Eddy Current Testing of Conductive Coatings Using a Pot-Core Sensor

Abstract

1. Introduction

2. Analytical Model

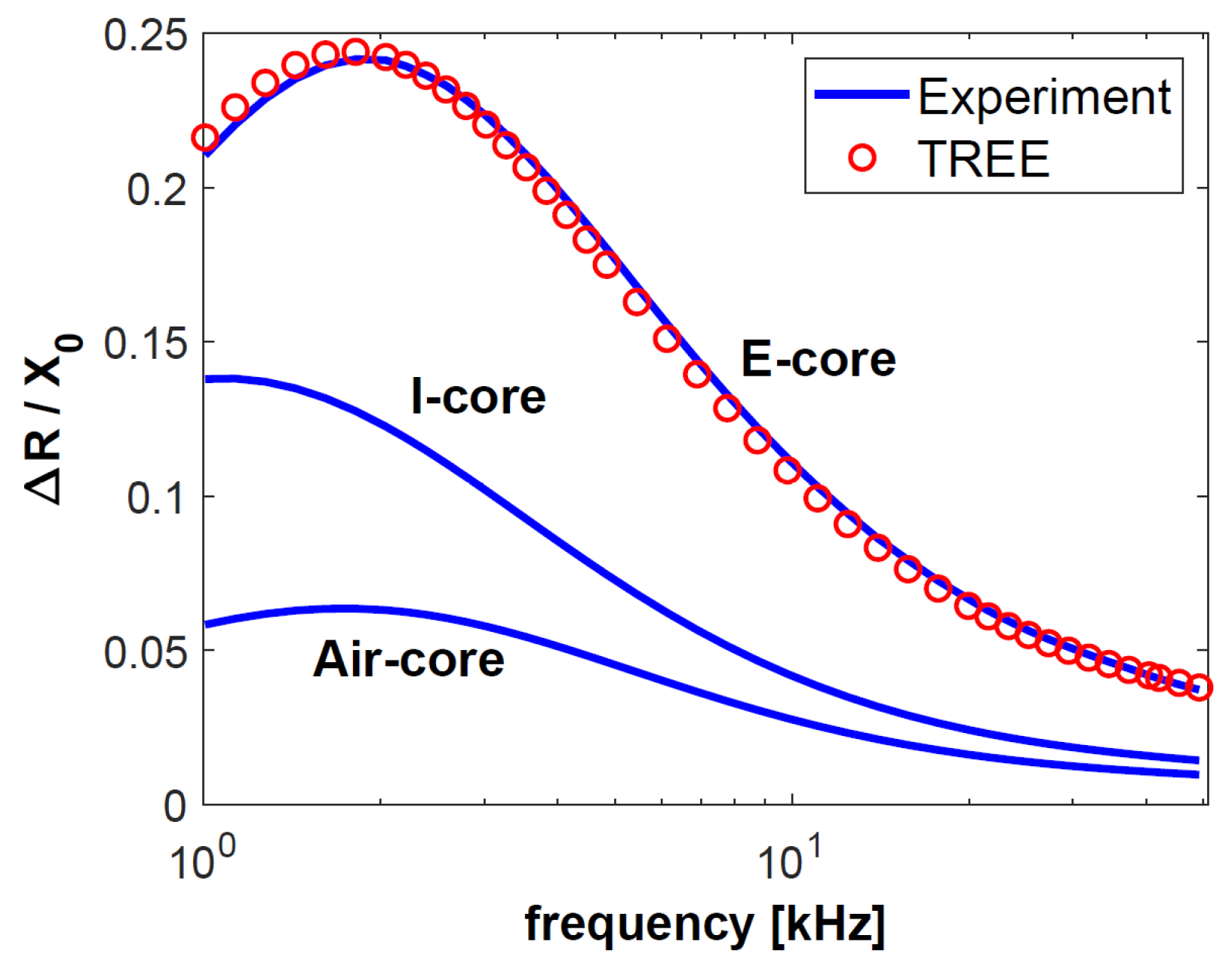

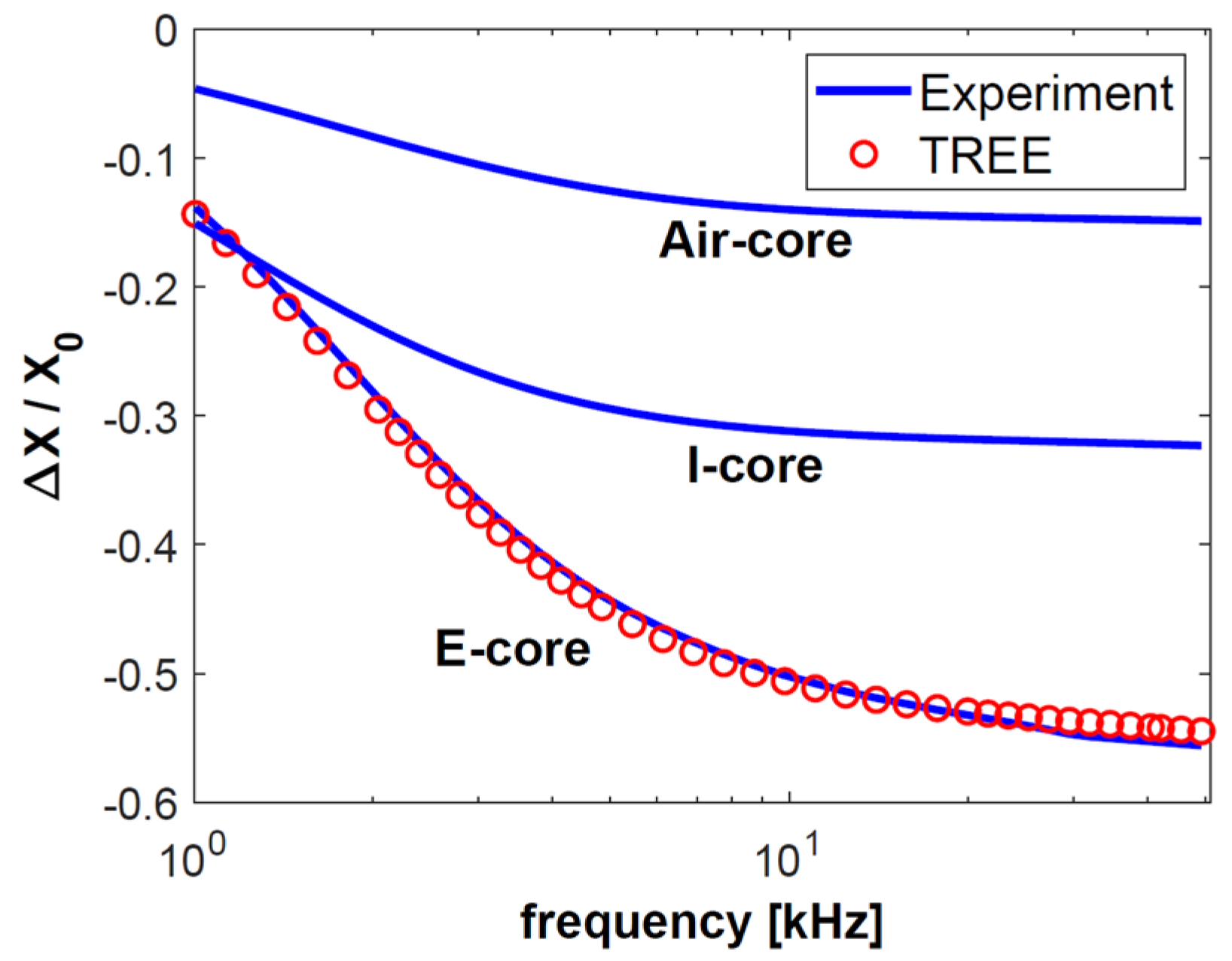

3. Results

4. Discussion

- -

- relatively low frequency in order to obtain the highest sensitivity of the sensor resistance,

- -

- high frequency in order to ensure the sensitivity of the imaginary part of the sensor impedance that is much higher than that of the real part.

