Direct Fabrication of a Copper RTD over a Ceramic-Coated Stainless-Steel Tube by Combination of Magnetron Sputtering and Sol–Gel Techniques

Abstract

:1. Introduction

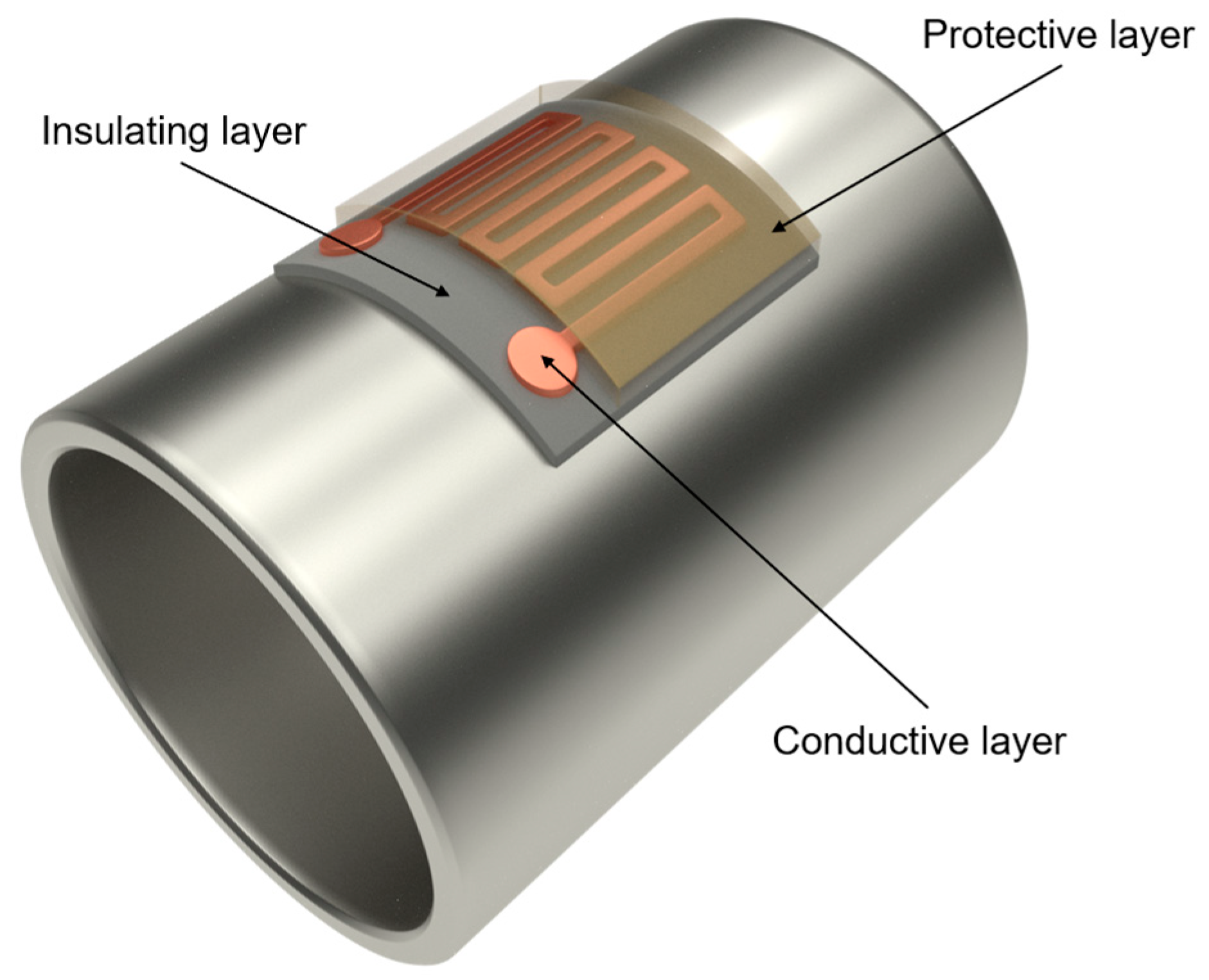

- A layer of electrical insulator on the surface of the stainless-steel tube. Its function is to avoid electrical contact between the sensor layer and the tube.

- An electrically conductive or sensing layer, which is the RTD itself. This metallic layer has a varied electrical resistance as the temperature changes.

- A protective layer to protect the sensor layer from degradation phenomena such as high-temperature oxidation.

