Determination of the Accuracy of the Straight Bevel Gear Profiles by a Novel Optical Coaxial Multi-Ring Measurement Method

Abstract

1. Introduction

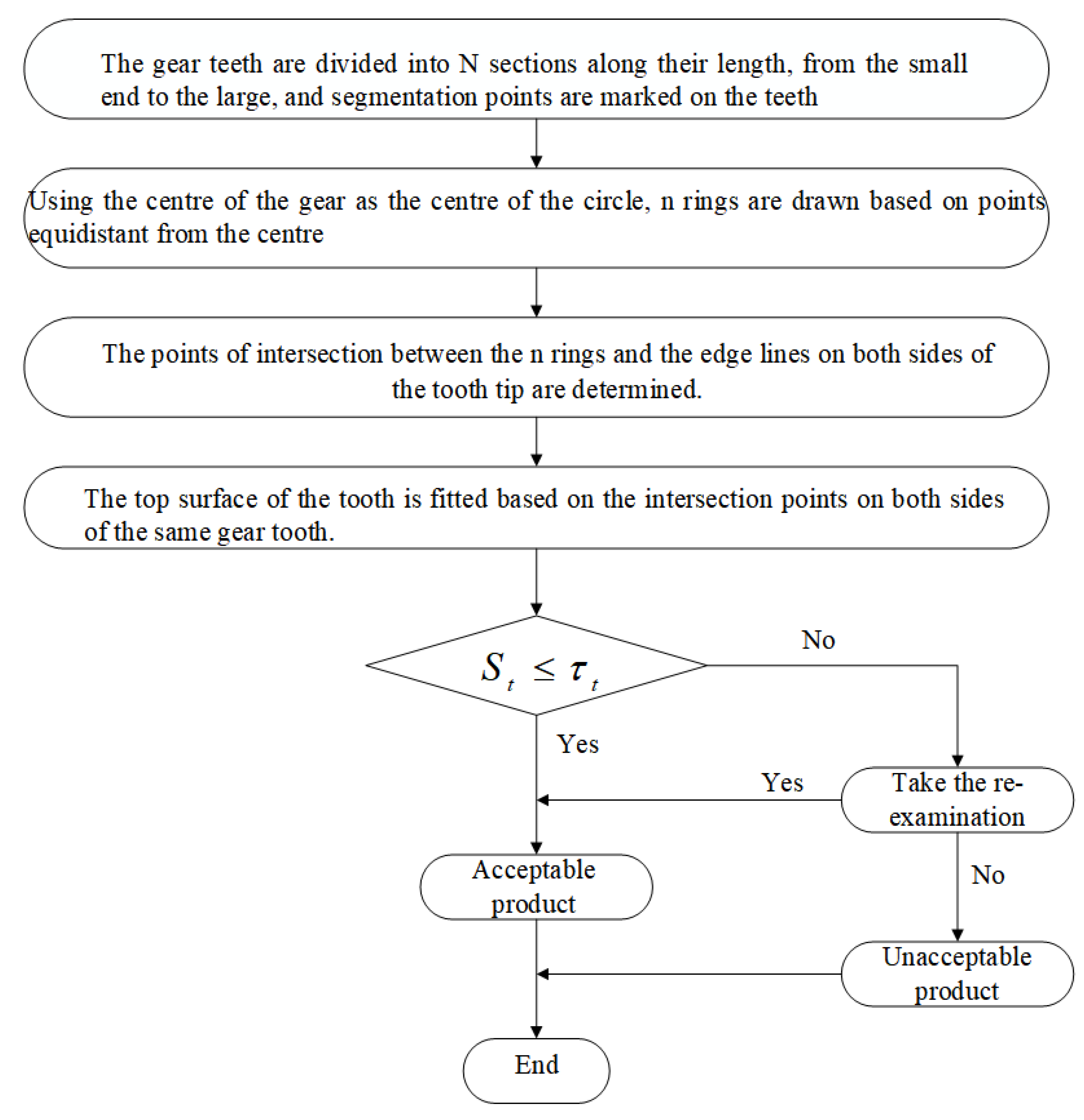

2. Principle of Measurement

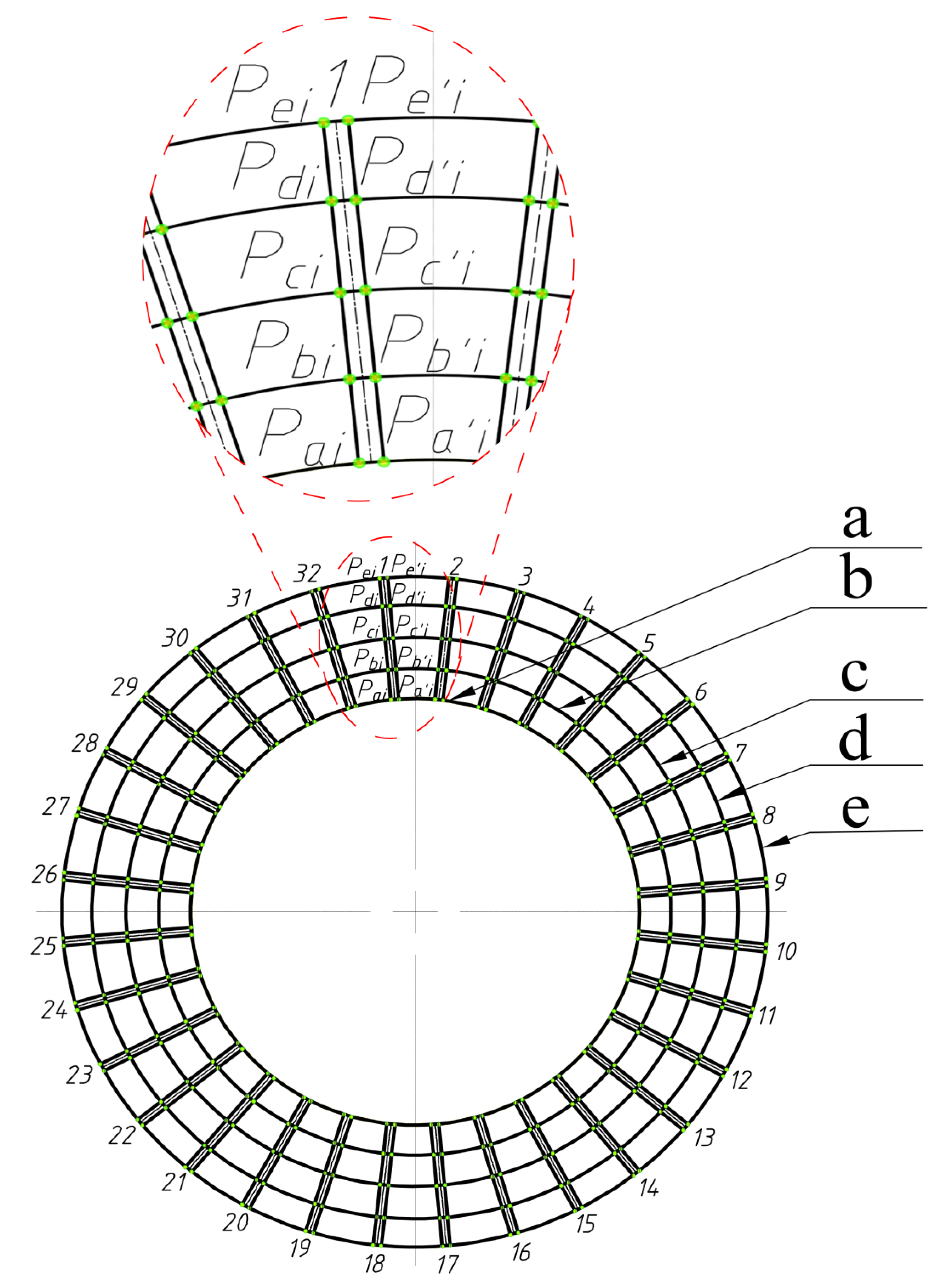

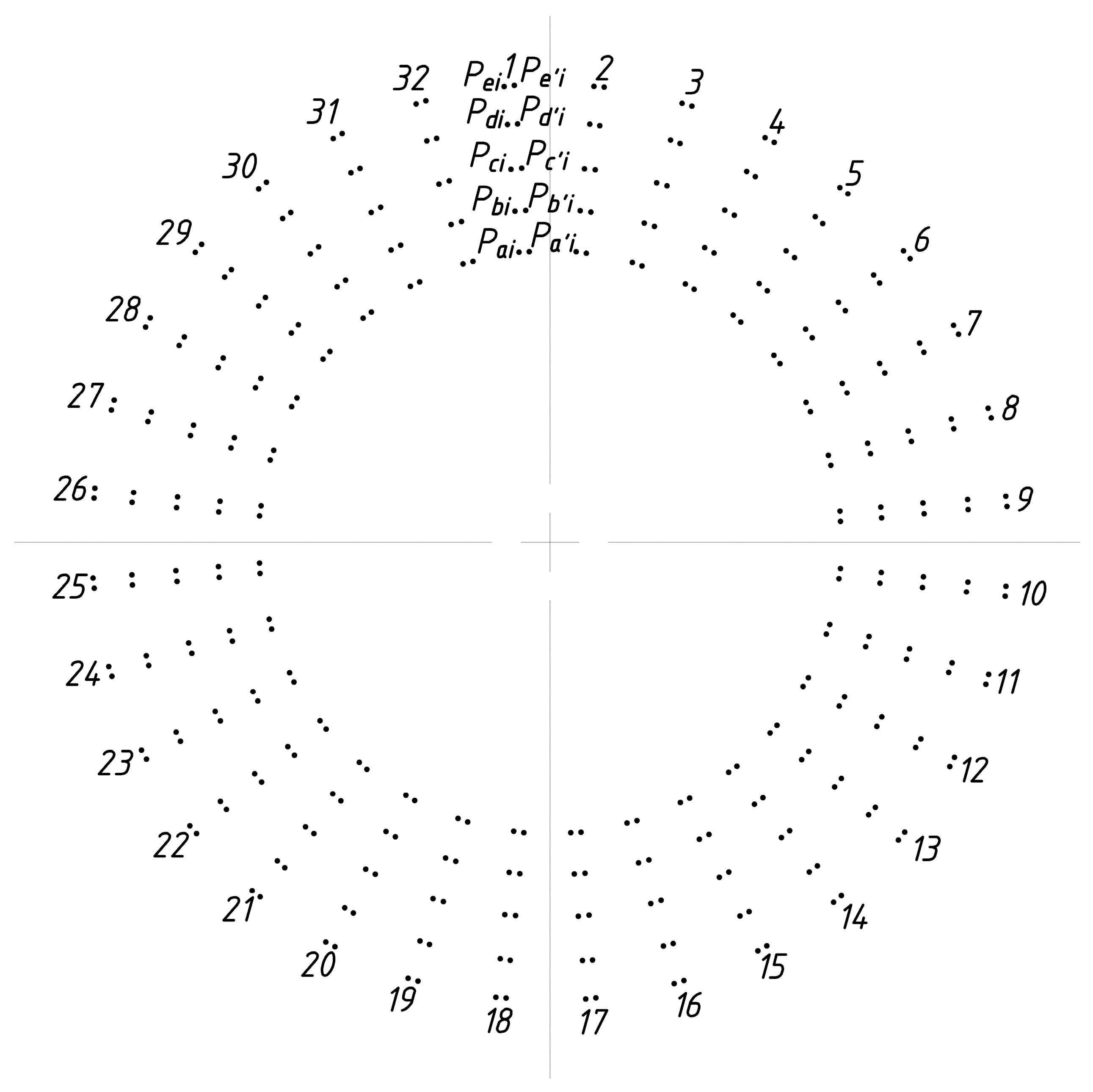

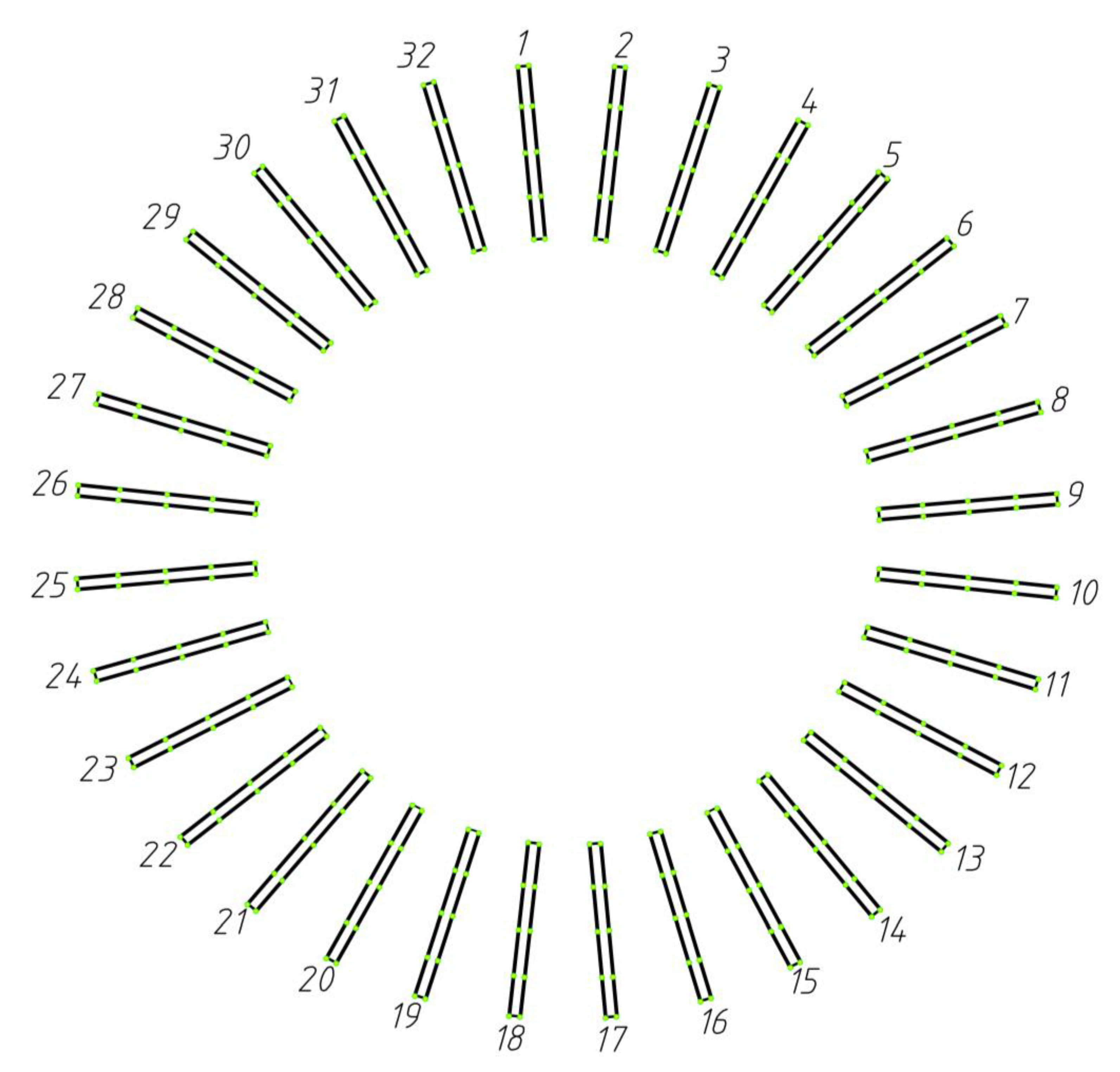

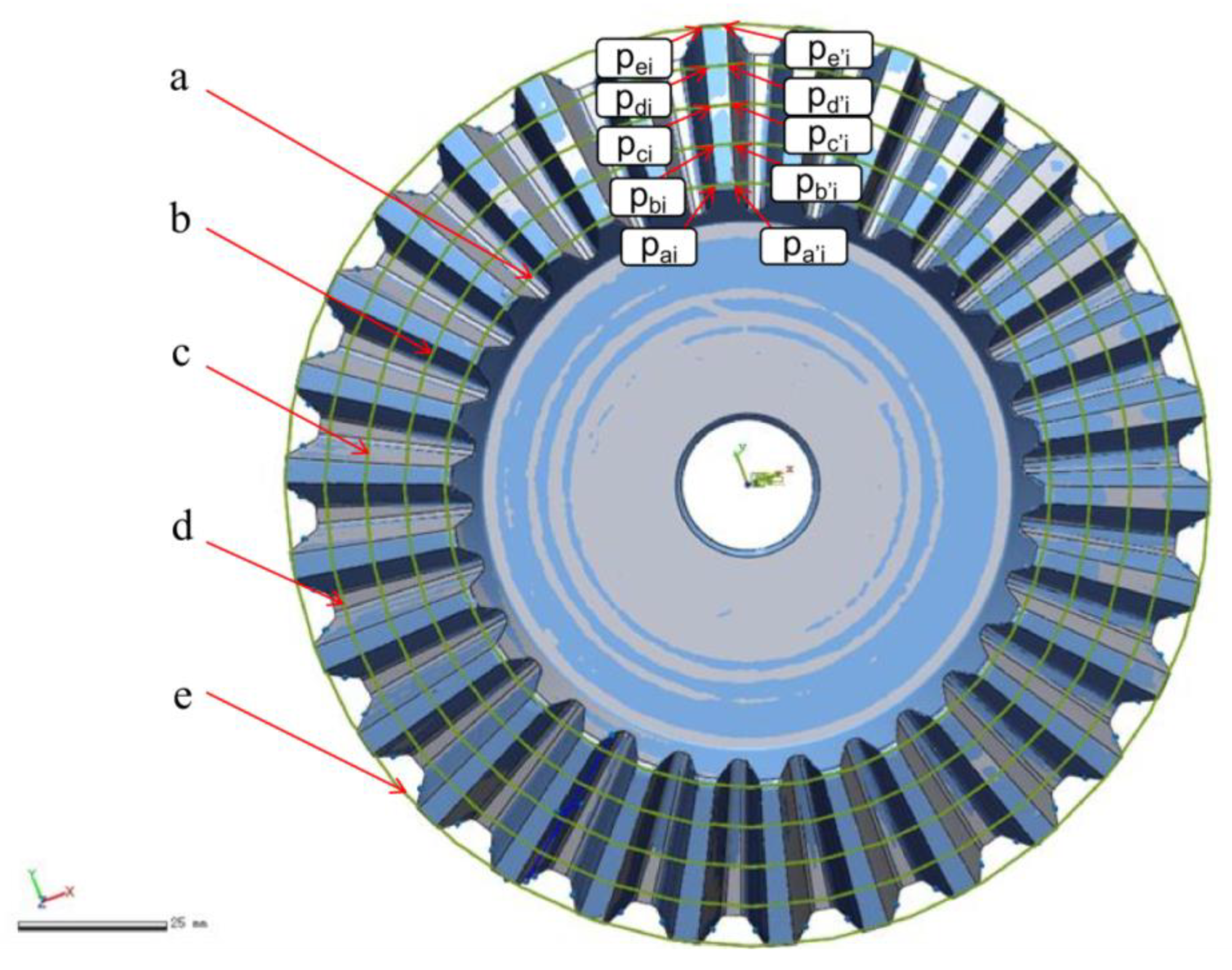

2.1. Step 1: Set Up Multiple Detection Circles

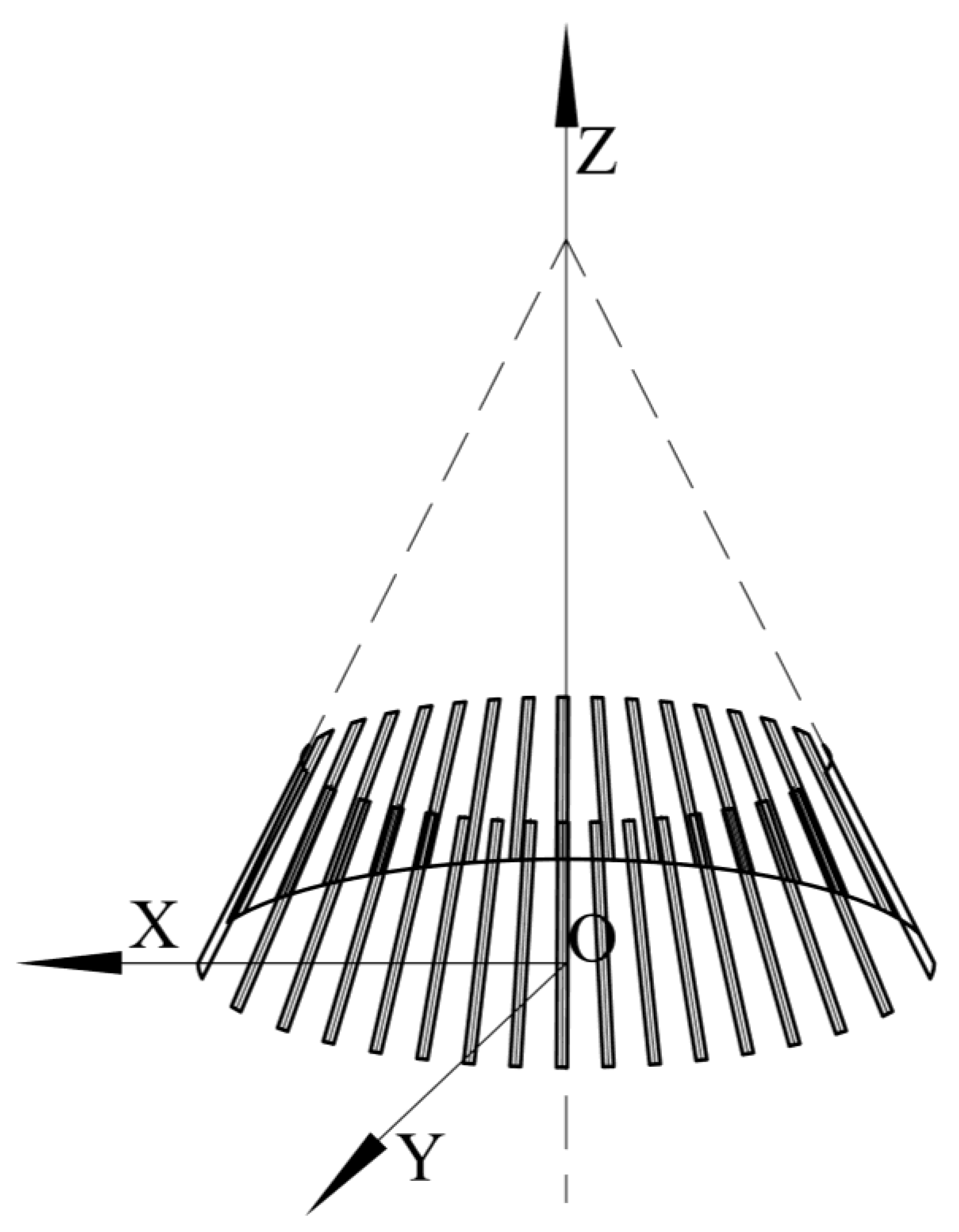

- Use the intersection point between the straight bevel gear’s central axis and its bottom surface as the origin and the bottom surface of the straight bevel gear as the O-XY plane to establish a Cartesian coordinate system. In the straight bevel gear, the Z axis is perpendicular to the bottom surface.

- We divide the straight bevel gear teeth into n segments with equal spacing for each tooth, from the small end to the larger one.

- We establish n detection circles by taking the distance from the center axis of the gear to all split points within the range of equal distances of 360° as the radius and using the center axis of the gear as the center. The number of detection circles will be determined based on the size of the straight bevel gear and the requirements for accurate measurement. In this case, we use an example with five detection circles;

- Figure 2 shows the detection circles from the small end to the large end of the straight bevel gear (labeled a, b, c, d, and e).

