Precise Measurement and Compensation of the Micro Product of Inertia for Float Assembly in Pendulous Integrating Gyroscopic Accelerometers

Abstract

1. Introduction

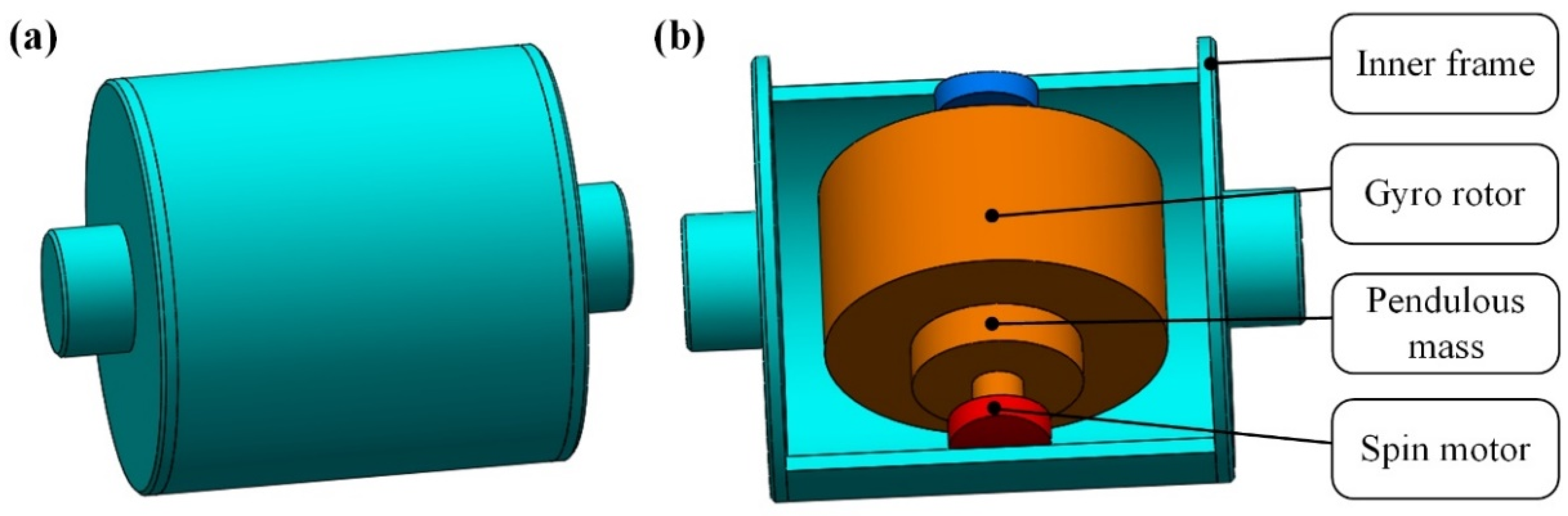

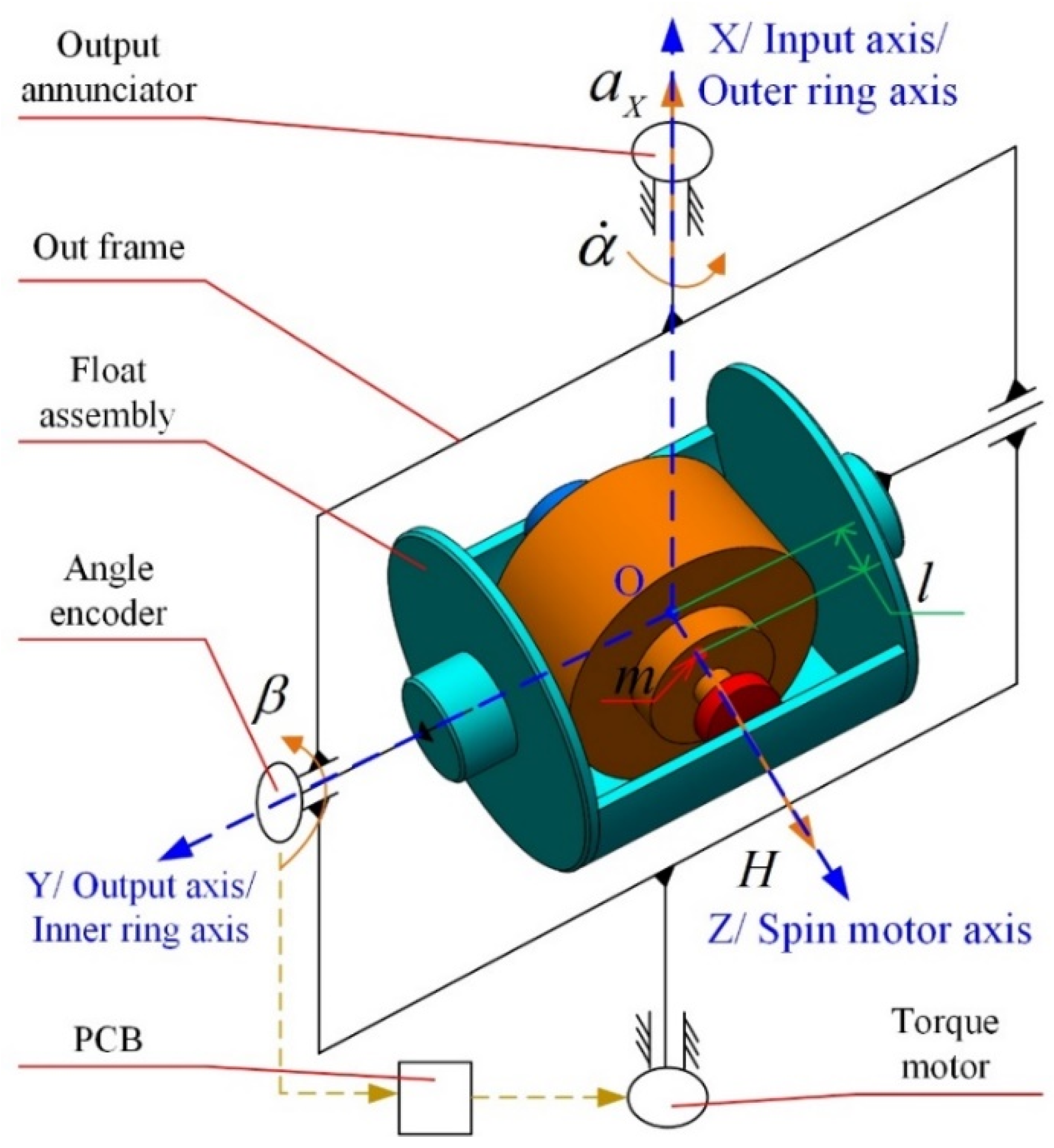

2. Impact of MPOI on PIGA

2.1. Error Analysis

2.2. Source of MPOI

- (1)

- Asymmetry in structural design: for example, the inflation nozzle can be designed at only one end of the float assembly, and the MPOI caused by this asymmetry is 4.2 × 10−10 kg·m2;

- (2)

- Inhomogeneity of material: if there is inhomogeneity in the material in the or axis directions, it will produce an MPOI in the order of 10−9 kg·m2;

- (3)

- Processing error of parts: processing errors such as asymmetry, roundness and concentricity of parts will produce an MPOI; for example, if the asymmetry of the inner frame along the axis is 0.01 mm, the MPOI will be 2 × 10−10 kg·m2;

- (4)

- Assembly error: assembly errors such as fit clearance, installation error and asymmetry of glue coating, for example, the positioning gap deviation in the axis direction, will cause an MPOI which is in the order of 10−9 kg·m2.

