Estimation of Shape Error with Monitoring Signals

Abstract

:1. Introduction

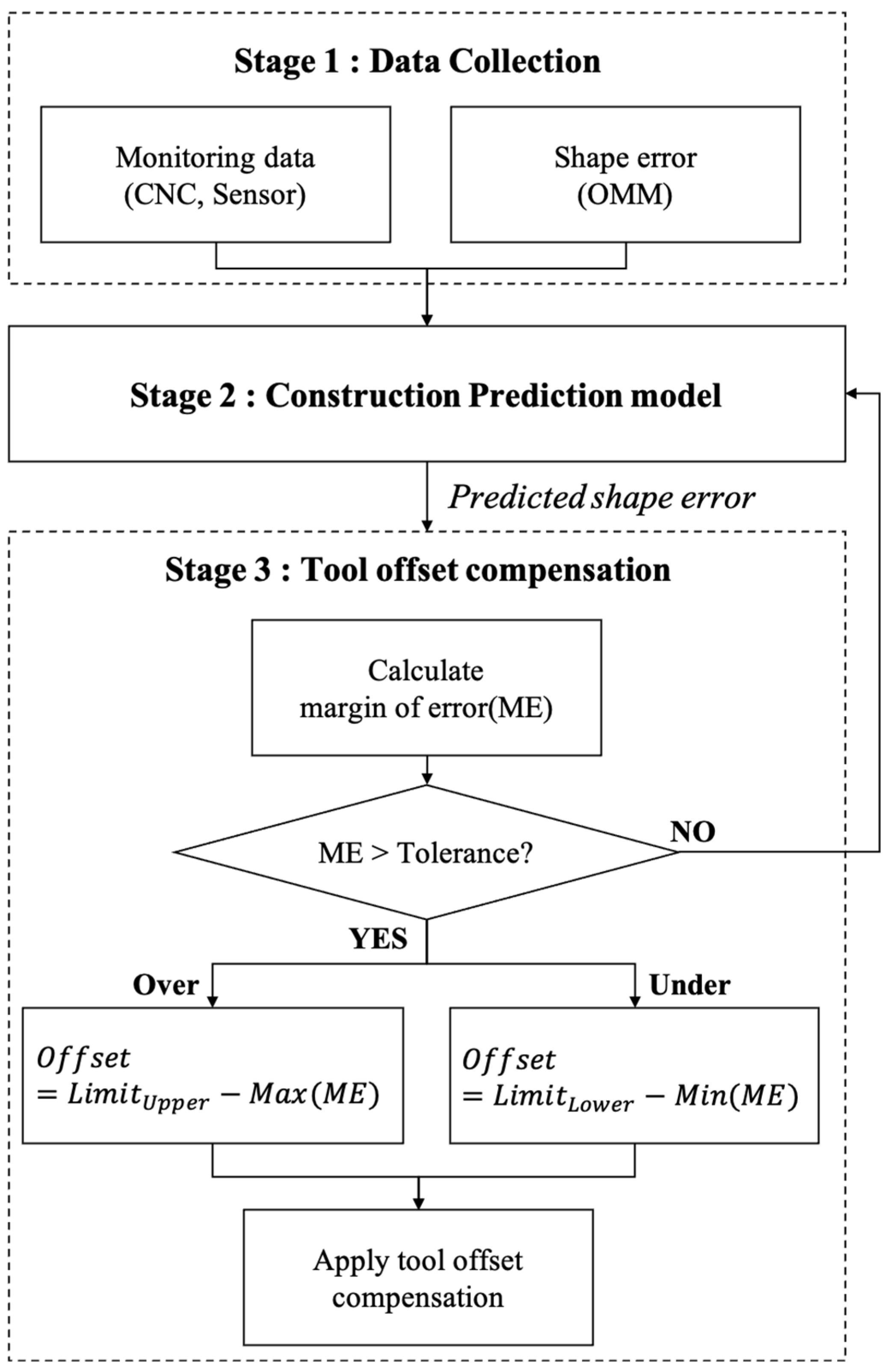

2. Shape Error Compensation Methodology

2.1. Proposed Error Compensation Methodology

2.2. Monitoring System

2.3. OMM System

2.4. Experimental Setup and Conditions

3. Data Processing and Feature Extraction

3.1. Signal Preprocessing

3.2. Feature Selection

3.2.1. Filter Method

3.2.2. Embedded Method

4. Shape Error Compensation Results

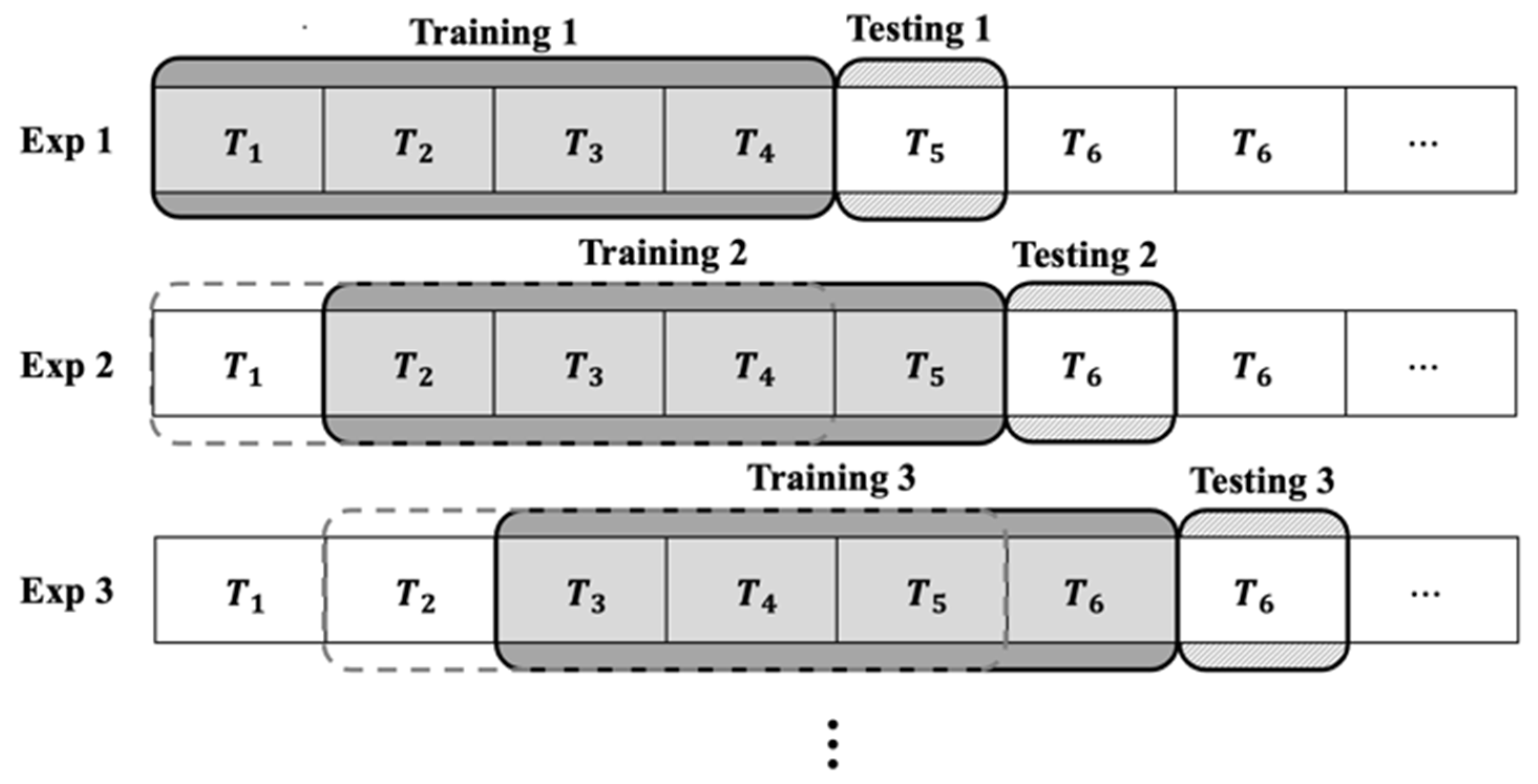

