Abstract

Wheel burn can affect the wheel–rail contact state and ride quality. With long-term operation, it can cause rail head spalling or transverse cracking, which will lead to rail breakage. By analyzing the relevant literature on wheel burn, this paper reviews the characteristics, mechanism of formation, crack extension, and NDT methods of wheel burn. The results are as follows: Thermal-induced, plastic-deformation-induced, and thermomechanical-induced mechanisms have been proposed by researchers; among them, the thermomechanical-induced wheel burn mechanism is more probable and convincing. Initially, the wheel burns appear as an elliptical or strip-shaped white etching layer with or without deformation on the running surface of the rails. In the latter stages of development, this may cause cracks, spalling, etc. Magnetic Flux Leakage Testing, Magnetic Barkhausen Noise Testing, Eddy Current Testing, Acoustic Emission Testing, and Infrared Thermography Testing can identify the white etching layer, and surface and near-surface cracks. Automatic Visual Testing can detect the white etching layer, surface cracks, spalling, and indentation, but cannot detect the depth of rail defects. Axle Box Acceleration Measurement can be used to detect severe wheel burn with deformation.

1. Introduction

Rails, as the key component of the railway system, are subjected to intense bending, shear, contact, and thermal and residual stresses during operation [1]. These complex loading conditions may cause formation and deterioration of different defects which mainly originate from manufacturing, inappropriate handling, and rolling contact fatigue or corrosion [2]. Among these defects, wheel burn has lately received much attention.

In recent years, wheel burn has been detected on many high-speed railway lines in China at the early stage of operation [3,4,5,6,7,8]. Wheel burn accounts for around 36% of the total defects on 17 high-speed railway lines in China [9]. Wheel burn can affect the wheel–rail contact state and ride quality, and under long-term operation, it may cause cracking, spalling, or even rail breakage.

Research on wheel burn can be divided into the macro-scale and micro-scale. Macro-scale research involves the study of characteristics and causes of wheel burn, while at the micro-scale, the mechanism of formation and crack extension of the white etching layer (WEL) formed by wheel burn have captured the attention of some scholars.

1.1. The Characteristics and Causes of Wheel Burn

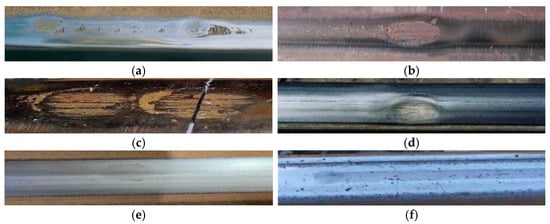

In terms of the macro-scale, the characteristics and causes of wheel burn have been described according to many standards. In UIC712, wheel burn is classified as either single wheel burn or repeated wheel burn [10]. Single wheel burn is identified as an elliptical white self-quenched layer, while repeated wheel burns are identified as a combination of single wheel burns, which are characterized by a wavy rail surface (see Figure 1a). They are caused by wheel-slipping (when the length traveled by a wheel during one rotation cycle is less than its circumference), breaking (also called wheel-skidding, where the length traveled by a wheel during one rotation cycle is larger than its circumference), or wheel-slipping while moving. They mostly occur at signals and railway stations. Under long-term operation, horizontal and transverse cracks developed from wheel burn may cause rail head spalling or rail breakage. Australian Railway [11] claims that excessive slope, improper driver operation, insufficient traction, and decreased friction caused by rail surface contamination will lead to locomotive slipping during the starting and operating stages, resulting in wheel burns. Mild wheel burn may gradually develop into spalling (see Figure 1b), while severe wheel burn may cause transverse cracks and lead to rail fracture (see Figure 1c). The US Railway [12] claims that thermal cracks formed by the consecutive increase in rail surface temperature due to locomotive slipping and then rapid decreases when the train leaves, can cause the transverse fracture of the rail. Typically, multiple wheel burns will appear within a relatively short distance. According to Chinese standards [13], wheel burn is caused by wheel-slipping during locomotive start-up. Wheel burns are elliptical, are distributed symmetrically on both rails, and have spacing equal to the locomotive wheelbase. Continuous longitudinal wheel burns or repeated wheel burns may lead to spalling or transverse breakage.

Figure 1.

Macroscopic appearance of wheel burn [10,11]. (a) Repeated wheel burn caused by locomotive running; (b) Rail surface spalling caused by wheel burn; (c) Transverse breakage caused by wheel burn; (d) Oval-shaped wheel burn caused by locomotive slipping; (e) Oval-shaped WEL caused by wheel burn; (f) Strip-shaped WEL caused by wheel burn.

Wheel burn usually appears as an oval-shaped or strip-shaped white self-quenching layer, with approximately 0.3–2.5 mm depth, 15 mm–10 m length, and 15–30 mm width, located on the running surface of the rail [14]. It is usually distributed near home and departure signals, long ramps, and small-radius curves [9,15]. Based on its morphological and distribution characteristics, it can be deduced whether wheel burn is produced by wheel-slipping or wheel-skidding [6,9]. When a vehicle starts or runs, insufficient traction force will cause wheel-slipping, by which oval-shaped WEL will be produced. In more serious cases, rail tread depression will be created immediately, and a hump can be observed at the edge of the depression because of the plastic flow (see Figure 1d). Likewise, when the vehicle brakes, wheel-skidding will cause the production of oval-shaped or strip-shaped WELs (see Figure 1e,f). These WELs will develop into rail head spalling, transverse cracks, and other rail defects under periodic wheel–rail contact loading [16,17].

1.2. The Mechanism of Formation and Crack Extension of the White Etching Layer

The formation mechanism, microstructure, and crack propagation of WEL have been studied at the micro-scale by many scholars; however, the results are still a matter of controversy [18,19,20]. The conception of the white layer was initially presented by Stead [21] in 1912 after the discovery of the white layer on steel wire rope. Since then, the WEL has been found in many different situations on both ferrous and non-ferrous materials [22]. Based on earlier research, WEL, which is considered to be a form of martensite, is formed by a sequential process during wheel-skidding, in which temperature rises beyond the austenitization temperature, followed by rapid cooling (or quenching) [23,24,25,26,27]. By investigating the microstructure of WEL from rails, retained austenite has been found by multiple researchers, which provides strong proof of a thermal-induced formation mechanism [28,29,30]. Except for the heat source generated by wheel–rail contact, electrical arcing caused by current leakage is a new potential heat source of the thermal-induced formation mechanism of WEL [31,32]. However, this thermo-induced theory is objected to by other researchers [33,34,35,36,37,38], who believe that the austenitization temperature of the wheel–rail contact zone is not reachable under normal rolling conditions. Instead, WEL is considered to be a nanocrystalline Fe-C alloy with a high density of dislocations and occasional twins, which is supersaturated by carbon because of severe plastic deformation. Furthermore, a 2GPa contact pressure loading and a high-pressure torsion experiment were applied to pearlitic rail steel, and WEL was produced under this condition of pure severe plastic deformation. This verified the plastic-deformation-induced mechanism [32]. Recently, another verification experiment to reproduce WEL under pure plastic deformation conditions has been conducted by Pierrick et al. on a circular rail test bench [39].

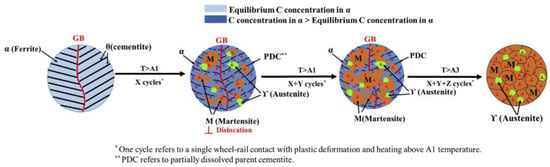

Based on these two formation mechanisms, contradiction is quite easy to find. If severe plastic deformation is the only mechanism, the sharp phase transition process is unable to be explained. In addition, if thermal phase transformation is the only mechanism, WEL will be produced within one cycle of loading, which cannot explain why WEL is loading-history-dependent [40]. Hence, WEL is believed to be formed by a combination of these two mechanisms [25,41,42,43,44,45,46,47]; the thermomechanical mechanism of WEL formation is illustrated in Figure 2. At the initial cycling stage, pearlitic starts to transform to austenite when the temperature rises above A1, and some of the formed austenite is transformed to martensite during the cooling process. At the same time, cementite dissolves due to plastic deformation and temperature rise, and a nanocrystalline structure is produced. After that, martensite and austenite grow gradually during cyclic loading, and a large austenite area is formed. At the end of the cooling stage, some part of austenite has been transformed into martensite, while some of it remains as austenite. However, full austenitization is needed to completely dissolve cementite and form martensite and austenite, which requires more cycles with temperatures beyond A3 [29].

Figure 2.

Schematic drawing of thermomechanical mechanism of WEL formation [29].

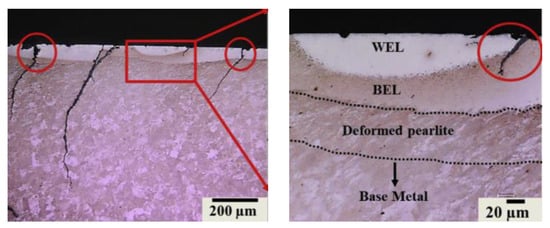

To summarize, the microstructures of WEL are considered to be: (1) martensite [48,49]; (2) nanocrystalline Fe-C alloy [36]; (3) martensite and retained austenite [24,28]; (4) deformed pearlite, nanocrystalline martensite, austenite, and cementite [29,43]. Interestingly, a new tribologically transformed structure named brown etching layer (BEL) has been found near WEL and has been studied in recent works (See Figure 3) [29,40,50,51,52]. Usually, BEL coexists with WEL, forming an internal sandwich structure. BEL is considered to be thermal-induced or thermomechanical-induced, but the mechanism of its formation is not clear yet.

Figure 3.

Optical micrograph of the rail cross-section with WEL, BEL, and cracks [29].

