Concept and Implementation of Measurement Systems for Stationary and Remote Testing of Sensors for Electrical and Non-Electrical Quantities

Abstract

:1. Introduction

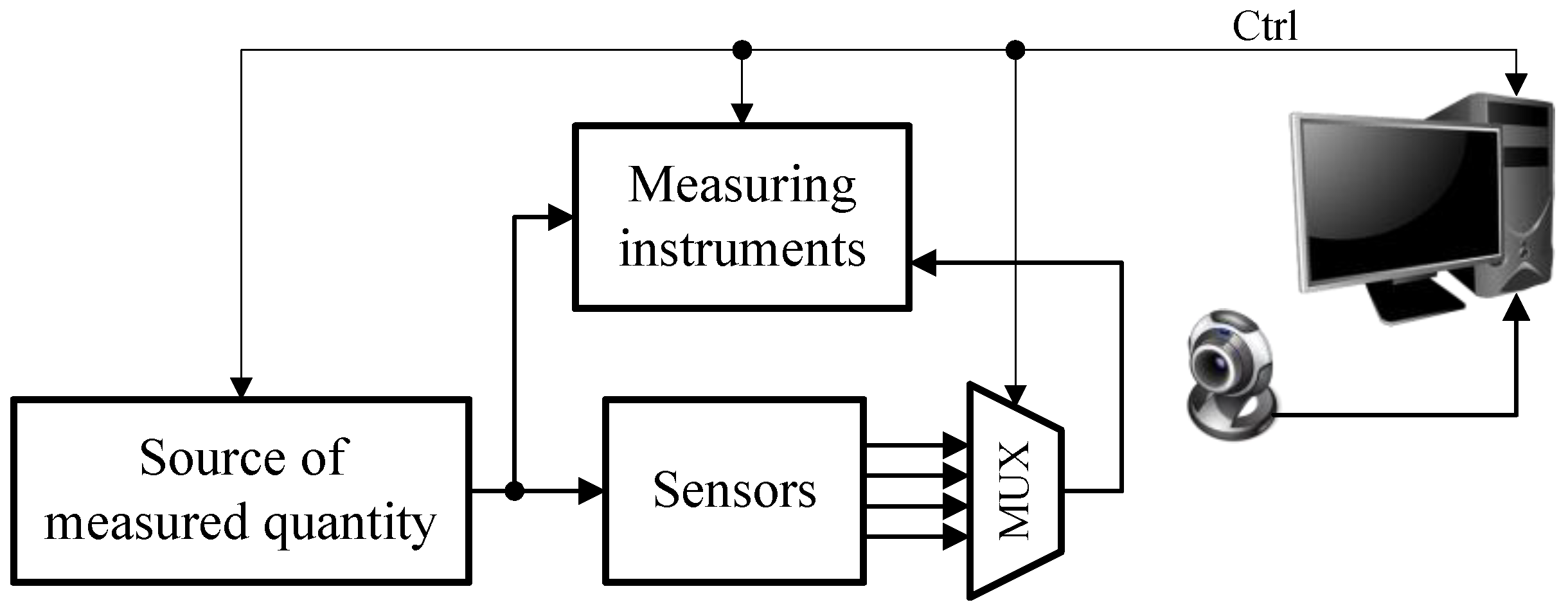

2. Concept of the Laboratory Stand

2.1. Hardware

2.2. Software

2.3. Remote Access

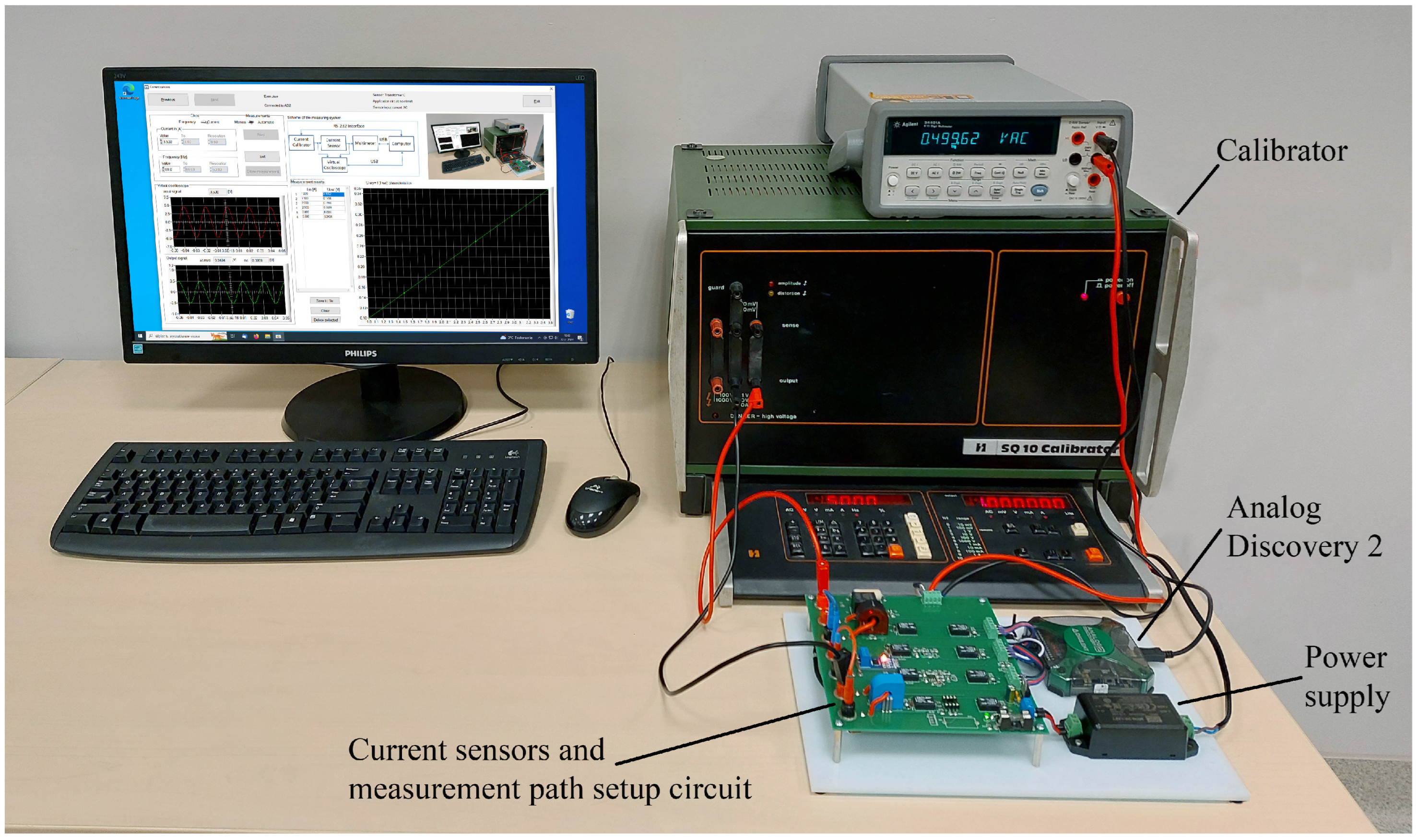

