Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision

Abstract

1. Introduction

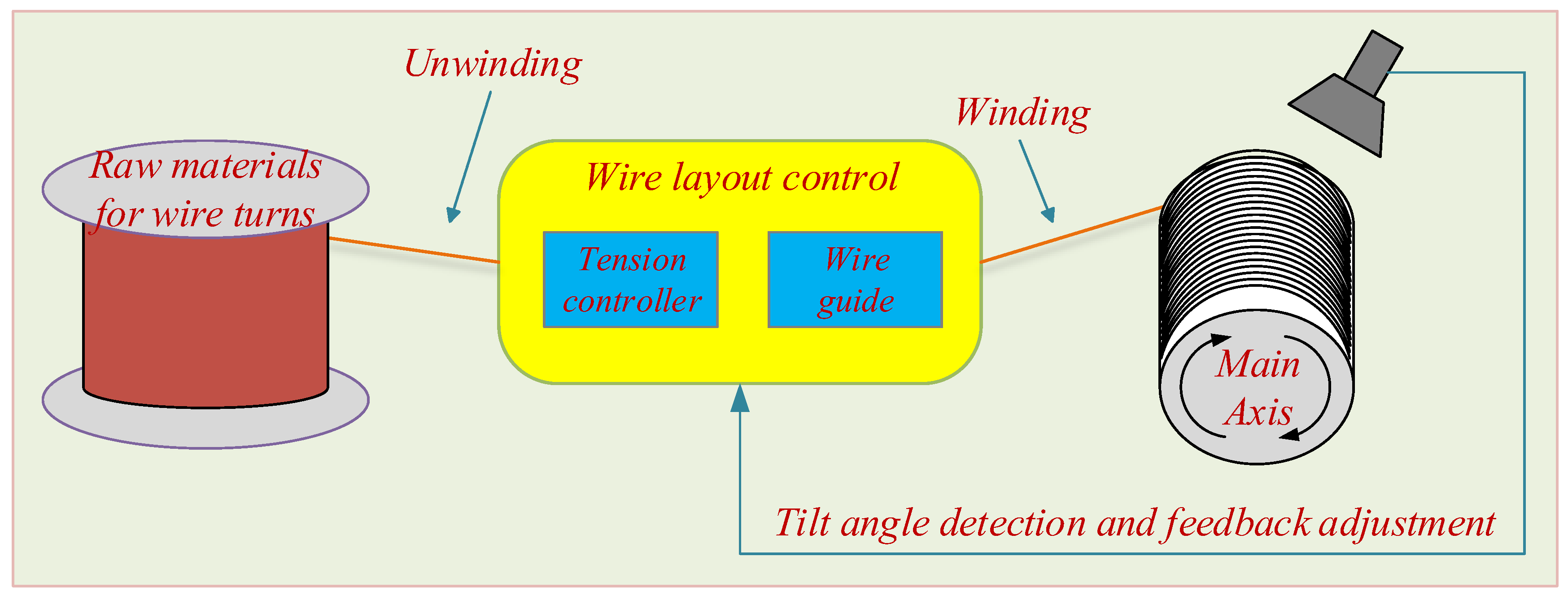

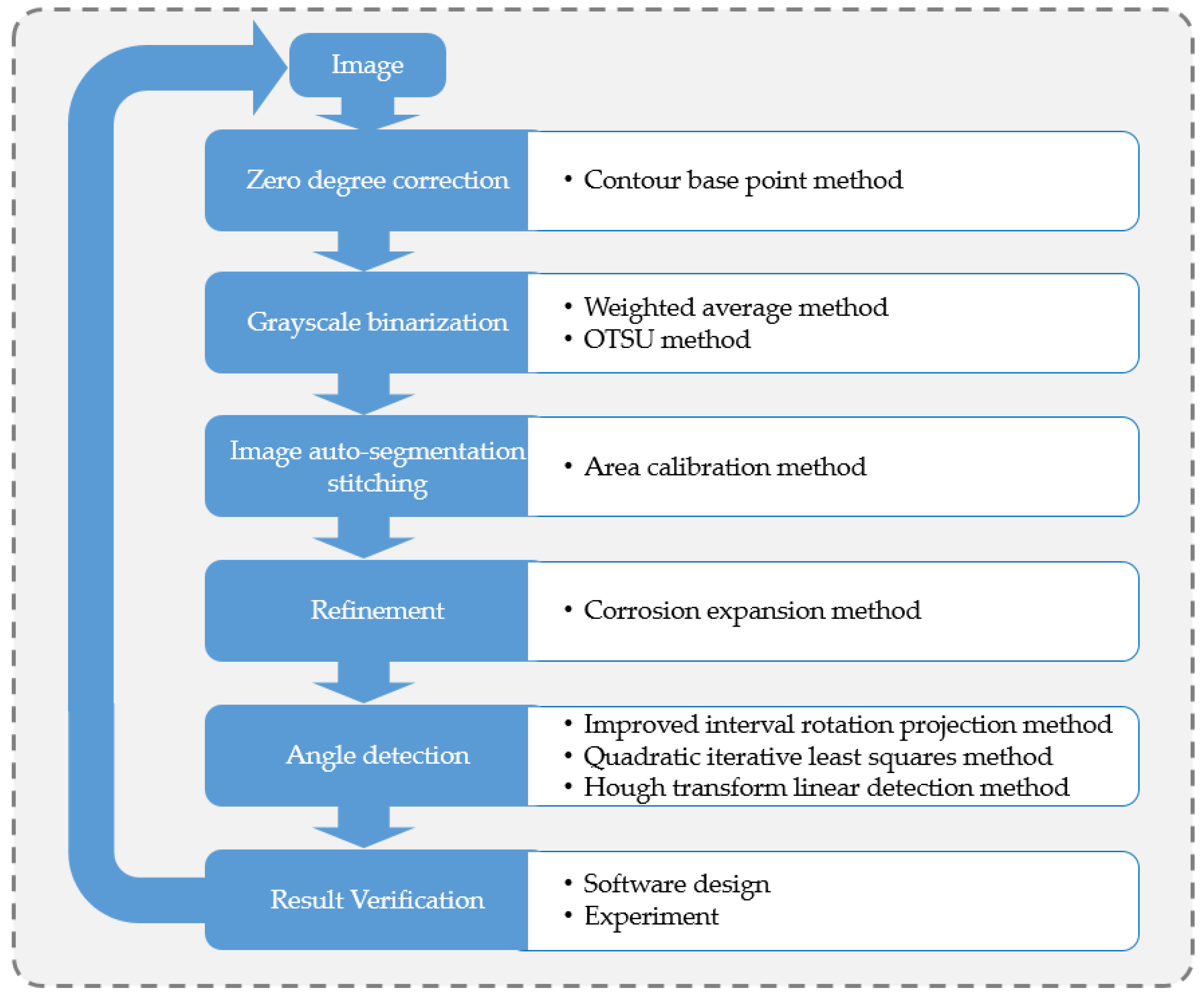

2. Methods Design

3. Image Preprocessing

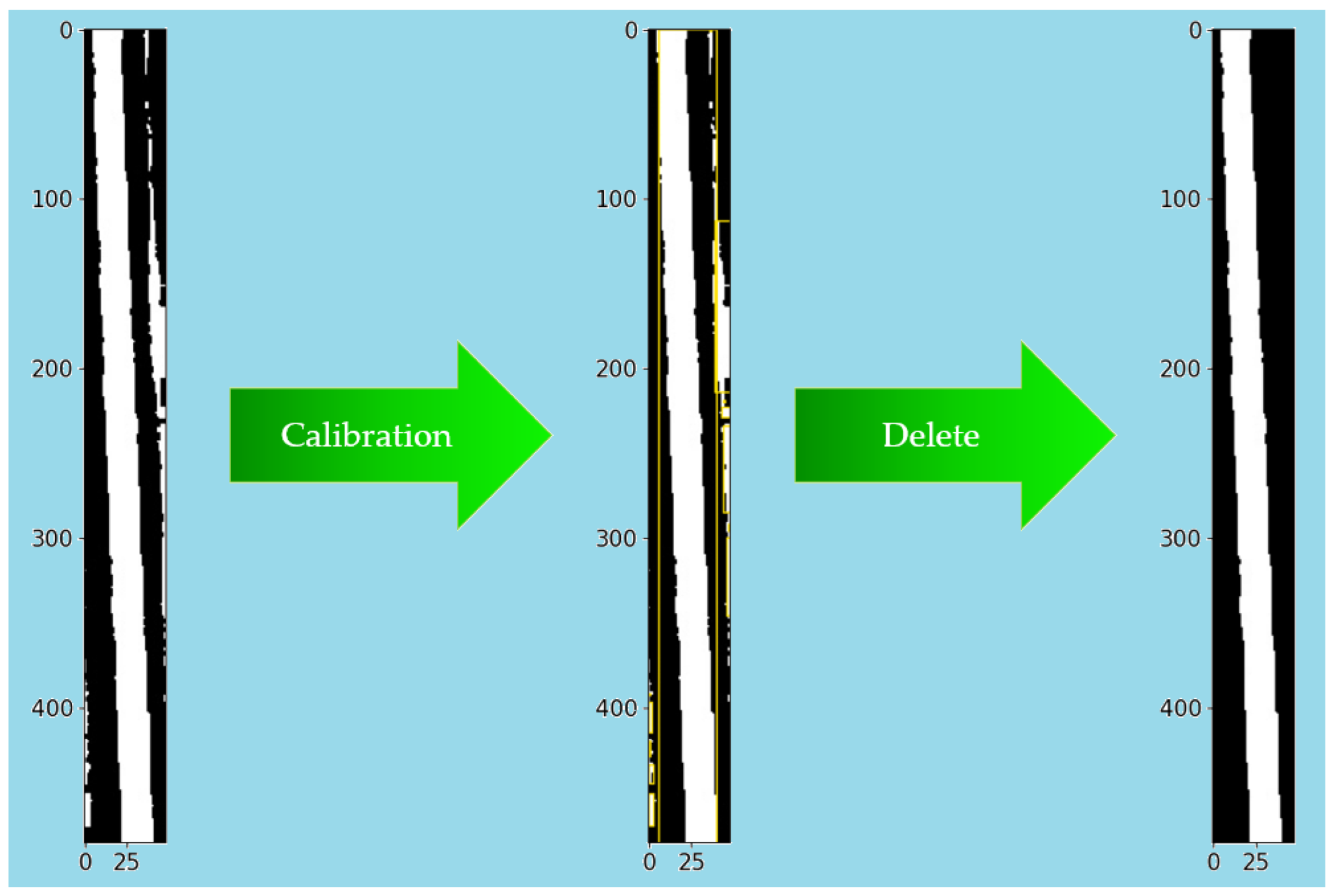

3.1. 0° Correction

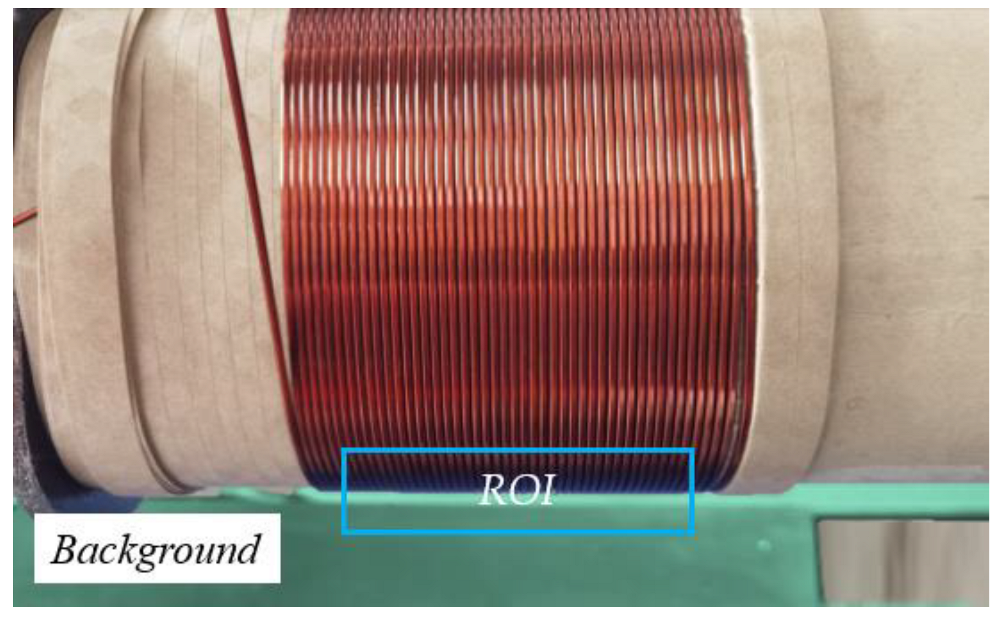

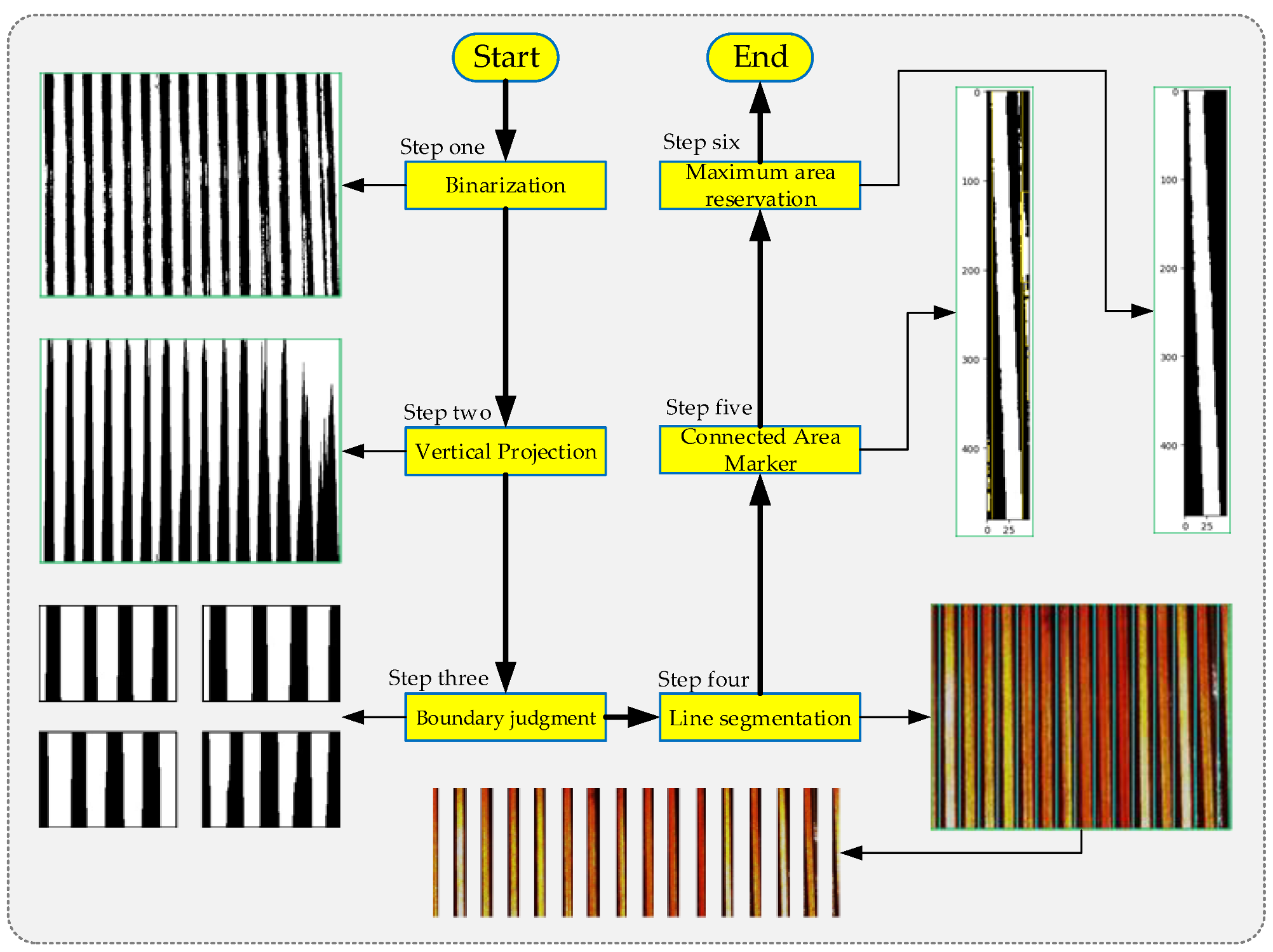

3.2. Detection of Location Segmentation

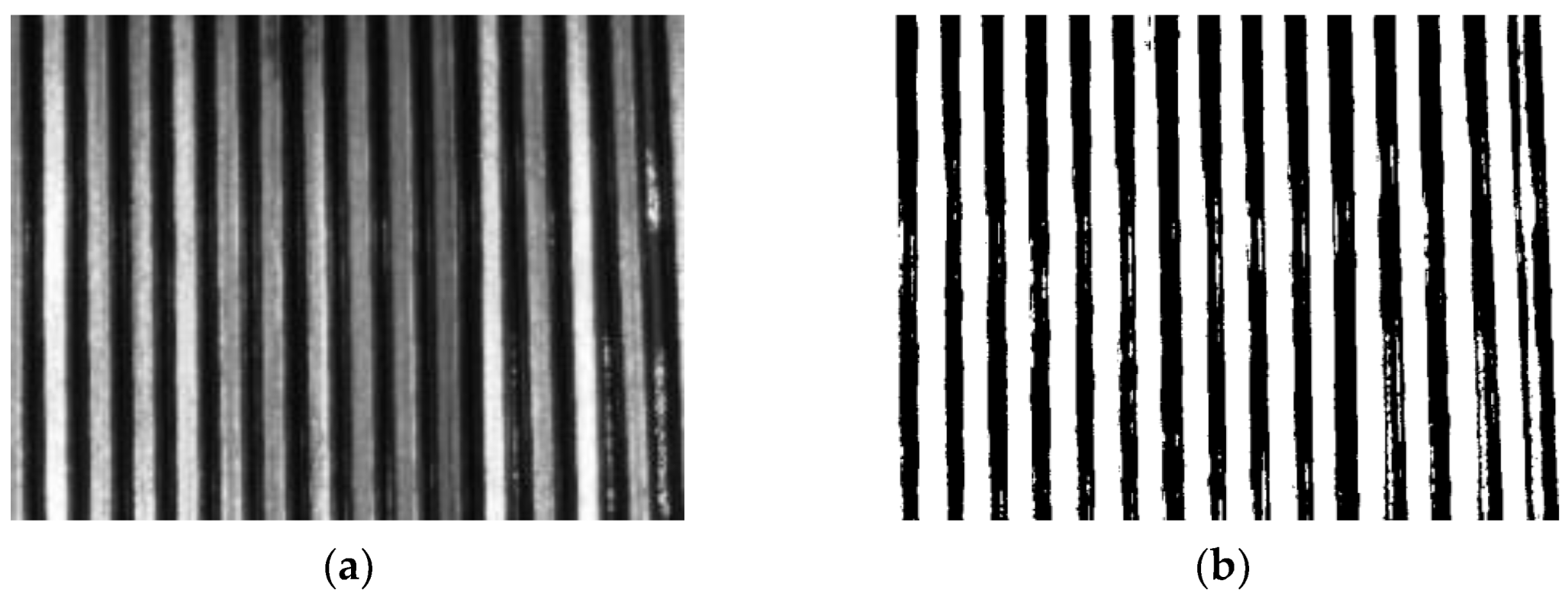

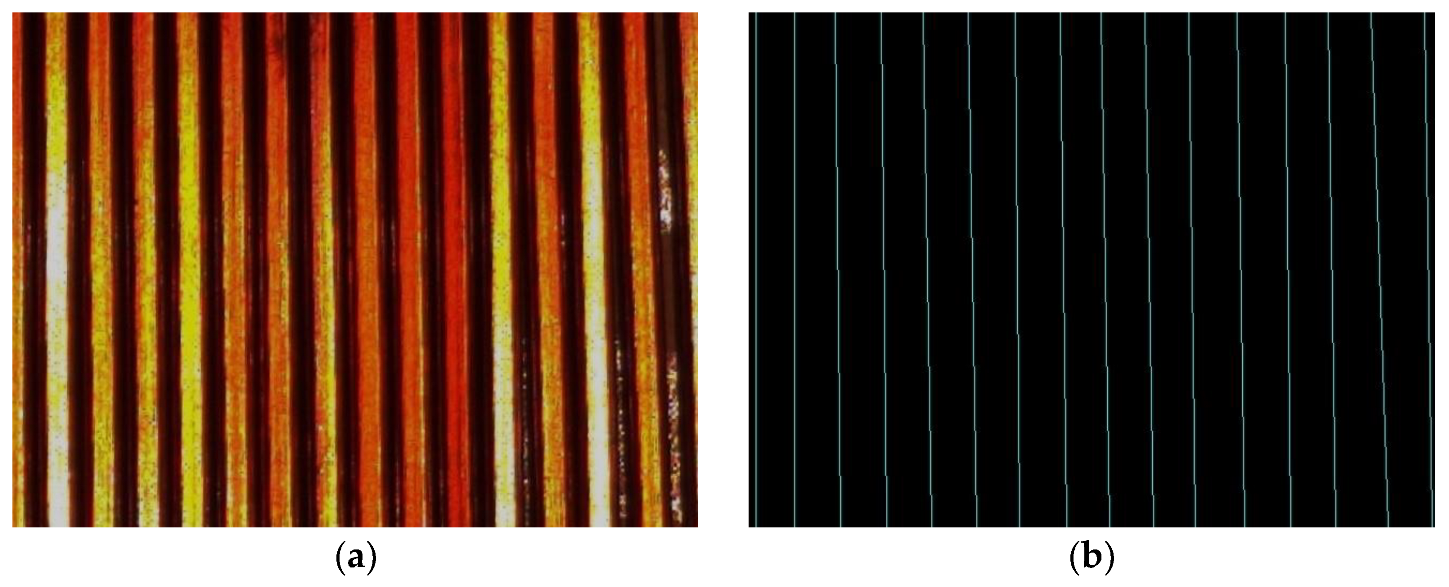