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Beavers, J.A.; Thompson, N.G. External corrosion of oil and natural gas pipelines. In ASM Handbook, Corrosion: Environments and Industries; ASM International Geauga County: Novelty, OH, USA, 2006; Volume 13C, pp. 1015–1026. [Google Scholar]

- Yong, L.; Wang, Y.; Liu, Z.; Mukriz, I.; Abidin, Z.; Chen, Z. Characteristics Regarding Lift-Off Intersection of Pulse-Modulation Eddy Current Signals for Evaluation of Hidden Thickness Loss in Cladded Conductors. Sensors 2019, 19, 4102. [Google Scholar]

- Li, Y. Quantitative evaluation of thermal barrier coating based on eddy current technique. NDTE Int. 2012, 50, 29–35. [Google Scholar]

- Wen, S.Q.; He, A.J.; Wang, H. Development of TBCs on turbine blade of aero-engine. Gas Turbine Exp. Res. 2009, 22, 59–62. [Google Scholar]

- Li, Y.; Yan, B.; Li, W.; Li, D. Thickness Assessment of Thermal Barrier Coatings of Aeroengine Blades Via Dual-Frequency Eddy Current Evaluation. IEEE Magn. Lett. 2016, 7, 1304905. [Google Scholar] [CrossRef]

- Fukuchi, T.; Ozeki, T.; Okada, M.; Fujii, T. Nondestructive Inspection of Thermal Barrier Coating of Gas Turbine High Temperature Components. IEEJ Trans. 2016, 11, 391–400. [Google Scholar] [CrossRef]

- Moskal, G.; Mikuśkiewicz, M.; Jasik, A. Thermal diffusivity measurement of ceramic materials used in spraying of TBC systems. J. Therm. Anal. Calorim. 2019, 138, 4261–4269. [Google Scholar] [CrossRef]

- Moskal, G.; Jasik, A.; Mikuśkiewicz, M.; Jucha, S. Thermal resistance determination of Sm2Zr2O7+8YSZ composite type of TBC. Appl. Surf. Sci. 2020, 515, 145998. [Google Scholar] [CrossRef]

- Båvall, L. Determination of Thickness of Silver Coatings on Brass by Measuring the Impedance of a Thin Elliptic Coil. IEEE Trans. Instrum. Meas. 2007, 56, 790–799. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, Z.; Yin, W.; Zhu, S.; Chen, Z.; Xu, H. Conductivity classification of non-magnetic tilting metals by eddy current sensors. Sensors 2020, 20, 2608. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Yin, W.; Chen, H.; Ma, H.; Zhou, G.; Zhang, Y. Conductivity Classification of Multi-Shape Nonmagnetic Metal Considering Spatial Position Drift Effect with a Triple-Coil Electromagnetic Sensor. Sensors 2022, 22, 5694. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Z.; Yin, W.; Chen, H.; Ma, H.; Zhou, G.; Zhang, Y. Linear Characteristics of the Differences in Phase Tangents of Triple-Coil Electromagnetic Sensors and Their Application in Nonmagnetic Metal Classification. Sensors 2022, 22, 7511. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Lu, M.; Yin, W.; Bennecer, A.; Kirk, K.J. Evaluation of Coating Thickness Using Lift-Off Insensitivity of Eddy Current Sensor. Sensors 2021, 21, 419. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Huang, J.; Liu, L.; Qin, S.; Fu, Z. A Novel Pulsed Eddy Current Criterion for Non-Ferromagnetic Metal Thickness Quantifications under Large Liftoff. Sensors 2022, 22, 614. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Lu, M.; Zhang, Z.; Zhao, Q.; Xie, Y.; Tao, Y.; Meng, T.; Peyton, A.; Theodoulidis, T.; Yin, W. Measurement of the radius of metallic plates based on a novel finite region eigenfunction expansion (FREE) method. IEEE Sens. J. 2020, 20, 15099–15106. [Google Scholar] [CrossRef]

- Hu, G.; Huang, R.; Lu, M.; Zhou, L.; Yin, W. Measurement of radius of a metallic ball using eddy current testing based on peak frequency difference feature. Measurement 2021, 184, 109876. [Google Scholar] [CrossRef]

- Wendler, F.; Munjal, R.; Waqas, M.; Laue, R.; Härtel, S.; Awiszus, B.; Kanoun, O. Eddy Current Sensor System for Tilting Independent In-Process Measurement of Magnetic Anisotropy. Sensors 2021, 21, 2652. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yu, Y. Thickness and Conductivity Measurement of Multilayered Electricity-Conducting Coating by Pulsed Eddy Current Technique: Experimental Investigation. IEEE Trans. Instrum. Meas. 2019, 68, 3166–3172. [Google Scholar] [CrossRef]

