Emissivity Correction and Thermal Pattern Reconstruction in Eddy Current Pulsed Thermography

Abstract

1. Introduction

2. Physical Process Modelling of Eddy Current Pulsed Thermography

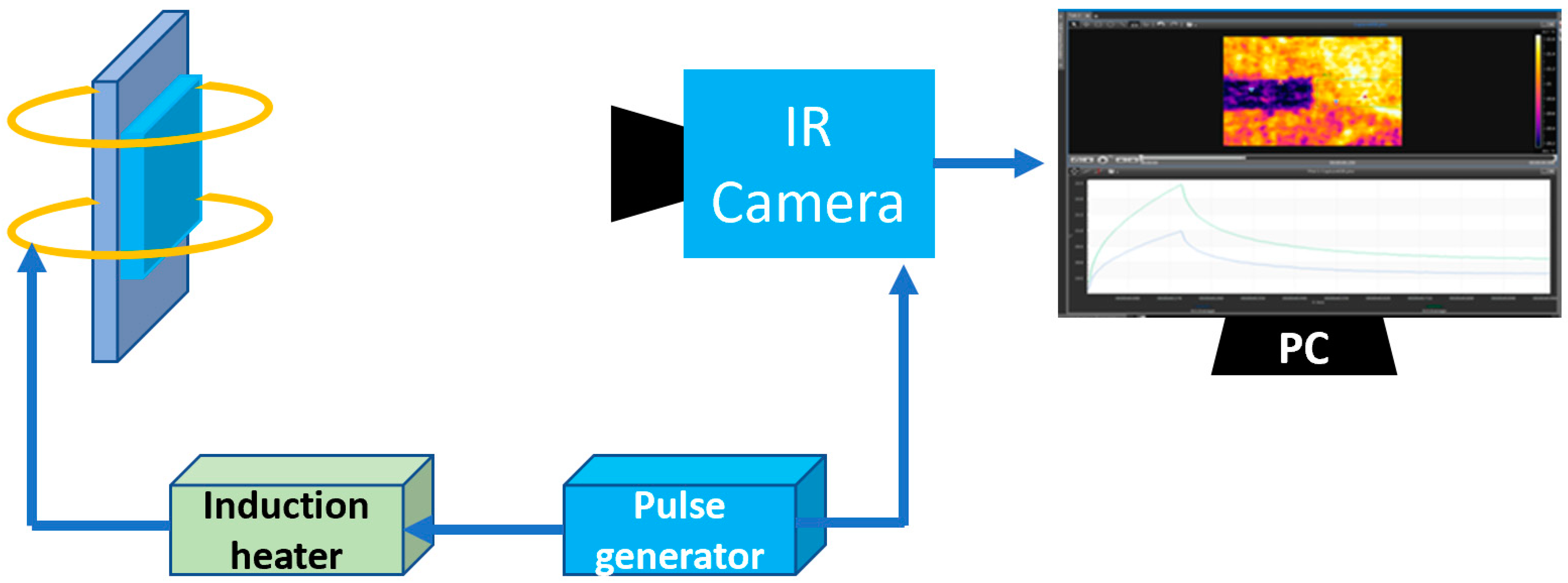

2.1. Eddy Current Pulsed Thermography

2.2. Emissivity Correction Algorithm

3. Results of the Experimental Study of Material Analysis and Gear Fault Detection

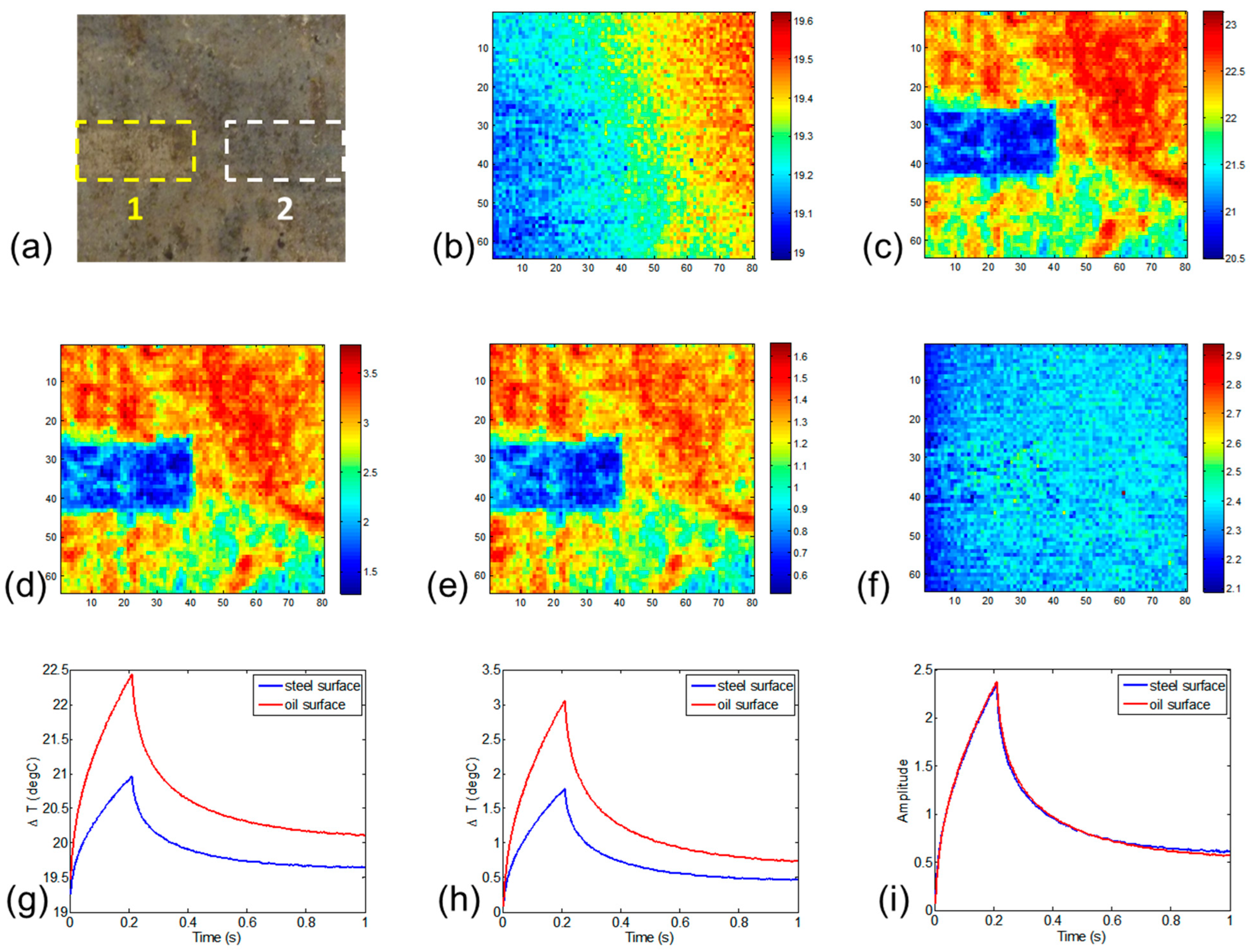

3.1. Emissivity Correction and Case-Depth Separation

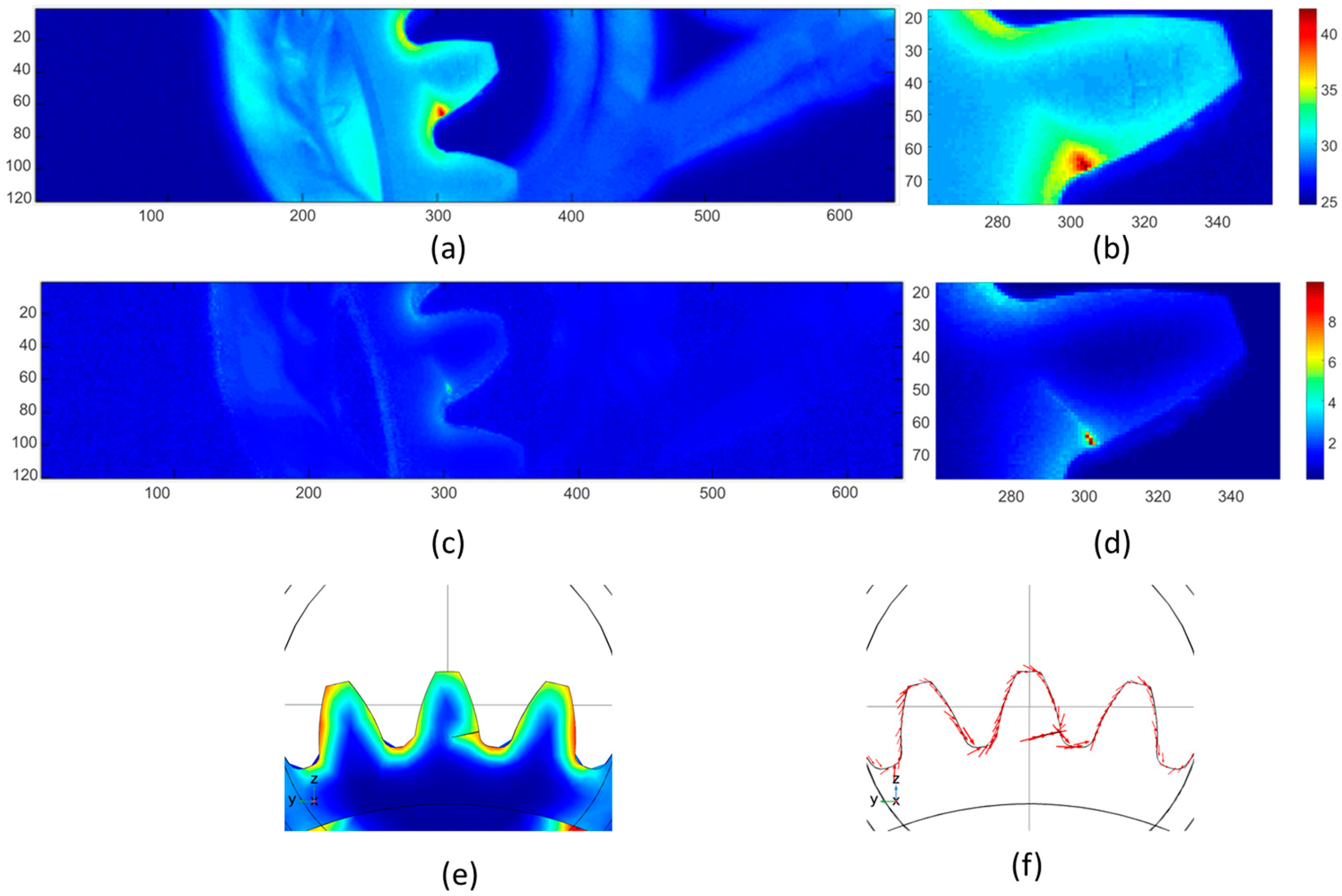

3.2. Fault Detection in Gears