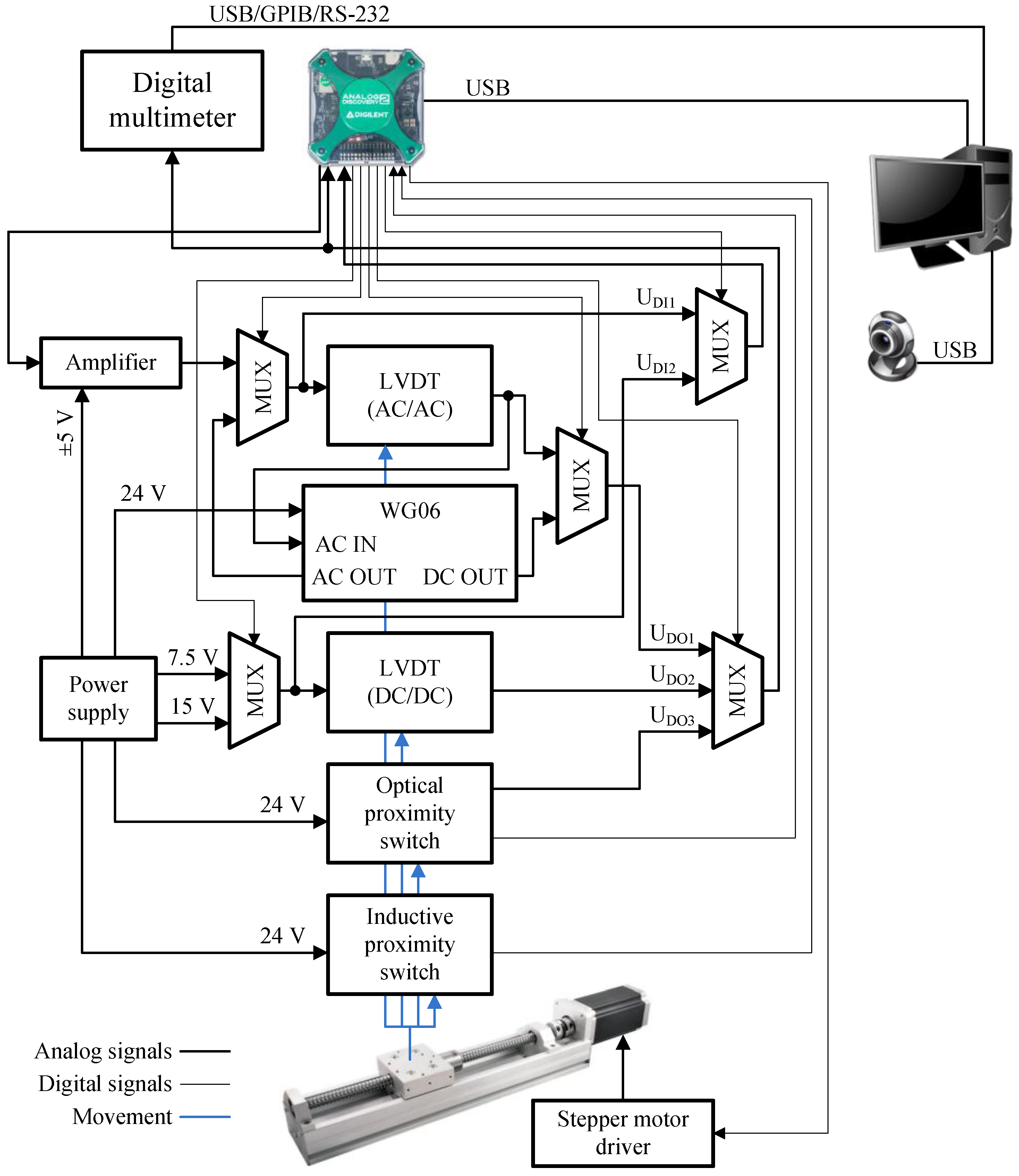

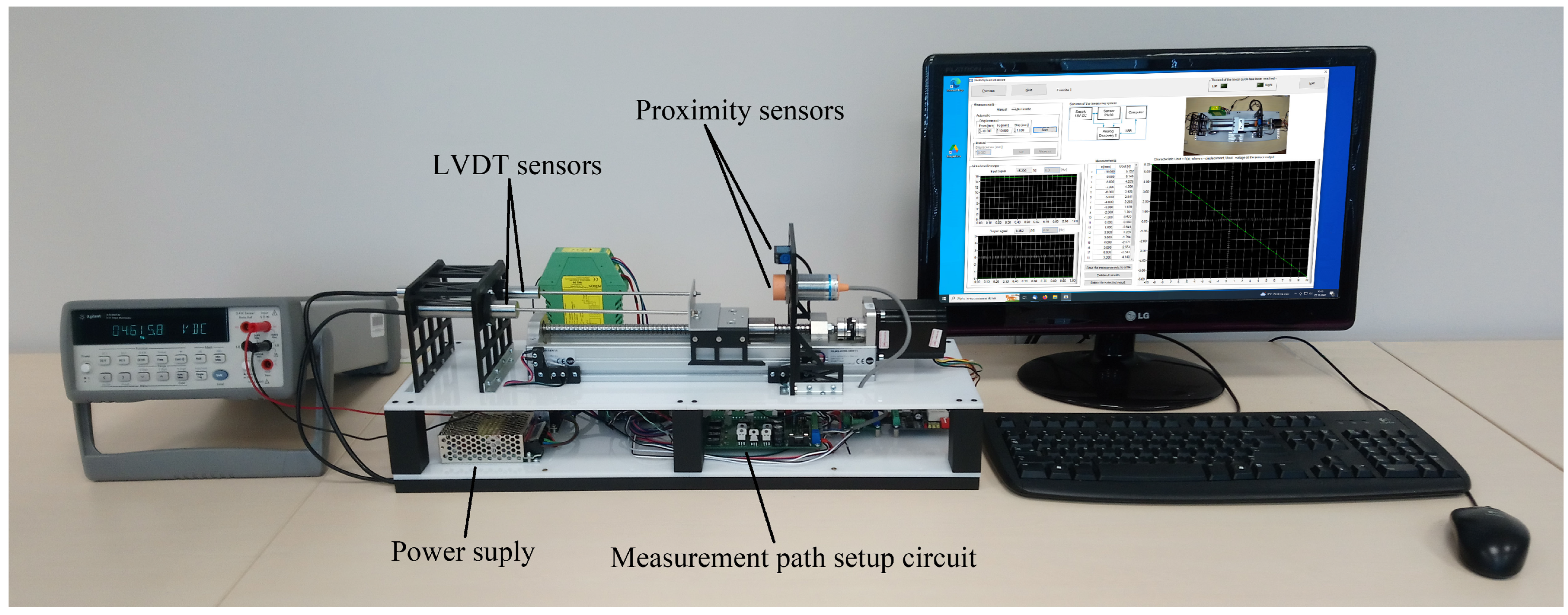

3. Implementation of the Laboratory Stands

3.1. Hardware

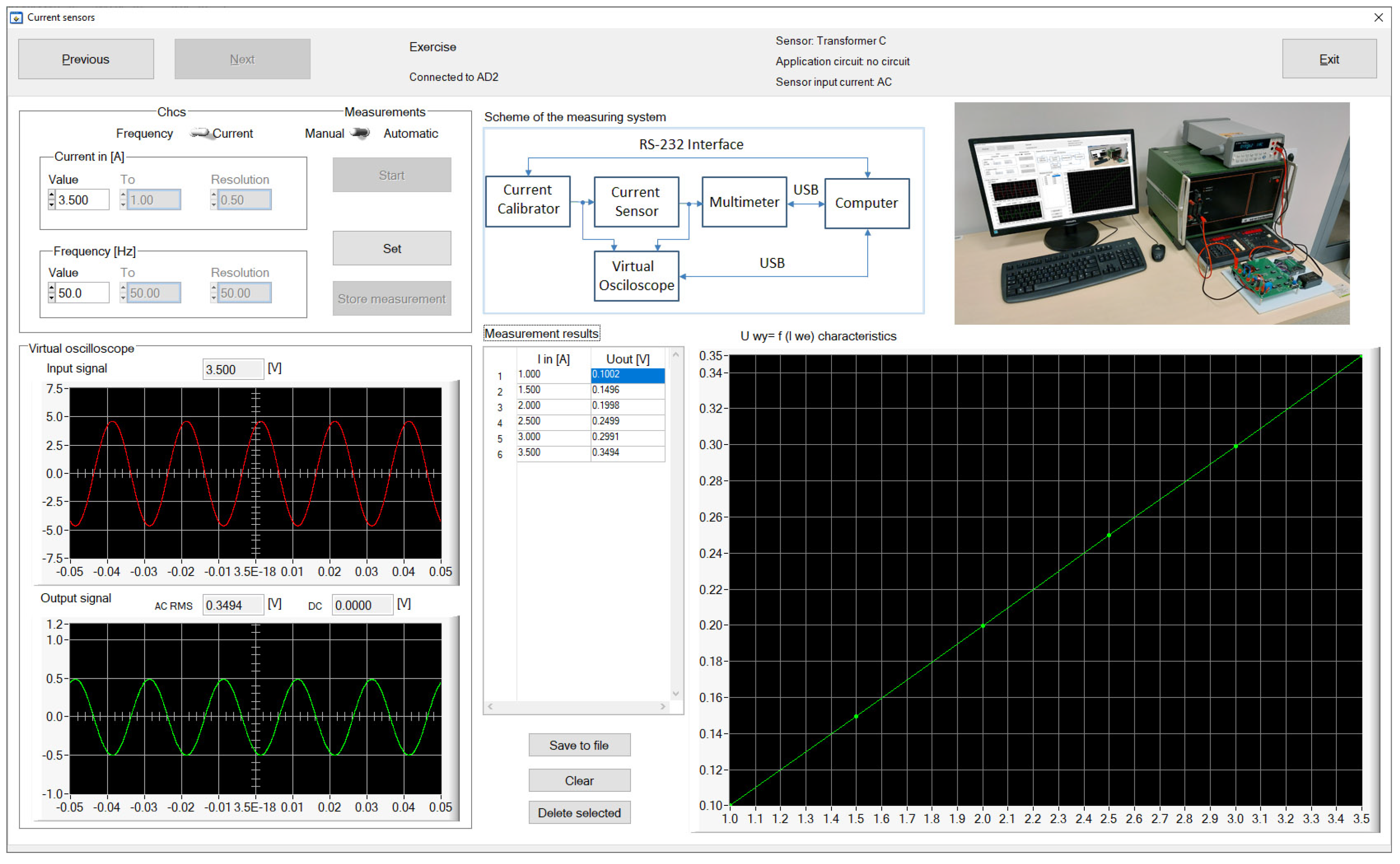