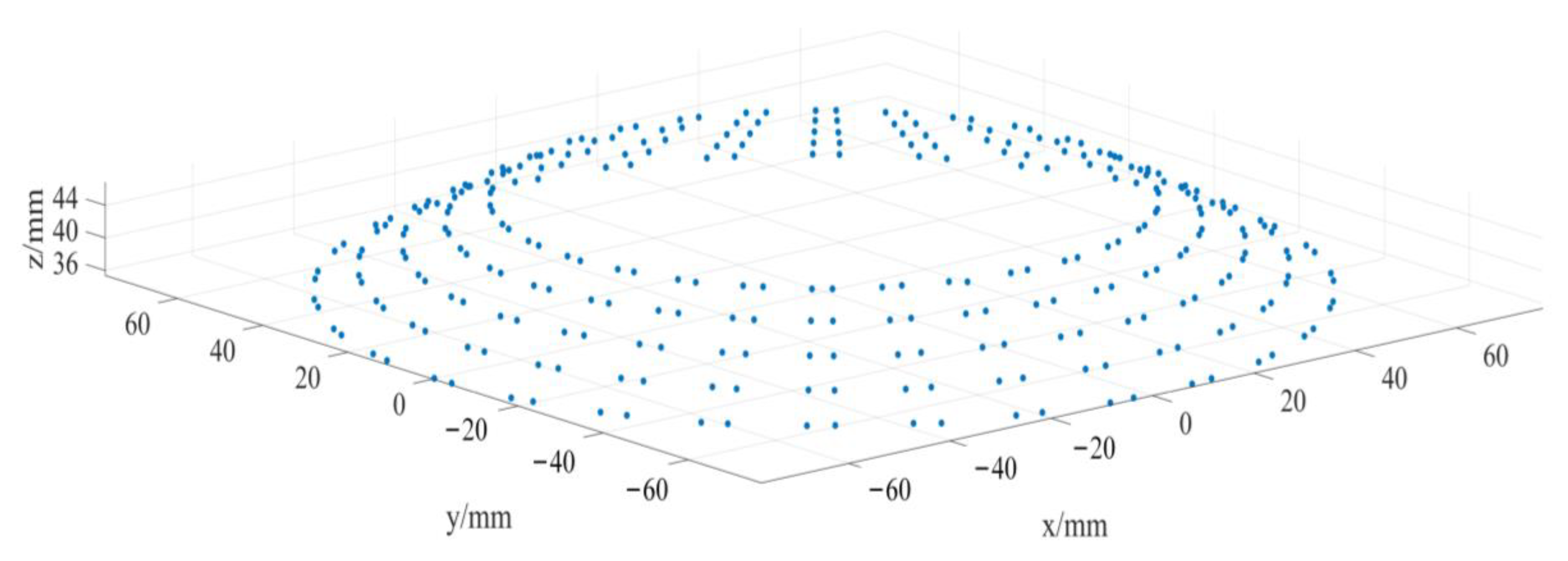

2.2. Step 2: Extraction of Intersection Coordinates

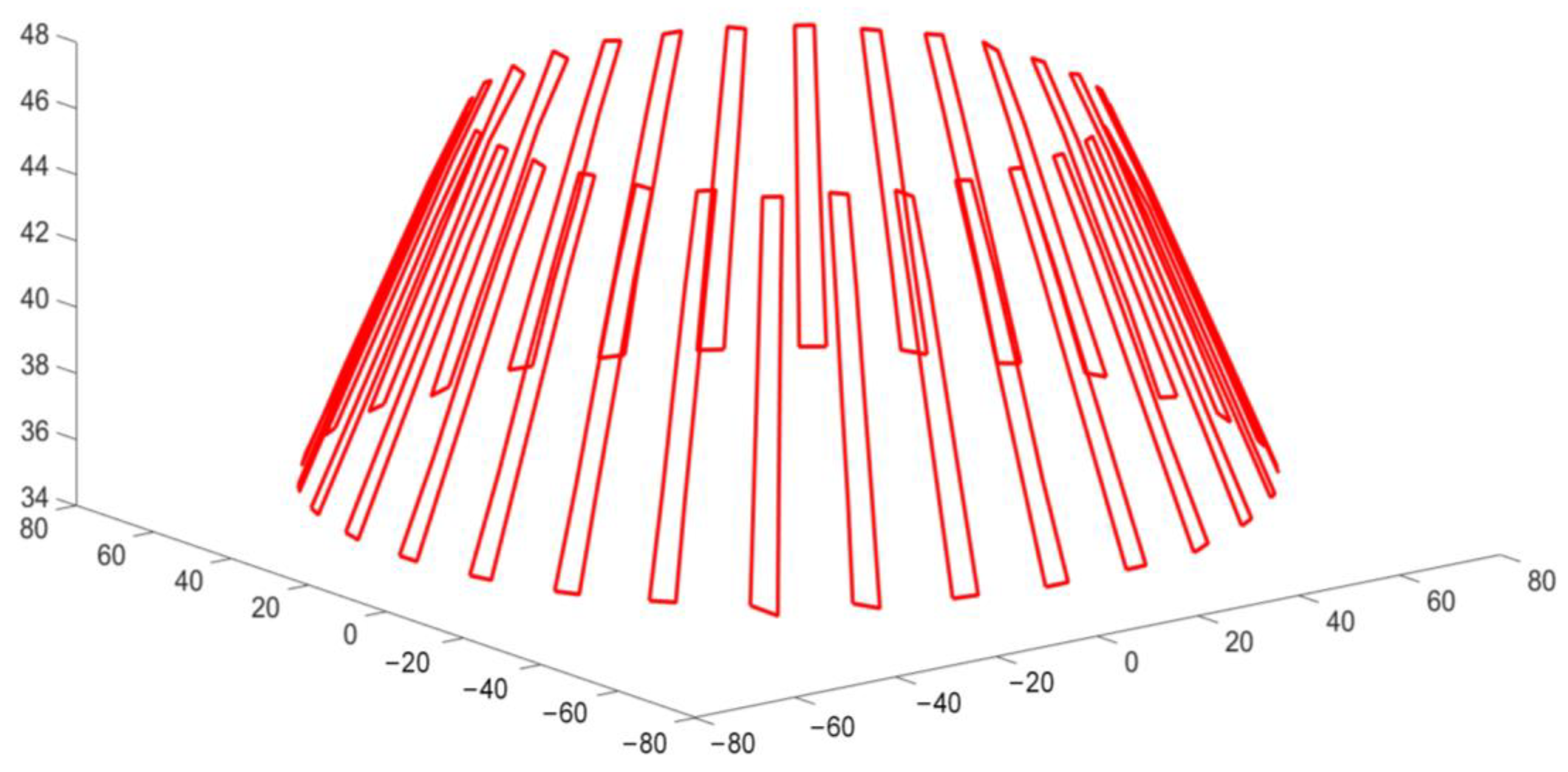

2.3. Step 3: Fitting of the Tooth Top Surface

2.3.1. Cubic NURBS Curve

2.3.2. NURBS Cube Matrix Representation

2.4. Cubic NURBS Curve Interpolation

2.4.1. Computation of the Node Vector Using Cumulative Chord Parameterization

2.4.2. Calculation of the Curve Control Points Using Boundary Tangents

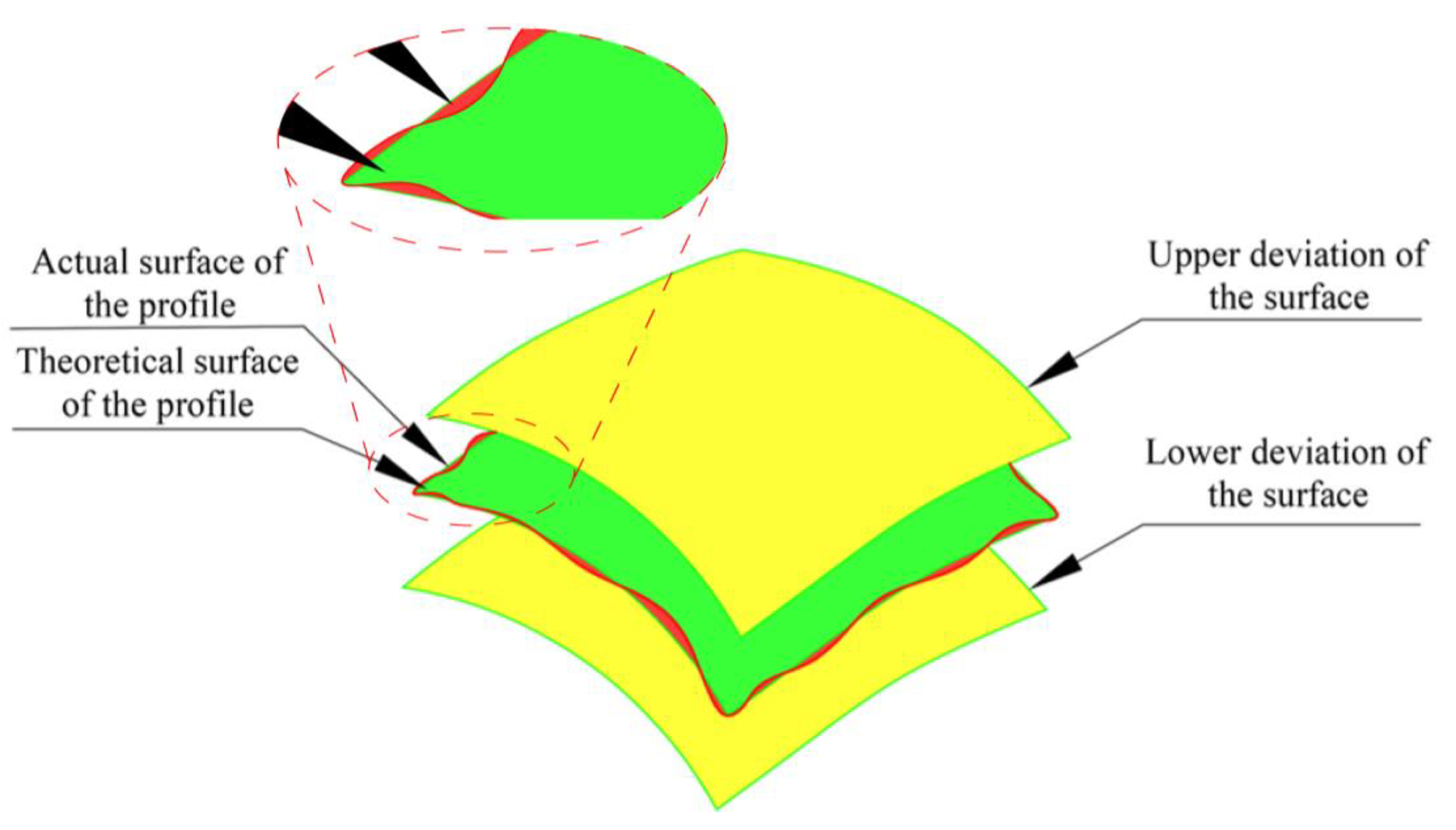

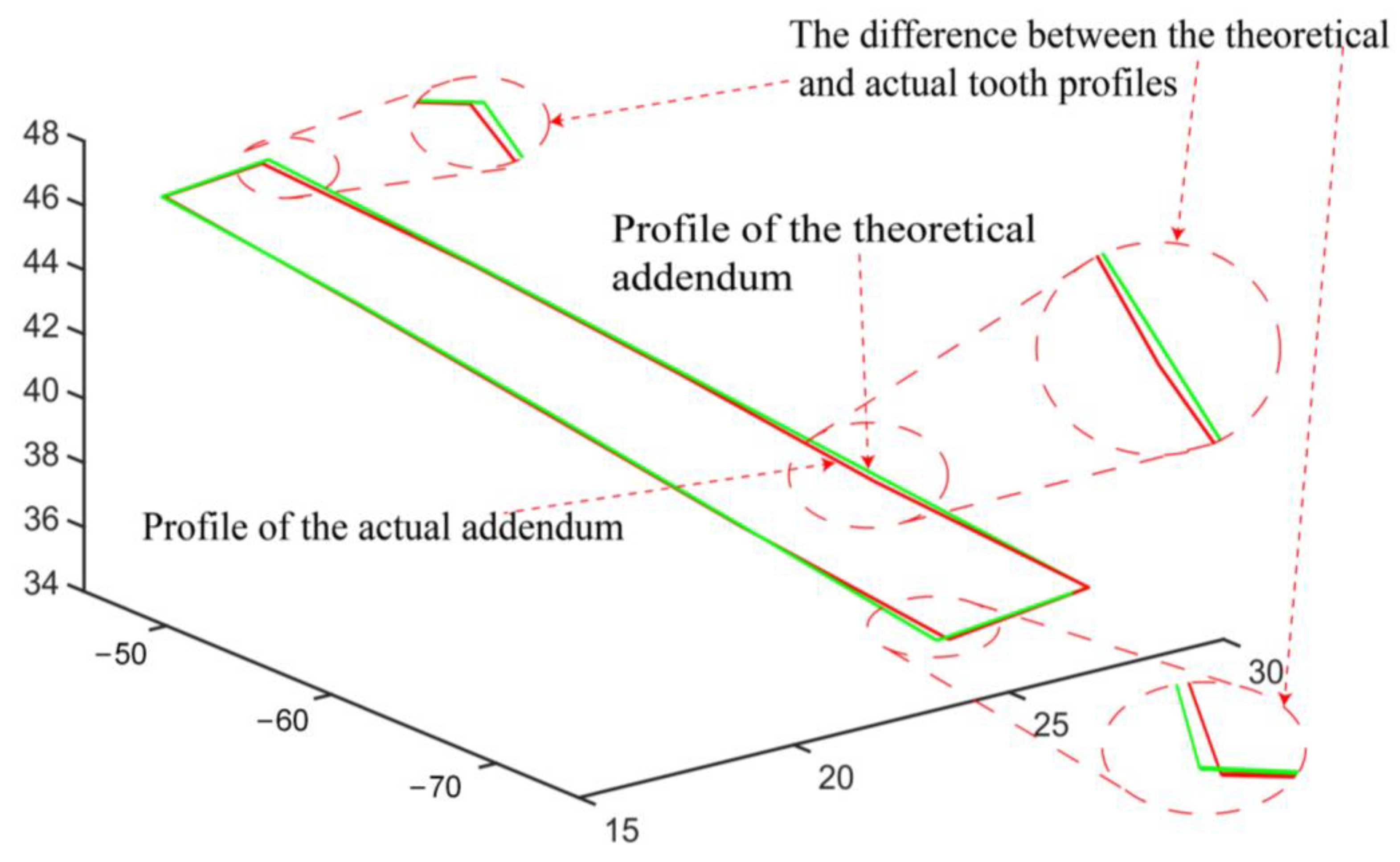

2.5. Measurements of the Surface Profile Deviation

3. Experiments

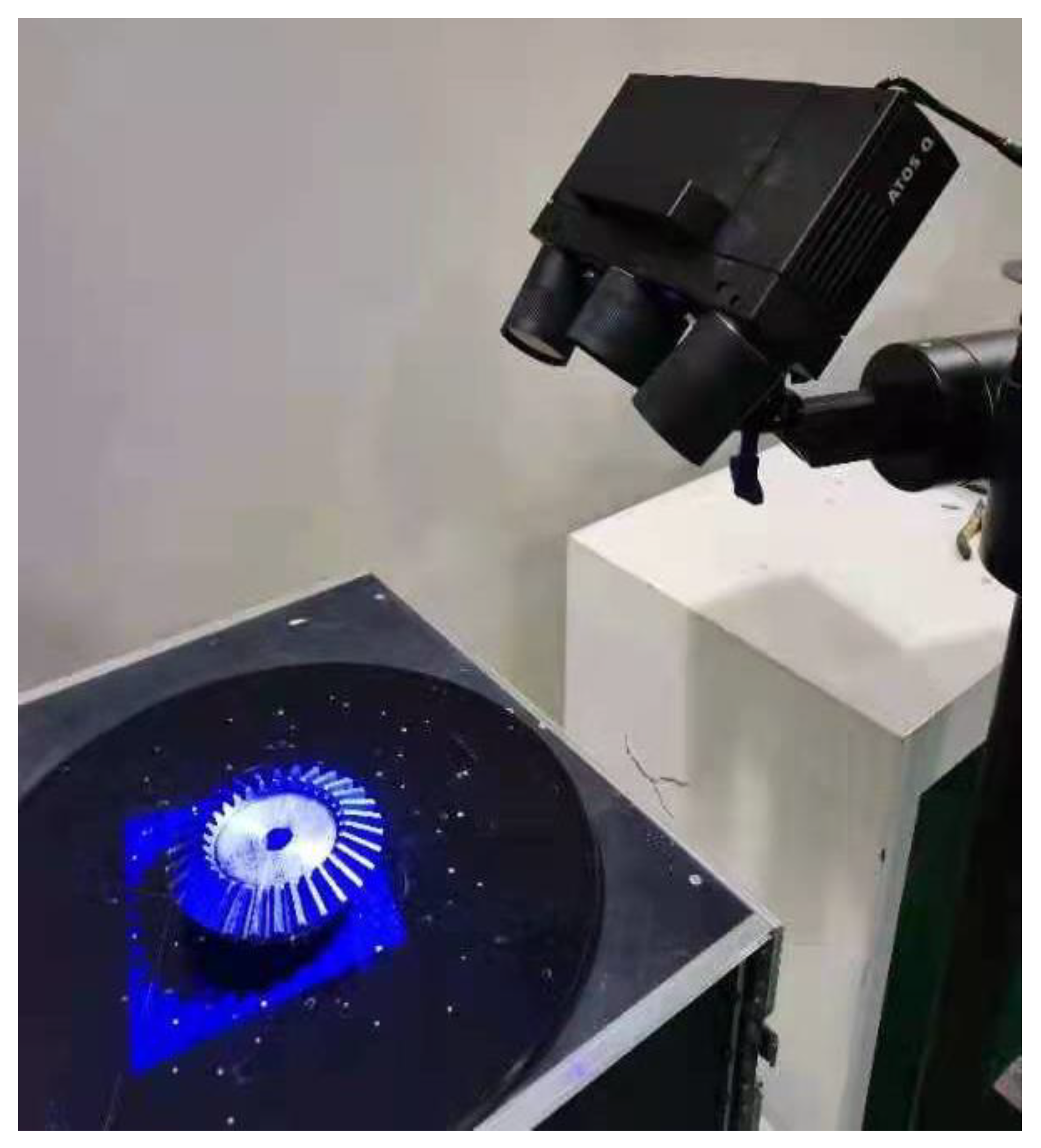

3.1. Measurement Device

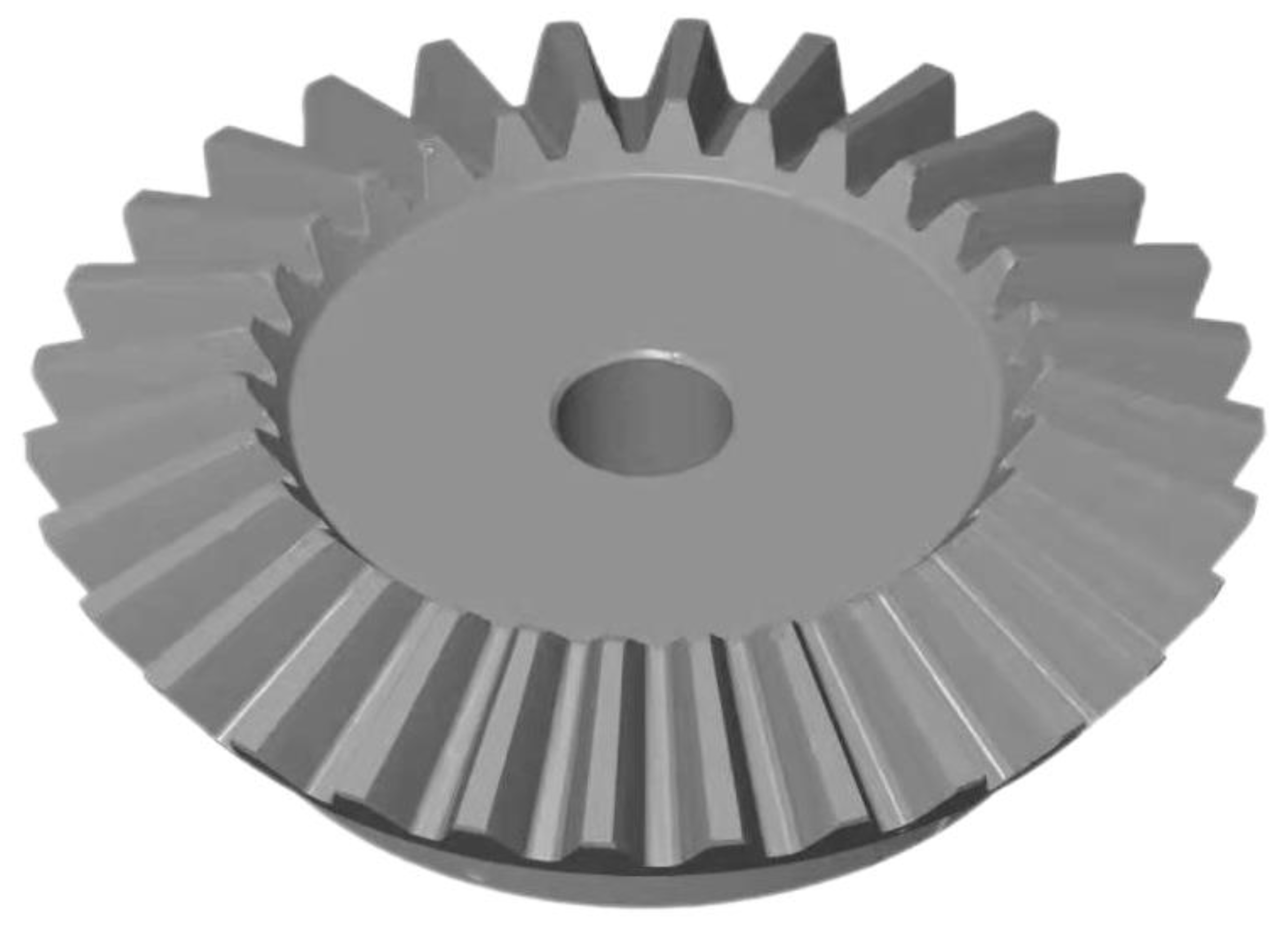

3.2. Preparation

- 5.

- The gear was milled using a 275 HC bevel gear milling machine. The gears were cleaned with an ultrasonic gear cleaner before testing to ensure that the surfaces were clean;

- 6.

- Multiple copies of the marker points were made and were pasted randomly onto the surface of the tested gear to improve the accuracy of stitching of the gear point cloud data;

- 7.

