Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning

Abstract

1. Introduction

2. Method

| Algorithm 1: Blending |

| Input: |

| Training Data, Optimized parameter of signal processing transform….are found, tier zero learners….and tier one meta learner. |

| Step 1: Train tier zero learners |

| For = 1, 2, …. T do |

| Apply Optimized on and Train to obtain , |

| Save |

| End for |

| Step 2: Concatenate new dataset from validation set prediction |

| For = 1, 2, …. m do |

| , |

| End for |

| Step 3: Learn meta-classifier |

| Learn H based on the concatenated data |

| Output: Ensemble classifier H |

2.1. Selection of Signal Processing Technique

2.1.1. Cyclic Spectra Coherence

2.1.2. Spectral Kurtosis

2.1.3. Bicoherence Analysis

2.1.4. Time Synchronous Averaging

2.2. Convolutional Neural Network

2.3. Blending Ensemble Learning

3. Experiments

3.1. Experimental Description

3.1.1. GIDTEC Bearing Data

3.1.2. Labelled Prognosis Health Management Society 09 Data

3.1.3. COMFAULDA Data

3.2. Data Split

3.3. Description of Performance Metrics

- (a)

- Accuracy (ACC): Accuracy is one of the most widely used metrics to quantify the performance of machine learning or deep learning model. The accuracy of a given model provides the degree of effectiveness of the model. It is expressed mathematically by Equation (14) below, where TP is the True Positives, TN is the True Negatives, FN is the False Negatives, and FP is the False Positives:

- (b)

- Precision: It is the ratio of positive samples appropriately classified to the number of samples labelled as positive by the network. The precision of a deep learning model can be expressed as Equation (15):

- (c)

- Recall: The recall of a model is an indication of the portion of the actual positive samples identified correctly. In other words, the recall gives the number of samples belonging to a class that was correctly classified. Mathematically, recall can be estimated using Equation (16).

- (d)

- False Negative Rate (FNR): This metric is the probability that a true positive will be missed during a test by the network. The False Negative Rate is expressed mathematically by Equation (17):

- (e)

- F1-score: This is the harmonic mean or average between the recall and the precision. This metric is expressed mathematically by Equation (18).

- (f)

- False Positive Rate (FPR): The False Positive rate is the probability of samples predicted to belong to each of the classes that are incorrectly classified. It is also known as the false alarm rate and is given by Equation (19).