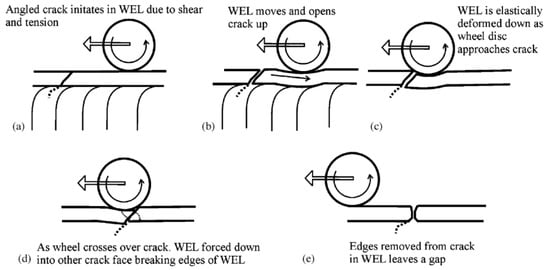

Because WEL is hard (up to 1200 HV) and brittle, small cracks usually initiate from here and propagate to generate other rail defects [53,54]. Cracks usually appear at the edge and in the middle of the WEL area. After crack initiation, cracks will penetrate from the WEL area to the parent rail matrix, and grow into the rail matrix [55,56,57]. Figure 4 [58] explains the propagation mechanism of microcracks generated by the white etching layer microstructure under the loading of moving wheels. In the process of rolling forward, the wheelset acts on the rail before and after the microcrack, making the crack open and forcing different fracture surfaces of the white etching layer to contact, which causes the crack edge to wear, and makes the crack grow and expand continuously, thus leading to other defects such as spalling. Based on the theory of Liu et al. [17], the WEL produced by wheel burn of starting or braking of the high-speed train is thinner (less than 0.2 mm), and is more likely to develop into cracks, while the WEL formed by a heavy axle load locomotive is thicker (greater than 0.5 mm), and is more likely to develop into spalling.

Figure 4.

Schematic of crack development as wheel rolls over [58].

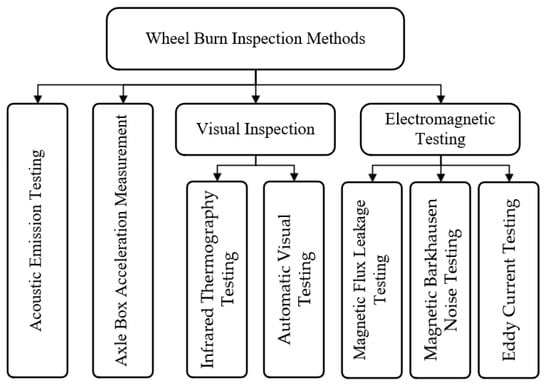

To avoid catastrophic outcomes caused by wheel burns, accurate identification at the early stage of wheel burns is necessary. Currently, optical microscope and hardness tests are used to identify and characterize WEL, which are effective but destructive, expensive, and time-consuming [59]. NDT methods are better choices to overcome these weaknesses, but there is no such widely researched method commonly used for WEL detection. At present, the main methods of rail surface defect detection are: Magnetic Flux Leakage (MFL) Testing, Magnetic Barkhausen Noise (MBN) Testing, Eddy Current (EC) Testing, Acoustic Emission (AE) Testing, Inferred Thermography (IRT) Testing, Automatic Visual (AV) Testing, Ultrasonic Testing (UT), and Axle Box Acceleration (ABA) Measurement. Although UT can detect some wheel burns, its sensitivity to surface and near-surface defects is low and it is mostly used for internal damage detection [60,61]. Therefore, this paper will discuss the detection methods listed above, except for ultrasonic testing. The classification diagram of the NDT methods for wheel burn detection is shown in Figure 5.

Figure 5.

Classification of the NDT methods for wheel burn detection.

This paper focuses on methods for detecting rail surface and near-surface defects, which are suitable for wheel burn detection. The first section demonstrates the characteristics, causes of wheel burn, and the mechanisms of WEL formation and crack extension. The second, third, fourth, and fifth section discuss electromagnetic testing, AE testing, visual inspection, and ABA measurement, respectively, including principles and state-of-the-art applications. The sixth section summarizes the findings and perspectives.

2. Electromagnetic Testing

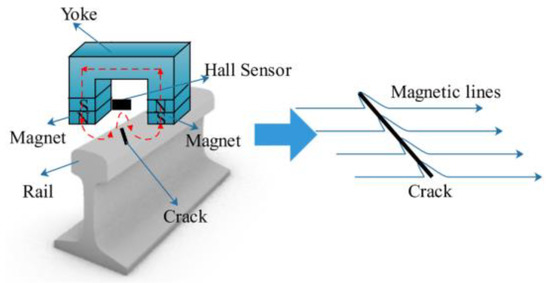

2.1. Magnetic Flux Leakage Testing

As a mature electromagnetic NDT method, MFL testing has already been used for inspecting storage containers, rails, pipelines, etc. When a magnetic material is magnetized, defects on its surface cause changes in magnetic permeability, which shifts the magnetic flux and alters the orientation of the magnetic induction line. This results in magnetic flux leaking to the surface of material, bypassing defects in the atmosphere, and then re-entering the material, creating a leakage magnetic field. Magnetic field signals from the surface will be collected by magnetic sensors to identify rail defects [62,63,64]. The principle of MFL testing is shown in Figure 6.

Figure 6.

The principle of MFL testing of rail [64].

MFL testing is suitable for detecting surface and near-surface cracks, and most researchers are focusing on how to improve the speed, efficiency, and resolution of crack detection [65,66,67,68]. Based on the principle of MFL testing, the magnetic flux leakage is caused by changes in magnetic permeability because of the existence of defects [69]. Formation of WEL may experience phase transformation, grain refinement, dislocation concentration, plastic deformation, etc. Most changes in microstructure will result in changes of magnetic permeability of the component [70], which will cause the leakage of magnetic flux and be captured by the magnetic sensor. Therefore, MFL testing is a possible detection method for WEL.

Under periodic wheel–rail interaction, cracks will initiate and grow from the WEL. In order to determine the size of near-surface and far-surface cracks, Ali et al. [71] proposed a pulsed MFL technique for crack detection and characterization, and its feasibility was shown using simulations and experiments. By using magneto-optical sensors, Tehranchi et al. [72] investigated the relationship between the sensor signal and the length of the cracks, which has great potential to obtain high-resolution magnetic imaging of small cracks.

In addition, Yong et al. [73] proposed a 3D MFL testing method to achieve arbitrary defect detection on rail tracks, and the results gave comprehensive information on the position and shape of defects.

As early as the late 1920s, Sperry Company had developed the induction method for rail inspection, which provided a solution for crack detection [74]. The team from Nanjing University of Aeronautics and Astronautics (NUAA) carried out research on different aspects of MFL testing, inspection speed, lift-up distance, and other influencing factors, as well as improving the detection probe [65,75,76,77,78]. In China, an MFL testing system has been installed in the GTC-80X rail defect detection vehicle, and on-board tests are completed with a running speed of 40 km/h [79]. Antipov et al. [80] investigated the effectiveness of the MFL system installed on the Russian rail defect detection vehicle AVIKON-03 (See Figure 7) under the inspection speed of 80 km/h, and adjusted the interpole distance accordingly.

Figure 7.

Russian rail flaw detection vehicle AVIKON-03 with magnetizing system: (1) the maximum magnetic induction region, and (2) magnetic sensor [80].

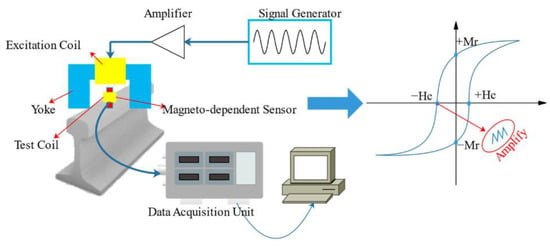

2.2. Magnetic Barkhausen Noise Testing

The MBN signal is a pulsed current signal produced by the movement and deflection of magnetic domains (Bloch wall motion) within a ferromagnetic material under an alternating magnetic field, which is sensitive to changes in stress condition and microstructure of the material [81]. The microstructure of the rail matrix can be described by carbide precipitation [82], dislocation density [83], grain size, or non-ferromagnetic phases [84]. These microstructure changes may occur during the formation process of WEL, so MBN inspection is a feasible method to achieve WEL detection. The principle of MBN testing is shown in Figure 8.

Figure 8.

The principle of MBN testing on rails [64].

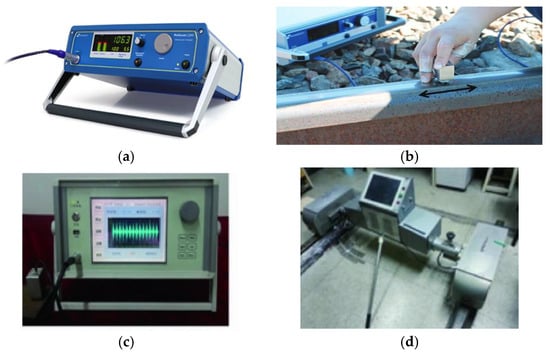

A simple way to identify WEL is to compare hardness between WEL and the rail matrix; MBN inspection is a feasible way to achieve this hardness measurement [85]. In studies by Neslušan et al. [86,87], an evidently lower MBN signal was found in the thick WEL, which is due to: 1. Carbon-supersaturated martensite has a high degree of lattice tetragonality and high hardness; 2. Retained austenite exists in WEL and hinders the Bloch wall motion; 3. Oxides (FeO and Fe2O3) and carbides pin the Bloch wall motion; 4. Microcracks do not produce MBN emissions. Similarly, Jiang et al. [88] built a non-destructive testing system based on MBN technology, and investigated how MBN signals were affected by prefabricated WEL on U75V rails. Compared to the rail matrix, the appearance of WEL causes a rapid decrease in MBN signal. Furthermore, with an increase in WEL thickness, the strength of the MBN signal becomes weaker. From the perspective of quantitative analysis, the peak-to-peak value and RMS value of the MBN signal show a good linear negative correlation with the thickness and area of WEL, which means the appearance and thickness of WEL can be described by the MBN signal. However, MBN signals are temperature-related, so temperature changes need to be considered when conducting the MBN inspection. In order to eliminate the temperature effect, Wang et al. [89] found that the MBN signal has a monotonic relationship with temperature, and so created a back propagation (BP) neural network model to obtain an accurate stress value. At present, some MBN equipment has already been used for detecting rail surface condition, such as the Rollscan 250 from Stresstech Company and the rail stress and crack inspection trolley from NUAA (See Figure 9).