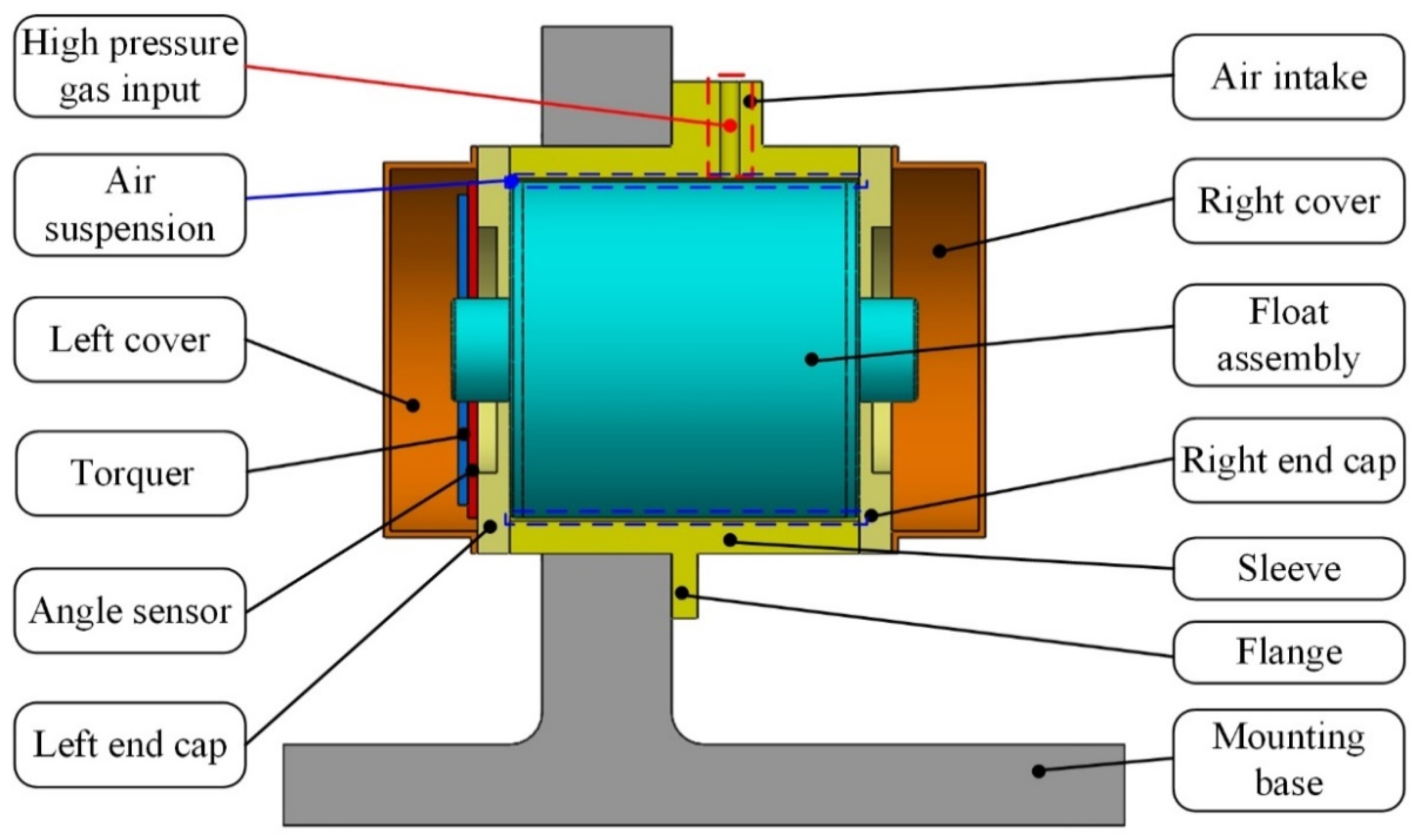

3. Measurement of MPOI

3.1. Measurement Principle

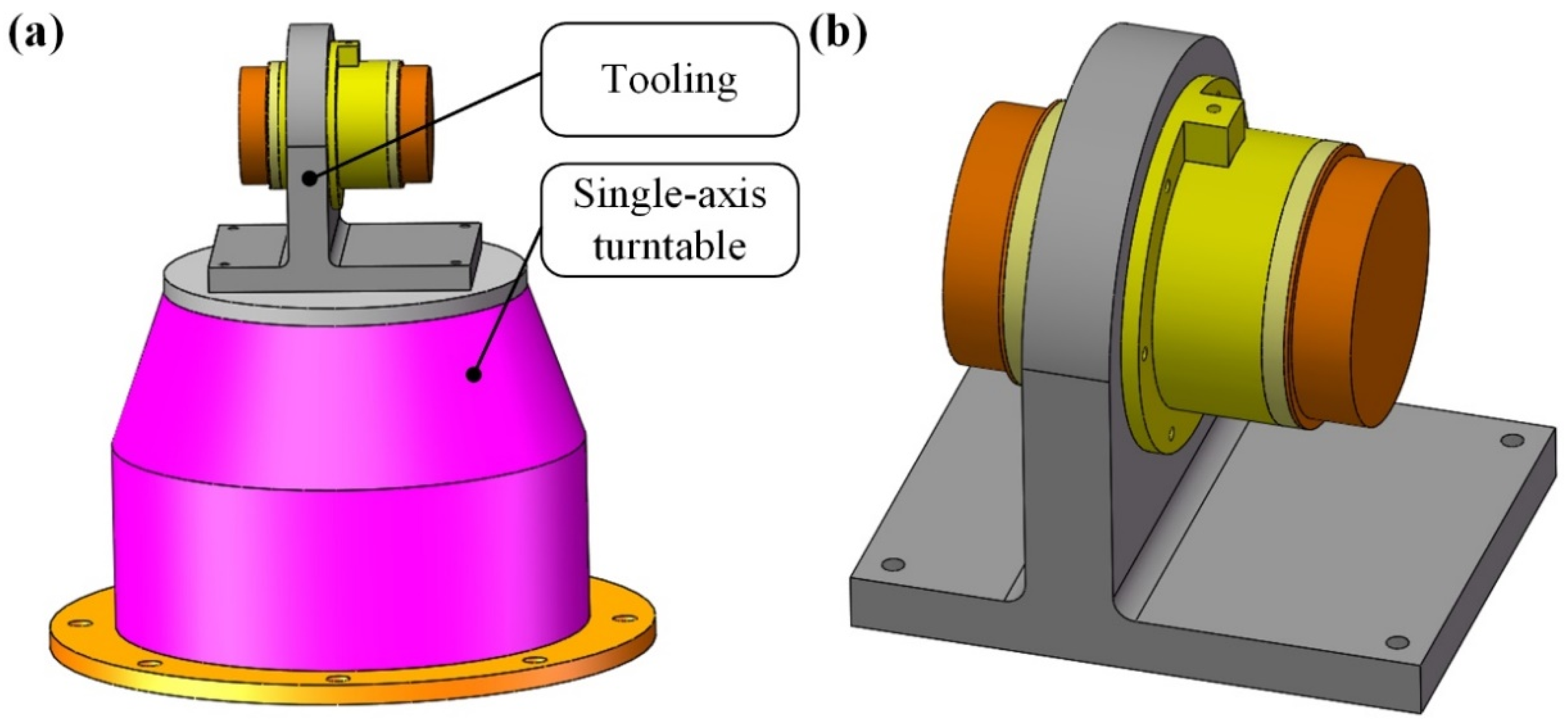

3.2. Equipment of MPOI Measurement

3.3. Measurement Error Analysis

- (1)

- Measurement principle error

- (2)

- Measurement error caused by gravity

- (3)

- Measurement error caused by installation error

- (4)

