Numerical Simulation and Analysis of Turbulent Characteristics near Wake Area of Vacuum Tube EMU

Abstract

1. Introduction

2. Numerical Simulation Method

2.1. Fluid Model

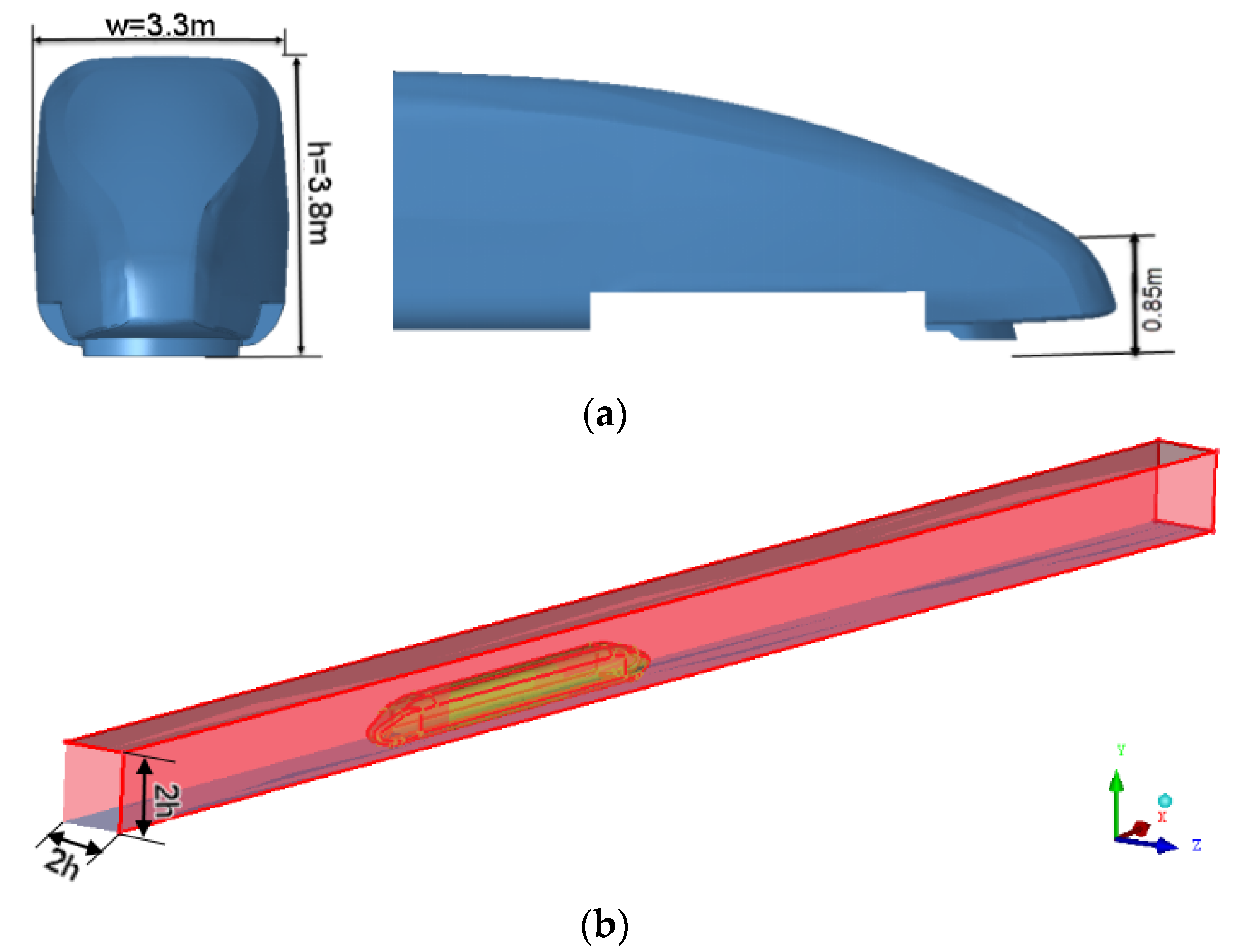

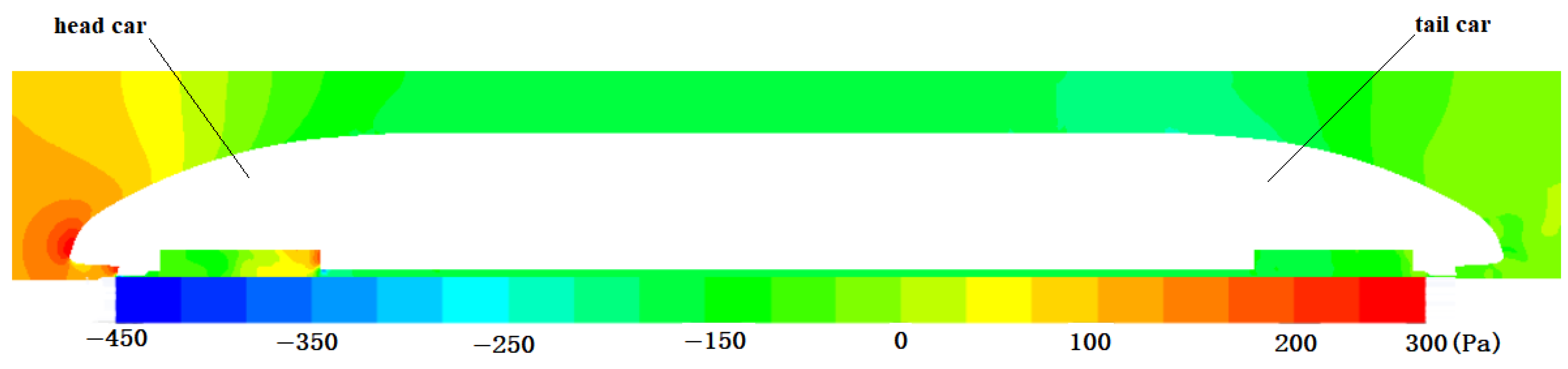

2.2. High-Speed Train Model and Calculation Domain

- (1)

- Three length models (denoted as atm1, atm2, atm3) are adopted: head-1 carriage-tail train, head-2 carriages-tail train and head-3 carriages-tail train. The height and width of the model are set in proportion to the actual EMU. According to the experience of dealing with related problems, the simplified model has little change in the basic distribution law of the flow field compared with the complete EMU model.

- (2)

- Due to the complex structures of pantographs, door handles, bogies, etc., the structures that affect the grid division are ignored as much as possible, and smooth surfaces are simplified to replace these structures when processing.

