The Challenges and Advantages of Distributed Fiber Optic Strain Monitoring in and on the Cementitious Matrix of Concrete Beams

Abstract

:1. Introduction

2. Experimental Program

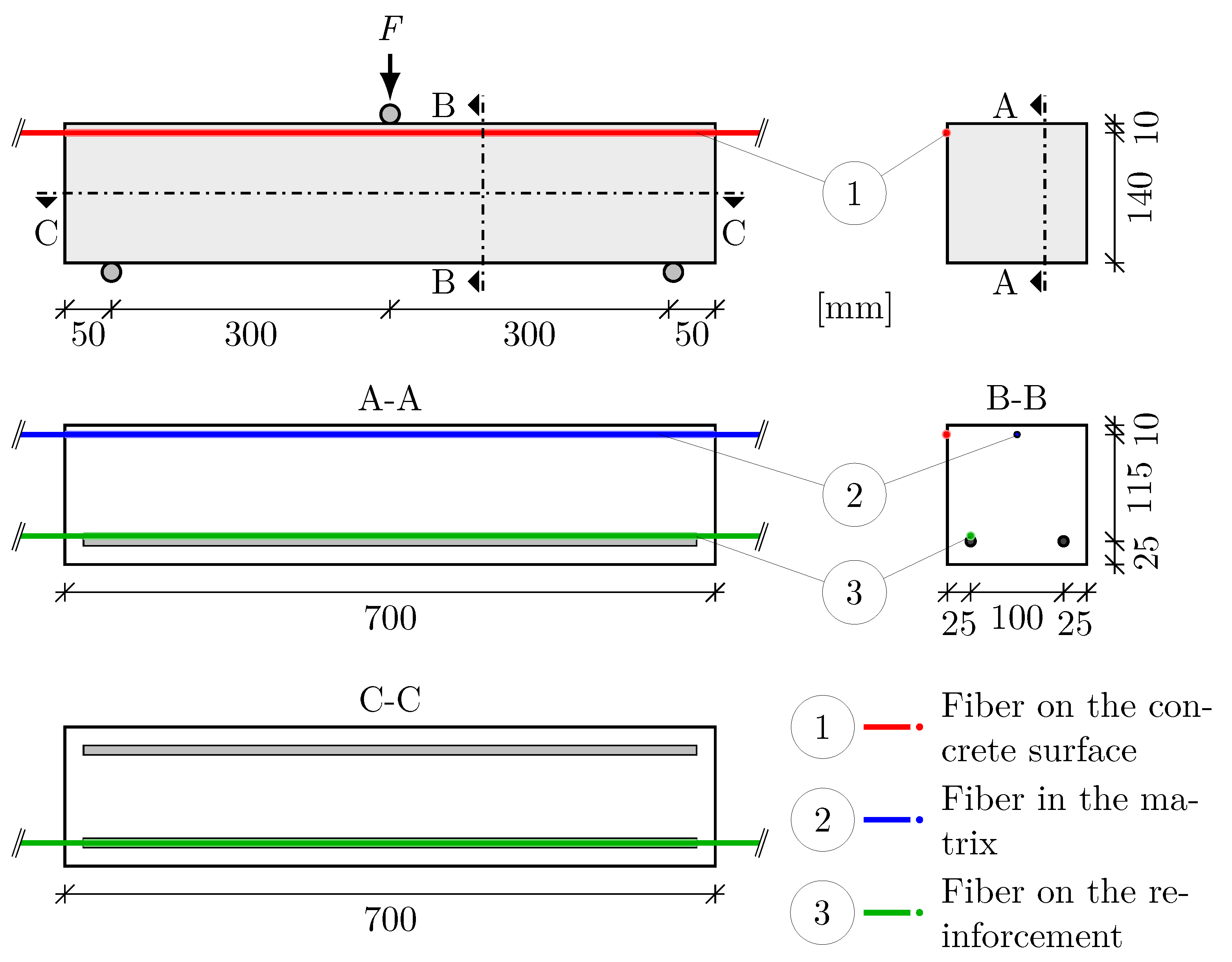

2.1. Experimental Design

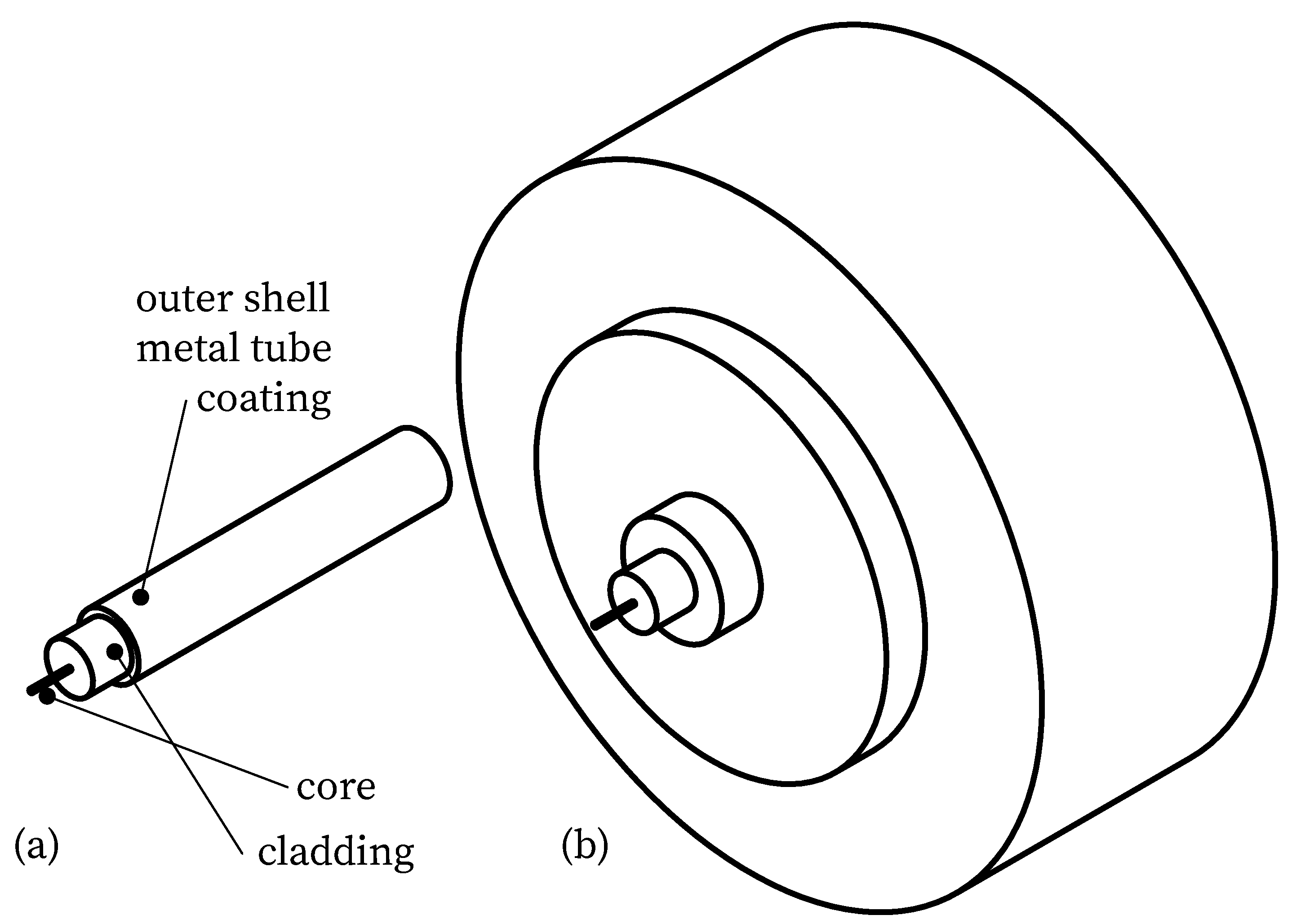

2.2. Concrete Mixture, Material of Application, and Fiber Types

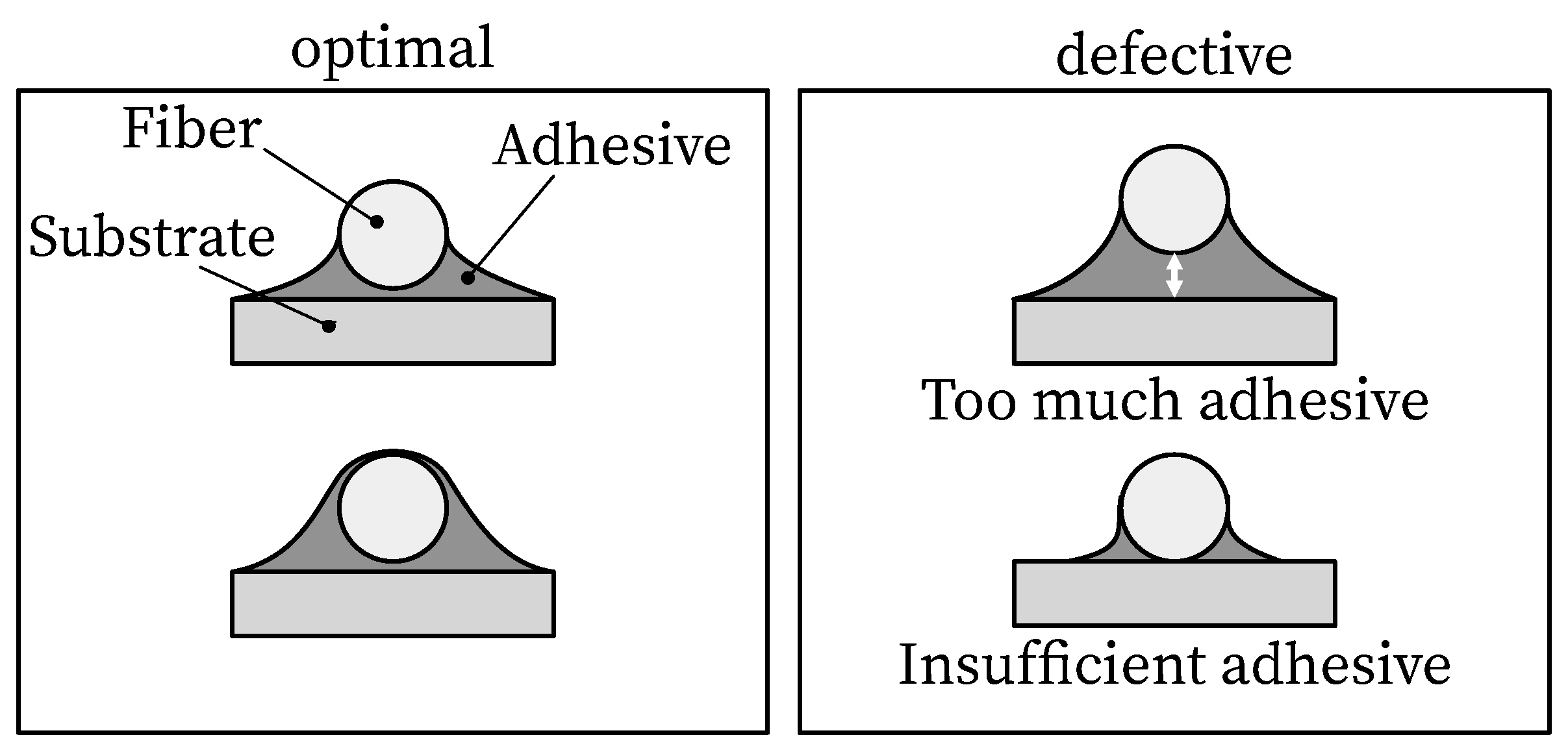

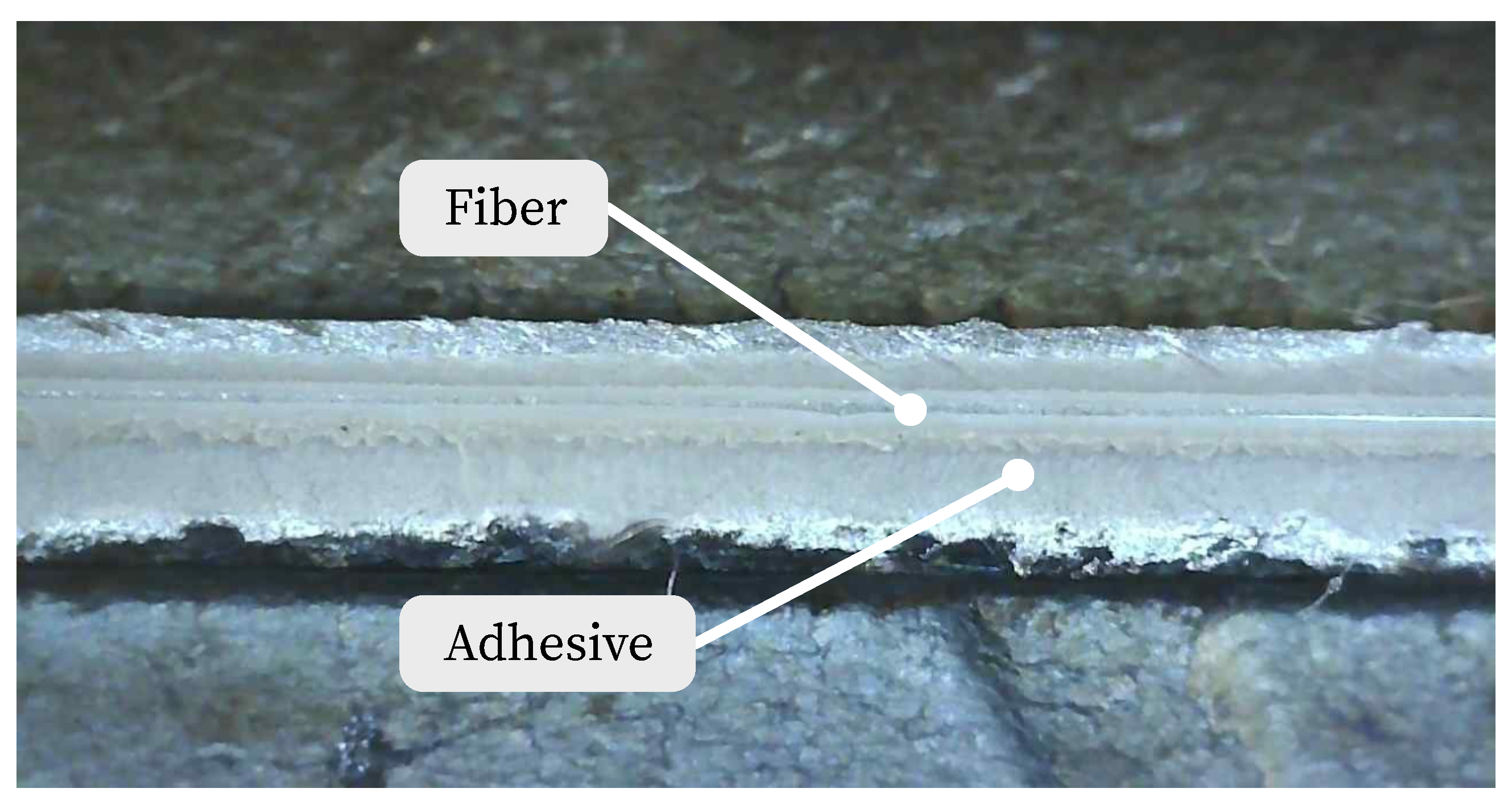

2.3. Application and Integration of the Sensors

3. Prediction of the Deformation

4. Results

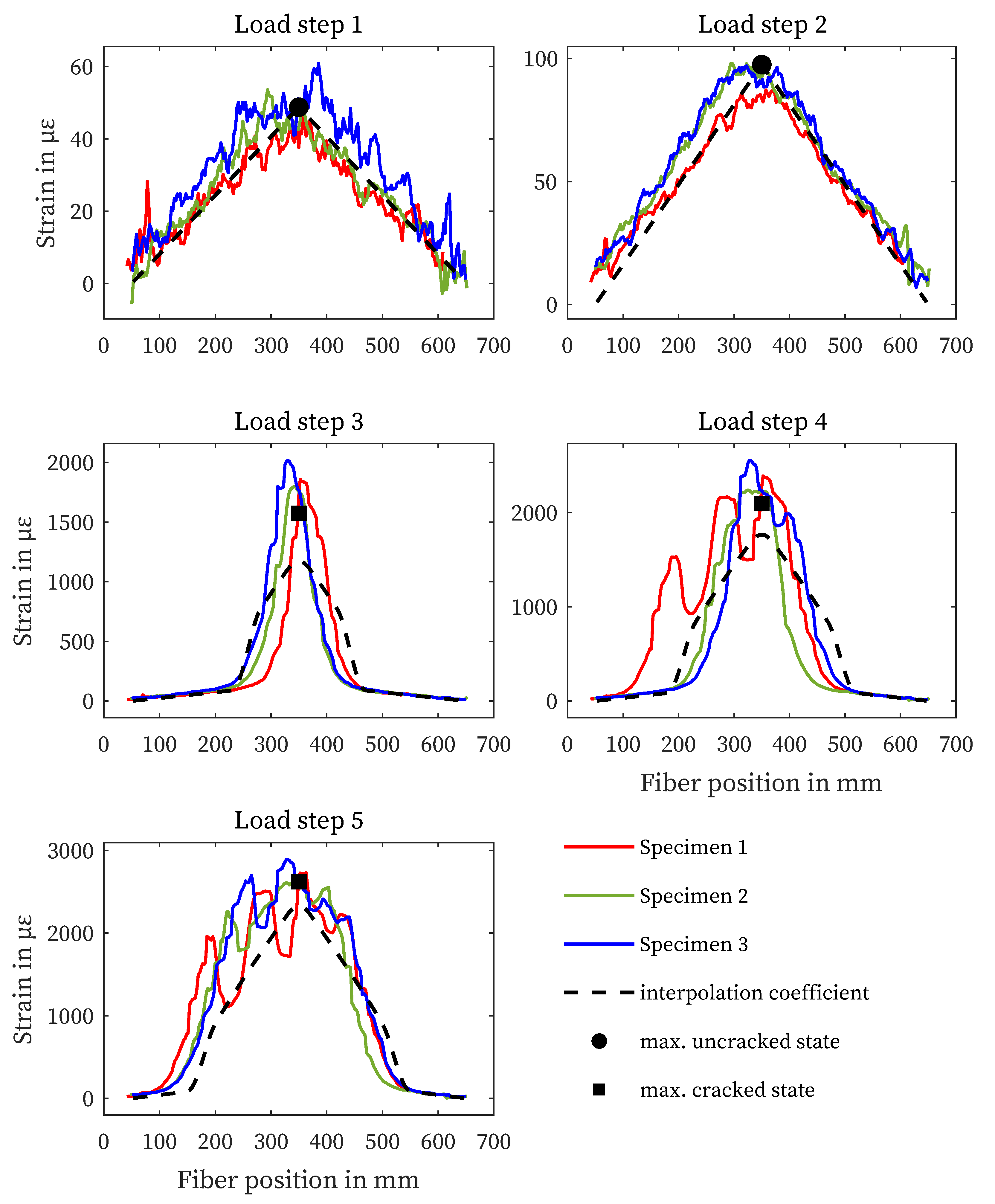

4.1. Strain Measurement on the Reinforcement Bar

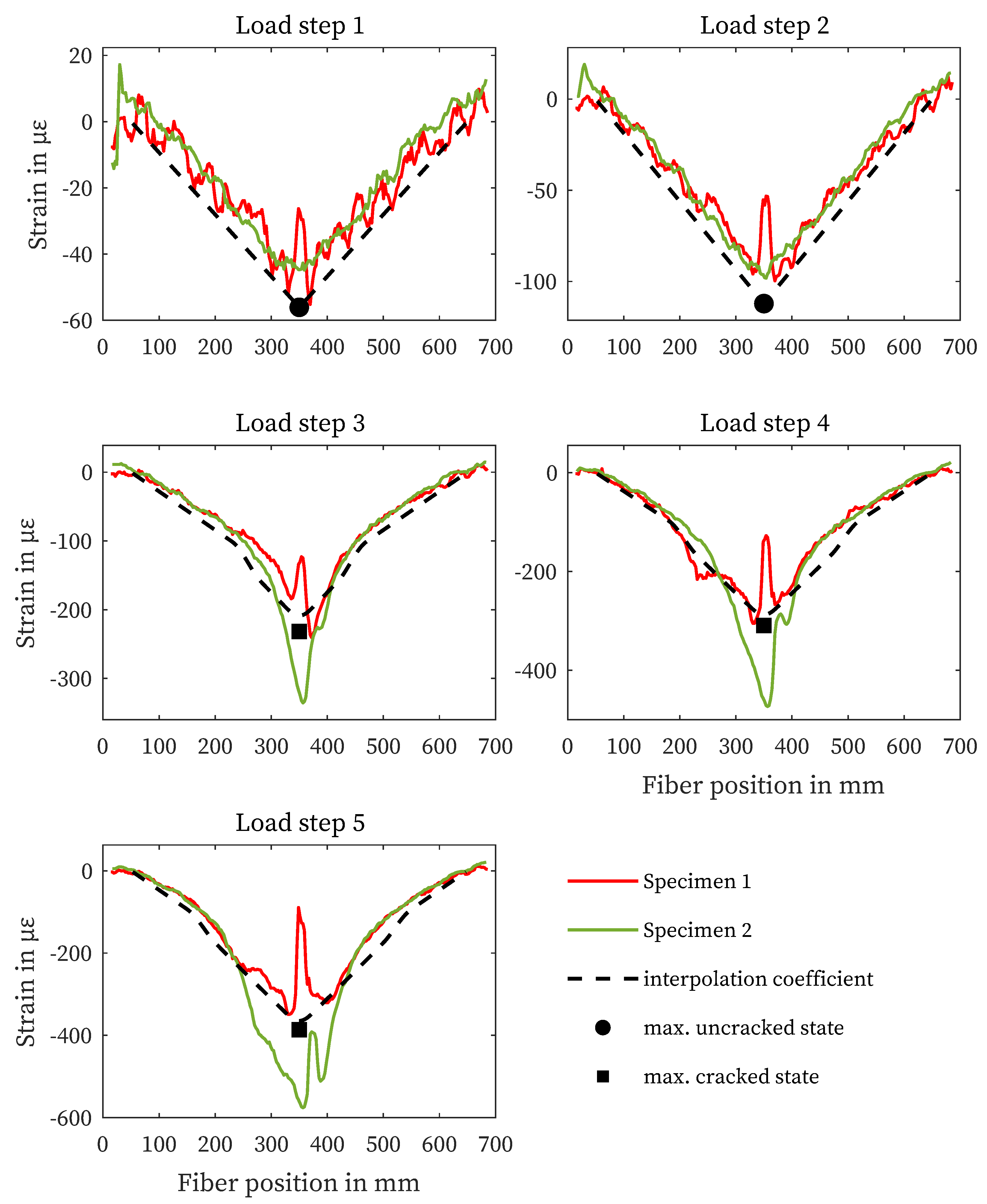

4.2. Strain Measurement on the Concrete Surface

4.3. Strain Measurement in the Cementitious Matrix

5. Discussion and Conclusions