- Measurement error caused by the support disturbance moment

4. Compensation of MPOI

4.1. Compensation Principle

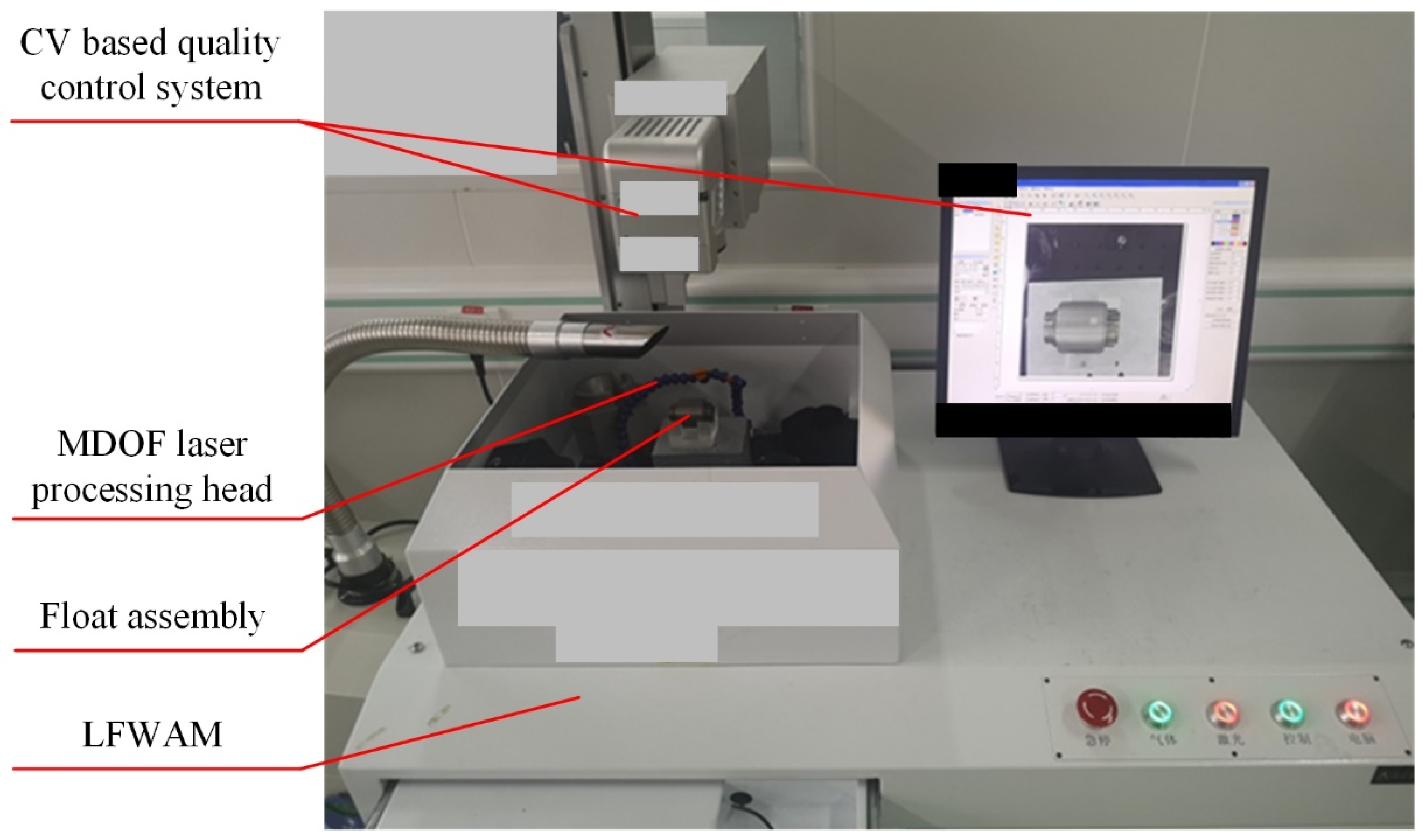

4.2. Compensation Equipment

5. Experimental Validations

5.1. Experimental Validation for Measurement Accuracy

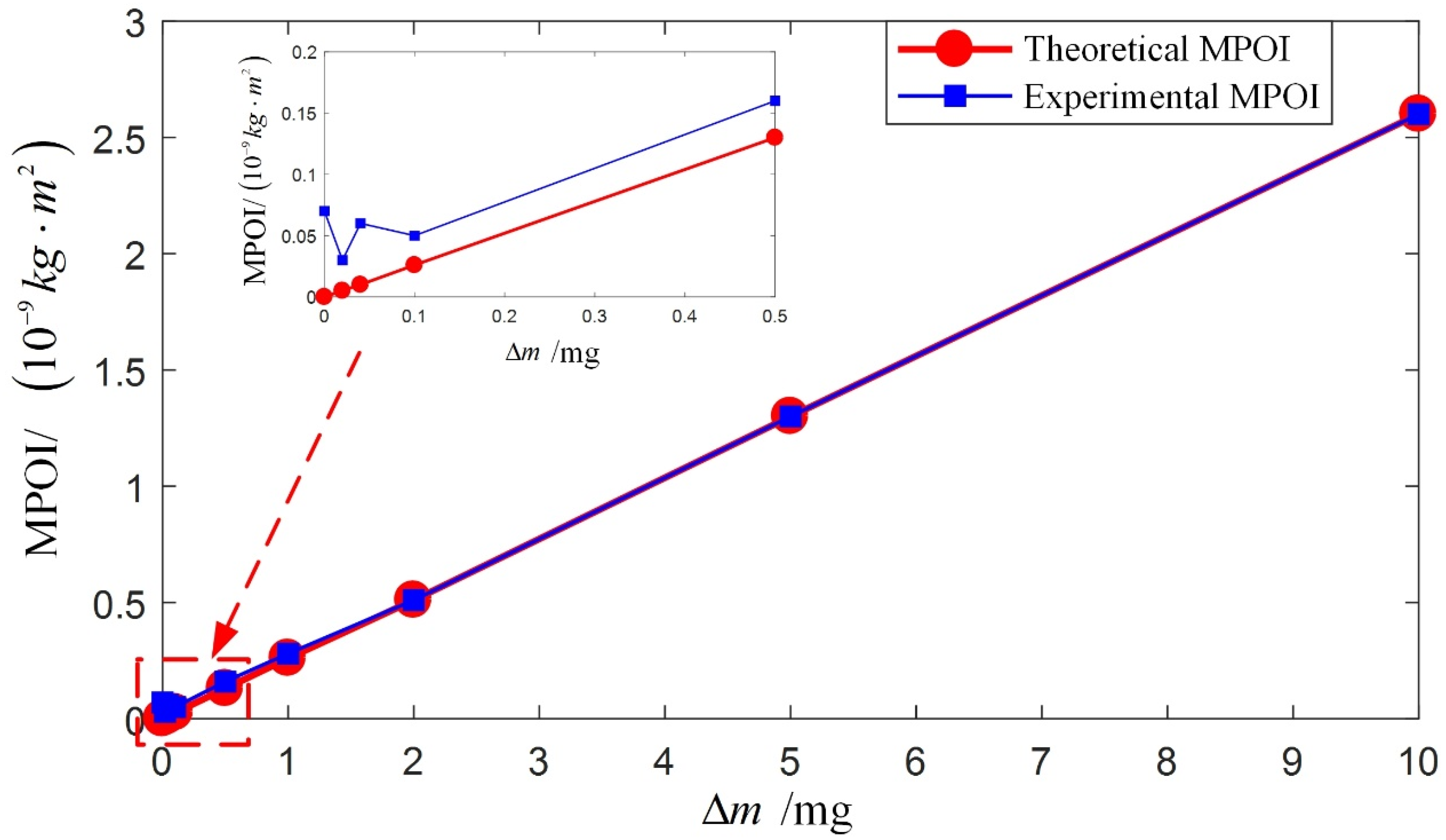

5.2. Experimental Validation for Compensation Accuracy

5.3. Measurement and Compensation of Float Assembly

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cai, Q.; Yang, G.; Quan, W.; Song, N.; Tu, Y.; Liu, Y. Error Analysis of the K-Rb-21Ne Comagnetometer Space-Stable Inertial Navigation System. Sensors 2018, 18, 670. [Google Scholar] [CrossRef]

- Tu, Y.; Yang, G.; Cai, Q.; Wang, L.; Zhou, X. Optimal design of SINS’s Stewart platform bumper for restoration accuracy based on genetic algorithm. Mech. Mach. Theory 2018, 124, 42–54. [Google Scholar] [CrossRef]

- Sun, Y.; Ren, S.; Wang, C. Calibration method of quartz accelerometer on dynamic centrifuge. Chin. J. Aeronaut. 2022, 35, 262–272. [Google Scholar] [CrossRef]

- Zhao, S.; Guo, C.; Ke, C.; Zhou, Y.; Shu, X. Temperature drift compensation of fiber strapdown inertial navigation system based on GSA-SVR. Measurement 2022, 195, 111117. [Google Scholar] [CrossRef]