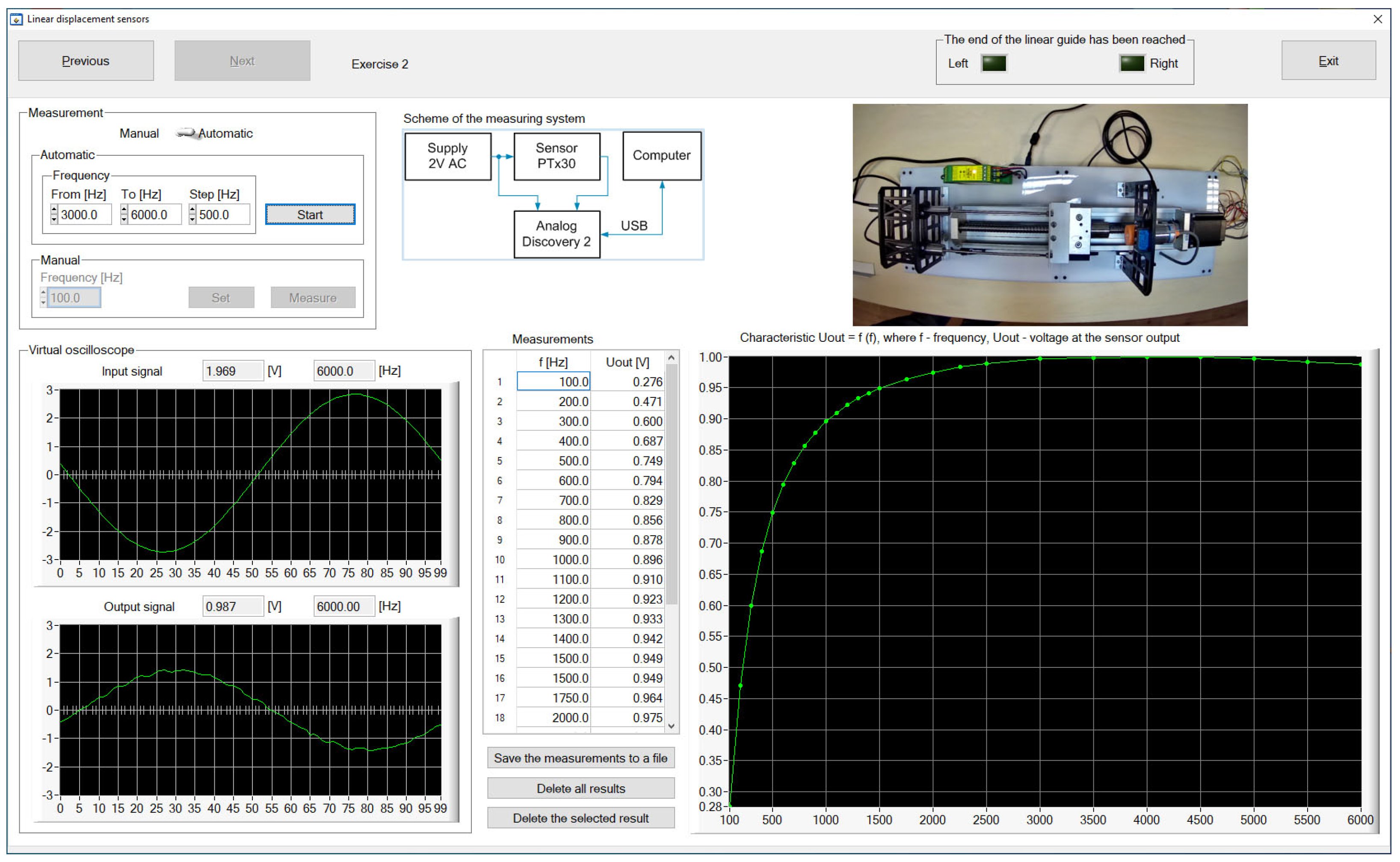

3.2. Software

- System configuration—selection of the sensor for testing, its application system, and measuring instrument;

- System calibration—checking the correct operation of the current source (CSTS) or positioning the linear guide (DSTS);

- Measurements—selection of the test type and measurement mode (manual, automatic).