- Measured values in the area of punctual load application must be viewed critically or excluded. Adjusting or re-positioning would be beneficial here.

- All aspects of the bonded joint (pre-treatment, bonding process, and coating if necessary) form the basis for accurate strain measurement and must be performed carefully and professionally.

- Based on the strain signal, it is difficult or impossible to detect measurement errors due to defective bonded joints. This should be taken into account when using any method that is based on bonding for displacement or deformation measurement, especially under dynamic loading and harsh environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of open access journals |

| DFOS | Distributed fiber optic sensor systems |

| SHM | Structural Health Monitoring |

| STG | Strain gauges |

| DT | Displacement transducer |

| FBG | Fiber Bragg gratings |

| LS | Load step |

References

- Becks, H.; Baktheer, A.; Marx, S.; Classen, M.; Hegger, J.; Chudoba, R. Monitoring concept for the propagation of compressive fatigue in externally prestressed concrete beams using digital image correlation and fiber optic sensors. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 514–526. [Google Scholar] [CrossRef]

- Bado, M.F.; Casas, J.R. A Review of Recent Distributed Optical Fiber Sensors Applications for Civil Engineering Structural Health Monitoring. Sensors 2021, 21, 1818. [Google Scholar] [CrossRef] [PubMed]

- Kishida, K.; Imai, M.; Kawabata, J.; Guzik, A. Distributed Optical Fiber Sensors for Monitoring of Civil Engineering Structures. Sensors 2022, 22, 4368. [Google Scholar] [CrossRef] [PubMed]

- Monsberger, C.M.; Lienhart, W. Distributed Fiber Optic Shape Sensing of Concrete Structures. Sensors 2021, 21, 6098. [Google Scholar] [CrossRef] [PubMed]

