Low-Temperature 3D Printing Technology of Poly (Vinyl Alcohol) Matrix Conductive Hydrogel Sensors with Diversified Path Structures and Good Electric Sensing Properties

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

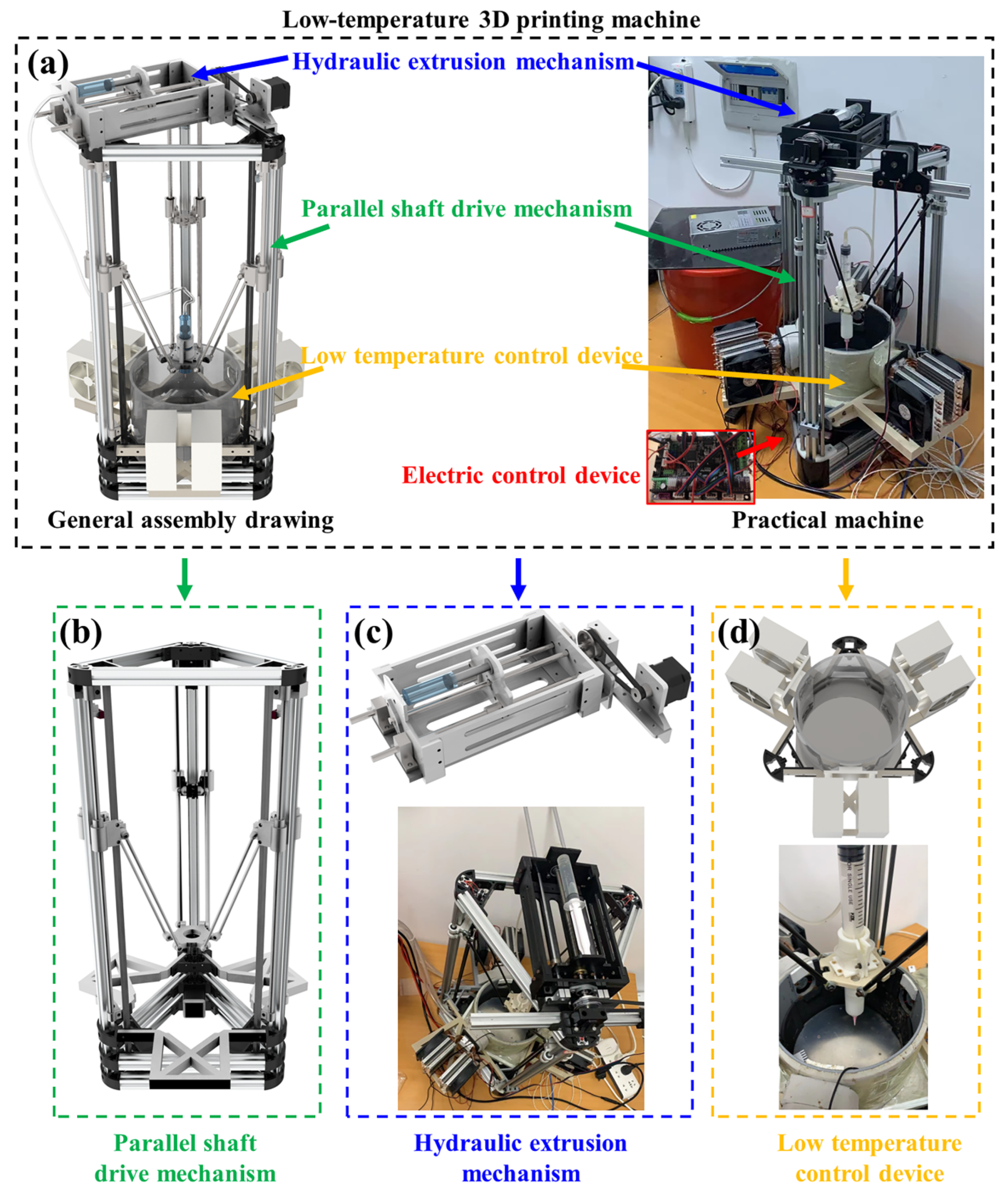

2.2. Design and Components of Low-Temperature 3D Printing Machine

2.3. Low-Temperature 3D Printing of PVA Matrix Hydrogels

2.3.1. Preparation of PVA Matrix Hydrogel Reaction Liquids

2.3.2. Low-Temperature 3D Printing Process of PVA Matrix Hydrogels

2.3.3. Functionalization of Low-Temperature 3D Printing PVA Matrix Hydrogels

2.4. Material Characteristics

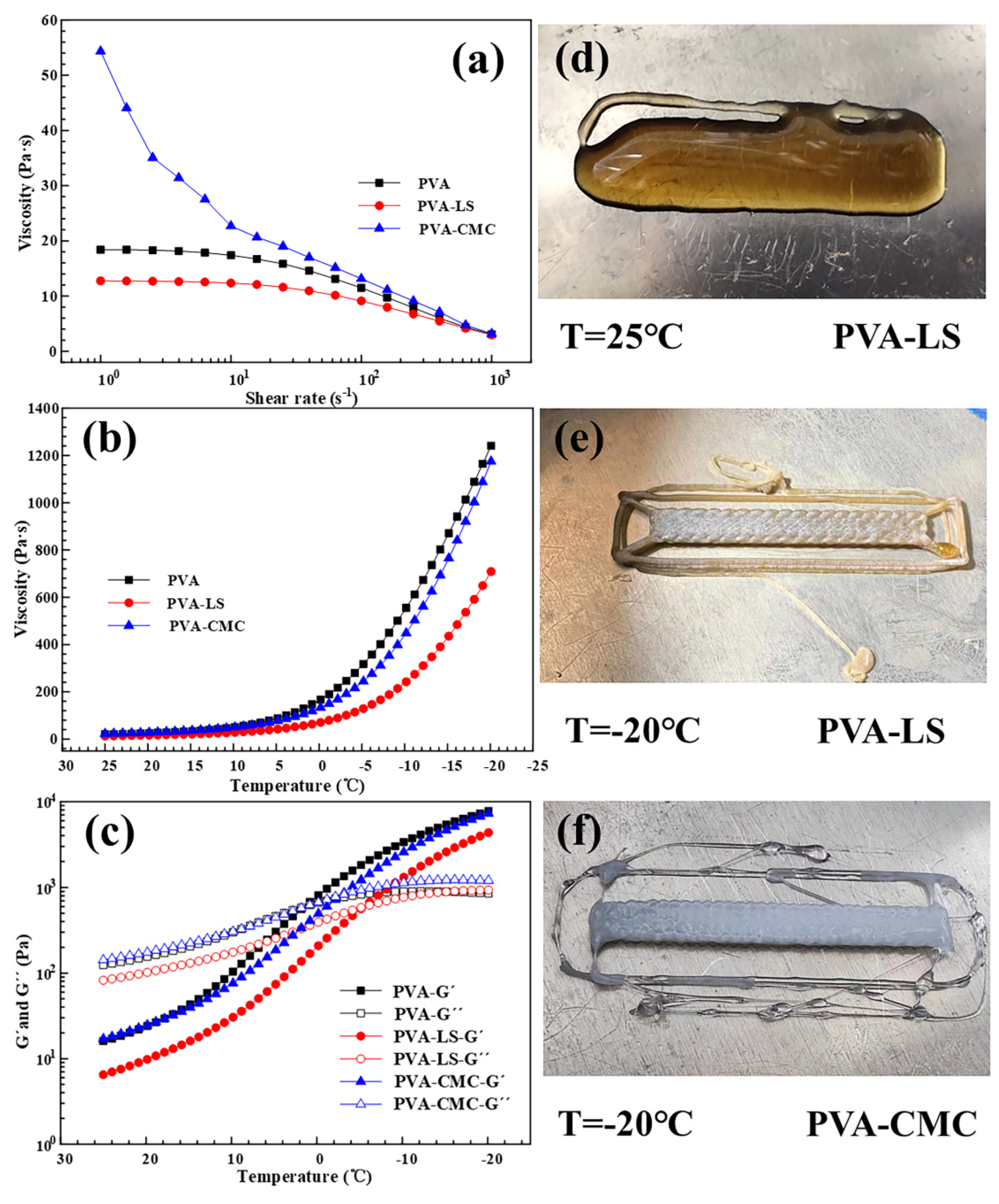

2.4.1. Rheology Tests

2.4.2. Mechanical Tests

2.4.3. Microstructure and Phase Component Tests

