Single-Frame Infrared Image Non-Uniformity Correction Based on Wavelet Domain Noise Separation

Abstract

:1. Introduction

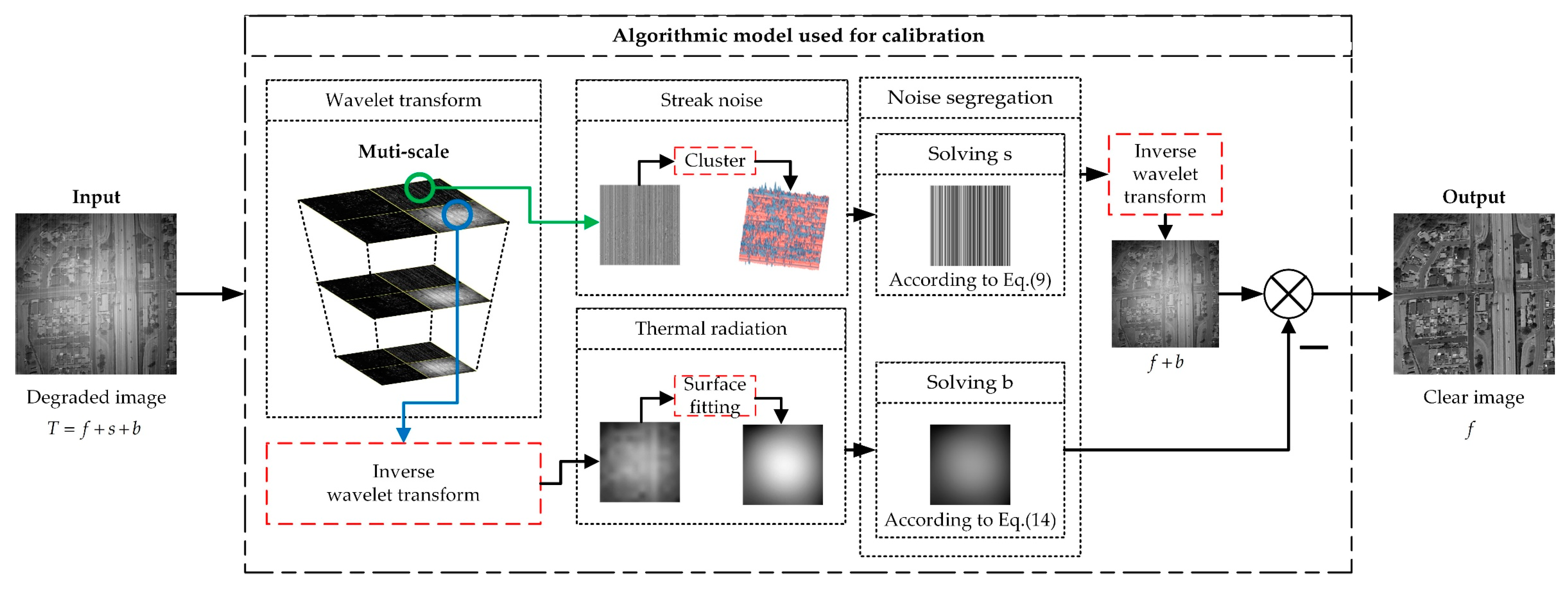

- This paper introduces a noise model that accounts for the superposition of stripe non-uniformity noise and thermal radiation non-uniformity noise. In contrast to previous correction models, this model can effectively address the intricacies of non-uniformity noise present in real-world scenarios;

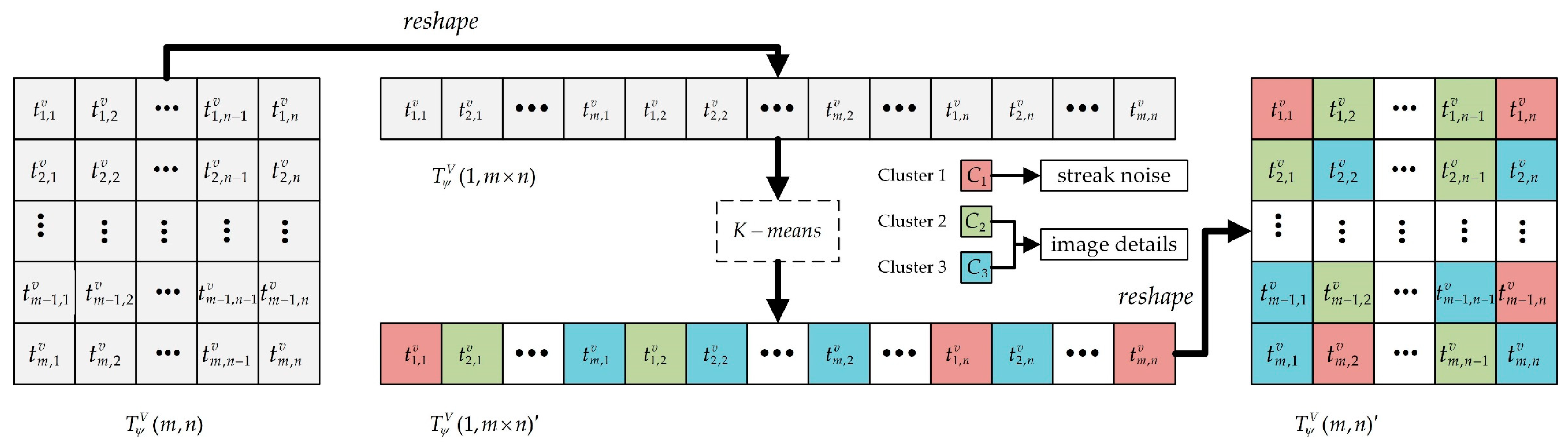

- In order to remove high-frequency noise, this paper designs a scheme based on cluster analysis in the wavelet domain for strip non-uniformity noise. This scheme adaptively generates clusters according to the varying strengths of noise components. By categorizing the wavelet domain’s vertical components into noise information and detail information, this approach effectively removes stripe noise while preserving the utmost level of image detail;

- In order to remove low-frequency noise, this paper designs a scheme based on fitting the approximated components in the wavelet domain for thermal radiation non-uniformity noise. This approach capitalizes on the alignment between low-frequency components in the wavelet domain and the thermal radiation noise. By employing Bezier surface fitting, the scheme reconstructs a smoothed representation of the thermal radiation noise, thereby enhancing the overall uniformity of the corrected image.

