The Rapid Identification and Evaluation of the Resonant Noise of a Cooling Module Based on the Frequency Difference Sensitivity Method

Abstract

:1. Introduction

2. Noise Identification and Evaluation Theory Based on Frequency Difference Sensitivity Method

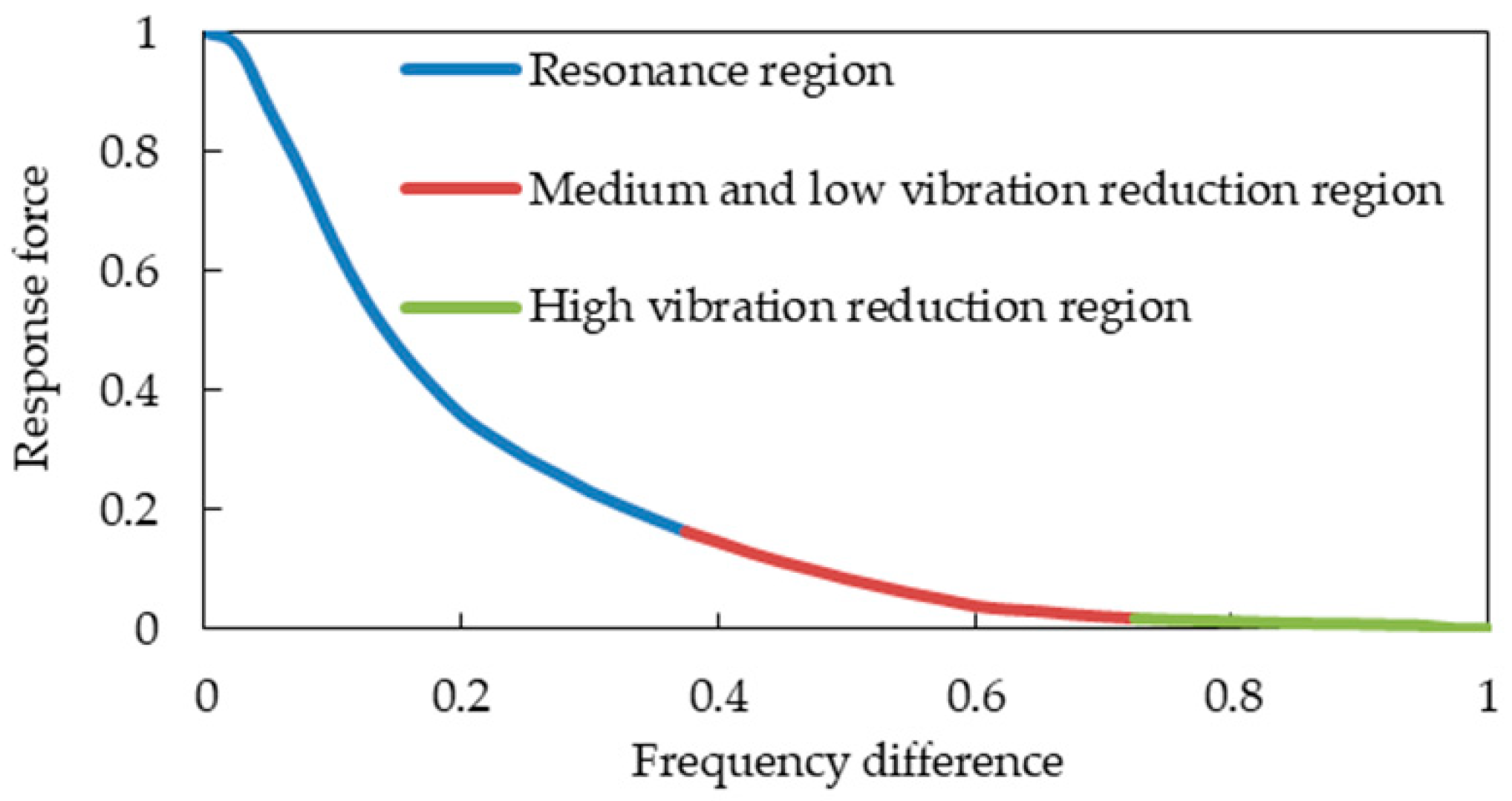

2.1. Noise Identification Based on the Frequency Difference Sensitivity Method

2.2. Noise Evaluation Based on Frequency Difference Sensitivity Method

3. Noise Identification and Evaluation Accuracy Based on the Frequency Difference Sensitivity Method

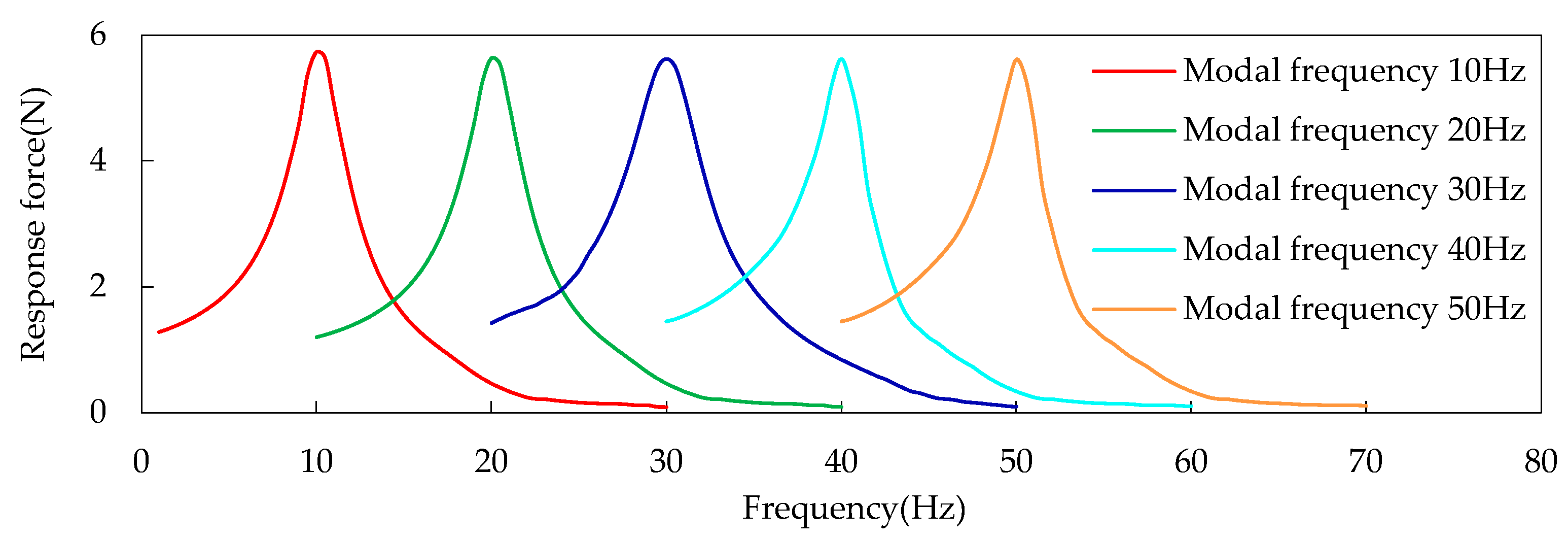

3.1. Simulation Analysis

3.2. Trial Verification

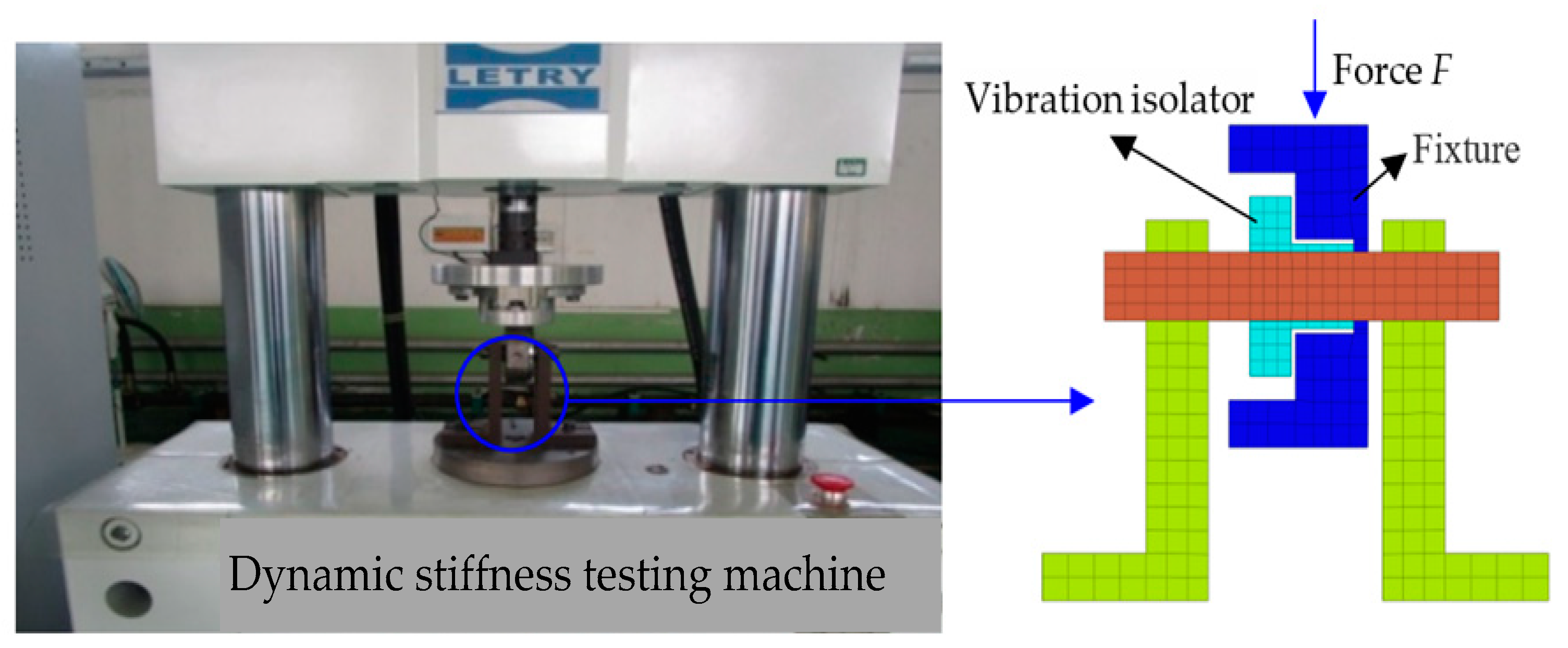

3.2.1. Method of Obtaining Exciting Force

3.2.2. Acquisition Method of Response Force

3.3. Analysis of Noise Identification Accuracy Based on the Frequency Difference Sensitivity Method

3.4. Precision Analysis of Noise Evaluation Based on the Frequency Difference Sensitivity Method

4. Noise Identification and Evaluation Effect Based on Frequency Difference Sensitivity Method