- Minardo, A.; Persichetti, G.; Testa, G.; Zeni, L.; Bernini, R. Long term structural health monitoring by Brillouin fibre-optic sensing: A real case. J. Geophys. Eng. 2012, 9, S64–S69. [Google Scholar] [CrossRef]

- Inaudi, D.; Glisic, B. Application of distributed fiber optic sensory for SHM. In Proceedings of the 2nd International Conference on Structural Health Monitoring of Intelligent Infrastructure, SHMII 2005, Shenzhen, China, 16–18 November 2005; pp. 163–169. [Google Scholar]

- Udd, E. Fiber Optic Sensors: An Introduction for Engineers and Scientists; Wiley-Interscience: Hoboken, NJ, USA, 2010. [Google Scholar]

- Lopez-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber Optic Sensors in Structural Health Monitoring. J. Light. Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Wan, K.T.; Inaudi, D.; Bao, X.; Habel, W.; Zhou, Z.; Ou, J.; Ghandehari, M.; Wu, H.C.; Imai, M. Review: Optical fiber sensors for civil engineering applications. Mater. Struct. 2013, 48, 871–906. [Google Scholar] [CrossRef]

- Moser, F.; Lienhart, W.; Woschitz, H.; Schuller, H. Long-term monitoring of reinforced earth structures using distributed fiber optic sensing. J. Civ. Struct. Health Monit. 2016, 6, 321–327. [Google Scholar] [CrossRef]

- Nöther, N. Distributed Fiber-optic Measurements in Geotechnical Applications—Capabilities and Challenges of Brillouin Sensing. In EAGE/DGG Workshop 2017; EAGE Publications BV: Utrecht, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Barrias, A.; Rodriguez, G.; Casas, J.R.; Villalba, S. Application of distributed optical fiber sensors for the health monitoring of two real structures in Barcelona. Struct. Infrastruct. Eng. 2018, 14, 967–985. [Google Scholar] [CrossRef]