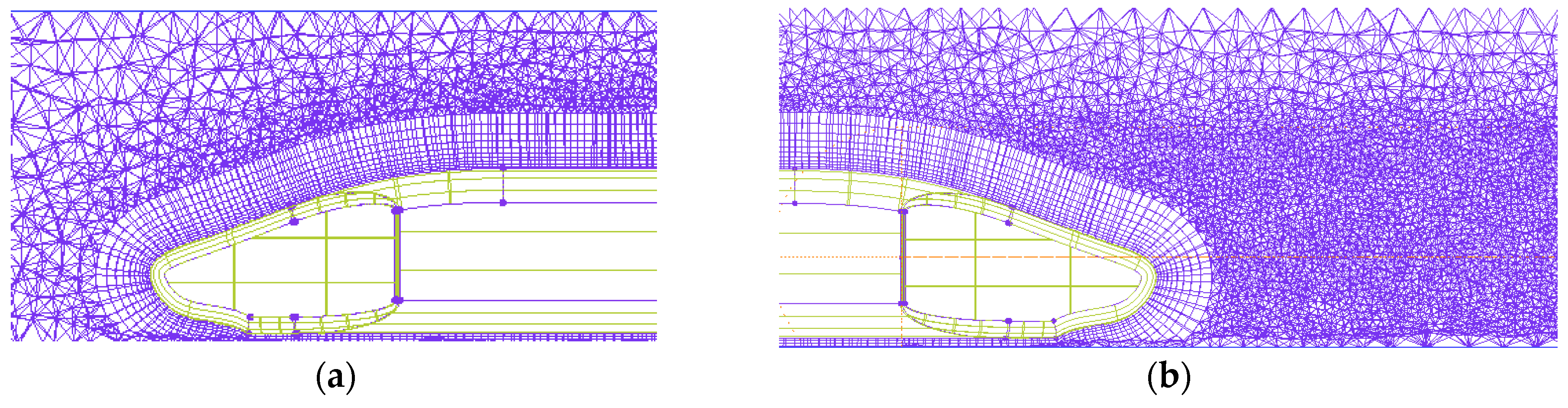

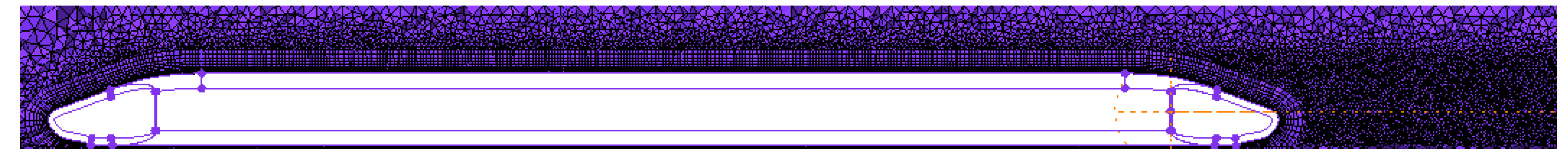

2.3. Meshing

- (1)

- Set the global grid size and scale factor.

- (2)

- Set the prism for the car body. The boundary layer grid is a triangular prism grid. Set the height, height ratio, and number of layers. A schematic diagram of the local grid of the front of the car is shown in Figure 2.

- (3)