3.3. Remote Access

3.4. Tests

- The quality of the remote connection;

- The problems with the software application caused by remote work;

- The ergonomics of the user interface of the prepared software;

- The noticed bugs in the operation of the software;

- The comprehensibility of the user interface;

- The clarity of the presented measurement results;

- The ease of recording the measurement results for their later use;

- The improvement in the application functionality.

- Remote work did not cause any difficulties in the operation of the software applications.

- Students did not report any serious bugs in the operation of the applications.

- The applications’ graphical interface needed to be modified due to a poorly chosen function description.

- The method of saving measurements implemented in both applications should be unified and improved.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vanderschuren, M.; Mckune, A. Inteligent Transport Systems. In The Sustainable Transport and Mobility Handbook, The Essential Guide-South Africa Volume 2; van Wyk, L., Ed.; Alive2Green: Cape Town, South Africa, 2011; pp. 117–127. [Google Scholar]

- Directive 2010/40/EU of the European Parliament and of the Council of 7 July 2010 on the framework for the deployment of Intelligent Transport Systems in the field of road transport and for interfaces with other modes of transport. Off. J. Eur. Union 2010, 53, 1–13.

- Heradio, R.; de la Torre, L.; Galan, D.; Cabrerizo, F.J.; Herrera-Viedma, E.; Dormido, S. Virtual and remote labs in education: A bibliometric analysis. Comput. Educ. 2016, 98, 14–38. [Google Scholar] [CrossRef]

- Esqueda-Elizondo, J.J.; Jiménez-Beristáin, L.; Martínez-Verdín, A.S.; Serrano-Trujillo, A. Electronics engineering virtual laboratory for COVID-19 pandemic. J. Comput. Technol. 2021, 5, 12–19. [Google Scholar]

- Todos, P.; Virlan, P.; Tertea, G. Training of Practical Engineering Skills in the Context of the COVID-19 Pandemic. J. Soc. Sci. 2021, 4, 18–27. [Google Scholar] [CrossRef] [PubMed]

- Vergara, D.; Fernández-Arias, P.; Extremera, J.; Dávila, L.P.; Rubio, M.P. Educational trends post COVID-19 in engineering: Virtual laboratories. Mater. Today Proc. 2022, 49, 155–160. [Google Scholar] [CrossRef] [PubMed]

- Isa, I.S.; Abdullah, H.; Kasim, N.M.; Ismail, N.A.; Faiza, Z. Open distance learning simulation-based virtual laboratory experiences during COVID-19 pandemic. Int. J. Electr. Comput. Eng. (IJECE) 2022, 12, 4042–4053. [Google Scholar]

- Valencia de Almeida, F.; Hayashi, V.T.; Arakaki, R.; Midorikawa, E.; de Mello Canovas, S.; Cugnasca, P.S.; Corrêa, P.L.P. Teaching Digital Electronics during the COVID-19 Pandemic via a Remote Lab. Sensors 2022, 22, 6944. [Google Scholar] [CrossRef] [PubMed]

- Jacko, P.; Bereš, M.; Kováčová, I.; Molnár, J.; Vince, T.; Dziak, J.; Fecko, B.; Gans, Š.; Kováč, D. Remote IoT Education Laboratory for Microcontrollers Based on the STM32 Chips. Sensors 2022, 22, 1440. [Google Scholar] [CrossRef] [PubMed]

- Maya, D.; Morkosa, B.; Jackson, A.; Hunsua, N.J.; Ingalls, A.; Beyette, F. Rapid transition of traditionally hands-on labs to online instruction in engineering courses. Eur. J. Eng. Educ. 2022, 1–19. [Google Scholar] [CrossRef]

- Monzo, C.; Cobo, G.; Morán, J.A.; Santamaría, E.; García-Solórzano, D. Remote Laboratory for Online Engineering Education: The RLAB-UOC-FPGA Case Study. Electronics 2021, 10, 1072. [Google Scholar] [CrossRef]