2. Related Work

2.1. Calibration-Based Non-Uniformity Correction

2.2. Multi-Frame Scene-Based Non-Uniformity Correction

2.3. Single-Frame Scene-Based Non-Uniformity Correction

3. Proposed Method

3.1. Non-Uniformity Model

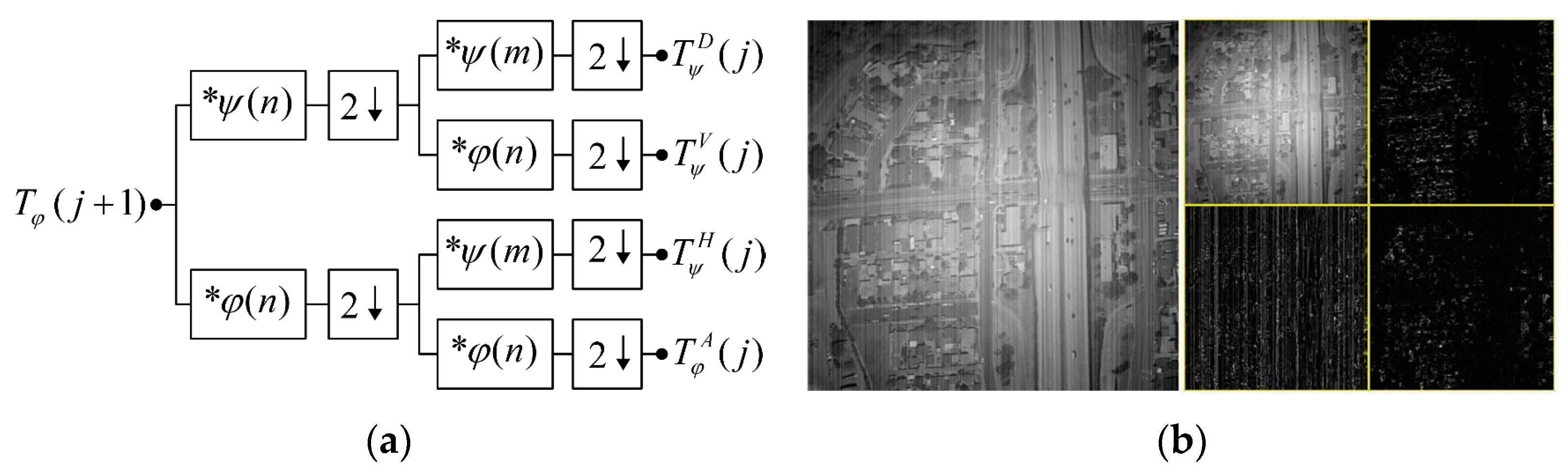

3.2. Wavelet Transform of Images

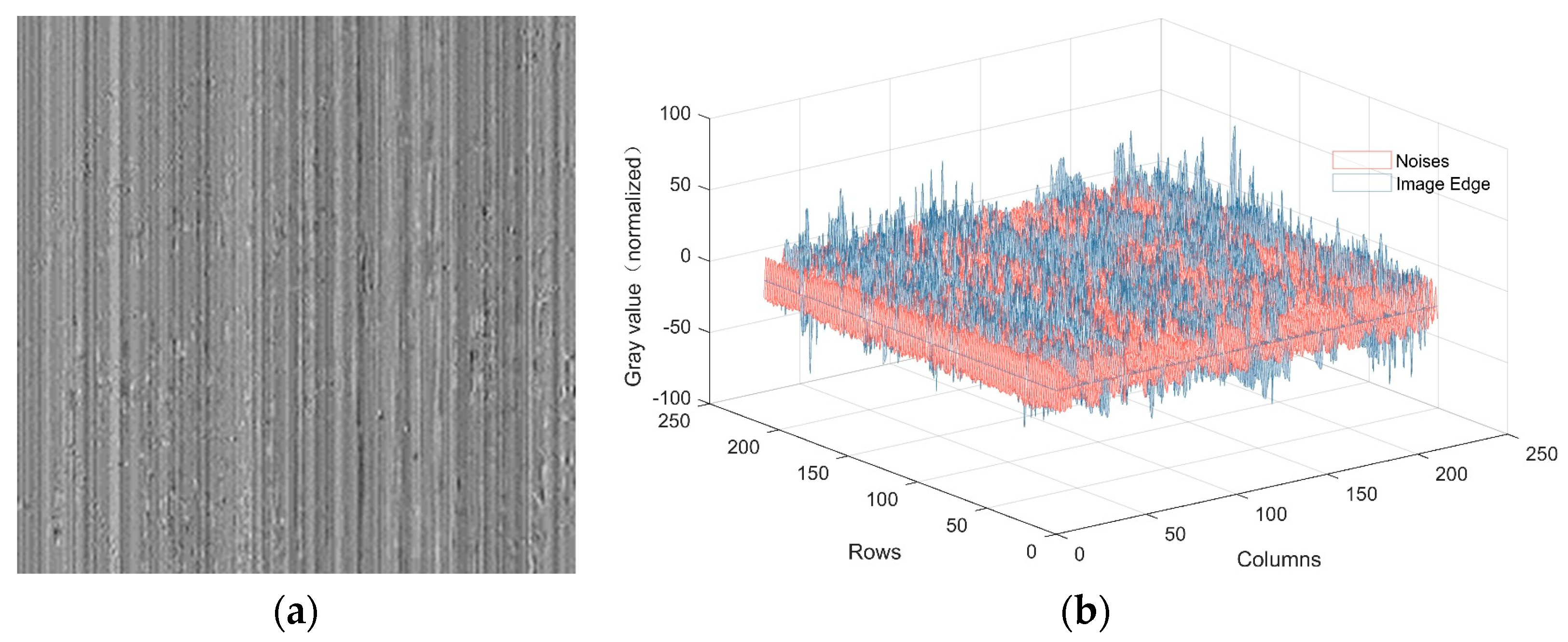

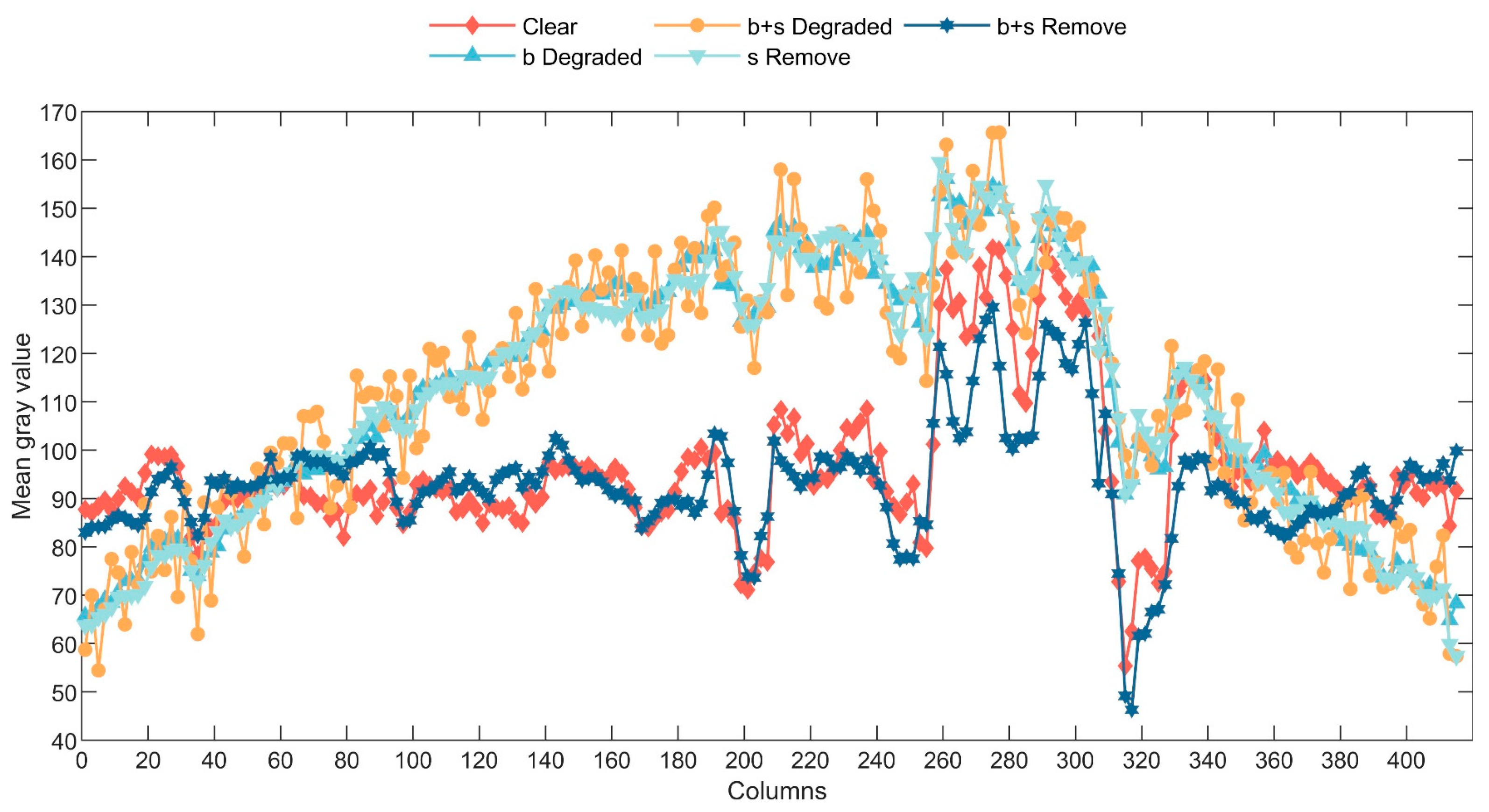