2. Background

2.1. Design of the Sensor Layer

2.2. Base Materials

2.3. Isolation Layer

3. Experimental Section

3.1. Isolation Layer Preparation

3.2. Sensor Layer

3.3. Protective Layer

3.4. Film Characterization

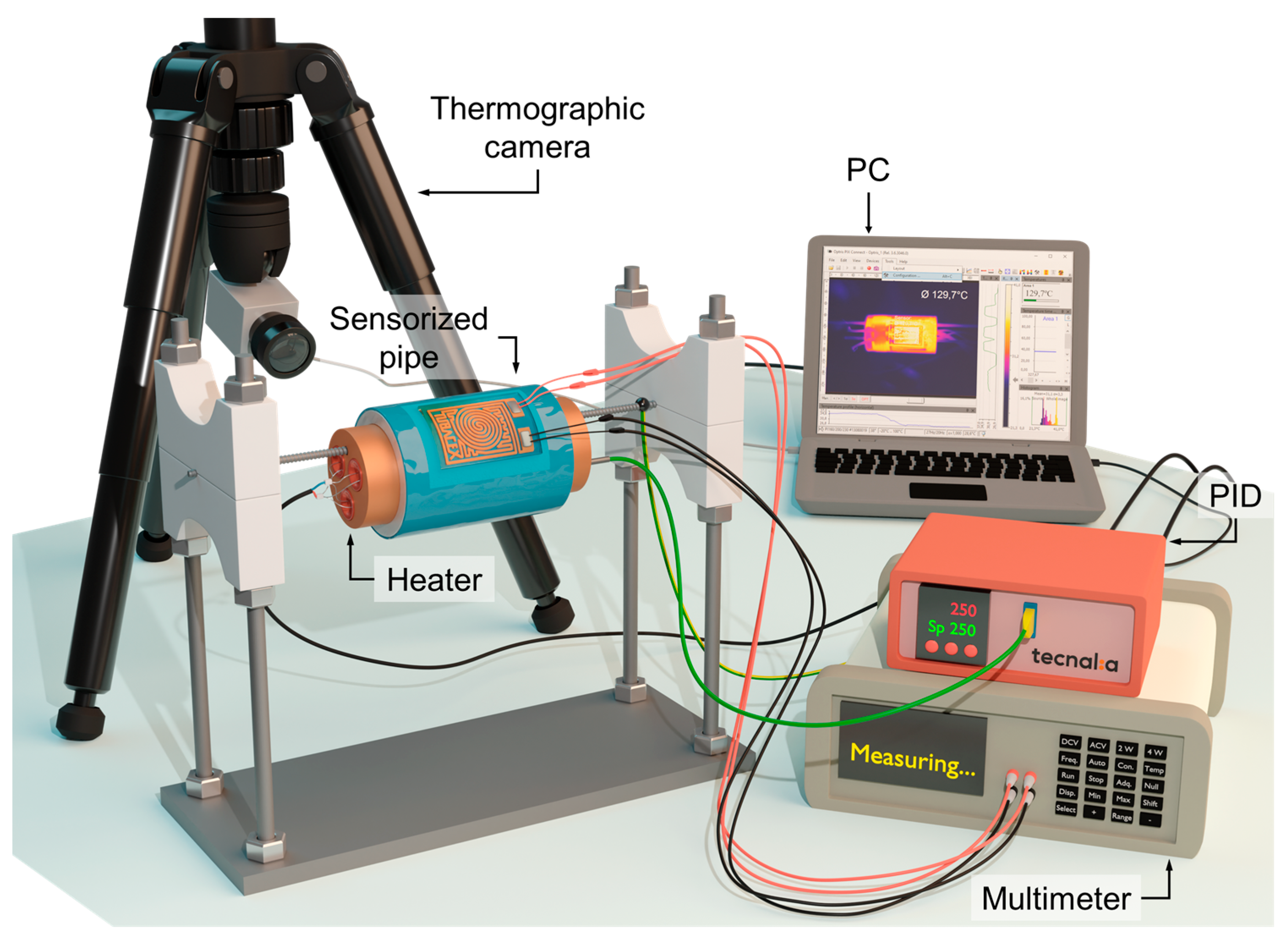

3.5. Electrical Characterization

4. Results/Discussion

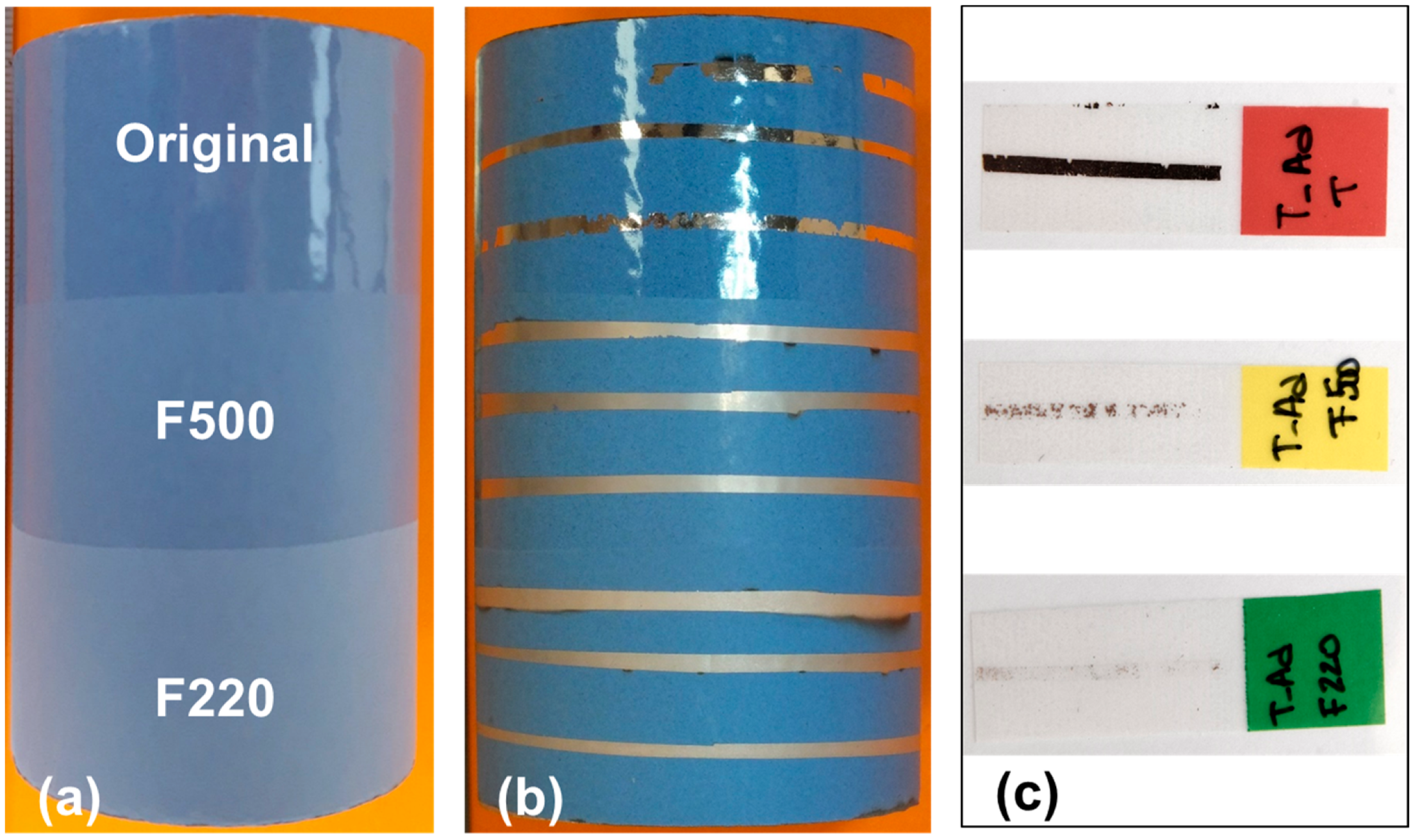

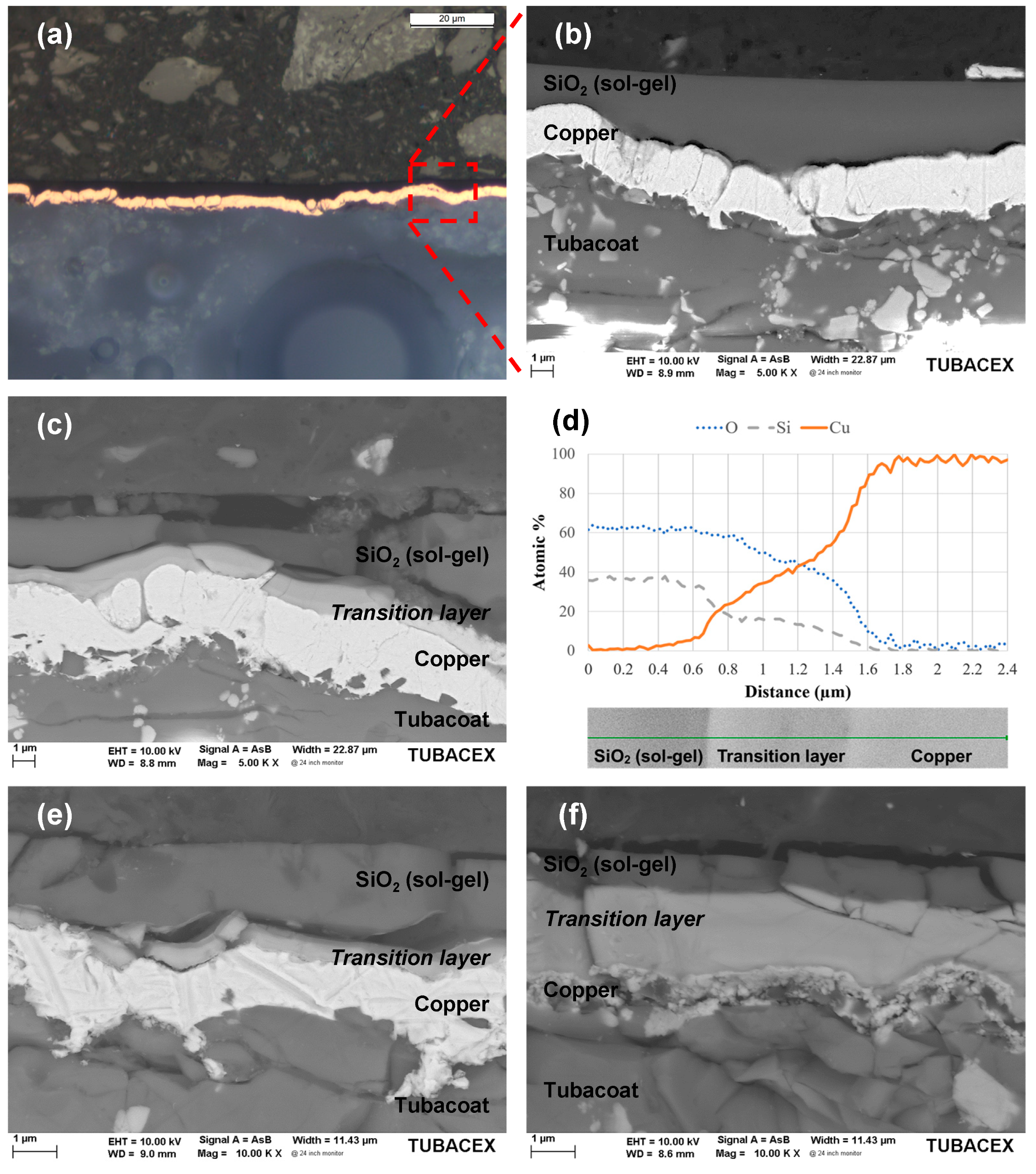

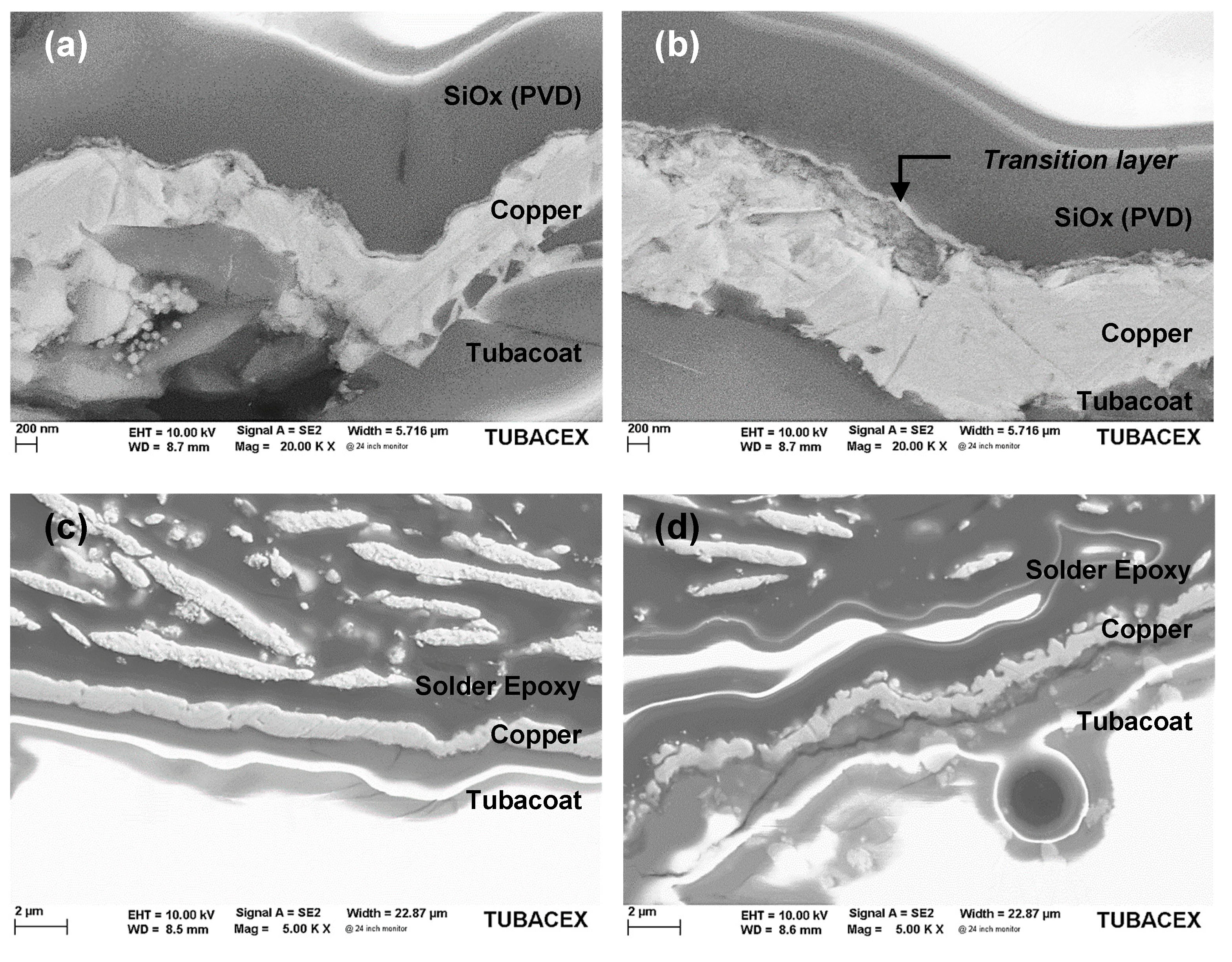

4.1. Adhesion Study

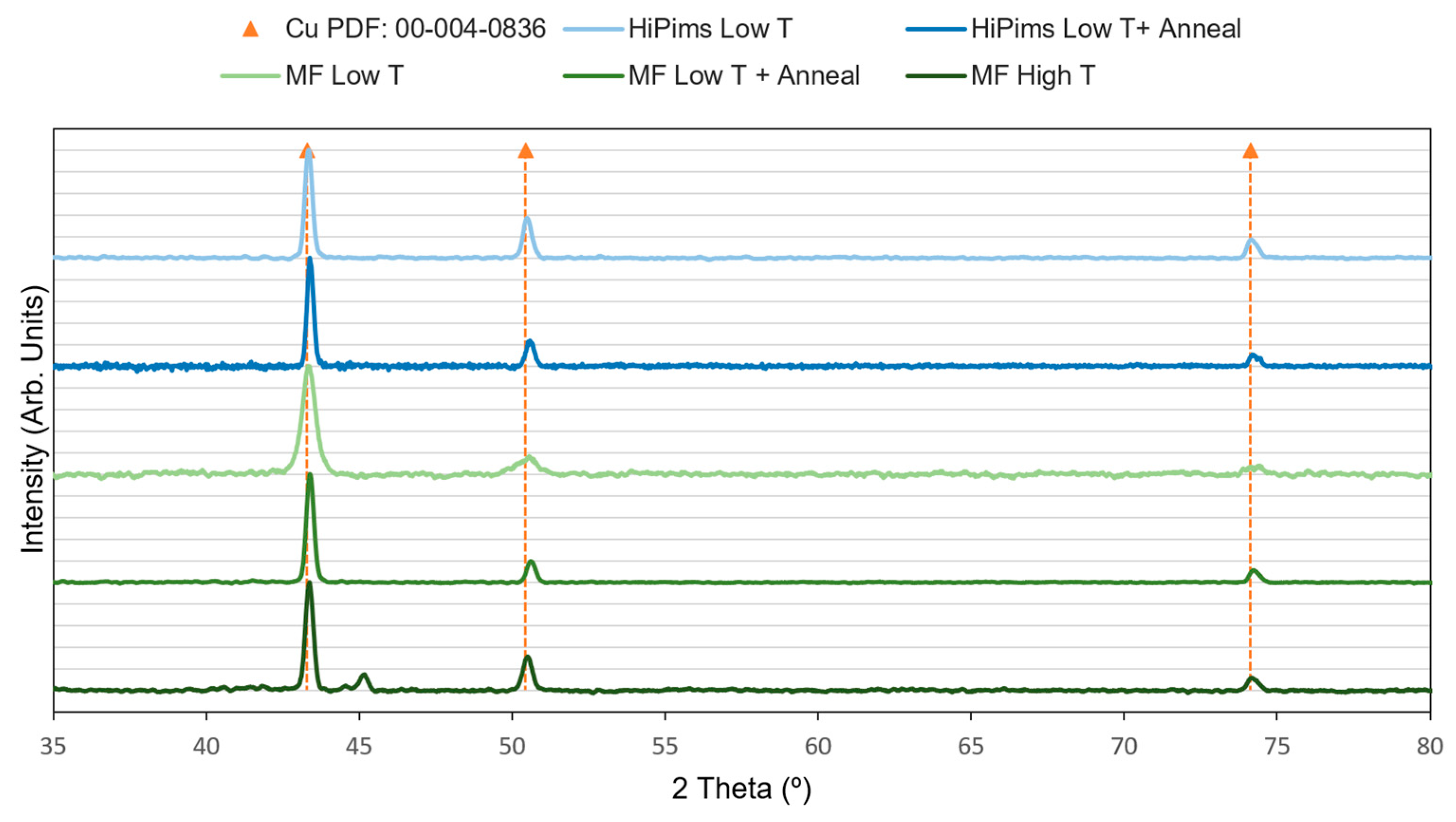

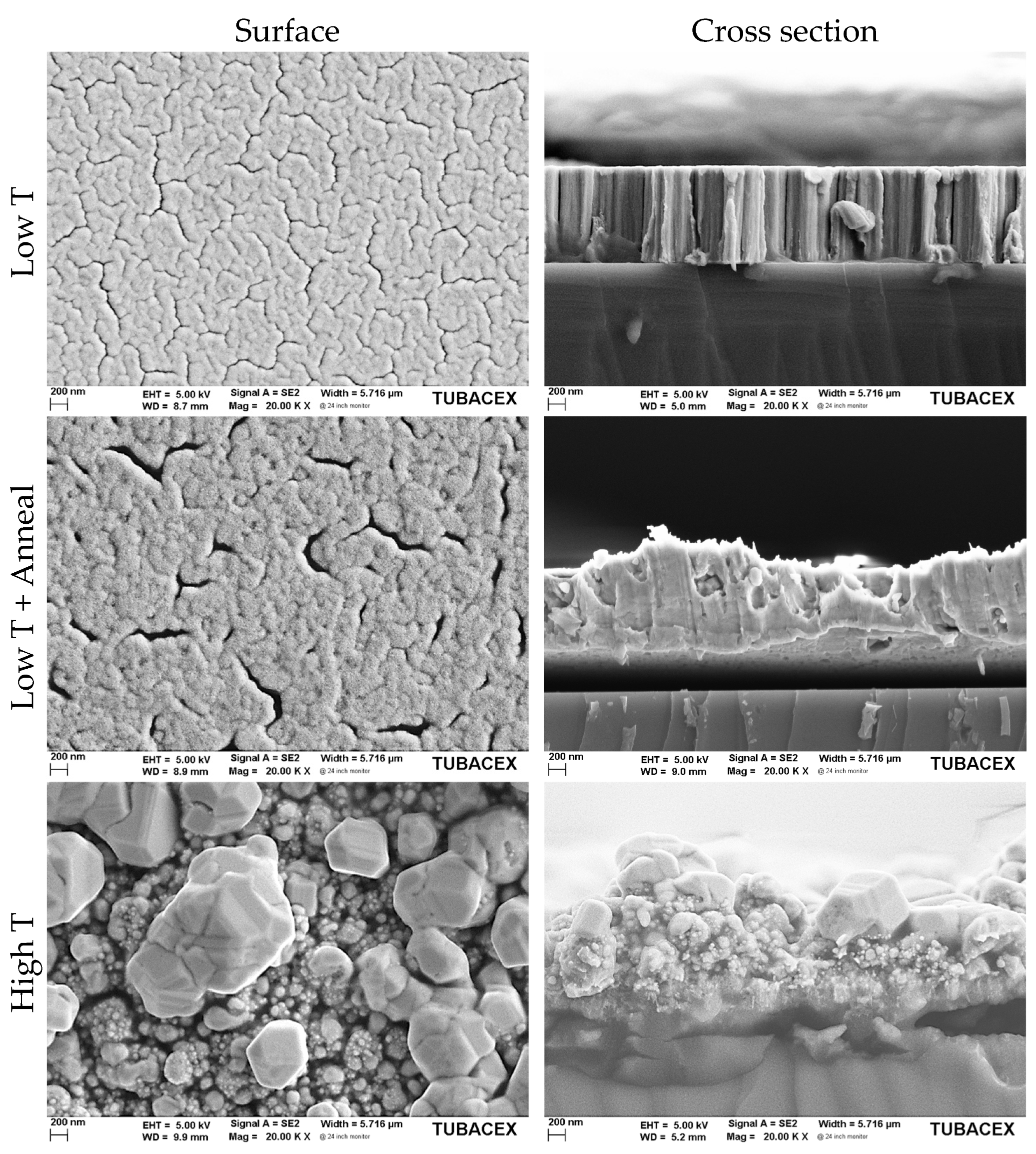

4.2. Sensor Layer Study

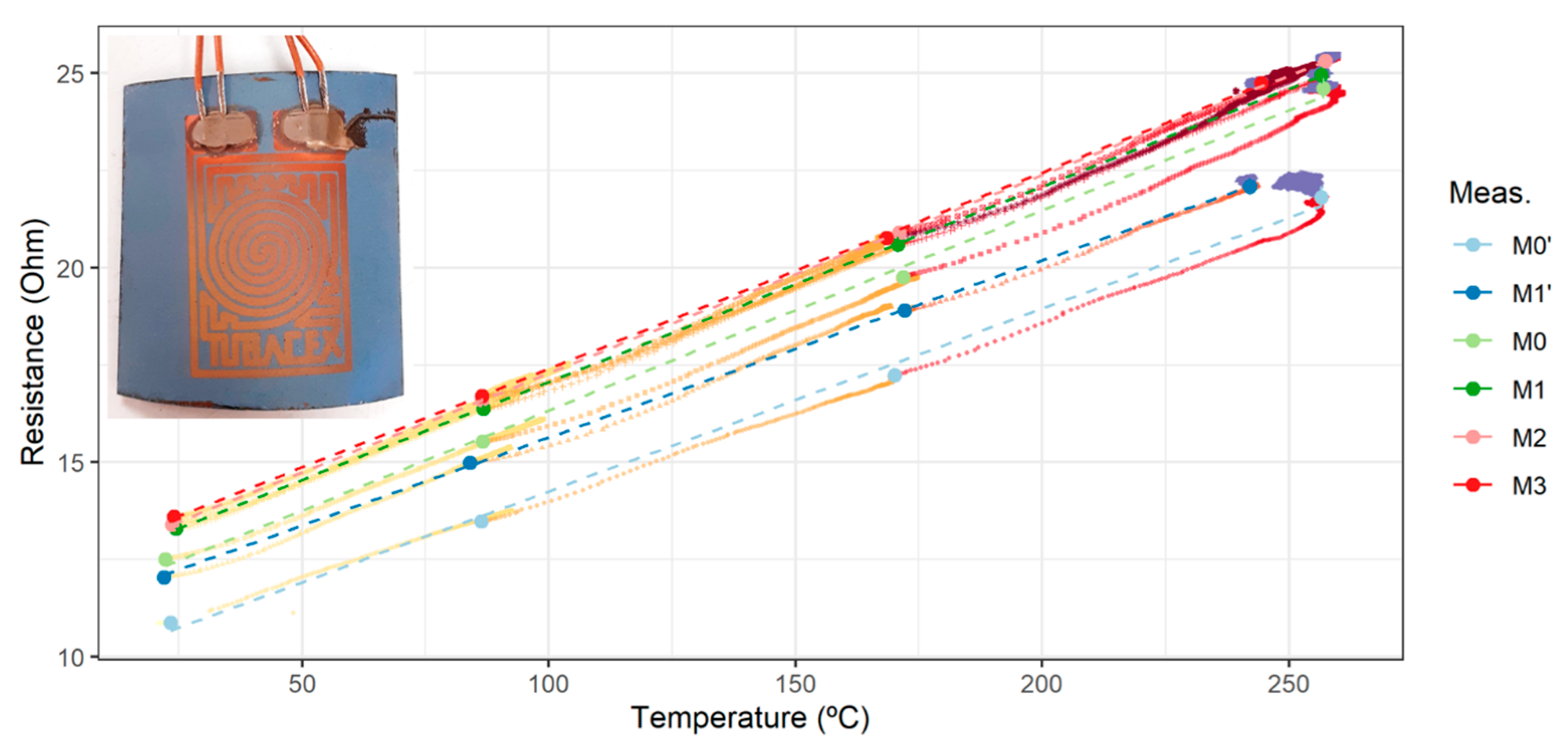

4.3. Electrical Response

