A Flow Sensing Device Formed Exclusively by Employing Additive Manufacturing for On-Site Fabrication Aboard a Ship

Abstract

:1. Introduction

2. Materials and Methods

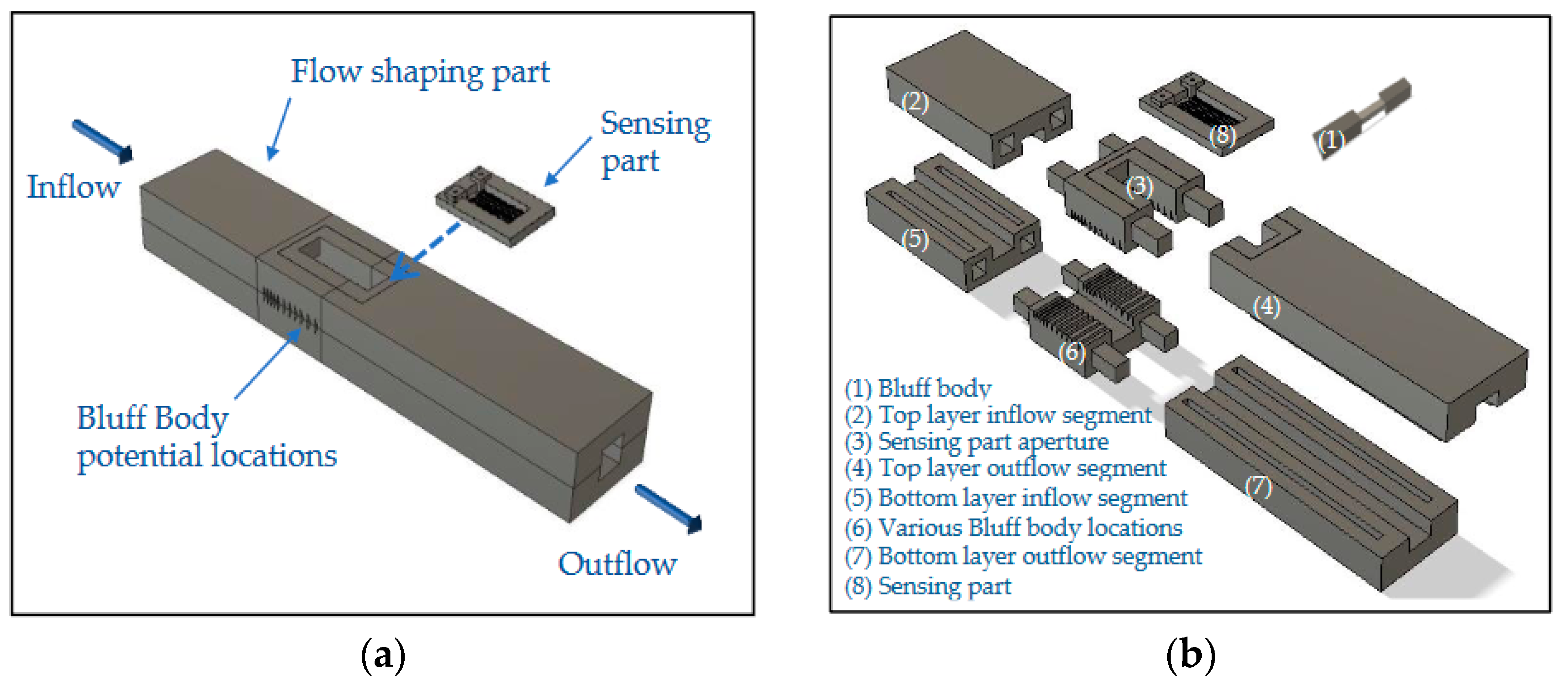

