Defect Detection Algorithm for Wing Skin with Stiffener Based on Phased-Array Ultrasonic Imaging

Abstract

1. Introduction

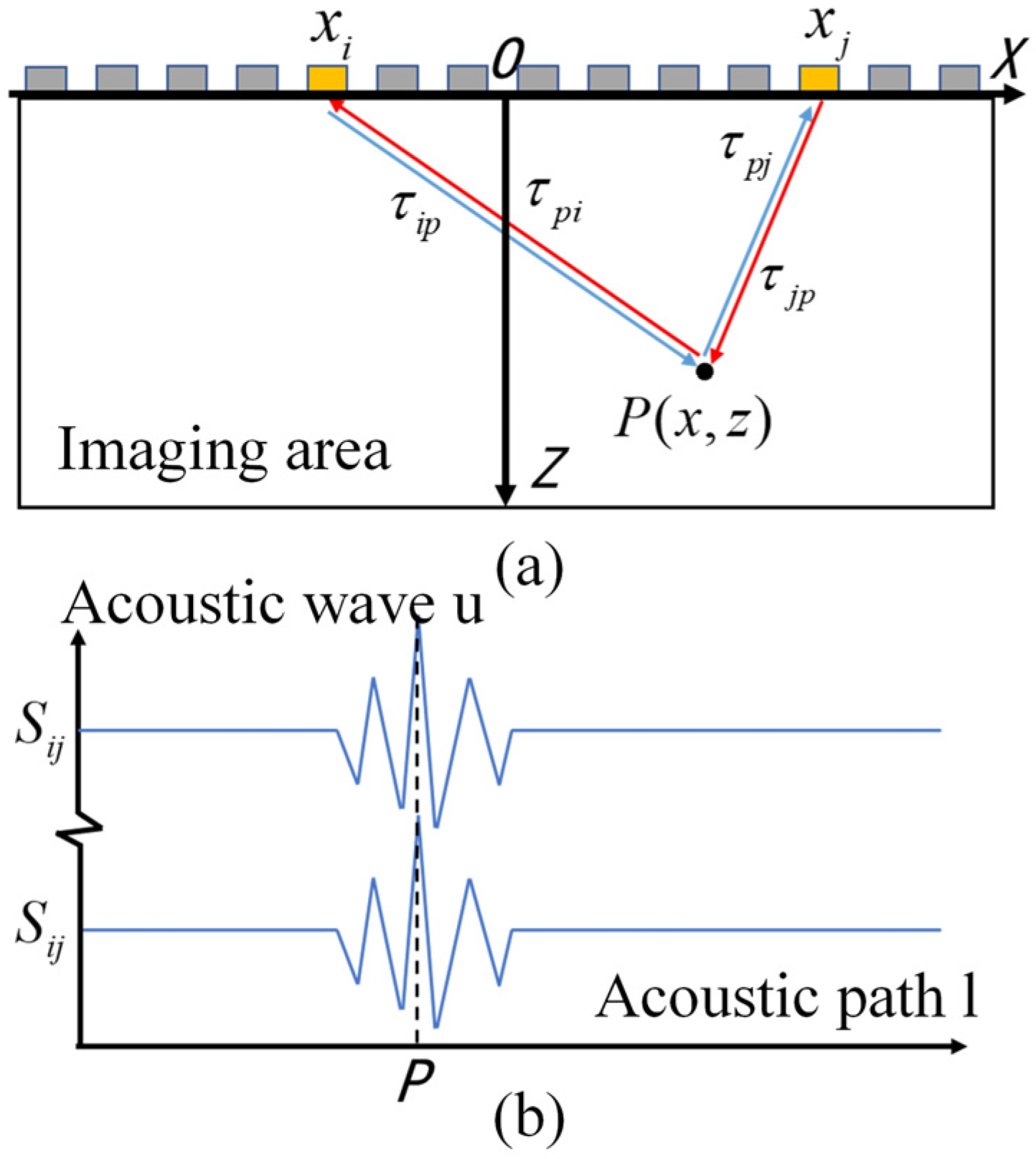

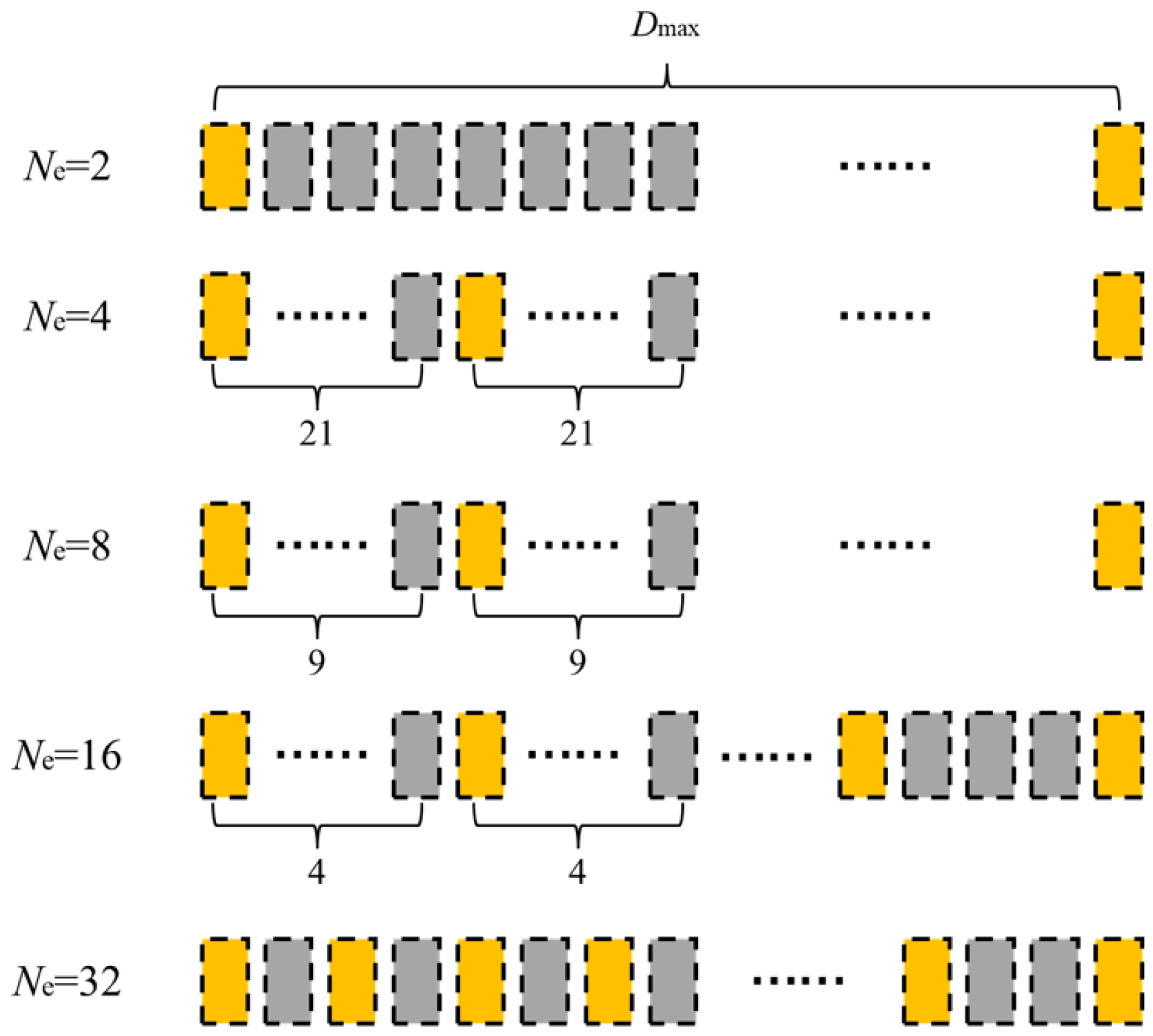

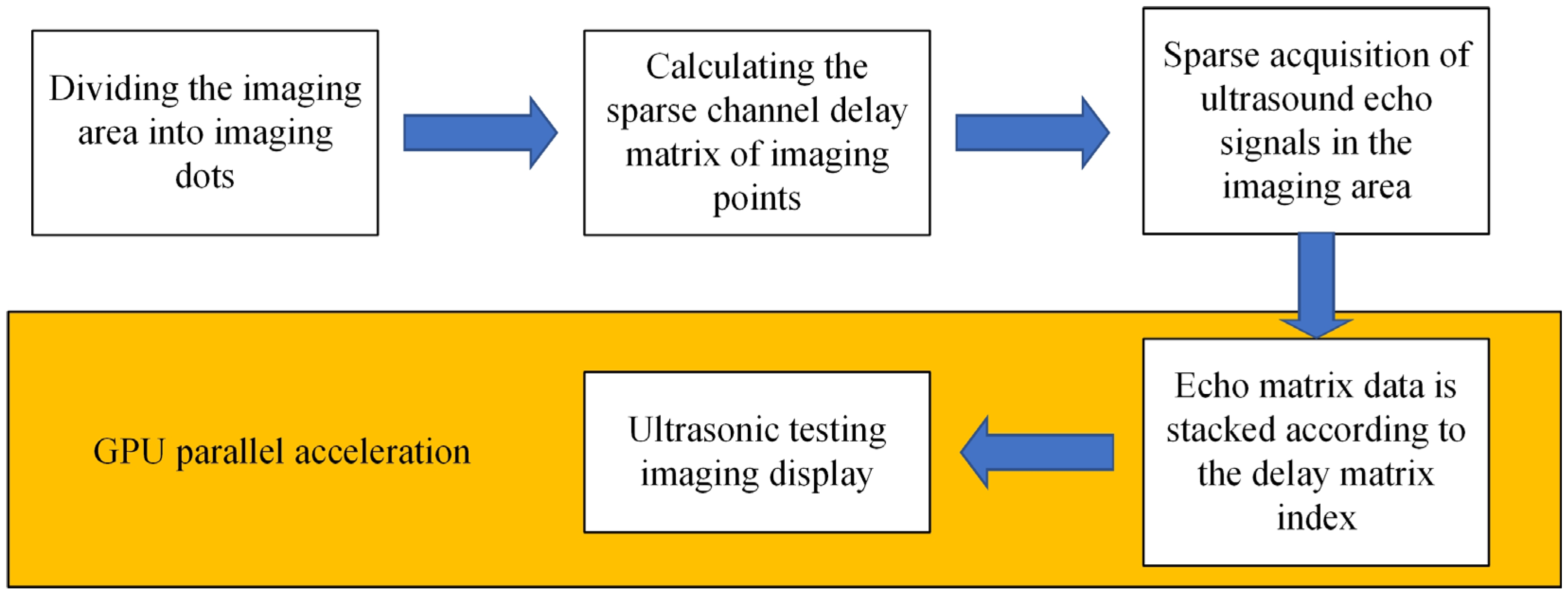

2. Analysis of Ultrasonic Testing Imaging Scheme

- (1)

- Firstly, the acoustic-field simulation environment is initialized, and based on the experimental results of the calibrated measurement of the detection specimen and the actual indicators of the ultrasonic phased-array probe, the acoustic imaging simulation environment parameters and probe array parameters are set, with specific input parameters shown in Table 2.

- (2)

- As shown in Figure 2, the linear phased-array probe was modeled based on the input parameters, and the impulse response of the transmission and reception apertures was set to a sinusoidal wave. The excitation signal was a Hanning windowed, 3-cycle, 5 MHz sine wave, and the excitation signal waveform and impulse response waveform are shown in Figure 3a.

- (3)