2.4.4. Conductivity and Electrical Sensing Tests

3. Results and Discussion

3.1. Low-Temperature Rheology Analysis of PVA Matrix Hydrogels

3.2. Construct and Operation of Low-Temperature 3D Printing Machine

3.3. Structure Properties of Low-Temperature 3D Printing Technology

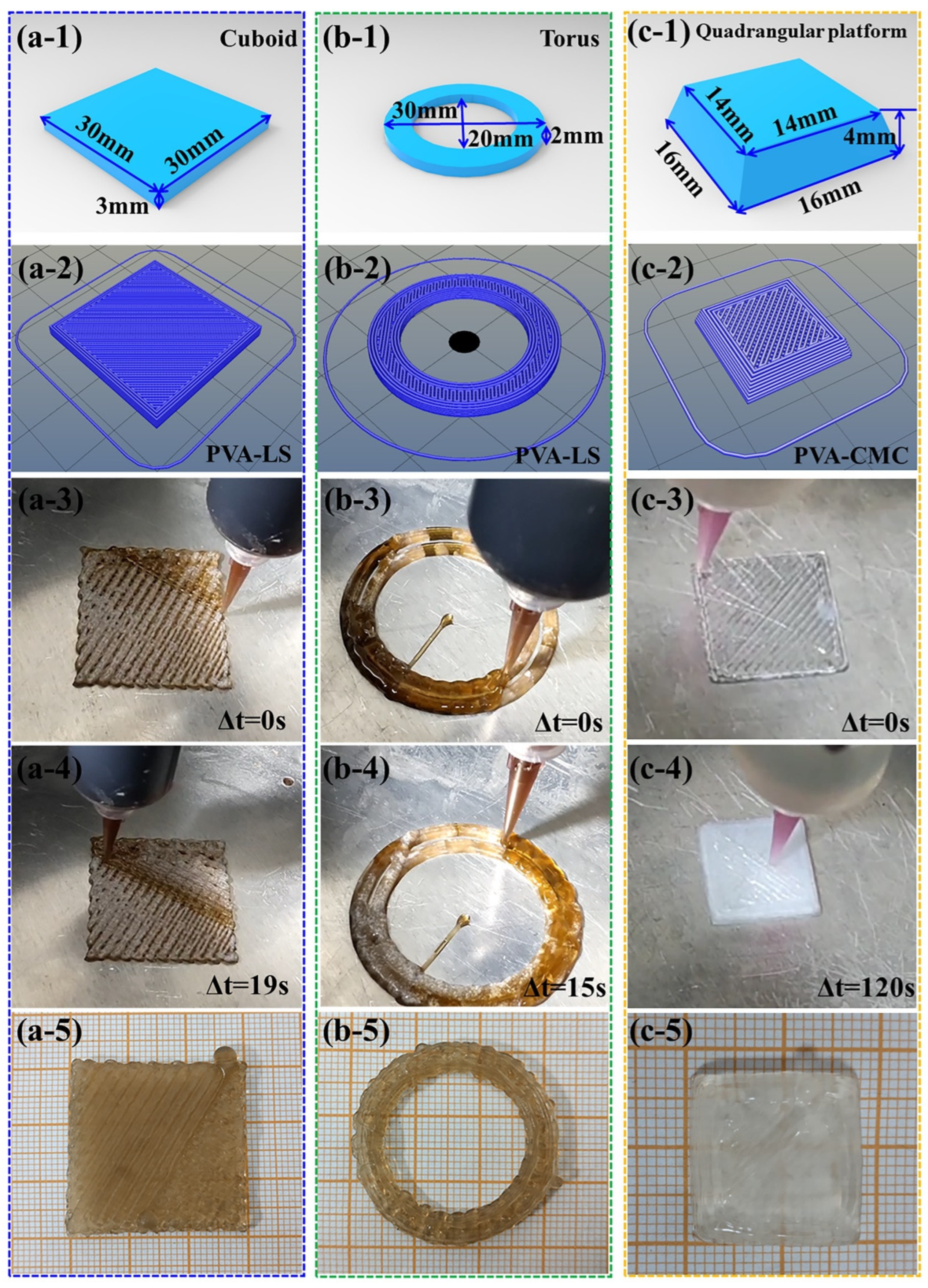

3.3.1. Low-Temperature 3D Printing of Simple Structures

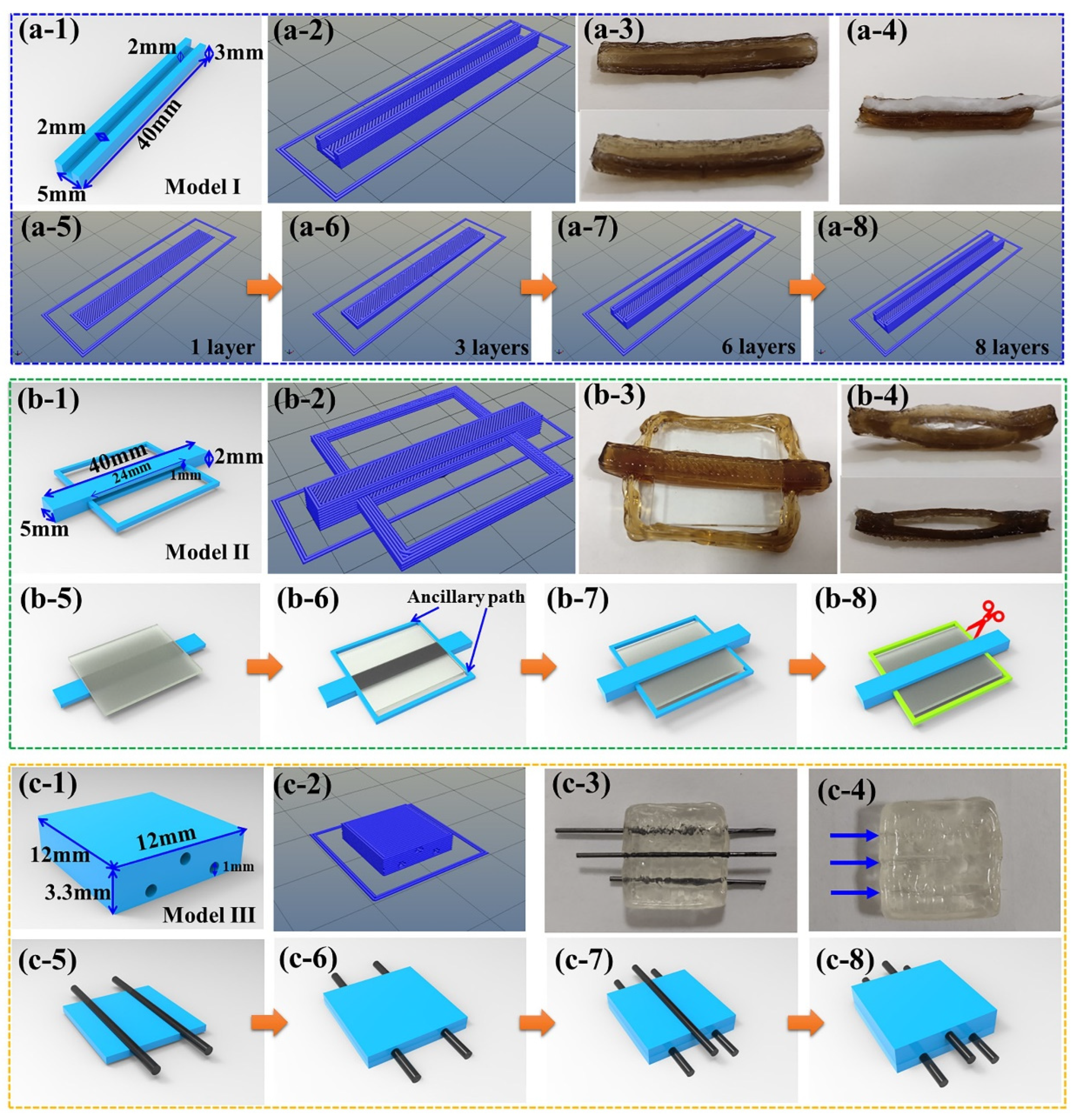

3.3.2. Low-Temperature 3D Printing of Complex Structures

3.4. Function Properties of Low-Temperature 3D Printing Technology

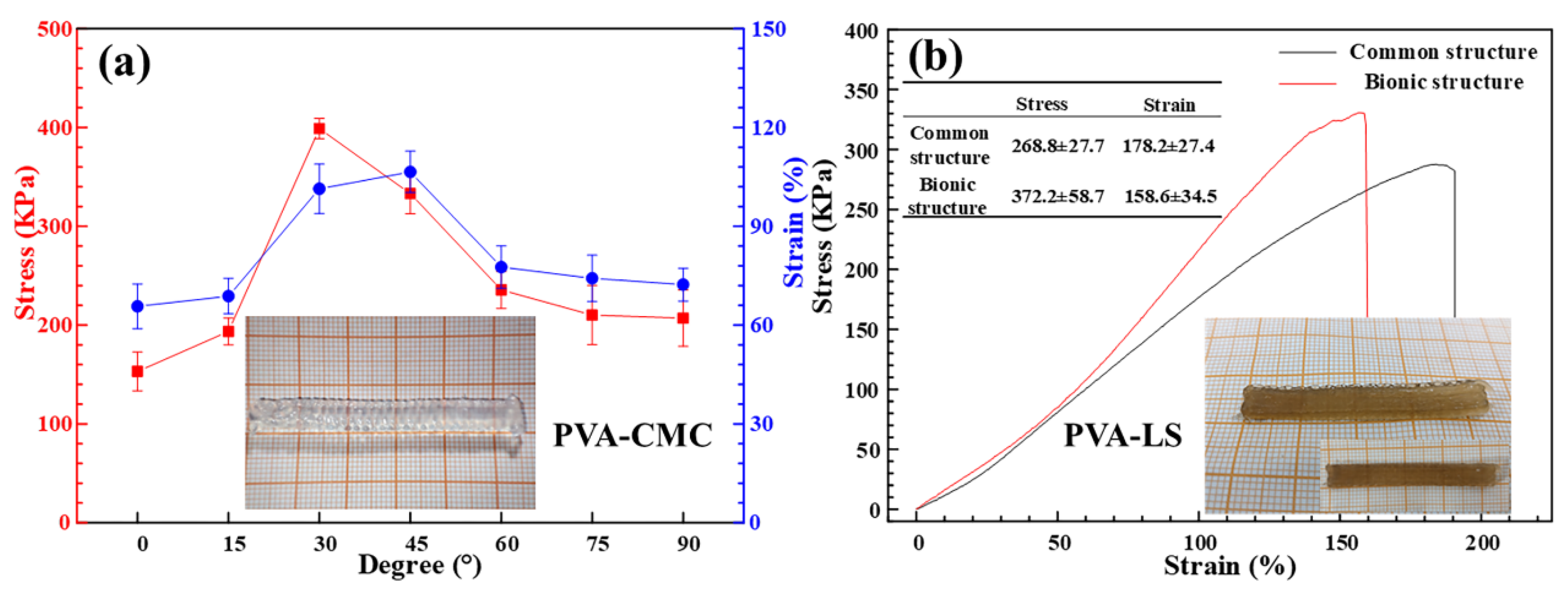

3.4.1. Structure Strength of Low-Temperature 3D Printing PVA Matrix Hydrogels

3.4.2. Conductivity and Sensing of Low-Temperature 3D Printing PVA Matrix Hydrogels