2.4. Simulation Method

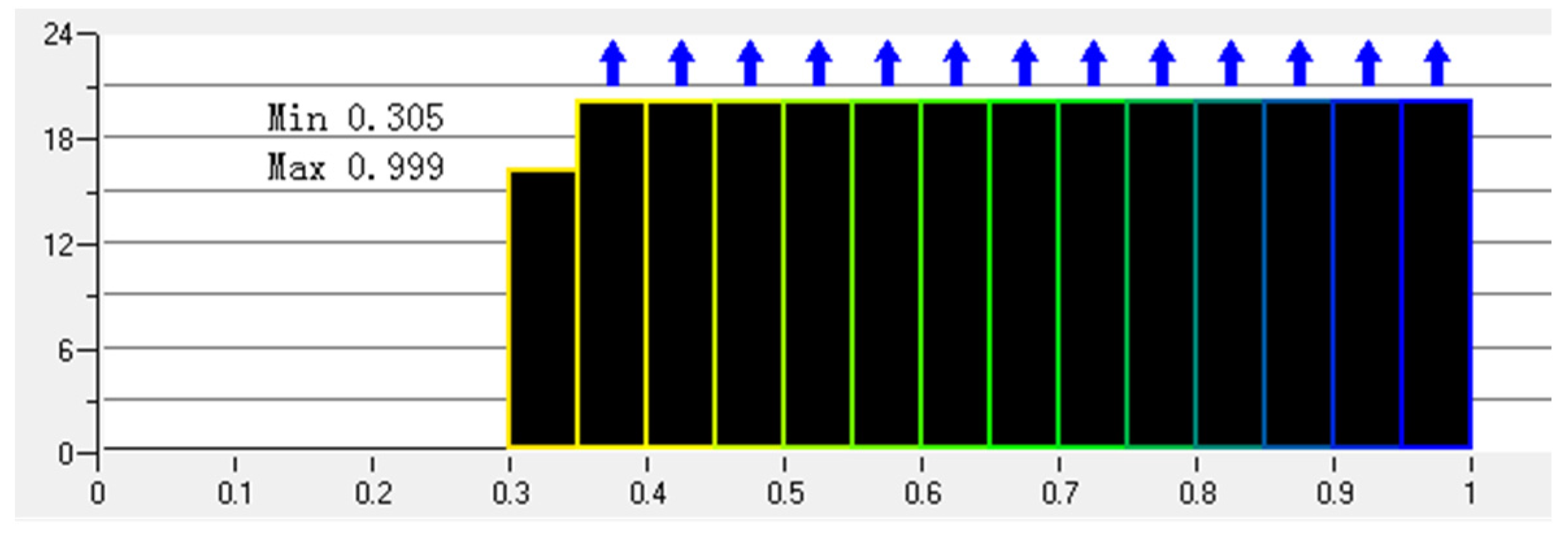

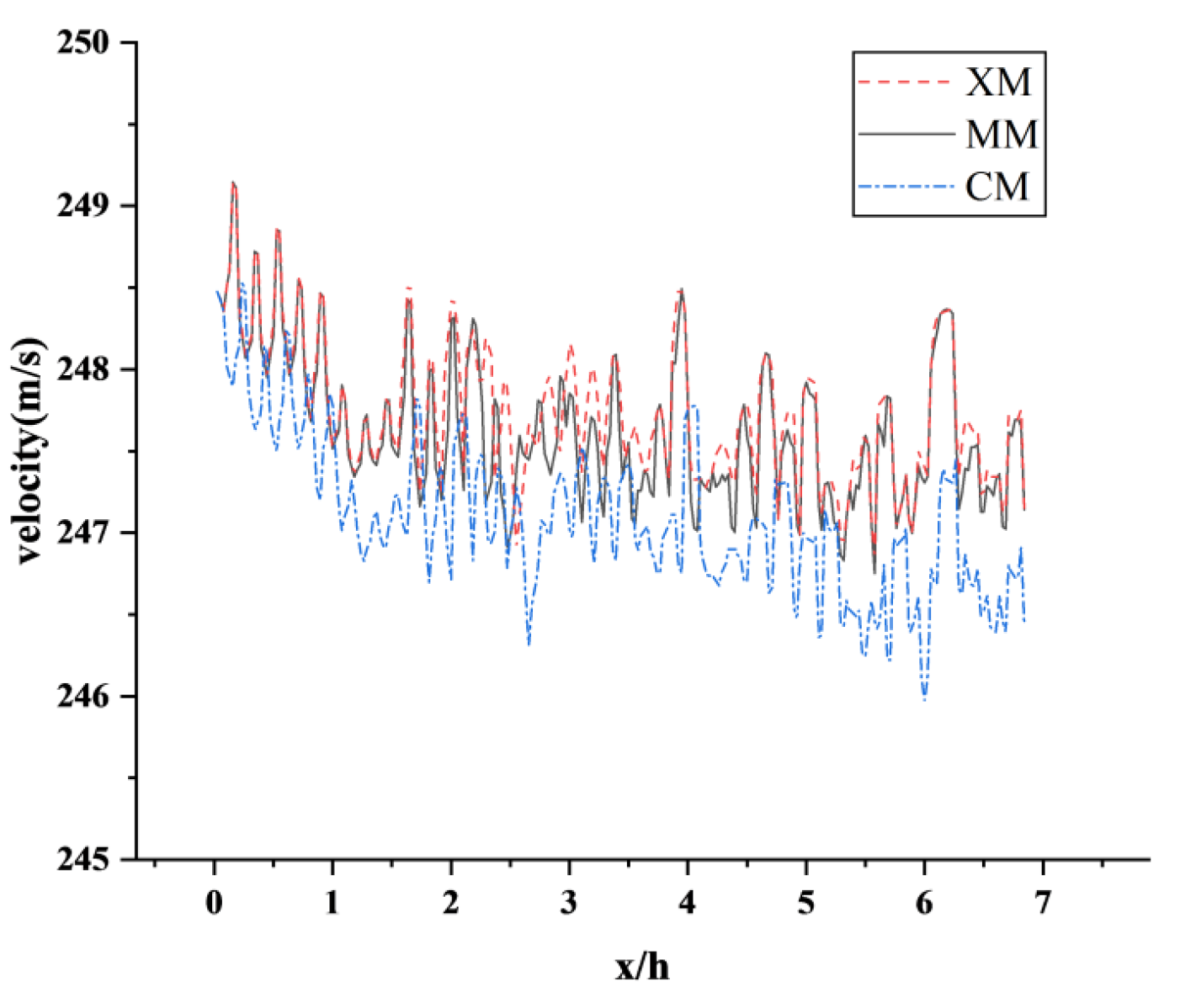

2.5. Reliability Analysis

3. Turbulence Characteristics Analysis

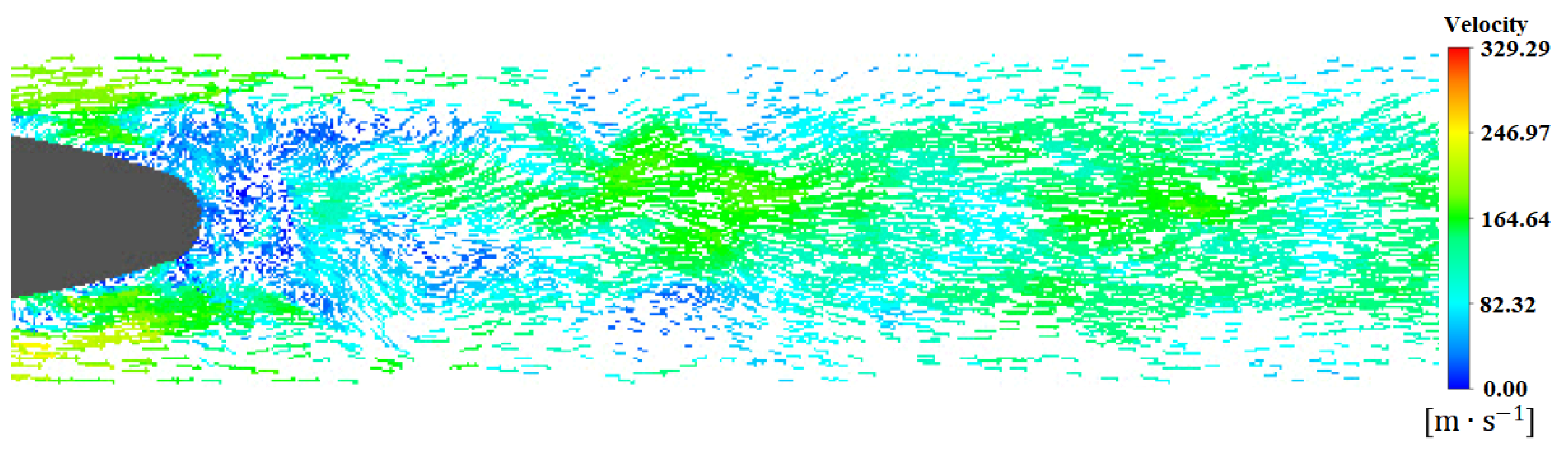

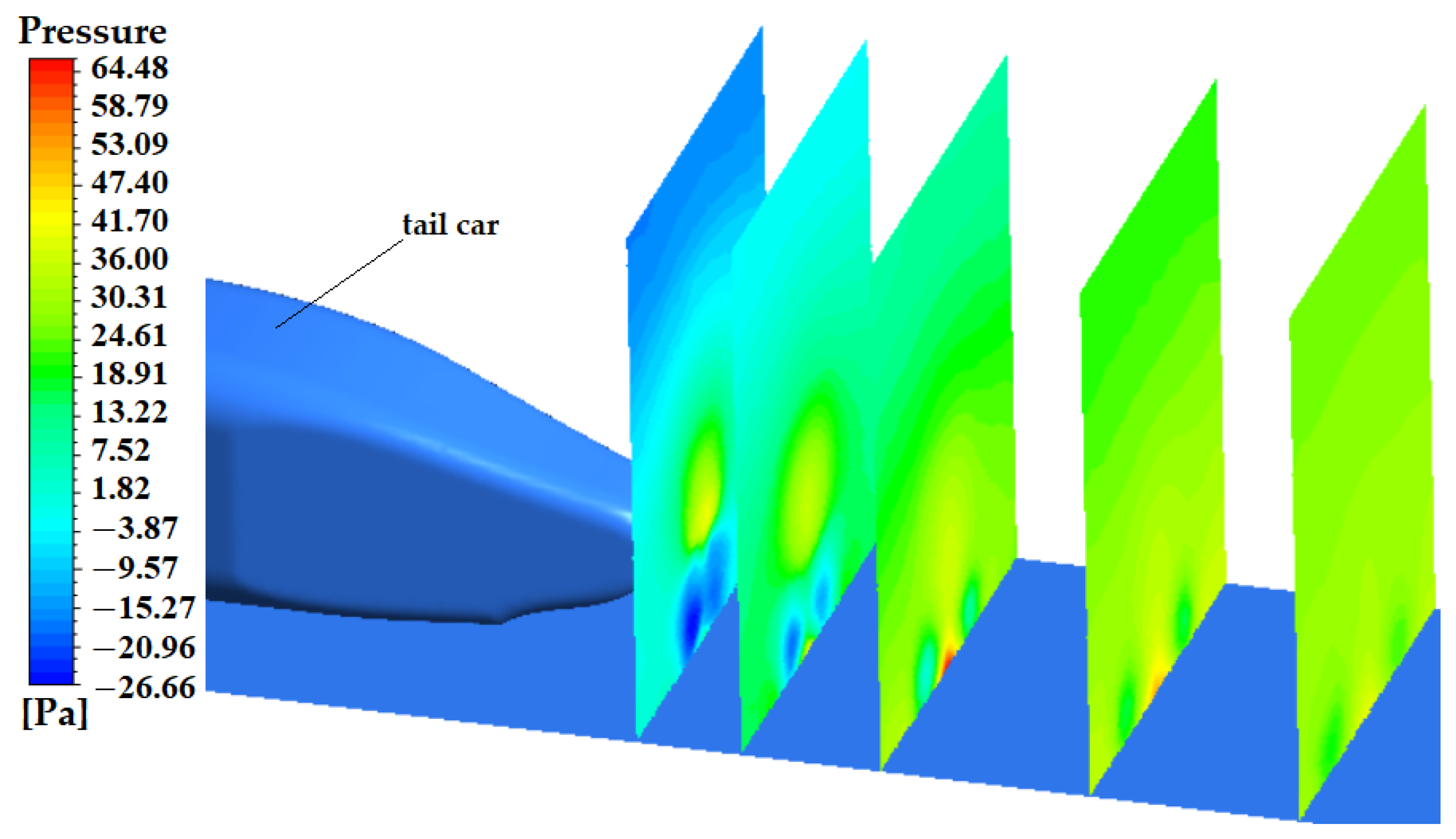

3.1. Wake Vortex Structure