Figure 9.

MBN testing devices [81,90]. (a) Rollscan 250 from Stresstech (Finland); (b) MBN measurement at rail surface with Rollscan 250; (c) MBN stress detector from NUAA; (d) Hand-pushed rail stress and crack inspection device from NUAA.

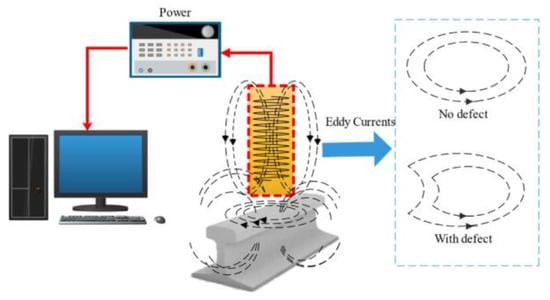

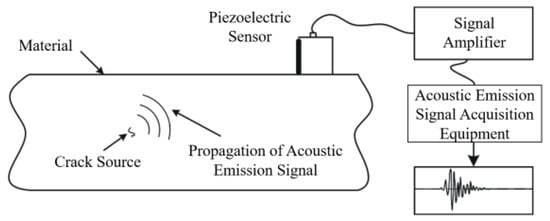

2.3. Eddy Current Testing

Due to the principle of electromagnetic induction, alternating current in a coil sensor creates a changing magnetic field, which will produce an eddy current on the rail surface. The eddy current will produce a new magnetic field, the direction of which is opposite to that of the initial magnetic field. Thus, when defects exist, the fluctuation in difference between the two magnetic fields will cause variation in the impedance and electromotive force [91,92]. Eddy current detection is appropriate for rail surface and near-surface flaw detection, since it is more sensitive to small cracks. The skin effect causes the intensity of eddy currents to diminish from the surface of the specimen downwards, and so detection depth is related to excitation frequency. The principle of EC testing is shown in Figure 10.

Figure 10.

The principle of EC testing of rail [64].

The different microstructures of WEL cause different electrical conductivity compared to the rail matrix, which can be captured by a coil sensor to identify WEL at an early stage. By using a four-channel portable eddy current detector, Xiong et al. [93] conducted on-site testing of 10 wheel burns. By extracting the characteristic voltage signals of wheel burns, damage levels are classified based on the length and width of wheel burns. Therefore, wheel burn (or WEL) can not only can be detected by the EC testing method, but can also be analyzed quantitatively. As shown in Figure 11 [94], Thomas et al. studied the ability of the ultrasonic and eddy current inspection device installed on rail inspection vehicles used by a German railway company, and the results showed that eddy current inspection equipment could determine the location and size of rail surface defects, such as wheel burns, rail head cracks, and squats. It should be mentioned that eddy current is sensitive to rail surface roughness, so rusting and corrosion may affect detection accuracy [95].

Huang [96] conducted experiments on the quantitative assessment of eddy current detection of cracks on the rail surface; due to the skin effect, detection results are not accurate if the depth is greater than 5 mm. By conducting simulation and experiment analysis, a new technique for non-destructive testing based on velocity-induced eddy currents was proposed and validated by Ramos et al. [97]. As the sensitivity of this method increases with speed, it shows a great advantage for on-board inspection of rail. Liu et al. [98] proposed an electromagnetic tomography (EMT) technique to achieve crack detection on the rail surface. They used tomographic methods to measure the alternating magnetic signals from cracks and reconstruct the distribution of the cracks, which can obtain the shape and location of cracks.

For the EC testing device, the Vossloh company developed a rail grinding system with an integrated EC inspection module, which can detect rolling contact fatigue defects after rail grinding [99]. By using an eddy current, Huang et al. [100] developed a rail surface detection system that is applicable for both switches and mainline rails; Hu et al. [101] developed an eddy current detection method and device that can quantitatively and accurately detect small cracks on the rail surface; Park et al. [102] designed a hand-pushed 16-channel eddy current detection device, which is more accurate at measuring the length and width of rail surface damage.

Figure 11.

EC testing devices [94,99]. (a) German rail inspection vehicle with eddy current sensors installed (red arrows); (b) Rail grinding system with integrated EC inspection module from Vossloh.

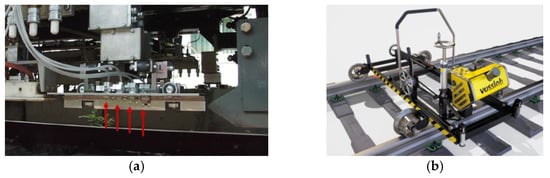

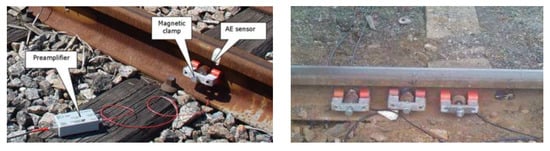

3. Acoustic Emission Testing

The rapid release of energy from an object or substance causes a transient elastic wave to be created, which is known as acoustic emission [103,104]. Usually, plastic deformation and cracks of materials are the main sources of acoustic emission, as well as phase changes, corrosion, friction, and magnetization [105]. The elastic waves generated by AE sources are conducted to the surface, causing vibration of surface particles, which is captured and converted into an electrical signal by a piezoelectric transducer, processed by an amplifier, and collected by the instrument. The frequency range of AE testing is typically 20 kHz to 1 MHz [106]. The principle of AE testing is shown in Figure 12. In practice, the sensor is usually fixed to the flat surface of the rail web through clamps, and the couplant is needed [107]. The onsite installation is shown in Figure 13.

Figure 12.

The principle of AE testing [64].

AE testing is frequently used for monitoring rail cracks and wheel defects. Muravev et al. [108] have analyzed the stress–strain conditions of rails when trains are passing, taking into account the effects of mechanical and electromagnetic noise on detection, and have theoretically demonstrated that cracks in rails can be detected using acoustic emission methods. Bianchi et al. [109] researched the development of rail head fatigue defects by using individual AE sensors, and the wavelet packet approach was used to extract the signal character. To simulate high-speed situations, Xin et al. [110] constructed a wheel–rail platform that can accelerate up to 177 km/h, and by using the time–Shannon entropy method, defect signals can be detected at 124 km/h. BOLLAS et al. [111] analyzed AE signals from rail-installed AE sensors, as shown in Figure 13, and captured different characters of AE signals of damaged and non-damaged wheels, which demonstrates the potential of AE testing for wheel defect diagnosis.

As for WEL, increased brittleness causes decreased damping, which will result in a larger amplitude of vibrations [59]. Based on the research of Guo et al. [112], the existence of WEL increases the amplitude and frequency of the AE signal, which provides fundamental information for WEL detection. Surface roughness is another important factor that can affect the AE signal, so the noise generated by rough surfaces needs to be eliminated. From the perspective of microstructure, by analyzing the AE characteristics of the martensitic transformation process, Jiang et al. [113,114,115] propose a new dynamic monitoring method for martensitic transformation based on AE, and obtained accurate laws of martensitic transformation, which provides a theoretical basis for WEL identification.

Figure 13.

Installation of AE sensor on rail [107,111].

4. Visual Inspection

4.1. Infrared Thermography Inspection

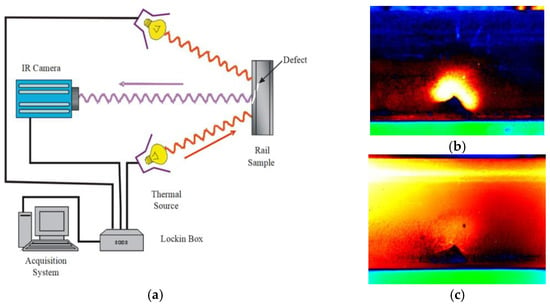

Thermal imaging detection, which can also be referred to as IRT inspection, can be classified into active and passive types depending on how the temperature change is caused. Active IRT inspection uses external thermal input to cause the object to lose thermal equilibrium and to detect infrared before it reaches equilibrium internally, while passive IRT inspection uses the heat exchange between the object and its surroundings to achieve infrared detection [116].

Because rails cannot heat themselves, rail defect detection is generally carried out using active IRT inspection. Depending on the heating method, active IRT inspection can be divided into pulsed thermography, step heating thermography, lock-in thermography, laser thermography, and ultrasonic thermography [116].

In pulsed thermography, a high-frequency alternating current is brought close to the rail surface, which induces eddy currents with different densities because of defects. Based on Joule’s law, eddy currents are further transformed into heat, creating high- and low-temperature regions within the material and inducing temperature variation at the material surface through heat conduction. The temperature anomalies are recorded by a thermal imaging camera and processed to extract the defect information [117,118]. This testing method is used more for rail crack detection. Peng et al. [119] used eddy current pulsed thermography to quantitatively investigate the characteristics of closed cracks and natural cracks produced by rolling contact fatigue, and established a model of closed cracks with rust as a filler. The results demonstrated that the higher temperature at the crack tip is caused by a higher eddy current density, and that the maximum temperature at the crack tip rises with increasing crack length. Bai Jie et al. [120] investigated the crack closure effect caused by the filling of a third substance by using pulsed thermography. Feng et al. [121] researched the progress of squat crack growth by using eddy current pulse thermography and verified the feasibility of eddy current pulse thermography detection for squat identification.

While pulsed thermography is not very sensitive to small-sized or fatigue defects, the phase information of lock-in thermography effectively reduces the impact of noise and improves the signal-to-noise ratio of the temperature signal, so the location and shape of defects can be accurately determined by extraction of phase information [122]. As shown in Figure 14a, by using heat lamps as a heat source, Daren et al. [123] successively identify the appearance and location of squats, but their measurement of squat depth was not accurate based on angle images. Likewise, Peng et al. [124] also investigated the reliability of lock-in thermography for squat identification. The results showed that lock-in thermography can accurately identify squats of different sizes and depths with higher sensitivity than ultrasonic testing. In addition, because the amplitude of heat input and convection loss are not able to change the phase response of the rail surface, phase images can only be affected by material properties and defect geometry. Lv [125] conducted crack extension experiments on the head, web, and bottom of U71Mn rails, and proved the feasibility of this method by comparing the results with the traditional compliance method and visual method.