- Wen, D.; Fan, M.; Cao, B.; Xue, Z.; Wang, P. A PEC Thrice Subtraction Method for Obtaining Permeability Invariance Feature in Conductivity Measurement of Ferromagnetic Samples. Appl. Sci. 2019, 9, 2745. [Google Scholar] [CrossRef]

- Kucheryavskiy, S.; Egorov, A.; Polyakov, V. Coupling Analytical Models and Machine Learning Methods for Fast and Reliable Resolution of Effects in Multifrequency Eddy-Current Sensors. Sensors 2021, 21, 618. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, B.; Luo, Y.; Kyrgiazoglou, A. Integral and Series Solutions for Inductance of Rectangular Coils with Parallel End Faces. IET Electr. Power Appl. 2019, 13, 1032–1041. [Google Scholar] [CrossRef]

- Luo, Y.; Theodoulidis, T.; Zhou, X.; Kyrgiazoglou, A. Calculation of AC resistance of single-layer coils using boundary-element method. IET Electr. Power Appl. 2021, 15, 1–12. [Google Scholar] [CrossRef]

- Faria, A.; Marques, L.; Ferreira, C.; Alves, F.; Cabral, J. A Fast and Precise Tool for Multi-Layer Planar Coil Self-Inductance Calculation. Sensors 2021, 21, 4864. [Google Scholar] [CrossRef] [PubMed]

- Farag, H.E.; Toyserkani, E.; Khamesee, M.B. Non-Destructive Testing Using Eddy Current Sensors for Defect Detection in Additively Manufactured Titanium and Stainless-Steel Parts. Sensors 2022, 22, 5440. [Google Scholar] [CrossRef]

- Bao, Y.; Xu, M.; Qiu, J.; Song, J. Efficient Model Assisted Probability of Detection Estimations in Eddy Current NDT with ACA-SVD Based Forward Solver. Sensors 2022, 22, 7625. [Google Scholar] [CrossRef] [PubMed]

- Xia, Z.; Huang, R.; Chen, Z.; Yu, K.; Zhang, Z.; Salas-Avila, J.R.; Yin, W. Eddy Current Measurement for Planar Structures. Sensors 2022, 22, 8695. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, B.; Luo, Y.; Zhu, R. Inductance calculations for coils with an iron core of arbitrary axial position. Electromagnetics 2019, 39, 99–119. [Google Scholar] [CrossRef]

- Zhang, S. Analytical Model of an I-core Coil for Nondestructive Evaluation of a Conducting Cylinder below an Infinite Plane Conductor. Meas. Sci. Rev. 2021, 21, 99–105. [Google Scholar] [CrossRef]

- Vasic, D.; Rep, I.; Špikic, D.; Kekelj, M. Model of Magnetically Shielded Ferrite-Cored Eddy Current Sensor. Sensors 2022, 22, 326. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, C. Model of Ferrite-cored Driver-pickup Coil Probe Application of TREE Method for Eddy Current Nondestructive Evaluation. ACES J. 2022, 37, 632–638. [Google Scholar] [CrossRef]

- Tai, C.-C. Characterization of coatings on magnetic metal using the swept-frequency eddy current method. Rev. Sci. Instrum. 2000, 71, 3161. [Google Scholar] [CrossRef]

- Yang, H.-C.; Tai, C.-C. Pulsed eddy-current measurement of a conducting coating on a magnetic metal plate. Meas. Sci. Technol. 2002, 13, 1259. [Google Scholar] [CrossRef]

- Gao, K.; Yu, Y.; Yang, J.; Shen, P. Study on Eddy-current Nondestructive Testing Method of the Double-layers Conductive Coating Thickness. J. Mech. Eng. 2017, 53, 114–119. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, M.; Cao, B.; Ye, B.; Wen, D. Measurement of coating thickness using lift-off point of intersection features from pulsed eddy current signals. NDT E Int. 2020, 116, 102333. [Google Scholar] [CrossRef]

- Yin, W.; Dickinson, S.J.; Peyton, A.J. Evaluating the Permeability Distribution of a Layered Conductor by Inductance Spectroscopy. IEEE Trans. Magn. 2006, 42, 3645–3651. [Google Scholar] [CrossRef]

