Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor

Abstract

:1. Introduction

2. Fundamentals of the RF-Based Measurement Systems

2.1. Determination of Dielectric Properties Using the Microwave Cavity Perturbation

2.2. RF-Based Filter Monitoring

3. Methodology for Evaluating the RF Properties of Soot

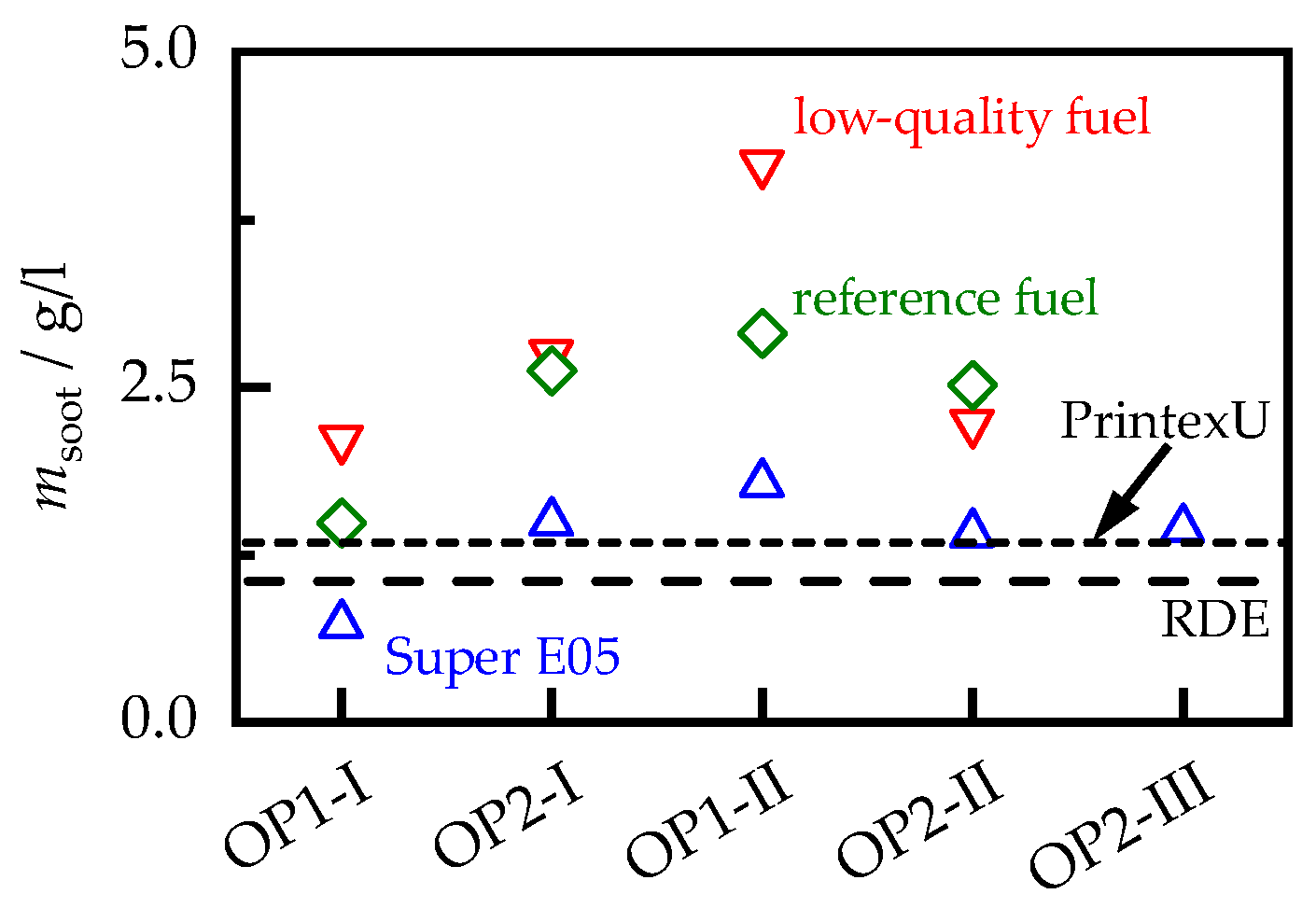

3.1. Generation of Soot-Loaded Particulate Filters