Figure 14.

Detection of squats by lock-in thermography [123]. (a) Schematic of lock-in thermography experiment setup; (b) Phase angle image of squat; (c) Temperature image of squat.

In laser thermography, the laser is used as a heat source to heat the surface of the defect, and an infrared imaging camera is used to measure the thermal dispersion during the heating process, thus the characterization of the defect is captured [126]. Based on the research of Giuseppe [127], laser thermography was used to distinguish the ferritic and martensitic structure in boron steel and found a difference in the thermal diffusivity between the two of 35%. There are thermal diffusivity differences among different phases of steel, which means the martensite phase of WEL can be identified by using laser thermography.

4.2. Automatic Visual Testing

Recently, AV testing has been widely used for track inspection. AV testing mainly uses cameras to obtain image signals, and then image processing systems are used to convert image signals into digital signals so that computers can make reasonable judgments instead of human eyes. However, similar to human eyes, machine vision can only detect rail surface defects, and internal cracks or near-surface defects are not detectable. At present, some developed countries have established some industry systems and standards, which have been broadly used in the railway industry, among which the representative ones are [128]:

- The RSIS system developed by ENSCO in the United States uses the line scanning imaging method to collect and record continuous high-resolution track surface images from moving vehicles, and can successfully identify spalling, cracks, squats, wheel burns, etc.;

- The V-CUBE rail vision inspection system developed by the MERMEC Company in Italy can obtain images and inspection data of up to 50 types of defects of rail surfaces, fasteners, sleepers, and ballast beds at a speed of 200 km/h;

- The RailCheck system developed by the bvSys Company in Germany uses an industrial linear scanning camera and high-powered LED light to inspect rail surfaces, fasteners, sleepers, turnouts, and other structures at a speed of 200 km/h.

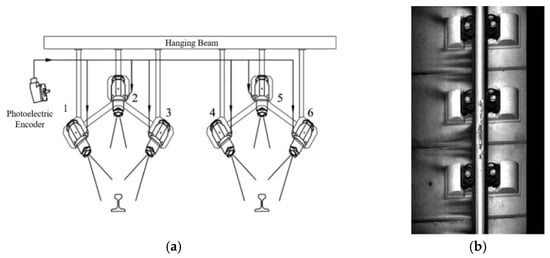

A vehicle-mounted track inspection system has been developed by China Academy of Railway Science [129,130,131], which uses six linear CCD cameras to scan the full track (See Figure 15). Principal component analysis and linear discriminant analysis are used to build a machine learning model to realize automatic identification of wheel burns and other defects. The system has achieved a 95% detection rate of wheel burns with a 160 km/h inspection speed. Ren et al. [132] proposed a wheel burn identification algorithm, which mainly includes four processes: rail region extraction, gray contrast image generation, binarization based on the maximum entropy principle, and wheel burn determination. They achieved a detection rate of 90.7%. Based on this research, Zhao et al. [133] proposed a wheel burn detection algorithm based on spatial filtering. In this algorithm, the mean gray value of the original image is used to fill the defect area, which enhances the contrast between the wheel burn area and the background area in the gray image, therefore improving the wheel burn detection rate.

Figure 15.

A vehicle-mounted track inspection system developed by China Academy of Railway Science [129,130,131]. (a) The principle of track inspection (1–6 are line scan cameras); (b) Wheel burn detected by track inspection system.

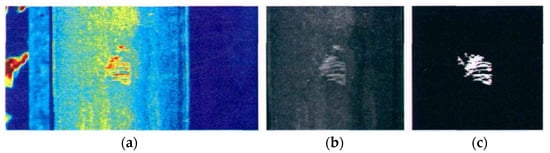

Ding [128] designed an experimental portable rail surface detection trolley with a 4K linear camera and extracted the wheel burn features by using the maximally stable extremal regions method (MSER), realizing the automatic identification of wheel burn. The track inspection trolley and identification process are shown in Figure 16 and Figure 17, respectively. Based on the principle of blind source separation, Li et al. [134] proposed a sparseness representation model of defect images and realized the recognition of wheel burn.

Figure 16.

Track inspection trolley [128].

Figure 17.

Photograph of wheel burn detection [128]. (a) Target image; (b) Detection region; (c) Wheel burn.

With the aid of the deep learning technique and the Cuda parallel computing architecture, Santur et al. [135,136] were able to classify rail surface defect images captured by 3D laser cameras. With 99% detection accuracy, this technique can identify rail surface defects in real-time at speeds of up to 144 km/h. Shang et al. [137] proposed a sequential processing method that uses Canny edge detection to locate the rail and uses a convolutional neural network (CNN) to classify and identify the rail images with a 92.08% detection accuracy. A rail surface detection method was proposed by Tangbo et al. [138], which improves the detection rate of minor defects on the rail surface by building a lightweight and quick-response improved YOLOv4 model.

5. Axle Box Acceleration Measurement

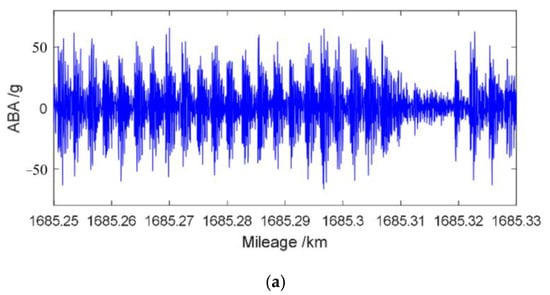

The axle box and wheelset are rigidly connected, and the short-wave irregularity of the rail excites the vibration of the wheelset, which will transmit to the axle box directly, so the ABA can reflect the disturbance caused by rail defects to a certain extent, which means some rail defects can be identified by using ABA [139]. For mild wheel burn with phase transformation only, usually, no excitations can be detected by the ABA sensor. However, for severe wheel burn with plastic deformation or spalling developed from wheel burn, obvious excitation signals can be detected by ABA detection.

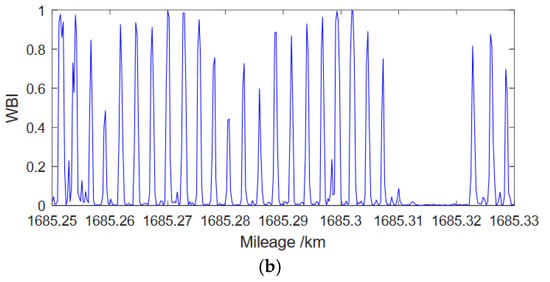

Much research has been carried out on evaluating rail state by using ABA, among which Molodova et al. [140] used wavelet power spectrum to classify squats of different severity based on the frequency domain response of the ABA signal, and could differentiate the severity of squats based on frequency magnitude. The detection rate of minor squats was 78%, while the detection rate of moderate and severe squats was 100%. Zili et al. [141] proposed three improved methods for detecting minor squats based on ABA. The first method is to use longitudinal ABA to improve the sensitivity of squat detection. The second method is to use multi-sensors, adopt noise reduction technology, and repeat measurement. The third method is to reduce the interference of wheel defects using signal processing. Cao et al. [142] used the Hilbert–Huang transform method to perform time–frequency analysis of ABA, and realized localization of short-wave irregularity. By using the maximum power spectral density, Jamshidi et al. [143] evaluated the length of squat from ABA signals and established a robust model to predict the growth of squat. Liu et al. [144] proposed a track impact index method based on vertical ABA, which reduces the influence of random factors such as rail joint welds and turnouts on the results, and achieves the identification of short-wave irregularity defects. XU et al. [145] proposed a wheel burn index (WBI) to identify continuous and equidistant wheel burn, which uses a demodulated envelope signal to replace the original signal, so an energy signal with low-frequency is extracted to achieve efficient wheel burn diagnosis. The original ABA signal and WBI signal of continuous and equidistant wheel burn can be seen in Figure 18.

Figure 18.

Original ABA signal and WBI signal of continuous and equidistant wheel burn [145]. (a) Original ABA signal; (b) WBI signal.

6. Summary and Perspective

In summary, the characteristics, mechanism of formation, crack extension, and detection methods of wheel burn are reviewed, and the main findings and conclusions are summarized below:

- Initially, the wheel burns appear as an elliptical or strip-shaped white etching layer with or without deformation on the running surface of the rails. In the latter stages of development, they may cause cracks, spalling, etc. Three main mechanisms of WEL formation have been proposed by scholars: Thermal-induced, plastic deformation-induced, and thermomechanical-induced mechanisms. The thermomechanical-deformation-induced mechanism is the most likely;

- Four main types of rail defect detection methods can be used to achieve wheel burn detection. They are electromagnetic, acoustic, visual, and axle box acceleration detection methods. Among them, magnetic flux leakage testing, magnetic Barkhausen noise testing, and eddy current testing can identify wheel burn at an early stage according to the different magnetic permeability and conductivity caused by the white etching layer. Acoustic emission testing takes advantage of the brittleness of the white etching layer to identify wheel burn at an early stage. Infrared thermography testing utilizes the difference in thermal diffusivity between WEL and the rail matrix to identify wheel burn at an early stage. When the WEL is developed, these methods can also detect near-surface cracks, but more research is needed for the fast detection and automatic identification of wheel burn. Automatic visual testing is not able to see through rails; white etching layer, surface cracks, spalling, indentation can be identified, but the depth of rail defects cannot be measured. Axle box acceleration measurement can detect severe wheel burn with plastic deformation and spalling developed from wheel burn.