- Li, Y.; Jing, H.; Mukriz, I.; Abidin, Z.; Yan, B. A Gradient-Field Pulsed Eddy Current Probe for Evaluation of Hidden Material Degradation in Conductive Structures Based on Lift-Off Invariance. Sensors 2017, 17, 943. [Google Scholar] [CrossRef]

- Cheng, W.; Hashizume, H. Determination of Layers’ Thicknesses by Spectral Analysis of Swept-Frequency Measurement Signals. IEEE Sens. J. 2020, 20, 8643–8655. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Ren, S.; Ren, Y.; Mukriz, I.; Abidin, Z.; Chen, Z. Pulse-Modulation Eddy Current Evaluation of Interlaminar Corrosion in Stratified Conductors: Semi-Analytical Modeling and Experiments. Sensors 2022, 22, 3458. [Google Scholar] [CrossRef]

- Tytko, G. Measurement of multilayered conductive discs using eddy current method. Measurement 2022, 204, 112053. [Google Scholar] [CrossRef]

- Tytko, G.; Dziczkowski, L.; Magnuski, M.; Zhang, Z.; Luo. Y. Eddy current testing of conductive discs using the pot-core sensor. Sens. Actuators A Phys. 2023, 349, 114060. [Google Scholar] [CrossRef]

- Bayani, H.; Theodoulidis, T.; Sasada, I. Solution to the Problem of Cup-Cored Coil Above a Layered Half-Space. Iran. Phys. J. 2008, 2, 49–53. [Google Scholar]

- Sakkakia, F.; Bayani, H. Solution to the problem of E-cored coil above a layered half-space using the method of truncated region eigenfunction expansion. J. Appl. Phys. 2012, 111, 07E717. [Google Scholar] [CrossRef]

- Tytko, G.; Dziczkowski, L. E-Cored Coil with a Circular Air Gap Inside the Core Column Used in Eddy Current Testing. IEEE Trans. Magn. 2015, 51, 6201804. [Google Scholar] [CrossRef]

- Tytko, G. An eddy current model of pot-cored coil for testing multilayer conductors with a hole. Bull. Pol. Ac. Tech. 2020, 68, 1311–1317. [Google Scholar]

- Theodoulidis, T.P.; Bowler, J.R. The truncated region eigenfunction expansion method for the solution of boundary value problems in eddy current non-destructive evaluation. Rev. Prog. Quant. Nondestruct. Eval. 2004, 24, 403–408. [Google Scholar]

- Theodoulidis, T.P.; Kriezis, E.E. Eddy Current Canonical Problems (with Applications to Nondestructive Evaluation); Tech Science Press: Forsyth, GA, USA, 2006. [Google Scholar]

- Vasic, D.; Ambru, D.; Bilas, V. Computation of the eigenvalues for bounded domain eddy-current models with coupled regions. IEEE Trans. Magn. 2016, 52, 7004310. [Google Scholar] [CrossRef]

