Two-Axial Measurement of the Angular Microdeflection of a Laser Beam Using One Single-Axis Sensor

Abstract

:1. Introduction

2. Materials and Methods

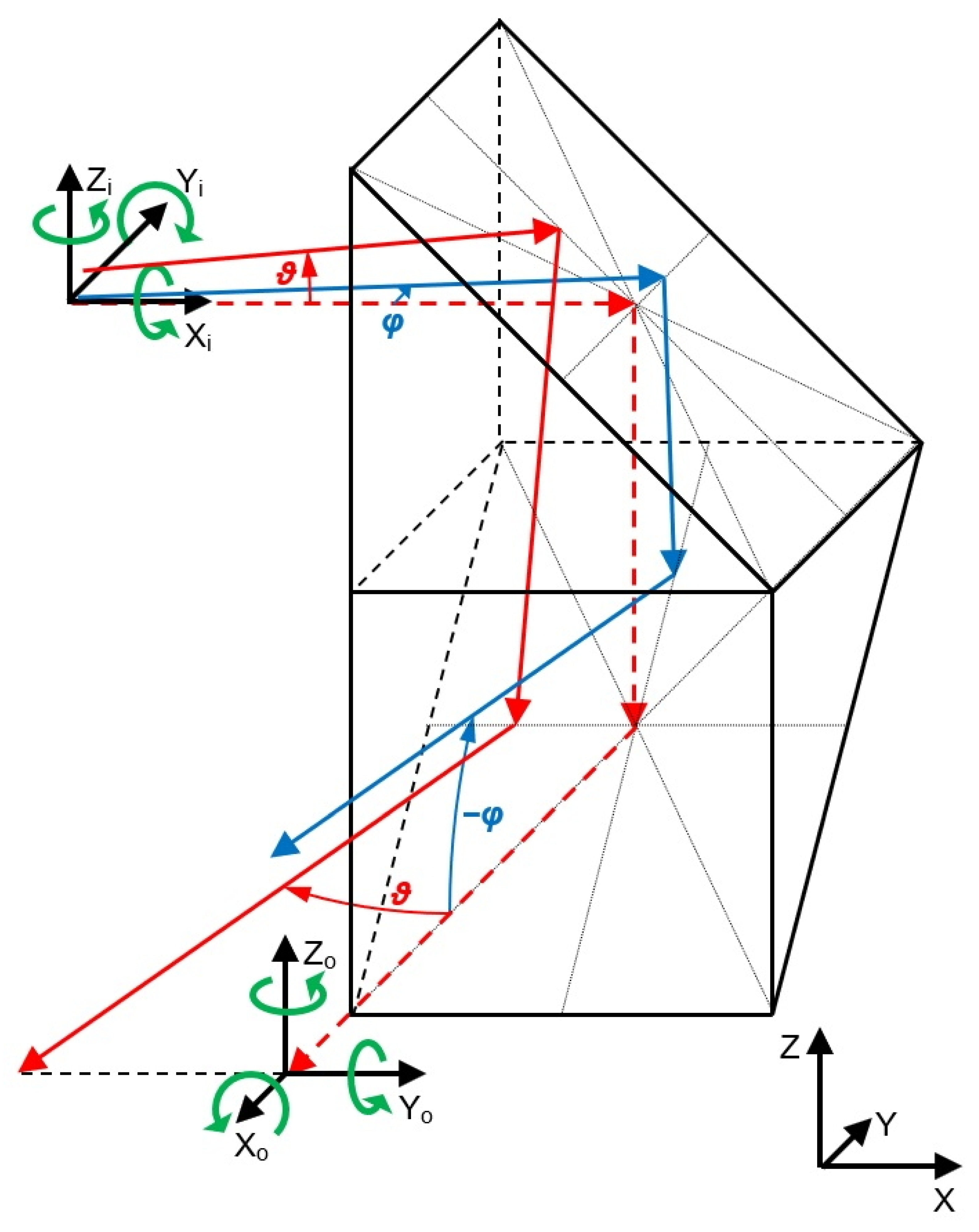

2.1. Optical Element for the Rotation of Laser Beam Deflections

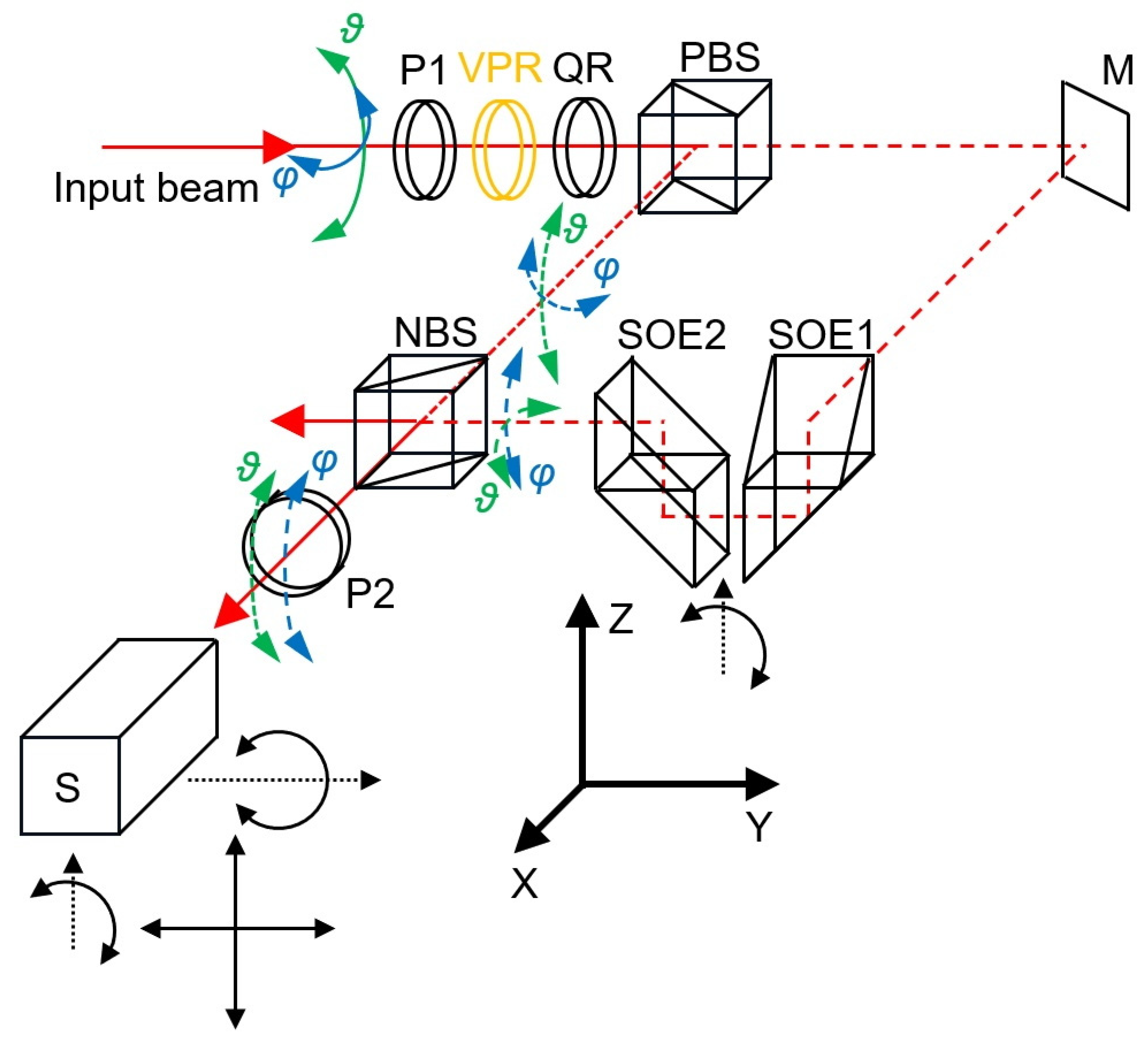

2.2. Method of Two-Axial Measurement with One Single-Axis Sensor