- Monsberger, C.M.; Lienhart, W. Distributed fiber optic shape sensing along shotcrete tunnel linings: Methodology, field applications, and monitoring results. J. Civ. Struct. Health Monit. 2021, 11, 337–350. [Google Scholar] [CrossRef]

- Webb, G.T.; Vardanega, P.J.; Hoult, N.A.; Fidler, P.R.A.; Bennett, P.J.; Middleton, C.R. Analysis of Fiber-Optic Strain-Monitoring Data from a Prestressed Concrete Bridge. J. Bridge Eng. 2017, 22, 05017002. [Google Scholar] [CrossRef]

- Zdanowicz, K.; Gebauer, D.; Koschemann, M.; Speck, K.; Steinbock, O.; Beckmann, B.; Marx, S. Distributed fiber optic sensors for measuring strains of concrete, steel, and textile reinforcement: Possible fields of application. Struct. Concr. 2022, 23, 3367–3382. [Google Scholar] [CrossRef]

- Weisbrich, M.; Holschemacher, K.; Bier, T. Comparison of different fiber coatings for distributed strain measurement in cementitious matrices. J. Sens. Sens. Syst. 2020, 9, 189–197. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, Z. Deformation-Based Monitoring of Water Migration in Rocks Using Distributed Fiber Optic Strain Sensing: A Laboratory Study. Water Resour. Res. 2019, 55, 8368–8383. [Google Scholar] [CrossRef]

- Lienhart, W.; Buchmayer, F.; Klug, F.; Monsberger, C.M. Distributed Fiber Optic Sensing on a Large Tunnel Construction Site: Increased Safety, More Efficient Construction and Basis for Condition-Based Maintenance. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC), Cambridge, UK, 8–10 July 2019; pp. 595–604. [Google Scholar] [CrossRef]

- Wijaya, H.; Rajeev, P.; Gad, E. Distributed optical fibre sensor for infrastructure monitoring: Field applications. Opt. Fiber Technol. 2021, 64, 102577. [Google Scholar] [CrossRef]

- Fischer, O.; Thoma, S.; Crepaz, S. Quasikontinuierliche faseroptische Dehnungsmessung zur Rissdetektion in Betonkonstruktionen. Beton Stahlbetonbau 2019, 114, 150–159. [Google Scholar] [CrossRef]

- Henault, J.M.; Quiertant, M.; Delepine-Lesoille, S.; Salin, J.; Moreau, G.; Taillade, F.; Benzarti, K. Quantitative strain measurement and crack detection in RC structures using a truly distributed fiber optic sensing system. Constr. Build. Mater. 2012, 37, 916–923. [Google Scholar] [CrossRef]

- Xu, P.; Ba, D.; He, W.; Hu, H.; Dong, Y. Distributed Brillouin optical fiber temperature and strain sensing at a high temperature up to 1000 °C by using an annealed gold-coated fiber. Opt. Express 2018, 26, 29724. [Google Scholar] [CrossRef]

- Herbers, M.; Richter, B.; Gebauer, D.; Classen, M.; Marx, S. Crack monitoring on concrete structures: Comparison of various distributed fiber optic sensors with digital image correlation method. Struct. Concr. 2023, 24, 6123–6140. [Google Scholar] [CrossRef]

- Sienko, R.; Zych, M.; Bednarski, L.; Howiacki, T. Strain and crack analysis within concrete members using distributed fibre optic sensors. Struct. Health Monit. 2019, 18, 1510–1526. [Google Scholar] [CrossRef]

- Howiacki, T.; Sienko, R.; Bednarski, L.; Zuziak, K. Crack Shape Coefficient: Comparison between Different DFOS Tools Embedded for Crack Monitoring in Concrete. Sensors 2023, 23, 566. [Google Scholar] [CrossRef] [PubMed]

- Luna Inc. ODiSI 6000 Series Optical Distributed Sensor Interrogators. 2022. Available online: https://lunainc.com/product/odisi-6000-series (accessed on 10 July 2023).

- fibrisTerre Systems GmbH. Distributed Fiber-Optic Brillouin Sensing The fTB 5020 Series. 2020. Available online: https://www.fibristerre.de/file_download/15/fTB+5020+-+Product+Brochure.pdf (accessed on 10 July 2023).

- Weisbrich, M. Verbesserte Dehnungsmessung im Betonbau Durch Verteilte Faseroptische Sensorik. Ph.D. Thesis, Technische Universität Bergakademie Freiberg, Freiberg, Germany, 2020. [Google Scholar]

- Song, K.Y.; Chin, S.; Primerov, N.; Thevenaz, L. Time-Domain Distributed Fiber Sensor with 1 cm Spatial Resolution Based on Brillouin Dynamic Grating. J. Light. Technol. 2010, 28, 2062–2067. [Google Scholar] [CrossRef]

- Xue, Z.; Shi, J.Q.; Yamauchi, Y.; Durucan, S. Fiber Optic Sensing for Geomechanical Monitoring: (1)-Distributed Strain Measurements of Two Sandstones under Hydrostatic Confining and Pore Pressure Conditions. Appl. Sci. 2018, 8, 2103. [Google Scholar] [CrossRef]