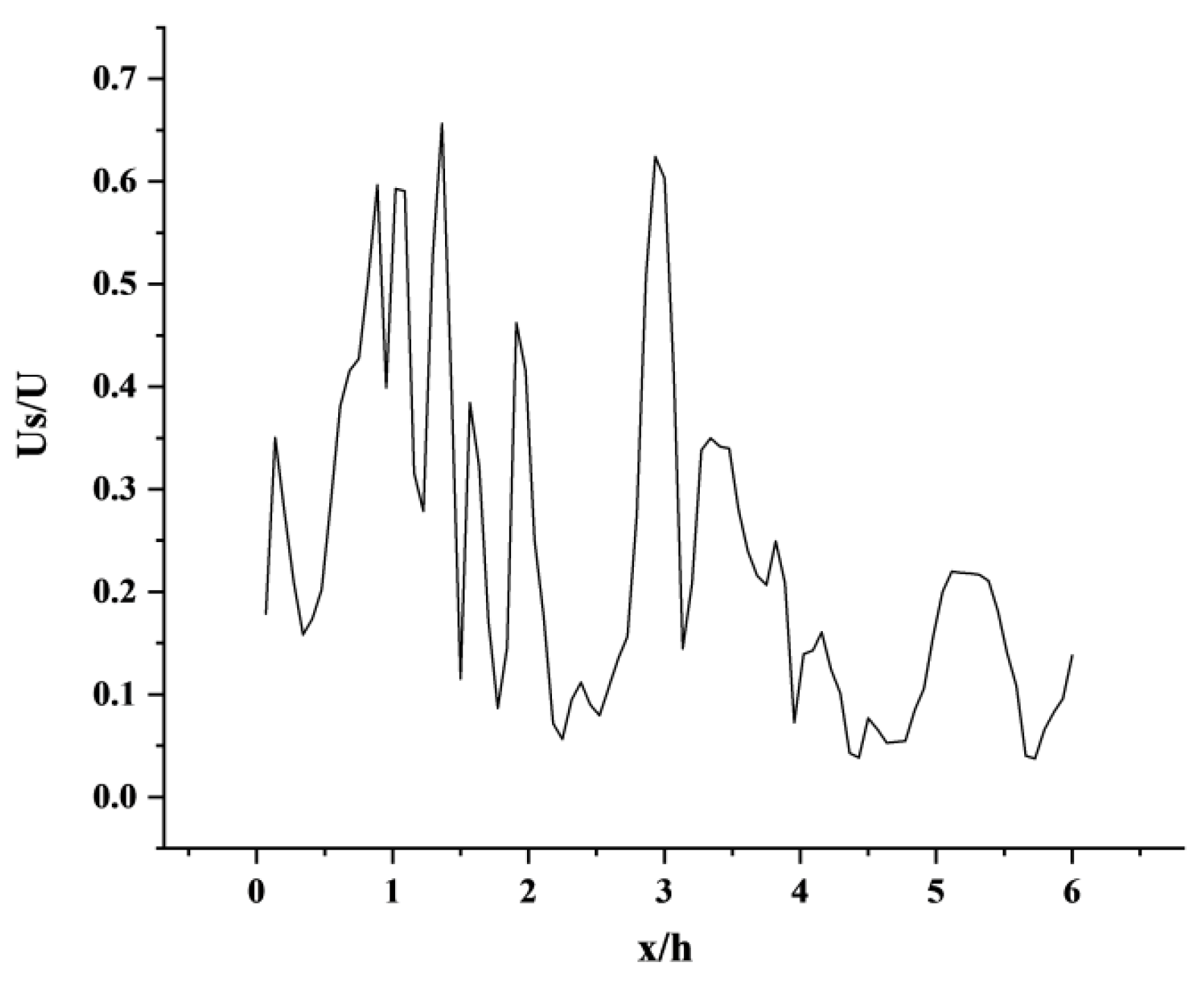

3.2. Train Wind

3.3. Analysis of Aerodynamic Characteristics

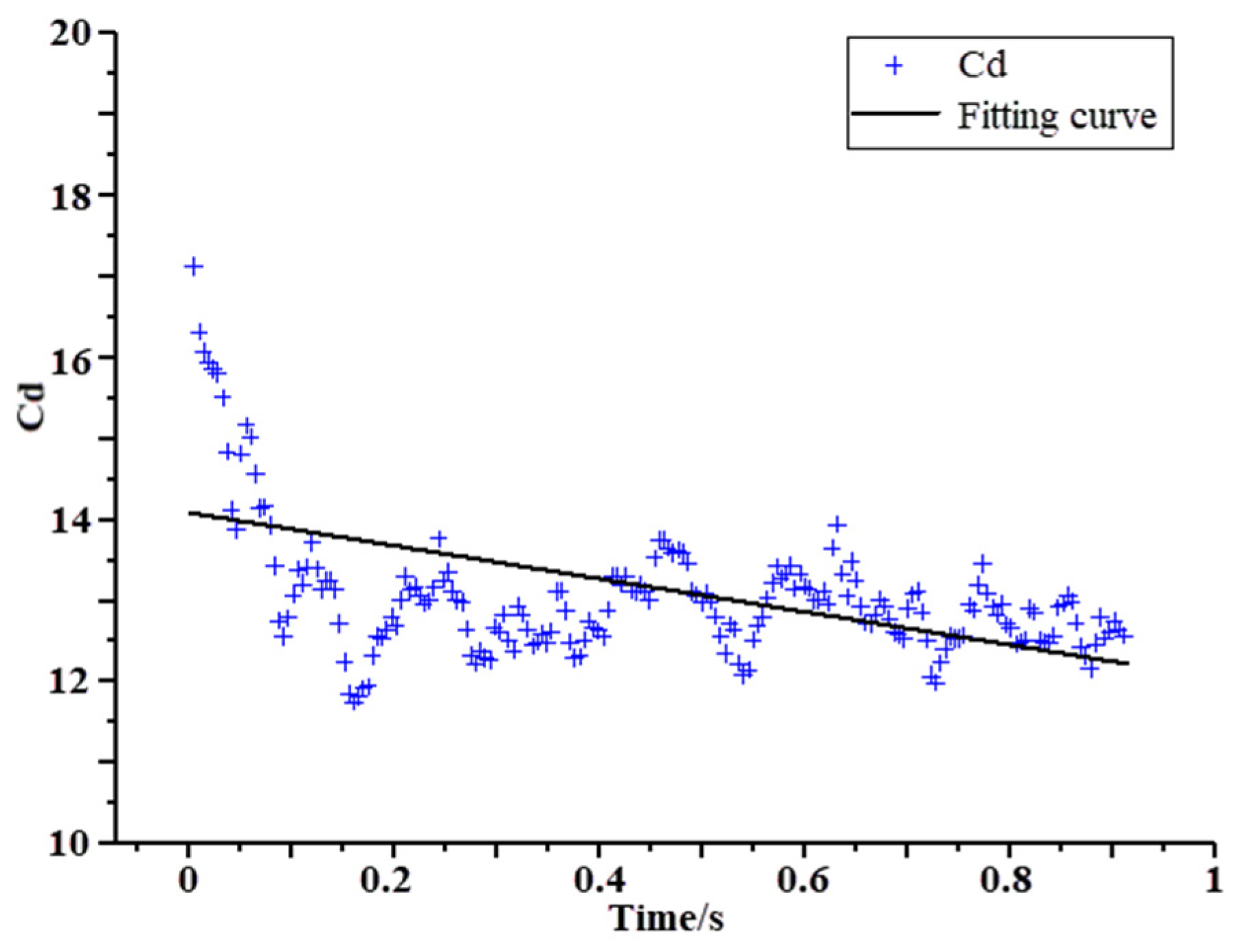

3.3.1. Aerodynamic Characteristics of atm1

3.3.2. Drag Analysis of Three Different Length Models

3.4. Analysis of Turbulence Kinetic Energy Analysis