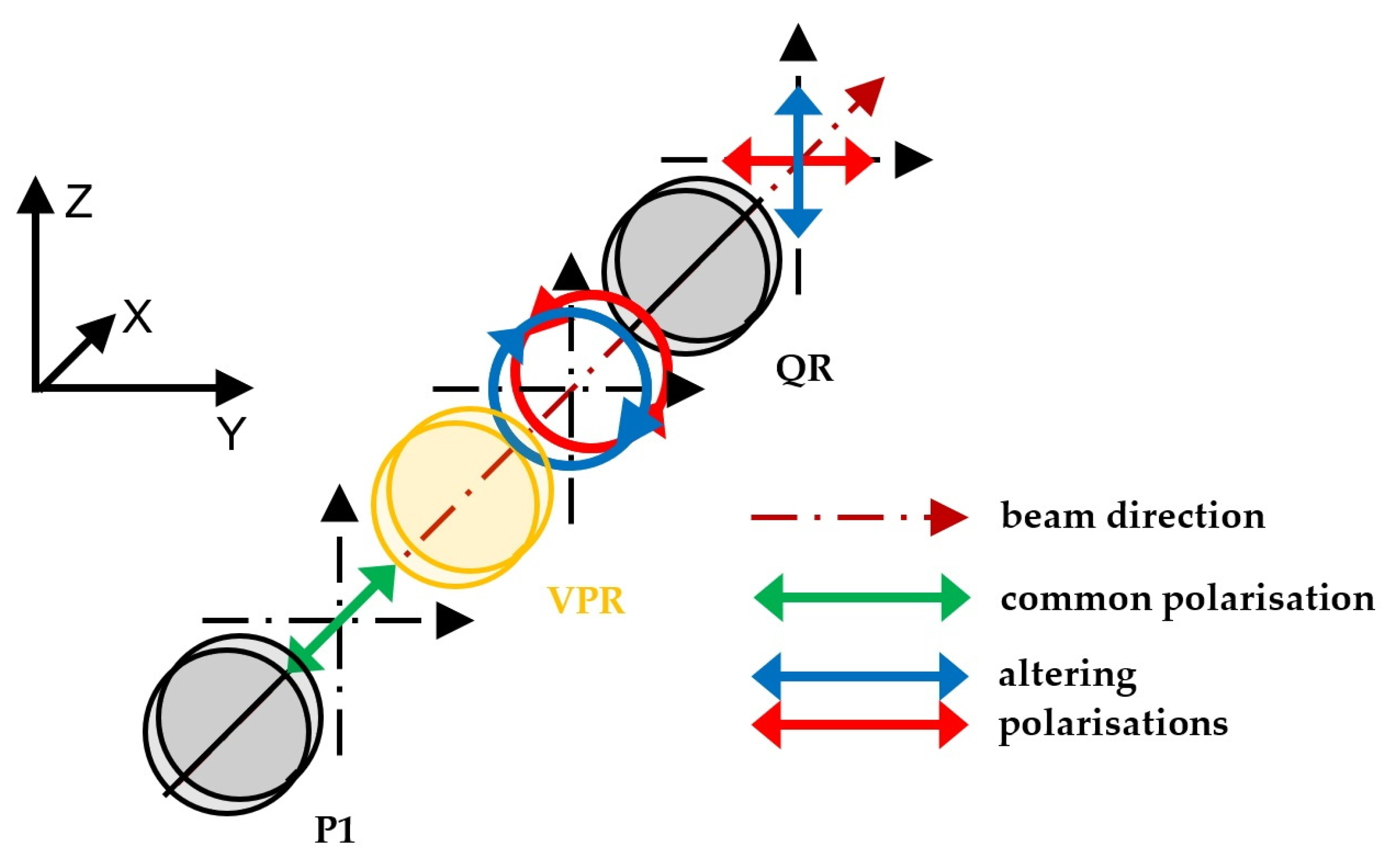

2.3. Subsystem for Altering the Beam Polarisation

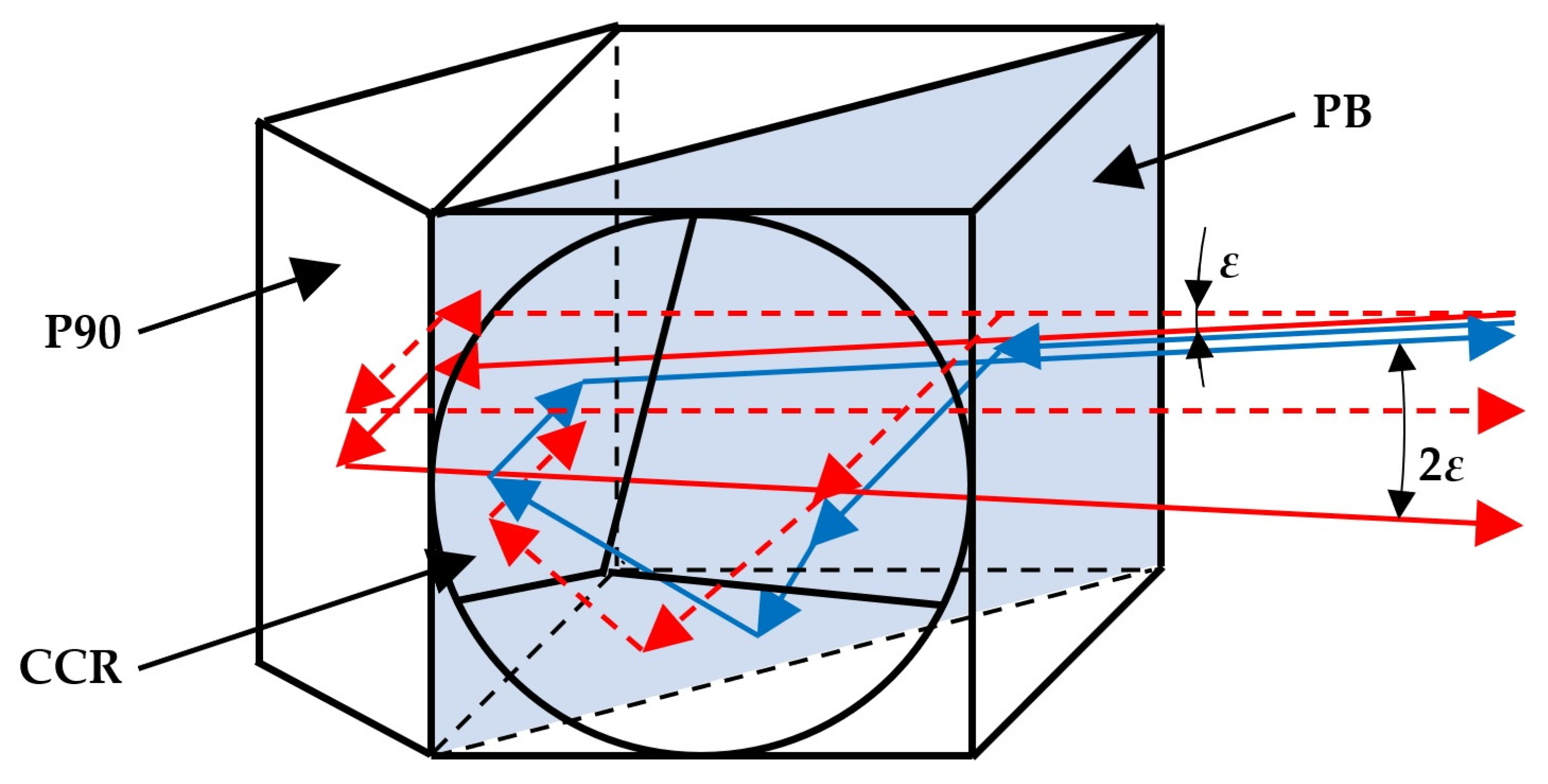

2.4. Single-Axis Sensor for Laser Beam Deflection

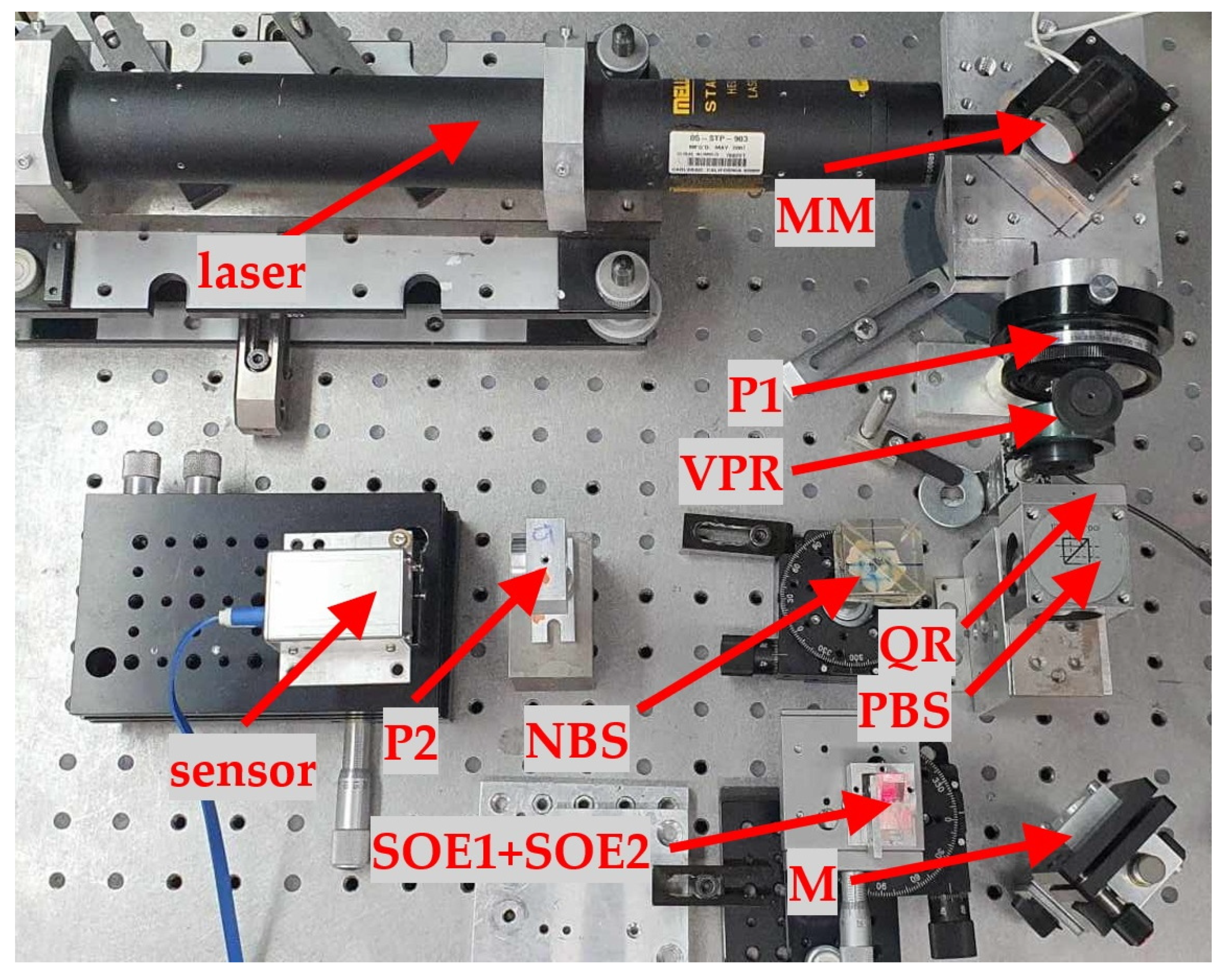

2.5. Setup Used for Experimental Verification of the Proposed Method