- He, J.; Zhou, W.; Yu, H.; He, X.; Peng, P. Structural Designing of a MEMS Capacitive Accelerometer for Low Temperature Coefficient and High Linearity. Sensors 2018, 18, 643. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.M.; Hanif, M.U.; Khan, A.; Hassan, M.U.; Javanmardi, A.; Ahmad, A. Damage assessment of reinforced concrete beams using cost-effective MEMS accelerometers. Structures 2022, 41, 602–618. [Google Scholar] [CrossRef]

- Li, C.; Zhao, Y.; Li, B.; Cheng, R.; Sun, D.; Han, C.; Zhao, Y. A micro-machined differential resonance accelerometer based on silicon on quartz method. Sens. Actuators A Phys. 2017, 253, 1–9. [Google Scholar] [CrossRef]

- Fang, Z.; Yin, Y.; Chen, C.; Zhang, S.; Liu, Y.; Han, F. A sensitive micromachined resonant accelerometer for moving-base gravimetry. Sens. Actuators A Phys. 2021, 325, 112694. [Google Scholar] [CrossRef]

- Yuan, Z.; Lu, Y.; Jinyun, Z.; Pei, Y. Specific azimuth self-calibration of PIGA of inertial platform system. In Proceedings of the 2015 IEEE 28th Canadian Conference on Electrical and Computer Engineering (CCECE), Halifax, NS, Canada, 3–6 May 2015; pp. 286–290. [Google Scholar] [CrossRef]

- Haeussermann, W.; Mueller, F.; Hopkins, R. The pendulous integrating gyroscope accelerometer (PIGA) from the V-2 to trident D5, the strategic instrument of choice. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Montreal, QC, Canada, 6–9 August 2001. [Google Scholar] [CrossRef]