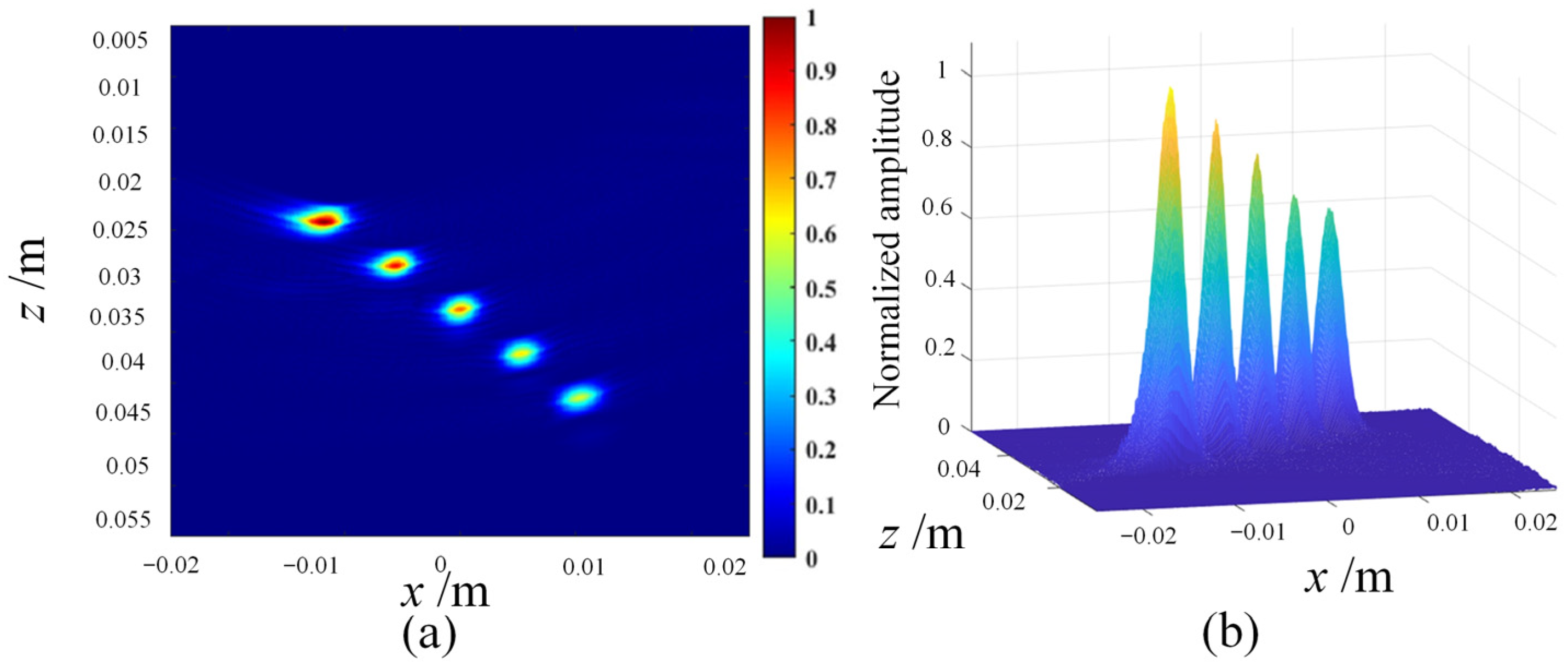

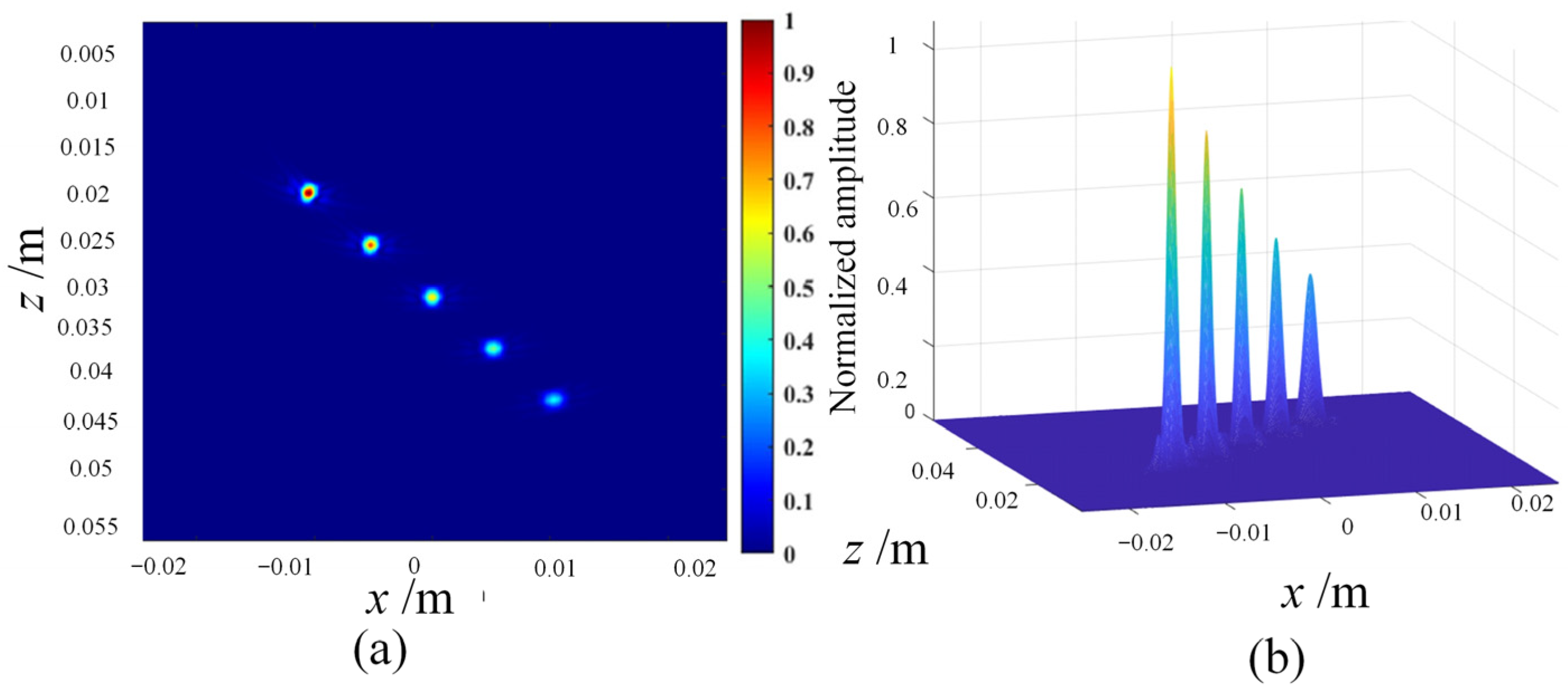

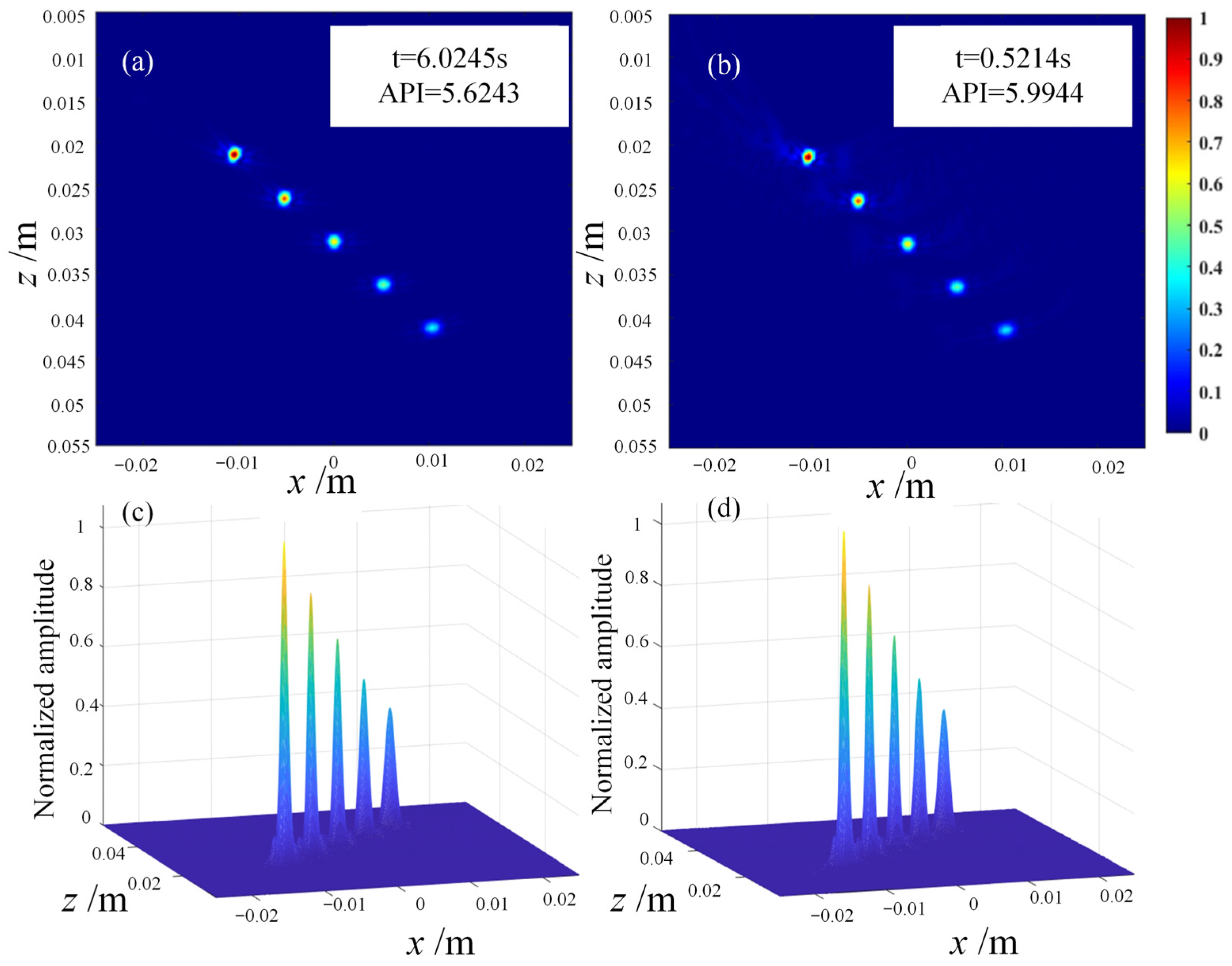

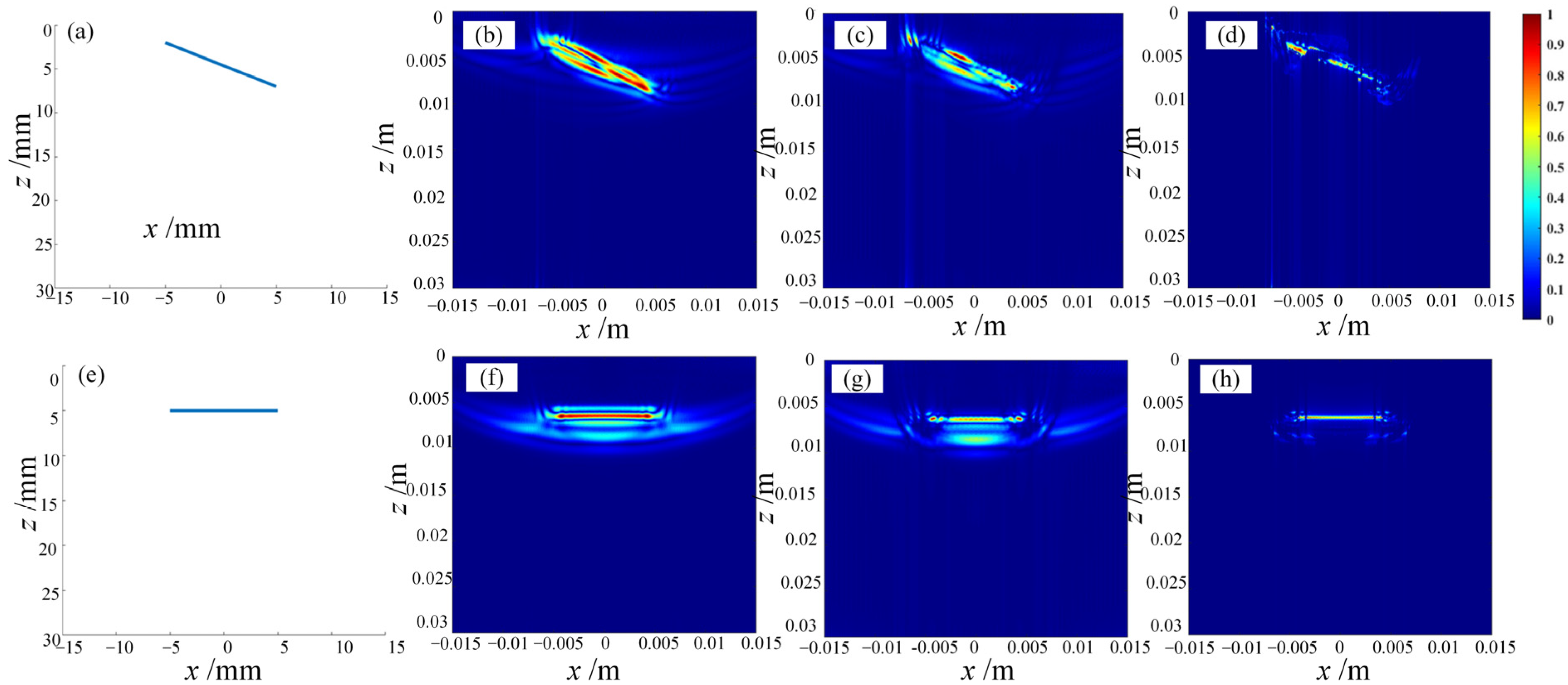

- In order to evaluate the imaging characterization performance of different data post-processing algorithms, a group of point scatter defects with different depth distributions were set in the planar space, and the algorithm was evaluated by simulating the imaging of the reference defects. The spatial positions of the 5 point defects are shown in Figure 3b, with a characterization range of a spatial plane of 50 mm × 50 mm, an imaging range of 5 mm–55 mm along the z-axis, an imaging range of −25 mm–25 mm along the x-axis, and an imaging grid spacing of 0.1 mm.

- (4)

- Through linear simulation, the sound field distribution and reflection defect echo data of the phased array are calculated. Based on the imaging algorithm, the phased-array echo data is subjected to time-delayed stacking, and the focal point intensity values within the imaging area are computed to obtain the ultrasound detection imaging results.