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mathur, S.; Gosnell, G.; Sovacool, B.K.; Del Rio, D.D.F.; Griffiths, S.; Bazilian, M.; Kim, J. Industrial decarbonization via natural gas: A critical and systematic review of developments, socio-technical systems and policy options. Energy Res. Soc. Sci. 2022, 90, 102638. [Google Scholar] [CrossRef]

- Yue, K.; Shen, Y. An overview of disruptive technologies for aquaculture. Aquac. Fish. 2021, 7, 111–120. [Google Scholar] [CrossRef]

- Kumar, S.; Baalisampang, T.; Arzaghi, E.; Garaniya, V.; Abbassi, R.; Salehi, F. Synergy of green hydrogen sector with offshore industries: Opportunities and challenges for a safe and sustainable hydrogen economy. J. Clean. Prod. 2023, 384, 135545. [Google Scholar] [CrossRef]

- Islam, M.T.; Nabi, M.; Arefin, M.; Mostakim, K.; Rashid, F.; Hassan, N.; Rahman, S.; McIntosh, S.; Mullins, B.; Muyeen, S. Trends and prospects of geothermal energy as an alternative source of power: A comprehensive review. Heliyon 2022, 8, e11836. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Khan, I.H.; Suman, R. Understanding the potential applications of Artificial Intelligence in Agriculture Sector. Adv. Agrochem. 2023, 2, 15–30. [Google Scholar] [CrossRef]

- Bhuiyan, E.A.; Hossain, Z.; Muyeen, S.; Fahim, S.R.; Sarker, S.K.; Das, S.K. Towards next generation virtual power plant: Technology review and frameworks. Renew. Sustain. Energy Rev. 2021, 150, 111358. [Google Scholar] [CrossRef]

- Vandrangi, S.K.; Lemma, T.A.; Mujtaba, S.M.; Ofei, T.N. Developments of leak detection, diagnostics, and prediction algorithms in multiphase flows. Chem. Eng. Sci. 2021, 248, 117205. [Google Scholar] [CrossRef]

- Jayawickrema, U.; Herath, H.; Hettiarachchi, N.; Sooriyaarachchi, H.; Epaarachchi, J. Fibre-optic sensor and deep learning-based structural health monitoring systems for civil structures: A review. Measurement 2022, 199, 111543. [Google Scholar] [CrossRef]

- Djeddi, A.Z.; Hafaifa, A.; Hadroug, N.; Iratni, A. Gas turbine availability improvement based on long short-term memory networks using deep learning of their failures data analysis. Process. Saf. Environ. Prot. 2021, 159, 1–25. [Google Scholar] [CrossRef]

