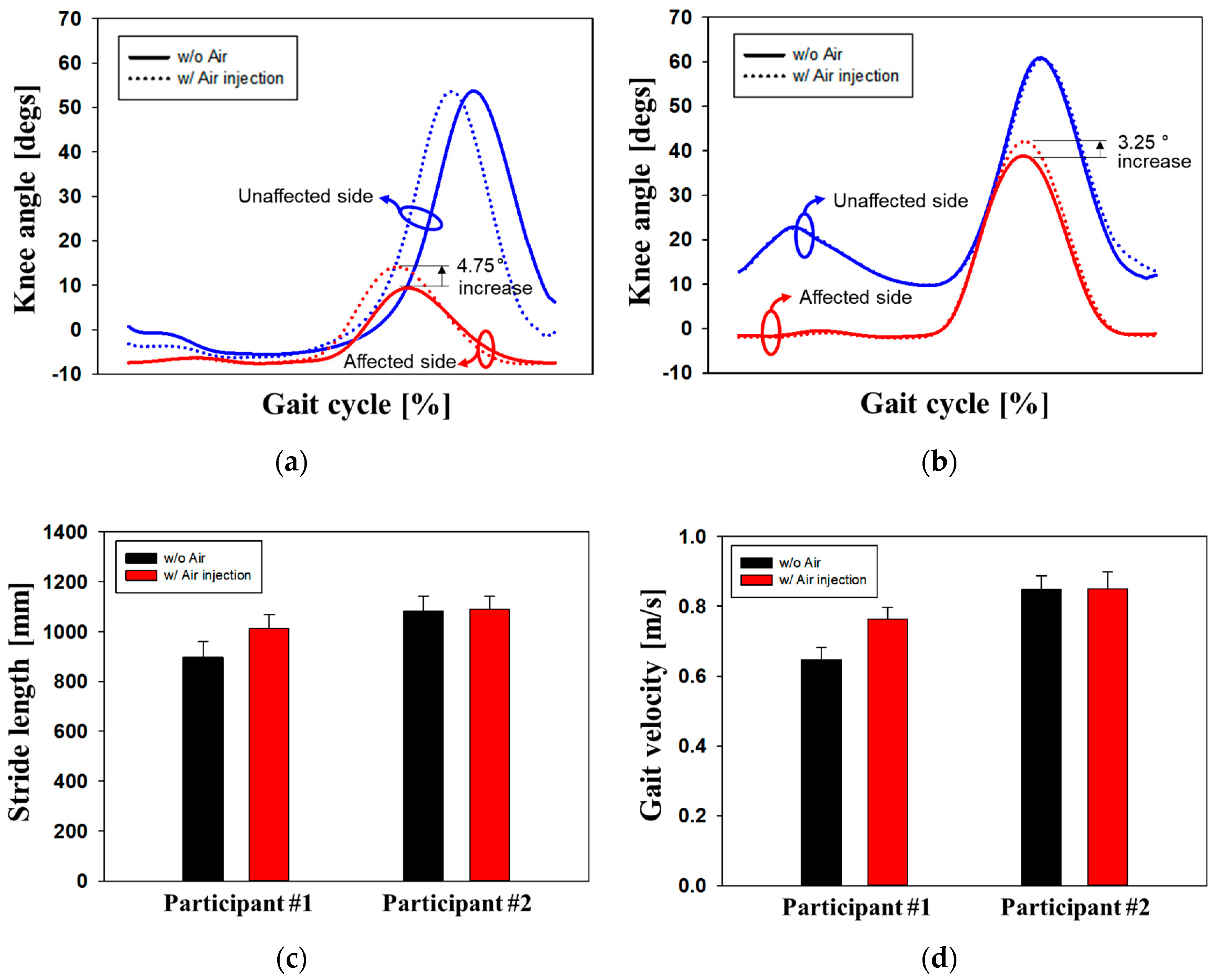

3.2. Performance of Pneumatically Controlled Prosthetic Socket

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harding, J.L.; Andes, L.J.; Rolka, D.B.; Imperatore, G.; Gregg, E.W.; Li, Y.; Albright, A. National and State-Level Trends in Nontraumatic Lower-Extremity Amputation among U.S. Medicare Beneficiaries with Diabetes, 2000–2017. Diabetes Care 2020, 43, 2453–2459. [Google Scholar] [CrossRef] [PubMed]