3. Improvement of Ultrasonic Imaging Algorithms

4. Improvement of Noise Artifacts in Ultrasound Imaging Algorithms

4.1. Adaptive Beamforming

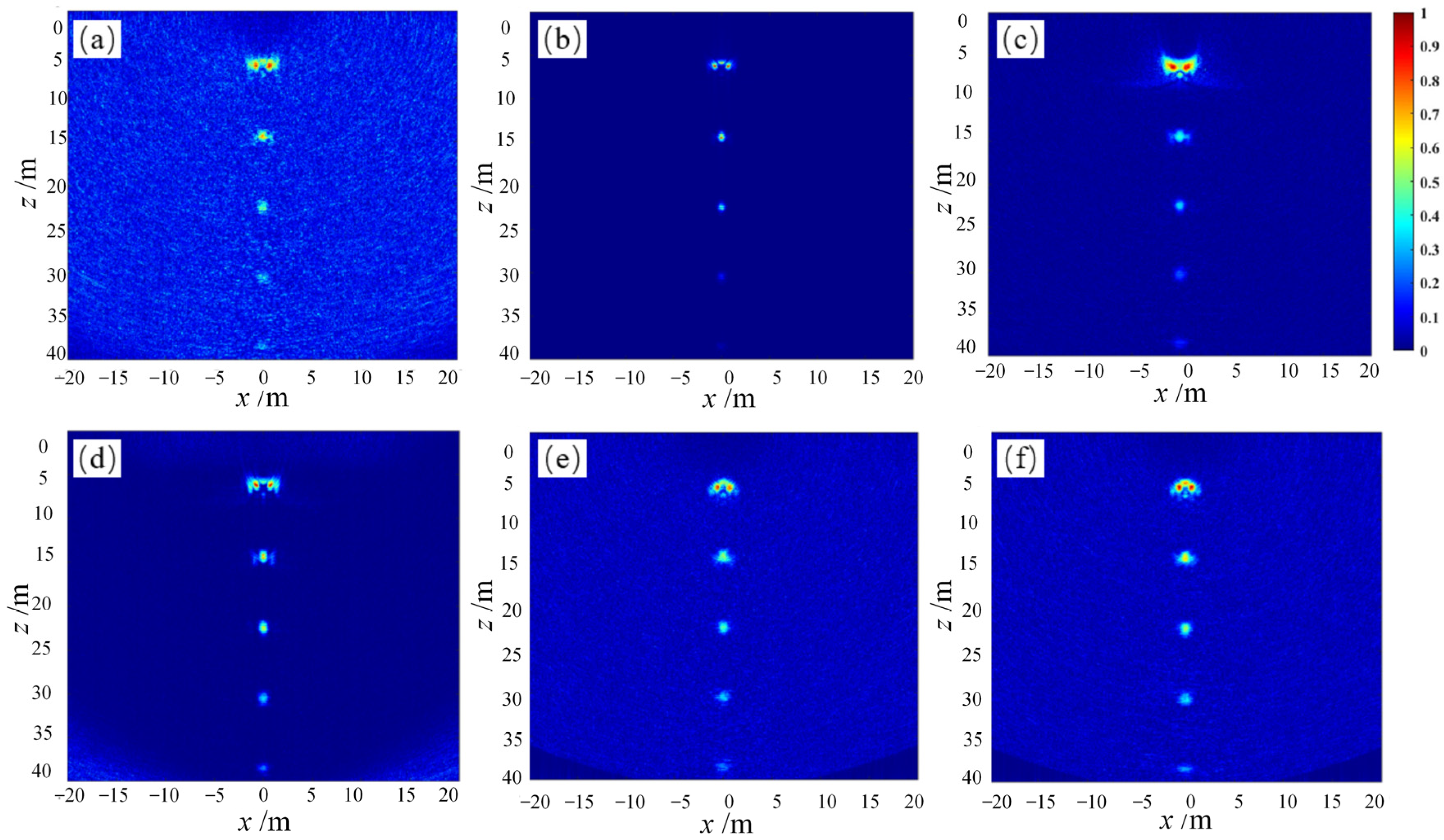

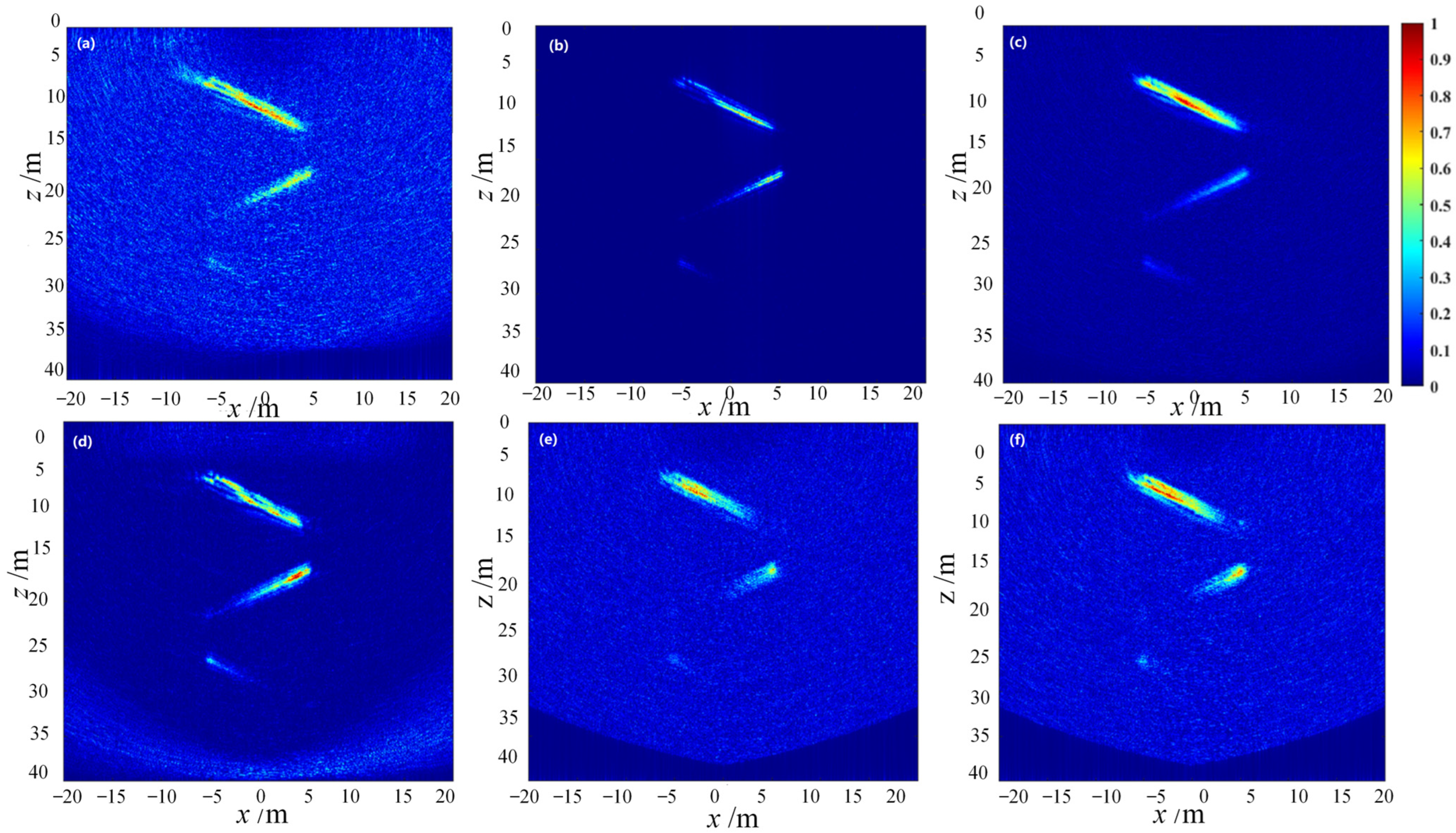

4.2. Simulation and Evaluation of Defect Imaging

4.3. Equivalent-Path-Length Pseudo-Echoes Dynamic Elimination

- (1)

- The envelope of the echo signals collected from E effective channels is obtained by Hilbert transform:

- (2)

- The minimum peak value of the E echo envelopes is determined, and the mean value Mean () is calculated:

- (3)

- The mean value Mean () is selected as the binary threshold, and the peak values of small envelopes are divided into two sets, C1 and C2.