- Kang, Y.; Zhao, L.; Cheng, J.; Wu, M.; Fan, X. A Novel Grid SINS/DVL Integrated Navigation Algorithm for Marine Application. Sensors 2018, 18, 364. [Google Scholar] [CrossRef]

- Cai, Q.; Quan, W.; Xing, L.; Yang, G.; Song, N.; Tu, Y. Research on case rotating modulation for nuclear-spin comagnetometer in space-stable INS. Measurement 2019, 140, 388–394. [Google Scholar] [CrossRef]

- Tu, Y.; Yang, G.; Cai, Q.; Wang, L.; Yin, H. Dynamical analysis and experimental verification of deviation angles caused by rubber dampers deformation in high precision mechanically dithered RLG dual-axis RINS. Mech. Syst. Signal Process. 2019, 126, 553–567. [Google Scholar] [CrossRef]

- Kaiser, T.J.; Allen, M.G. A pendulous oscillating gyroscopic accelerometer fabricated using deep-reactive ion etching. J. Microelectromech. Syst. 2003, 12, 21–28. [Google Scholar] [CrossRef]

- Wei, Y.; Yang, J.; Li, P.; Zhang, X.; Liang, P. Analysis and Optimization Method of the Vibration Rectification Error of a Pendulous Accelerometer. IEEE Sens. J. 2021, 21, 19847–19856. [Google Scholar] [CrossRef]

- Ren, S.; Wang, Y.; Cheng, Y.; Chen, S. Testing error analysis of accelerometer error model coefficients on indexing table. In Proceedings of the Sixth International Symposium on Precision Engineering Measurements and Instrumentation, Hangzhou, China, 8–10August 2010; p. 75445B. [Google Scholar] [CrossRef]

- Coulter, J.; Meehan, J. Test methodology for evaluation of the input axis of a Pendulous Integrating Gyro Accelerometer. In Proceedings of the Guidance and Control Conference, Albuquerque, NM, USA, 19–21 August 1981. [Google Scholar] [CrossRef]

- Xu, F.; Lu, Z.; Zhang, J. Study total least squares method compensate the test error of testing PIGA. In Proceedings of the 2010 Chinese Control and Decision Conference, Xuzhou, China, 26–28 May 2010; pp. 3280–3283. [Google Scholar] [CrossRef]

- Xu, F.; Lu, Z.; Dai, X. The application of total least squares method in the error model identification of PIGA. In Proceedings of the 2010 3rd International Symposium on Systems and Control in Aeronautics and Astronautics, Harbin, China, 8–10 June 2010; pp. 406–409. [Google Scholar] [CrossRef]

- Tkachuk, A.; Bezvesilna, O.; Dobrzhansky, O.; Ostapchuk, A. Single-rotor integrating gyroscopic gravimeter. J. Phys. Conf. Ser. 2021, 1840, 012023. [Google Scholar] [CrossRef]

- Kaiser, T.J. A micromachined pendulous oscillating gyroscopic accelerometer; In Proceedings of the Solid-State Sensors, Actuators, and Microsystems Workshop, Hilton Head Island, Beaufort, 4–8 June 2000. [CrossRef]

- Wang, S.; Ren, S. Calibration of cross quadratic term of gyro accelerometer on centrifuge and error analysis. Aerosp. Sci. Technol. 2015, 43, 30–36. [Google Scholar] [CrossRef]

- Ren, S.Q.; Sun, C. A New Method for Calibrating Nonlinear Coefficients of PIGA on Linear Vibrator. IEEE Trans. Instrum. Meas. 2019, 68, 2898–2906. [Google Scholar] [CrossRef]

- Sun, C.; Ren, S.Q.; Zeng, M.; Wang, C.H.; Huo, R. Sequential Calibration Method of Nonlinear Errors of PIGA on Counter-Rotating Platform Centrifuge. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Sun, C.; Ren, S.Q.; Cao, J.; Huo, R. Symmetric calibration method of pendulous Integrating Gyroscopic accelerometer on centrifuge. Measurement 2022, 200, 111685. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, S.; Yang, G.; Zhou, X.; Liu, H. An Improved Online Self-Calibration Method Utilizing Angular Velocity Observation for Ultra High Accuracy PIGA-Based IMU. Sensors 2022, 22, 8136. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, G.; Niu, W.; Tu, Y. Analysis and Suppression of Nonlinear Error of Pendulous Integrating Gyroscopic Accelerometer at Instrument Level. Sensors 2023, 23, 1221. [Google Scholar] [CrossRef]