- Chmielewski, T.; Zielińska, K. Survey on Remotely Controlled Laboratories for Research and Education. Appl. Comput. Sci. 2017, 13, 85–96. [Google Scholar] [CrossRef]

- Al-Zahrani, F. Web-Based Learning and Training for Virtual Metrology Lab. J. Telecommun. 2010, 1, 42–54. [Google Scholar]

- Ballua, A.; Yana, X.; Blanchardb, A.; Cletb, T.; Moutonc, S.; Niandoua, H. Virtual metrology laboratory for e-learning. In Proceedings of the 14th CIRP Conference on Computer Aided Tolerancing (CAT), Gothenburg, Sweden, 18–20 May 2016; pp. 148–153. [Google Scholar]

- Gustavsson, I.; Alves, G.; Costa, R.; Nilsson, K.; Zackrisson, J.; Hernandez-Jayo, U.; Garcia-Zubia, J. The VISIR Open Lab Platform 5.0—An architecture for a federation of remote laboratories. In Proceedings of the Remote Engineering and Virtual Instrumentation (REV 2011) Congress, Brasov, Romania, 29 June–2 July 2011. [Google Scholar]

- Orduña, P.; Sancristobal, E.; Emaldi, M.; Castro, M.; López-de-Ipiña, D.; Garcia-Zubia, J. Modelling remote laboratories integrations in e-learning tools through remote laboratories federation protocols. In Proceedings of the 2012 Frontiers in Education (FIE) Conference, Seattle, WA, USA, 3–6 October 2012; pp. 1–6. [Google Scholar]

- Orduña, P.; Larrakoetxea, X.; Buján, D.; Angulo, I.; Dziabenko, O.; Rodriguez-Gil, L.; López-de-Ipiña, D.; García-Zubia, J. WebLab-Deployer: Exporting remote laboratories as SaaS through federation protocols. In Proceedings of the 10th International Conference on Remote Engineering and Virtual Instrumentation (REV), Sydney, Australia, 6–8 February 2013; pp. 1–5. [Google Scholar]

- ReLabEMA Project Web Site. Available online: http://www.relabema.imei.uz.zgora.pl/en/ (accessed on 10 October 2022).

- Ferreira, J.M.M.; Alves, G.R.C.; Costa, R.; Hine, N. Collaborative Learning in a Web-Accessible Workbench. In Proceedings of the 8th International Workshop, CRIWG 2002, La Serena, Chile, 1–4 September 2002; pp. 25–34. [Google Scholar]

- Gustavsson, I.; Zackrisson, J.; Åkesson, H.; Håkansson, L.; Claesson, I.; Lagö, T. Remote Operation and Control of Traditional Laboratory Equipment. Int. J. Online Eng. (IJOE) 2006, 2, 1–8. [Google Scholar]

- Tripathi, P.K.; Mohan, J.M.; Gangadharan, K.V. Design and Implementation of Web based Remote Laboratory for Engineering Education. Int. J. Eng. Technol. 2012, 2, 270–278. [Google Scholar]

- Mejías Borrero, A.; Márquez Sánchez, M.A.; Andújar Márquez, J.M.; Sánchez Herrera, M.R. A Complete Solution for Developing Remote Labs. In Proceedings of the 10th IFAC Symposium Advances in Control Education, Sheffield, UK, 28–30 August 2013; pp. 96–101. [Google Scholar]

- Zapata Rivera, L.F.; Larrondo-Petrie, M.M.; Ribeiro Da Silva, L. Implementation of cloud-based smart adaptive remote laboratories for education. In Proceedings of the 2017 Frontiers in Education (FIE) Conference, Indianapolis, IN, USA, 18–21 October 2017; pp. 1–5. [Google Scholar]

- Letowski, B.; Lavayssière, C.; Larroque, B.; Schröder, M.; Luthon, F. A Fully Open Source Remote Laboratory for Practical Learning. Electronics 2020, 9, 1832. [Google Scholar] [CrossRef]

- Azad, A.K.M. Design and Development of Remote Laboratories with Internet of Things Setting. Adv. Internet Things 2021, 11, 95–112. [Google Scholar] [CrossRef]

- Samuelsen, D.A.H.; Graven, O.H. Assessment Of The Quality Of Low Cost Data Acquisition Equipment For Remote Lab Setups. In Proceedings of the 10th International Conference on Remote Engineering and Virtual Instrumentation (REV 2013), Sydney, Australia, 6–8 February 2013; pp. 82–87. [Google Scholar]