- (4)

- The variances σ1 and σ2 of data points in sets C1 and C2 are calculated, respectively:

- (5)

- The threshold value ΔI of the effective is defined as follows:

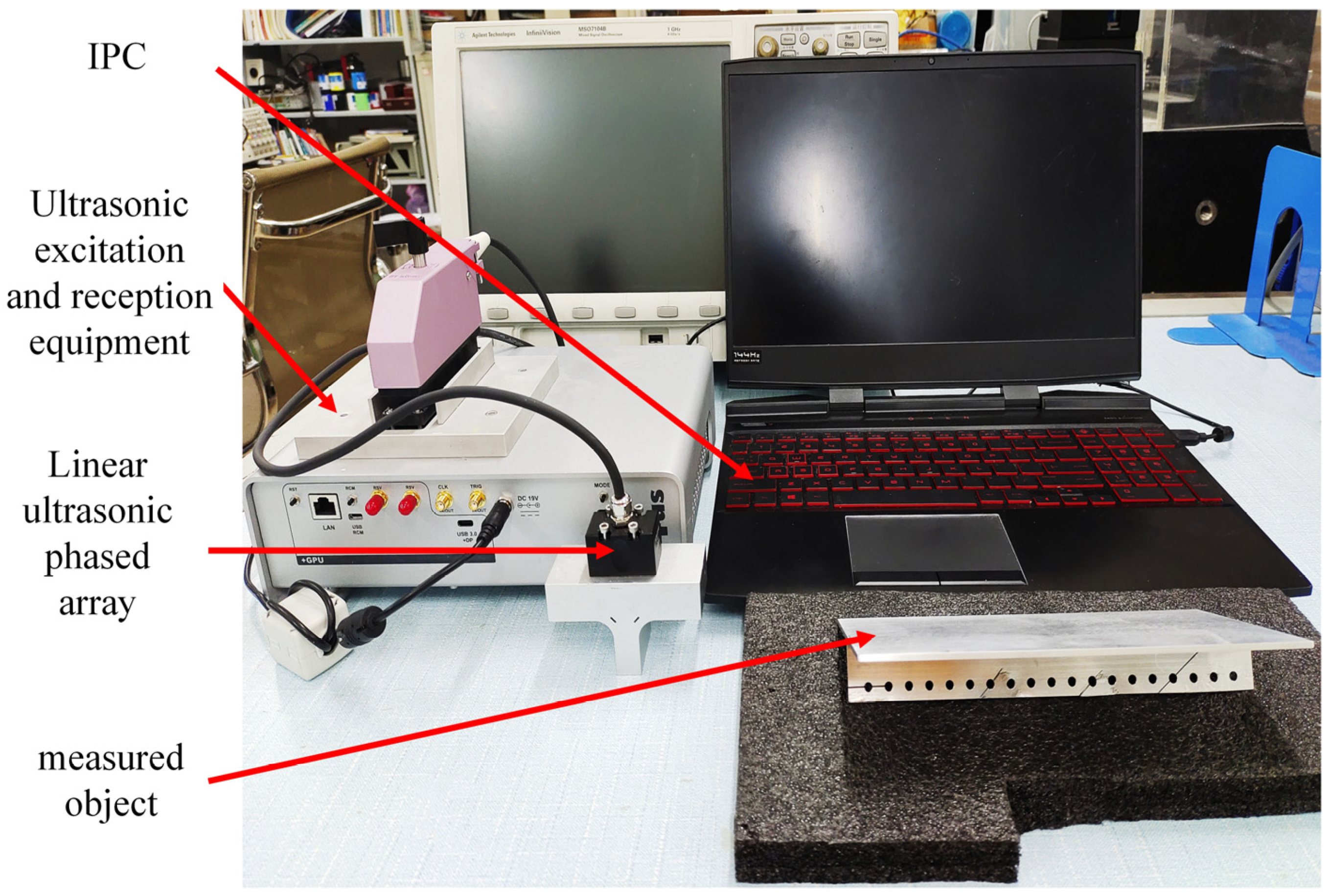

5. Ultrasonic Imaging Framework Design and System Setup

5.1. Setup of Ultrasonic Detection and Imaging System

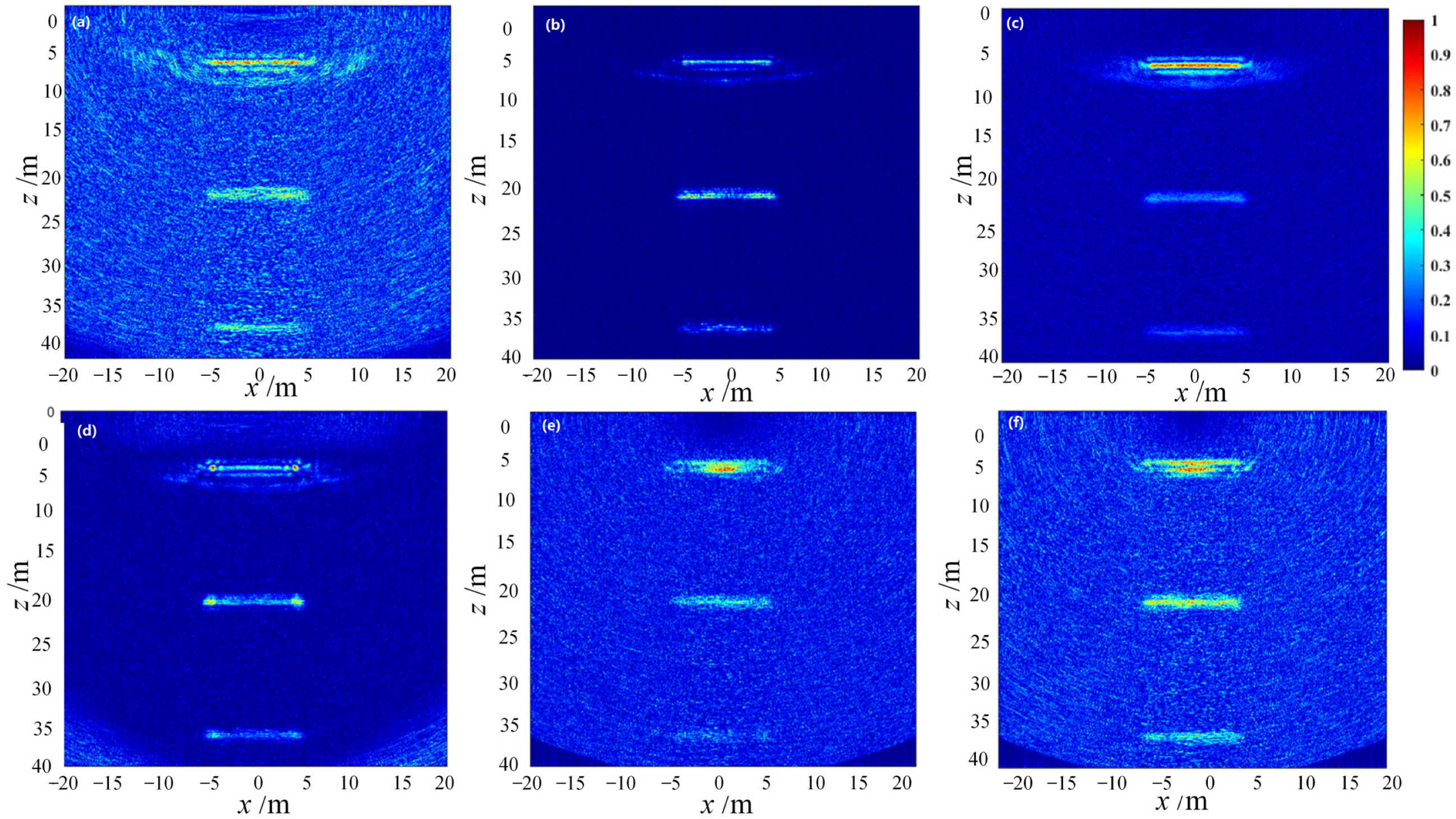

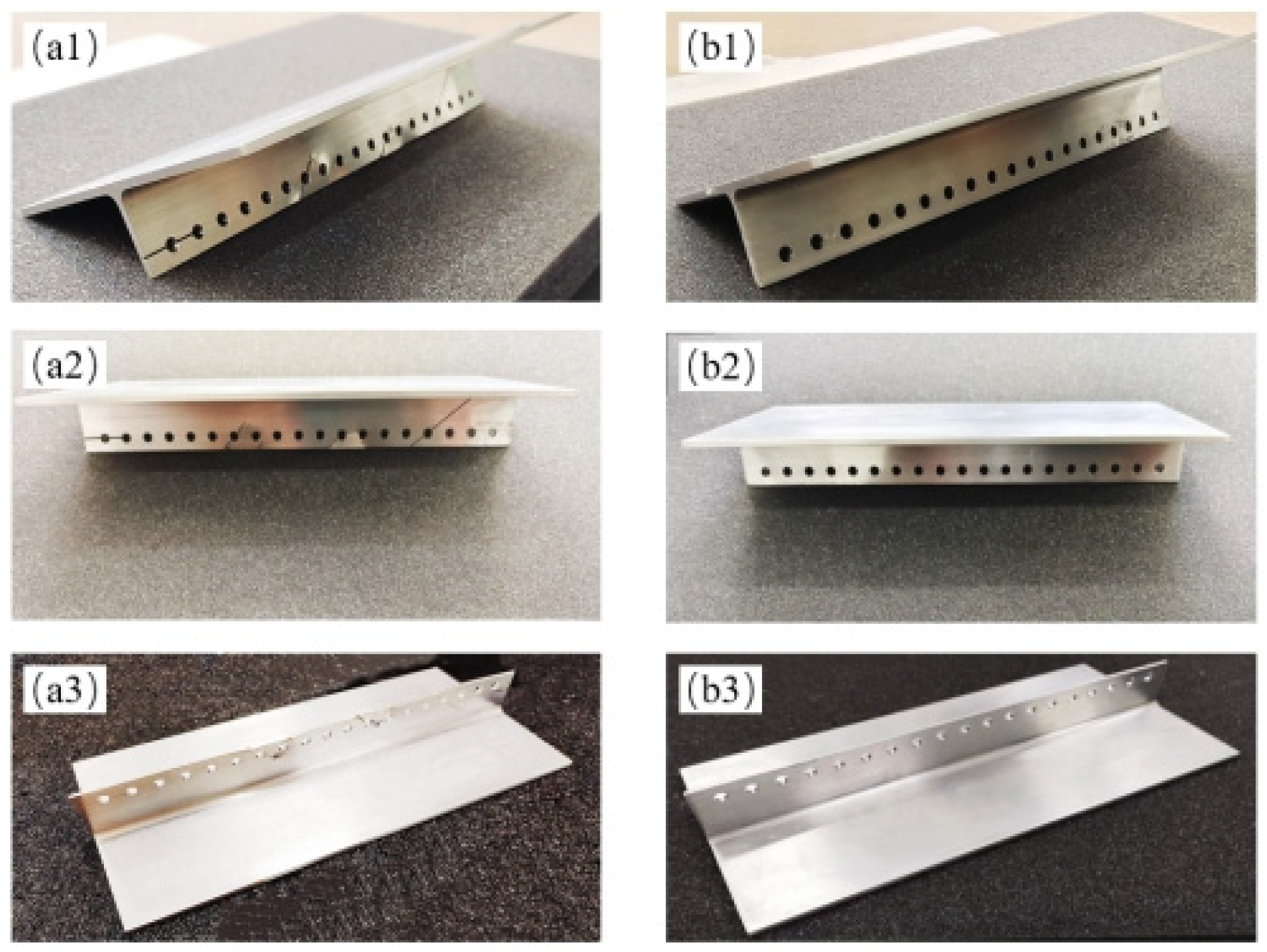

5.2. Defective Component Imaging Characterization

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qing, F.; Wang, Y.H.; Gao, Y. Aircraft Body and Systems; China Civil Aviation Press: Beijing, China, 2016; pp. 30–36.

- Ding, M.; Zeng, C.; Binienda, W.K. Assessment on aerodynamic degradation for wing-damaged transport aircraft. Aircr. Eng. Aerosp. Technol. 2020, 92, 973–979. [Google Scholar]

- Wei, X.J. Design and Implementation of Intelligent Wing Defect Detection System. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Lei, Y. Nondestructive Testing Technology Q&A; China Petrochemical Press: Beijing, China, 2013; p. 1. [Google Scholar]

- Shi, K.R. Phased Array Ultrasonic Imaging Detection; Higher Education Press: Beijing, China, 2010; pp. 6–8. [Google Scholar]

- Xu, Z. Transducer and testing scheme design of phased array ultrasonic detection for wind turbine main shaft in service. IOP Conf. Ser. Earth Environ. Sci. 2020, 546, 042006. [Google Scholar]

- Zhang, K.; Yang, L.; Wang, X.Q.; Xu, G.P.; Sun, D.P.; Luo, J.D.; Zhang, M. Development of phased array ultrasonic technology and its application in nondestructive testing of nuclear engineering. Nondestruct. Test. 2017, 39, 42. [Google Scholar]