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamoun, E.A.; Chen, X.; Eldin, M.S.M.; Kenawy, E.R.S. Crosslinked poly (viny alcohol) hydrogels for wound dressing applications: A review of remarkably blended polymers. Arabian J. Chem. 2015, 8, 1–14. [Google Scholar] [CrossRef]

- Kong, W.; Li, Q.; Li, X.; Su, Y.; Yue, Q.; Gao, B. A biodegradable biomass-based polymeric composite for slow release and water retention. J. Environ. Manag. 2019, 230, 190–198. [Google Scholar] [CrossRef] [PubMed]

- Hassan, C.M.; Ward, J.H.; Peppas, N.A. Modeling of crystal dissolution of poly (vinyl alcohol) gels produced by freezing/thawing processes. Polymer 2000, 41, 6729–6739. [Google Scholar] [CrossRef]

- Jing, Y.; Wang, A.; Li, J.; Li, Q.; Han, Q.; Zheng, X.; Cao, H.; Bai, S. Preparation of conductive and transparent dipeptide hydrogels for wearable biosensor. Bio-Des. Manuf. 2022, 5, 153–162. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, L.; Wang, T.; Sun, W.; Tong, Z. NIR-triggered rapid shape memory PAM-GO-gelatin hydrogels with high mechanical strength. ACS Appl. Mater. Interfaces 2016, 8, 12384–12392. [Google Scholar] [CrossRef]

- Han, L.; Lu, X.; Liu, K.; Wang, K.; Fang, L.; Weng, L.T.; Zhang, H.; Tang, Y.; Ren, F.; Zhao, C.; et al. Mussel-inspired adhesive and tough hydrogel based on nanoclay confined dopamine polymerization. ACS Nano 2017, 11, 2561–2574. [Google Scholar] [CrossRef]