- Since a gear is a highly reflective component, to obtain a more complete and accurate gear point cloud, it was necessary to apply a thin layer of an imaging agent to the gear surface to reduce the adverse effects of reflection on the optical measurements. A titanium powder developer with the least impact on optical measurements was selected to achieve highly accurate gear measurements, and the size increased by 1–2 μm once sprayed [31]. The developer had a negligible impact on the overall gear size since it was large. A surface-treated straight bevel gear is shown in Figure 8, and the gear parameters are shown in Table 2.

3.3. Data Collection

3.4. Cloud-Based Data Processing

- 8.

- Filter design

- 9.

- Smoothing and denoizing of data

3.5. Implementation of the Proposed Straight Bevel Gear Coaxial Multi-Ring Measurement System

4. Results and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guenther, A.; Kniel, K.; Hartig, F.; Lindner, I. Introduction of a new bevel gear measurement standard. Cirp Ann. -Manuf. Technol. 2013, 62, 515–518. [Google Scholar] [CrossRef]

- Hua, Z.; Piao, S. The Measurement and Evaluation Method of Global Error of Spiral Bevel Gear. In Proceedings of the International Conference on Industry, Information System and Material Engineering, Guangzhou, China, 16–17 April 2011; pp. 1299–1304. [Google Scholar]