Based on reviews and conclusions, a few future research directions of wheel burn are recommended below:

- Improve the accuracy of individual inspection methods. Enhance the accuracy, repeatability, and speed of existing detection methods for wheel burn. For instance, research can focus on improving the sensitivity, resolution, and inspection speed of electromagnetic and visual testing techniques for wheel burn detection; research can also focus on improving the sensitivity of acoustic emission testing techniques for wheel burn monitoring.

- Integrate multiple inspection methods. Combine different non-destructive testing techniques to enhance the accuracy of detecting various types of wheel burn. For example, integrating electromagnetic testing, visual testing, and axle box acceleration measurement can provide a more detailed assessment of wheel burn at different stages and can be mutually verified by each other. Acoustic emission testing can be used to monitor the long-term development of wheel burn.

- Conduct theoretical research and experimental validation: Utilize finite element analysis and other methods to study the formation mechanism and crack extension of wheel burns. Further theoretical research and experimental validation are needed to gain a deeper understanding of these processes.

- Conduct wheel burn identification and classification research: Utilize statistical approaches and neural network methods to achieve automatic identification and classification of wheel burn. Multi-source data fusion analysis is worth studying to increase the detectability rate of wheel burn.

- Address challenges in implementing NDT techniques on railways: Overcome challenges associated with implementing NDT techniques in the railway industry, such as the requirement for specialized equipment and trained personnel. Collaboration among researchers, industry professionals, and regulatory bodies is necessary to develop standardized procedures for NDT testing on railways.

Author Contributions

Conceptualization, X.L. and Y.Z.; methodology, X.L. and Y.Z.; formal analysis, X.L., Y.Z. and L.X.; investigation, Y.Z., L.X., Z.C. and J.W.; resources, X.L., Y.Z., Z.C. and J.W.; data curation, X.L., Y.Z., L.X., Z.C. and J.W.; writing—original draft preparation, writing review and editing, Y.Z., X.L. and L.X.; supervision, X.L. and L.X.; project administration, X.L.; funding acquisition, X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Research and Development Program of China State Railway Group Co., Ltd. (K2022T002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cannon, D.F.; Edel, K.-O.; Grassie, S.L.; Sawley, K. Rail Defects: An Overview. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 865–886. [Google Scholar] [CrossRef]

- Papaelias, M.P.; Roberts, C.; Davis, C.L. A Review on Non-Destructive Evaluation of Rails: State-of-the-Art and Future Development. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2008, 222, 367–384. [Google Scholar] [CrossRef]

- Deng, Y.; Deng, J. Analysis of damage causes of high-speed railway rails. Phys. Test. Chem. Anal. (Part A Phys. Test.) 2013, 49, 766–769. [Google Scholar]

- Xu, W.; Chen, Z. Analysis of rail damage in the early operation period of high-speed railway ballastless track and countermeasures. Shanghai Railw. Sci. Technol. 2014, 147, 37–39. [Google Scholar] [CrossRef]

- Ning, G. Analysis of the causes of wheel burn on high-speed railway rails and treatment measures. Shanghai Railw. Technol. 2017, 158, 46–48. [Google Scholar] [CrossRef]

- Liu, F.; Li, C.; Tian, C. Early damage research on high-speed railway rails in China. Railw. Eng. 2018, 58, 138–140. [Google Scholar] [CrossRef]

- Zhao, K. Analysis of common surface damage on high-speed railway rails and countermeasures. China High-Tech Enterp. 2020, 77, 83–84. [Google Scholar] [CrossRef]

- Qi, Z.; Liu, F.; Jiang, Z. Analysis of defects in construction of high-speed railway rails and suggestions for rail protection management. Railw. Eng. 2022, 62, 44–48+55. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Tian, C.; Wang, Z.; Shi, T.; Liu, F. Study on service status and disease control of high-speed railway rails. Railw. Eng. 2020, 60, 126–129+142. [Google Scholar] [CrossRef]

- International Union of Railways (UIC). UIC 712: Rail Defects; International Union of Railways: Paris, France, 2002; pp. 64–67. [Google Scholar]

- Kerr, M.; Wilson, A. TMC 226: Rail Defects Handbook; NSW Transport RailCorp: Sydney, Australia, 2012; pp. 64–68. [Google Scholar]

- FRA (Federal Railroad Administration). Track Inspector Rail Defect Reference Manual; FRA (Federal Railroad Administration): Washington, DC, USA, 2015; pp. 23–24. [Google Scholar]

- Ministry of Railways of the People’s Republic of China. Rail Damage Classification; Ministry of Railways of the People’s Republic of China: Beijing, China, 2010; pp. 14–15. [Google Scholar]

- Yang, G.; Liu, F.; Li, C.; Tian, C.; Zhou, S.; Wang, Z. Research on influencing factors of service life of high-speed railway rails in China. Adv. Mater. High Speed Railw. 2022, 1, 15–19+25. [Google Scholar]

- Wei, T.; Liu, L.; Li, J.; Zuo, X. Analysis on the causes of wheel burn on passenger dedicated line. J. Railw. Sci. Eng. 2015, 12, 489–495. [Google Scholar] [CrossRef]

- Yang, D.; Deng, Y.; Dong, X.; Zhao, J. Research on rail damage and its formation mechanism in a certain railway. Iron Steel Vanadium Titan. 2022, 43, 184–190+197. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Tian, C.; Li, Y.; Liu, F. Formation mechanism and maintenance strategy of hidden damage on high-speed railway rails in China. China Railw. Sci. 2022, 43, 40–47. [Google Scholar] [CrossRef]

- Kirk, A.M.; Shipway, P.H.; Sun, W.; Bennett, C.J. The Effect of Frequency on Both the Debris and the Development of the Tribologically Transformed Structure during Fretting Wear of a High Strength Steel. Wear 2019, 426–427, 694–703. [Google Scholar] [CrossRef]

- Saxena, A.K.; Kumar, A.; Herbig, M.; Brinckmann, S.; Dehm, G.; Kirchlechner, C. Micro Fracture Investigations of White Etching Layers. Mater. Des. 2019, 180, 107892. [Google Scholar] [CrossRef]

- Gutiérrez Guzmán, F.; Sous, C.; Van Lier, H.; Jacobs, G. An Energetic Approach for the Prognosis of Thermally Induced White Etching Layers in Bearing Steel 100CrMn6. Tribol. Int. 2020, 143, 106096. [Google Scholar] [CrossRef]

- Stead, J. Micro-Metallography and Its Practical Application. J. West. Scott. Iron Steel Inst. 1912, 19, 169–204. [Google Scholar]

- Griffiths, B.J. Mechanisms of White Layer Generation with Reference to Machining and Deformation Processes. J. Tribol. 1987, 109, 525–530. [Google Scholar] [CrossRef]

- Ahlström, J.; Karlsson, B. Analytical 1D Model for Analysis of the Thermally Affected Zone Formed during Railway Wheel Skid. Wear 1999, 232, 15–24. [Google Scholar] [CrossRef]

- Pyzalla, A.; Wang, L.; Wild, E.; Wroblewski, T. Changes in Microstructure, Texture and Residual Stresses on the Surface of a Rail Resulting from Friction and Wear. Wear 2001, 251, 901–907. [Google Scholar] [CrossRef]

- Österle, W.; Rooch, H.; Pyzalla, A.; Wang, L. Investigation of White Etching Layers on Rails by Optical Microscopy, Electron Microscopy, X-Ray and Synchrotron X-Ray Diffraction. Mater. Sci. Eng. A 2001, 303, 150–157. [Google Scholar] [CrossRef]

- Jirásková, Y.; Svoboda, J.; Schneeweiss, O.; Daves, W.; Fischer, F.D. Microscopic Investigation of Surface Layers on Rails. Appl. Surf. Sci. 2005, 239, 132–141. [Google Scholar] [CrossRef]

- Pal, S.; Daniel, W.J.; Valente, C.H.; Wilson, A.; Atrens, A. Surface Damage on New AS60 Rail Caused by Wheel Slip. Eng. Fail. Anal. 2012, 22, 152–165. [Google Scholar] [CrossRef]

- Wang, L.; Pyzalla, A.; Stadlbauer, W.; Werner, E.A. Microstructure Features on Rolling Surfaces of Railway Rails Subjected to Heavy Loading. Mater. Sci. Eng. A 2003, 359, 31–43. [Google Scholar] [CrossRef]

- Kumar, A.; Agarwal, G.; Petrov, R.; Goto, S.; Sietsma, J.; Herbig, M. Microstructural Evolution of White and Brown Etching Layers in Pearlitic Rail Steels. Acta Mater. 2019, 171, 48–64. [Google Scholar] [CrossRef]

- Al-Juboori, A.; Zhu, H.; Wexler, D.; Li, H.; Lu, C.; McCusker, A.; McLeod, J.; Pannila, S.; Barnes, J. Characterization of White Etching Layers Formed on Rails Subjected to Different Traffic Conditions. Wear 2019, 436–437, 202998. [Google Scholar] [CrossRef]

- Al-Juboori, A.; Zhu, H.; Wexler, D.; Li, H.; Lu, C.; Gazder, A.A.; McLeod, J.; Pannila, S.; Barnes, J. Microstructural Changes on Railway Track Surfaces Caused by Electrical Leakage between Wheel and Rail. Tribol. Int. 2019, 140, 105875. [Google Scholar] [CrossRef]

- Zhu, H.; Li, H.; Al-Juboori, A.; Wexler, D.; Lu, C.; McCusker, A.; McLeod, J.; Pannila, S.; Barnes, J. Understanding and Treatment of Squat Defects in a Railway Network. Wear 2020, 442–443, 203139. [Google Scholar] [CrossRef]

- Newcomb, S.B.; Stobbs, W.M. A Transmission Electron Microscopy Study of the White-Etching Layer on a Rail Head. Mater. Sci. Eng. 1984, 66, 195–204. [Google Scholar] [CrossRef]

- Baumann, G.; Fecht, H.J.; Liebelt, S. Formation of White-Etching Layers on Rail Treads. Wear 1996, 191, 133–140. [Google Scholar] [CrossRef]