3.3. Stripe Removal

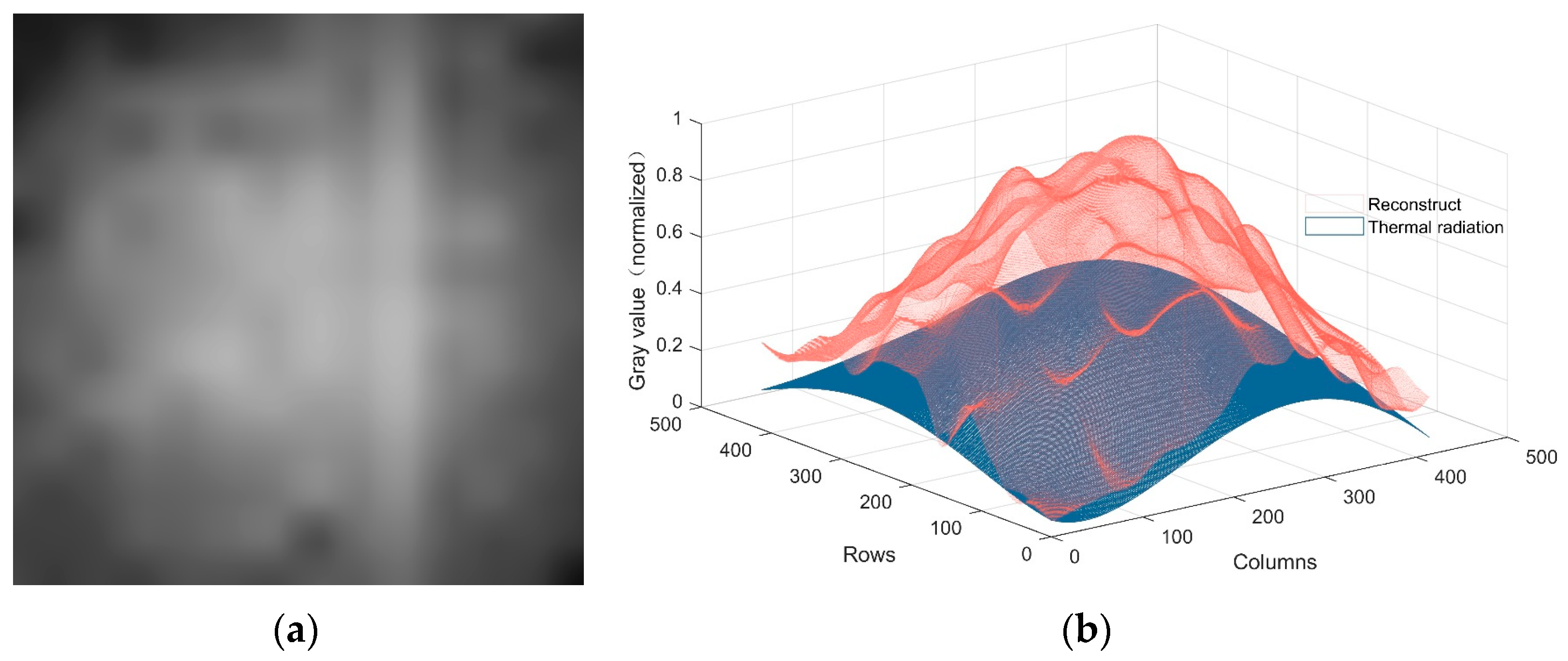

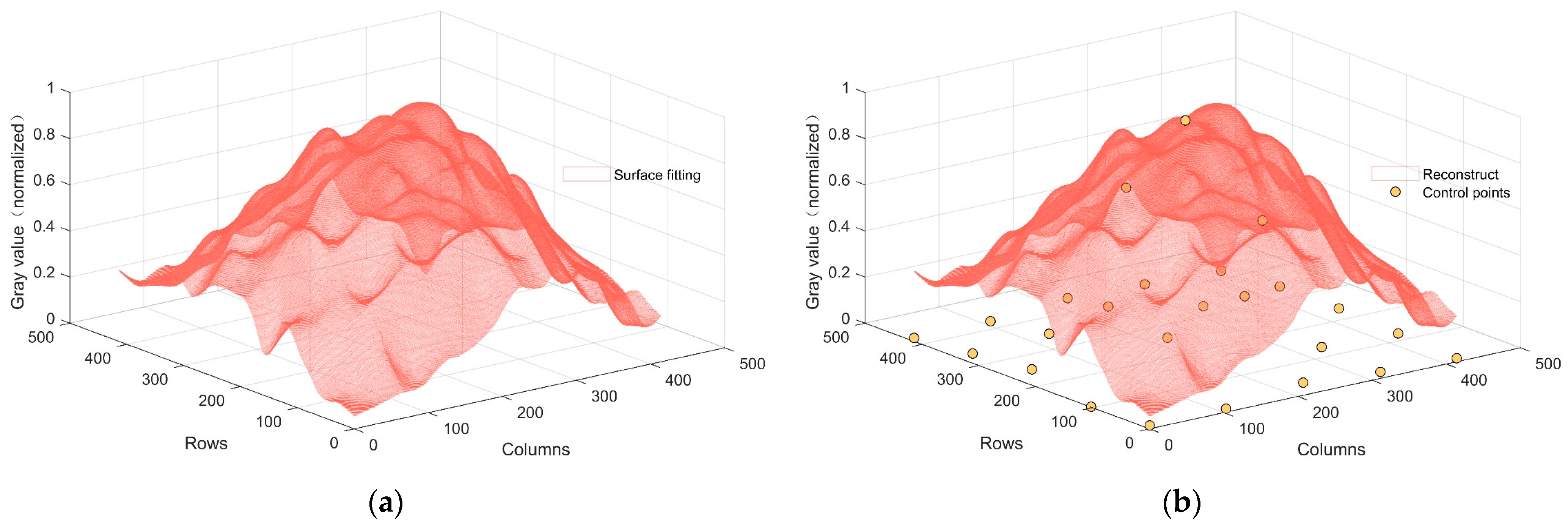

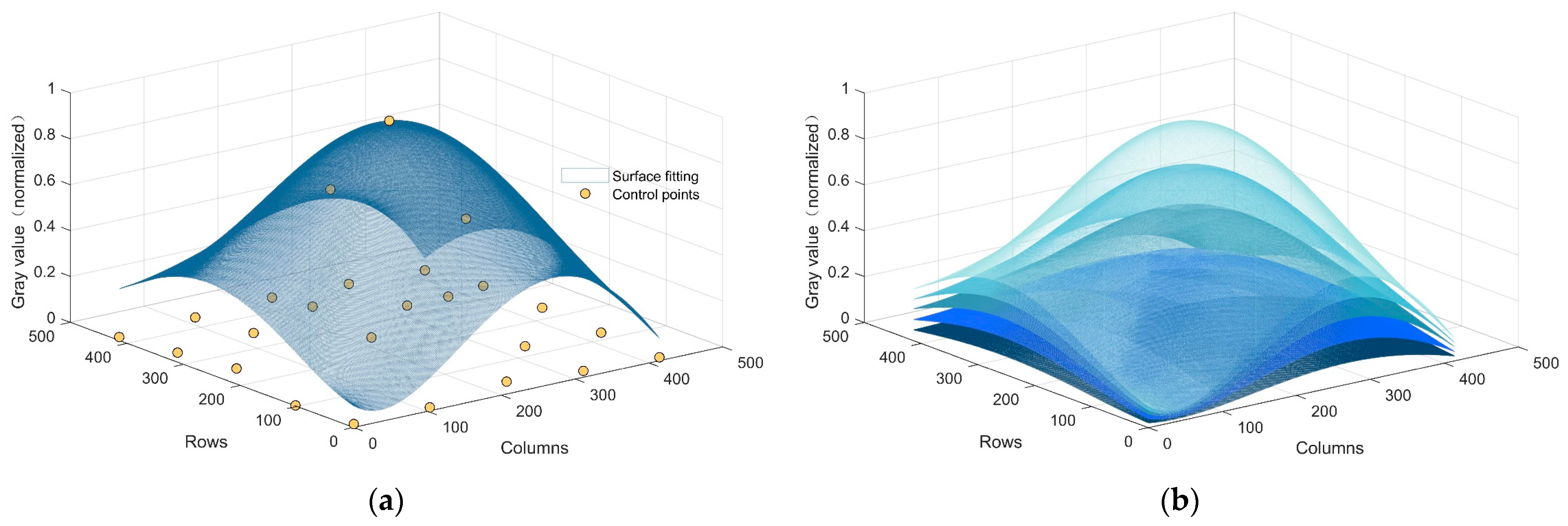

3.4. Thermal Radiation Noise Removal

4. Experimental Results

4.1. Simulated Image Correction

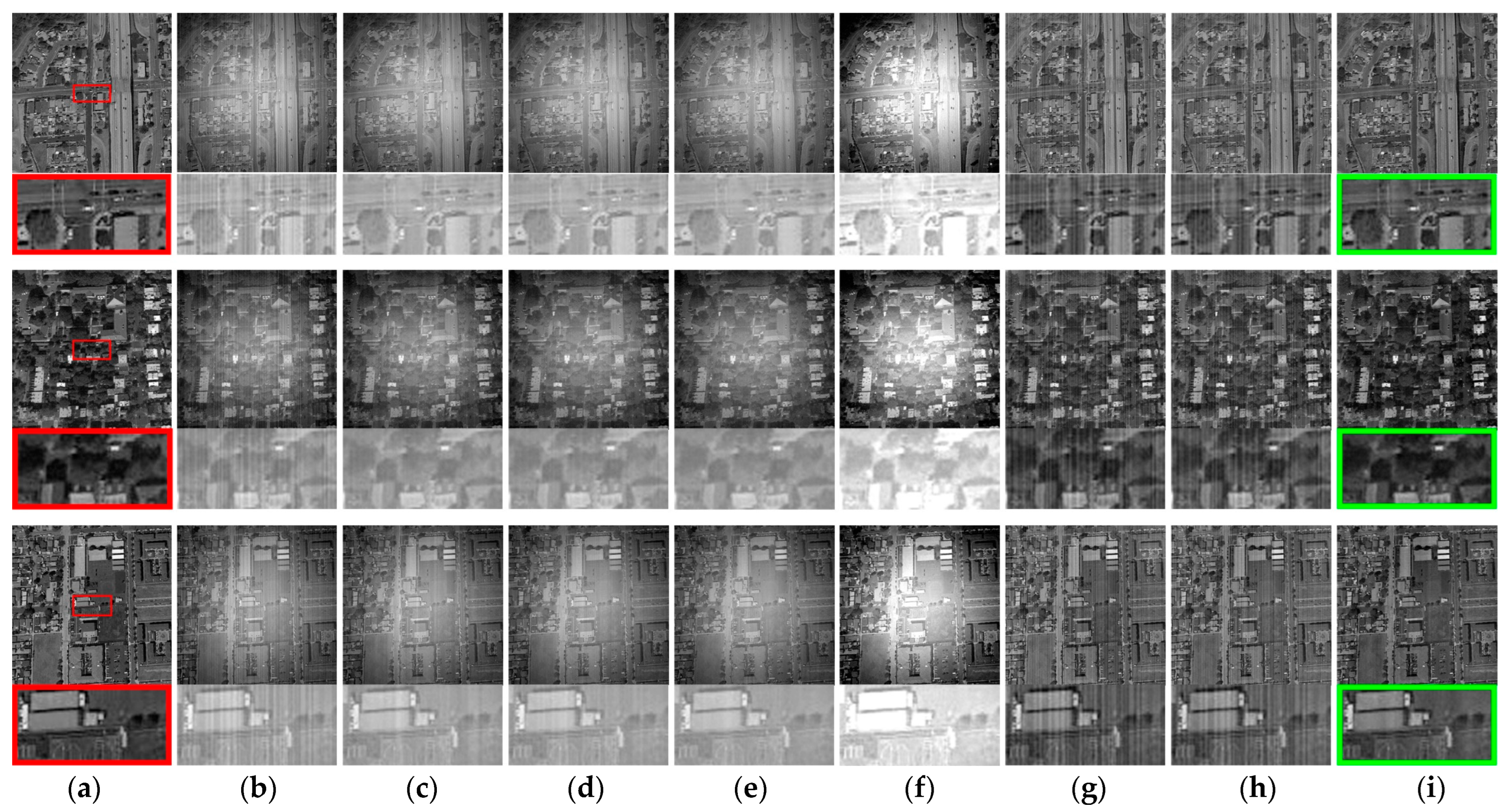

4.2. Real Image Correction

5. Discussion

5.1. Interpretation of Results

5.2. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Sui, X.; Liu, Y.; Kuang, X.; Gu, G.; Then, Q. FPN estimation based nonuniformity correction for infrared imaging system. Infrared Phys. Technol. 2019, 96, 22–29. [Google Scholar] [CrossRef]

- Wang, Z.; Zhan, J.; Li, Y.; Zhong, Z.; Cao, Z. A new scheme of vehicle detection for severe weather based on multi-sensor fusion. Measurement 2022, 191, 110737. [Google Scholar] [CrossRef]

- Yim, J.J.; Singh, S.P.; Xia, A.; Kashfi-Sadabad, R.; Tholen, M.; Huland, D.M.; Zarabanda, D.; Cao, Z.; Solis-Pazmino, P.; Bogyo, M.; et al. Short-Wave Infrared Fluorescence Chemical Sensor for Detection of Otitis Media. ACS Sens. 2020, 5, 3411–3419. [Google Scholar] [CrossRef] [PubMed]