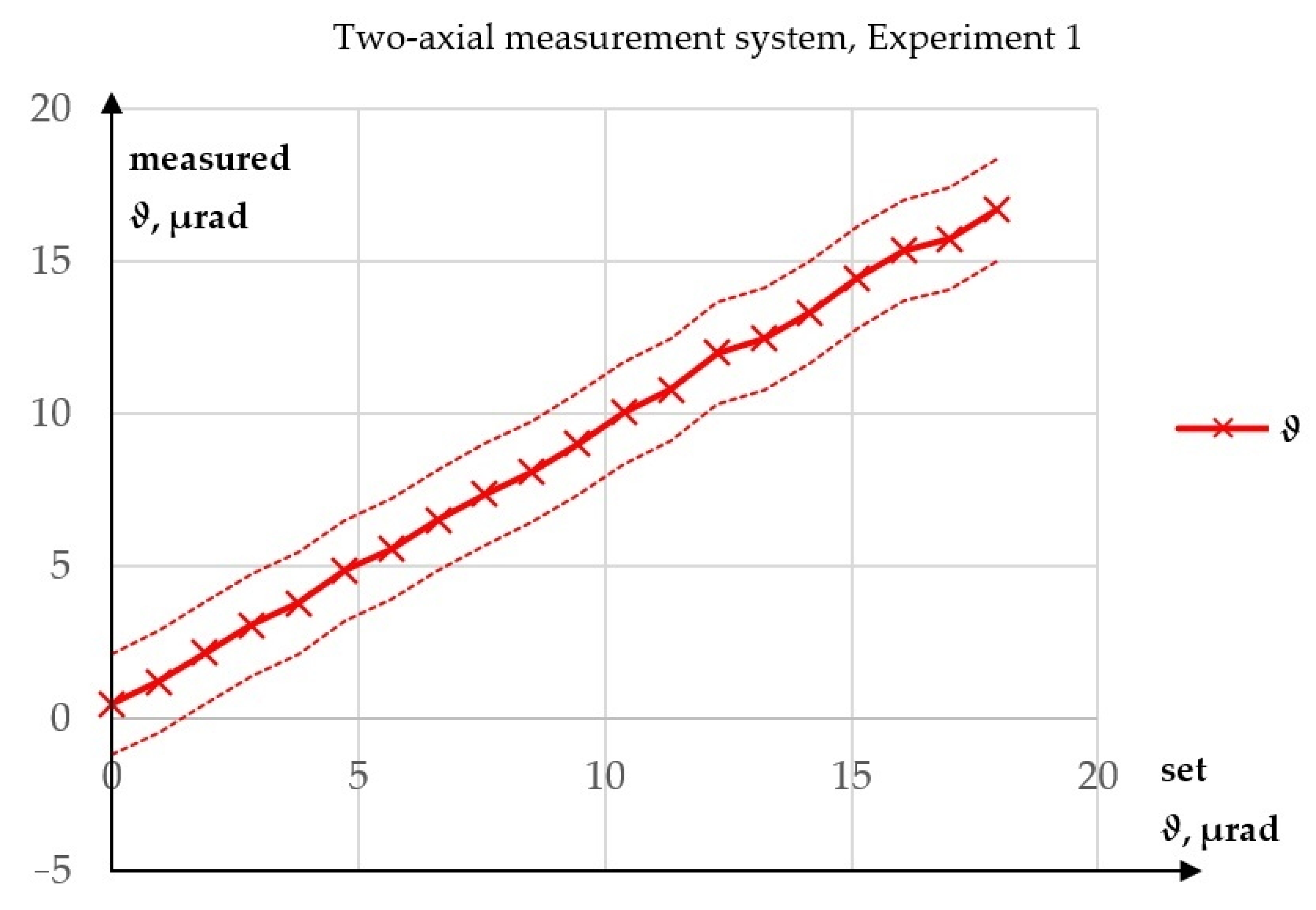

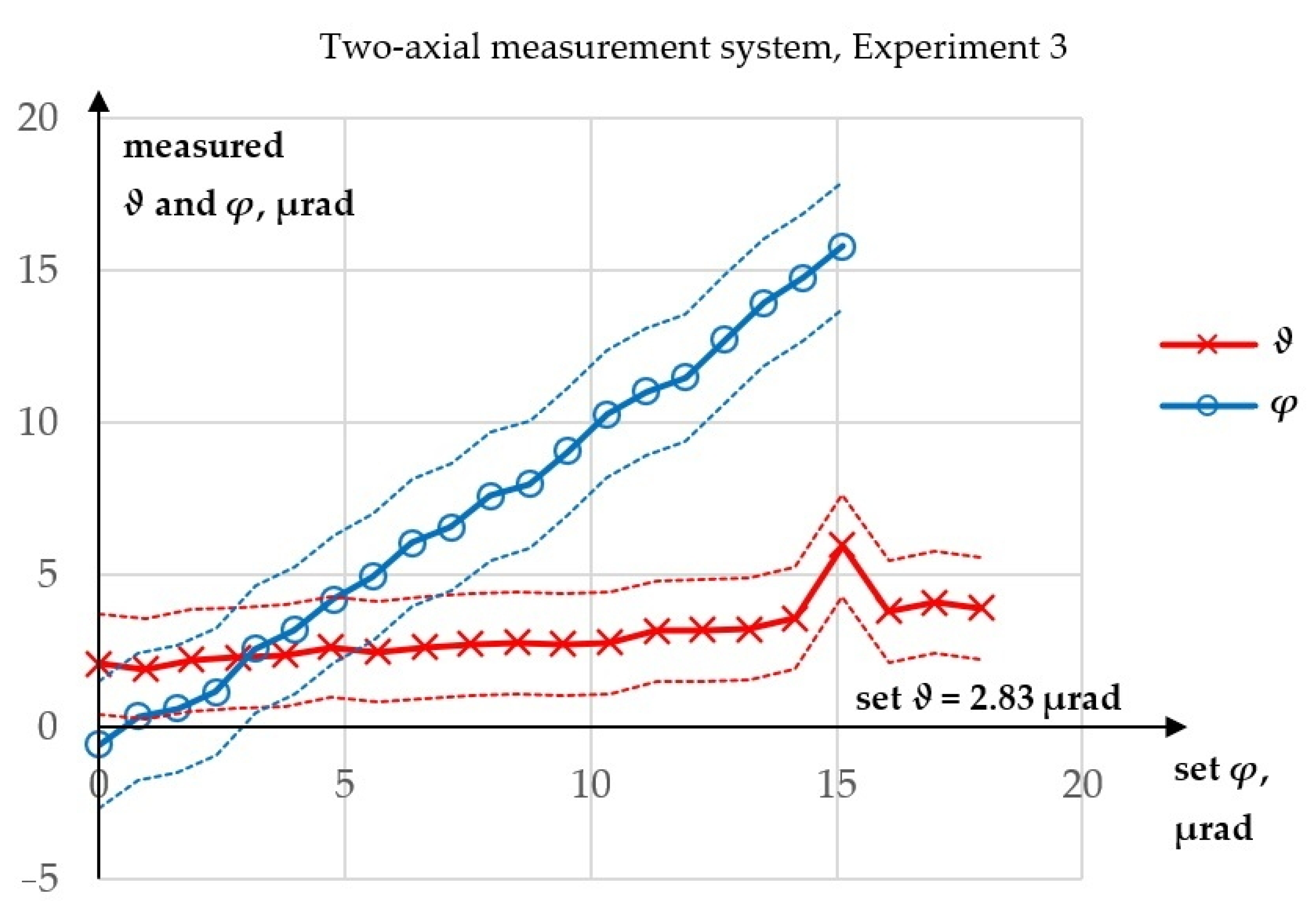

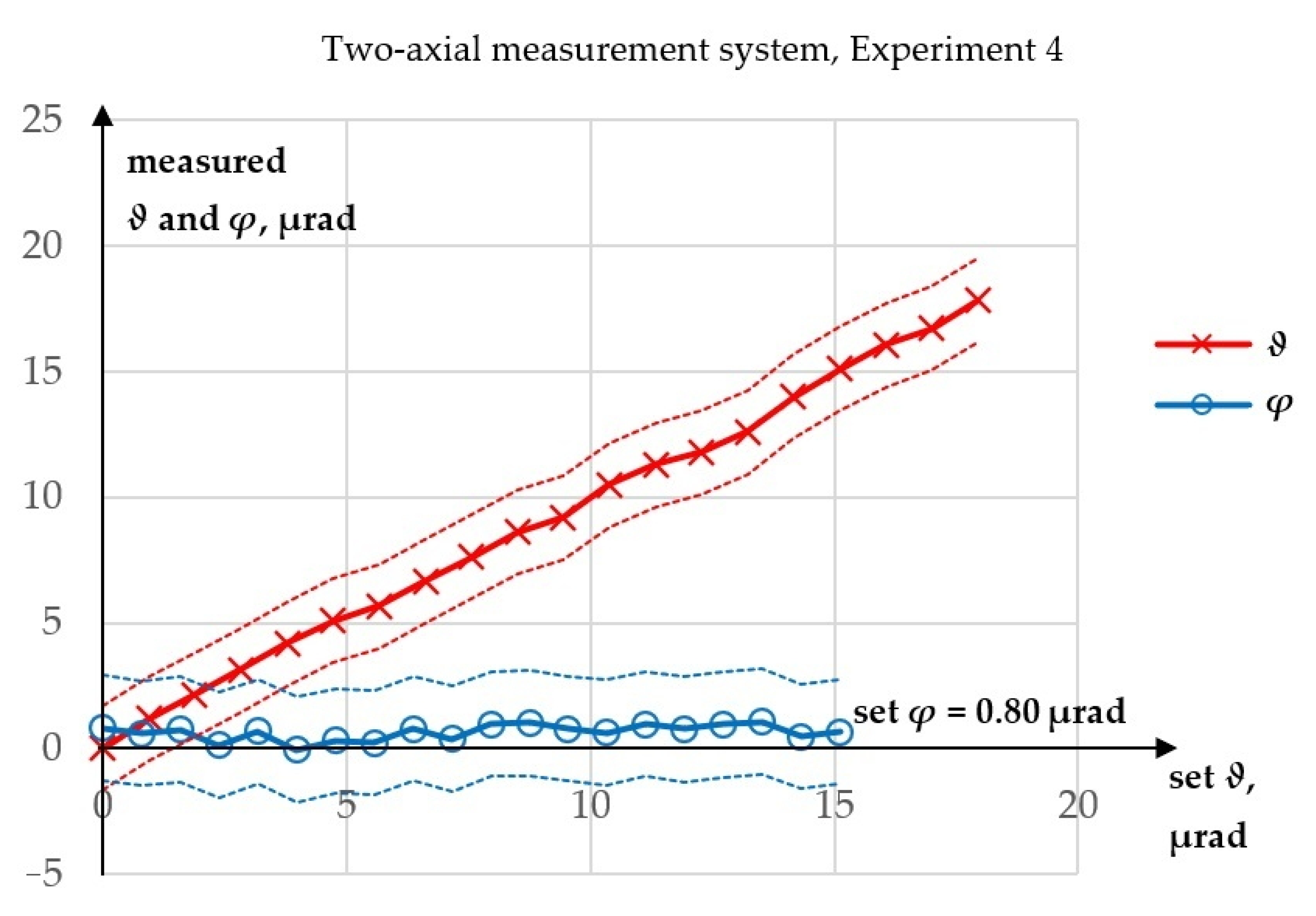

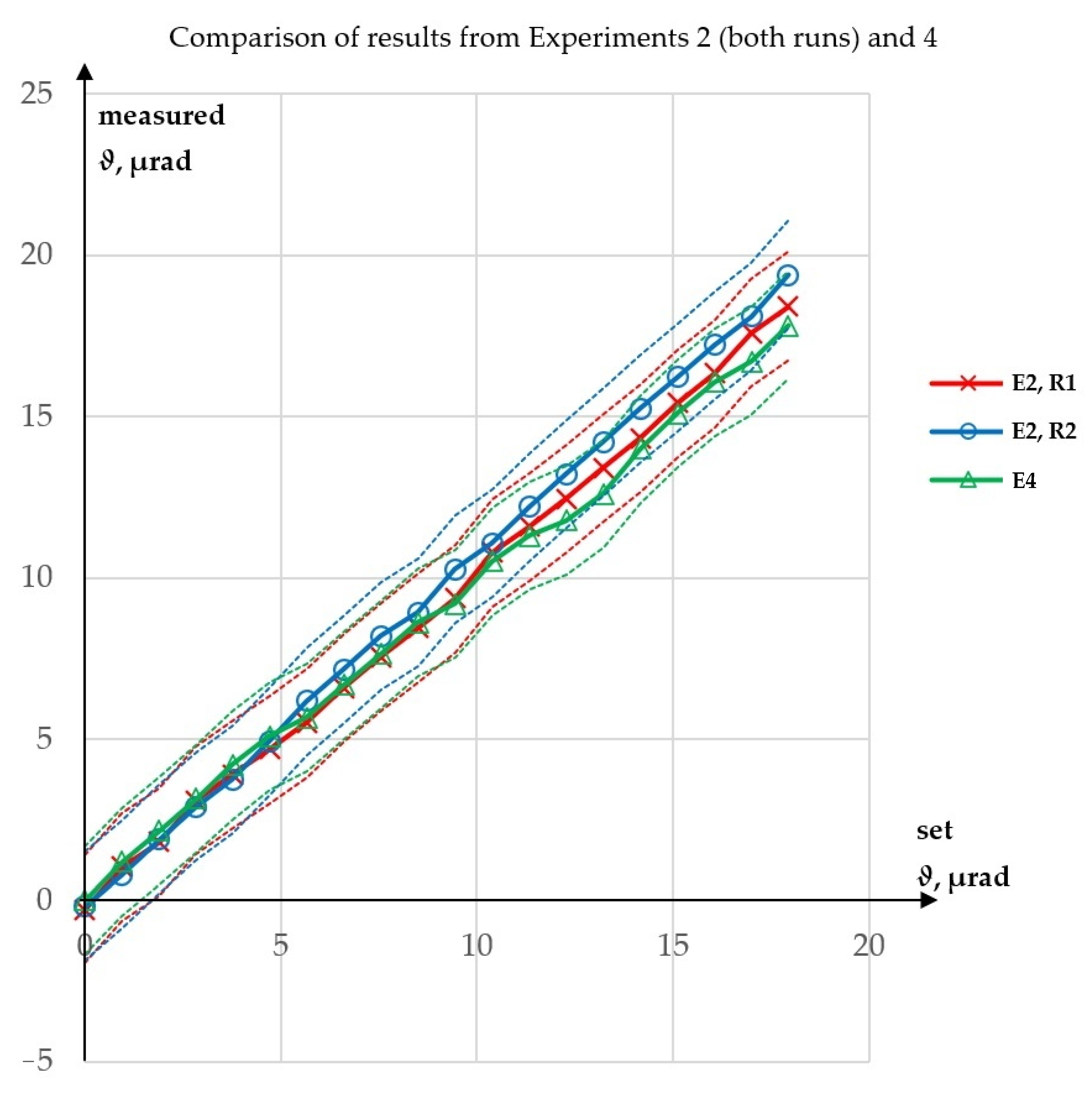

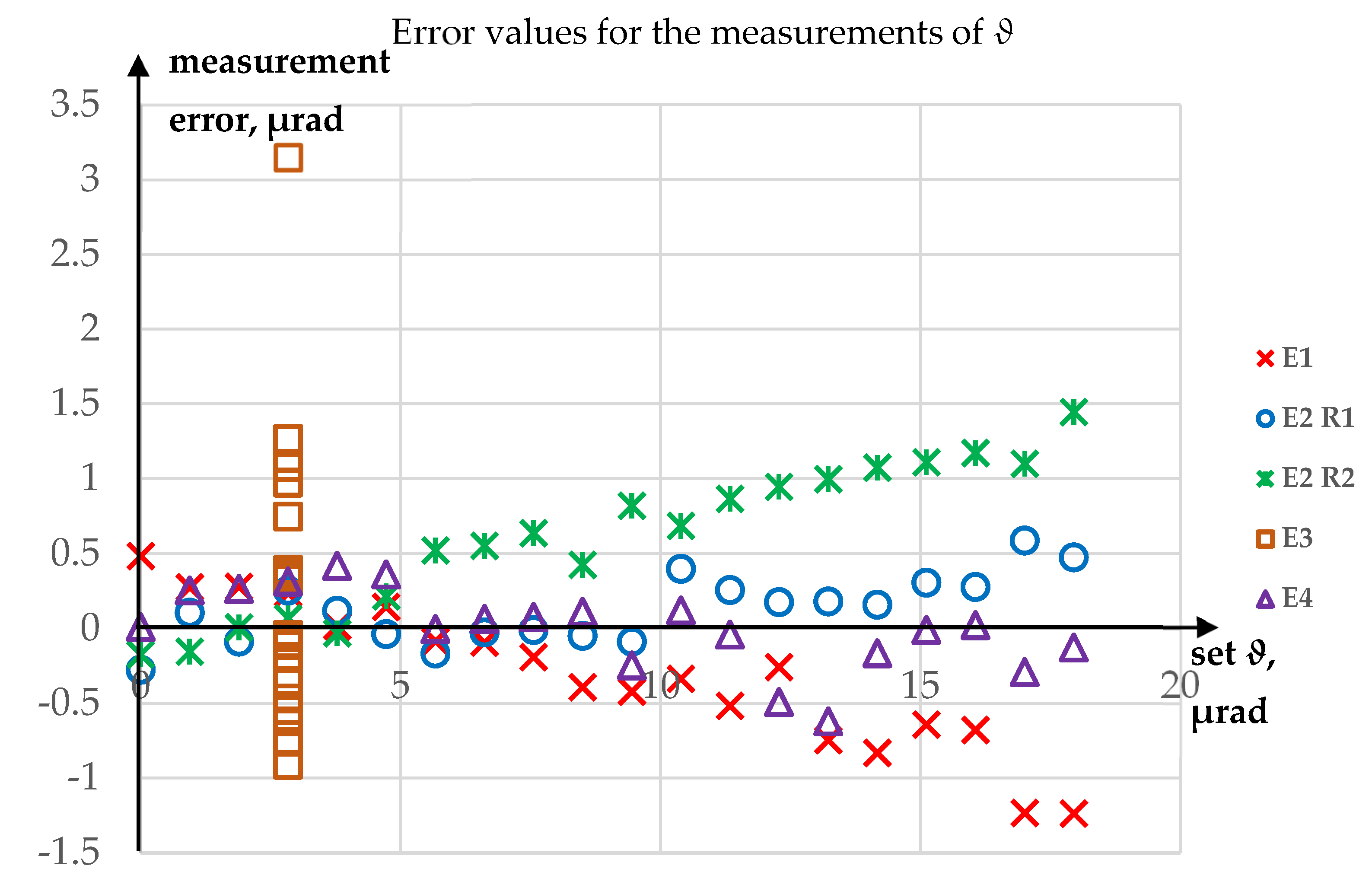

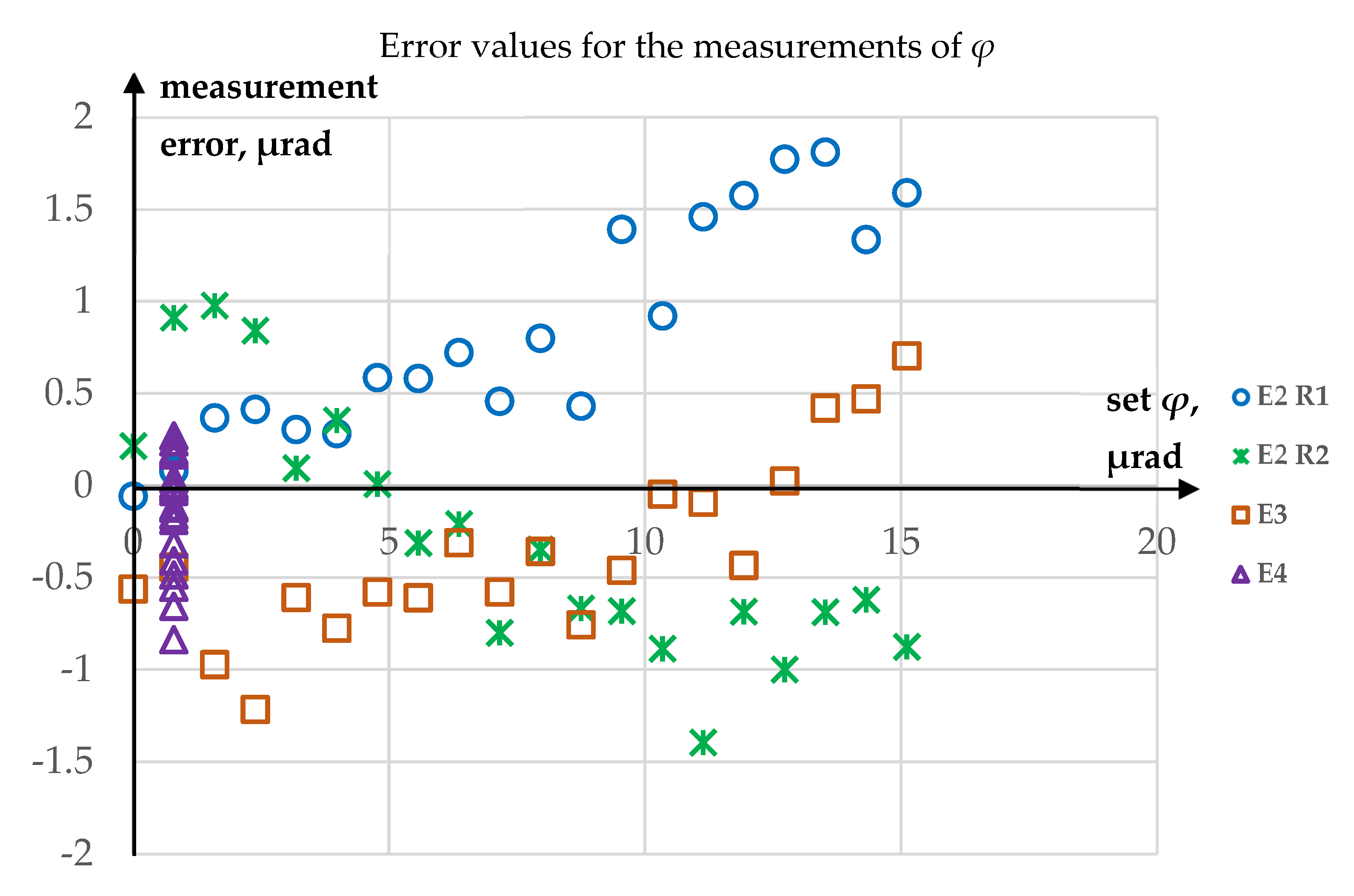

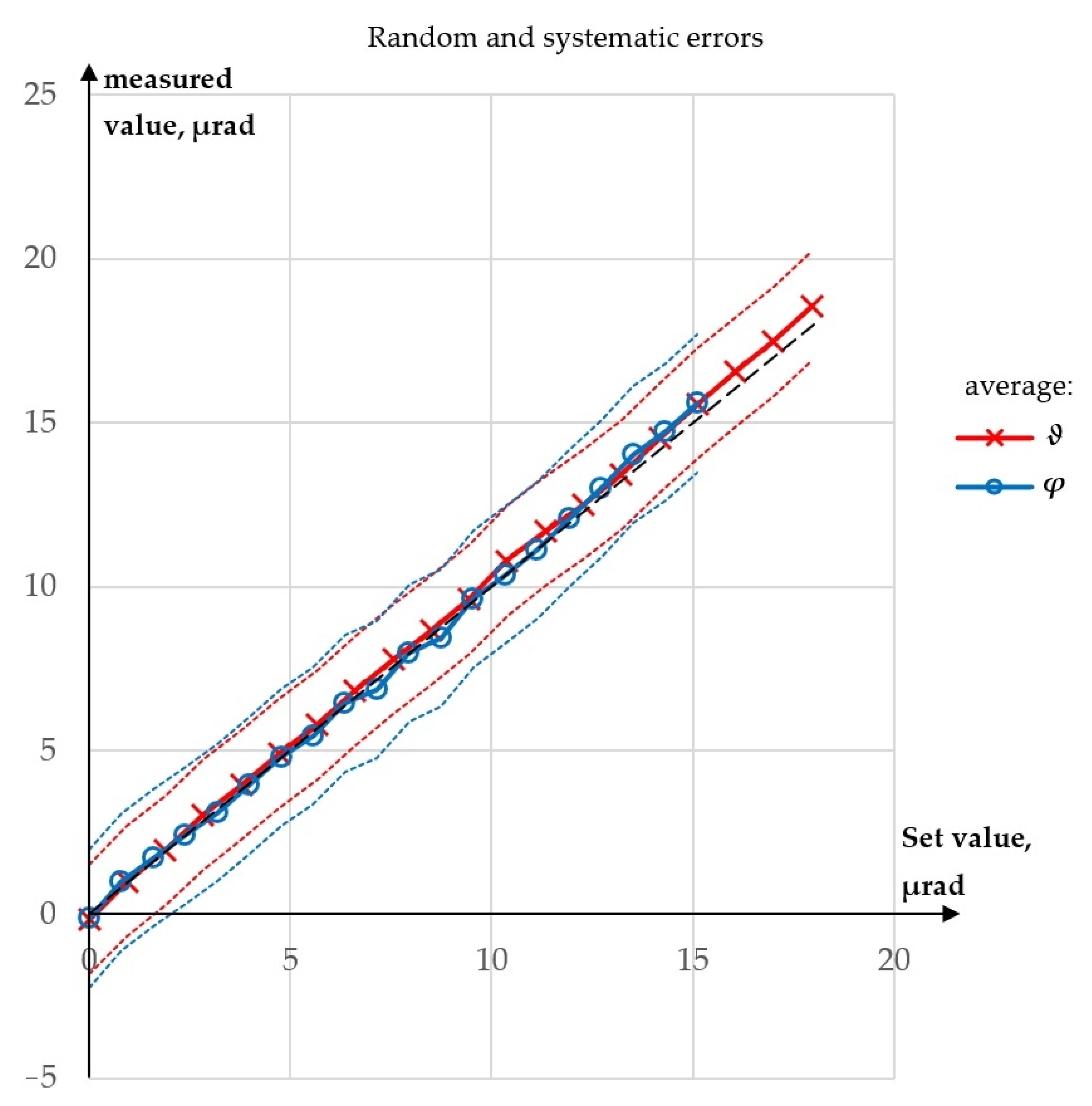

3. Results

3.1. Results Overwiev

3.2. Uncertainty Analysis