3.3. Grayscale Binarization

- Calculate the histogram of the grayscale image and calculate the number of pixels occupied by each pixel value from 0 to 255.

- Iterate through the threshold values 0–255, with pixels less than or equal to the threshold value being the background and pixels greater than the threshold value being the foreground.

- Calculate the ratio of the number of background pixels to the total number of pixels and the average value of the background pixels.

- Calculate the proportion of the number of foreground pixels to the total number of pixels and the average value of the foreground pixels.

- Calculate the interclass variance or intraclass variance, when the threshold that maximizes the interclass variance or minimizes the intraclass variance is the optimal threshold.

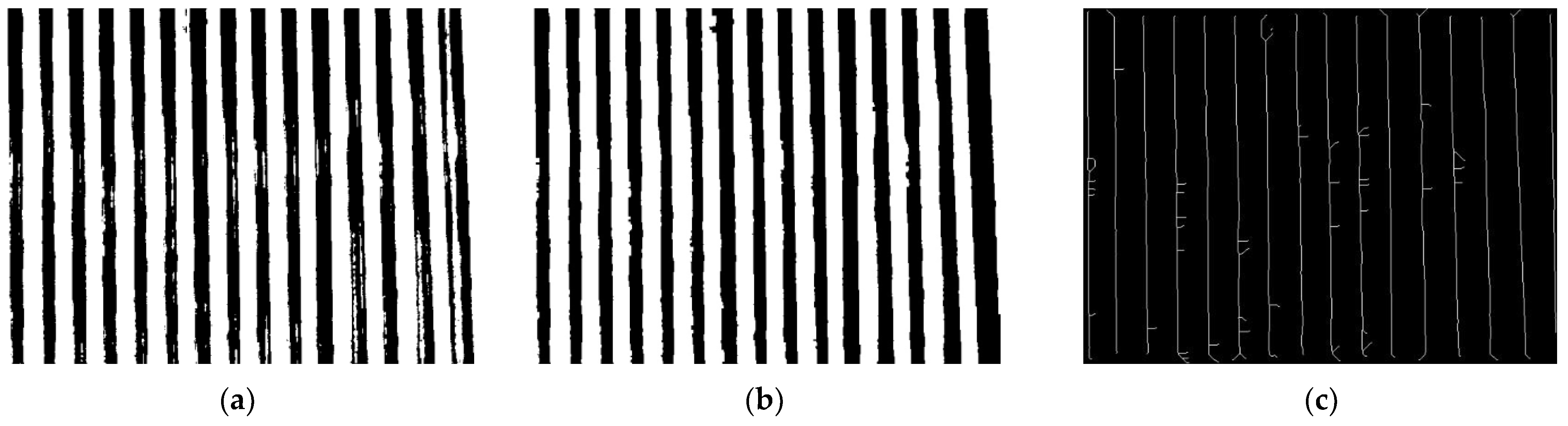

- Binarize the image using the best threshold. After the binarization process, the binarized image obtained from the grayscale image is shown in Figure 9b.

3.4. Image Self-Segmentation and Splicing

3.5. Skeleton Extraction

- First, use the etching operation on the image; each time the etching becomes narrower and thinner.

- Perform image open operation processing; some pixels of the image will be deleted, and these deleted pixels are part of the skeleton.

- Add the deleted pixels to the skeleton map.

- When the sample image is eroded to no pixels, end the iteration, and finally obtain the skeleton image of the previous step.