5. Conclusions

- (1)

- The frequency difference sensitivity method proposed herein was applied to identify the resonant noise of a vehicle cooling module. A theoretical model for identifying the resonant noise amplification of a vehicle cooling module was established. The results show that the prediction error of this model is less than 5%.

- (2)

- The frequency difference sensitivity method proposed herein was applied to evaluate the resonant noise of a vehicle cooling module. A theoretical model for evaluating the improved resonant noise reduction effect of a vehicle cooling module was established. The results show that the prediction error of this model is less than 5%.

- (3)

- The interior noise amplified by the cooling module’s mode resonance was taken as an example to verify the high efficiency and practical effectiveness of the frequency difference sensitivity method proposed in this paper. Comparisons between the frequency difference sensitivity method and the conventional method were made. Our research shows that the energy amplification factor from the fan to the passive end of the cooling module can be predicted using the frequency difference sensitivity method more efficiently, meeting accuracy requirements. The quantized noise reduction effect achieved by the improvement scheme adopted herein can be predicted and evaluated more efficiently, also meeting accuracy requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mo, J.O.; Choi, J.H. Numerical investigation of unsteady flow and aerodynamic noise characteristics of an automotive axial cooling fan. Appl. Sci. 2020, 10, 5432–5448. [Google Scholar] [CrossRef]

- Sun, H.J.; Yu, G.Y.; Dai, W.; Zhang, L.M.; Luo, E. Dynamic and thermodynamic characterization of a resonance tube-coupled free-piston Stirling engine-based combined cooling and power system. Appl. Energy 2022, 322, 119437–119448. [Google Scholar] [CrossRef]

- Wang, X.D.; Hu, A.; Hu, L.; Tu, Q.R.; Li, Y.R.; Wu, Z.W. Experimental investigation of added mass and damping on model of sink roll in fluid media. J. Mech. Eng. 2020, 56, 235–243. [Google Scholar]