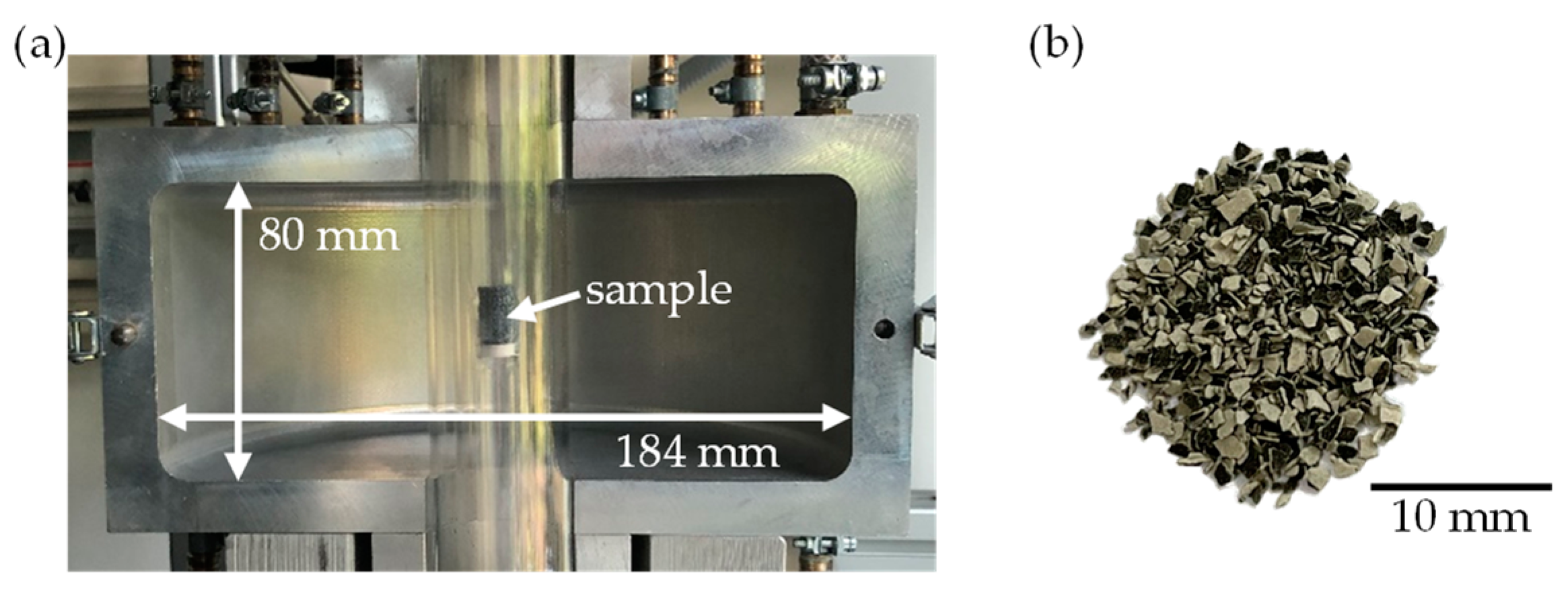

3.2. Examination of the Crushed Soot-Loaded Filter Samples Using the MCP

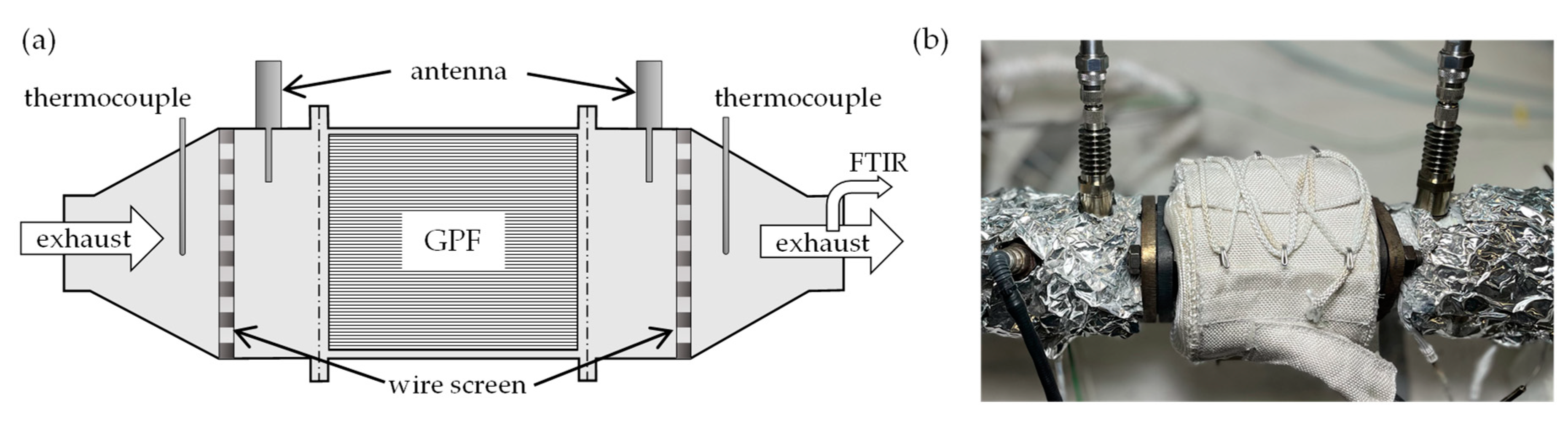

3.3. Examination of the Filter Cores on a Lab Test Bench

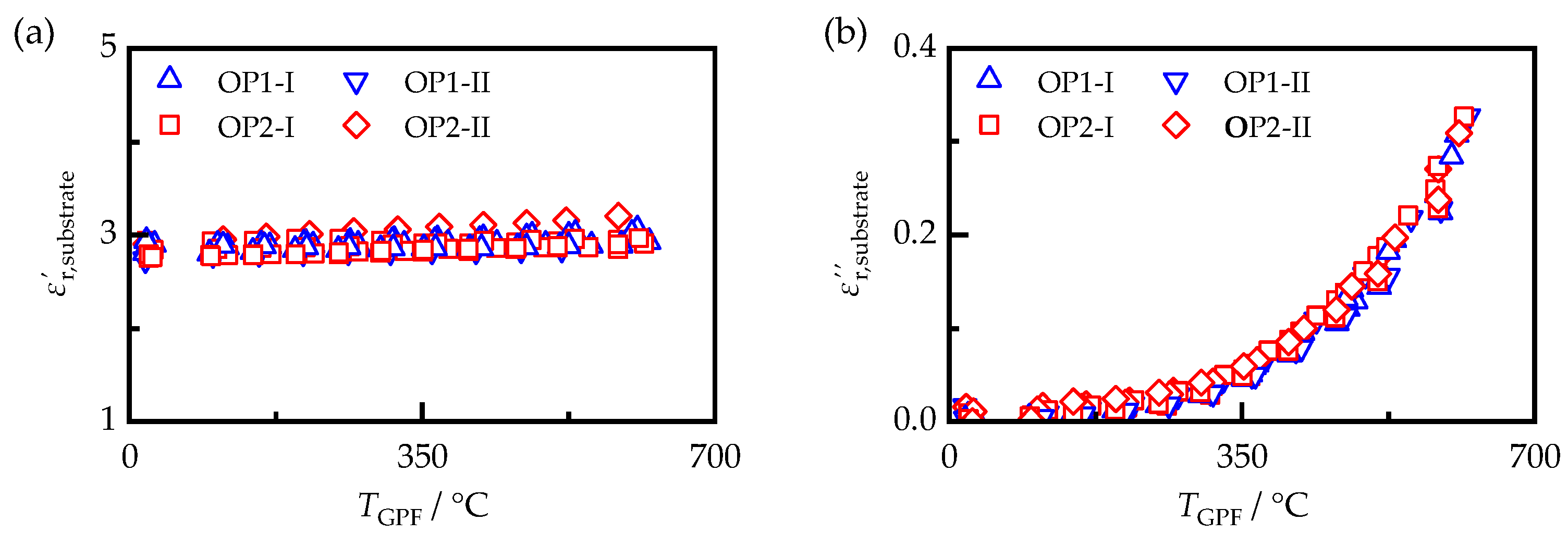

4. RF Properties of Filter Substrate

5. RF Properties of Soot

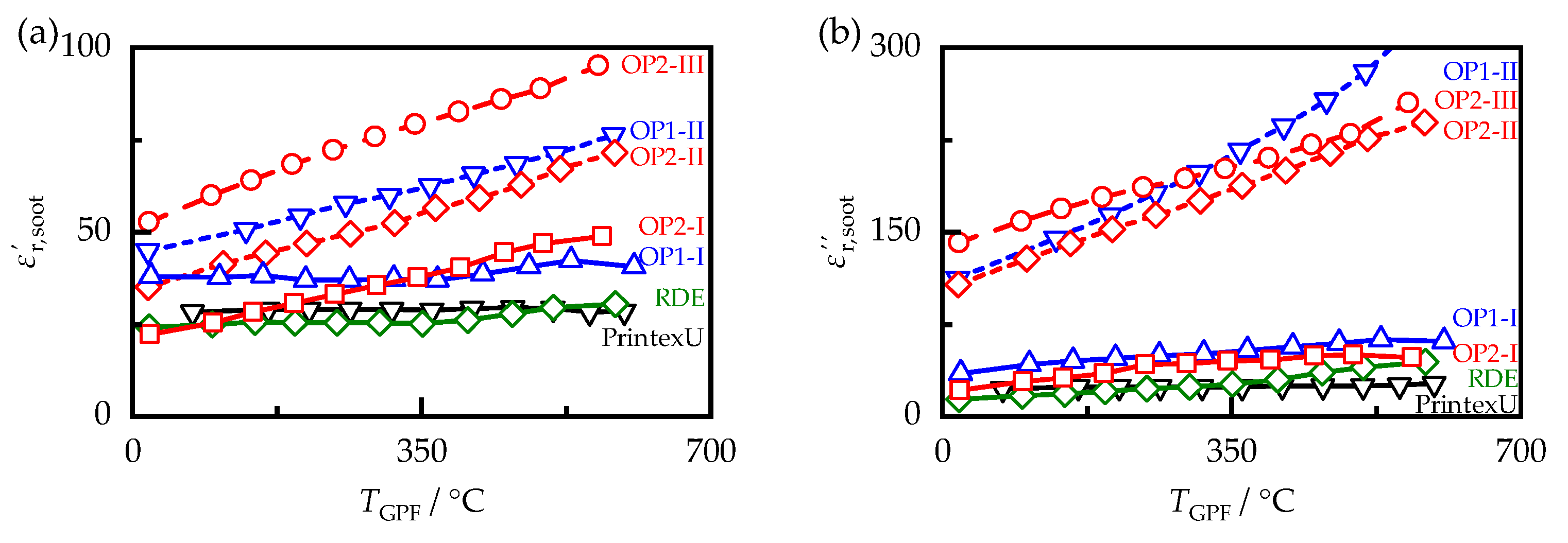

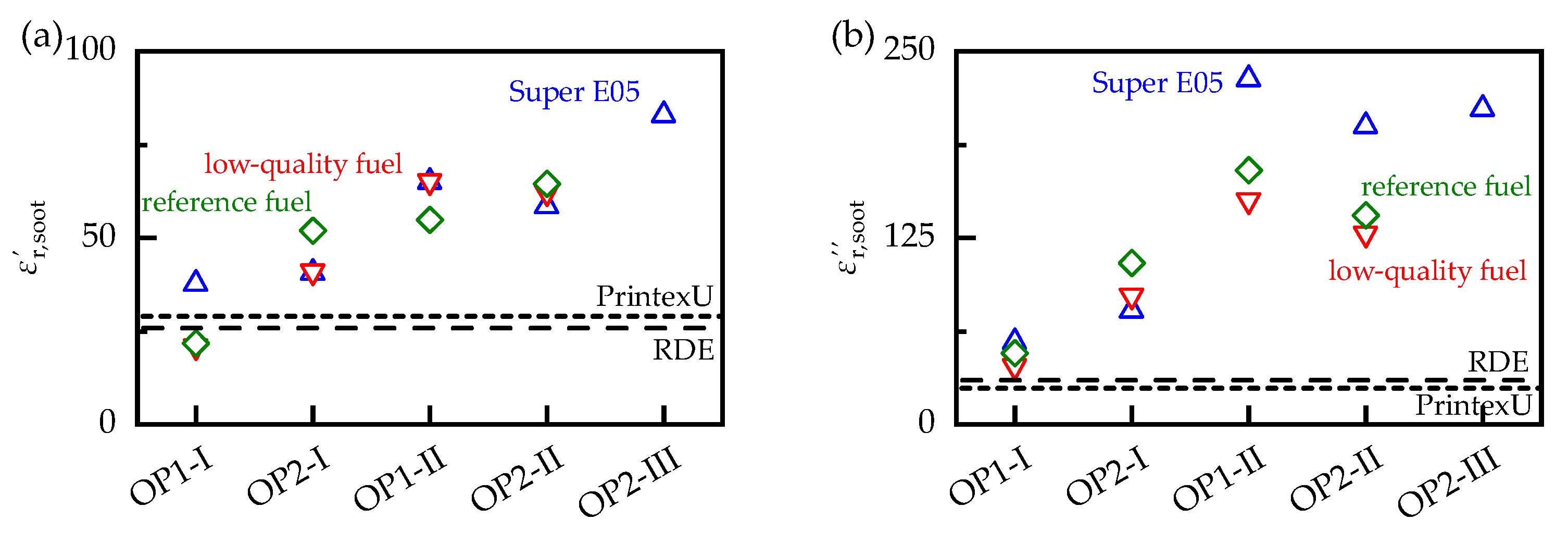