4. Detection Method

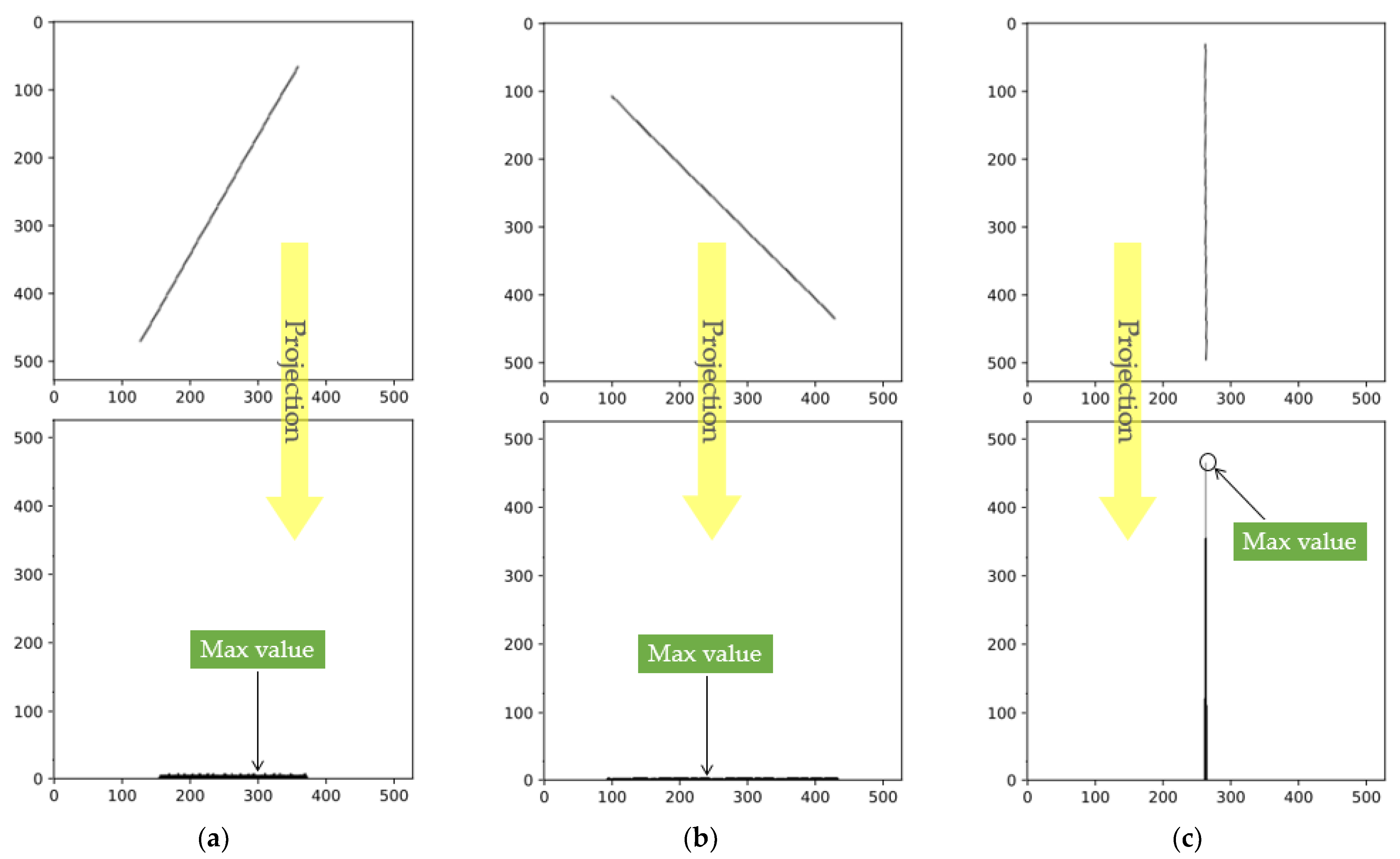

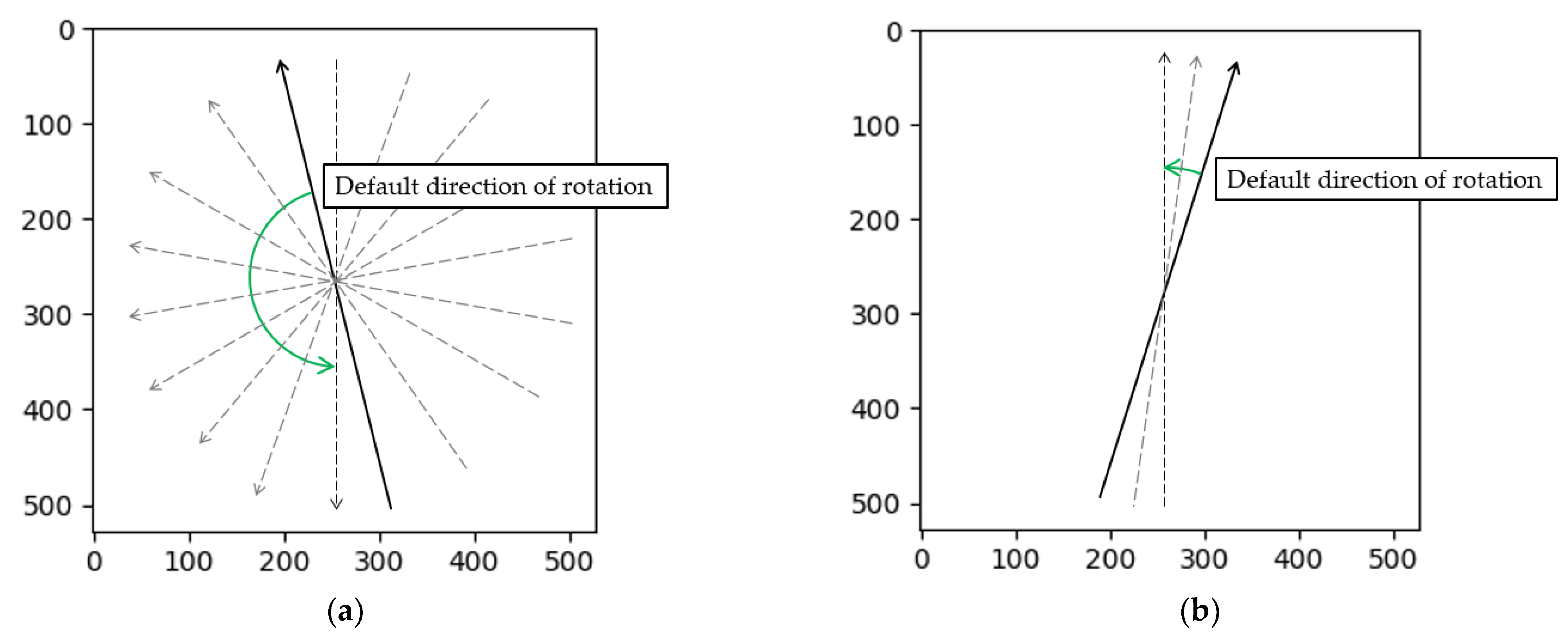

4.1. Improved Interval Rotation Projection Method

4.2. Quadratic Iterative Least Squares

- Perform a least squares fit on the initial data points to obtain the first fitting result;