- Piccolo, A.; Delepine-Lesoille, S.; Leduc, D.; Lecieux, Y. Distributed optical fiber strain and temperature sensing system performances: Brillouin vs Rayleigh. In Proceedings of the Seventh European Workshop on Optical Fibre Sensors, Limassol, Cyprus, 1–4 October 2019. [Google Scholar] [CrossRef]

- Hoult, R.; Bertholet, A.; De Almeida, J.P. Core versus Surface Sensors for Reinforced Concrete Structures: A Comparison of Fiber-Optic Strain Sensing to Conventional Instrumentation. Sensors 2023, 23, 1745. [Google Scholar] [CrossRef] [PubMed]

- Berrocal, C.G.; Fernandez, I.; Rempling, R. Crack monitoring in reinforced concrete beams by distributed optical fiber sensors. Struct. Infrastruct. Eng. 2021, 17, 124–139. [Google Scholar] [CrossRef]

- Slowik, V.; Schlattner, E.; Klink, T. Experimental investigation into early age shrinkage of cement paste by using fibre Bragg gratings. Cem. Concr. Compos. 2004, 26, 473–479. [Google Scholar] [CrossRef]

- Serovaev, G.; Kosheleva, N.; Gusev, G. Strain measurement in concrete sample under static loading using embedded fiber-optic sensors. AIP Conf. Proc. 2021, 2371, 030003. [Google Scholar] [CrossRef]

- Weisbrich, M.; Holschemacher, K. Comparison between different fiber coatings and adhesives on steel surfaces for distributed optical strain measurements based on Rayleigh backscattering. J. Sens. Sens. Syst. 2018, 7, 601–608. [Google Scholar] [CrossRef]

- Weisbrich, M.; Holschemacher, K.; Bier, T. Validierung verteilter faseroptischer Sensorik zur Dehnungsmessung im Betonbau. Beton Stahlbetonbau 2021, 116, 648–659. [Google Scholar] [CrossRef]

- Ansari, F.; Libo, Y. Mechanics of Bond and Interface Shear Transfer in Optical Fiber Sensors. J. Eng. Mech. 1998, 124, 385–394. [Google Scholar] [CrossRef]

- Chapeleau, X.; Bassil, A. A general solution to determine strain profile in the core of distributed fiber optic sensors under any arbitrary strain fields. Sensors 2021, 21, 5423. [Google Scholar] [CrossRef] [PubMed]

- Li, D.S.; Sr., H.L.; Ren, L.; Song, G. Strain transferring analysis of fiber Bragg grating sensors. Opt. Eng. 2006, 45, 024402. [Google Scholar] [CrossRef]

- Li, H.N.; Zhou, G.D.; Ren, L.; Li, D.S. Strain transfer coefficient analyses for embedded fiber bragg grating sensors in different host materials. J. Eng. Mech. 2009, 135, 1343–1353. [Google Scholar] [CrossRef]

- Leung, C.K.Y. Interfacial changes of optical fibers in the cementitious environment. J. Mater. Sci. 2000, 35, 6197–6208. [Google Scholar] [CrossRef]

- Samiec, D. Distributed fibre-optic temperature and strain measurement with extremely high spatial resolution. Photonik Int. 2012, 1, 10–13. [Google Scholar]

- Zhang, S.; Liu, H.; Govindjee, S.; DeJong, M.J. Strain Transfer Mechanisms and Mechanical Properties of Optical Fiber Cables. Sensors 2022, 22, 9966. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Shi, B.; Zhang, C.C.; Sun, Y.; Zhang, L.; Han, H. Strain transfer mechanism in surface-bonded distributed fiber-optic sensors subjected to linear strain gradients: Theoretical modeling and experimental validation. Measurement 2021, 179, 109510. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Coulibaly, A.A.S.; DeJong, M. Fiber optic sensing of concrete cracking and rebar deformation using several types of cable. Struct. Control Health Monit. 2021, 28, e2664. [Google Scholar] [CrossRef]

- Luna Inc. ODiSI-B Optical Distributed Sensor Interrogator. 2017. Available online: https://www.advancedphotonix.com/wp-content/uploads/2016/07/ODB5_DataSheet_Rev13_020217.pdf (accessed on 15 November 2023).

- DIN EN 12390-1:2021-09; Testing Hardened Concrete–Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds; German Version EN 12390-1:2021. German Institute for Standardisation: Berlin, Germany, 2021. [CrossRef]

- DIN EN 12390-3:2019-10; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; German Version EN 12390-3:2019. German Institute for Standardisation: Berlin, Germany, 2019. [CrossRef]

- Deutscher Ausschuss für Stahlbeton. DAfStb-Richtlinie „Stahlfaserbeton“; Deutscher Ausschuss für Stahlbeton: Berlin, Germany, 2012. [Google Scholar]

- Litzner, H.U. Grundlagen der Bemessung nach Eurocode 2—Vergleich mit DIN 1045 und DIN 4227. In Beton-Kalender 1995; Eibl, J., Ed.; Ernst & Sohn’: Berlin, Germany, 1994; pp. 519–725. [Google Scholar]

- Dyckerhoff GmbH. C3 Carbon Concrete Composite. Bindemittel für hochfeste Carbonbetone. 2017. Available online: https://www.dyckerhoff.com/documents/209745/0/423C3Bindemittel_D_.pdf (accessed on 15 November 2023).