- Byrd, B.K.; Marois, M.; Tichauer, K.M.; Wirth, D.J.; Hong, J.; Leonor, J.P.; Elliott, J.T.; Paulsen, K.D.; Davis, S.C. First experience imaging short-wave infrared fluorescence in a large animal: Indocyanine green angiography of a pig brain. J. Biomed. Opt. 2019, 24, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kang, M.G. Infrared Image Deconvolution Considering Fixed Pattern Noise. Sensors 2023, 23, 3033. [Google Scholar] [CrossRef]

- Li, Z.; Xu, G.; Cheng, Y.; Wang, Z.; Wu, Q.; Yan, F. A structure prior weighted hybrid l(2)-l(p) variational model for single infrared image intensity nonuniformity correction. Optik 2021, 229, 165867. [Google Scholar] [CrossRef]

- Chang, S.; Li, Z. Single-reference-based solution for two-point nonuniformity correction of infrared focal plane arrays—ScienceDirect. Infrared Phys. Technol. 2019, 101, 96–104. [Google Scholar] [CrossRef]

- Qian, W.; Chen, Q.; Gu, G. Space low-pass and temporal high-pass nonuniformity correction algorithm. Opt. Rev. 2010, 17, 24–29. [Google Scholar] [CrossRef]

- Zuo, C.; Chen, Q.; Gu, G.; Qian, W. New temporal high-pass filter nonuniformity correction based on bilateral filter. Opt. Rev. 2011, 18, 197–202. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Zheng, X.; Wu, Q. Adaptive Temporal High-pass Infrared Non-uniformity Correction Algorithm Based on Guided Filter. In Proceedings of the 2021 7th International Conference on Computing and Artificial Intelligence, Tianjin China, 23–26 April 2021; pp. 459–464. [Google Scholar]

- Harris, J.G.; Chiang, Y.-M. Nonuniformity correction of infrared image sequences using the constant-statistics constraint. IEEE Trans. Image Process. 1999, 8, 1148–1151. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, W. Scene-based nonuniformity correction using local constant statistics. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 2008, 25, 1444–1453. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Wang, D.; Huo, L.; Liu, R.; Jia, P. Scene-based nonuniformity correction for airborne point target detection systems. Opt. Express 2017, 25, 14210–14226. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Tong, S.; Liu, Q.; Sun, H. Statistical Scene-Based Non-Uniformity Correction Method with Interframe Registration. Sensors 2019, 19, 5395. [Google Scholar] [CrossRef] [PubMed]

- Lai, R.; Yang, Y.; Zhou, D.; Li, Y. Improved neural network based scene-adaptive nonuniformity correction method for infrared focal plane arrays. Appl. Opt. 2008, 47, 4331–4335. [Google Scholar]

- Rong, S.; Zhou, H.; Wen, Z.; Qin, H.; Qian, K.; Cheng, K. An improved non-uniformity correction algorithm and its hardware implementation on FPGA. Infrared Phys. Technol. 2017, 85, 410–420. [Google Scholar] [CrossRef]

- Hardie, R.C.; Hayat, M.M.; Armstrong, E.; Yasuda, B. Scene-based nonuniformity correction with video sequences and registration. Appl. Opt. 2000, 39, 1241–1250. [Google Scholar] [CrossRef]

- Yan, W.; Tan, R.T.; Dai, D. Nighttime Defogging Using High-Low Frequency Decomposition and Grayscale-Color Networks. In Proceedings of the European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 473–488. [Google Scholar]

- Liu, Y.; Yan, Z.; Tan, J.; Li, Y. Multi-purpose oriented single nighttime image haze removal based on unified variational retinex model. IEEE Trans. Circuits Syst. Video Technol. 2022, 33, 1643–1657. [Google Scholar] [CrossRef]

- Li, B.; Chen, W.; Zhang, Y. A Nonuniformity Correction Method Based on 1D Guided Filtering and Linear Fitting for High-Resolution Infrared Scan Images. Appl. Sci. 2023, 13, 3890. [Google Scholar] [CrossRef]

- Cao, Y.; Yang, M.Y.; Tisse, C.-L. Effective Strip Noise Removal for Low-Textured Infrared Images Based on 1-D Guided Filtering. IEEE Trans. Circuits Syst. Video Technol. 2016, 26, 2176–2188. [Google Scholar] [CrossRef]

- Zhang, T.; Li, X.; Li, J.; Xu, Z. Elimination of CMOS fixed pattern noise based on PCA wavelet transform. In Proceedings of the Seventh Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 5–7 November 2020; SPIE: Washington, DC, USA, 2021; pp. 1144–1150. [Google Scholar]

- Li, F.; Zhao, Y.; Xiang, W. Single-frame-based column fixed-pattern noise correction in an uncooled infrared imaging system based on weighted least squares. Appl. Opt. 2019, 58, 9141–9153. [Google Scholar] [CrossRef]

- Liu, L.; Yan, L.; Zhao, H.; Dai, X.; Zhang, T. Correction of aeroheating-induced intensity nonuniformity in infrared images. Infrared Phys. Technol. 2016, 76, 235–241. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, J.; Hong, H.; Zhang, Y.; Sang, N.; Zhang, T. Multi-scale thermal radiation effects correction via a fast surface fitting with Chebyshev polynomials. Appl. Opt. 2022, 61, 7498–7507. [Google Scholar] [CrossRef] [PubMed]

- Hong, H.; Liu, J.; Shi, Y.; Xiong, L.; Sang, N.; Zhang, T. Progressive Nonuniformity Correction for Aero-Optical Thermal Radiation Images via Bilateral Filtering and Bézier Surface Fitting. IEEE Photonics J. 2023, 15, 7800611. [Google Scholar] [CrossRef]