- Calculate the vertical distance of all data points to the first fitting result;

- Set a threshold for the vertical distance and exclude the data points whose distance exceeds the threshold;

- Perform another least squares fit on the remaining points to obtain the second fitting result.

4.3. Hough Transform Linear Detection Method

- Randomly select foreground points in the edge image and map them to a polar coordinate system to draw curves.

- When the curves intersect in the polar coordinate system and reach the minimum threshold, find the position of the intersection in the image space.

- Search for points on the edge image that are on this line, connect them to form line segments, and record the starting and ending coordinates.

- Repeat steps 1–3, and the final fitted result is shown in Figure 25.

5. Experiment and Discussion

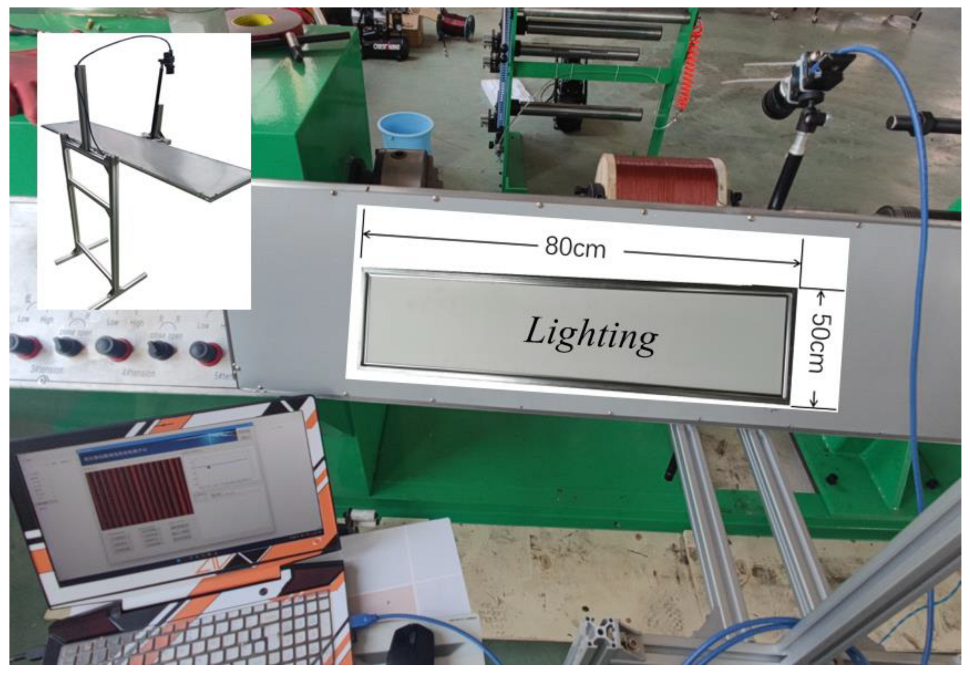

5.1. Software Design and Hardware Construction

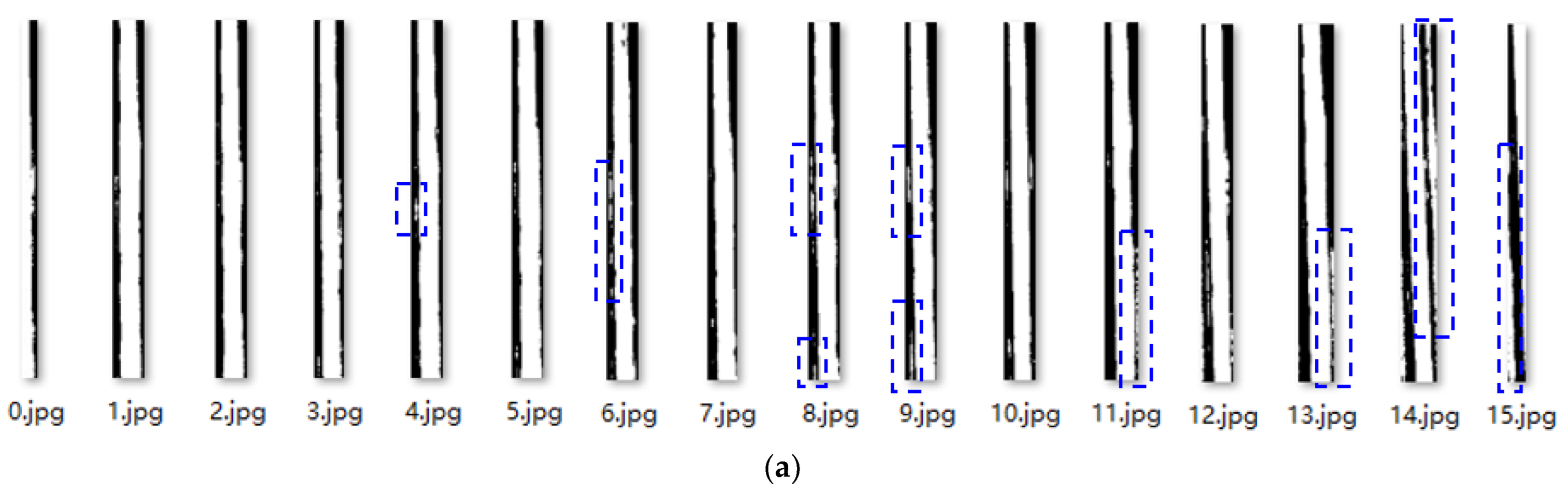

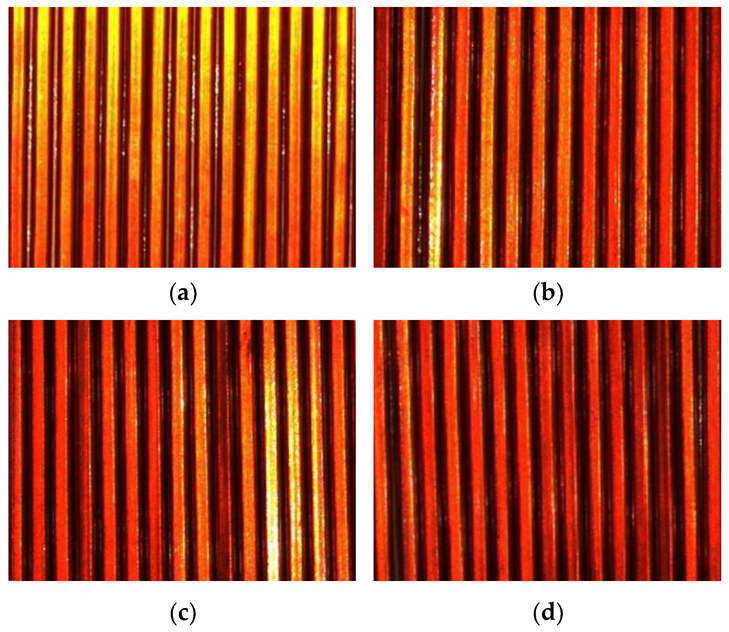

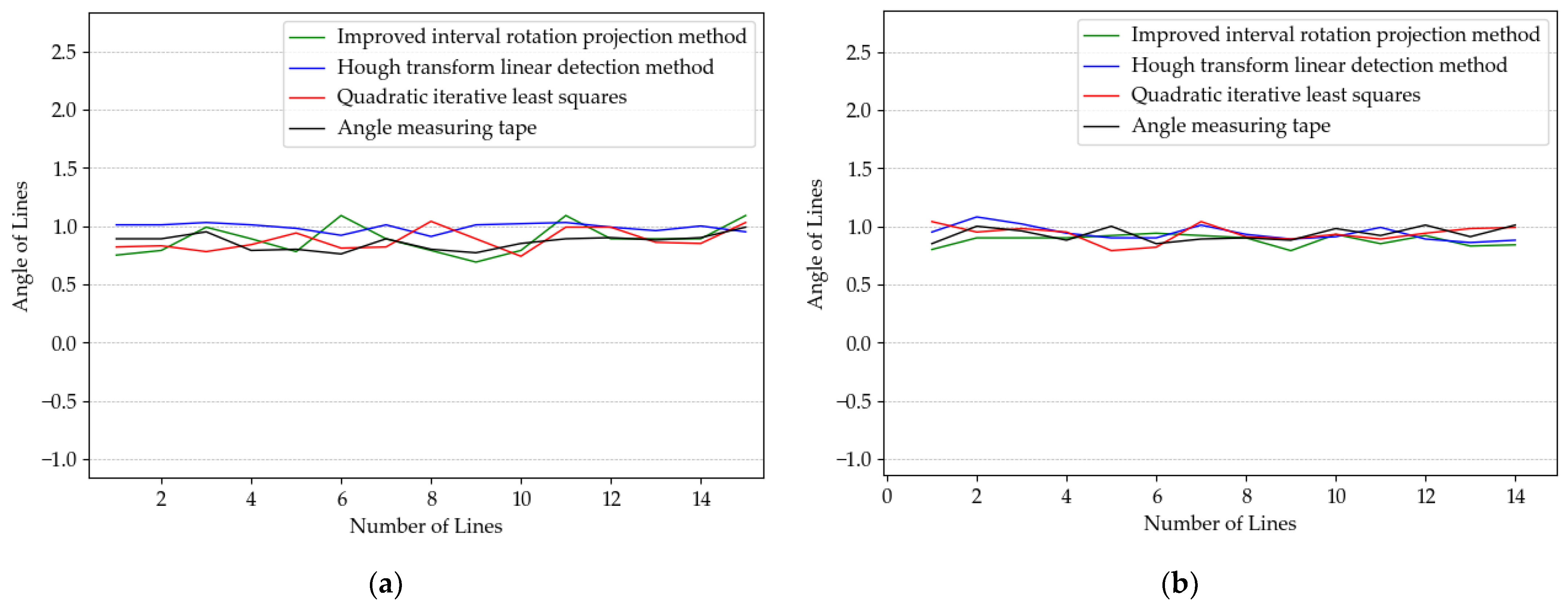

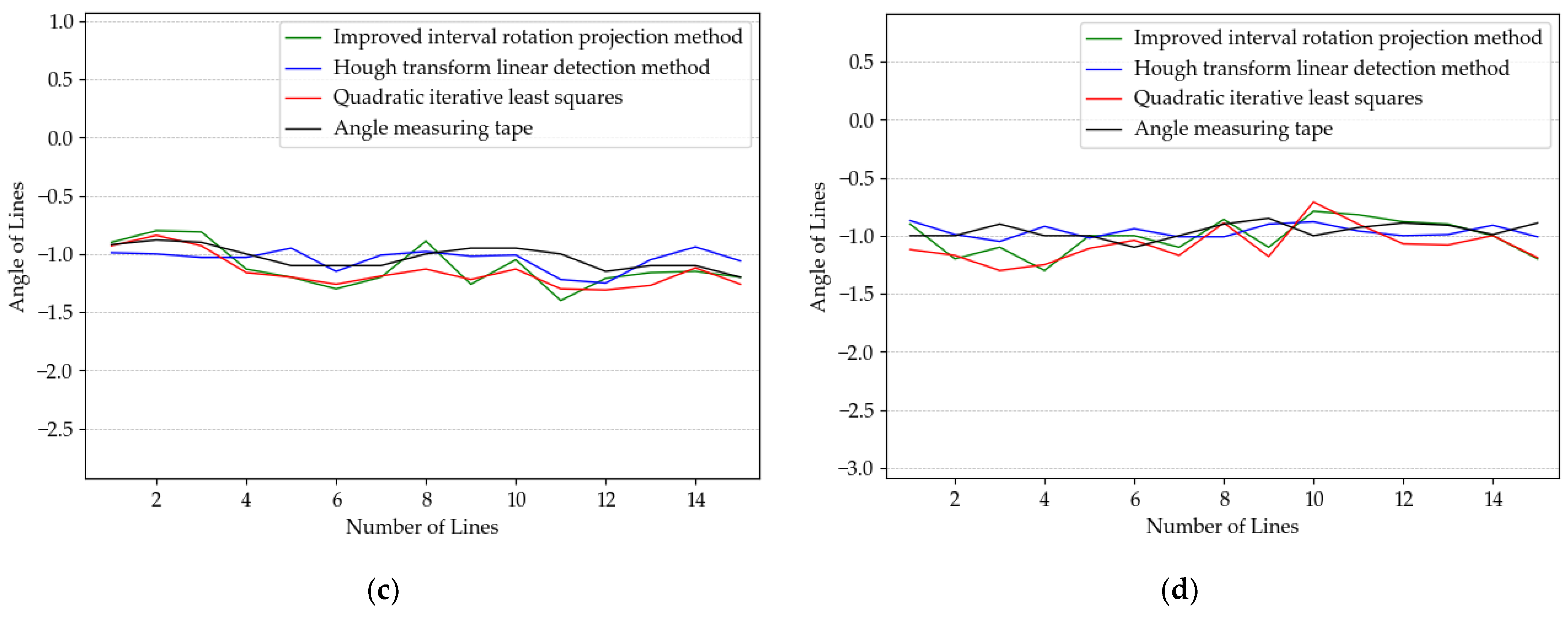

5.2. Single Conductor Winding Tilt Angle Detection Experiment

5.3. Multiconductor Winding Tilt Angle Detection Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amin, D.; Walvekar, R.; Khalid, M.; Vaka, M.; Mubarak, N.M.; Gupta, T.C.S.M. Recent Progress and Challenges in Transformer Oil Nanofluid Development: A Review on Thermal and Electrical Properties. IEEE Access 2019, 7, 151422–151438. [Google Scholar] [CrossRef]

- Lu, J.-S.; Cheng, M.-Y.; Su, K.-H.; Tsai, M.-C. Wire tension control of an automatic motor winding machine—An iterative learning sliding mode control approach. Robot. Comput.-Integr. Manuf. 2018, 50, 50–62. [Google Scholar] [CrossRef]

- Tran, Q.T.; Davies, K.; Roose, L.; Wiriyakitikun, P.; Janjampop, J.; Riva Sanseverino, E.; Zizzo, G. A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids. Appl. Sci. 2020, 10, 8115. [Google Scholar] [CrossRef]