- Wulff, M. Basisvorhaben B2—Nachhaltige Bindemittel und Betone für die Zukunft: Teilvorhaben: Zemente und Bindemittelsysteme für hochfeste C3-Betone: Abschlussbericht zum Verbundprojekt: Förderzeitraum: 01.03.2015-31.08.2016; Technical report; Deuna Zement GmbH, Dyckerhoff: Deuna, Germany, 2016. [Google Scholar] [CrossRef]

- FBGS International N.V. DTG Coating Ormocer®-T for Temperature Sensing Applications. 2015. Available online: https://fbgs.com/wp-content/uploads/2019/03/Introducing_and_evaluating_Ormocer-T_for_temperature_sensing_applications.pdf (accessed on 15 November 2023).

- Micro Measurements. Micro-Measurements. M-Bond 200. Strain Gage Adhesive. 2021. Available online: https://docs.micro-measurements.com/?id=6671 (accessed on 15 November 2023).

- Sika Schweiz AG. Sikadur®-330. 2-Komponentiger, Thixotroper Epoxidharzkleber. 2021. Available online: https://che.sika.com/content/dam/dms/ch01/k/sikadur_-330.pdf (accessed on 15 November 2023).

- Skontorp, A.; Levin, K.; Benmoussa, M. Surface-mounted optical strain sensors for structural health monitoring of composite structures. In Proceedings of the Sixteenth Technical Conference of the American Society for Composites, Blacksburg, VA, USA, 9–12 September 2001; Volume 2001. [Google Scholar]

- DIN EN 12390-13:2021-09; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression; German Version EN 12390-13:2021. German Institute for Standardisation: Berlin, Germany, 2021. [CrossRef]

- DIN 488-2:2009-08; Reinforcing Steels—Reinforcing Steel Bars. German Institute for Standardisation: Berlin, Germany, 2009. [CrossRef]

- DIN EN 1992-1-1:2011-01; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; German Version EN 1992-1-1:2004 + AC:2010. German Institute for Standardisation: Berlin, Germany, 2011. [CrossRef]

| Characteristic | Rayleigh Scatter | Brillouin Scatter |

|---|---|---|

| Max. measuring range in | 50 to 100 | 80,000 |

| Measuring rate in | 250 | 0.05 to 0.001 |

| Resolution in mm | 200 to 2500 | |

| Max. strain in | 30,000 | |

| Max. temperature in | −200 to 1000 |

| Method | STG | DT | FBG | DFOS |

|---|---|---|---|---|

| Electromagnetic influence | − | − | + | + |

| Resolution | − | − | o | + |

| Price per sensor | o | − | − | + |

| Price of measurement system | + | + | o | − |

| Amount of data | + | + | + | − |

| Information content per sensor | − | − | o | + |

| Combined temperature sensing | − | − | + | + |

| Measuring range | − | − | o | + |

| Load Step | Uncracked (I) Cracked (II) | Force | Moment | Strain Fiber pos. 1 and 2 | Strain Fiber pos. 3 |

|---|---|---|---|---|---|

| με | |||||

| 1 | I | 12 | 1.8 | −61 | 49 |

| 2 | I | 24 | 3.6 | −121 | 98 |

| 3 | II | 36 | 5.4 | −310 | 1573 |

| 4 | II | 48 | 7.2 | −414 | 2097 |

| 5 | II | 60 | 9.0 | −517 | 2621 |

| Matrix | Quantity |

|---|---|

| BMK-D5-1 (Compound) | 815 |

| Sand BCS 0.06/0.2 | 340 |

| Sand 0/2 | 965 |

| Water | 190 |

| Superplasticizer (MC-VP-16-0205-02) | 17 |

| Specimen | Ultimate Force in kN | Compressive Strength in N/mm2 | |

|---|---|---|---|

| beam 1 | 1.1 | 898 | 114 |

| 1.2 | 879 | 112 | |

| 1.3 | 896 | 114 | |

| beam 2 | 2.1 | 832 | 106 |

| 2.2 | 890 | 113 | |

| 2.3 | 867 | 110 | |

| beam 3 | 3.1 | 874 | 111 |

| 3.2 | 888 | 113 | |

| 3.3 | 861 | 110 | |

| Mean | 876 | 111 |

| Description | Ormocer® |

|---|---|

| Fiber type | LAL-1550-125 |

| ∅ Core in µm | 9 |

| ∅ Cladding in µm | 125(1) |

| ∅ Coating in µm | 195 |

| Attenuation in dB | |

| Strain coefficients in |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weisbrich, M.; Messerer, D.; Holschemacher, K. The Challenges and Advantages of Distributed Fiber Optic Strain Monitoring in and on the Cementitious Matrix of Concrete Beams. Sensors 2023, 23, 9477. https://doi.org/10.3390/s23239477

Weisbrich M, Messerer D, Holschemacher K. The Challenges and Advantages of Distributed Fiber Optic Strain Monitoring in and on the Cementitious Matrix of Concrete Beams. Sensors. 2023; 23(23):9477. https://doi.org/10.3390/s23239477

Chicago/Turabian StyleWeisbrich, Martin, Dennis Messerer, and Klaus Holschemacher. 2023. "The Challenges and Advantages of Distributed Fiber Optic Strain Monitoring in and on the Cementitious Matrix of Concrete Beams" Sensors 23, no. 23: 9477. https://doi.org/10.3390/s23239477

APA StyleWeisbrich, M., Messerer, D., & Holschemacher, K. (2023). The Challenges and Advantages of Distributed Fiber Optic Strain Monitoring in and on the Cementitious Matrix of Concrete Beams. Sensors, 23(23), 9477. https://doi.org/10.3390/s23239477