2.1. Proposed Device’s Geometry and Principle of Operation

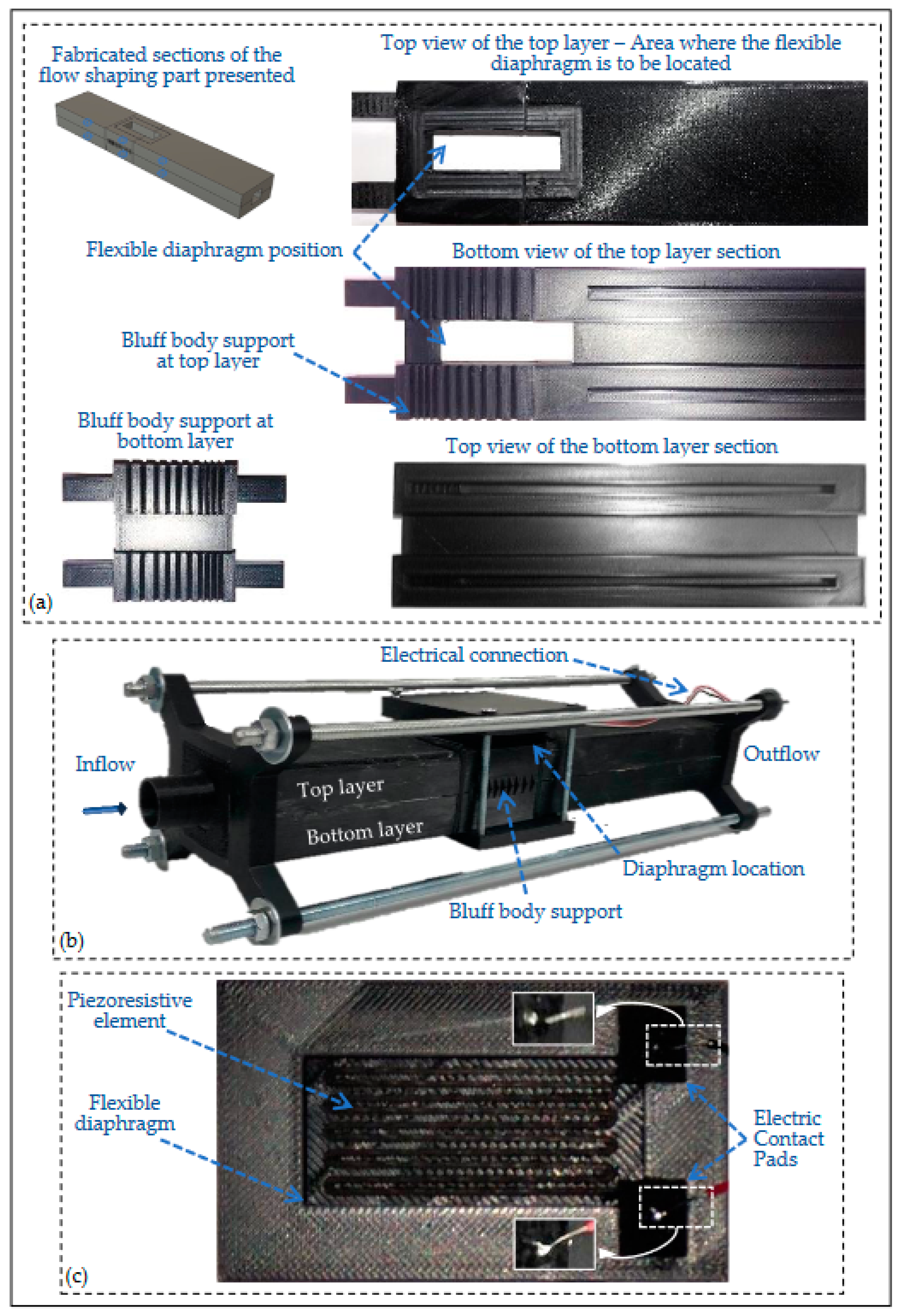

2.2. Flow-Shaping Part Design—Building Material Employed