- Hidalgo-Mompeán, F.; Fernández, J.F.G.; Cerruela-García, G.; Márquez, A.C. Dimensionality analysis in machine learning failure detection models. A case study with LNG compressors. Comput. Ind. 2021, 128, 103434. [Google Scholar] [CrossRef]

- Wang, X.; Lin, L.; Lu, S.; Zhang, L.; Li, B.; Zhang, D.; Luo, Y. Evaluation of embedded buckypaper sensors in composite overwrappedped pressure vessels for progressive damage monitoring. Compos. Struct. 2022, 284, 115223. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Lu, Y.; Ma, Z.; Wang, X.; Song, X. Cutting tool wear monitoring based on a smart toolholder with embedded force and vibration sensors and an improved residual network. Measurement 2022, 199, 111520. [Google Scholar] [CrossRef]

- Kausar, A.Z.; Reza, A.W.; Saleh, M.U.; Ramiah, H. Energizing wireless sensor networks by energy harvesting systems: Scopes, challenges and approaches. Renew. Sustain. Energy Rev. 2014, 38, 973–989. [Google Scholar] [CrossRef]

- Aalsalem, M.Y.; Khan, W.Z.; Gharibi, W.; Khan, M.K.; Arshad, Q. Wireless Sensor Networks in oil and gas industry: Recent advances, taxonomy, requirements, and open challenges. J. Netw. Comput. Appl. 2018, 113, 87–97. [Google Scholar] [CrossRef]

- Virk, M.-U.A.; Mysorewala, M.F.; Cheded, L.; Aliyu, A. Review of energy harvesting techniques in wireless sensor-based pipeline monitoring networks. Renew. Sustain. Energy Rev. 2022, 157, 112046. [Google Scholar] [CrossRef]

- Cho, S.H.; Suh, J.M.; Jeong, B.; Lee, T.H.; Choi, K.S.; Eom, T.H.; Kim, T.; Jang, H.W. Fast responding and highly reversible gasochromic H2 sensor using Pd-decorated amorphous WO3 thin films. Chem. Eng. J. 2022, 446, 136862. [Google Scholar] [CrossRef]

- Li, T.; Shi, T.; Tang, Z.; Liao, G.; Han, J.; Duan, J. Temperature monitoring of the tool-chip interface for PCBN tools using built-in thin-film thermocouples in turning of titanium alloy. J. Mater. Process. Technol. 2019, 275, 116376. [Google Scholar] [CrossRef]

- Wang, H.; Rajamani, R. A remote position sensing method based on passive high magnetic permeability thin films. Sens. Actuators A Phys. 2019, 295, 217–223. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Shin, Y.; Yoon, Y. A study on the fabrication of an RTD (resistance temperature detector) by using Pt thin film. Korean J. Chem. Eng. 2001, 18, 61–66. [Google Scholar] [CrossRef]

- Shao, L.; Zhao, X.; Gu, S.; Ma, Y.; Liu, Y.; Deng, X.; Jiang, H.; Zhang, W. Pt thin-film resistance temperature detector on flexible Hastelloy tapes. Vacuum 2020, 184, 109966. [Google Scholar] [CrossRef]

- Sim, J.K.; Hyun, J.; Doh, I.; Ahn, B.; Kim, Y.T. Thin-film resistance temperature detector array for the measurement of temperature distribution inside a phantom. Metrologia 2017, 55, L5–L11. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Cheng, P.; Wang, H.; Zhang, C.; Zhang, J.; Wang, Y.; Duan, L.; Ding, G. MEMS-based Pt film temperature sensor on an alumina substrate. Mater. Lett. 2014, 125, 224–226. [Google Scholar] [CrossRef]

- Zhai, Y.; Cai, C.; Huang, J.; Liu, H.; Zhou, S.; Liu, W. Study on the Resistance Characteristic of Pt Thin Film. Phys. Procedia 2012, 32, 772–778. [Google Scholar] [CrossRef] [Green Version]

- Phatthanakun, R.; Deekla, P.; Pummara, W.; Sriphung, C.; Pantong, C.; Chomnawang, N. Design and fabrication of thin-film aluminum microheater and nickel temperature sensor. In Proceedings of the 2012 7th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Kyoto, Japan, 5–8 March 2012; pp. 112–115. [Google Scholar]

- Santos, E.J.; Vasconcelos, I.B. RTD-based smart temperature sensor: Process development and circuit design. In Proceedings of the 2008 26th International Conference on Microelectronics, Nis, Serbia, 11–14 May 2008; pp. 333–336. [Google Scholar] [CrossRef]

- Pacardo, D.B.; Neupane, B.; Wang, G.; Gu, Z.; Walker, G.M.; Ligler, F.S. A temperature microsensor for measuring laser-induced heating in gold nanorods. Anal. Bioanal. Chem. 2014, 407, 719–725. [Google Scholar] [CrossRef] [PubMed]

- Turkani, V.S.; Maddipatla, D.; Narakathu, B.B.; Altay, B.N.; Fleming, D.; Bazuin, B.J.; Atashbar, M.Z. A Screen-Printed Nickel Based Resistance Temperature Detector (RTD) on Thin Ceramic Substrate. In Proceedings of the 2020 IEEE International Conference on Electro Information Technology (EIT), Chicago, IL, USA, 31 July–1 August 2020; pp. 577–580. [Google Scholar] [CrossRef]

- Martinez-Quijada, J.; Caverhill-Godkewitsch, S.; Reynolds, M.; Gutierrez-Rivera, L.; Johnstone, R.; Elliott, D.; Sameoto, D.; Backhouse, C. Fabrication and characterization of aluminum thin film heaters and temperature sensors on a photopolymer for lab-on-chip systems. Sens. Actuators A Phys. 2013, 193, 170–181. [Google Scholar] [CrossRef]

- Stankevič, V.; Šimkevičius, Č. Application of aluminum films as temperature sensors for the compensation of output thermal shift of silicon piezoresistive pressure sensors. Sens. Actuators A Phys. 1998, 71, 161–166. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Kim, J.-D.; Kim, Y.-S.; Song, H.-J.; Park, C.-Y. Resistance Temperature Detector Sensor with a Copper Pattern on the Printed Circuit Board. Int. J. Control. Autom. 2015, 8, 67–74. [Google Scholar] [CrossRef]

- Namisnak, L.H.; Khoshnevis, S.; Diller, K.R. A Conformable Two-Dimensional Resistance Temperature Detector for Measuring Average Skin Temperature. J. Med. Devices 2021, 15, 031010. [Google Scholar] [CrossRef]

- Souza, A.L.R.; Correa, M.A.; Bohn, F.; Castro, H.; Fernandes, M.M.; Vaz, F.; Ferreira, A. High Performance of Metallic Thin Films for Resistance Temperature Devices with Antimicrobial Properties. Sensors 2022, 22, 7665. [Google Scholar] [CrossRef]