- Yang, J.; Luo, L.; Yang, K.; Zhang, Y. Ultrasonic Phased Array Sparse TFM Imaging Based on Virtual Source and Phase Coherent Weighting. IEEE Access 2020, 8, 185609–185618. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, H. Sound Field Modeling Method and Key Imaging Technology of an Ultrasonic Phased Array: A Review. Appl. Sci. 2022, 12, 7962. [Google Scholar] [CrossRef]

- Li, J.; Zhan, X.; Jin, S. Research on ultrasonic phased array system for automatic defect detection of pipeline girth welds. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009; pp. 1-903–1-907. [Google Scholar]

- Hu, H.; Du, J.; Ye, C.; Li, X. Ultrasonic Phased Array Sparse-TFM Imaging Based on Sparse Array Optimization and New Edge-Directed Interpolation. Sensors 2018, 18, 1830. [Google Scholar] [CrossRef]

- Casula, O.; Poidevin, C.; Cattiaux, G.; Fleury, G. A flexible phased array transducer for contact examination of components with complex geometry. In Proceedings of the 16th World Conference on Nondestructive Testing, Montreal, QC, Canada, 30 August–3 September 2004. [Google Scholar]

- Mahaut, S.; Cattiaux, G.; Roy, O.; Benosit, P. Self-Focusing and Defect Characterization with the Faust System; Springer: Boston, MA, USA, 1997. [Google Scholar]

- Kortbek, J.; Jensen, J.A.; Gammelmark, K.L. Sequential beamforming for synthetic aperture imaging. Ultrasonics 2013, 53, 1–16. [Google Scholar] [CrossRef]

- Merabet, L.; Robert, S.; Prada, C. The multi-mode plane wave imaging in the Fourier domain: Theory and applications to fast ultrasound imaging of cracks. NDT E Int. 2020, 110, 102171. [Google Scholar] [CrossRef]

- Trahey, G.E.; Nock, L.F. Synthetic receive aperture imaging with phase correction for motion and for tissue inhomogeneities. II. Effects of and correction for motion. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 496–501. [Google Scholar] [CrossRef] [PubMed]

- Hunter, A.J.; Drinkwater, B.W.; Wilcox, P.D. The wavenumber algorithm for full-matrix imaging using an ultrasonic array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2450–2462. [Google Scholar] [CrossRef] [PubMed]

- Lopez, A.B.; Santos, J.; Sousa, J.P.; Santos, T.G.; Quintino, L. Phased Array Ultrasonic Inspection of Metal Additive Manufacturing Parts. J. Nondestruct. Eval. 2019, 38, 1–11. [Google Scholar] [CrossRef]

- Hunter, A.J.; Drinkwater, B.W.; Wilcox, P.D. Autofocusing ultrasonic imagery for non-destructive testing and evaluation of specimens with complicated geometries. NDT E Int. 2010, 43, 78–85. [Google Scholar] [CrossRef]

- Lewandowski, M.; Walczak, M.; Witek, B.; Rozbicki, J.; Steifer, T. A GPU-based portable phased-array system with full-matrix capture. In Proceedings of the IEEE International Ultrasonics Symposium, Kobe, Japan, 22–25 October 2018; pp. 1–3. [Google Scholar]

- Jin, S.J.; Liu, C.F.; Shi, S.Q.; Luo, Z.B.; Wang, C.; Lin, L. Comparison of morphology characterization for regular cracks with multi-mode total focusing method. In Proceedings of the IEEE Far East NDT New Technology & Application Forum (FENDT), Qingdao, China, 24–27 June 2019; pp. 21–25. [Google Scholar]

- Holmes, C.; Drinkwater, B.; Wilcox, P. The post-processing of ultrasonic array data using the total focusing method. Insight-Non-Destr. Test. Cond. Monit. 2004, 46, 677–680. [Google Scholar] [CrossRef]

| Non-Destructive Testing Method | Principle | Advantages | Disadvantages | Defect Features |

|---|---|---|---|---|

| Magnetic Particle Testing | Magnetic particles visualized by the leakage magnetic field at defect areas | Intuitive display, high sensitivity, simple process, low cost | Limited to ferromagnetic materials, difficult to achieve automation | Surface and near-surface defects |

| Eddy Current Testing | Detection of eddy currents generated by alternating magnetic fields | Non-contact inspection, fast detection, high sensitivity | Difficult to quantitatively characterize, low detection depth, low accuracy | Surface defects |

| Liquid Penetrant Testing | Amplification of defects through penetration of liquid penetrant | Not limited by material type and external shape constraints, high sensitivity | Slow detection speed, low robustness, difficult to automate | Surface defects |

| X-ray Testing | Imaging based on sample’s absorption and scattering of X-rays | Strong penetration, not affected by external shape and structure, high efficiency | Harmful radiation effects on inspection personnel | Surface and internal defects |

| Parameter Type | Parameter | Setting |

|---|---|---|

| Acoustic Environment Parameter | Sound Velocity | 6300 m/s |

| Signal Sampling Rate | 100 MHZ | |

| Phased-Array Ultrasonic Parameter | Number of Phased-Array Elements | 64 |

| Element Spacing | 0.5 mm | |

| Element Length | 10 mm | |

| Element Gap | 0.1 mm | |

| Center Frequency | 5 MHZ |

| Imaging Algorithm | API Value |

|---|---|

| CPWC (M = 17) | 26.0346 |

| CPWC (M = 21) | 29.1079 |

| MSAF (M = 2) | 12.3590 |

| MSAF (M = 4) | 8.7711 |

| MSAF (M = 8) | 16.6226 |

| MSAF (M = 16) | 23.7635 |

| FMC-TFM | 4.4898 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Xu, G.; Shan, Y.; Fan, X.; Zhang, X.; Liu, Y. Defect Detection Algorithm for Wing Skin with Stiffener Based on Phased-Array Ultrasonic Imaging. Sensors 2023, 23, 5788. https://doi.org/10.3390/s23135788

Wu C, Xu G, Shan Y, Fan X, Zhang X, Liu Y. Defect Detection Algorithm for Wing Skin with Stiffener Based on Phased-Array Ultrasonic Imaging. Sensors. 2023; 23(13):5788. https://doi.org/10.3390/s23135788

Chicago/Turabian StyleWu, Chuangui, GuiLi Xu, Yimeng Shan, Xin Fan, Xiaohui Zhang, and Yaxing Liu. 2023. "Defect Detection Algorithm for Wing Skin with Stiffener Based on Phased-Array Ultrasonic Imaging" Sensors 23, no. 13: 5788. https://doi.org/10.3390/s23135788

APA StyleWu, C., Xu, G., Shan, Y., Fan, X., Zhang, X., & Liu, Y. (2023). Defect Detection Algorithm for Wing Skin with Stiffener Based on Phased-Array Ultrasonic Imaging. Sensors, 23(13), 5788. https://doi.org/10.3390/s23135788