4. Discussion

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Putman, C.A.J.; De Grooth, B.G.; Van Hulst, N.F.; Greve, J. A Detailed Analysis of the Optical Beam Deflection Technique for Use in Atomic Force Microscopy. J. Appl. Phys. 1992, 72, 6–12. [Google Scholar] [CrossRef]

- Meyer, G.; Amer, N.M. Optical-beam-deflection Atomic Force Microscopy: The NaCl (001) Surface. Appl. Phys. Lett. 1990, 56, 2100–2101. [Google Scholar] [CrossRef]

- Levesque, M.; Mailloux, A.; Morin, M.; Galarneau, P.; Champagne, Y.; Plomteux, O.; Tiedtke, M. Laser Pointing Stability Measurements. In Third International Workshop on Laser Beam and Optics Characterization; Morin, M., Giesen, A., Eds.; SPIE: Bellingham, WA, USA, 1996; Volume 2870, pp. 216–224. [Google Scholar] [CrossRef]

- Virdee, M.S. High Accuracy Form Measurement of Specularly Reflecting Surfaces by Laser Autocollimation. In Ultraprecision Machining and Automated Fabrication of Optics; SPIE: Bellingham, WA, USA, 1987; Volume 0676, pp. 66–73. [Google Scholar] [CrossRef]

- Shimizu, Y.; Matsukuma, H.; Gao, W. Optical Angle Sensor Technology Based on the Optical Frequency Comb Laser. Appl. Sci. 2020, 10, 4047. [Google Scholar] [CrossRef]

- ISO 11670:2003; Lasers and Laser-Related Equipment—Test Methods for Laser Beam Parameters—Beam Positional Stability. ISO: Geneva, Switzerland, 2003.