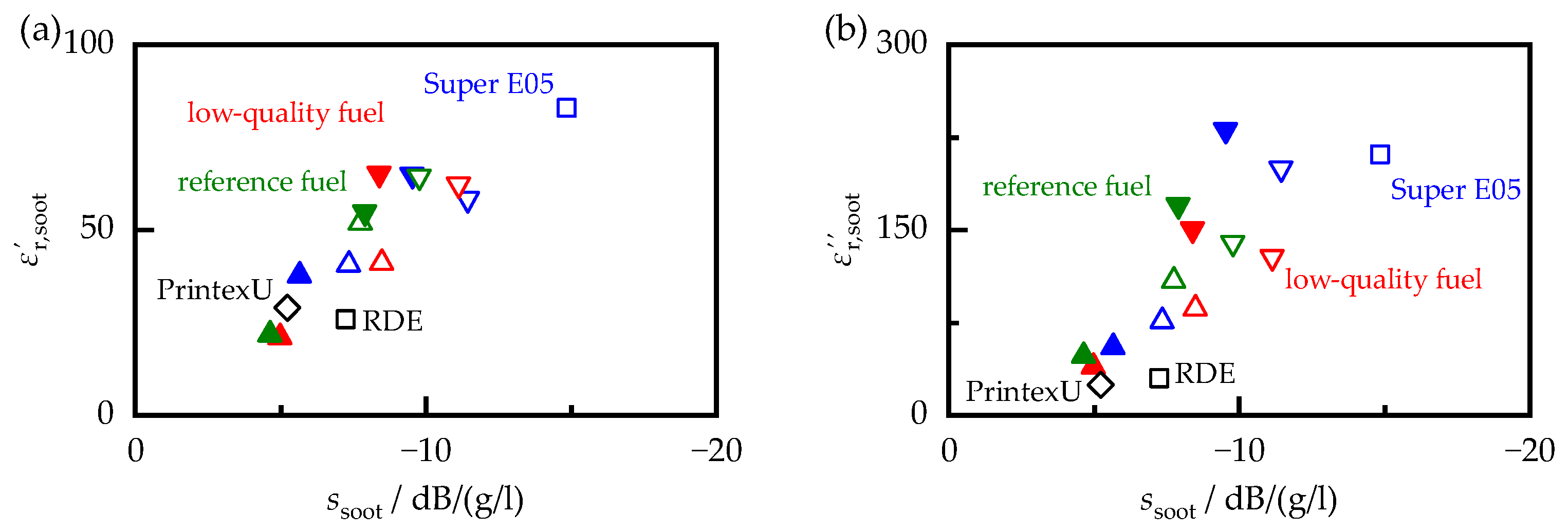

5.1. Dielectric Properties of Soot

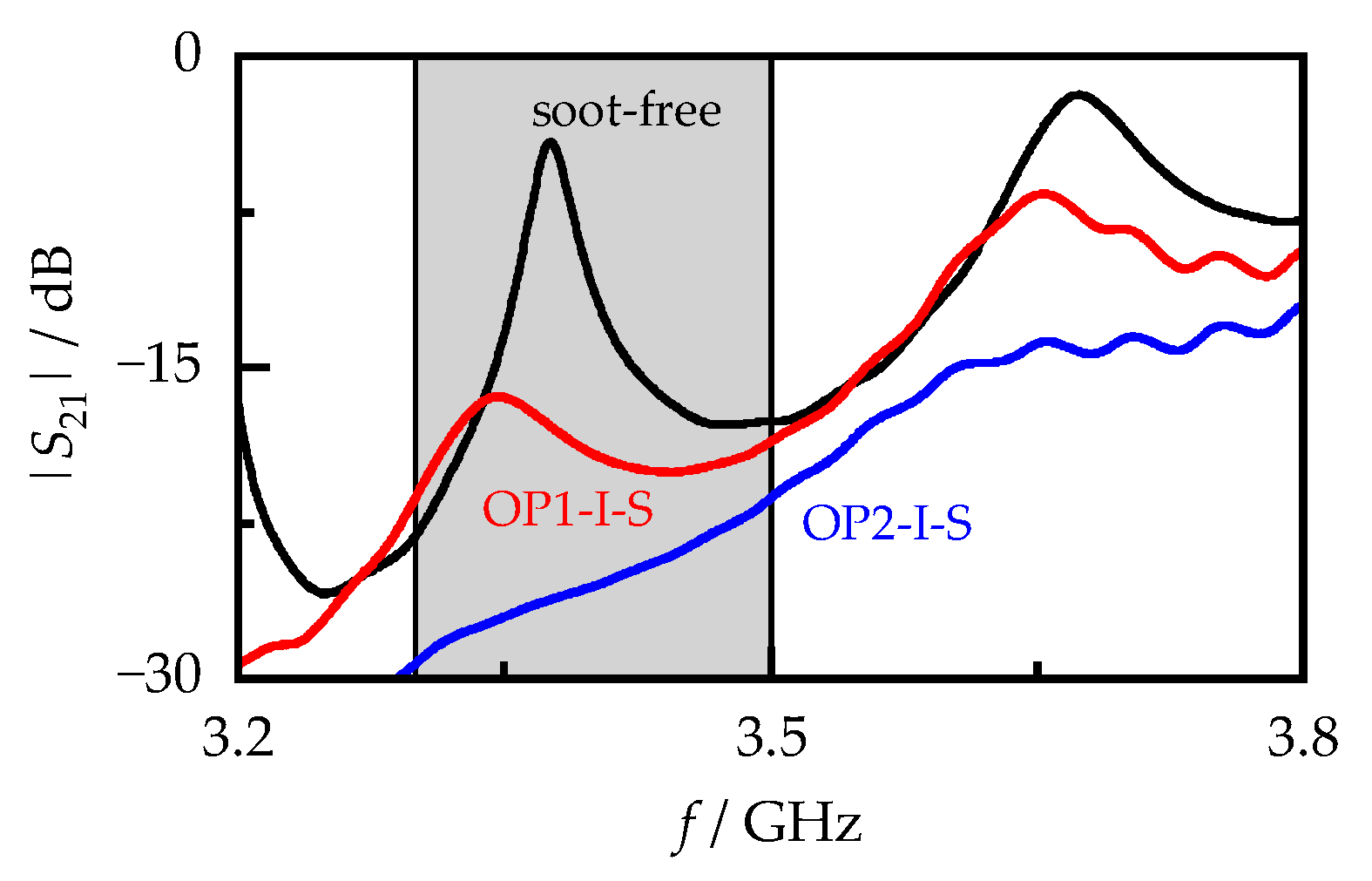

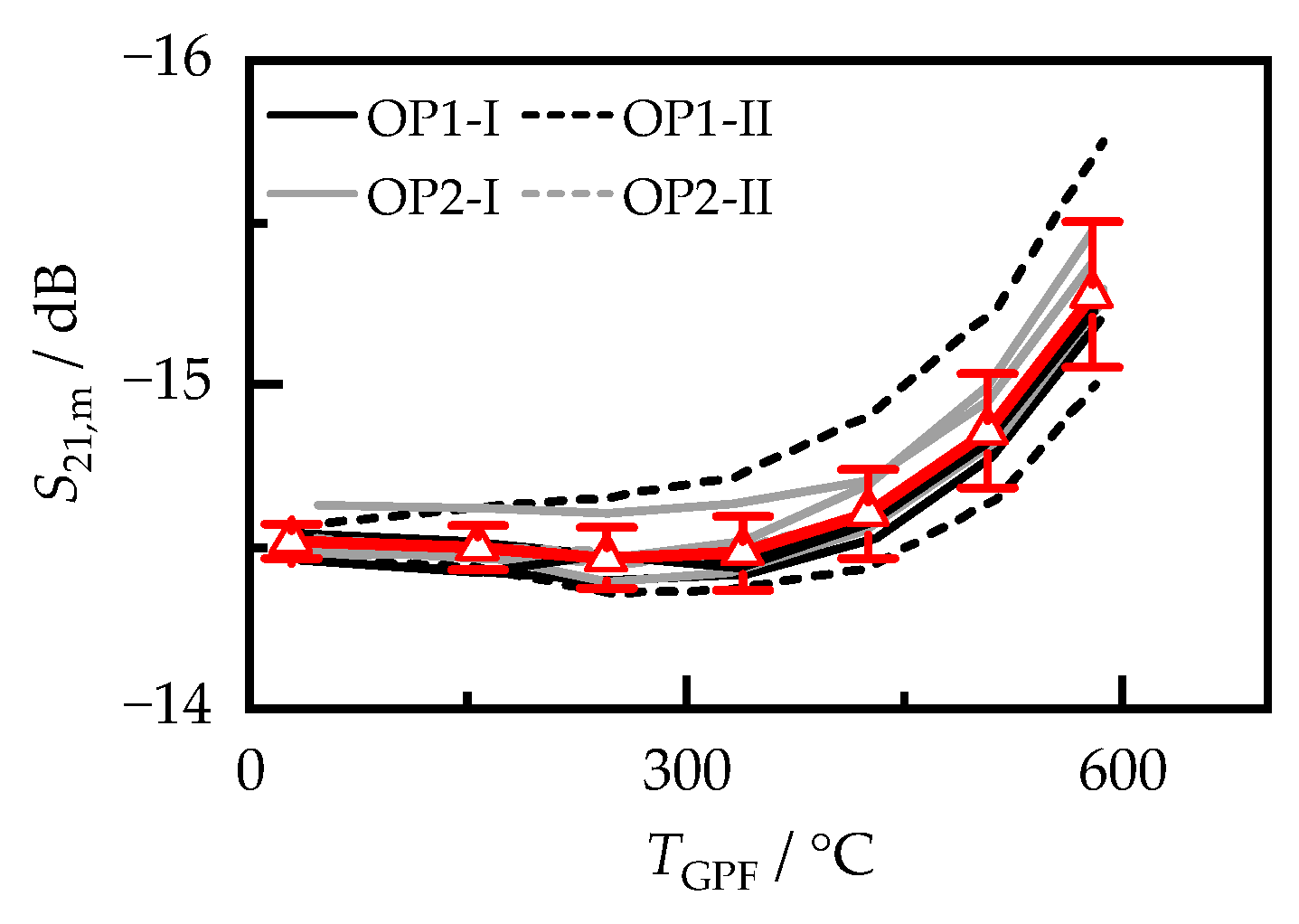

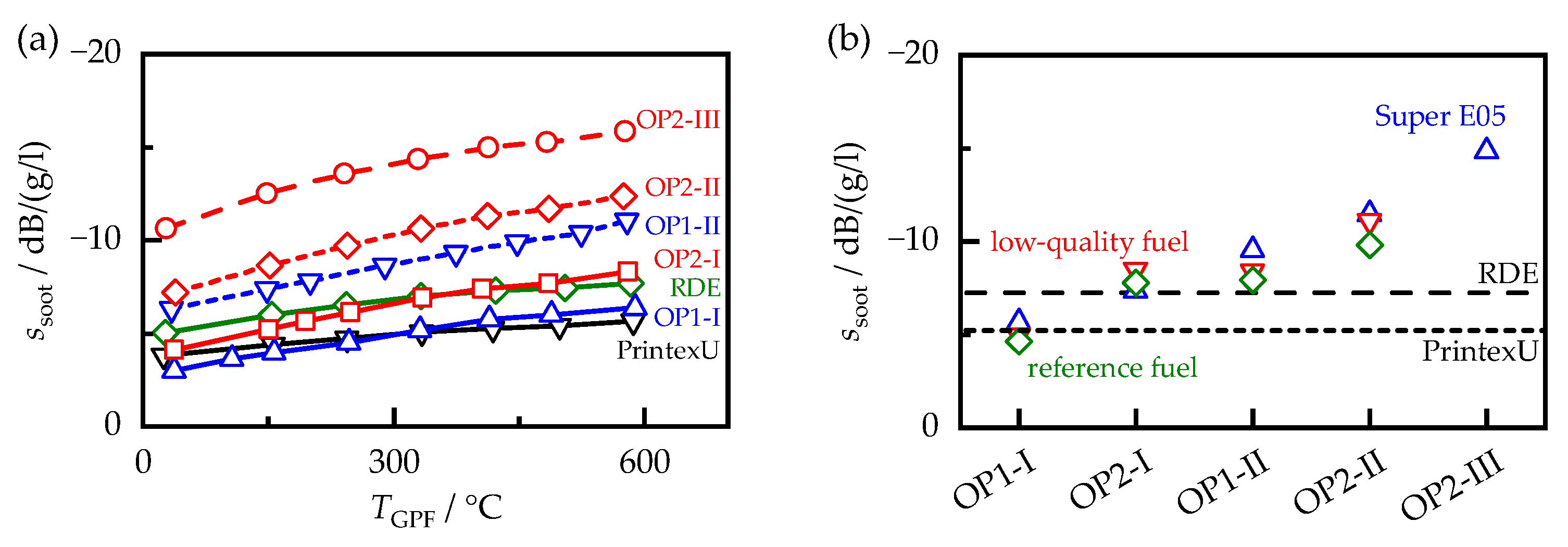

5.2. Signal of the RF Sensor

6. Method for Correcting the Engine Influence on the RF Sensor

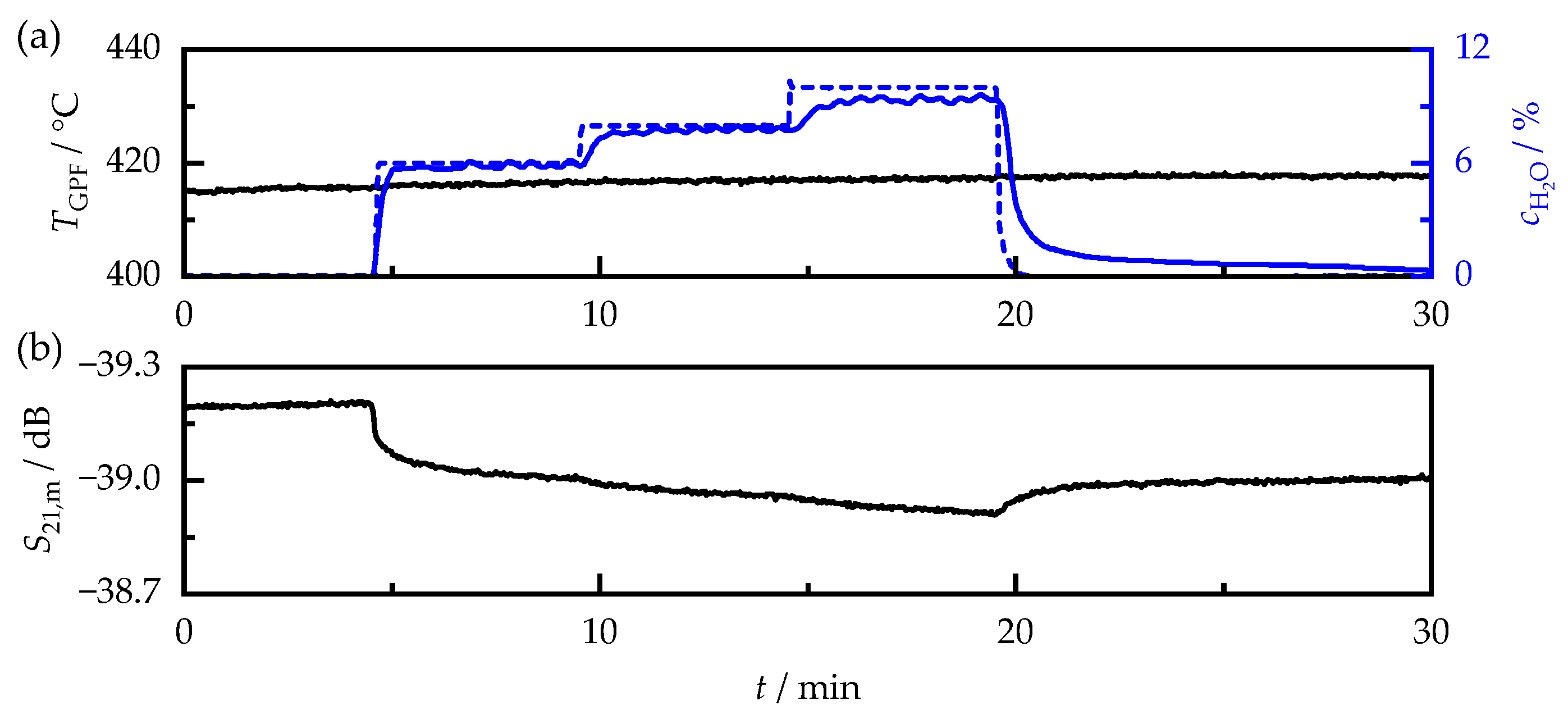

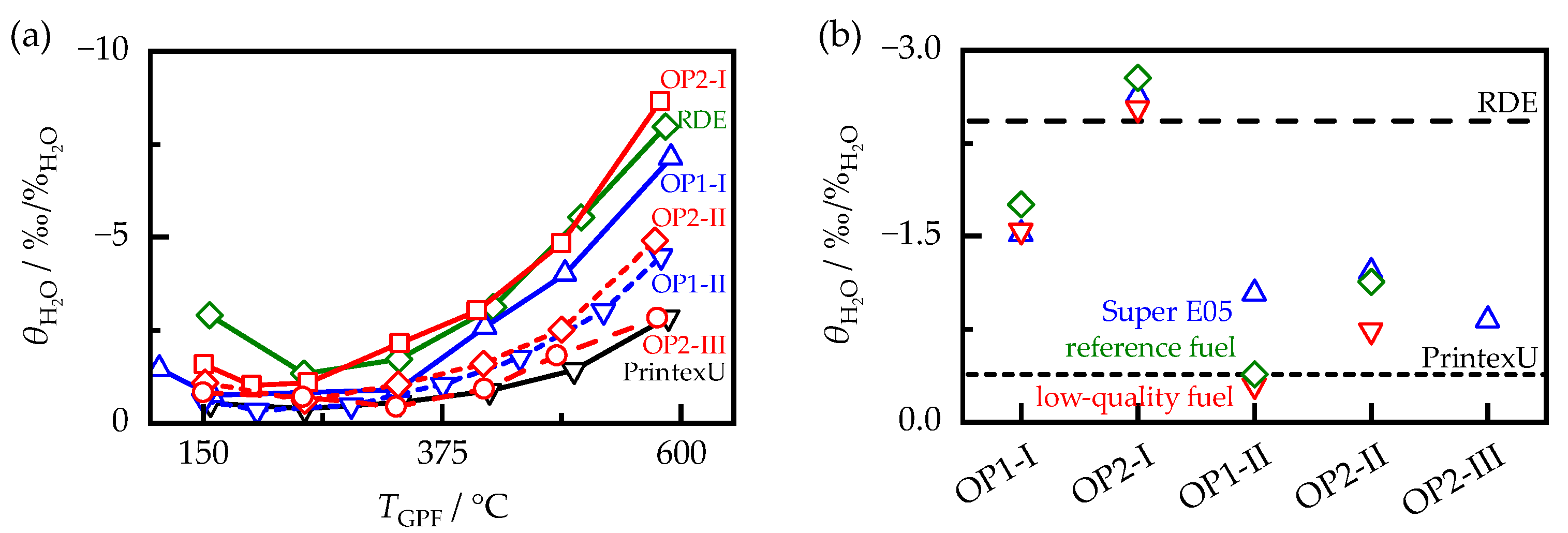

6.1. Influcence of Humidity on the RF Sensor