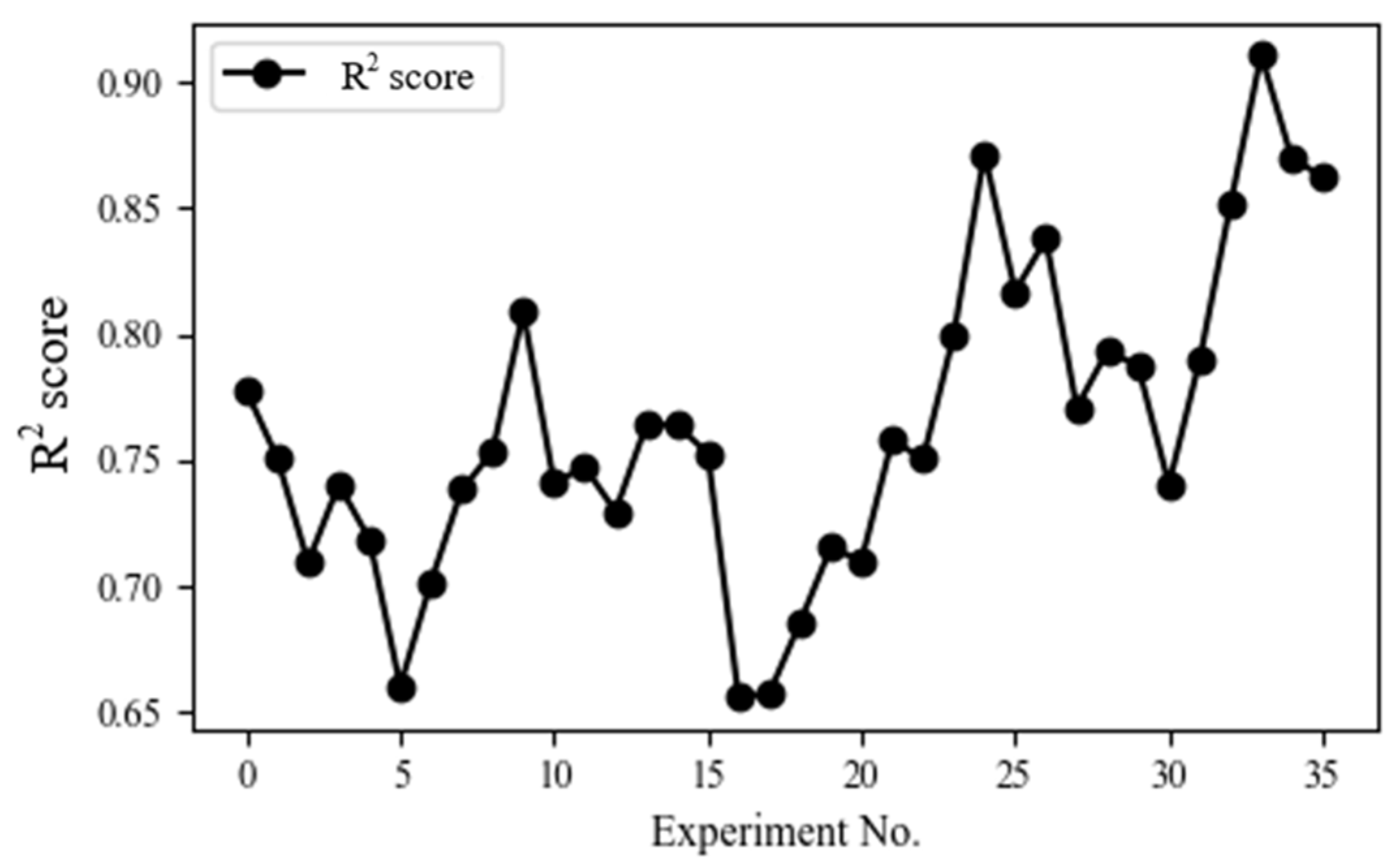

4.1. MLP Model Construction

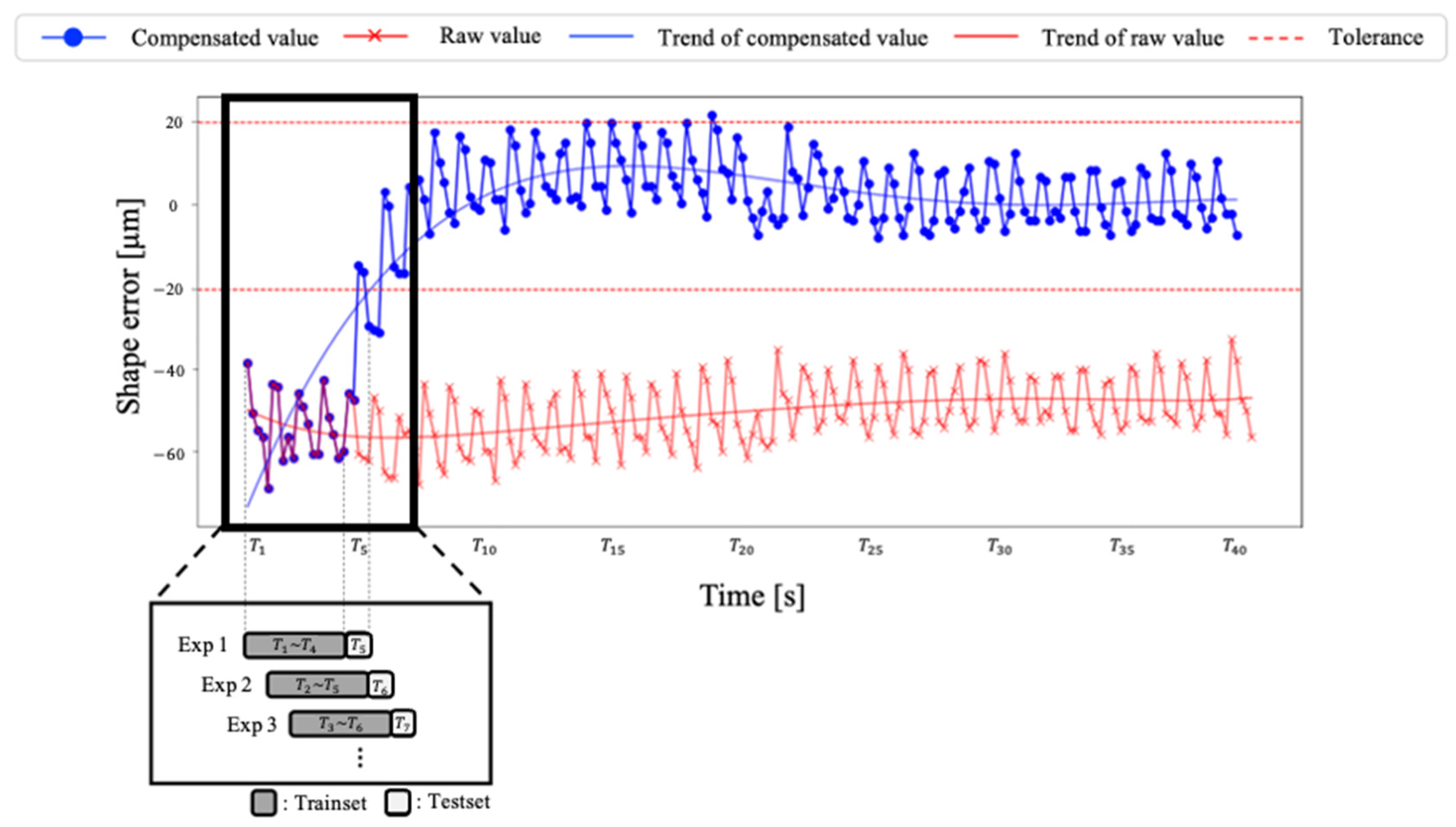

4.2. Shape Error Compensation Result

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramesh, R.; Mannan, M.A.; Poo, A.N. Error compensation in machine tools-a review part 1: Geometric, cutting-force induced and fixture-dependent errors. Int. J. Mach. Tools Manuf. 2000, 40, 1235–1256. [Google Scholar] [CrossRef]

- Ramesh, R.; Mannan, M.A.; Poo, A.N. Error compensation in machine tools-a review part 2: Thermal errors. Int. J. Mach. Tools Manuf. 2000, 40, 1257–1284. [Google Scholar] [CrossRef]

- Cichosz, P.; Karolczak, P.; Waszczuk, K. Review of Cutting Temperature Measurement Methods. Materials 2023, 16, 6365. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Zhang, G.; Li, H.; Yang, X.; Shao, W.; Liu, Z. Dynamic compensation strategy for scanning error of contact probe based on damping ratio and frequency mapping. IEEE Sens. J. 2023. [Google Scholar] [CrossRef]

- Lyu, D.; Liu, Q.; Liu, H.; Zhao, W. Dynamic error of CNC machine tools: A state-of-the-art review. Int. J. Adv. Manuf. Technol. 2020, 106, 1869–1891. [Google Scholar] [CrossRef]

- Geng, Z.; Tong, Z.; Jiang, X. Review of geometric error measurement and compensation techniques of ultra-precision machine tools. Light Adv. Manuf. 2021, 2, 211–227. [Google Scholar] [CrossRef]

- Lo, C.C.; Hsiao, C.Y. A method of tool path compensation for repeated machining process. Int. J. Mach. Tools Manuf. 1998, 38, 205–213. [Google Scholar] [CrossRef]