- Santi, W.N.; Toifur, M. Analysis of Micro Structure and the Resistivity of Cu / Ni Thin Coat as a Low Temperature Sensor Using Electroplating Method Assisted with Magnetic Field outside of the Ion Flow. Key Eng. Mater. 2021, 885, 141–147. [Google Scholar] [CrossRef]

- Mehmood, Z.; Mansoor, M.; Haneef, I.; Ali, S.Z.; Udrea, F. Evaluation of thin film p-type single crystal silicon for use as a CMOS Resistance Temperature Detector (RTD). Sens. Actuators A Phys. 2018, 283, 159–168. [Google Scholar] [CrossRef]

- Navarro, A.; Lechner, M.; Ruiz, U.; Lopez, A. Sensitivity analysis of the Expansion Process for Alloy UNS N08028. MATEC Web Conf. 2016, 80, 10005. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Martin, J.; González-Fernández, R.; Calleja-Saenz, B.; Ferreño-Blanco, D. Measurement of hardness increase for shot-peened austenitic TX304HB stainless steel tubes with electromagnetic Non-Destructive testing. Measurement 2019, 149, 106925. [Google Scholar] [CrossRef]

- Bartzsch, H.; Glöß, D.; Böcher, B.; Frach, P.; Goedicke, K. Properties of SiO2 and Al2O3 films for electrical insulation applications deposited by reactive pulse magnetron sputtering. Surf. Coatings Technol. 2003, 174–175, 774–778. [Google Scholar] [CrossRef]

- Martinez-Perdiguero, J.; Mendizabal, L.; Morant-Miñana, M.C.; Castro-Hurtado, I.; Juarros, A.; Ortiz, R.; Rodriguez, A. Electrical insulation and breakdown properties of SiO2 and Al2O3 thin multilayer films deposited on stainless steel by physical vapor deposition. Thin Solid Films 2015, 595, 171–175. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, S.; Zhao, X.; Jiang, H.; Zhang, W. YSZ/Al2O3 multilayered film as insulating layer for high temperature thin film strain gauge prepared on Ni-based superalloy. Sens. Actuators A Phys. 2018, 279, 272–277. [Google Scholar] [CrossRef]

- Djugum, R.; I Jolic, K. A fabrication process for vacuum-deposited strain gauges on thermally sprayed Al2O3. J. Micromechanics Microengineering 2006, 16, 457–462. [Google Scholar] [CrossRef]

- Li, Y.-Q.; Yu, Z.-N.; Leng, J.; Zhang, D.-P.; Chen, S.; Jin, G. Electrical insulation and bending properties of SiOx barrier layers prepared on flexible stainless steel foils by different preparing methods. Thin Solid Films 2011, 519, 4234–4238. [Google Scholar] [CrossRef] [Green Version]

- Advanced Coating Technology—Tubacoat. Available online: https://www.tubacoat.com/ (accessed on 16 September 2022).

- Shabareesh, N. TUBACOAT—An Efficient and Cost Effective Advanced Coating Solution for Tubular Products in Extreme Refinery and Petrochemical Applications, Presented at the Refcomm, Mumbai, 2019. Available online: https://refiningcommunity.com/wp-content/uploads/2019/08/118-An-Efficient-and-Cost-Effective-Advanced-Coating-Solution-for-Tubular-Products-in-Extreme-Refinery-and-Petrochemical-Applications-Tubacex-Group-DCU-Mumbai-2019.pdf (accessed on 22 March 2021).

- Morris, A.S.; Langari, R. Temperature measurement. Meas. Instrum. 2020, 413–468. [Google Scholar] [CrossRef]

- Schuster, C.E.; Vangel, M.G.; Scha, H.A. Improved estimation of the resistivity of pure copper and electrical determination of thin copper ®lm dimensions q. Microelectron. Reliab. 2001, 41, 239–252. [Google Scholar] [CrossRef]

- Samuelsson, M.; Lundin, D.; Jensen, J.; Raadu, M.A.; Gudmundsson, J.T.; Helmersson, U. On the film density using high power impulse magnetron sputtering. Surf. Coatings Technol. 2010, 205, 591–596. [Google Scholar] [CrossRef] [Green Version]

- Lakhonchai, A.; Chingsungnoen, A.; Poolcharuansin, P.; Pasaja, N.; Bunnak, P.; Suwanno, M. Comparison of the structural and optic al properties of amorphous silicon thin films prepared by direct current, bipolar pulse, and high-power impulse magnetron sputtering methods. Thin Solid Films 2022, 747, 139140. [Google Scholar] [CrossRef]

- Mitrašinovi, A. Characterization of the Cu-Si System and Utilization of Metallurgical Techniques in Silicon Refining for Solar Cell Applications; Department of Materials Science and Engineering, University of Toronto: Toronto, ON, Canada, 2010; p. 231. [Google Scholar]

- Liu, W.; Chen, W.; Tsai, T.; Hsieh, S.; Liu, C. Effect of tin-doped indium oxide film thickness on the diffusion barrier between silicon and copper. Thin Solid Films 2006, 515, 2387–2392. [Google Scholar] [CrossRef]

- Chen, W.J.; Lai, T.-Y. Effectiveness of tungsten addition on the performance of electroplated nickel diffusion barriers for copper metallization on textured silicon. Thin Solid Films 2022, 746, 139122. [Google Scholar] [CrossRef]

- Cui, J.; Liu, H.; Li, X.; Jiang, S.; Zhang, B.; Song, Y.; Zhang, W. Fabrication and characterization of nickel thin film as resistance temperature detector. Vacuum 2020, 176, 109288. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- West, G.; Kelly, P.; Barker, P.; Mishra, A.; Bradley, J. Measurements of Deposition Rate and Substrate Heating in a HiPIMS Discharge. Plasma Process. Polym. 2009, 6, S543–S547. [Google Scholar] [CrossRef]

- An, B.-S.; Kwon, Y.; Oh, J.-S.; Lee, C.; Choi, S.; Kim, H.; Lee, M.; Pae, S.; Yang, C.-W. Characteristics of an Amorphous Carbon Layer as a Diffusion Barrier for an Advanced Copper Interconnect. ACS Appl. Mater. Interfaces 2019, 12, 3104–3113. [Google Scholar] [CrossRef]

- Wen, C.; Cao, B.; Shi, Z.; Ma, Y.; Wang, J.; Yang, W. Quantitative analysis on the oxygen diffusion in pyramidal textured surfaces of silicon and copper via transmission electron microscopy. Mater. Sci. Semicond. Process. 2020, 121, 105464. [Google Scholar] [CrossRef]

- Chang, C. Outdiffusion of Cu through Au: Comparison of (100) and (111) Cu films epitaxially deposited on Si, and effects of annealing ambients. Appl. Phys. Lett. 1989, 55, 2754–2756. [Google Scholar] [CrossRef]