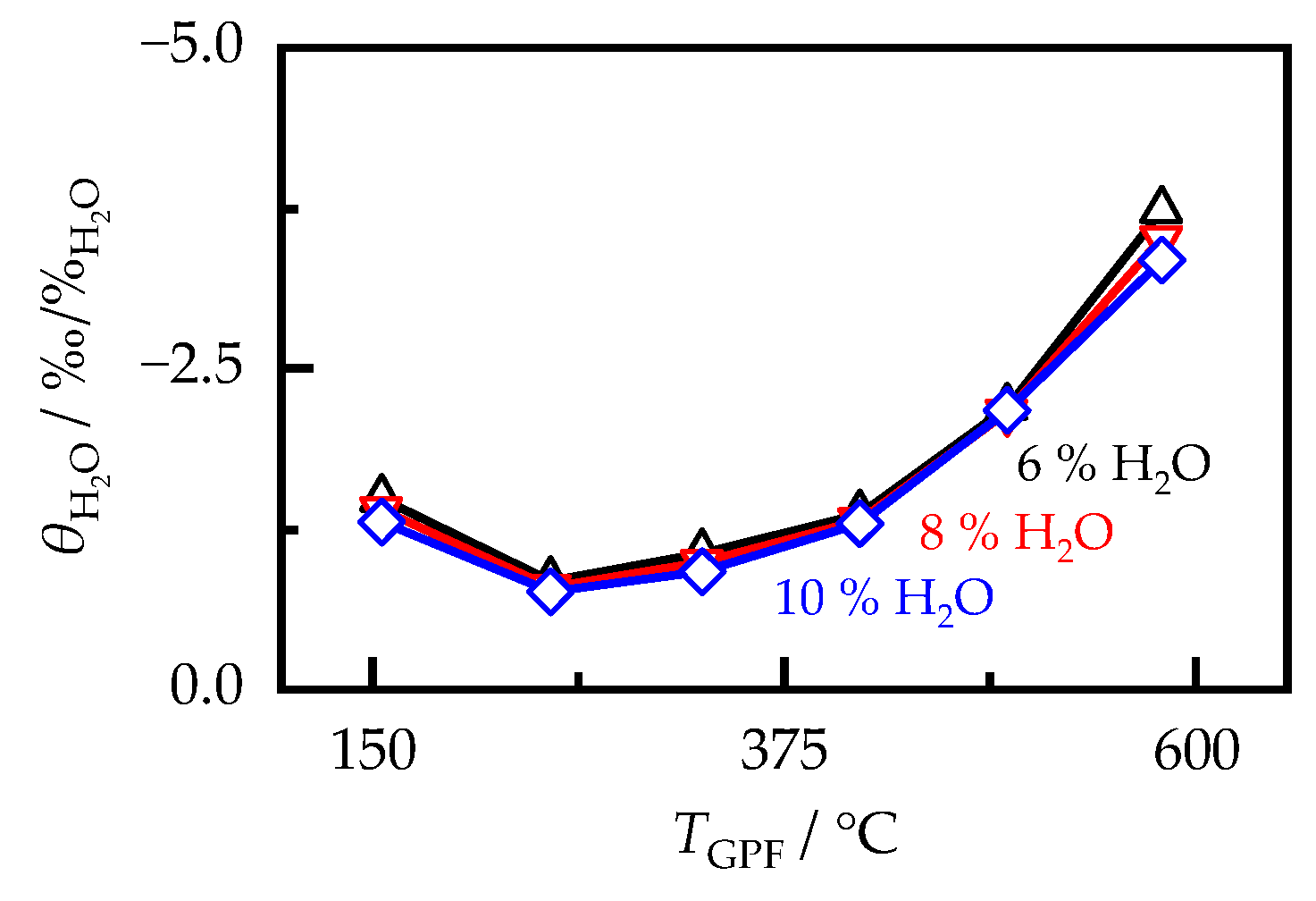

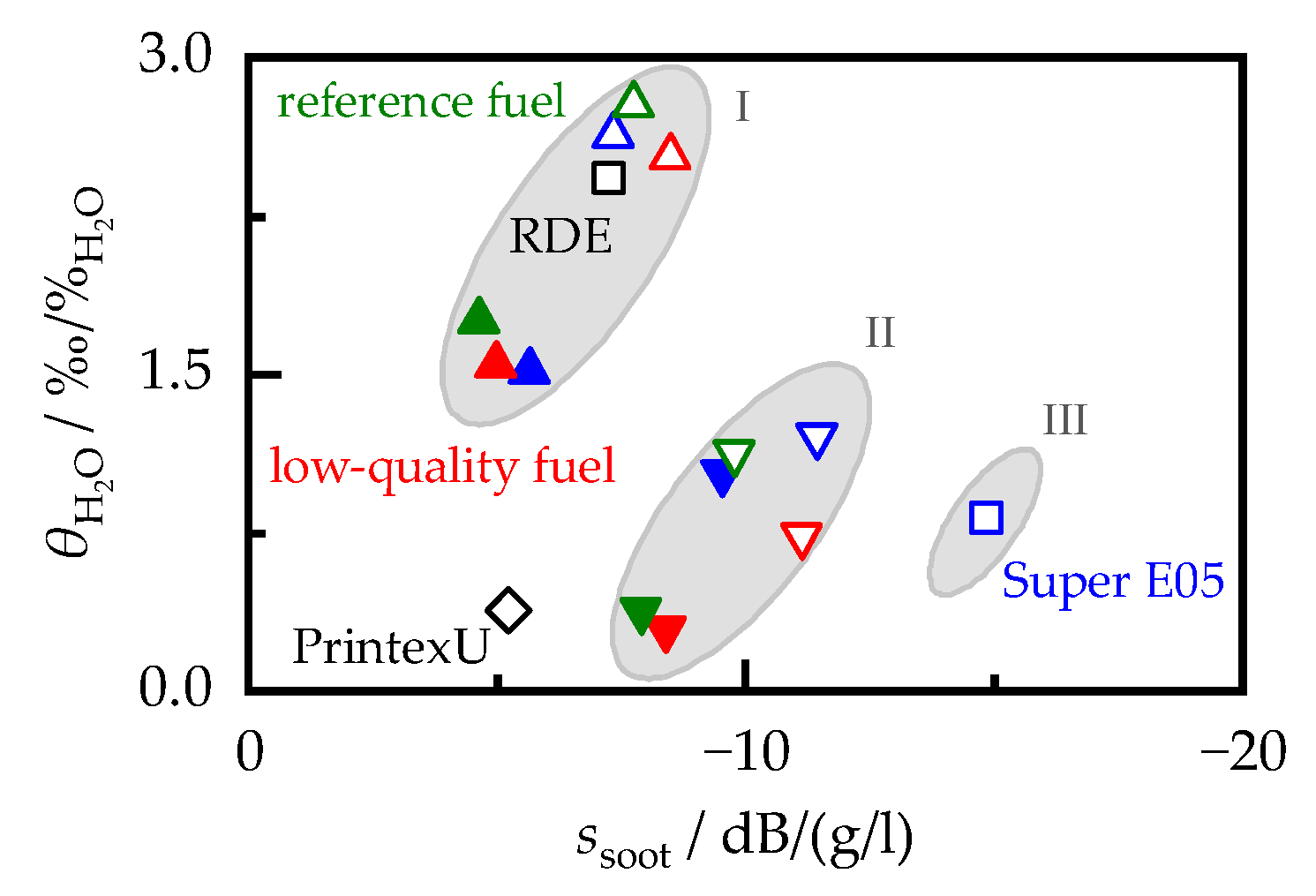

6.2. Correlation between Humidity and the RF Sensor Sensitivity

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Platt, S.M.; El Haddad, I.; Pieber, S.M.; Zardini, A.A.; Suarez-Bertoa, R.; Clairotte, M.; Daellenbach, K.R.; Huang, R.-J.; Slowik, J.G.; Hellebust, S.; et al. Gasoline cars produce more carbonaceous particulate matter than modern filter-equipped diesel cars. Sci. Rep. 2017, 7, 4926. [Google Scholar] [CrossRef] [PubMed]

- European Environment Agency. Air Quality in Europe: 2020 Report; EEA Report No 9/2020; European Environment Agency: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Lohmann, U.; Friebel, F.; Kanji, Z.A.; Mahrt, F.; Mensah, A.A.; Neubauer, D. Future warming exacerbated by aged-soot effect on cloud formation. Nat. Geosci. 2020, 13, 674–680. [Google Scholar] [CrossRef]

- Lanzerath, P.; Wunsch, R.; Schön, C. The first series-production particulate filter for Mercedes-Benz gasoline engines. In 17. Internationales Stuttgarter Symposium: Automobil- und Motorentechnik; Bargende, M., Reuss, H.-C., Wiedemann, J., Eds.; Springer: Wiesbaden, Germany, 2017; pp. 851–865. [Google Scholar] [CrossRef]