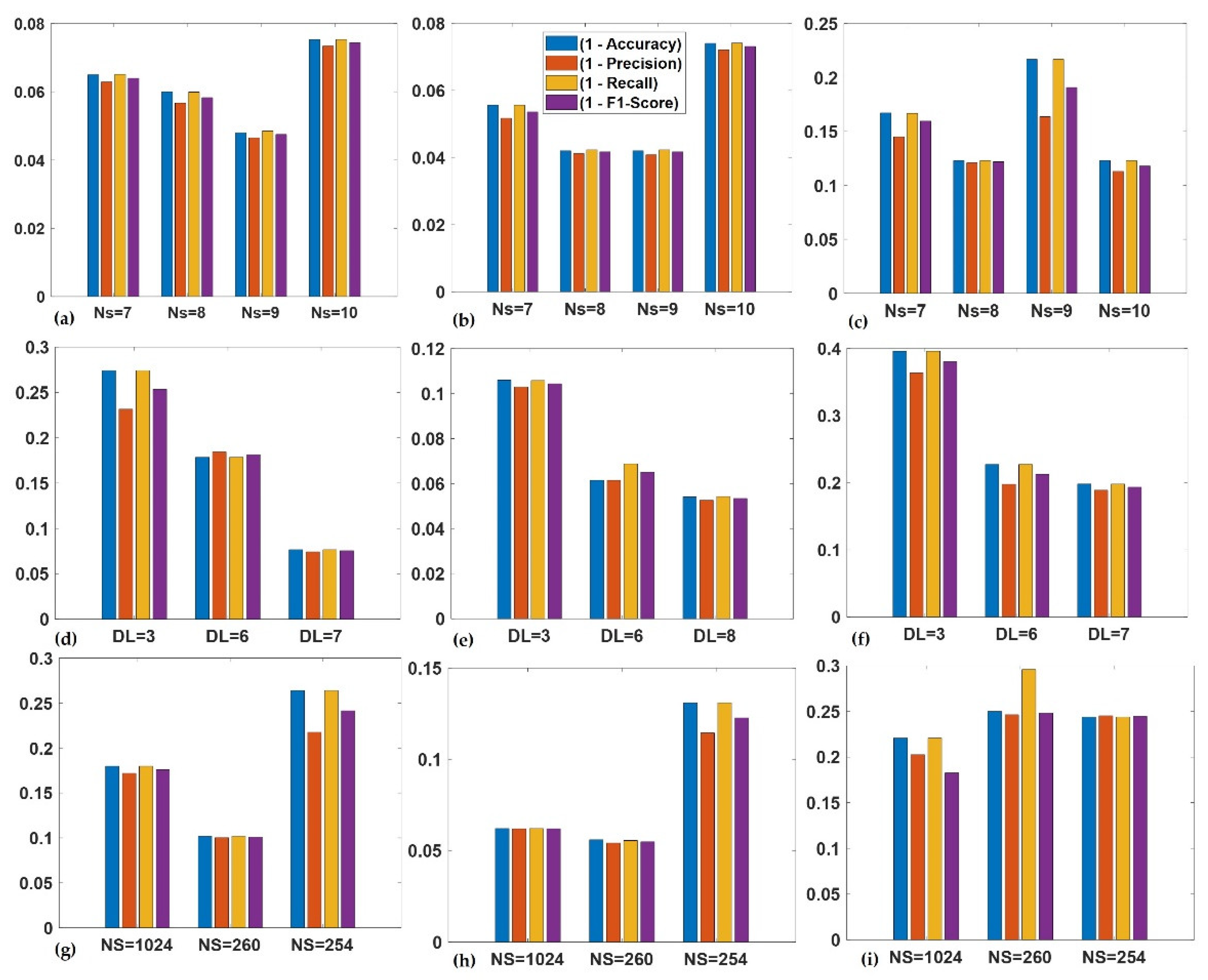

3.4. Signal Processing Optimization

- Step 1:

- A specified length of the signal is chosen for each of the data.

- Step 2:

- Key parameters such as the decomposition level for spectral kurtosis (), the window length (WL) for cyclic spectral coherence, and the number of samples per segment for the bicoherence analysis are used in creating the kurtogram, cyclic spectral coherence maps, and bicoherence maps.

- Step 3:

- Train the CNN using either the kurtogram or cyclic spectral coherence maps or bicoherence maps created with a specific key parameter.

- Step 4:

- Repeat the CNN training with the next set of maps from the subsequent value of the key parameter and record the accuracy, precision, recall, and F1-score from each training.

4. Results and Discussions

4.1. Optimization Results

4.2. Testing

4.3. Feature Analysis

4.4. Comparison with Other Deep Ensemble Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Mathew, J.; Ma, L. Fault diagnosis of rolling element bearings using basis pursuit. Mech. Syst. Signal Process. 2005, 19, 341–356. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Hamadache, M.; Jung, J.H.; Park, J.; Youn, B.D. A comprehensive review of artificial intelligence-based approaches for rolling element bearing PHM: Shallow and deep learning. JMST Adv. 2019, 1, 125–151. [Google Scholar] [CrossRef]

- Saimurugan, M.; Ramachandran, K.I.; Sugumaran, V.; Sakthivel, N.R. Multi component fault diagnosis of rotational mechanical system based on decision tree and support vector machine. Expert Syst. Appl. 2011, 38, 3819–3826. [Google Scholar] [CrossRef]

- Tiwari, R.; Bordoloi, D.J.; Bansal, S.; Sahu, S. Multi-class fault diagnosis in gears using machine learning algorithms based on time domain data. Int. J. COMADEM 2017, 20, 3–13. [Google Scholar]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of Deep Learning: Concepts, CNN Architectures, Challenges, Applications, Future Directions; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; Volume 8, ISBN 4053702100444. [Google Scholar]

- Mushtaq, S.; Manjurul Islam, M.M.; Sohaib, M. Deep learning aided data-driven fault diagnosis of rotatory machine: A comprehensive review. Energies 2021, 14, 5150. [Google Scholar] [CrossRef]