- Chadwell, A.; Diment, L.; Mico-Amigo, M.; Ramirez, D.Z.; Dickinson, A.; Granat, M.; Kenny, L.; Kheng, S.; Sobuh, M.; Ssekitoleko, R.; et al. Technology for monitoring everyday prosthesis use: A systematic review. J. Neuroeng. Rehabil. 2020, 17, 93. [Google Scholar] [CrossRef] [PubMed]

- Raschke, S.U. Limb Prostheses: Industry 1.0 to 4.0: Perspectives on Technological Advanced in Prosthetic Care. Front. Rehabil. Sci. 2022, 3, 854404. [Google Scholar] [CrossRef] [PubMed]

- Sewell, P.; Noroozi, S.; Vinney, J.; Andrews, S. Developments in the trans-tibial prosthetic socket fitting process: A review of past and present research. Prosthet. Orthot. Int. 2000, 24, 97–107. [Google Scholar] [CrossRef]

- Young, P.R.; Hebert, J.S.; Marasco, P.D.; Carey, J.P.; Schofield, J.S. Advances in the measurement of prosthetic socket interface mechanics: A review of technology, techniques, and a 20-year update. Expert Rev. Med. Devices 2023, 20, 729–739. [Google Scholar] [CrossRef]

- Paterno, L.; Ibrahimi, M.; Gruppioni, E.; Menciassi, A.; Ricotti, L. Sockets for limb prostheses: A review of existing technologies and open challenges. IEEE Trans. Biomed. Eng. 2018, 65, 1996–2010. [Google Scholar] [CrossRef]

- Montgomery, J.T.; Vaughan, M.R.; Crawford, R.H. Design of an Actively Actuated Prosthetic Socket. Rapid Prototyp. J. 2010, 16, 194–201. [Google Scholar] [CrossRef]

- Youngblood, R.T.; Hafner, B.J.; Allyn, K.; Cagle, J.C.; Hinrichs, P.; Redd, C.; Vamos, A.C.; Ciol, M.A.; Bean, N.; Sanders, J.E. Effects of activity intensity, time, and intermittent doffing on daily limb fluid volume change in people with transtibial amputation. Prosthet. Orthot. Int. 2019, 43, 28–38. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Abu Osman, N.A.; Lúvíksdóttir, Á.G.; Eshraghi, A.; Kamyab, M.; Wan Abas, W.A.B. A new approach for the pistoning measurement in transtibial prosthesis. Prosthet. Orthot. Int. 2011, 35, 360–364. [Google Scholar] [CrossRef]

- Sanders, J.E.; Fatone, S. Residual limb volume change: Systematic review of measurement and management. J. Rehabil. Res. Dev. 2011, 48, 949–986. [Google Scholar] [CrossRef]

- Kahle, J.T.; Klenow, T.D.; Highsmith, M.J. Comparative Effectiveness of an Adjustable Transfemoral Prosthetic Interface Accommodating Volume Fluctuation: Case Study. Technol. Innov. 2016, 18, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.B.; Schuch, C.M.; Nitschke, R.O. A Variable Volume Socket for Below-knee Prostheses. Clin. Prosthet. Orthot. 1987, 11, 11–19. [Google Scholar]

- Dakhil, N.; Evin, M.; Llari, M.; Mo, F.; Thefenne, L.; Liu, T.; Behr, M. Is skin pressure a relevant factor for socket assessment in patients with lower limb amputation? Technol. Health Care 2019, 27, 669–677. [Google Scholar] [CrossRef] [PubMed]

- Polliack, A.A.; Sieh, R.C.; Craig, D.D.; Landsberger, S.; Mcneil, D.R.; Ayyappa, E. Scientific validation of two commercial pressure sensor systems for prosthetic socket fit. Prosthet. Orthot. Int. 2000, 24, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Jasni, F.; Hamzaid, N.A.; Muthalf, A.G.A.; Zakaria, Z.; Shasmin, H.N.; Ng, S.C. In-Socket Sensory System for Transfemoral Amputees Using Piezoelectric Sensors: An Efficacy Study. IEEE/ASME Trans. Mechatron. 2016, 21, 2466–2476. [Google Scholar] [CrossRef]