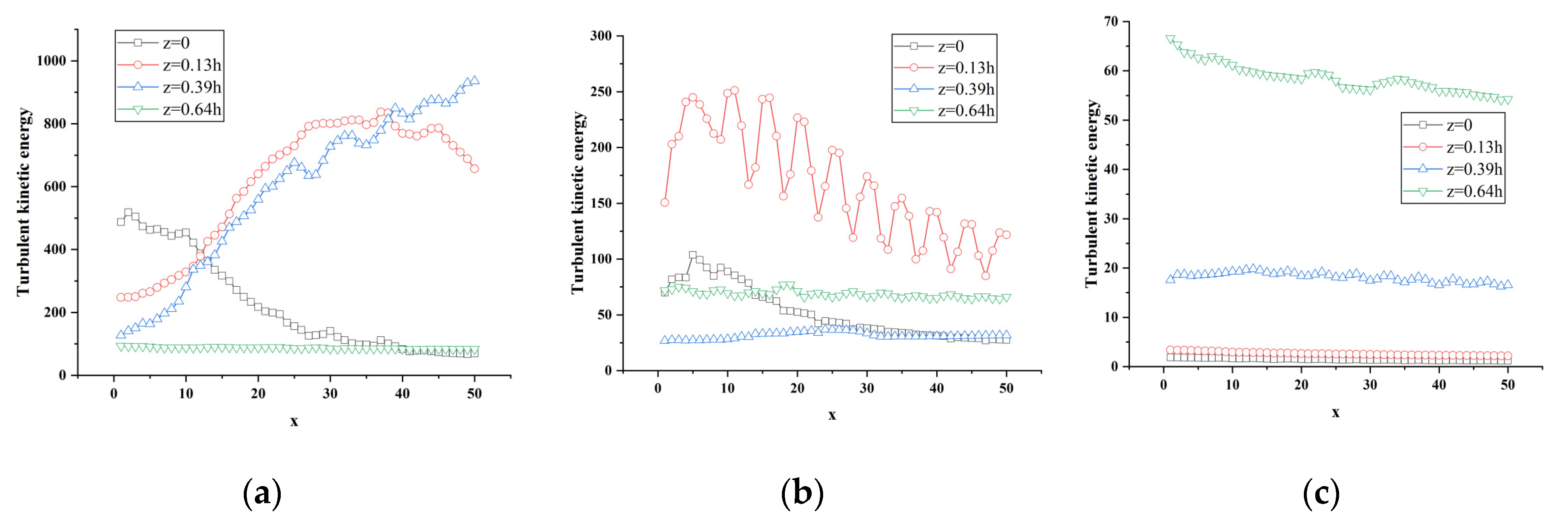

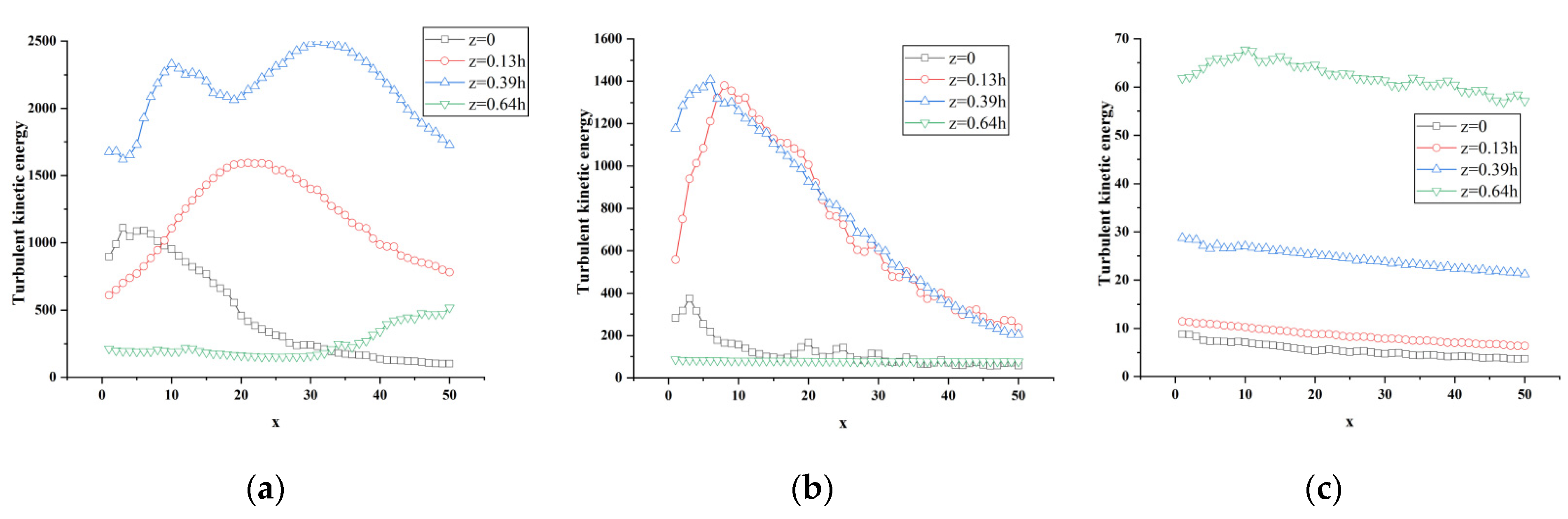

3.4.1. Under atm1 Conditions

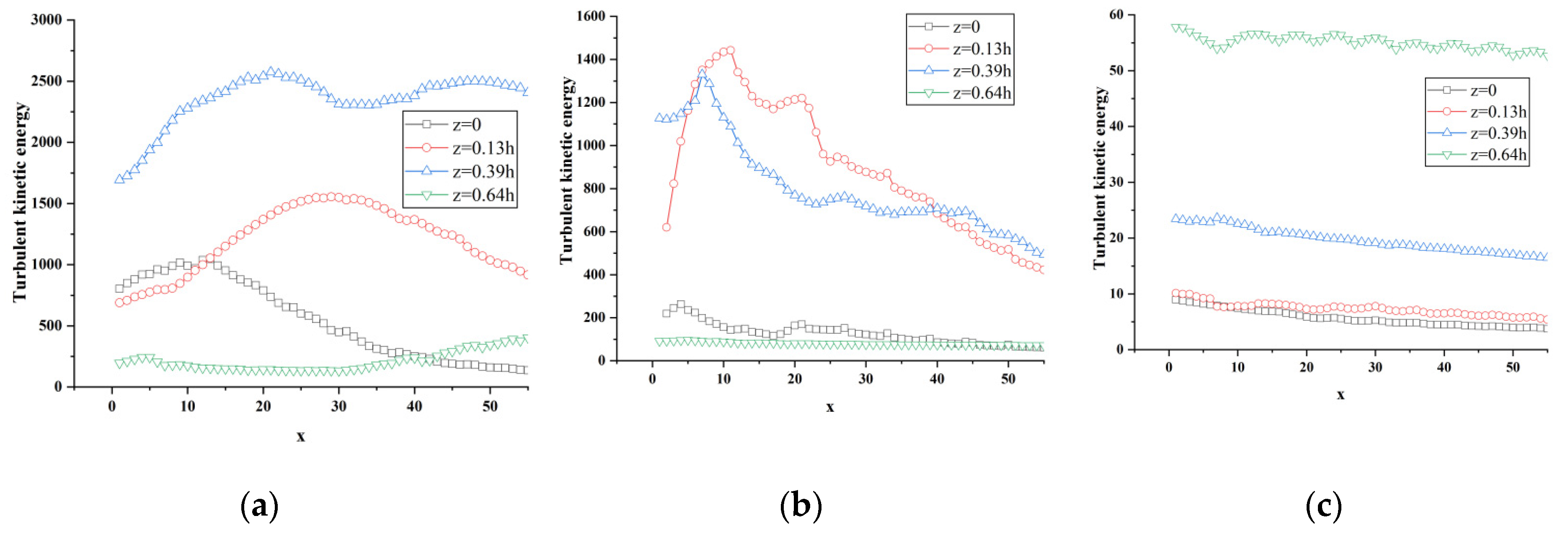

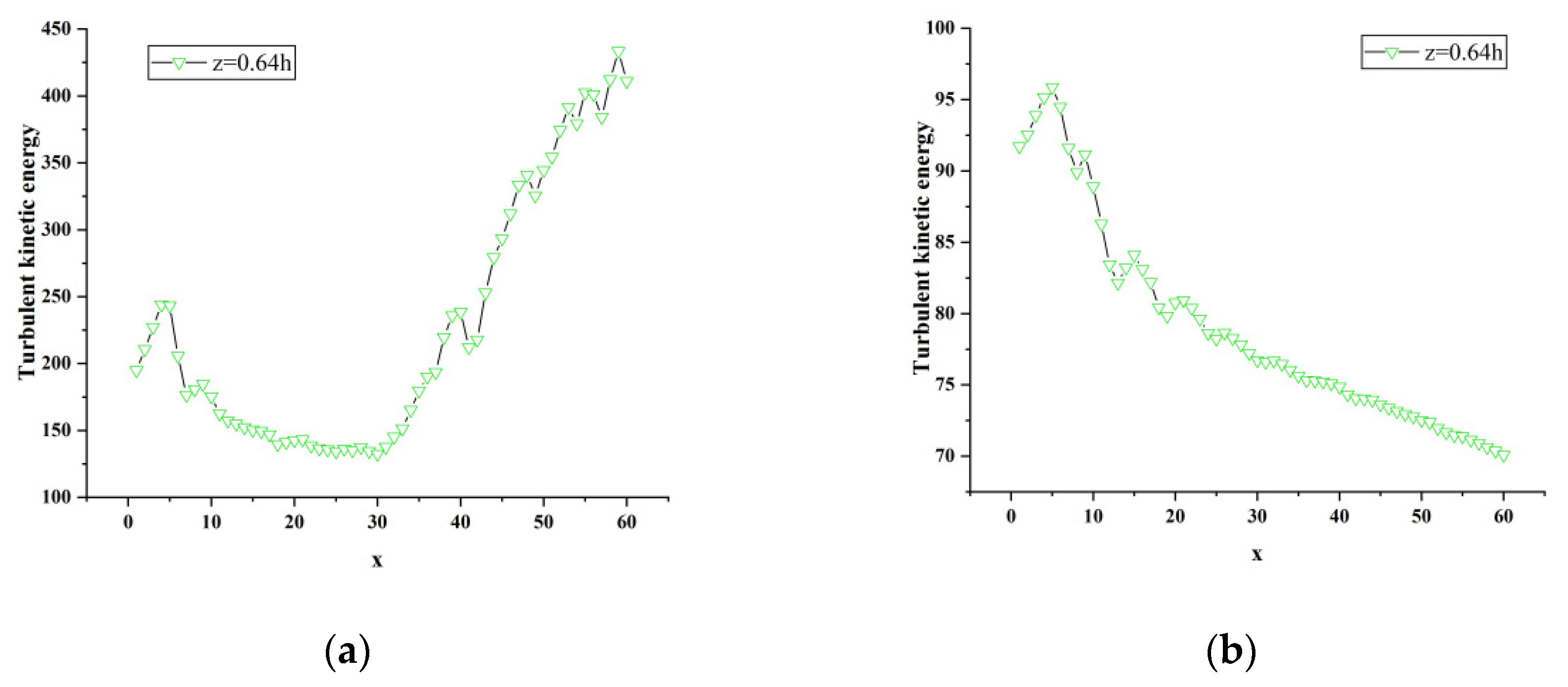

3.4.2. Under atm2 and atm3 Conditions

4. Conclusions

- (1)