- Eren, L. Bearing fault detection by one-dimensional convolutional neural networks. Math. Probl. Eng. 2017, 2017, 8617315. [Google Scholar] [CrossRef]

- Eren, L.; Ince, T.; Kiranyaz, S. A Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J. Signal Process. Syst. 2019, 91, 179–189. [Google Scholar] [CrossRef]

- Hsiao, J.C.; Shivam, K.; Kam, T.Y. Fault diagnosis method for worm gearbox using convolutional network and ensemble learning. J. Phys. Conf. Ser. 2020, 1509, 012030. [Google Scholar] [CrossRef]

- Souza, R.M.; Nascimento, E.G.S.; Miranda, U.A.; Silva, W.J.D.; Lepikson, H.A. Deep learning for diagnosis and classification of faults in industrial rotating machinery. Comput. Ind. Eng. 2021, 153, 107060. [Google Scholar] [CrossRef]

- Qian, W.; Li, S.; Wang, J.; An, Z.; Jiang, X. An intelligent fault diagnosis framework for raw vibration signals: Adaptive overlapping convolutional neural network. Meas. Sci. Technol. 2018, 29, 095009. [Google Scholar] [CrossRef]

- Verstraete, D.; Ferrada, A.; Droguett, E.L.; Meruane, V.; Modarres, M. Deep learning enabled fault diagnosis using time-frequency image analysis of rolling element bearings. Shock Vib. 2017, 2017, 5067651. [Google Scholar] [CrossRef]

- Duy, T.H.; Tran, X.T.; Van, M.; Kang, H.J. A Deep Neural Network-Based Feature Fusion for Bearing. Sensors 2021, 21, 244. [Google Scholar]

- Pham, M.T.; Kim, J.M.; Kim, C.H. 2D Cnn-Based Multi-Output Diagnosis for Compound Bearing Faults Under Variable Rotational Speeds. Machines 2021, 9, 199. [Google Scholar] [CrossRef]

- Dibaj, A.; Ettefagh, M.M.; Hassannejad, R.; Ehghaghi, M.B. A hybrid fine-tuned VMD and CNN scheme for untrained compound fault diagnosis of rotating machinery with unequal-severity faults. Expert Syst. Appl. 2021, 167, 114094. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Data Preprocessing Techniques in Convolutional Neural Network Based on Fault Diagnosis towards Rotating Machinery. IEEE Access 2020, 8, 149487–149496. [Google Scholar] [CrossRef]

- Chang, H.; Borghesani, P.; Peng, Z. Automated assessment of gear wear mechanism and severity using mould images and convolutional neural networks. Tribol. Int. 2020, 147, 106280. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Meas. J. Int. Meas. Confed. 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Chen, Z.; Mauricio, A.; Li, W.; Gryllias, K. A deep learning method for bearing fault diagnosis based on Cyclic Spectral Coherence and Convolutional Neural Networks. Mech. Syst. Signal Process. 2020, 140, 106683. [Google Scholar] [CrossRef]

- Udmale, S.S.; Patil, S.S.; Phalle, V.M.; Singh, S.K. A bearing vibration data analysis based on spectral kurtosis and ConvNet. Soft Comput. 2019, 23, 9341–9359. [Google Scholar] [CrossRef]

- Zeng, X.; Liao, Y.; Li, W. Gearbox fault classification using S-transform and convolutional neural network. In Proceedings of the International Conference on Sensing Technology (ICST), Nanjing, China, 11–13 November 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Qu, Y.; He, D. Gear pitting fault diagnosis using integrated CNN and GRU network with both vibration and acoustic emission signals. Appl. Sci. 2019, 9, 768. [Google Scholar] [CrossRef]

- Han, B.; Yang, X.; Ren, Y.; Lan, W. Comparisons of different deep learning-based methods on fault diagnosis for geared system. Int. J. Distrib. Sens. Networks 2019, 15, 1–17. [Google Scholar] [CrossRef]