- Fu, X.B.; Zhang, G.R.; Zhang, Y.C.; Li, Y.B.; Jia, L.S.; Guan, Y. A Novel Flatness Detection Method for Spiral Bevel Gears in an Automobile Gearbox. Lasers Eng. 2020, 45, 189–200. [Google Scholar]

- Liu, Y.S.; Fang, S.P.; Chen, Y.X.; Zhang, J.Y. Compensation Method for Inclination Errors in Measurement Results of Tooth Surface of Spiral Bevel Gear. Math. Probl. Eng. 2021, 2021, 6617077. [Google Scholar] [CrossRef]

- Meng, L.L.; Lu, C.G.; Xi, P.X.Y.; Zhao, P.H.Z. Application of Six Sigma Method in Improving the Quality of the Spiral Bevel Gear. In Proceedings of the International Conference on Advanced Engineering Materials and Technology (AEMT2011), Sanya, China, 29–31 July 2011; pp. 2655–2660. [Google Scholar]

- Wan, P.; Guo, J.J.; Wu, P.L.; Fei, Z.G. Tooth surface modeling and measurement evaluation for spiral bevel gear based on gear measuring center. In Proceedings of the 4th International Seminar on Modern Cutting and Measurement Engineering, Beijing, China, 10–12 December 2010; pp. 697–702. [Google Scholar]

- Kawasaki, K.; Shinma, K. Accuracy Measurement and Evaluation of Straight Bevel Gear Manufactured by End Mill Using CNC Milling Machine. J. Mech. Des. 2009, 131, 011001. [Google Scholar] [CrossRef]