- There are strong vortices in the wake area, and the energy carried by them is concentrated at the lower vertical position. The tail vortex is falling off from the tail end. In the process of propagating downstream, the vortex structure away from the tail vehicle is gradually increasing, but from the characterization of velocity, the strength of vortex is gradually decreasing.

- (2)

- When the vertical position is closer to the ground, the train wind shows a chaotic state, and the vortex has a large energy concentration near the ground. In the wake area, the train wind speed peak appears many times, but the peak value is gradually decreasing, and the overall trend is gradually decreasing.

- (3)

- When the train speed is constant, with the increase of the characteristic length of the EMU model, the train surface area increases, the proportion of differential pressure resistance decreases gradually, the proportion of viscous resistance in aerodynamic resistance is more significant, and the contribution to aerodynamic resistance increases.

- (4)

- The turbulent kinetic energy of the three train models with different lengths is basically the same, gradually decreasing and then rising to the peak, repeating many times and gradually decreasing. The maximum turbulent kinetic energy of each vertical position is also gradually declining, indicating that the wake vortex in the near wake area is mainly concentrated near the lower end of the nose tip near the ground, and continues to propagate downstream and move horizontally.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, C.; Zhou, X.; Ran, X.J.; Liu, Y.; Deng, W.Q.; Deng, W. Co-evolutionary competitive swarm optimizer with three-phase for large-scale complex optimization problem. Inf. Sci. 2022, 619, 2–18. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Du, C.; Fan, X.; Cui, L.; Chen, H.; Deng, F.; Tong, Q.; He, M.; Yang, M.; et al. Custom-molded offloading footwear effectively prevents recurrence and amputation and lowers mortality rates in high-risk diabetic foot patients: A multicenter, prospective observational study. Diabetes Metab. Syndr. Obes. Targets Ther. 2022, 15, 103–109. [Google Scholar] [CrossRef] [PubMed]

- He, Z.Y.; Shao, H.D.; Wang, P.; Janet, L.; Cheng, J.S.; Yang, Y. Deep transfer multi-wavelet auto-encoder for intelligent fault diagnosis of gearbox with few target training samples. Knowl. Based Syst. 2020, 191, 105313. [Google Scholar] [CrossRef]

- Jin, T.; Zhu, Y.; Shu, Y.; Cao, J.; Yan, H.; Jiang, D. Uncertain optimal control problem with the first hitting time objective and application to a portfolio selection model. J. Intell. Fuzzy Syst. 2023, 44, 1585–1599. [Google Scholar] [CrossRef]

- Song, Y.; Cai, X.; Zhou, X.; Zhang, B.; Chen, H.; Li, Y.; Deng, W.; Deng, W. Dynamic hybrid mechanism-based differential evolution algorithm and its application. Expert Syst. Appl. 2022, 213, 118834. [Google Scholar] [CrossRef]

- Li, W.; Zhong, X.; Shao, H.; Cai, B.; Yang, X. Multi-mode data augmentation and fault diagnosis of rotating machinery using modified ACGAN designed with new framework. Adv. Eng. Inform. 2022, 52, 101552. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, Z.; Li, G.; Liu, Y.; Yang, R.; Liu, H. Optimal search mapping among sensors in heterogeneous smart homes. Math. Biosci. Eng. 2023, 20, 1960–1980. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.; Chen, H.; Chen, J.; Li, Y.; Xu, J.; Deng, W. Intelligent Diagnosis Using Continuous Wavelet Transform and Gauss Convolutional Deep Belief Network. IEEE Trans. Reliab. 2022, 1–11. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, L.; Zhou, X.; Zhou, Y.; Sun, Y.; Zhu, W.; Chen, H.; Deng, W.; Chen, H.; Zhao, H. Multi-strategy particle swarm and ant colony hybrid optimization for airport taxiway planning problem. Inf. Sci. 2022, 612, 576–593. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, W.G.; Liao, Y.; Song, Z.; Shi, J.; Jiang, X.; Shen, C.; Zhu, Z. Bearing fault diagnosis via generalized logarithm sparse regularization. Mech. Syst. Signal Process. 2022, 167, 108576. [Google Scholar] [CrossRef]

- Zhao, H.M.; Zhang, P.P.; Zhang, R.C.; Yao, R.; Deng, W. A novel performance trend prediction approach using ENBLS with GWO. Meas. Sci. Technol. 2023, 34, 025018. [Google Scholar] [CrossRef]

- Deng, W.; Xu, J.J.; Gao, X.Z.; Zhao, H.M. An enhanced MSIQDE algorithm with novel multiple strategies for global optimization problems. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 1578–1587. [Google Scholar] [CrossRef]

- Ren, Z.; Han, X.; Yu, X.; Skjetne, R.; Leira, B.J.; Sævik, S.; Zhu, M. Data-driven simultaneous identification of the 6DOF dynamic model and wave load for a ship in waves. Mech. Syst. Signal Process. 2023, 184, 109422. [Google Scholar] [CrossRef]

- Jin, T.; Gao, S.; Xia, H.; Ding, H. Reliability analysis for the fractional-order circuit system subject to the uncertain random fractional-order model with Caputo type. J. Adv. Res. 2021, 32, 15–26. [Google Scholar] [CrossRef]

- Baker, C. The simulation of unsteady aerodynamic cross wind forces on trains. J. Wind Eng. Ind. Aerodyn. 2010, 98, 88–99. [Google Scholar] [CrossRef]

- Baker, C. The flow around high speed trains. J. Wind Eng. Ind. Aerodyn. 2010, 98, 277–298. [Google Scholar] [CrossRef]

- Hemida, H.; Baker, C.; Gao, G. The calculation of train slipstreams using large-eddy simulation. J. Rail Rapid Transit 2014, 228, 25–36. [Google Scholar] [CrossRef]

- Choi, H.; Moin, P.; Kim, J. Active turbulence control for drag reduction in wall-bounded flows. J. Fluid Mech. 1994, 262, 75–110. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, X.; Chang, N. Analysis on simulation algorithm for train outflow field of vacuum pipeline traffic. J. Eng. Thermophys. 2018, 39, 1244–1250. [Google Scholar]

- Pan, Y. Numerical Investigation on the Boundary-Layer and Wake Flows of a High-Speed Train. Ph.D. Thesis, China Academy of Railway Sciences, Beijing, China, 2018. [Google Scholar]

- Bell, J.R.; Burton, D.; Thompson, M.C.; Herbst, A.; Sheridan, J. Wind tunnel analysis of the slipstream and wake of a high-speed train. J. Wind. Eng. Ind. Aerod. 2014, 134, 122–138. [Google Scholar] [CrossRef]

- Bell, J.R.; Burton, D.; Thompson, M.C.; Herbst, A.; Sheridan, J. Moving model analysis of the slipstream and wake of a high-speed train. J. Wind. Eng. Ind. Aerod. 2015, 136, 127–137. [Google Scholar] [CrossRef]

- Bell, J.R.; Burton, D.; Thompson, M.C.; Herbst, A.; Sheridan, J. Flow topology and unsteady features of the wake of a generic high-speed train. J. Fluids Struct. 2016, 61, 168–183. [Google Scholar] [CrossRef]