- Jantunen, E.; El-Thalji, I.; Baglee, D.; Lagö, T. Problems with using Fast Fourier Transform for rotating equipment: Is it time for an update? In Proceedings of the Comadem 2014—Implications of Life Cycle Analysis in Asset and Maintenance Management, Brisbane, Australia, 16–18 September 2014; pp. 2005–2009. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Y.; Xu, M.; Huang, W. A review of early fault diagnosis approaches and their applications in rotating machinery. Entropy 2019, 21, 409. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; He, Z.; Zhang, Z.; Zi, Y. Fault diagnosis of rotating machinery based on improved wavelet package transform and SVMs ensemble. Mech. Syst. Signal Process. 2007, 21, 688–705. [Google Scholar] [CrossRef]

- Wan, S.; Zhang, X.; Dou, L. Compound Fault Diagnosis of Bearings Using an Improved Spectral Kurtosis by MCDK. Math. Probl. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Qiu, X.; Zhang, L.; Ren, Y.; Suganthan, P.; Amaratunga, G. Ensemble deep learning for regression and time series forecasting. In Proceedings of the 2014 IEEE Symposium on Computational Intelligence in Ensemble Learning, Orlando, FL, USA, 9–12 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Cao, Z.; Li, Z.; Zhang, J.; Fu, H. A Homogeneous Stacking Ensemble Learning Model for Fault Diagnosis of Rotating Machinery With Small Samples. IEEE Sens. J. 2022, 22, 8944–8959. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing fault diagnosis method based on deep convolutional neural network and random forest ensemble learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Chu, F. Ensemble deep learning-based fault diagnosis of rotor bearing systems. Comput. Ind. 2019, 105, 143–152. [Google Scholar] [CrossRef]

- Li, S.; Liu, G.; Tang, X.; Lu, J.; Hu, J. An ensemble deep convolutional neural network model with improved D-S evidence fusion for bearing fault diagnosis. Sensors 2017, 17, 1729. [Google Scholar] [CrossRef]

- Jin, Z.; He, D.; Ma, R.; Zou, X.; Chen, Y.; Shan, S. Fault diagnosis of train rotating parts based on multi-objective VMD optimization and ensemble learning. Digit. Signal Process. 2022, 121, 103312. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, X.; Zhang, C.A.; Liu, W. An ensemble convolutional neural networks for bearing fault diagnosis using multi-sensor data. Sensors 2019, 19, 5300. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Huang, J.; Ji, S. Bearing fault diagnosis with a feature fusion method based on an ensemble convolutional neural network and deep neural network. Sensors 2019, 19, 2034. [Google Scholar] [CrossRef] [PubMed]

- Obuchowski, J.; Zimroz, R.; Wylomanska, A. Identification of cyclic components in presence of non-Gaussian noise—Application to crusher bearings damage detection. J. Vibroengineering 2015, 17, 1242–1252. [Google Scholar]

- Cheng, Y.; Chen, B.; Zhang, W. Enhanced spectral coherence and its application to bearing fault diagnosis. Meas. J. Int. Meas. Confed. 2022, 188, 110418. [Google Scholar] [CrossRef]

- Gong, X.; Du, W.; Georgiadis, A.; Zhao, B. Identification of multi-fault in rotor-bearing system using spectral kurtosis and EEMD. J. Vibroengineering 2017, 19, 5036–5046. [Google Scholar] [CrossRef]

- Sawalhi, N. The application of spectral kurtosis to bearing diagnostics. In Proceedings of the Acoustics-Conference, Gold Coast, Australia, 3–5 November 2004; pp. 393–398. Available online: http://www.acoustics.asn.au/conference_proceedings/AAS2004/ACOUSTIC/PDF/AUTHOR/AC040115.PDF (accessed on 12 September 2022).