- Yang, R.; Chen, X.; Zheng, Y.; Chen, K.; Zeng, W.; Wu, X. Recent advances in the 3D printing of electrically conductive hydrogels for flexible electronics. J. Mater. Chem. C 2022, 10, 5380–5399. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, H.; Chen, W.; Li, Q.; Yan, B.; Jin, X.; Ma, A.; Liu, H.; Zhao, W. Dually synergetic network hydrogels with integrated mechanical stretchability, thermal responsiveness, and electrical conductivity for strain sensors and temperature alertors. ACS Appl. Mater. Interfaces 2018, 10, 14045–14054. [Google Scholar] [CrossRef]

- Pan, S.; Xia, M.; Li, H.; Jiang, X.; He, P.; Sun, Z.; Zhang, Y. Transparent, high-strength, stretchable, sensitive and anti-freezing poly (vinyl alcohol) ionic hydrogel strain sensors for human motion monitoring. J. Mater. Chem. C 2020, 8, 2827–2837. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Wang, X.; Yang, Y.; Hu, Z.; Liu, L.; Huang, Y. Highly conductive PVA/Ag coating by aqueous in situ reduction and its stretchable structure for strain sensor. ACS Appl. Mater. Interfaces 2020, 12, 1427–1435. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Cai, J.; Huang, J.; Qiu, X. Equip the hydrogel with armor: Strong and super tough biomass reinforced hydrogels with excellent conductivity and anti-bacterial performance. J. Mater. Chem. A 2019, 7, 26917–26926. [Google Scholar] [CrossRef]

- Zhou, Y.; Wan, C.; Yang, Y.; Yang, H.; Wang, S.; Dai, Z.; Ji, K.; Jiang, H.; Chen, X.; Long, Y. Highly stretchable, elastic, and ionic conductive hydrogel for artificial soft electronics. Adv. Funct. Mater. 2019, 29, 1806220. [Google Scholar] [CrossRef]