- Joshi, A.; Johnson, T.V. Gasoline Particulate Filters—A Review. Emiss. Control Sci. Technol. 2018, 4, 219–239. [Google Scholar] [CrossRef]

- Saito, C.; Nakatani, T.; Miyairi, Y.; Yuuki, K.; Makino, M.; Kurachi, H.; Heuss, W.; Kuki, T.; Furuta, Y.; Kattouah, P.; et al. New Particulate Filter Concept to Reduce Particle Number Emissions; 2011-01-0814; SAE Technical Papers: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Gaiser, G.; Mucha, P. Prediction of Pressure Drop in Diesel Particulate Filters Considering Ash Deposit and Partial Regenerations; 2004-01-0158; SAE Technical Papers: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Dietrich, M.; Jahn, C.; Lanzerath, P.; Moos, R. Microwave-Based Oxidation State and Soot Loading Determination on Gasoline Particulate Filters with Three-Way Catalyst Coating for Homogenously Operated Gasoline Engines. Sensors 2015, 15, 21971–21988. [Google Scholar] [CrossRef]

- Nicolin, P.; Boger, T.; Dietrich, M.; Haft, G.; Bachurina, A. Soot Load Monitoring in Gasoline Particulate Filter Applications with RF-Sensors; 2020-01-2171; SAE Technical Papers: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Chen, P.; Schönebaum, S.; Simons, T.; Rauch, D.; Dietrich, M.; Moos, R.; Simon, U. Correlating the Integral Sensing Properties of Zeolites with Molecular Processes by Combining Broadband Impedance and DRIFT Spectroscopy-A New Approach for Bridging the Scales. Sensors 2015, 15, 28915–28941. [Google Scholar] [CrossRef]

- Chen, L. Microwave Electronics: Measurement and Materials Characterization; Wiley: Chichester, UK, 2005. [Google Scholar] [CrossRef]

- Parkash, A.; Vaid, J.K.; Mansingh, A. Measurement of Dielectric Parameters at Microwave Frequencies by Cavity-Perturbation Technique. IEEE Trans. Microw. Theory Tech. 1979, 27, 791–795. [Google Scholar] [CrossRef]

- Steiner, C.; Walter, S.; Malashchuk, V.; Hagen, G.; Kogut, I.; Fritze, H.; Moos, R. Determination of the Dielectric Properties of Storage Materials for Exhaust Gas Aftertreatment Using the Microwave Cavity Perturbation Method. Sensors 2020, 20, 6024. [Google Scholar] [CrossRef]

- Walter, S.; Schwanzer, P.; Steiner, C.; Hagen, G.; Rabl, H.-P.; Dietrich, M.; Moos, R. Mixing Rules for an Exact Determination of the Dielectric Properties of Engine Soot Using the Microwave Cavity Perturbation Method and Its Application in Gasoline Particulate Filters. Sensors 2022, 22, 3311. [Google Scholar] [CrossRef]

- Steiner, C.; Hagen, G.; Kogut, I.; Fritze, H.; Moos, R. Analysis of defect chemistry and microstructural effects of non-stoichiometric ceria by the high-temperature microwave cavity perturbation method. J. Eur. Ceram. Soc. 2022, 42, 499–511. [Google Scholar] [CrossRef]

- Walter, S.; Schwanzer, P.; Hagen, G.; Haft, G.; Dietrich, M.; Rabl, H.-P.; Moos, R. Hochfrequenzsensorik zur direkten Beladungserkennung von Benzinpartikelfiltern. In Automobil-Sensorik 3; Tille, T., Ed.; Springer Vieweg: Berlin, Germany, 2020; pp. 185–208. [Google Scholar] [CrossRef]

- Sethia, S.; Kubinski, D.; Nerlich, H.; Naber, J. RF Studies of Soot and Ammonia Loadings on a Combined Particulate Filter and SCR Catalyst. J. Electrochem. Soc. 2020, 167, 147516. [Google Scholar] [CrossRef]

- Sappok, A.; Ragaller, P.; Guarino, A.; Mandelbaum, J.; Lapenta, L.; Kolberg, D.; Newman, R.; Lu, X.; Cors, D.; Bromberg, L. Direct Measurement of Aftertreatment System Stored Water Levels for Improved Dew Point Management Using Radio Frequency Sensing; 2019-01-0739; SAE Technical Papers: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Feulner, M.; Seufert, F.; Müller, A.; Hagen, G.; Moos, R. Influencing Parameters on the Microwave-Based Soot Load Determination of Diesel Particulate Filters. Top. Catal. 2017, 60, 374–380. [Google Scholar] [CrossRef]

- Potenza, M.; Milanese, M.; de Risi, A. Effect of injection strategies on particulate matter structures of a turbocharged GDI engine. Fuel 2019, 237, 413–428. [Google Scholar] [CrossRef]

- Notheis, D.; Bertsch, M.; Velji, A.; Koch, T. Untersuchung der Partikelemissionen für unterschiedliche Einspritzstrategien an einem aufgeladenen Ottomotor mit Direkteinspritzung. In 10. Tagung Diesel- und Benzindirekteinspritzung 2016; Tschöke, H., Marohn, R., Eds.; Springer: Wiesbaden, Germany, 2017; pp. 403–424. [Google Scholar] [CrossRef]

- Kalvakala, K.C.; Pal, P.; Aggarwal, S.K. Effects of fuel composition and octane sensitivity on polycyclic aromatic hydrocarbon and soot emissions of gasoline–ethanol blend surrogates. Combust. Flame 2020, 221, 476–486. [Google Scholar] [CrossRef]

- Graves, B.M.; Koch, C.R.; Olfert, J.S. Morphology and volatility of particulate matter emitted from a gasoline direct injection engine fuelled on gasoline and ethanol blends. J. Aerosol Sci. 2017, 105, 166–178. [Google Scholar] [CrossRef]

- Luo, Y.; Zhu, L.; Fang, J.; Zhuang, Z.; Guan, C.; Xia, C.; Xie, X.; Huang, Z. Size distribution, chemical composition and oxidation reactivity of particulate matter from gasoline direct injection (GDI) engine fueled with ethanol-gasoline fuel. Appl. Therm. Eng. 2015, 89, 647–655. [Google Scholar] [CrossRef]

- Xing, J.; Shao, L.; Zheng, R.; Peng, J.; Wang, W.; Guo, Q.; Wang, Y.; Qin, Y.; Shuai, S.; Hu, M. Individual particles emitted from gasoline engines: Impact of engine types, engine loads and fuel components. J. Clean. Prod. 2017, 149, 461–471. [Google Scholar] [CrossRef]

- Manin, J.; Skeen, S.; Pickett, L.; Kurtz, E.; Anderson, J.E. Effects of Oxygenated Fuels on Combustion and Soot Formation/Oxidation Processes. SAE Int. J. Fuels Lubr. 2014, 7, 704–717. [Google Scholar] [CrossRef]

- Yang, J.; Roth, P.; Durbin, T.D.; Karavalakis, G. Impacts of gasoline aromatic and ethanol levels on the emissions from GDI vehicles: Part 1. Influence on regulated and gaseous toxic pollutants. Fuel 2019, 252, 799–811. [Google Scholar] [CrossRef]

- Fatouraie, M.; Frommherz, M.; Mosburger, M.; Chapman, E.; Li, S.; McCormick, R.; Fioroni, G. Investigation of the Impact of Fuel Properties on Particulate Number Emission of a Modern Gasoline Direct Injection Engine; 2018-01-0358; SAE Technical Papers: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Boger, T.; Rose, D.; Nicolin, P.; Gunasekaran, N.; Glasson, T. Oxidation of Soot (Printex® U) in Particulate Filters Operated on Gasoline Engines. Emiss. Control Sci. Technol. 2015, 1, 49–63. [Google Scholar] [CrossRef]