- Carrigan, W.; Nothnagle, C.; Savant, P.; Gao, F.; Wijesundara, M.B.J. Pneumatic actuator inserts for interface pressure mapping and fit improvement in lower extremity prosthetics. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 26–29. [Google Scholar]

- Pirouzi, G.; Abu Osman, N.A.; Oshkour, A.A.; Ali, S.; Gholizadeh, H.; Wan Abas, W.A. Development of an air pneumatic suspension system for transtibial prostheses. Sensors 2014, 14, 16754–16765. [Google Scholar] [CrossRef]

- Seo, J.; Lee, H.; Seo, D.W.; Lee, D.; Kwon, O.; Kwak, M.K.; Lee, K.H. A Prosthetic Socket with Active Volume Compensation for Amputated Lower Limb. Sensors 2021, 21, 407. [Google Scholar] [CrossRef]

- Weathersby, E.J.; Garbini, J.L.; Larsen, B.J.; McLean, J.B.; Vamos, A.V.; Sanders, J.E. Automatic control of prosthetic socket size for people with transtibial amputation: Implementation and evaluation. IEEE Trans. Biomed. Eng. 2020, 68, 36–46. [Google Scholar] [CrossRef]

- Weathersby, E.J.; Vamos, A.C.; Larsen, B.G.; McLean, J.B.; Carter, R.V.; Allyn, K.J.; Ballesteros, D.; Wang, H.; deGrasse, N.S.; Friedly, J.L.; et al. Performance of an auto-adjusting prosthetic socket during walking with intermittent socket release. J. Rehabil. Assist. Technol. Eng. 2022, 9, 1–14. [Google Scholar] [CrossRef]

- Kharb, A.; Saini, V.; Jain, Y.K.; Dhiman, S. A review of gait cycle and its parameters. Int. J. Comput. Eng. Manag. 2011, 13, 78–83. [Google Scholar]

- Pornpipatsakul, K.; Ajavakom, N. Estimation of Knee Assistive Moment in a Gait Cycle Using Knee Angle and Knee Angular Velocity through Machine Learning and Artificial Stiffness Control Strategy (MLASCS). Robotics 2023, 12, 44. [Google Scholar] [CrossRef]

| Participant | Gender | Age (y) | Circumference of Limb (cm) | Length of Limb (cm) | Time Since Amputation (y) |

|---|---|---|---|---|---|

| #1 | M | 57 | 42 | 23.1 | 8 |

| #2 | M | 67 | 40 | 33 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.-H.; Heo, H.-S.; Kim, J.; Cho, J.H.; Kim, K.T.; Hur, J.-Y.; Kim, J.H.; Lee, Y. A Pneumatically Controlled Prosthetic Socket for Transfemoral Amputees. Sensors 2024, 24, 133. https://doi.org/10.3390/s24010133

Lee K-H, Heo H-S, Kim J, Cho JH, Kim KT, Hur J-Y, Kim JH, Lee Y. A Pneumatically Controlled Prosthetic Socket for Transfemoral Amputees. Sensors. 2024; 24(1):133. https://doi.org/10.3390/s24010133

Chicago/Turabian StyleLee, Kang-Ho, Hyun-Seok Heo, Jeongmin Kim, Jang Hyuk Cho, Kyoung Tae Kim, Jeong-Yong Hur, Jang Hwan Kim, and Yongkoo Lee. 2024. "A Pneumatically Controlled Prosthetic Socket for Transfemoral Amputees" Sensors 24, no. 1: 133. https://doi.org/10.3390/s24010133

APA StyleLee, K.-H., Heo, H.-S., Kim, J., Cho, J. H., Kim, K. T., Hur, J.-Y., Kim, J. H., & Lee, Y. (2024). A Pneumatically Controlled Prosthetic Socket for Transfemoral Amputees. Sensors, 24(1), 133. https://doi.org/10.3390/s24010133