- Kuang, X.; Sui, X.; Liu, Y.; Chen, Q.; Guohua, G. Single infrared image optical noise removal using a deep convolutional neural network. IEEE Photonics J. 2017, 10, 7800615. [Google Scholar] [CrossRef]

- Chang, Y.; Chen, M.; Yan, L.; Zhao, X.-L.; Li, Y.; Zhong, S. Toward universal stripe removal via wavelet-based deep convolutional neural network. IEEE Trans. Geosci. Remote Sens. 2019, 58, 2880–2897. [Google Scholar] [CrossRef]

- Lin, D.; Cui, X.; Wang, Y.; Yang, B.; Tian, P. Pixel-wise radiometric calibration approach for infrared focal plane arrays using multivariate polynomial correction. Infrared Phys. Technol. 2022, 123, 104110. [Google Scholar] [CrossRef]

- Liu, B.; Zhu, K.; Zheng, X.; Li, Y.; Wu, W.; Zhang, F. A non-uniformity correction method for space-borne multichannel large array CMOS remote sensing camera based on image. In Proceedings of the Advanced Optical Manufacturing Technologies and Applications 2022 and 2nd International Forum of Young Scientists on Advanced Optical Manufacturing (AOMTA and YSAOM 2022), Changchun, China, 29–31 July 2022; SPIE: Washington, DC, USA, 2023; pp. 479–484. [Google Scholar]

- Chang, S.G.; Yu, B. Adaptive wavelet thresholding for image denoising and compression. IEEE Trans. Image Process. A Publ. IEEE Signal Process. Soc. 2000, 9, 1532. [Google Scholar] [CrossRef]

- Ju, L.; Fan, Z.; Liu, B.; Ming, Y.; Shi, X.; Li, X. Time characteristics of the imaging quality degradation caused by aero-optical effects under hypersonic conditions. IEEE Photonics J. 2022, 14, 7952409. [Google Scholar] [CrossRef]

- Wang, H.; Chen, S.; Du, H.; Dang, F.; Ju, L.; Ming, Y.; Zhang, R.; Shi, X.; Yu, J.; Fan, Z. Influence of altitude on aero-optic imaging quality degradation of the hemispherical optical dome. Appl. Opt. 2019, 58, 274–282. [Google Scholar] [CrossRef]

- Cheng, G.; Han, J.; Zhou, P.; Guo, L. Multi-class geospatial object detection and geographic image classification based on collection of part detectors. ISPRS J. Photogramm. Remote Sens. 2014, 98, 119–132. [Google Scholar] [CrossRef]

- Cheng, G.; Han, J. A Survey on Object Detection in Optical Remote Sensing Images. Isprs J. Photogramm. Remote Sens. 2016, 117, 11–28. [Google Scholar] [CrossRef]

- Cheng, G.; Zhou, P.; Han, J. Learning Rotation-Invariant Convolutional Neural Networks for Object Detection in VHR Optical Remote Sensing Images. IEEE Trans. Geosci. Remote Sens. 2016, 54, 7405–7415. [Google Scholar] [CrossRef]

- Wu, Z.; Fuller, N.; Theriault, D.; Betke, M. A Thermal Infrared Video Benchmark for Visual Analysis. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition Workshops, Washington, DC, USA, 23–28 June 2014; ACM: New York, NY, USA, 2014; pp. 201–208. [Google Scholar]

- Sui, X.; Chen, Q.; Gu, G. A novel non-uniformity evaluation metric of infrared imaging system. Infrared Phys. Technol. 2013, 60, 155–160. [Google Scholar] [CrossRef]

- A Dataset for Infrared Image Dim-Small Aircraft Target Detection and Tracking under Ground/Air Background. Available online: https://www.scidb.cn/en/detail?dataSetId=720626420933459968 (accessed on 28 October 2019).

| Image | Index | Degraded | Zhang. [22] | Li. [20] | Cao. [21] | Li-F. [23] | Shi. [25] | Hong. [26] | Proposed |

|---|---|---|---|---|---|---|---|---|---|

| Street | 1475 | 1483 | 1445 | 1492 | 3989 | 335.62 | 324.08 | 162.25 | |

| 16.44 | 16.49 | 16.53 | 16.39 | 12.12 | 22.87 | 23.02 | 26.03 | ||

| 0.71 | 0.80 | 0.81 | 0.77 | 0.80 | 0.74 | 0.75 | 0.94 | ||

| Residence | 1917 | 1877 | 1887 | 1894 | 5069 | 339.25 | 339.48 | 234.70 | |

| 15.31 | 15.39 | 15.37 | 15.36 | 11.08 | 22.83 | 22.18 | 24.43 | ||

| 0.66 | 0.76 | 0.76 | 0.77 | 0.76 | 0.71 | 0.71 | 0.93 | ||

| Plants | 1737 | 1722 | 1712 | 1752 | 4373 | 373.94 | 422.04 | 180.27 | |

| 15.73 | 15.76 | 15.79 | 15.70 | 11.72 | 22.40 | 21.88 | 25.57 | ||

| 0.70 | 0.78 | 0.79 | 0.77 | 0.81 | 0.74 | 0.74 | 0.93 |

| Image | Index | Input | Zhang. [22] | Li. [20] | Cao. [21] | Li-F. [23] | Shi. [25] | Hong. [26] | Proposed |