- Lim, H.; Shimizu, Y. Feasible Resolution of Angular Displacement Measurement by an Optical Angle Sensor Based on Laser Autocollimation. Nanomanuf. Metrol. 2023, 6, 32. [Google Scholar] [CrossRef]

- Huang, P.S.; Kiyono, S.; Kamada, O. Angle Measurement Based on the Internal-Reflection Effect: A New Method. Appl. Opt. 1992, 31, 6047–6055. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.S.; Ni, J. Angle Measurement Based on the Internal-Reflection Effect Using Elongated Critical-Angle Prisms. Appl. Opt. 1996, 35, 2239–2241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Kiyono, S.; Uda, Y. Nanoradian Angle Sensor and in Situ Self-Calibration. Appl. Opt. 1998, 37, 4154–4159. [Google Scholar] [CrossRef] [PubMed]

- Villatoro, J.; García-Valenzuela, A. Measuring Optical Power Transmission near the Critical Angle for Sensing Beam Deflection. Appl. Opt. 1998, 37, 6648–6653. [Google Scholar] [CrossRef] [PubMed]

- Gray, J.; Thomas, P.; Zhu, X.D. Laser Pointing Stability Measured by an Oblique-Incidence Optical Transmittance Difference Technique. Rev. Sci. Instrum. 2001, 72, 3714–3717. [Google Scholar] [CrossRef]

- García-Valenzuela, A.; Diaz-Uribe, R. Detection Limits of an Internal-Reflection Sensor for the Optical Beam Deflection Method. Appl. Opt. 1997, 36, 4456–4462. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.; Huang, P.S. Total Internal Reflection for Precision Small-Angle Measurement. Appl. Opt. 2001, 40, 1617–1622. [Google Scholar] [CrossRef] [PubMed]

- García-Valenzuela, A.; Sandoval-Romero, G.E.; Sánchez-Pérez, C. High-Resolution Optical Angle Sensors: Approaching the Diffraction Limit to the Sensitivity. Appl. Opt. 2004, 43, 4311–4321. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Valenzuela, A.; Pena-Gomar, M.; Villatoro, J. Sensitivity Analysis of Angle-Sensitive Detectors Based on a Film Resonator. Opt. Eng. 2003, 42, 1084–1092. [Google Scholar] [CrossRef]

- Garcia-Valenzuela, A.; Diaz-Uribe, R. Approach to Improve the Angle Sensitivity and Resolution of the Optical Beam Deflection Method Using a Passive Interferometer and a Ronchi Grating. Opt. Eng. 1997, 36, 1770–1778. [Google Scholar] [CrossRef]

- Kwee, P.; Seifert, F.; Willke, B.; Danzmann, K. Laser Beam Quality and Pointing Measurement with an Optical Resonator. Rev. Sci. Instrum. 2007, 78, 73103. [Google Scholar] [CrossRef] [PubMed]

- Morrison, E.; Meers, B.J.; Robertson, D.I.; Ward, H. Automatic Alignment of Optical Interferometers. Appl. Opt. 1994, 33, 5041–5049. [Google Scholar] [CrossRef] [PubMed]

- Dobosz, M. Interference Sensor for Ultra-Precision Measurement of Laser Beam Angular Deflection. Rev. Sci. Instrum. 2018, 89, 115003. [Google Scholar] [CrossRef] [PubMed]

- Taylor Hobson Taylor Hobson: Autocollimators. Online Resource. Available online: https://www.taylor-hobson.com/products/alignment-level/autocollimators (accessed on 4 November 2023).

- Möller Wedel Optical: Electronic Autocollimators. Online Resource. Available online: https://moeller-wedel-optical.com/en/products/electronic-autocollimators/ (accessed on 4 November 2023).

- Dobosz, M.; Jankowski, M.; Mruk, J. Application of Interference Sensor of Angular Micro-Displacement in Measurements of Machine Rotational Errors. Precis. Eng. 2019, 60, 12–20. [Google Scholar] [CrossRef]

- Renishaw XL-80 Laser System. Online Resource. Available online: https://www.renishaw.com/en/xl-80-laser-system--8268 (accessed on 4 November 2023).

- Renishaw XM-60 and XM-600 Multi-Axis Calibrator. Online Resource. Available online: https://www.renishaw.com/en/xm-60-and-xm-600-multi-axis-calibrator--39258 (accessed on 4 November 2023).

- Nadolski, A. Badanie Wpływu Ustawienia Układu Zmieniającego Kierunek Odchyleń Wiązki Lasera Na Działanie Czujnika Mikroodchyleń Wiązki 2021. Master’s Thesis, Warsaw University of Technology, Warsaw, Poland, 2021. [Google Scholar]

- Mad City Labs Inc. Piezo Nanopositioning Systems, Vacuum Nanopositioning, Microscope Stages & Micropositioners. Atomic Force Microscopes, Near Field Scanning Optical Microscopes, Single Molecule Microscopes. Product Catalog 800A. Available online: http://www.madcitylabs.com (accessed on 4 November 2023).

- Mad City Labs, Inc. MCL Nano-Drive Technical Specification. Online Resource. Available online: http://www.madcitylabs.com/nanodrive.html (accessed on 4 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobosz, M.; Jankowski, M.; Mruk, J. Two-Axial Measurement of the Angular Microdeflection of a Laser Beam Using One Single-Axis Sensor. Sensors 2023, 23, 9276. https://doi.org/10.3390/s23229276

Dobosz M, Jankowski M, Mruk J. Two-Axial Measurement of the Angular Microdeflection of a Laser Beam Using One Single-Axis Sensor. Sensors. 2023; 23(22):9276. https://doi.org/10.3390/s23229276

Chicago/Turabian StyleDobosz, Marek, Michał Jankowski, and Jakub Mruk. 2023. "Two-Axial Measurement of the Angular Microdeflection of a Laser Beam Using One Single-Axis Sensor" Sensors 23, no. 22: 9276. https://doi.org/10.3390/s23229276

APA StyleDobosz, M., Jankowski, M., & Mruk, J. (2023). Two-Axial Measurement of the Angular Microdeflection of a Laser Beam Using One Single-Axis Sensor. Sensors, 23(22), 9276. https://doi.org/10.3390/s23229276