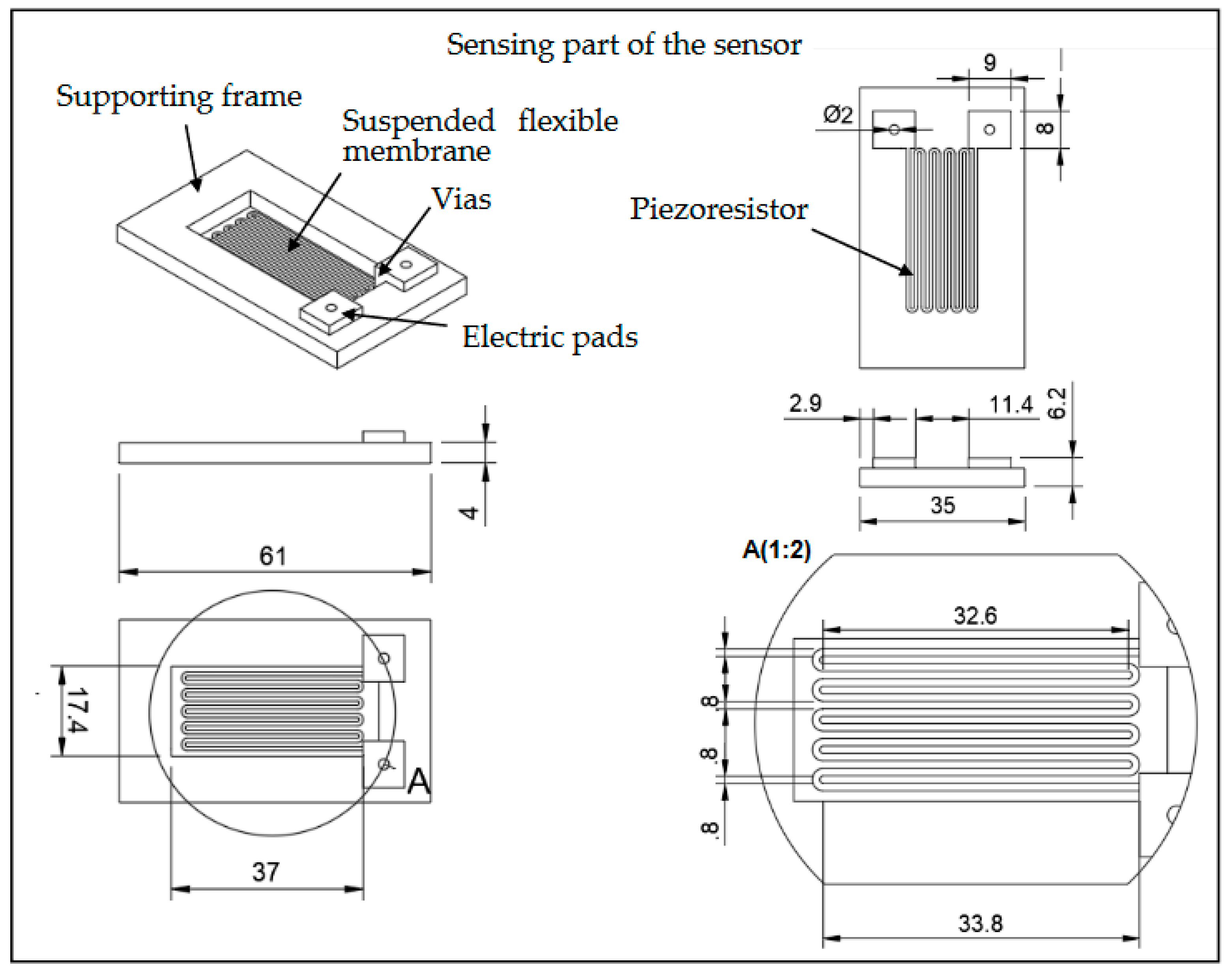

2.3. Sensing Part Design—Building Material Employed

2.4. Fabrication of the Prototype Sensor Device

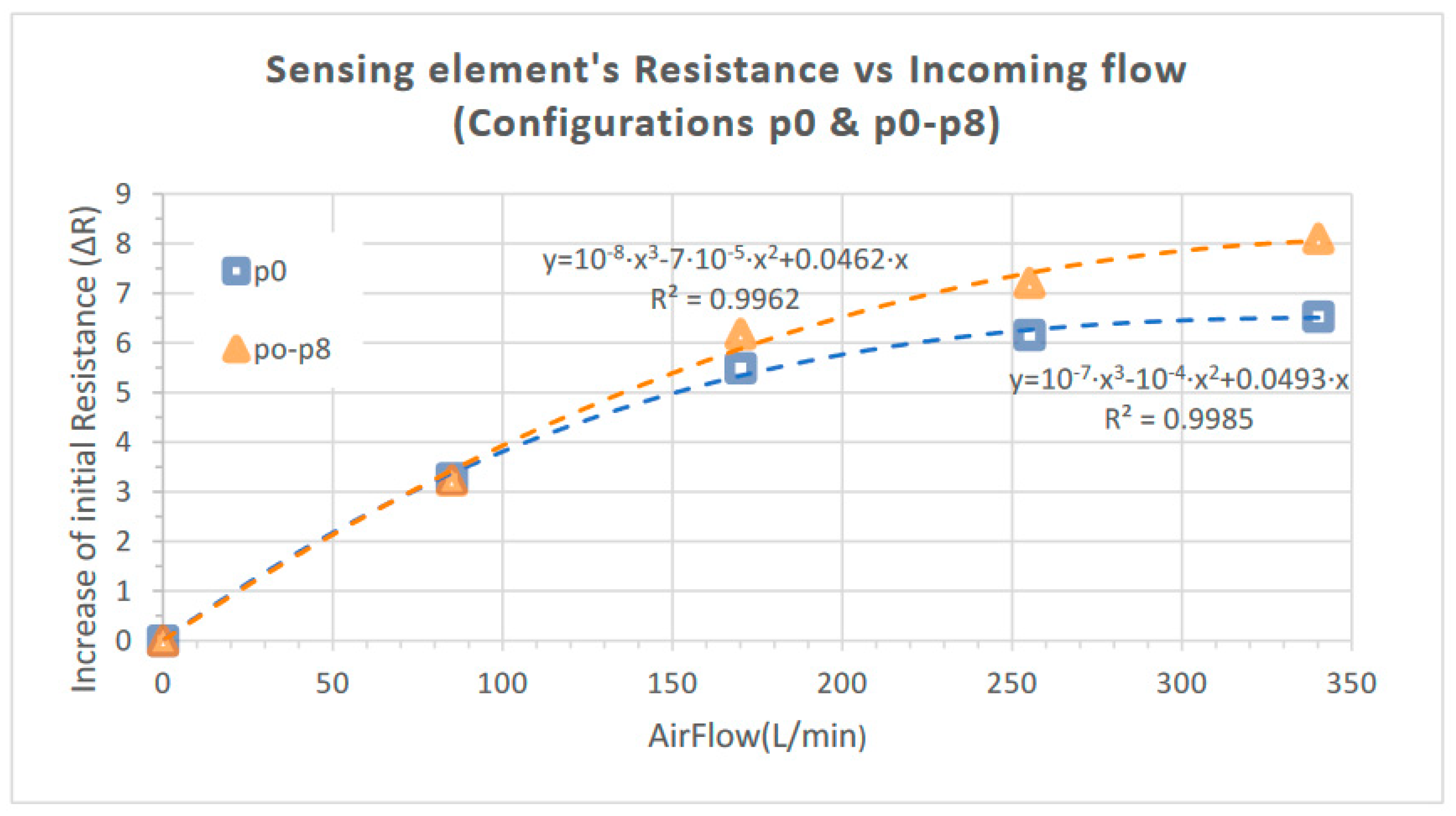

3. Results