- Bom, S.; Martins, A.M.; Ribeiro, H.M.; Marto, J. Diving into 3D (bio) printing: A revolutionary tool to customize the production of drug and cell-based systems for skin delivery. Int. J. Pharm. 2021, 605, 1–20. [Google Scholar] [CrossRef]

- Zhang, X.N.; Zheng, Q.; Wu, Z.L. Recent advances in 3D printing of tough hydrogels: A review. Compos. Pt. B-Eng. 2022, 238, 109895. [Google Scholar] [CrossRef]

- Pulatsu, E.T.; Su, J.; Lin, J.; Lin, M. Factors affecting 3D printing and postprocessing capacity of cookie dough. Innov. Food. Sci. Emerg. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Tohic, C.L.; Osullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food. Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- Azad, M.A.; Olawuni, D.; Kimbell, G.; Badruddoza, A.Z.M.; Hossain, M.S.; Sultana, T. Polymers for extrusion-based 3D printing of pharmaceuticals: A holistic materials-process perspective. Pharmaceutics 2020, 12, 124. [Google Scholar] [CrossRef]

- Bom, S.; Santos, C.; Barros, R.; Martins, A.M.; Paradiso, P.; Cl’audio, R.; Pinto, P.C.; Ribeiro, H.M.; Marto, J. Effects of starch incorporation on the physicochemical properties and release kinetics of alginate-based 3D hydrogel patches for topical delivery. Pharmaceutics 2020, 12, 719. [Google Scholar] [CrossRef]

- Vithani, K.; Goyanes, A.; Jannin, V.; Basit, A.W.; Gaisford, S.; Boyd, B.J. An overview of 3D printing technologies for soft materials and potential opportunities for lipid-based drug delivery systems. Pharm. Res. 2019, 36, 4. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Derakhshanfar, S.; Mbeleck, R.; Xu, K.; Zhang, X.; Zhong, W.; Xing, M. 3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances. Bioact. Mater. 2018, 3, 144–156. [Google Scholar] [CrossRef]

- Wang, S.; Lee, J.M.; Yeong, W.Y. Smart hydrogels for 3D bioprinting. Int. J. Bioprinting 2015, 1, 3–14. [Google Scholar] [CrossRef]

- Ma, T.; Lv, L.X.; Ouyang, C.Z.; Hu, X.N.; Liao, X.J.; Song, Y.; Hu, X.S. Rheological behavior and particle alignment of cellulose nanocrystal and its composite hydrogels during 3D printing, Carbohyd. Polym. 2021, 253, 117217. [Google Scholar]

- Zhao, Q.; Liang, Y.H.; Ren, L.; Qiu, F.; Zhang, Z.H.; Ren, L.Q. Study on temperature and near-infrared driving characteristics of hydrogel actuator fabricated via molding and 3D printing. J. Mech. Behav. Biomed. 2018, 78, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Lin, Z.Y.; Wenger, A.; Tam, K.C.; Tang, X. 3D bioprinting of livermimetic construct with alginate/cellulose nanocrystal hybrid bioink. Bioprinting 2018, 9, 1–6. [Google Scholar] [CrossRef]

- Studart, A.R. Additive manufacturing of biologically-inspired materials. Chem. Soc. Rev. 2016, 45, 359–376. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, Q.; Liang, Y.H.; Ren, L.; Ren, L.Q. Hypersensitized strain sensors based on conductive hydrogels with excellent conductivity and good mechanical properties. ACS Sustain. Chem. Eng. 2022, 10, 4425–4437. [Google Scholar] [CrossRef]