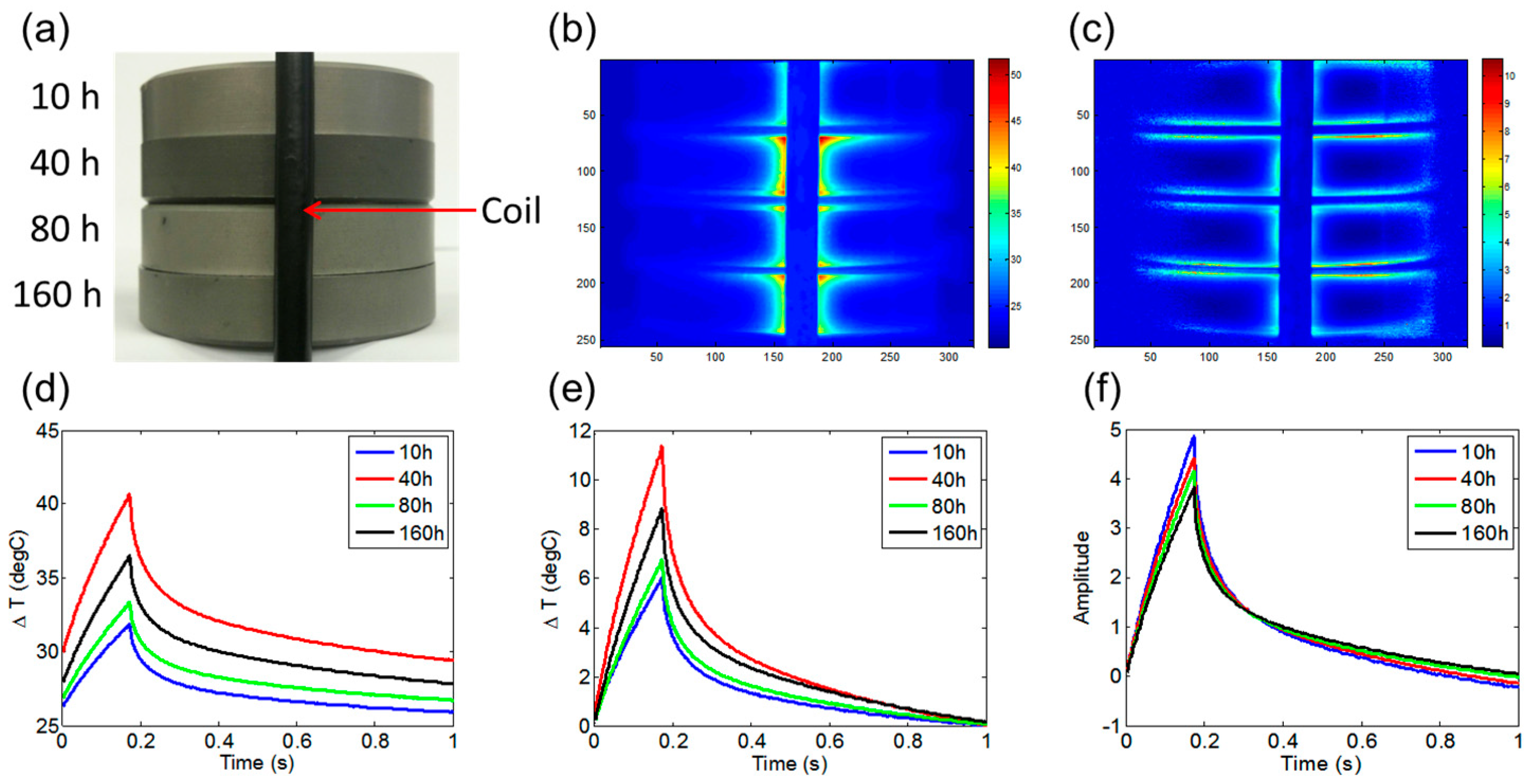

3.3. Gear Fatigue Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Tian, G.; Ding, S.; Ahmed, J.; Woo, W.L. Tomographic Reconstruction of Rolling Contact Fatigues in Rails Using 3D Eddy Current Pulsed Thermography. IEEE Sens. J. 2021, 21, 18488–18496. [Google Scholar] [CrossRef]

- Li, K.; Tian, G.; Cheng, L.; Yin, A.; Cao, W.; Crichton, S. State Detection of Bond Wires in IGBT Modules Using Eddy Current Pulsed Thermography. IEEE Trans. Power Electron. 2014, 29, 5000–5009. [Google Scholar] [CrossRef]