- Baumann, G.; Knothe, K.; Fecht, H.-J. Surface Modification, Corrugation and Nanostructure Formation of High Speed Railway Tracks. Nanostructured Mater. 1997, 9, 751–754. [Google Scholar] [CrossRef]

- Lojkowski, W.; Djahanbakhsh, M.; Bürkle, G.; Gierlotka, S.; Zielinski, W.; Fecht, H.-J. Nanostructure Formation on the Surface of Railway Tracks. Mater. Sci. Eng. A 2001, 303, 197–208. [Google Scholar] [CrossRef]

- Djahanbakhsh, M.; Lojkowski, W.; Bürkle, G.; Baumann, G.; Ivanisenko, J.; Valiev, R.; Fecht, H.J. Nanostructure Formation and Mechanical Alloying in the Wheel/Rail Contact Area of High-Speed Trains in Comparison with Other Synthesis Routes. JMNM 2001, 10, 175–182. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, J.F.; Luo, Z.P.; Cao, B.B.; Jin, X.S.; Zhu, M.H. Phase and Microstructural Evolution in White Etching Layer of a Pearlitic Steel during Rolling–Skidding Friction. Wear 2016, 362–363, 8–17. [Google Scholar] [CrossRef]

- Pierrick, M.; Sophie, C.; Vincent, L.; Marion, R.; Aurélien, S.; Salima, B.; Julie, M.; Yves, B. An Attempt to Generate Mechanical White Etching Layer on Rail Surface on a New Rolling Contact Test Bench. Wear 2021, 482–483, 203945. [Google Scholar] [CrossRef]

- Steenbergen, M.; Dollevoet, R. On the Mechanism of Squat Formation on Train Rails—Part I: Origination. Int. J. Fatigue 2013, 47, 361–372. [Google Scholar] [CrossRef]

- Shur, E.A.; Kleshcheva, I.I. Structure and Properties of White Layers Formed at High Velocities of Friction. Mater. Sci. 1978, 14, 280–284. [Google Scholar] [CrossRef]

- Kondo, K.; Yoroizaka, K.; Sato, Y. Cause, Increase, Diagnosis, Countermeasures and Elimination of Shinkansen Spalling. Wear 1996, 191, 199–203. [Google Scholar] [CrossRef]

- Zhang, H.W.; Ohsaki, S.; Mitao, S.; Ohnuma, M.; Hono, K. Microstructural Investigation of White Etching Layer on Pearlite Steel Rail. Mater. Sci. Eng. A 2006, 421, 191–199. [Google Scholar] [CrossRef]

- Beneš, L. On Wheel–Rail Contact Surface Phenomena with Structural Changes and ‘White Etching Layers’ Generation. Transport 2012, 27, 196–205. [Google Scholar] [CrossRef]

- Petrov, R.; Wu, J.; Sietsma, J. Microstructure of White Etching Layer of In-Field Loaded Railway Steel. Mach. Technol. Mater. 2017, 11, 453–456. [Google Scholar]

- Al-Juboori, A.; Wexler, D.; Li, H.; Zhu, H.; Lu, C.; McCusker, A.; McLeod, J.; Pannil, S.; Wang, Z. Squat Formation and the Occurrence of Two Distinct Classes of White Etching Layer on the Surface of Rail Steel. Int. J. Fatigue 2017, 104, 52–60. [Google Scholar] [CrossRef]

- Gao, G.; Liu, M.; Gui, X.; Hu, J.; Luan, J.H.; Jiao, Z.B.; Wang, X.; Bai, B.; Yang, Z. A Novel Mechanism of the Formation of White and Brown Etching Layer in Bainitic Rail Steel. SSRN J. 2021. [Google Scholar] [CrossRef]

- Clayton, P.; Allery, M.B.P. Metallurgical Aspects of Surface Damage Problems in Rails. Can. Metall. Q. 1982, 21, 31–46. [Google Scholar] [CrossRef]

- Kerr, M.; Wilson, A.; Marich, S. The Epidemiology of Squats And Related Rail Defects. In Proceedings of the CORE 2008, Rail: The Core of Integrated Transport, Conference on Railway, Engineering, Perth, Australia, 7–10 September 2008. [Google Scholar]

- Li, S.; Wu, J.; Petrov, R.H.; Li, Z.; Dollevoet, R.; Sietsma, J. “Brown Etching Layer”: A Possible New Insight into the Crack Initiation of Rolling Contact Fatigue in Rail Steels? Eng. Fail. Anal. 2016, 66, 8–18. [Google Scholar] [CrossRef]

- Wu, J.; Petrov, R.H.; Li, S.; Li, Z.; Godet, S.; Malet, L.; Sietsma, J. Characterization of Structural Change in Rail Surface Using Advanced Automatic Crystallographic Orientation Microscopy. In Proceedings of the 15th International Conference on Railway Engineering Design and Operation, Madrid, Spain, 19 July 2016; pp. 367–376. [Google Scholar]

- Al-Juboori, A.; Zhu, H.; Wexler, D.; Li, H.; Lu, C.; McCusker, A.; McLeod, J.; Pannila, S.; Barnes, J. Evolution of Rail Surface Degradation in the Tunnel: The Role of Water on Squat Growth under Service Conditions. Eng. Fract. Mech. 2019, 209, 32–47. [Google Scholar] [CrossRef]

- Stephen, M. The Development of Squat Defects Under High Axle Load Operations; Railway Technical Society of Australasia/Rail Track Association of Australia: Wollongong, Australia, 2002; Volume 10. [Google Scholar]

- Seo, J.W.; Kwon, S.J.; Jun, H.K.; Lee, D.H. Microstructure Features and Contact Fatigue Crack Growth on Rail. MSF 2010, 654–656, 2491–2494. [Google Scholar] [CrossRef]

- Seo, J.W.; Kwon, S.J.; Jun, H.K.; Lee, D.H. Numerical Stress Analysis and Rolling Contact Fatigue of White Etching Layer on Rail Steel. Int. J. Fatigue 2011, 33, 203–211. [Google Scholar] [CrossRef]

- Pal, S.; Daniel, W.J.T.; Farjoo, M. Early Stages of Rail Squat Formation and the Role of a White Etching Layer. International Journal of Fatigue 2013, 52, 144–156. [Google Scholar] [CrossRef]

- Lian, Q.; Deng, G.; Al-Juboori, A.; Li, H.; Liu, Z.; Wang, X.; Zhu, H. Crack Propagation Behavior in White Etching Layer on Rail Steel Surface. Eng. Fail. Anal. 2019, 104, 816–829. [Google Scholar] [CrossRef]

- Carroll, R.I.; Beynon, J.H. Rolling Contact Fatigue of White Etching Layer: Part 1: Crack Morphology. Wear 2007, 262, 1253–1266. [Google Scholar] [CrossRef]

- Brown, M.; Wright, D.; M’Saoubi, R.; McGourlay, J.; Wallis, M.; Mantle, A.; Crawforth, P.; Ghadbeigi, H. Destructive and Non-Destructive Testing Methods for Characterization and Detection of Machining-Induced White Layer: A Review Paper. CIRP J. Manuf. Sci. Technol. 2018, 23, 39–53. [Google Scholar] [CrossRef]

- Wilsonl, A.; Kerrl, M.; Marich, S.; Kaewunruen, S. Wheel/Rail Conditions and Squat Development on Moderately Curved Tracks. In Proceedings of the CORE 2012: Global Perspectives, Conference on Railway Engineering, Brisbane, Australia, 10–12 September 2012. [Google Scholar]

- Sakdirat, K. Identification and Prioritization of Rail Squat Defects in the Field Using Rail Magnetisation Technology. In Proceedings of the Structural Health Monitoring and Inspection of Advanced Materials, Aerospace, and Civil Infrastructure 2015, San Diego, CA, USA, 9–12 March 2015; Shull, P.J., Ed.; SPIE: San Diego, CA, USA, 2015; Volume 9437, pp. 374–384. [Google Scholar]

- Lin, J.M. Research on Magnetic Particle Inspection Technology and Its Development Status. Nondestruct. Test. Technol. 2006, 30, 1–5+11. [Google Scholar] [CrossRef]

- Wilson, J.W.; Tian, G.Y. 3D Magnetic Field Sensing for Magnetic Flux Leakage Defect Characterisation. Insight-Non-Destr. Test. Cond. Monit. 2006, 48, 357–359. [Google Scholar] [CrossRef]

- Gong, W.; Muhammad, F.; Ghassan, N.; Mohamed, F.; Mohd, N. Nondestructive Testing Technologies for Rail Inspection: A Review. Coatings 2022, 12, 1790. [Google Scholar] [CrossRef]

- Xiong, L.H.; Wang, P.; Qi, J.; Wang, H.; Tian, G.; Gao, Y. Research on the Magnetization Intensity of Rails in High-speed Magnetic Particle Inspection. Nondestruct. Test. 2013, 35, 2–6+10. [Google Scholar]

- Zhang, R.; Jia, Y.; Wang, P. A Method to Suppress the Interference of Lifting in Magnetic Particle Inspection of Surface Defects on Rails. Electron. Meas. Technol. 2020, 43, 148–153. [Google Scholar] [CrossRef]

- Jia, Y.; Lu, Y.; Xiong, L.; Zhang, Y.; Wang, P.; Zhou, H. A Filtering Method for Suppressing the Lift-Off Interference in Magnetic Flux Leakage Detection of Rail Head Surface Defect. Appl. Sci. 2022, 12, 1740. [Google Scholar] [CrossRef]

- Antipov, A.G.; Markov, A.A. Using a Tail Field in High-Speed Magnetic Flux Leakage Testing. J. Nondestruct. Eval. 2022, 41, 2. [Google Scholar] [CrossRef]

- Cui, L. Defect Identification Technology of Magnetic Particle Inspection for High-Speed Railway. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2011. [Google Scholar]