- Zhao, Q.; Chang, Y.J.; Lin, Z.H.; Zhang, Z.Z.; Han, Z.W.; Ren, L.Q. Microstructure and in-situ tensile strength of propodus of mantis shrimp. Microsc. Res. Tech. 2021, 84, 415–421. [Google Scholar] [CrossRef]

| Name | Model | Location |

|---|---|---|

| Fish-eye rod end joint bearing | SA3T/K | Parallel-shaft drive mechanism |

| Carbon Fiber Rods | Diameter 5 mm | |

| M3 Fish-eye rod hanging platform | PLA, 3D printed | |

| Bolt | M3 | |

| Pulley | Mounted with M8 linear bearings | |

| Steel Shaft | M8 | |

| Synchronous wheel | 2GT, 16 teeth, M5 | |

| Passive Wheel | 2GT, M3 | |

| Synchronous belt | 2GT, 5 mm | |

| Stepper motors | 42BYGH40S | |

| Stepper motors | 42BYGH60-401A | Hydraulic extrusion mechanism |

| Synchronous wheel | 2GT, 20 teeth, M5 | |

| Synchronous wheel | 2GT, 60 teeth, M8 | |

| Silica gel tube | M5 | |

| LUER taper | M5 | |

| Injector | 20 mL | |

| Extruder support | PLA, 3D printed | |

| Cryogenic system main control board | Arduino MEGA2560 R3 | Low-temperature control device |

| Temperature Sensor | DS18B20 | |

| Semiconductor chilling plate | 19,906, 12 V, 10 W | |

| Cooling Fan | 9025 | |

| Cooling Fan | 4010 | |

| Aluminum plate | 200 mm × 200 mm | |

| 3D printer main control board | MKS Gen-L V2.1 | Electric control device |

| limit switch | KW8 |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Nominal voltage | 3.7 V | Rated current | 2.3 A |

| Location torque | ≥2.6 N·cm | No-load torque | 15 N·m |

| Rotational inertia | 110 g·cm2 | Stepping angle | 1.8° |

| Resistance | 1.6 Ω | Rated speed | 300 r/min |

| Direction of rotation | Axial clockwise | Wiring harness | 4 |

| Phase number | 2 | Diameter of axle | 8 mm |

| Gravity | 470 g |

| Parameters | Units | Values |

|---|---|---|

| Inner diameter of nozzle | mm | 0.6 |

| Environment temperature | °C | −20 |

| Feed rate | mm3/s | 37.17 |

| Extrusion rate | mm/s | 10 |

| Moving speed multiplier | - | 80–100 |

| 3D printing rate | mm/s | 7 |

| Layer height | mm | 0.3 |

| 3D printing path | - | Self design |

| Filling rate | - | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Liu, C.; Chang, Y.; Wu, H.; Hou, Y.; Wu, S.; Guo, M. Low-Temperature 3D Printing Technology of Poly (Vinyl Alcohol) Matrix Conductive Hydrogel Sensors with Diversified Path Structures and Good Electric Sensing Properties. Sensors 2023, 23, 8063. https://doi.org/10.3390/s23198063

Zhao Q, Liu C, Chang Y, Wu H, Hou Y, Wu S, Guo M. Low-Temperature 3D Printing Technology of Poly (Vinyl Alcohol) Matrix Conductive Hydrogel Sensors with Diversified Path Structures and Good Electric Sensing Properties. Sensors. 2023; 23(19):8063. https://doi.org/10.3390/s23198063

Chicago/Turabian StyleZhao, Qian, Chang Liu, Yanjiao Chang, Han Wu, Yihao Hou, Siyang Wu, and Mingzhuo Guo. 2023. "Low-Temperature 3D Printing Technology of Poly (Vinyl Alcohol) Matrix Conductive Hydrogel Sensors with Diversified Path Structures and Good Electric Sensing Properties" Sensors 23, no. 19: 8063. https://doi.org/10.3390/s23198063

APA StyleZhao, Q., Liu, C., Chang, Y., Wu, H., Hou, Y., Wu, S., & Guo, M. (2023). Low-Temperature 3D Printing Technology of Poly (Vinyl Alcohol) Matrix Conductive Hydrogel Sensors with Diversified Path Structures and Good Electric Sensing Properties. Sensors, 23(19), 8063. https://doi.org/10.3390/s23198063