- Almarshoud, A.F. The advancement in using remote laboratories in electrical engineering education: A review. Eur. J. Eng. Educ. 2011, 36, 425–433. [Google Scholar] [CrossRef]

- Sancristobal, E.; Castro, M.; Martin, S.; Tawkif, M.; Pesquera, A.; Gil, R.; Díaz, G.; Peire, J. Remote Labs as Learning Services in the Educational Arena. In Proceedings of the 2011 IEEE Global Engineering Education Conference (EDUCON), Amman, Jordan, 4–10 April 2011; pp. 1189–1194. [Google Scholar]

- Ak, A.; Topuz, V.; Altıkardeş, A.; Oral, B. Development of a Remote Laboratory Infrastructure and LMS for Mechatronics Distance Education. EURASIA J. Math. Sci. Technol. Educ. 2018, 14, 2493–2508. [Google Scholar] [CrossRef] [PubMed]

- Eslami, A.; Williams, A.; Lapat, L.; Krauss, K.; Osareh, A.R. A Remote Control Project to Enhance Undergraduate Students’ Interest and Knowledge in Industrial Automation. In Proceedings of the 2008 IAJC-IJME International Conference, Nashville, TN, USA, 17–19 November 2008. [Google Scholar]

- Beynon-Davies, P.; Carne, C.; Mackay, H.; Tudhope, D. Rapid application development (RAD): An empirical review. Eur. J. Inf. Syst. 1999, 8, 211–223. [Google Scholar] [CrossRef]

| Sensor | Input | Output | Basic | |

|---|---|---|---|---|

| Type | Part No. | Current (A) | Signal | Error (%) |

| Current transformer | TA 100 | 5 | 5 mA | ±1 |

| Open-loop Hall-effect sensor | ACS 712 | 5 | 2.5 ± 0.925 V | ±1.5 |

| Closed-loop Hall-effect sensor | LTS 6-NP | 6 | 2.5 ± 0.625 V | ±0.7 |

| Sensor | Range | Output | Digital | Linearity | |

|---|---|---|---|---|---|

| Type | Part No. | (mm) | Signal (V) | Output | (%) |

| LVDT (AC/AC) | PTx30 | ±30 | 0–1 RMS | – | ≤0.5 |

| LVDT (DC/DC) | PIz20 | ±20 | ±5 | – | ≤0.5 |

| Optical proximity switch | FT20RA-60-F-K4 | 20–80 | 10–0 | PNP/NPN | – |

| Inductive proximity switch | LJ30A3-15-Z-CY | 15 | – | PNP/NPN | – |

| University Name | Country | No. of Students |

|---|---|---|

| Politehnica University of Timisoara | Romania | 4 |

| Silesian University of Technology | Poland | 8 |

| Tallinn University of Technology | Estonia | 5 |

| University of Applied Sciences Mittelhessen | Germany | 4 |

| University of Zielona Góra | Poland | 5 |

| Vilnius Gediminas Technical University | Lithuania | 6 |

| Zespół Szkół Technicznych in Wodzisław Śl. | Poland | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furmankiewicz, L.; Kozioł, M.; Rybski, R.; Szulim, R. Concept and Implementation of Measurement Systems for Stationary and Remote Testing of Sensors for Electrical and Non-Electrical Quantities. Sensors 2023, 23, 1928. https://doi.org/10.3390/s23041928

Furmankiewicz L, Kozioł M, Rybski R, Szulim R. Concept and Implementation of Measurement Systems for Stationary and Remote Testing of Sensors for Electrical and Non-Electrical Quantities. Sensors. 2023; 23(4):1928. https://doi.org/10.3390/s23041928

Chicago/Turabian StyleFurmankiewicz, Leszek, Mirosław Kozioł, Ryszard Rybski, and Robert Szulim. 2023. "Concept and Implementation of Measurement Systems for Stationary and Remote Testing of Sensors for Electrical and Non-Electrical Quantities" Sensors 23, no. 4: 1928. https://doi.org/10.3390/s23041928

APA StyleFurmankiewicz, L., Kozioł, M., Rybski, R., & Szulim, R. (2023). Concept and Implementation of Measurement Systems for Stationary and Remote Testing of Sensors for Electrical and Non-Electrical Quantities. Sensors, 23(4), 1928. https://doi.org/10.3390/s23041928