- Bell, J.R.; Burton, D.; Thompson, M.C.; Herbst, A.; Sheridan, J. Dynamics of trailing vortices in the wake of a generic high-speed train. J. Fluids Struct. 2016, 65, 238–256. [Google Scholar] [CrossRef]

- Liu, W.; Guo, D.; Zhang, Z.; Yang, G. Study of dynamic characteristics in wake flow of high-speed train based on POD. J. China Railw. Soc. 2020, 42, 49–57. [Google Scholar]

- Muld, T.W. Analysis of Flow Structures in Wake Flows for Train Aerodynamics. Ph.D. Thesis, Department of Mechanics Royal Institute of Technology, Stockholm, Sweden, 2010. [Google Scholar]

- Muld, T.W.; Efraimsson, G.; Dan, S.H. Flow structures around a high-speed train extracted using proper orthogonal decomposition and dynamic mode decomposition. Comput. Fluids 2012, 57, 87–97. [Google Scholar] [CrossRef]

- Muld, T.W.; Fraimsson, G.E.; Henningson, D.S. Wake characteristics of high-speed trains with different lengths. J. Rail Rapid Transit 2014, 228, 333–342. [Google Scholar] [CrossRef]

- Xia, C.; Wang, H.; Bao, D.; Yang, Z. Unsteady flow structures in the wake of a high-speed train. Exp. Therm. Fluid Sci. 2018, 98, 381–396. [Google Scholar] [CrossRef]

- Xia, C.; Wang, H.; Shan, X.; Yang, Z.; Li, Q. Effects of ground configurations on the slipstream and near wake of a high-speed train. J. Wind Eng. Ind. Aerodyn. 2017, 168, 177–189. [Google Scholar] [CrossRef]

- Xia, C.; Shan, X.; Yang, Z. Detached-eddy simulation of ground effect on the wake of a high-speed train. J. Fluids Eng. 2017, 139, 051101. [Google Scholar] [CrossRef]

- Wang, D.; Chen, C.; Hu, J.; He, Z. The effect of Reynolds number on the unsteady wake of a high-speed train. J. Wind Eng. Ind. Aerodyn. 2020, 204, 104223. [Google Scholar] [CrossRef]

- Yao, S.; Sun, Z.; Guo, D.; Chen, D.; Yang, G. Numerical study on wake characteristics of high-speed trains. Acta Mech. Sin. 2013, 29, 811–822. [Google Scholar] [CrossRef]

- Sterling, M.; Baker, C.J.; Jordan, S.C.; Johnson, T. A study of the slipstreams of high-speed passenger trains and freight trains. P. I. Mech. Eng. F-J. Rai. 2008, 222, 177–193. [Google Scholar] [CrossRef]

- Kim, J.H.; Rho, J.H. Pressure wave characteristics of a high-speed train in a tunnel according to the operating conditions. J. Rail Rapid Transit 2018, 232, 928–935. [Google Scholar] [CrossRef]

- Shin, C.H.; Park, W.G. Numerical study of flow characteristics of the high speed train entering into a tunnel. Mech. Res. Commun. 2003, 30, 287–296. [Google Scholar] [CrossRef]

- Gillani, S.A.; Panikulam, V.P.; Sadasivan, S.; Yaoping, Z. CFD analysis of aerodynamic drag effects on vacuum tube trains. J. Appl. Fluid Mech. 2019, 12, 303–309. [Google Scholar] [CrossRef]

- Zhong, S.; Qian, B.; Yang, M.; Wu, F.; Wang, T.; Tan, C.; Ma, J. Investigation on flow field structure and aerodynamic load in vacuum tube transportation system. J. Wind Eng. Ind. Aerodyn. 2021, 215, 104681. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, X.; Chen, G.; Li, X. Effect of the ballast height on the slipstream and wake flow of high-speed train. J. Wind Eng. Ind. Aerodyn. 2020, 207, 104404. [Google Scholar] [CrossRef]

- Li, X.; Liang, X.; Wang, Z.; Xiong, X.; Chen, G.; Yu, Y.; Chen, C. On the correlation between aerodynamic drag and wake flow for a generic high-speed train. J. Wind Eng. Ind. Aerodyn. 2021, 215, 104698. [Google Scholar] [CrossRef]

- Jia, L.; Zhou, D.; Niu, J. Numerical calculation of boundary layers and wake characteristics of high-speed trains with different lengths. PLoS ONE 2017, 12, e0189798. [Google Scholar] [CrossRef]

- Niu, J.; Wang, Y.; Zhang, L.; Yuan, Y. Numerical analysis of aerodynamic characteristics of high-speed train with different train nose lengths. Int. J. Heat. Mass Transf. 2018, 127, 188–199. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, J.; Li, T.; Zhang, W. Numerical study on wave phenomena produced by the super high-speed evacuated tube maglev train. J. Wind Eng. Ind. Aerodyn. 2019, 190, 61–70. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, J.; Li, T. Effects of blocking ratio and Mach number on aerodynamic characteristics of the evacuated tube train. Int. J. Rail Transp. 2020, 8, 27–44. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, J. Aerothermal mechanisms induced by the super high-speed evacuated tube maglev train. Vacuum 2020, 173, 109142. [Google Scholar] [CrossRef]

- Kwon, H.B.; Kang, B.B.; Kim, B.Y.; Lee, D.H.; Jung, H.J. Parametric study on the aerodynamic drag of ultra high-speed train in evacuated tube-part 1. J. Korean Soc. Railw. 2010, 13, 44–50. [Google Scholar]

- Kwon, H.B.; Nam, S.W.; Kim, D.H.; Jang, Y.J.; Kang, B.B. Parametric study on the aerodynamic drag of ultra high-speed train in evacuated tube-part 2. J. Korean Soc. Railw. 2010, 13, 51–57. [Google Scholar]

- Tan, C.; Zhou, D.; Chen, G.; Sheridan, J.; Krajnovic, S. Influences of marshalling length on the flow structure of a maglev train. Int. J. Heat Fluid Flow 2020, 85, 108604. [Google Scholar] [CrossRef]

- Sui, Y.; Niu, J.; Ricco, P.; Yuan, Y.; Yu, Q.; Cao, X.; Yang, X. Impact of vacuum degree on the aerodynamics of a high-speed train capsule running in a tube. Int. J. Heat Fluid Flow 2021, 88, 108752. [Google Scholar] [CrossRef]

- Dong, T.; Minelli, G.; Wang, J.; Liang, X.; Krajnovic, S. The effect of ground clearance on the aerodynamics of a generic high-speed train. J Fluid Struct. 2020, 95, 102990. [Google Scholar] [CrossRef]

- Tian, H.; Huang, S.; Yang, M. Flow structure around high-speed train in open air. J. Cent. S. Univ. 2015, 22, 747–752. [Google Scholar] [CrossRef]

- Tian, H. Formation mechanism of aerodynamic drag of high-speed train and some reduction measures. J. Cent. S. Univ. Tehnol. 2009, 16, 166–171. [Google Scholar] [CrossRef]

- Chen, H.L.; Li, C.Y.; Mafarja, M.; Heidari, A.A.; Chen, Y.; Cai, Z.N. Slime mould algorithm: A comprehensive review of recent variants and applications. Int. J. Syst. Sci. 2023, 54, 204–235. [Google Scholar] [CrossRef]

- Xu, J.J.; Zhao, Y.L.; Chen, H.Y.; Deng, W. ABC-GSPBFT: PBFT with grouping score mechanism and optimized consensus process for flight operation data-sharing. Inf. Sci. 2023, 624, 110–127. [Google Scholar] [CrossRef]

- Bi, J.; Zhou, G.; Zhou, Y.; Luo, Q.; Deng, W. Artificial Electric Field Algorithm with Greedy State Transition Strategy for Spherical Multiple Traveling Salesmen Problem. Int. J. Comput. Intell. Syst. 2022, 15, 5. [Google Scholar] [CrossRef]

- Duan, Z.; Song, P.; Yang, C.; Deng, L.; Jiang, Y.; Deng, F.; Jiang, X.; Chen, Y.; Yang, G.; Ma, Y.; et al. The impact of hyperglycaemic crisis episodes on long-term outcomes for inpatients presenting with acute organ injury: A prospective, multicentre follow-up study. Front. Endocrinol. 2022, 13, 1057089. [Google Scholar] [CrossRef]