- Denkena, B.; Dittrich, M.A.; Uhlich, F. Augmenting milling process data for shape error prediction. Procedia CIRP 2016, 57, 487–491. [Google Scholar] [CrossRef]

- Cho, M.W.; Kim, G.H.; Seo, T.I.; Hong, Y.C.; Cheng, H.H. Intergrated machining error compensation method using OMM data and modified PNN algorithm. Int. J. Mach. Tools Manuf. 2006, 46, 1417–1427. [Google Scholar] [CrossRef]

- Ge, G. An intergrated error compensation method based on on-machine measurement for thin web parts machining. Precis. Eng. 2020, 63, 206–213. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Watanabe, T.; Iwai, S. A control system to improve the accuracy of finished surfaces in milling. J. Dyn. Syst. Meas. Control. 1983, 105, 192–199. [Google Scholar] [CrossRef]

- Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S. A comparative study on machine learning algorithms for smart manufacturing: Tool wear prediction using random forests. J. Manuf. Sci. Eng. 2017, 139, 071018. [Google Scholar] [CrossRef]

- Rodriguez-Galiano, V.F.; Luque-Espinar, J.A.; Chica-Olmo, M.; Mendes, M.P. Feature selection approaches for predictive modelling of groundwater nitrate pollution: An evaluation of filters, embedded and wrapper methods. Sci. Total Environ. 2018, 624, 661–672. [Google Scholar] [CrossRef] [PubMed]

- Jović, A.; Brkić, K.; Bogunović, N. A review of feature selection methods with applications. In Proceedings of the 2015 38th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 25–29 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1200–1205. [Google Scholar]

- Hasan, M.A.M.; Nasser, M.; Ahmad, S.; Molla, K.I. Feature selection for intrusion detection using random forest. J. Inf. Secur. 2016, 7, 129–140. [Google Scholar] [CrossRef]

- Xiong, T.; Bao, Y.; Hu, Z. Multiple-output support vector regression with a firefly algorithm for interval-valued stock price index forecasting. Knowl.-Based Syst. 2014, 55, 87–100. [Google Scholar] [CrossRef]

- Chou, J.S.; Nguyen, T.K. Forward forecast of stock price using sliding-window metaheuristic-optimized machine-learning regression. IEEE Trans. Ind. Inform. 2018, 14, 3132–3142. [Google Scholar] [CrossRef]

| Source | Signal Type | Unit |

|---|---|---|

| CNC | Spindle speed | min−1 |

| Spindle load | % | |

| X/Y/Z axis position | mm | |

| X/Y/Z axis load | % | |

| X/Y/Z current | mv/A | |

| Actual feed rate | mm/min | |

| Sensors (DAQ) | Spindle axis current | mA |

| Spindle axis voltage | mV | |

| X/Y/Z axis current | mA | |

| X/Y/Z axis voltage | mV | |

| Sound | Pa | |

| X/Y axis acceleration | m/s2 |

| Tool Properties | |

| Type | Flat endmill |

| Diameter | 16 mm |

| Material | Tungsten carbide (WC-Co) |

| Number of flutes | 2 |

| Workpiece properties | |

| Material | C45E4 |

| Machining length | 120 mm |

| Machining conditions | |

| Spindle speed | 4100 min−1 |

| Feed per tooth | 0.1 mm/tooth |

| Axial depth of cut | 2 mm |

| Radial depth of cut | 2 mm |

| Hyperparameter | Optimal Value |

|---|---|

| Hidden layer1 node | 32 |

| Hidden layer2 node | 8 |

| Dropout | 0.8 |

| Activation function | ReLU |

| Kernel initializer | He uniform |

| Optimizer | Adam |

| Learning rate | 0.91 |

| Epochs | 1000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Nam, S.; Nam, E. Estimation of Shape Error with Monitoring Signals. Sensors 2023, 23, 9416. https://doi.org/10.3390/s23239416

Kim H, Nam S, Nam E. Estimation of Shape Error with Monitoring Signals. Sensors. 2023; 23(23):9416. https://doi.org/10.3390/s23239416

Chicago/Turabian StyleKim, Hyein, Soohyun Nam, and Eunseok Nam. 2023. "Estimation of Shape Error with Monitoring Signals" Sensors 23, no. 23: 9416. https://doi.org/10.3390/s23239416

APA StyleKim, H., Nam, S., & Nam, E. (2023). Estimation of Shape Error with Monitoring Signals. Sensors, 23(23), 9416. https://doi.org/10.3390/s23239416