- Antoni, Ã. The spectral kurtosis: A useful tool for characterising non-stationary signals. Mech. Syst. Signal Process. 2006, 20, 282–307. [Google Scholar] [CrossRef]

- Yang, D.M.; Stronach, A.F.; MacConnell, P. The application of advanced signal processing techniques to induction motor bearing condition diagnosis. Meccanica 2003, 38, 297–308. [Google Scholar] [CrossRef]

- Cheng, L.; Fu, S.; Xue, D. Fault severity assessment of rolling element bearings based on bicoherence spectrum. Vibroengineering Procedia 2016, 10, 132–137. [Google Scholar]

- Bechhoefer, E.; Kingsley, M. A review of time synchronous average algorithms. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, PHM 2009, San Diego, CA, USA, September 27 – October 1 2009. [Google Scholar]

- Sim, J.; Kim, S.; Park, H.J.; Choi, J.H. A tutorial for feature engineering in the prognostics and health management of gears and bearings. Appl. Sci. 2020, 10, 5639. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Shen, W. A Review of Ensemble Learning Algorithms Used in Remote Sensing Applications. Appl. Sci. 2022, 12, 8654. [Google Scholar] [CrossRef]

- Mathworks Mathworks, Statistics and Machine Learning Toolbox User’s Guide. 2022. Available online: //oemmndcbldboiebfnladdacbdfmadadm/https://uk.mathworks.com/help/pdf_doc/stats/stats.pdf (accessed on 20 September 2022).

- Ponti, M.P. Combining classifiers: From the creation of ensembles to the decision fusion. In Proceedings of the 24th SIBGRAPI Conference on Graphics, Patterns, and Images Tutorials, SIBGRAPI-T 2011, Alagoas, Brazil, 28–30 August 2011; pp. 1–10. [Google Scholar] [CrossRef]

- Chen, Z.; Deng, S.; Chen, X.; Li, C.; Sanchez, R.V.; Qin, H. Deep neural networks-based rolling bearing fault diagnosis. Microelectron. Reliab. 2017, 75, 327–333. [Google Scholar] [CrossRef]

- PHM Society PHM Society Data Challenge 2009. Available online:https://www.phmsociety.org/competition/PHM/09 (accessed on 1 August 2022).

- Martins, D.; Pestana-viana, D.; Lima, A.; Hadadd, D.; Homero, R. Composed Fault Dataset (COMFAULDA), IEEE Dataport. Available online: https://ieee-dataport.org/documents/composed-fault-dataset-comfaulda (accessed on 8 January 2023).

- Denys, M.; Viana, P.; Azevedo, A.; de Lima, A.A.; Faria, M.; Lu, P.; Fabr, T.; Homero, R. Diagnostic and severity analysis of combined failures composed by imbalance and misalignment in rotating machines. Int. J. Adv. Manuf. Technol. 2021, 114, 3077–3092. [Google Scholar]

- Van Der Maaten, L.; Hinton, G. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2625. [Google Scholar]

- Senanayaka, J.S.L.; Van Khang, H.; Robbersmyr, K.G. Multiple Classifiers and Data Fusion for Robust Diagnosis of Gearbox Mixed Faults. IEEE Trans. Ind. Inform. 2018, 15, 4569–4579. [Google Scholar] [CrossRef]

- Inyang, U.; Petrunin, I. Health Condition Estimation of Bearings with Multiple Faults by a Composite Learning-Based Approach. Sensors 2021, 21, 4424. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Gao, L.; Chen, W.; Li, P. Ensemble deep contractive auto-encoders for intelligent fault diagnosis of machines under noisy environment. Knowledge-Based Syst. 2020, 196, 105764. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Niu, M.; Wang, R. An enhanced selective ensemble deep learning method for rolling bearing fault diagnosis with beetle antennae search algorithm. Mech. Syst. Signal Process. 2020, 142, 106752. [Google Scholar] [CrossRef]

- Han, Y.; Tang, B.; Deng, L. Multi-level wavelet packet fusion in dynamic ensemble convolutional neural network for fault diagnosis. Meas. J. Int. Meas. Confed. 2018, 127, 246–255. [Google Scholar] [CrossRef]

| S/No. | Label | Bearing 1 | Bearing 2 |

|---|---|---|---|

| 1 | C1 | Healthy | Healthy |

| 2 | C4 | Inner race fault | Healthy |

| 3 | C5 | Outer race fault | Healthy |

| 4 | C8 | Inner race fault | Outer race fault |

| 5 | C6 | Inner race fault | Ball fault |

| 6 | C9 | Outer race fault | Ball fault |

| Gear | Bearing | Shaft | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Label | 32 T | 96 T | 48 T | 80 T | IS: IS | ID: IS | OS: IS | IS: OS | ID: OS | OS: OS | Input |