- Li, T.X.; Li, Y.L.; Deng, X.Z.; Li, J.F. A measurement method for tooth surface errors of straight bevel gears based on 3D model. Meas. Sci. Technol. 2021, 32, 025011. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Yan, H.B. Gear Visual Inspection System and Application in Logarithmic Spiral Bevel Gear. In Proceedings of the 4th International Conference on Machine Vision (ICMV)—Machine Vision, Image Processing and Pattern Analysis, Singapore, 9–10 December 2011; pp. 295–299. [Google Scholar]

- Pillarz, M.; von Freyberg, A.; Stobener, D.; Fischer, A. Gear Shape Measurement Potential of Laser Triangulation and Confocal-Chromatic Distance Sensors. Sensors 2021, 21, 937. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Kou, H.L.; Shi, Z.Y.; Sun, Y.Q. A Virtual Measurement Method of the Transmission Error Based on Point Clouds of the Gear. Meas. Sci. Rev. 2022, 22, 92–99. [Google Scholar] [CrossRef]

- Wang, B.H.; Tang, J.; Shi, Z.Y. Measurement and Control Software for Transmission Error of Bevel Gear Pair. In Proceedings of the ASME International Design Engineering Technical Conferences/Computers and Information in Engineering Conference (IDETC/CIE 2017), Cleveland, OH, USA, 6–9 August 2017; pp. 1–5. [Google Scholar]