- Guan, Q.H.; Zhou, Y.M.; Li, W.; Wen, Z.F.; Jin, X.S. Study on the P2 Resonance Frequency of Vehicle Track System. J. Mech. Eng. 2019, 55, 118–127. [Google Scholar] [CrossRef]

- You, T.W.; Zhou, J.S.; Gong, D. Shi; S.Y. Research on local vibration control of high-speed EMU floor. J. Mech. Eng. 2021, 57, 140–147. [Google Scholar]

- Mo, S.; Zhang, Y.X.; Luo, B.R.; Bao, H.Y.; Cen, G.J.; Huang, Y.S. The global behavior evolution of non-orthogonal face gear-bearing transmission system. Mech. Mach. Theory 2022, 175, 104969. [Google Scholar] [CrossRef]

- Zeng, Y.S.; Qi, X.; Yao, Z.F.; Wang, J.Z.; Wang, Y.W.; Wang, F.J. Experimental investigation on damping characteristics of a vibrating hydrofoil in low-order modes. J. Mech. Eng. 2022, 58, 108–118. [Google Scholar]

- Ge, S.; Cheng, G.; Sheng, X.Z.; Shi, J.W. Analysis of the influence of rotation on the noise reduction effect of damped wheels. J. Mech. Eng. 2021, 57, 164–173. [Google Scholar]

- Xiao, W.Q.; Chen, H.; Xu, Z.H.; Wang, X.M.; Jian, S.S.; Pan, D.K. Study on the Vibration Reduction of Internal Combustion EMU Powerpack Frame under Multiple Loading Conditions Based on Particle Damping. J. Mech. Eng. 2022, 58, 250–257. [Google Scholar]

- Jacobson, K.E.; Kiviaho, J.F.; Kennedy, G.J.; Smith, M.J. Evaluation of time-domain damping identification methods for flutter-constrained optimization. J. Fluids Struct. 2019, 87, 174–188. [Google Scholar] [CrossRef]

- Zhong, Y.H.; Li, Y.N.; Gao, F. Optimization of Vehicle Fan Noise Based on Transfer Path Trial and Analysis. J. Vib. Meas. Diagn. 2020, 40, 689–695. [Google Scholar]

- Lin, S.; Zhong, C.P.; Du, M.S.; Xu, G.X.; Gao, Y.N.; Xu, W.J. Analysis and optimization of 2nd-order vibration of a vehicle at idle speed. Mach. Des. Manuf. Eng. 2022, 51, 81–85. [Google Scholar]

- Huang, H.B.; Huang, X.R.; Ding, W.P.; Yang, M.L.; Yu, X.Y.; Pang, J. Vehicle vibro-acoustical comfort optimization using a multi-objective interval analysis method. Expert Syst. Appl. 2023, 213, 119001–119015. [Google Scholar] [CrossRef]

- Kalita, B.; Dwivedy, S.K. Nonlinear dynamics of a parametrically excited pneumatic artificial muscle (PAM) actuator with simultaneous resonance condition. Mech. Mach. Theory 2019, 135, 281–297. [Google Scholar] [CrossRef]

- Rossi, A.; Botta, F.; Giovannelli, A.; Belfiore, N.P. A novel approach to reduce fan rotor blades stress in case of resonance due to inlet flow distortion by means of piezoelectric actuators. J. Sound Vib. 2023, 548, 117552–117568. [Google Scholar] [CrossRef]

- Liu, H.L.; Zhang, Z.Y.; Li, B.T.; Xie, M.X.; Hong, J.; Zheng, S. Topology optimization of high frequency vibration problems using the EFEM-based approach. Thin-Walled Struct. 2021, 160, 107324–107336. [Google Scholar] [CrossRef]

- Zhu, H.M.; Chen, W.F.; Zhu, R.P.; Zhang, L.; Gao, J.; Liao, M.J. Dynamic analysis of a flexible rotor supported by ball bearings with damping rings based on FEM and lumped mass theory. J. Cent. South Univ. 2020, 27, 3684–3701. [Google Scholar] [CrossRef]

- Wang, P.F.; Yang, Y.; Ma, H.; Xu, H.Y.; Li, X.; Luo, Z.; Wen, B.C. Vibration characteristics of rotor-bearing system with angular misalignment and cage fracture: Simulation and experiment. Mech. Syst. Signal Process. 2023, 182, 109545–109558. [Google Scholar] [CrossRef]