- Xing, L.; Zhang, H.; Zhu, Y.; Yang, Y. Review of Nondestructive Testing of Magnetic Conductivity of Iron and Steel. Coll. Phys. Exp. 2013, 26, 31–35. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Zairi, S. Pulsed Magnetic Flux Leakage Techniques for Crack Detection and Characterisation. Sens. Actuators A Phys. 2006, 125, 186–191. [Google Scholar] [CrossRef]

- Tehranchi, M.M.; Hamidi, S.M.; Eftekhari, H.; Karbaschi, M.; Ranjbaran, M. The Inspection of Magnetic Flux Leakage from Metal Surface Cracks by Magneto-Optical Sensors. Sens. Actuators A Phys. 2011, 172, 365–368. [Google Scholar] [CrossRef]

- Li, Y.; Wilson, J.; Tian, G.Y. Experiment and Simulation Study of 3D Magnetic Field Sensing for Magnetic Flux Leakage Defect Characterisation. NDT E Int. 2007, 40, 179–184. [Google Scholar] [CrossRef]

- Clark, R. Rail Flaw Detection: Overview and Needs for Future Developments. NDT E Int. 2004, 37, 111–118. [Google Scholar] [CrossRef]

- Wang, P.; Ding, S.; Tian, G.; Wang, H.; Yang, Y. Electromagnetic Testing of High-speed Railway Steel Rails. Nondestruct. Test. 2010, 32, 829–832+835. [Google Scholar]

- Gao, Y.; Wang, P.; Tian, G.; Wang, H.; Xiong, L.; Hao, S. Analysis of Dynamic Magnetization and Speed Effect in High-speed Magnetic Particle Inspection of Rail Cracks. Nondestruct. Test. 2013, 35, 53–58. [Google Scholar]

- Gao, Y.; Wang, P.; Tian, G.; Hao, S.; Xiong, L. High-speed Online Inspection Method for Rail Cracks Based on Electromagnetic Principles. Nondestruct. Test. 2012, 34, 1–11. [Google Scholar]

- Xiong, L. Research on Magnetic Particle Inspection Technology for Rail Cracks. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2014. [Google Scholar]

- Xu, Q.; Shi, Y.; Xiong, L.; Wang, P. Research on Magnetic Particle Inspection Technology for Top Surface Damage Based on Large-scale Rail Flaw Detection Vehicle. China Railw. 2017, 664, 39–44. [Google Scholar] [CrossRef]

- Antipov, A.G.; Markov, A.A. Evaluation of Transverse Cracks Detection Depth in MFL Rail NDT. Russ. J. Nondestruct. Test. 2014, 50, 481–490. [Google Scholar] [CrossRef]

- Santa-aho, S.; Sorsa, A.; Nurmikolu, A.; Vippola, M. Review of Railway Track Applications of Barkhausen Noise and Other Magnetic Testing Methods. Insight 2014, 56, 657–663. [Google Scholar] [CrossRef]

- Neslušan, M.; Čížek, J.; Kolařík, K.; Minárik, P.; Čilliková, M.; Melikhova, O. Monitoring of Grinding Burn via Barkhausen Noise Emission in Case-Hardened Steel in Large-Bearing Production. J. Mater. Process. Technol. 2017, 240, 104–117. [Google Scholar] [CrossRef]

- Čížek, J.; Neslušan, M.; Čilliková, M.; Mičietová, A.; Melikhova, O. Modification of Steel Surfaces Induced by Turning: Non-Destructive Characterization Using Barkhausen Noise and Positron Annihilation. J. Phys. D Appl. Phys. 2014, 47, 445301. [Google Scholar] [CrossRef]

- Anglada-Rivera, J.; Padovese, L.R.; Capó-Sánchez, J. Magnetic Barkhausen Noise and Hysteresis Loop in Commercial Carbon Steel: Influence of Applied Tensile Stress and Grain Size. J. Magn. Magn. Mater. 2001, 231, 299–306. [Google Scholar] [CrossRef]

- Li, Q.; Miao, L.; Wang, R.; Sun, Y.; Zou, H. Nondestructive Measurement of Hardness of Ferromagnetic Materials Using Barkhausen Noise Test Research. J. North. Jiaotong Univ. 2000, 24, 84–86. [Google Scholar] [CrossRef]

- Neslušan, M.; Zgútová, K.; Kolařík, K.; Šramek, J.; Čapek, J. Analysis of Structure Transformations in Rail Surface Induced by Plastic Deformation via Barkhausen Noise Emission. Acta Phys. Pol. A 2017, 131, 1099–1101. [Google Scholar] [CrossRef]

- Neslušan, M.; Čížek, J.; Zgútová, K.; Kejzlar, P.; Šramek, J.; Čapek, J.; Hruška, P.; Melikhova, O. Microstructural Transformation of a Rail Surface Induced by Severe Thermoplastic Deformation and Its Non-Destructive Monitoring via Barkhausen Noise. Wear 2018, 402–403, 38–48. [Google Scholar] [CrossRef]

- Jiang, S.; Ding, H.; Zhang, X.; Peng, J.; Wang, W.; Liu, Q.; Guo, J. Nondestructive Testing of White Layer on Rails Based on Magnetic Barkhausen Noise. J. Mech. Eng. 2021, 57, 49–56. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, L.; Zhu, Q.; Ji, X.; Wang, H.; Tian, G.; Yao, E. An Application of Back Propagation Neural Network for the Steel Stress Detection Based on Barkhausen Noise Theory. NDT E Int. 2013, 55, 9–14. [Google Scholar] [CrossRef]

- Tian, G.; Gao, B.; Gao, Y.; Wang, P.; Wang, H.; Shi, Y. Review of Rail Defect Damage Inspection and Monitoring. Chin. J. Sci. Instrum. 2016, 37, 1763–1780. [Google Scholar] [CrossRef]

- Khan, S.H.; Ali, F.; Khan, A.N.; Iqbal, M.A. Eddy Current Detection of Changes in Stainless Steel after Cold Reduction. Comput. Mater. Sci. 2008, 43, 623–628. [Google Scholar] [CrossRef]

- Li, G.; Huang, P.; Chen, P.; Hou, D.; Zhang, G.; Zhou, Z. Application of Eddy Current Testing in Quantitative Evaluation of Rail Cracks. J. Zhejiang Univ. (Eng. Sci.) 2011, 45, 2038–2042+2049. [Google Scholar] [CrossRef]

- Xiong, L.; Liu, X.; Zhang, Y.; Shi, Y.; Zhang, Y.; Chen, Z. Identification of High-speed Railway Wheel Burn Based on Eddy Current Testing. Railw. Eng. 2022, 62, 8–12. [Google Scholar] [CrossRef]

- Thomas, H.-M.; Heckel, T.; Hanspach, G. Advantage of a Combined Ultrasonic and Eddy Current Examination for Railway Inspection Trains. Insight-Non-Destr. Test. Cond. Monit. 2007, 49, 341–344. [Google Scholar] [CrossRef]

- Anandika, R.; Lundberg, J. Limitations of Eddy Current Inspection for the Characterization of Near-Surface Cracks in Railheads. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 532–544. [Google Scholar] [CrossRef]

- Huang, F. Quantitative Evaluation Method of Eddy Current Detection for Rail Surface Crack. China Railw. Sci. 2017, 38, 28–33. [Google Scholar] [CrossRef]

- Ramos, H.M.G.; Rocha, T.; Pasadas, D.; Ribeiro, A.L. Velocity Induced Eddy Currents Technique to Inspect Cracks in Moving Conducting Media. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; IEEE: Minneapolis, MN, USA, 2013; pp. 931–934. [Google Scholar]

- Liu, Z.; Li, W.; Xue, F.; Xiafang, J.; Bu, B.; Yi, Z. Electromagnetic Tomography Rail Defect Inspection. IEEE Trans. Magn. 2015, 51, 6201907. [Google Scholar] [CrossRef]

- Mićić, M.; Brajović, L.; Lazarević, L.; Popović, Z. Inspection of RCF Rail Defects—Review of NDT Methods. Mech. Syst. Signal Process. 2023, 182, 109568. [Google Scholar] [CrossRef]

- Huang, F.; Wang, X.; An, S.; Shi, Q. Research on Eddy Current Testing Technology for Turnout Rail Surface. Railw. Tech. Superv. 2019, 47, 25–28+33. [Google Scholar] [CrossRef]

- Hu, Q.; Zhao, W.; Zeng, X.; Hou, K.; Wang, D.; Wu, X.; Yang, G.; Xu, Q.A. Method and Device for Eddy Current Testing of Surface Cracks on Rails. CN202010424106.X, 11 August 2020. [Google Scholar]

- Park, J.W.; Lee, T.G.; Back, I.C.; Park, S.J.; Seo, J.M.; Choi, W.J.; Kwon, S.G. Rail Surface Defect Detection and Analysis Using Multi-Channel Eddy Current Method Based Algorithm for Defect Evaluation. J. Nondestruct. Eval. 2021, 40, 83. [Google Scholar] [CrossRef]

- Hase, A.; Mishina, H.; Wada, M. Correlation between Features of Acoustic Emission Signals and Mechanical Wear Mechanisms. Wear 2012, 292–293, 144–150. [Google Scholar] [CrossRef]

- Geng, R.; Jing, P. Application of Acoustic Emission Technology in Full-scale Aircraft Fatigue Test. Appl. Acoust. 2013, 32, 246–251. [Google Scholar]

- Sim, H.Y.; Ramli, R.; Saifizul, A.A.; Abdullah, M.A.K. Empirical Investigation of Acoustic Emission Signals for Valve Failure Identification by Using Statistical Method. Measurement 2014, 58, 165–174. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Hu, H.; Sun, M.; Shen, Y. Research and Application of Acoustic Emission Technology in Railway System Detection. Appl. Acoust. 2017, 36, 189–199. [Google Scholar] [CrossRef]