- Li, K.; Tian, G.Y.; Chen, X.; Tang, C.; Luo, H.; Li, W.; Gao, B.; He, X.; Wright, N. AR-Aided Smart Sensing for In-Line Condition Monitoring of IGBT Wafer. IEEE Trans. Ind. Electron. 2019, 66, 8197–8204. [Google Scholar] [CrossRef]

- Vellvehi, M.; Perpiñà, X.; Lauro, G.L.; Perillo, F.; Jorda, X. Irradiance-based emissivity correction in infrared thermography for electronic applications. Rev. Sci. Instrum. 2011, 82, 114901. [Google Scholar] [CrossRef] [PubMed]

- Gradhand, M.; Breitenstein, O. Preparation of nonconducting infrared-absorbing thin films. Rev. Sci. Instrum. 2005, 76, 053702. [Google Scholar] [CrossRef]

- Furstenberg, R.; Kendziora, C.A.; Stepnowski, S.V.; Mott, D.R.; McGill, R.A. Infrared micro-thermography of an actively heated preconcentrator device. Proc. SPIE 2008, 6939, 693902. [Google Scholar]

- Kasemann, M.; Walter, B.; Meinhardt, C.; Ebser, J.; Kwapil, W.; Warta, W. Emissivity-corrected power loss calibration for lock-in thermography measurements on silicon solar cells. J. Appl. Phys. 2008, 103, 113503. [Google Scholar] [CrossRef]