- Atamanchuk, G.; Giraldo, O. Staged Investment for Intelligent Automatic Transformers Winding Manufacturing Lines. In Proceedings of the 2020 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Chicago, IL, USA, 12–15 October 2020; pp. 1–5. [Google Scholar]

- Sun, K.; Xu, J.; Zheng, S.; Zhang, N. Transformer High-Voltage Primary Coil Quality Detection Method Based on Machine Vision. Appl. Sci. 2023, 13, 1480. [Google Scholar] [CrossRef]

- Murugan, R.; Ramasamy, R. Understanding the power transformer component failures for health index-based maintenance planning in electric utilities. Eng. Fail. Anal. 2019, 96, 274–288. [Google Scholar] [CrossRef]

- Kwon, J.-W.; Kwon, B.-I. Design of Novel High Performance Dual Rotor Flux-Switching Drum Winding Machine. J. Electr. Eng. Technol. 2019, 14, 2019–2025. [Google Scholar] [CrossRef]

- Bönig, J.; Bickel, B.; Spahr, M.; Fischer, C.; Franke, J. Simulation of orthocyclic windings using the linear winding technique. In Proceedings of the 2015 5th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–16 September 2015; pp. 1–6. [Google Scholar]

- Liu, X.; Jin, S.; Yang, Z.; Krolczyk, G.; Li, Z. Measuring Shape Parameters of Pearls in Batches Using Machine Vision: A Case Study. Micromachines 2022, 13, 546. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, H.; Ren, G. Development and Application of Standard Device for Calibrating Steel Measuring Tape Based on Machine Vision. Appl. Sci. 2022, 12, 7262. [Google Scholar] [CrossRef]

- Hunt, A.J.; Carey, J.P. A machine vision system for the braid angle measurement of tubular braided structures. Text. Res. J. 2018, 89, 2919–2937. [Google Scholar] [CrossRef]

- Pei, L.; Xiao, Z.; Geng, L.; Wu, J.; Zhang, F.; Sun, Y. Surface parameters measurement for braided composite preform based on gray projection. J. Eng. Fibers Fabr. 2019, 14, 1558925019887621. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Wang, X.; Tian, G.; Fan, J. Machine Vision-Based Method for Measuring and Controlling the Angle of Conductive Slip Ring Brushes. Micromachines 2022, 13, 447. [Google Scholar] [CrossRef] [PubMed]