| C3 | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good | Good |

| C10 | Chipped | Good | Eccentric | Good | Good | Good | Good | Good | Good | Good | Good |

| C11 | Good | Good | Eccentric | Good | Good | Good | Good | Good | Good | Good | Good |

| C12 | Good | Good | Eccentric | Broken | Ball | Good | Good | Good | Good | Good | Good |

| C13 | Chipped | Good | Eccentric | Broken | Inner | Ball | Outer | Good | Good | Good | Good |

| Component | Training Set, Images | Validation Set, Images | Testing Set, Images |

|---|---|---|---|

| Bearing | 400 | 50 | 50 |

| Gear | 400 | 50 | 50 |

| Shaft | 400 | 50 | 50 |

| Layer | Description | SK-CNN | CSC-CNN | BICO-CNN |

|---|---|---|---|---|

| 1 | Input | 224 × 224 × 3 | 224 × 224 × 3 | 224 × 224 × 3 |

| 2 | conv_1 | 8 × 5 × 5 × 3 | 8 × 5 × 5 × 3 | 8 × 5 × 5 × 3 |

| 3 | maxpool_1 | 3 × 3 | 3 × 3 | 3 × 3 |

| 4 | conv_2 | 16 × 5 × 5 × 8 | 16 × 5 × 5 × 8 | 16 × 5 × 5 × 8 |

| 5 | maxpool_2 | 3 × 3 | 3 × 3 | 3 × 3 |

| 6 | conv_3 | 32 × 5 × 5 × 16 | 32 × 5 × 5 × 16 | 32 × 5 × 5 × 16 |

| 7 | maxpool_3 | 3 × 3 | 3 × 3 | 3 × 3 |

| 8 | conv_4 | 64 × 5 × 5 × 32 | 64 × 5 × 5 × 32 | 64 × 5 × 5 × 32 |

| 9 | maxpool_4 | 3 × 3 | 3 × 3 | 3 × 3 |

| 10 | conv_5 | 128 × 5 × 5 × 64 | 128 × 5 × 5 × 64 | 128 × 5 × 5 × 64 |

| 11 | dropout | 70% | 70% | 70% |

| 12 | fully Connected | fully Connected | fully Connected | fully Connected |

| 13 | SoftMax | 1 | 1 | 1 |

| 14 | class output | 16 | 16 | 16 |

| S/N | Reference | Method | Faults Considered | Accuracy (%) |

|---|---|---|---|---|

| 1 | Ma et al. [33] | CNN, Autoencoder, and Deep Belief Network Ensemble | Rotor and bearing single fault | 98.09 |

| 2 | Sr et al. [55] | Decision fusion of CNN and MLP | Gearbox mixed signal | 96.07 (Ave) |

| 3 | Inyang et al. [56] | CNN-SVM | Bearings | 98.54 |

| 4 | Martins et al. [53] | Random Forest | Compound fault in rotating machinery | 81.41 |

| 5 | Zhang et al. [57] | Ensemble Deep Contractive Autoencoder | Gearbox and Bearings | 96.60 (Ave) |

| 6 | Li et al. [58] | Ensemble Deep learning with Beetle Antenna Search- | Rail locomotive bearings | 96.92 |

| 7 | Han et al. [59] | Dynamic Ensemble Convolutional Neural Network | Gearbox | 96.48 91.30 |

| 9 | Proposed | Proposed | Bearing, Gear, and Shaft Multiple faults | 98.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inyang, U.I.; Petrunin, I.; Jennions, I. Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning. Sensors 2023, 23, 1005. https://doi.org/10.3390/s23021005

Inyang UI, Petrunin I, Jennions I. Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning. Sensors. 2023; 23(2):1005. https://doi.org/10.3390/s23021005

Chicago/Turabian StyleInyang, Udeme Ibanga, Ivan Petrunin, and Ian Jennions. 2023. "Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning" Sensors 23, no. 2: 1005. https://doi.org/10.3390/s23021005

APA StyleInyang, U. I., Petrunin, I., & Jennions, I. (2023). Diagnosis of Multiple Faults in Rotating Machinery Using Ensemble Learning. Sensors, 23(2), 1005. https://doi.org/10.3390/s23021005