- Li, X.; Zhao, H.; Yu, L.; Chen, H.; Deng, W.; Deng, W. Feature extraction using parameterized multi-synchrosqueezing transform. IEEE Sens. J. 2022, 22, 14263–14272. [Google Scholar] [CrossRef]

- Li, T.Y.; Shi, J.Y.; Deng, W.; Hu, Z.D. Pyramid particle swarm optimization with novel strategies of competition and cooperation. Appl. Soft Comput. 2022, 121, 108731. [Google Scholar] [CrossRef]

- Deng, W.; Ni, H.; Liu, Y.; Chen, H.; Zhao, H. An adaptive differential evolution algorithm based on belief space and generalized opposition-based learning for resource allocation. Appl. Soft Comput. 2022, 127, 109419. [Google Scholar] [CrossRef]

- Yao, R.; Guo, C.; Deng, W.; Zhao, H. A novel mathematical morphology spectrum entropy based on scale-adaptive techniques. ISA Trans. 2022, 126, 691–702. [Google Scholar] [CrossRef]

- Li, T.; Qian, Z.; Deng, W.; Zhang, D.Z.; Lu, H.; Wang, S. Forecasting crude oil prices based on variational mode decomposition and random sparse Bayesian learning. Appl. Soft Comput. 2021, 113, 108032. [Google Scholar] [CrossRef]

- Liu, Y.; Heidari, A.A.; Cai, Z.N.; Liang, G.X.; Chen, H.L.; Pan, Z.F.; Alsufyani, A.; Bourouis, S. Simulated annealing-based dynamic step shuffled frog leaping algorithm: Optimal performance design and feature selection. Neurocomputing 2022, 503, 325–362. [Google Scholar] [CrossRef]

- Tian, C.; Jin, T.; Yang, X.; Liu, Q. Reliability analysis of the uncertain heat conduction model. Comput. Math. Appl. 2022, 119, 131–140. [Google Scholar] [CrossRef]

- Li, B.; Xu, J.; Jin, T.; Shu, Y. Piecewise parameterization for multifactor uncertain system and uncertain inventory-promotion optimization. Knowl. Based Syst. 2022, 255, 109683. [Google Scholar] [CrossRef]

- Jin, T.; Xia, H.; Deng, W.; Li, Y.; Chen, H. Uncertain Fractional-Order Multi-Objective Optimization Based on Reliability Analysis and Application to Fractional-Order Circuit with Caputo Type. Circuits Syst. Signal Process. 2021, 40, 5955–5982. [Google Scholar] [CrossRef]

- Huang, C.; Zhou, X.B.; Ran, X.J.; Wang, J.M.; Chen, H.Y.; Deng, W. Adaptive cylinder vector particle swarm optimization with differential evolution for UAV path planning. Eng. Appl. Artif. Intell. 2023, 121, 105942. [Google Scholar] [CrossRef]

- Jin, T.; Yang, X. Monotonicity theorem for the uncertain fractional differential equation and application to uncertain financial market. Math. Comput. Simul. 2021, 190, 203–221. [Google Scholar] [CrossRef]

- Zhao, H.M.; Zhang, P.P.; Chen, B.J.; Chen, H.Y.; Deng, W. Bearing fault diagnosis using transfer learning and optimized deep belief network. Meas. Sci. Technol. 2022, 33, 065009. [Google Scholar] [CrossRef]

- Jin, T.; Xia, H. Lookback option pricing models based on the uncertain fractional-order differential equation with Caputo type. J. Ambient. Intell. Humaniz. Comput. 2021, 1–14. [Google Scholar] [CrossRef]

- Zhou, X.B.; Ma, H.J.; Gu, J.G.; Chen, H.L.; Deng, W. Parameter adaptation-based ant colony optimization with dynamic hybrid mechanism. Eng. Appl. Artif. Intell. 2022, 114, 105139. [Google Scholar] [CrossRef]

- Chen, H.Y.; Miao, F.; Chen, Y.J.; Xiong, Y.J.; Chen, T. A hyperspectral image classification method using multifeature vectors and optimized KELM. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2021, 14, 2781–2795. [Google Scholar] [CrossRef]

- Wei, Y.Y.; Zhou, Y.Q.; Luo, Q.F.; Deng, W. Optimal reactive power dispatch using an improved slime Mould algorithm. Energy Rep. 2021, 7, 8742–8759. [Google Scholar] [CrossRef]

- Zhang, Z. Numerical Method of Rarefied Gas Dynamics, from Molecular flow to Continuous Flow. In Proceedings of the 14th International Conference on Vacuum Science and Engineering Application, Shenyang, China, 14 October 2019. [Google Scholar]

- Ou, L.; Zhao, L.; Chen, L. Numerical simulation of hypersonic flows with local rarefaction effect. Acta Aero. Sin. 2019, 37, 193–200. [Google Scholar]

- Tsien, H.S. Superaerodynamics, mechanics of rarefield gases. J. Aeronaut. Sci. 1946, 13, 653–664. [Google Scholar] [CrossRef]

- Mohamed, G.H. The fluid mechanics of microdevices-the freeman scholar lecture. J. Fluids Eng. 1999, 121, 5–33. [Google Scholar]

- Chen, L.; Liu, H.; Wang, P.; Wu, D.; Zeng, Y.; Chen, M. New method for reynolds and characteristic length in detouring tube bundles flow. Petro-Chem. Equip. 2015, 44, 32–36. [Google Scholar]

- Huang, Z.; Liang, X.; Chang, N. Numerical analysis of train aerodynamic drag of vacuum tube traffic. J. Mech. Eng. 2019, 55, 165–172. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Zhang, W. Analysis of aerodynamic characteristics of high-speed trains in the evacuated tube. J. Mech. Eng. 2013, 49, 137–143. [Google Scholar] [CrossRef]

- Pan, Y.; Yao, J.; Liang, C.; Li, C. Analysis on turbulence characteristics of vortex structure in near wake of high speed train. China Railw. Sci. 2017, 38, 83–88. [Google Scholar]

| Maximum Size of Grid Cell | CM | MM | XM |

|---|---|---|---|

| Region around body | 0.32 h | 0.02 h | 0.015 h |

| Region of tail flow field | 0.105 h | 0.08 h | 0.04 h |

| Total number of grids (106) | 3.2 | 5.8 | 8.3 |

| Method | X | Y | Z | Peak Train Wind Speed |

|---|---|---|---|---|

| IDDES | 5 × 105 | 0.18 | 0.3 | 0.66 |

| Test (track side) | 6 × 105 | 0.05 | 2.0 | 0.23 |

| Test (station) | 6 × 105 | 0.35 | 2.0 | 0.15 |

| LES | 3 × 105 | 0.05 | 2.0 | 0.31 |

| Model | Pressure Drag (N) | Friction Drag (N) | Aerodynamic Drag (N) |

|---|---|---|---|

| atm1 | 1207.24 | 559.88 | 1767.12 |

| atm2 | 1994.65 | 969.03 | 2963.68 |

| atm3 | 2268.87 | 1225.62 | 3494.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, H.; Chen, G.; Guan, Y.; Zhao, H. Numerical Simulation and Analysis of Turbulent Characteristics near Wake Area of Vacuum Tube EMU. Sensors 2023, 23, 2461. https://doi.org/10.3390/s23052461

Cui H, Chen G, Guan Y, Zhao H. Numerical Simulation and Analysis of Turbulent Characteristics near Wake Area of Vacuum Tube EMU. Sensors. 2023; 23(5):2461. https://doi.org/10.3390/s23052461

Chicago/Turabian StyleCui, Hongjiang, Guanxin Chen, Ying Guan, and Huimin Zhao. 2023. "Numerical Simulation and Analysis of Turbulent Characteristics near Wake Area of Vacuum Tube EMU" Sensors 23, no. 5: 2461. https://doi.org/10.3390/s23052461

APA StyleCui, H., Chen, G., Guan, Y., & Zhao, H. (2023). Numerical Simulation and Analysis of Turbulent Characteristics near Wake Area of Vacuum Tube EMU. Sensors, 23(5), 2461. https://doi.org/10.3390/s23052461