|---|---|---|---|---|---|---|---|---|---|

| Scenario 1 | 5.946 | 1.166 | 1.658 | 0.762 | 1.517 | 3.548 | 3.579 | 0.914 | |

| Scenario 2 | 5.954 | 1.156 | 4.019 | 0.789 | 1.098 | 3.504 | 3.221 | 0.629 | |

| Scenario 3 | 6.491 | 0.872 | 5.295 | 0.451 | 0.771 | 4.021 | 4.055 | 0.444 |

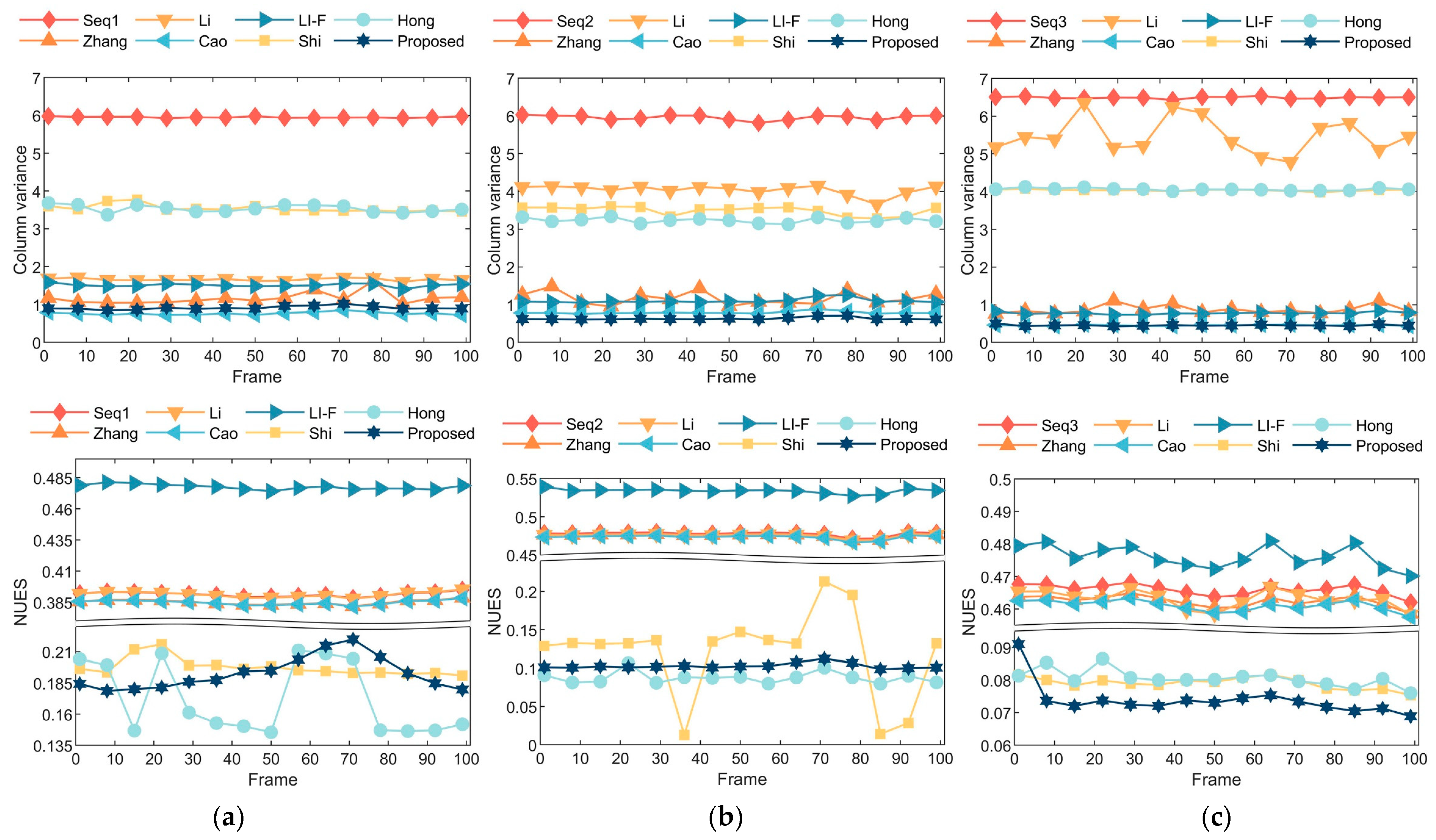

| Frames 1–100 | Index | Input | Zhang. [22] | Li. [20] | Cao. [21] | Li-F. [23] | Shi. [25] | Hong. [26] | Proposed |

|---|---|---|---|---|---|---|---|---|---|

| Scenario 1 | 0.391 | 0.385 | 0.391 | 0.384 | 0.478 | 0.098 | 0.179 | 0.142 | |

| Scenario 2 | 0.477 | 0.475 | 0.475 | 0.473 | 0.533 | 0.119 | 0.087 | 0.102 | |

| Scenario 3 | 0.466 | 0.462 | 0.463 | 0.461 | 0.476 | 0.079 | 0.081 | 0.073 |

| Frames | Index | Zhang. [22] | Li. [20] | Cao. [21] | Li-F. [23] | Shi. [25] | Hong. [26] | Proposed |

|---|---|---|---|---|---|---|---|---|

| Scenario 1 | Time/s | 0.425 | 0.211 | 0.328 | 0.344 | 12.870 | 22.795 | 1.064 |

| Scenario 2 | Time/s | 0.432 | 0.214 | 0.3162 | 0.382 | 6.472 | 65.664 | 1.049 |

| Scenario 3 | Time/s | 0.428 | 0.222 | 0.3326 | 0.353 | 6.591 | 29.548 | 1.038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, Y.; Sun, H. Single-Frame Infrared Image Non-Uniformity Correction Based on Wavelet Domain Noise Separation. Sensors 2023, 23, 8424. https://doi.org/10.3390/s23208424

Li M, Wang Y, Sun H. Single-Frame Infrared Image Non-Uniformity Correction Based on Wavelet Domain Noise Separation. Sensors. 2023; 23(20):8424. https://doi.org/10.3390/s23208424

Chicago/Turabian StyleLi, Mingqing, Yuqing Wang, and Haijiang Sun. 2023. "Single-Frame Infrared Image Non-Uniformity Correction Based on Wavelet Domain Noise Separation" Sensors 23, no. 20: 8424. https://doi.org/10.3390/s23208424

APA StyleLi, M., Wang, Y., & Sun, H. (2023). Single-Frame Infrared Image Non-Uniformity Correction Based on Wavelet Domain Noise Separation. Sensors, 23(20), 8424. https://doi.org/10.3390/s23208424