- D’Accardi, E.; Palano, F.; Tamborrino, R.; Palumbo, D.; Tatì, A.; Terzi, R.; Galietti, U. Pulsed Phase Thermography Approach for the Characterization of Delaminations in CFRP and Comparison to Phased Array Ultrasonic Testing. J. Nondestruct. Eval. 2019, 38, 20. [Google Scholar] [CrossRef]

- Maldague, X.; Galmiche, F.; Ziadi, A. Advances in pulsed phase thermography. Infrared Phys. Technol. 2002, 43, 175–181. [Google Scholar] [CrossRef]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Yang, R.; He, Y.; Gao, B.; Tian, G.Y. Inductive pulsed phase thermography for reducing or enlarging the effect of surface emissivity variation. Appl. Phys. Lett. 2014, 105, 184103. [Google Scholar] [CrossRef]

- Miao, L.; Gao, B.; Li, H.; Lu, X.; Liu, L.; Woo, W.L.; Wu, J. Novel interventional electromagnetic thermography for subsurface defect detection. Int. J. Therm. Sci. 2023, 184, 107960. [Google Scholar] [CrossRef]

- Bai, L.; Tian, S.; Cheng, Y.; Tian, G.Y.; Chen, Y.; Chen, K. Reducing the Effect of Surface Emissivity Variation in Eddy Current Pulsed Thermography. IEEE Sens. J. 2014, 14, 1137–1142. [Google Scholar] [CrossRef]

- Moradi, M.; Sfarra, S. Rectifying the emissivity variations problem caused by pigments in artworks inspected by infrared thermography: A simple, useful, effective, and optimized approach for the cultural heritage field. Infrared Phys. Technol. 2021, 115, 103718. [Google Scholar] [CrossRef]

- Gao, B.; He, Y.; Woo, W.L.; Tian, G.Y.; Liu, J.; Hu, Y. Multidimensional Tensor-Based Inductive Thermography With Multiple Physical Fields for Offshore Wind Turbine Gear Inspection. IEEE Trans. Ind. Electron. 2016, 63, 6305–6315. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, G.; Gao, B.; Lu, X.; Li, H.; Chen, X.; Zhang, Y.; Xiong, L. Depth quantification of rolling contact fatigue crack using skewness of eddy current pulsed thermography in stationary and scanning modes. NDT E Int. 2022, 128, 102630. [Google Scholar] [CrossRef]

- Li, H.; Gao, B.; Miao, L.; Liu, D.; Ma, Q.; Tian, G.; Woo, W.L. Multiphysics Structured Eddy Current and Thermography Defects Diagnostics System in Moving Mode. IEEE Trans. Ind. Inform. 2021, 17, 2566–2578. [Google Scholar] [CrossRef]

- Zhu, J.; Withers, P.J.; Wu, J.; Liu, F.; Yi, Q.; Wang, Z.; Tian, G.Y. Characterization of Rolling Contact Fatigue Cracks in Rails by Eddy Current Pulsed Thermography. IEEE Trans. Ind. Inform. 2021, 17, 2307–2315. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, G.; Huang, F. AIE opens new applications in super-resolution imaging. J. Mater. Chem. B 2016, 4, 7761–7765. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Rao, L.; Yu, G.; Cook, T.R.; Chen, X.; Huang, F. Supramolecular cancer nanotheranostics. Chem. Soc. Rev. 2021, 50, 2839–2891. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Tian, G.Y.; Ahmed, J. Emissivity Correction and Thermal Pattern Reconstruction in Eddy Current Pulsed Thermography. Sensors 2023, 23, 2646. https://doi.org/10.3390/s23052646

Li K, Tian GY, Ahmed J. Emissivity Correction and Thermal Pattern Reconstruction in Eddy Current Pulsed Thermography. Sensors. 2023; 23(5):2646. https://doi.org/10.3390/s23052646

Chicago/Turabian StyleLi, Kongjing, Gui Yun Tian, and Junaid Ahmed. 2023. "Emissivity Correction and Thermal Pattern Reconstruction in Eddy Current Pulsed Thermography" Sensors 23, no. 5: 2646. https://doi.org/10.3390/s23052646

APA StyleLi, K., Tian, G. Y., & Ahmed, J. (2023). Emissivity Correction and Thermal Pattern Reconstruction in Eddy Current Pulsed Thermography. Sensors, 23(5), 2646. https://doi.org/10.3390/s23052646