- Guzman, D.M.; Onofrio, N.; Strachan, A. Stability and migration of small copper clusters in amorphous dielectrics. J. Appl. Phys. 2015, 117, 195702. [Google Scholar] [CrossRef] [Green Version]

- Byrne, C.; Brennan, B.; Lundy, R.; Bogan, J.; Brady, A.; Gomeniuk, Y.; Monaghan, S.; Hurley, P.; Hughes, G. Physical, chemical and electrical characterisation of the diffusion of copper in silicon dioxide and prevention via a CuAl alloy barrier layer system. Mater. Sci. Semicond. Process. 2017, 63, 227–236. [Google Scholar] [CrossRef]

- Yu, Z.; Xue, J.; Yao, Q.; Hui, G.; Jiang, Y.; Xue, W. Annealing-free copper source-drain electrodes based on copper–calcium diffusion barrier for amorphous silicon thin film transistor. Thin Solid Films 2017, 624, 106–110. [Google Scholar] [CrossRef]

- Holloway, K.; Fryer, P.M. Tantalum as a diffusion barrier between copper and silicon. Appl. Phys. Lett. 1990, 57, 1736–1738. [Google Scholar] [CrossRef]

- Holloway, K.; Fryer, P.M.; Cabral, C., Jr.; Harper, J.M.E.; Bailey, P.J.; Kelleher, K.H. Tantalum as a diffusion barrier between copper and silicon: Failure mechanism and effect of nitrogen additions. J. Appl. Phys. 1992, 71, 5433–5444. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.H.; Huo, J.C.; Dai, X.H.; Wei, L.J.; Guo, J.X.; Li, X.H.; Wang, L.H.; Lu, C.J.; Wang, J.B.; Liu, B.T. Barrier properties of ultrathin amorphous Al–Ni alloy film in Cu/Si or Cu/SiO2 contact system. Phys. Status Solidi (A) 2016, 214, 1600522. [Google Scholar] [CrossRef]

- Hu, Z.; Ren, L.; Zhao, K.; Wei, G.; Zhang, Z.; Han, T.; Zhong, F.; Yuan, M. A novel diffusion barrier of electrodeposited CoWP layer between copper and silicon: Preparation and performance. Surf. Interfaces 2022, 30, 101925. [Google Scholar] [CrossRef]

- Istratov, A.A. Physics of Copper in Silicon. J. Electrochem. Soc. 2001, 149, G21. [Google Scholar] [CrossRef]

- Jiang, C.; Li, R.; Wang, X.; Shang, H.; Zhang, Y.; Liaw, P.K. Diffusion Barrier Performance of AlCrTaTiZr/AlCrTaTiZr-N High-Entropy Alloy Films for Cu/Si Connect System. Entropy 2020, 22, 234. [Google Scholar] [CrossRef] [Green Version]

| General Composition of the Coating | Borosilicate Glass |

|---|---|

| Thickness range (µm) | 100–150 |

| Average roughness, Ra (µm) | <0.04 |

| Average of the maximum peak-to-valley height, Rz (µm) | 0.2 |

| Emissivity, ε, at 20 °C [43] | 0.89 |

| Emissivity, ε, at 550 °C [43] | 0.84 |

| Sensor Layer Geometrical Parameters | |

|---|---|

| Length (mm) | 500 |

| Channel width (mm) | 1 |

| Thickness (µm) | 2 |

| Copper electrical properties at 20 °C [45] | |

| Resistivity (Ω*m) | 1.71 × 10−8 |

| Temperature coefficient of resistance (1/°C) | 0.00393 |

| Theoretical resistance (Ω) | 4.278 |

| Layer | Power Supply | Heating Output | Applied Power (W) | Thickness (µm) |

|---|---|---|---|---|

| Adhesion study | MF | 0 | 500 | 1.2 |

| Sensor layer study | HiPIMS | 0 | 500–1000 | 1.9 |

| MF | 0 | 500 | 1.1 | |

| 4000 W | 500 | 1.4 |

| Coating Name | Mean Thickness (µm) | Deposition Technique | Synthesis T (°C) | Curing T (°C) | Extraction v (mm/s) |

|---|---|---|---|---|---|

| TTW001 | 1–5 | sol–gel | RT | 200, 300, 450 | 575 |

| TTD001 | 5.5 | PVD-RMS | <300 | - | - |

| Surface Treatment | Particle Diameter (FEPA) | Ra (µm) | Rz (µm) | Adhesion |

|---|---|---|---|---|

| Original | - | <0.04 | 0.2 | Null |

| F500 | 12.8 µm | 0.19–0.22 | 1.5–2.5 | Very good |

| F220 | 58 µm | 1.1–1.3 | 6.7–11.7 | Excellent |

| Sample | β (rad) | 2θ (°) | D (nm) | Increment * |

|---|---|---|---|---|

| HiPims Low T | 0.0052 | 43.35 | 29 | - |

| HiPims Low T + Anneal | 0.0044 | 43.38 | 34 | 18% |

| MF Low T | 0.0088 | 43.32 | 17 | - |

| MF Low T + Anneal | 0.0052 | 43.38 | 29 | 69% |

| MF High T | 0.0055 | 43.38 | 27 | 59% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bikarregi, A.; Dominguez, S.; Brizuela, M.; López, A.; Suarez-Vega, A.; Agustín-Sáenz, C.; Presa, M.; López, G.A. Direct Fabrication of a Copper RTD over a Ceramic-Coated Stainless-Steel Tube by Combination of Magnetron Sputtering and Sol–Gel Techniques. Sensors 2023, 23, 5442. https://doi.org/10.3390/s23125442

Bikarregi A, Dominguez S, Brizuela M, López A, Suarez-Vega A, Agustín-Sáenz C, Presa M, López GA. Direct Fabrication of a Copper RTD over a Ceramic-Coated Stainless-Steel Tube by Combination of Magnetron Sputtering and Sol–Gel Techniques. Sensors. 2023; 23(12):5442. https://doi.org/10.3390/s23125442

Chicago/Turabian StyleBikarregi, Aitor, Santiago Dominguez, Marta Brizuela, Alejandra López, Ana Suarez-Vega, Cecilia Agustín-Sáenz, Micael Presa, and Gabriel A. López. 2023. "Direct Fabrication of a Copper RTD over a Ceramic-Coated Stainless-Steel Tube by Combination of Magnetron Sputtering and Sol–Gel Techniques" Sensors 23, no. 12: 5442. https://doi.org/10.3390/s23125442

APA StyleBikarregi, A., Dominguez, S., Brizuela, M., López, A., Suarez-Vega, A., Agustín-Sáenz, C., Presa, M., & López, G. A. (2023). Direct Fabrication of a Copper RTD over a Ceramic-Coated Stainless-Steel Tube by Combination of Magnetron Sputtering and Sol–Gel Techniques. Sensors, 23(12), 5442. https://doi.org/10.3390/s23125442