- Anastasopoulos, A.; Bollas, K.; Papasalouros, D.; Kourousis, D. Acoustic Emission On-Line Inspection of Rail Wheels. In Proceedings of the 29th Eur. Conf. Acoust. Emission Testing, Citeseer, Vienna, Austria, 8–10 September 2010; pp. 1–8. [Google Scholar]

- Murav’ev, V.V.; Murav’ev, M.V.; Murav’ev, T.V. The Possibilities of Acoustic Emission Testing of Rails during Exploitation. Russ. J. Nondestruct. Test. 2008, 44, 33–40. [Google Scholar] [CrossRef]

- Bianchi, D.; Mayrhofer, E.; Gröschl, M.; Betz, G.; Vernes, A. Wavelet Packet Transform for Detection of Single Events in Acoustic Emission Signals. Mech. Syst. Signal Process. 2015, 64–65, 441–451. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, N.; Wang, Y.; Shen, Y. Acoustic Emission Detection of Rail Defect Based on Wavelet Transform and Shannon Entropy. J. Sound Vib. 2015, 339, 419–432. [Google Scholar] [CrossRef]

- Bollas, K.; Papasalouros, D.; Kourousis, D.; Anastasopoulos, A. Acoustic Emission Inspection of Rail Wheels. J. Acoust. Emiss. 2010, 28, 215–228. [Google Scholar]

- Guo, Y.B.; Ammula, S.C. Real-Time Acoustic Emission Monitoring for Surface Damage in Hard Machining. Int. J. Mach. Tools Manuf. 2005, 45, 1622–1627. [Google Scholar] [CrossRef]

- Jiang, P. Research on Acoustic Emission Characteristics of Martensitic Transformation Process Based on Information Entropy. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2012. [Google Scholar]

- Jiang, P.; Dai, G.; Jiang, C. Experimental Study on Acoustic Emission of Martensitic Transformation Process of GCr15 Steel. Hot Work. Technol. 2012, 41, 36–38+42. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, L.; Wang, X.; Li, W. Acoustic Emission Characteristics of Martensitic Transformation of Metal Materials. Nondestruct. Test. 2016, 38, 22–25. [Google Scholar] [CrossRef]

- Dai, J.; Wang, Z. Infrared Thermal Imaging Nondestructive Testing Technology and Its Application Status. Tech. Autom. Appl. 2007, 26, 1–7. [Google Scholar] [CrossRef]

- Bai, L. Research on Eddy Current Pulsed Thermal Imaging Nondestructive Testing Technology. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2013. [Google Scholar]

- Peng, J. Research on the Method of Detecting Rail Rolling Contact Fatigue by Eddy Current Pulsed Thermal Imaging. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

- Peng, J.; Tian, G.; Wang, L.; Zhang, Y.; Li, K.; Gao, X. Investigation into Eddy Current Pulsed Thermography for Rolling Contact Fatigue Detection and Characterization. NDT E Int. 2015, 74, 72–80. [Google Scholar] [CrossRef]

- Bai, J.; Peng, J.; Zhang, K.; Feng, L.; Gao, X. Detection of Steady-state Closed Fatigue Cracks Based on Eddy Current Pulsed Thermal Imaging Method. Nondestruct. Test. 2018, 40, 12–16+86. [Google Scholar] [CrossRef]

- Feng, L.; Peng, J.; Zhang, K.; Bai, J.; Gao, X. Research on Eddy Current Pulsed Thermography for Squats in Railway. In Proceedings of the 2018 International Conference on Quantitative InfraRed Thermography, Berlin, Germany, 25–29 June 2018; QIRT Council: Queens, Australia, 2018. [Google Scholar]

- Xu, C. Pulsed Infrared Thermal Imaging and Lock-in Thermal Imaging. Master’s Thesis, Capital Normal University, Beijing, China, 2008. [Google Scholar]

- Peng, D.; Jones, R. NDI of Rail Squats and Estimating Defect Size and Location Using Lock-In Thermography. ENG 2013, 05, 29–38. [Google Scholar] [CrossRef]

- Peng, D.; Jones, R. Lock-in Thermographic Inspection of Squats on Rail Steel Head. Infrared Phys. Technol. 2013, 57, 89–95. [Google Scholar] [CrossRef]

- Lv, B. Experimental Study on Fatigue Crack Propagation of U71Mn Steel Rail Based on Infrared Thermal Imaging. Master’s Thesis, Dalian University of Technology, Dalian, China, 2014. [Google Scholar]

- Liu, J.; Zhang, Z.; Lin, Z.; Yin, L. Depth Detection of Metal Surface Defects Based on Laser Thermal Imaging. Laser Optoelectron. Prog. 2021, 58, 411002. [Google Scholar] [CrossRef]

- Dell’Avvocato, G.; Palumbo, D.; Palmieri, M.; Galietti, U. Evaluation of Effectiveness of Heat Treatments in Boron Steel by Laser Thermography. In Proceedings of the 16th International Workshop on Advanced Infrared Technology & Applications, Online, 26–28 October 2021; MDPI: Basel, Switzerland, 2021; p. 8. [Google Scholar]

- Ding, Z. Research on Rail Surface Defect Detection Technology Based on Machine Vision. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2017. [Google Scholar]

- Xu, G.; Shi, T.; Ren, S.; Han, Q.; Wang, D. Development of Vehicle-mounted Track Inspection System Based on Computer Vision. China Railw. Sci. 2013, 34, 139–144. [Google Scholar] [CrossRef]

- Han, Q.; Dai, P.; Tan, S.; Li, Y.; Ren, S.; Zhou, W.; Zhang, Y. Development of Vehicle-mounted Track Inspection System. Railw. Eng. 2014, 489, 144–147. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, E.; Fang, Y.; Han, Q. Development and Application of Vehicle-mounted Track Condition Inspection Technology. China Railw. 2017, 91–95. [Google Scholar] [CrossRef]

- Ren, S.; Li, Q.; Xu, G.; Han, Q.; Luo, S.; Feng, Q. Research on Robust Real-time Wheel Burn Detection Algorithm. China Railw. Sci. 2011, 32, 25–29. [Google Scholar]

- Zhao, H.; Huang, Y.; Wang, S.; Li, Q. An Improved Algorithm for Wheel Burn Detection Based on Spatial Filtering. Comput. Sci. 2014, 41, 130–133+137. [Google Scholar] [CrossRef]

- Li, Q.; Liang, Z.; Huang, Y.; Shi, Z. Sparse Representation Model for Defect Detection and Its Application. J. Comput. Res. Dev. 2014, 51, 1929–1935. [Google Scholar] [CrossRef]

- Santur, Y.; Karakose, M.; Akin, E. Chouqet Fuzzy Integral Based Condition Monitoring and Analysis Approach Using Simulation Framework for Rail Faults. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; IEEE: Poitiers, France, 2016; pp. 345–350. [Google Scholar]

- Santur, Y.; Karakose, M.; Akin, E. A New Rail Inspection Method Based on Deep Learning Using Laser Cameras. In Proceedings of the 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), Malatya, Turkey, 16–17 September 2017; IEEE: Malatya, Turkey, 2017; pp. 1–6. [Google Scholar]

- Shang, L.; Yang, Q.; Wang, J.; Li, S.; Lei, W. Detection of Rail Surface Defects Based on CNN Image Recognition and Classification. In Proceedings of the 2018 20th International Conference on Advanced Communication Technology (ICACT), Chuncheon, Republic of Korea, 11–14 February 2018; IEEE: Chuncheon, Republic of Korea, 2018; pp. 45–51. [Google Scholar]

- Bai, T.; Gao, J.; Yang, J.; Yao, D. A Study on Railway Surface Defects Detection Based on Machine Vision. Entropy 2021, 23, 1437. [Google Scholar] [CrossRef]

- Wu, N.; Wen, B.; Wang, L. Research on High-speed Railway Track State Detection Method Based on Variance Analysis of Axle Box Acceleration. Railw. Locomot. Car 2012, 32, 29–32. [Google Scholar] [CrossRef]

- Molodova, M.; Li, Z.; Nunez, A.; Dollevoet, R. Monitoring the Railway Infrastructure: Detection of Surface Defects Using Wavelets. In Proceedings of the International IEEE Conference on Intelligent Transportation Systems, Hague, The Netherlands, 6–9 October 2013. [Google Scholar]

- Li, Z.; Molodova, M.; Nunez, A.; Dollevoet, R. Improvements in Axle Box Acceleration Measurements for the Detection of Light Squats in Railway Infrastructure. IEEE Trans. Ind. Electron. 2015, 62, 4385–4397. [Google Scholar] [CrossRef]

- Cao, X.; Chai, X.; Zheng, S. Analysis of Axle Box Acceleration Signal of Track Vehicle Based on Hilbert-Huang Transform. Instrum. Tech. Sens. 2015, 386, 92–95. [Google Scholar] [CrossRef]

- Jamshidi, A.; Núñez, A.; Molodova, M.; Li, Z.; Dollevoet, R. Key Performance Indicators Using Robust Prediction Modelling to Consider Squats in Railway Infrastructure. In Proceedings of the 3rd International Conference on Railway Technology: Research, Development and Maintenance: RAILWAYS 2016, Cagliari, Italy, 5–8 April 2016; Civil-Comp Press: Cagliari, Italy, 2016; pp. 1–10. [Google Scholar]

- Liu, J.; Chen, D.; Zhao, G.; Liu, L.; Sun, S.; Guo, J.; Liang, Z. Track Impact Index Method for Evaluating Short-wave Unevenness Diseases of High-speed Railway Track. China Railw. Sci. 2016, 37, 34–41. [Google Scholar] [CrossRef]

- Xu, X.; Mao, X.; Sun, S.; Niu, L.; Liu, J.; Xiao, B. Dynamic Diagnosis Method for Continuous and Equidistant Wheel Burn Based on Axle Box Acceleration. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing), Nanjing, China, 15–17 October 2021; IEEE: Nanjing, China, 2021; pp. 1–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).