- Xu, Z.P.; Zhang, S. Gear Chamfering Profile Measurement System Based on Laser Sensor and Machine Vision. In Proceedings of the 2nd International Conference on Material and Manufacturing Technology (ICMMT 2011), Xiamen, China, 8–11 July 2011; pp. 888–893. [Google Scholar]

- Sun, J. Study on Gear Chamfering Method based on Vision Measurement. In Proceedings of the 2nd International Conference on Informatization in Education, Management and Business (IEMB), Guangzhou, China, 12–13 September 2015; pp. 145–149. [Google Scholar]

- Pillarz, M.; von Freyberg, A.; Fischer, A. Gear Shape Parameter Measurement Using a Model-Based Scanning Multi-Distance Measurement Approach. Sensors 2020, 20, 3910. [Google Scholar] [CrossRef]

- Pillarz, M.; von Freyberg, A.; Fischer, A. Scalable multi-distance measurement approach for the optical assessment of tooth-individual shape parameters of large gearings. Tm-Tech. Mess. 2022, 89, 544–553. [Google Scholar] [CrossRef]

- Tian, H.; Wu, F.; Gong, Y.J. Gear Tooth Profile Reconstruction via Geometrically Compensated Laser Triangulation Measurements. Sensors 2019, 19, 1589. [Google Scholar] [CrossRef]

- Miao, J.W.; Tan, Q.C.; Wang, S.; Liu, S.Y.; Chai, B.S.; Li, X.B. A Vision Measurement Method for the Gear Shaft Radial Runout with Line Structured Light. IEEE Access 2021, 9, 5097–5104. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, D.H.; Li, Y.Q.; Fu, L.; Zhu, Z.F.; Huang, Z.F.; Zhang, D.Q.; Guo, Z.C. A novel 3D, full-field optical method for measuring gears. Proc. Inst. Mech. Eng. Part E-J. Process Mech. Eng. Online Publ. OCT 2022, 1–12. [Google Scholar] [CrossRef]

- Masovic, R.; Breski, T.; Cular, I.; Vuckovic, K.; Zezelj, D. Numerical model for worm gear pair inspection based on 3d scanned data. Int. J. Simul. Model. 2021, 20, 637–648. [Google Scholar] [CrossRef]

- Urbas, U.; Zorko, D.; Cerne, B.; Tavcar, J.; Vukasinovic, N. A method for enhanced polymer spur gear inspection based on 3D optical metrology. Measurement 2021, 169, 108584. [Google Scholar] [CrossRef]

- Shi, F.Z. Computer Aided Geometric Design and Non-Uniform Rational B-Spline; Beijing University of Aeronautics and Astronautics Press: Beijing, China, 1994; pp. 102–126. [Google Scholar]

- Cao, X.M.; Zhang, J.F. Fitting Tooth Surfaces and Analysis Error for Straight Bevel Gears Based on Non-Uniform Rational B-Spline. Mach. Des. Manuf. 2017, 194–197. [Google Scholar]

- Choi, B.K.; Yoo, W.S.; Lee, C.S. Matrix representation for NURB curves and surfaces. Comput. -Aided Des. 1990, 22, 235–240. [Google Scholar] [CrossRef]

- Chen, S.P. Three times NURBS curve Interpolation and Application. Mech. Sci. Technol. Aerosp. Eng. 2001, 20, 692–693. [Google Scholar]

- Zhu, X.X. The Modeling Technology of the Free Curve Surface; Science Press: Beijing, China, 2001; pp. 112–117. [Google Scholar]

- Zhang, D.H.; Li, J.H.; Zhu, H.M.; Liu, S.J.; Yu, K.; Guo, Z.C.; Fu, L. The Researches and Applications of Reverse Engineering in the Protection and Inheritance of National Handcrafts. Nanosci. Nanotechnol. Lett. 2020, 12, 1063–1069. [Google Scholar] [CrossRef]

- Cheung, C.F.; Li, H.F.; Kong, L.B.; Lee, W.B.; To, S. Measuring ultra-precision freeform surfaces using a robust form characterization method. Meas. Sci. Technol. 2006, 17, 488–494. [Google Scholar] [CrossRef]

- ATOS Q 12M Scanner Parameters. Available online: https://www.gom.com/en/products/3d-scanning/atos-q (accessed on 4 February 2023).

- Lu, X.X.; Zhao, X.; Hu, B.; Zhou, Y.S.; Cao, Z.Z.; Tang, J.Y. A Measurement Solution of Face Gears with 3D Optical Scanning. Materials 2022, 15, 6069. [Google Scholar] [CrossRef]

- Li, X.L. All That Powder Dusting Stuff on the 3D Scan. Xian Lin 3D Technology Course 2021. Internet. Available online: https://www.sohu.com/a/459860058_120665612 (accessed on 2 February 2023).

- Sun, Q.C.; Ren, Z.M.; Zhu, J.L.; Dai, W.Y.; Wang, M.Z.; Sun, M.Y. A Three-Dimensional Structured Light Vision System by Using a Combination of Single-Line and Three-Line Lasers. Sensors 2023, 23, 13. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.X.; Wang, X.C.; Hao, A.M. Point clouds smoothing and enhancing based on empirical mode decomposition. J. Beijing Univ. Aeronaut. Astronaut. 2017, 43, 1045–1052. [Google Scholar]

| Lens Parameter | Data |

|---|---|

| Camera Pixel | 2 × 3296 × 2472 Pixels 0.2 mm–10 m (paired photogrammetry) |

| Scan range | |

| Camera model | MV170 |

| Measurement volume | 170 × 130 × 130 mm |

| Measurement Accuracy | 0.009 mm |

| Point spacing | 0.03–0.12 mm |

| Working distance | 490 mm |

| Projected light source | Structured blue light (LED) |

| Operating Temperature | 5–40 °C |

| Parameter | Value |

|---|---|

| Number of teeth | 30 5 |

| Module/mm | |

| Reference diameter/mm | 75 |

| Cone distance/mm | 83.853 |

| Tip angle/° | 49.12 |

| Root angle/° | 40.88 |

| Reference cone angle/° | 45 |

| Tooth width/mm | 27.951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhang, D.; Li, Y.; Ma, X.; Wang, T.; Wu, C. Determination of the Accuracy of the Straight Bevel Gear Profiles by a Novel Optical Coaxial Multi-Ring Measurement Method. Sensors 2023, 23, 2654. https://doi.org/10.3390/s23052654

Li J, Zhang D, Li Y, Ma X, Wang T, Wu C. Determination of the Accuracy of the Straight Bevel Gear Profiles by a Novel Optical Coaxial Multi-Ring Measurement Method. Sensors. 2023; 23(5):2654. https://doi.org/10.3390/s23052654

Chicago/Turabian StyleLi, Junheng, Dehai Zhang, Yanqin Li, Xuanxiong Ma, Tao Wang, and Chao Wu. 2023. "Determination of the Accuracy of the Straight Bevel Gear Profiles by a Novel Optical Coaxial Multi-Ring Measurement Method" Sensors 23, no. 5: 2654. https://doi.org/10.3390/s23052654

APA StyleLi, J., Zhang, D., Li, Y., Ma, X., Wang, T., & Wu, C. (2023). Determination of the Accuracy of the Straight Bevel Gear Profiles by a Novel Optical Coaxial Multi-Ring Measurement Method. Sensors, 23(5), 2654. https://doi.org/10.3390/s23052654