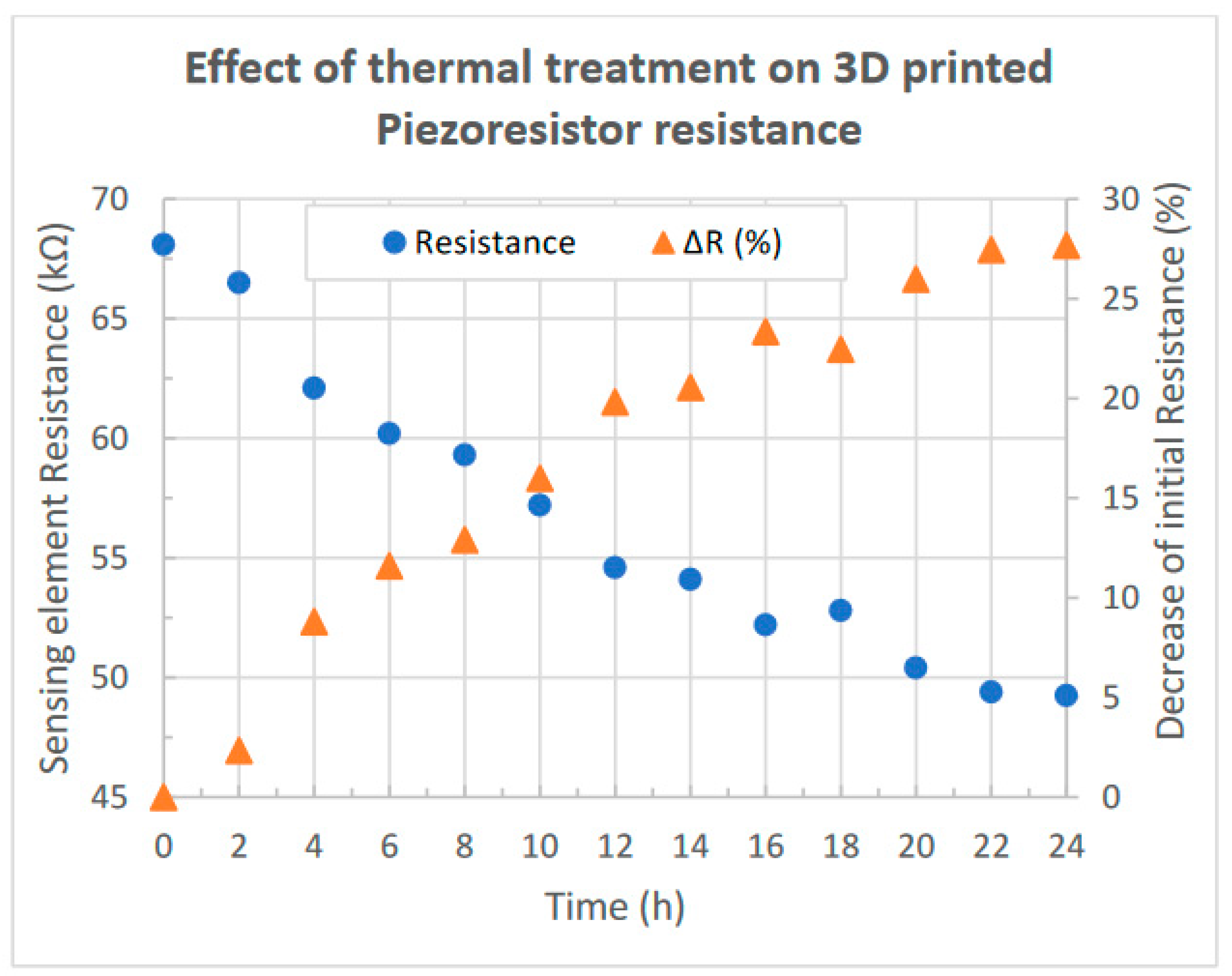

3.1. Thermal Treatment of the Piezoresistive Element

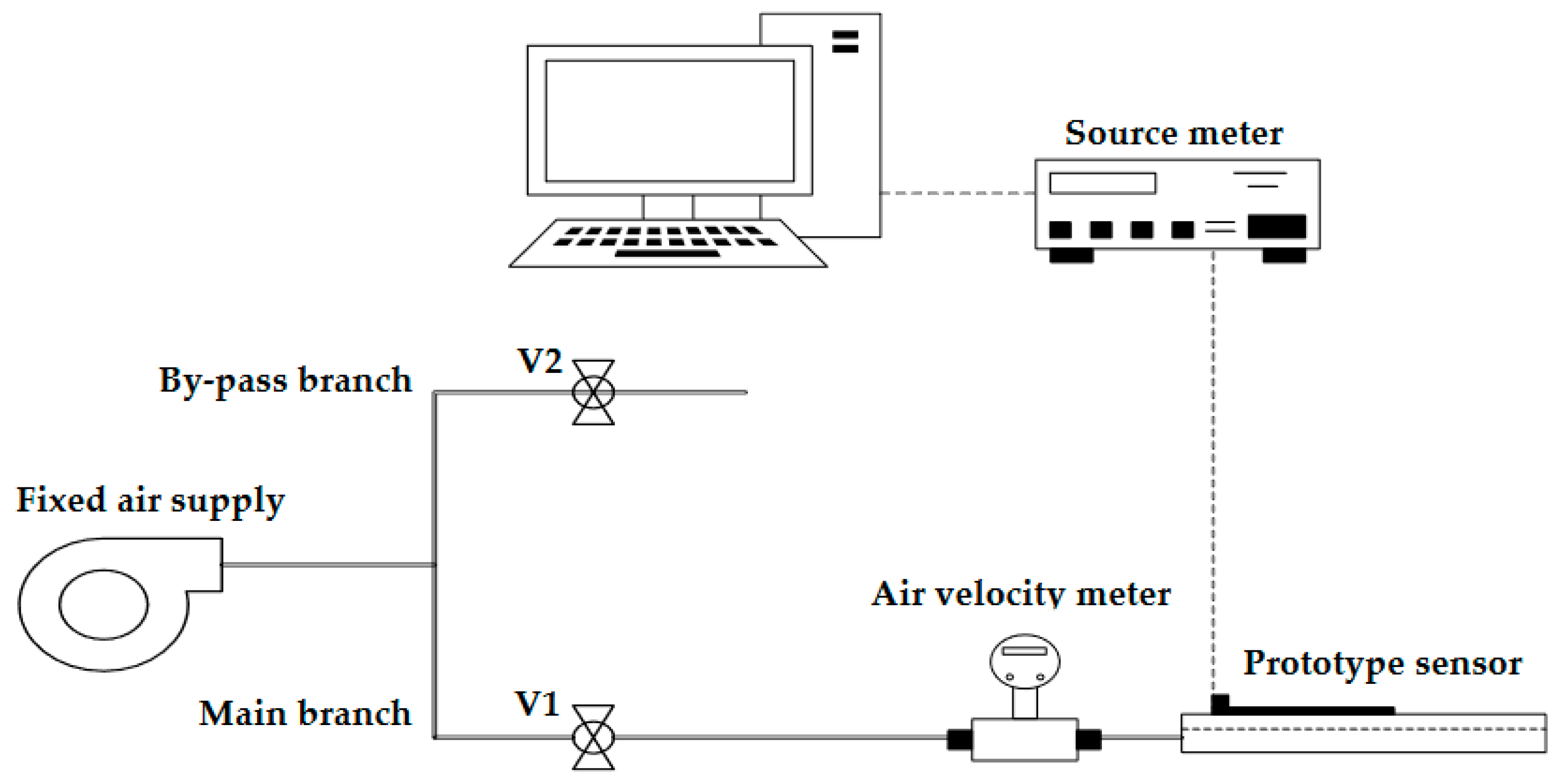

3.2. Experimental Setup Employed for the Characterization of the Sensor