- Pavan, G.; Anand, P. Prediction of sound transmission loss of cylindrical acoustic enclosure using statistical energy analysis and its experimental validation. J. Vib. Control 2022, 151, 544–560. [Google Scholar]

- Ding, J.K.; Wang, Y.; Qin, Y.; Tang, B.P. Deep time–frequency learning for interpretable weak signal enhancement of rotating machineries. Eng. Appl. Artif. Intell. 2023, 124, 106598–106614. [Google Scholar] [CrossRef]

- Chen, B.; Peng, F.; Wang, H.; Yu, Y. Compound fault identification of rolling element bearing based on adaptive resonant frequency band extraction. Mech. Mach. Theory 2020, 154, 104051–104067. [Google Scholar] [CrossRef]

| Modal Frequency (Hz) | Frequency Difference (Hz) | Frequency Difference (Normalization) | Response Force (Normalization) | ||

|---|---|---|---|---|---|

| Theory | Simulation | Trial | |||

| 40 | 0 | 0 | 1.052 | 1 | 1 |

| 38.5 | 1.5 | 0.075 | 0.740 | 0.752 | 0.772 |

| Scheme | Modal Frequency (Hz) | Frequency Difference (Hz) | Frequency Difference (Normalization) | Response Force (Normalization) | |

|---|---|---|---|---|---|

| Theory | Simulation | ||||

| Original state | 40 | 0 | 0 | 1.052 | 1 |

| Cut off bottom right vibration pad | 38.5 | 1.5 | 0.075 | 0.740 | 0.752 |

| Cut off bottom left vibration pad | 37.5 | 2.5 | 0.125 | 0.570 | 0.585 |

| Cut off top right vibration pad | 36.5 | 3.5 | 0.175 | 0.431 | 0.452 |

| Cut off top left vibration pad | 35.5 | 4.5 | 0.225 | 0.322 | 0.345 |

| Scheme | Frequency Difference (Hz) | Frequency Difference (Normalization) | Noise Reduction (dB (A)) | ||

|---|---|---|---|---|---|

| Theory | Simulation | Trial | |||

| Improvement effect | 1.5 | 0.075 | 3.8 | 3.2 | 3.0 |

| Scheme | Frequency Difference (Hz) | Frequency Difference (Normalization) | Noise Reduction (dB (A)) | ||

|---|---|---|---|---|---|

| Theory | Simulation | Trial | |||

| Cut off bottom right vibration pad | 1.5 | 0.075 | 3.8 | 3.2 | 3.0 |

| Cut off bottom left vibration pad | 2.5 | 0.125 | 6.5 | 6.0 | 5.8 |

| Cut off top right vibration pad | 3.5 | 0.175 | 9.4 | 8.8 | 8.5 |

| Cut off top left vibration pad | 4.5 | 0.225 | 12.4 | 11.7 | 11.2 |

| State Description | Y-Dynamic Stiffness (N/mm) | Natural Frequency of the Cooling Module (Hz) | |

|---|---|---|---|

| Top Vibration Pad | Bottom Vibration Pad | ||

| Original state | 135 | 157 | 40.1 |

| After improvement | 89 | 103 | 32.5 |

| Predicted Value of Single Fan | Measured Value of Single Fan Working | Test Value in Idle Conditions with Air Conditioning |

|---|---|---|

| 19.0 | 19.6 | 19.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, Y.; Li, Y. The Rapid Identification and Evaluation of the Resonant Noise of a Cooling Module Based on the Frequency Difference Sensitivity Method. Sensors 2023, 23, 9568. https://doi.org/10.3390/s23239568

Zhong Y, Li Y. The Rapid Identification and Evaluation of the Resonant Noise of a Cooling Module Based on the Frequency Difference Sensitivity Method. Sensors. 2023; 23(23):9568. https://doi.org/10.3390/s23239568

Chicago/Turabian StyleZhong, Yinhui, and Yinong Li. 2023. "The Rapid Identification and Evaluation of the Resonant Noise of a Cooling Module Based on the Frequency Difference Sensitivity Method" Sensors 23, no. 23: 9568. https://doi.org/10.3390/s23239568

APA StyleZhong, Y., & Li, Y. (2023). The Rapid Identification and Evaluation of the Resonant Noise of a Cooling Module Based on the Frequency Difference Sensitivity Method. Sensors, 23(23), 9568. https://doi.org/10.3390/s23239568