- Hou, Z.-C.; Lu, Y.-n.; Lao, Y.-x.; Liu, D. A new trifilar pendulum approach to identify all inertia parameters of a rigid body or assembly. Mech. Mach. Theory 2009, 44, 1270–1280. [Google Scholar] [CrossRef]

- Bacaro, M.; Cianetti, F.; Alvino, A. Device for measuring the inertia properties of space payloads. Mech. Mach. Theory 2014, 74, 134–153. [Google Scholar] [CrossRef]

- Brancati, R.; Russo, R.; Savino, S. Method and equipment for inertia parameter identification. Mech. Syst. Signal Process. 2010, 24, 29–40. [Google Scholar] [CrossRef]

- Barreto, J.P.; Muñoz, L.E. Low uncertainty method for inertia tensor identification. Mech. Syst. Signal Process. 2016, 68–69, 207–216. [Google Scholar] [CrossRef]

- Fakhari, V.; Shokrollahi, S. A theoretical and experimental disturbance analysis in a product of inertia measurement system. Measurement 2017, 107, 142–152. [Google Scholar] [CrossRef]

- Olmedo, N.A.; Barczyk, M.; Lipsett, M. Experimental determination of the inertial properties of small robotic systems using a torsion platform. Mech. Syst. Signal Process. 2019, 131, 71–96. [Google Scholar] [CrossRef]

- Li, T.; Shangguan, W.-B.; Yin, Z. Error analysis of inertia parameters measurement for irregular-shaped rigid bodies using suspended trifilar pendulum. Measurement 2021, 174, 108956. [Google Scholar] [CrossRef]

- El-Sheimy, N.; Youssef, A. Inertial sensors technologies for navigation applications: State of the art and future trends. Satell. Navig. 2020, 1, 2. [Google Scholar] [CrossRef]

| Experiment Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Measured MPOI (kg·m2) | 0.7 × 10−10 | 1.3 × 10−10 | −0.9 × 10−10 | 0.5 × 10−10 | −0.3 × 10−10 | −0.5 × 10−10 |

| Experiment Number | Removed Mass (mg) | Theoretical MPOI (kg·m2) | Experimental MPOI (kg·m2) |

|---|---|---|---|

| 1 | 0 | 0 | 0.7 × 10−10 |

| 2 | 0.02 | 5.1 × 10−12 | 0.3 × 10−10 |

| 3 | 0.04 | 1.0 × 10−11 | 0.6 × 10−10 |

| 4 | 0.1 | 2.6 × 10−11 | 0.5 × 10−10 |

| 5 | 0.5 | 1.3 × 10−10 | 1.6 × 10−10 |

| 6 | 1 | 2.6 × 10−10 | 2.8 × 10−10 |

| 7 | 2 | 5.1 × 10−10 | 5.1 × 10−10 |

| 8 | 5 | 1.3 × 10−9 | 1.3 × 10−9 |

| 9 | 10 | 2.6 × 10−9 | 2.6 × 10−9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Yang, G.; Niu, W.; Tu, Y. Precise Measurement and Compensation of the Micro Product of Inertia for Float Assembly in Pendulous Integrating Gyroscopic Accelerometers. Sensors 2023, 23, 1564. https://doi.org/10.3390/s23031564

Zhou X, Yang G, Niu W, Tu Y. Precise Measurement and Compensation of the Micro Product of Inertia for Float Assembly in Pendulous Integrating Gyroscopic Accelerometers. Sensors. 2023; 23(3):1564. https://doi.org/10.3390/s23031564

Chicago/Turabian StyleZhou, Xiaojun, Gongliu Yang, Wentao Niu, and Yongqiang Tu. 2023. "Precise Measurement and Compensation of the Micro Product of Inertia for Float Assembly in Pendulous Integrating Gyroscopic Accelerometers" Sensors 23, no. 3: 1564. https://doi.org/10.3390/s23031564

APA StyleZhou, X., Yang, G., Niu, W., & Tu, Y. (2023). Precise Measurement and Compensation of the Micro Product of Inertia for Float Assembly in Pendulous Integrating Gyroscopic Accelerometers. Sensors, 23(3), 1564. https://doi.org/10.3390/s23031564