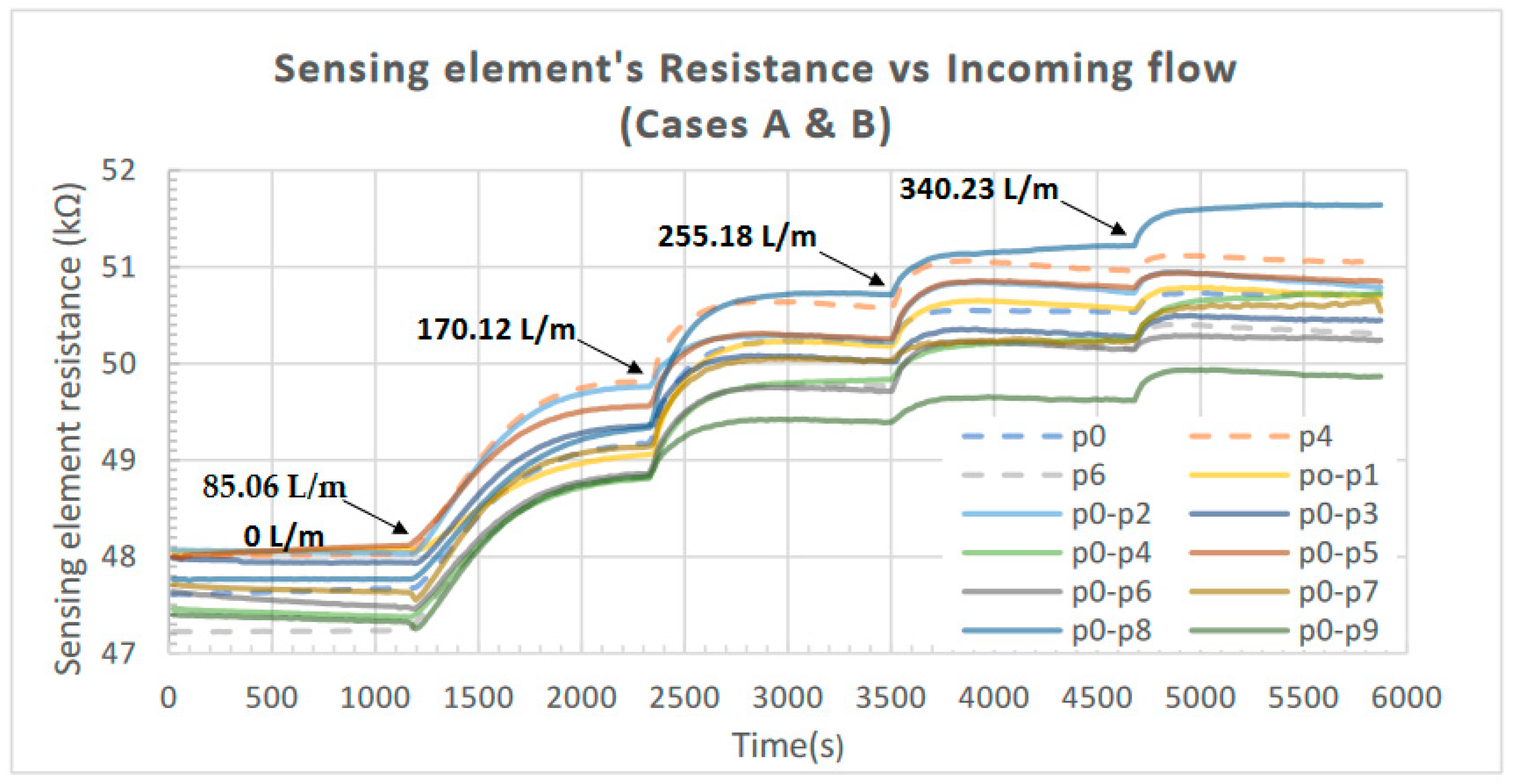

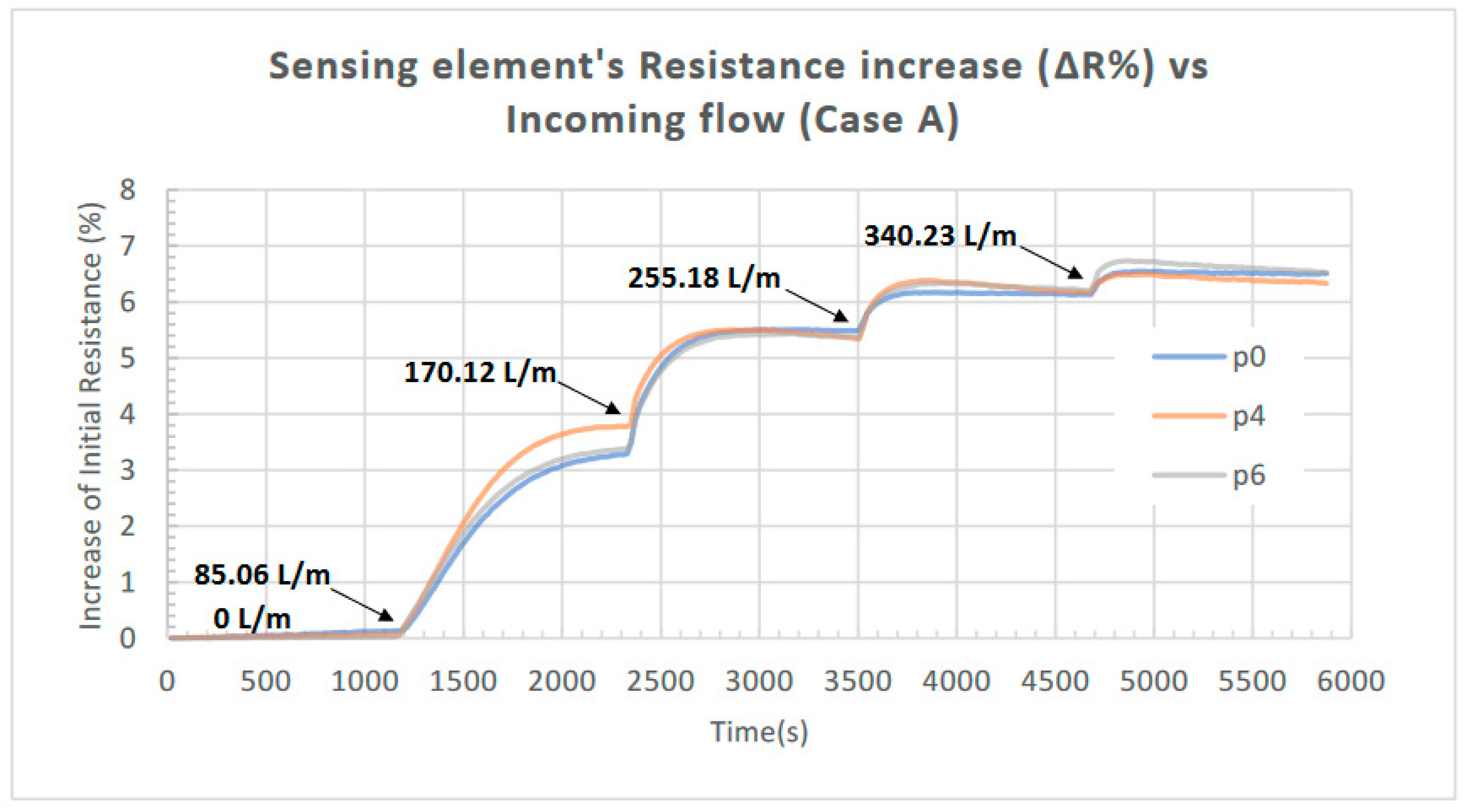

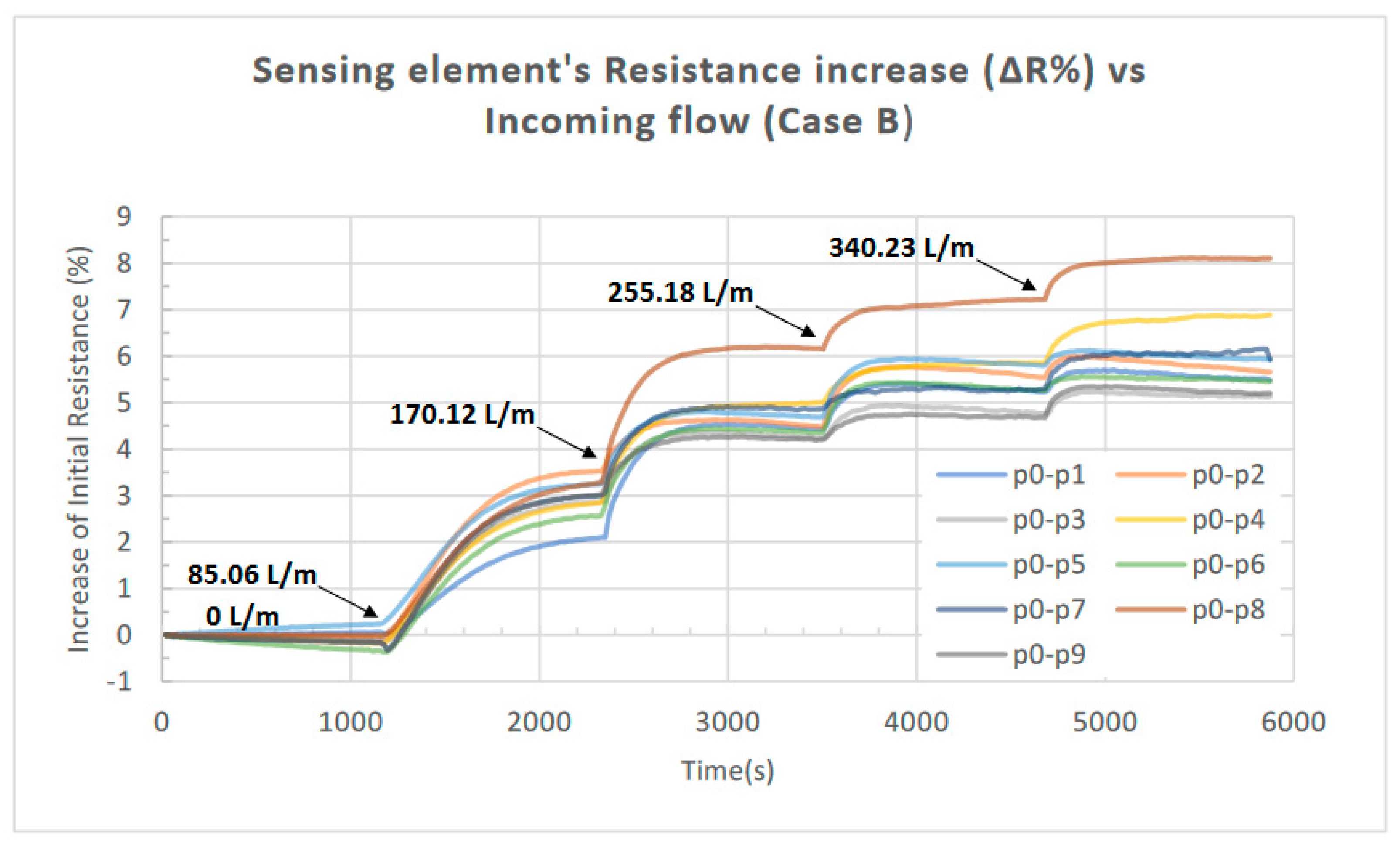

3.3. Initial Electrical Characterization of the Developed Sensor

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, W.; Zhang, X. 3D Printing: Print the Future of Ophthalmology. Investig. Ophthalmol. Vis. Sci. 2014, 55, 5380–5381. [Google Scholar] [CrossRef]