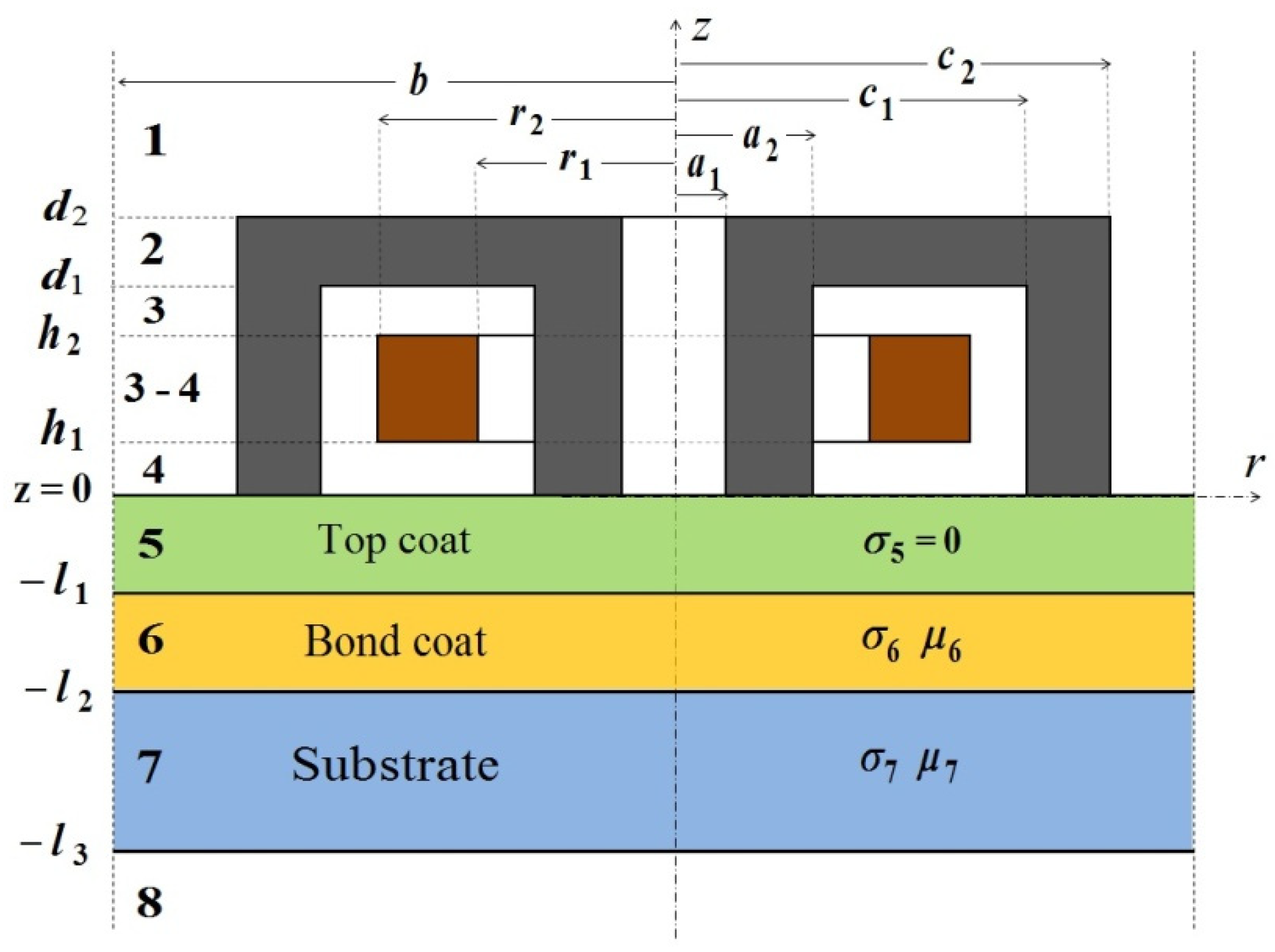

| I-Core Sensor | E-Core Sensor | |

|---|---|---|

| Number of turns N | 480 | 646 |

| Inner coil radius r1 | 2.6 mm | 4.3 mm |

| Outer coil radius r2 | 7.8 mm | 7.3 mm |

| Parameter h1 | 0.1 mm | 0.2 mm |

| Parameter h2 | 15.9 mm | 3.6 mm |

| Inner column radius a1 | 0.7 mm | 1.5 mm |

| Outer column radius a2 | 2.5 mm | 3.7 mm |

| Inner core radius c1 | - | 7.7 mm |

| Outer core radius c2 | - | 9.1 mm |

| Inner core height d1 | - | 3.7 mm |

| Outer core height d2 | 34.5 mm | 5.3 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tytko, G. Eddy Current Testing of Conductive Coatings Using a Pot-Core Sensor. Sensors 2023, 23, 1042. https://doi.org/10.3390/s23021042

Tytko G. Eddy Current Testing of Conductive Coatings Using a Pot-Core Sensor. Sensors. 2023; 23(2):1042. https://doi.org/10.3390/s23021042

Chicago/Turabian StyleTytko, Grzegorz. 2023. "Eddy Current Testing of Conductive Coatings Using a Pot-Core Sensor" Sensors 23, no. 2: 1042. https://doi.org/10.3390/s23021042

APA StyleTytko, G. (2023). Eddy Current Testing of Conductive Coatings Using a Pot-Core Sensor. Sensors, 23(2), 1042. https://doi.org/10.3390/s23021042