- Choi, S.; Seong, H. Oxidation characteristics of gasoline direct-injection (GDI) engine soot: Catalytic effects of ash and modified kinetic correlation. Combust. Flame 2015, 162, 2371–2389. [Google Scholar] [CrossRef]

- Huynh, C.T.; Johnson, J.H.; Yang, S.L.; Bagley, S.T.; Warner, J.R. A One-Dimensional Computational Model for Studying the Filtration and Regeneration Characteristics of a Catalyzed Wall-Flow Diesel Particulate Filter; 2003-01-0841; SAE Technical Papers: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Lupše, J.; Campolo, M.; Soldati, A. Modelling soot deposition and monolith regeneration for optimal design of automotive DPFs. Chem. Eng. Sci. 2016, 151, 36–50. [Google Scholar] [CrossRef]

- Rauch, D.; Dietrich, M.; Simons, T.; Simon, U.; Porch, A.; Moos, R. Microwave Cavity Perturbation Studies on H-form and Cu Ion-Exchanged SCR Catalyst Materials: Correlation of Ammonia Storage and Dielectric Properties. Top. Catal. 2017, 60, 243–249. [Google Scholar] [CrossRef]

- Dietrich, M.; Rauch, D.; Porch, A.; Moos, R. A Laboratory Test Setup for in Situ Measurements of the Dielectric Properties of Catalyst Powder Samples under Reaction Conditions by Microwave Cavity Perturbation: Set up and Initial Tests. Sensors 2014, 14, 16856–16868. [Google Scholar] [CrossRef] [PubMed]

- Rissler, J.; Messing, M.E.; Malik, A.I.; Nilsson, P.T.; Nordin, E.Z.; Bohgard, M.; Sanati, M.; Pagels, J.H. Effective Density Characterization of Soot Agglomerates from Various Sources and Comparison to Aggregation Theory. Aerosol Sci. Technol. 2013, 47, 792–805. [Google Scholar] [CrossRef]

- Maricq, M.; Xu, N. The effective density and fractal dimension of soot particles from premixed flames and motor vehicle exhaust. J. Aerosol Sci. 2004, 35, 1251–1274. [Google Scholar] [CrossRef]

- Momenimovahed, A.; Olfert, J.S. Effective Density and Volatility of Particles Emitted from Gasoline Direct Injection Vehicles and Implications for Particle Mass Measurement. Aerosol Sci. Technol. 2015, 49, 1051–1062. [Google Scholar] [CrossRef]

- Walter, S.; Schwanzer, P.; Hagen, G.; Haft, G.; Rabl, H.-P.; Dietrich, M.; Moos, R. Modelling the Influence of Different Soot Types on the Radio-Frequency-Based Load Detection of Gasoline Particulate Filters. Sensors 2020, 20, 2659. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Camerucci, M.A.; Urretavizcaya, G.; Castro, M.S.; Cavalieri, A.L. Electrical properties and thermal expansion of cordierite and cordierite-mullite materials. J. Eur. Ceram. Soc. 2001, 21, 2917–2923. [Google Scholar] [CrossRef]

- Synkiewicz-Musialska, B.; Szwagierczak, D.; Kulawik, J.; Pałka, N.; Piasecki, P. Structural, Thermal and Dielectric Properties of Low Dielectric Permittivity Cordierite-Mullite-Glass Substrates at Terahertz Frequencies. Materials 2021, 14, 4030. [Google Scholar] [CrossRef]

- Ohsato, H.; Kim, J.-S.; Kim, A.-Y.; Cheon, C.-I.; Chae, K.-W. Millimeter-Wave Dielectric Properties of Cordierite/Indialite Glass Ceramics. Jpn. J. Appl. Phys. 2011, 50, 09NF01. [Google Scholar] [CrossRef]

- Lou, W.; Mao, M.; Song, K.; Xu, K.; Liu, B.; Li, W.; Yang, B.; Qi, Z.; Zhao, J.; Sun, S.; et al. Low permittivity cordierite-based microwave dielectric ceramics for 5G/6G telecommunications. J. Eur. Ceram. Soc. 2022, 42, 2820–2826. [Google Scholar] [CrossRef]

- Schmidbauer, E.; Mirwald, P.W. Electrical conductivity of cordierite. Mineral. Petrol. 1993, 48, 201–214. [Google Scholar] [CrossRef]

- Labrincha, J.A.; Albuquerque, C.M.; Ferreira, J.M.; Ribeiro, M.J. Electrical characterisation of cordierite bodies containing Al-rich anodising sludge. J. Eur. Ceram. Soc. 2006, 26, 825–830. [Google Scholar] [CrossRef]

- Atwater, J.E.; Wheeler, J.R.R. Temperature dependent complex permittivities of graphitized carbon blacks at microwave frequencies between 0.2 and 26 GHz. J. Mater. Sci. 2004, 39, 151–157. [Google Scholar] [CrossRef]

- Hotta, M.; Hayashi, M.; Lanagan, M.T.; Agrawal, D.K.; Nagata, K. Complex Permittivity of Graphite, Carbon Black and Coal Powders in the Ranges of X-band Frequencies (8.2 to 12.4 GHz) and between 1 and 10 GHz. ISIJ Int. 2011, 51, 1766–1772. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Q.; Zhang, Z.; He, P.; Zhang, J.; Jiang, K. Microwave Absorption Performance of Carbon Black/Polylactic Acid Composite for Fused Filament Fabrication. Appl. Sci. 2022, 12, 12747. [Google Scholar] [CrossRef]

- Lambert, C.; Bumbaroska, M.; Dobson, D.; Hangas, J.; Pakko, J.; Tennison, P. Analysis of High Mileage Gasoline Exhaust Particle Filters. SAE Int. J. Engines 2016, 9, 1296–1304. [Google Scholar] [CrossRef]

- Bromberg, L.; Sappok, A.; Koert, P. Method and System for Controlling Filter Operation. US Patent application US 2013/0125745 A1, 17 January 2013. [Google Scholar]

- Dietrich, M.; Hagen, G.; Reitmeier, W.; Burger, K.; Hien, M.; Grass, P.; Kubinski, D.; Visser, J.; Moos, R. Radio-Frequency-Based NH3-Selective Catalytic Reduction Catalyst Control: Studies on Temperature Dependency and Humidity Influences. Sensors 2017, 17, 1615. [Google Scholar] [CrossRef]

- Popovicheva, O.B.; Persiantseva, N.M.; Tishkova, V.; Shonija, N.K.; Zubareva, N.A. Quantification of water uptake by soot particles. Environ. Res. Lett. 2008, 3, 25009. [Google Scholar] [CrossRef]

| Number of cylinders | 4, in line |

| Power | 125 kW at 3800 min−1 |

| Torque | 320 Nm at 1500 min−1 |

| Displaced volume | 1798 cm3 |

| Stroke | 84.1 mm |

| Bore | 82.5 mm |

| Compression ratio | 9.60:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walter, S.; Schwanzer, P.; Hagen, G.; Rabl, H.-P.; Dietrich, M.; Moos, R. Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor. Sensors 2023, 23, 7861. https://doi.org/10.3390/s23187861

Walter S, Schwanzer P, Hagen G, Rabl H-P, Dietrich M, Moos R. Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor. Sensors. 2023; 23(18):7861. https://doi.org/10.3390/s23187861

Chicago/Turabian StyleWalter, Stefanie, Peter Schwanzer, Gunter Hagen, Hans-Peter Rabl, Markus Dietrich, and Ralf Moos. 2023. "Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor" Sensors 23, no. 18: 7861. https://doi.org/10.3390/s23187861

APA StyleWalter, S., Schwanzer, P., Hagen, G., Rabl, H.-P., Dietrich, M., & Moos, R. (2023). Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor. Sensors, 23(18), 7861. https://doi.org/10.3390/s23187861