- Ho, C.; Ng, S.; Yoon, Y.-J. A review on 3D printed bioimplants. Int. J. Precis. Eng. Manuf. 2015, 16, 1035–1046. [Google Scholar] [CrossRef]

- Mosadegh, B.; Xiong, G.; Dunham, S.; Min, J.K. Current Progress in 3D Printing for Cardiovascular Tissue Engineering. 2015. Available online: https://iopscience.iop.org/article/10.1088/1748-6041/10/3/034002/meta (accessed on 5 October 2022).

- Holmes, C.M.B.; Faucett, S.; Zhang, L.G. Three-dimensional printing of nanomaterial scaffolds for complex tissue regeneration. Tissue Eng. Part B Rev. 2015, 21, 103–114. [Google Scholar] [CrossRef]

- Lee, H.; Kim, W.; Han, J.; Han, C. The technical trend of the exoskeleton robot system for human power assistance. Int. J. Precis. Eng. Manuf. 2012, 13, 1491–1497. [Google Scholar] [CrossRef]

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Baker, A.B.; Bates, S.G.R.; Llewellyn-Jones, T.M.; Valori, L.P.; Dicker, M.P.; Trask, R.S. 4D printing with robust thermoplastic polyurethane hydrogel-elastomer trilayers. Mater. Des. 2019, 163, 107544. [Google Scholar] [CrossRef]

- The Global Leader in Innovative Technologies and Lifecycle Solutions for the Marine and Energy Markets|Wärtsilä. Available online: https://www.wartsila.com/ (accessed on 29 March 2023).

- Marine and Energy Technology. Available online: https://static.markforged.com/downloads/WartsilaCaseStudy.pdf (accessed on 29 March 2023).

- Lotrecchianoa, N.; Sofiaa, D.; Giulianoa, A.; Barlettaa, D.; Polettoa, M. Real-time on-road monitoring network of air quality. Chem. Eng. Trans. 2019, 74, 241–246. [Google Scholar] [CrossRef]

- Livanos, G.A.; Theotokatos, G.; Pagonis, D.N. Techno-Economic Investigation of Alternative Propulsion Plants for Ferries and RoRo Ships. Energy Convers. Manag. 2014, 79, 640–651. Available online: https://www.sciencedirect.com/science/article/pii/S0196890414000156 (accessed on 5 October 2022).

- International Convention for the Safety of Life at Sea (SOLAS). 1974. Available online: https://www.imo.org/en/About/Conventions/Pages/International-Convention-for-the-Safety-of-Life-at-Sea-(SOLAS),-1974.aspx (accessed on 5 October 2022).

- Lynnworth, L.; Cohen, R.; Rose, J.; Kim, J. Vortex Shedder Fluid Flow Sensor. 2006. Available online: https://ieeexplore.ieee.org/abstract/document/4014172/ (accessed on 5 October 2022).

- Kaltsas, A.; Petropoulos, A.; Tsougeni, K.; Pagonis, D.N. A novel microfabrication technology on organic substrates–application to a thermal flow sensor. J. Phys. Conf. Ser. 2007, 92, 012046. [Google Scholar] [CrossRef]

- Petropoulos, A.; Pagonis, D.N.; Kaltsas, G. Flexible PCB-MEMS Flow Sensor. Procedia Eng. 2012, 47, 236–239. [Google Scholar] [CrossRef]

- Safety Critical Equipment and Spare Parts Guidance Safety Critical Equipment and Spare Parts Guidance (First Edition 2018). Available online: https://www.ocimf.org (accessed on 5 October 2022).

- Pankanin, G.L. The vortex flowmeter: Various methods of investigating phenomena. Meas. Sci. Technol. 2005, 16, R1. [Google Scholar] [CrossRef]

- Tam Nguyen, H.D.; Pham, H.T.; Wang, D.A. A miniature pneumatic energy generator using Kármán vortex street. J. Wind. Eng. Ind. Aerodyn. 2013, 116, 40–48. [Google Scholar] [CrossRef]

- Koubogiannis, D.G. Parametric CFD study of micro-energy harvesting in a flow channel exploiting vortex shedding. Open Eng. 2016, 6, 135–144. [Google Scholar] [CrossRef]

- BASF B.V. Available online: https://www.basf.com/global/en.html (accessed on 29 March 2023).

- Agarwala, S.; Goh, G.L.; Yeong, W.Y. Aerosol Jet Printed Strain Sensor: Simulation Studies Analyzing the Effect of Dimension and Design on Performance (September 2018); IEEE Access: Piscataway, NJ, USA, 2018; Volume 6, pp. 63080–63086. [Google Scholar] [CrossRef]

- Ultimaker S3: Easy-to-Use 3D Printing Starts Here. Available online: https://ultimaker.com/3d-printers/ultimaker-s3 (accessed on 5 April 2023).

- Fiberforce Ltd. Available online: https://www.fiberforce.it/ (accessed on 29 March 2023).

- Qi, X.; Ha, H.; Hwang, B.; Lim, S. Printability of the screen-printed strain sensor with carbon black/silver paste for sensitive wearable electronics. Appl. Sci. 2020, 10, 6983. [Google Scholar] [CrossRef]

- Verma, P.; Schiffer, A.; Kumar, S. Thermo-resistive and thermo-piezoresistive sensitivity of carbon nanostructure engineered thermoplastic composites processed via additive manufacturing. Polym. Test 2021, 93, 106961. [Google Scholar] [CrossRef]

- Cummins, G.; Desmulliez, M.P.Y. Inkjet printing of conductive materials: A review. Circuit World 2012, 38, 193–213. [Google Scholar] [CrossRef]

- Barmpakos, D.; Belessi, V.; Schelwald, R.; Kaltsas, G. Evaluation of Inkjet-Printed Reduced and Functionalized Water-Dispersible Graphene Oxide and Graphene on Polymer Substrate—Application to Printed Temperature Sensors. Nanomaterials 2021, 11, 2025. [Google Scholar] [CrossRef]

- Wiklund, J.; Karakoç, A.; Palko, T.; Yiğitler, H.; Ruttik, K.; Jäntti, R.; Paltakari, J. A Review on Printed Electronics: Fabrication Methods, Inks, Substrates, Applications and Environmental Impacts. J. Manuf. Mater. Process 2021, 5, 89. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.; Wajahat, M.; Ahn, J.; Pyo, J.; Chang, W.S.; Seol, S.K. 3D printing of highly conductive silver architectures enabled to sinter at low temperatures. Nanoscale 2019, 11, 17682–17688. [Google Scholar] [CrossRef]

- AMOLEN 3D Printer Filament, Conductive Black PLA Filament, 200G(0.44lb). Available online: https://amolen.com/products/amolen-3d-printer-filament-conductive-black-pla-filament-500g1-1lb (accessed on 6 April 2023).

- Recreus Filaflex|Impresión 3D|Venta de filamento 3D. Available online: https://recreus.com/gb/ (accessed on 6 April 2023).

- SUNLU—Affordable 3D Printing Filaments and Resins. Available online: https://www.sunlu.com/ (accessed on 6 April 2023).

- Kamyshny, A.; Magdassi, S. Conductive Nanomaterials for Printed Electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef]

- Magdassi, S. The chemistry of inkjet inks. In The Chemistry of Inkjet Inks; World Scientific Publishing Company: Singapore, 2009; pp. 1–345. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Çengel, Y.A.; Cimbala, J.M. Fluid Mechanics: Fundamentals and Applications, 3rd ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Lien, K. The Entrance Length for Fully Developed Turbulent Channel Flow. APS 2004, 57, KA.007. Available online: https://ui.adsabs.harvard.edu/abs/2004APS..DFD.KA007L/abstract (accessed on 10 April 2023).

- Benetatos, M.-V.N.; Koubogiannis, D.G. Numerical Investigation of The Energy Harvesting Potential from a Micro-Channel Flow. In Proceedings of the 10th International Conference from “Scientific Computing to Computational Engineering” 10th IC-SCCE, Athens, Greece, 6–9 July 2022. [Google Scholar]

| Main Characteristics | Value |

|---|---|

| Density | 1.35 g/cm3 |

| Melting Point | 145–160 °C |

| Tensile Strength | 30 MPa |

| Elastic Modulus | 1550 MPa |

| Surface Electric Resistivity | 10 Ω/sq |

| Printing Parameters | FiberForce Nylforce CNT Conductive | BASF Acrylonitrile Styrene Acrylate (ASA) |

|---|---|---|

| Nozzle Temperature | 260 | 215 |

| Nozzle Diameter | 0.6 mm | 0.4 mm |

| Nozzle Material | Brass | Brass |

| Printing Speed | 45 mm/s | 45 mm/s |

| Air Velocity (m/s) | Airflow (L/min) | Reynolds Number | Entrance Length (m) |

|---|---|---|---|

| 0 | 0 | 0 | 0 |

| 5 | 85.06 | 6505.03 | 0.23 |

| 10 | 170.12 | 13010.06 | 0.28 |

| 15 | 255.18 | 19515.09 | 0.31 |

| 20 | 340.23 | 26020.12 | 0.33 |

| Bluff Bodies Configuration | Location(s) of Bluff Body (or Bodies) |

|---|---|

| Case A (One Bluff Body employed) | p0; p4; p6 |

| Case B (Two Bluff Bodies employed) | p0-p1; p0-p2; p0-p3; p0-p4; p0-p5; p0-p6; p0-p7; p0-p8; p0-p9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pagonis, D.-N.; Matsoukas, I.; Kaltsas, G.; Pilatis, A. A Flow Sensing Device Formed Exclusively by Employing Additive Manufacturing for On-Site Fabrication Aboard a Ship. Sensors 2023, 23, 8481. https://doi.org/10.3390/s23208481

Pagonis D-N, Matsoukas I, Kaltsas G, Pilatis A. A Flow Sensing Device Formed Exclusively by Employing Additive Manufacturing for On-Site Fabrication Aboard a Ship. Sensors. 2023; 23(20):8481. https://doi.org/10.3390/s23208481

Chicago/Turabian StylePagonis, Dimitrios-Nikolaos, Ioannis Matsoukas, Grigoris Kaltsas, and Aggelos Pilatis. 2023. "A Flow Sensing Device Formed Exclusively by Employing Additive Manufacturing for On-Site Fabrication Aboard a Ship" Sensors 23, no. 20: 8481. https://doi.org/10.3390/s23208481

APA StylePagonis, D.-N., Matsoukas, I., Kaltsas, G., & Pilatis, A. (2023). A Flow Sensing Device Formed Exclusively by Employing Additive Manufacturing for On-Site Fabrication Aboard a Ship. Sensors, 23(20), 8481. https://doi.org/10.3390/s23208481