- Zambal, S.; Palfinger, W.; Stoger, M.; Eitzinger, C. Accurate fiber orientation measurement for carbon fiber surfaces. Pattern Recognit. 2015, 48, 3324–3332. [Google Scholar] [CrossRef]

- Hao, W. Design and Application of Mobile On-Line Inspection System for Enameled Wire Based on Machine Vision. Ph.D. Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2022. [Google Scholar]

- Vollbrecht, B.; Kohler, C.; Kolloch, M.; Jung, F.; Grigat, N.; Gries, T. Developing a camera-based measuring system to feedback control the fibre orientation for the braiding process of CFRP. Adv. Ind. Manuf. Eng. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Zhang, W. A visual recognition technology for optical fiber precision winding. Electron. Process Technol. 2015, 36, 172–174+178. [Google Scholar] [CrossRef]

- Xu, J.; He, X.; Ji, W. Mechanical System and Template-Matching-Based Position-Measuring Method for Automatic Spool Positioning and Loading in Welding Wire Winding. Appl. Sci. 2020, 10, 3762. [Google Scholar] [CrossRef]

- Ruiz-Rodriguez, I.; Pos, R.; Megaritis, T.; Ganippa, L.C. Investigation of Spray Angle Measurement Techniques. IEEE Access 2019, 7, 22276–22289. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Xu, K. Automatic Measurement of External Thread at the End of Sucker Rod Based on Machine Vision. Sensors 2022, 22, 8276. [Google Scholar] [CrossRef]

- Xiao, G.; Li, Y.; Xia, Q.; Cheng, X.; Chen, W. Research on the on-line dimensional accuracy measurement method of conical spun workpieces based on machine vision technology. Measurement 2019, 148, 106881. [Google Scholar] [CrossRef]

- Yang, X.; Ling, Y.; Li, S.; Hou, L.; Zhao, G.; Zeng, K. Graying for images with color-discrete characteristic. Optik 2011, 122, 1633–1637. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Ma, X.; Zheng, C.; Liang, Y. New method of SAR image contour matching based on significant contour features. J. Electron. Inf. Technol. 2021, 43, 3174–3184. [Google Scholar]

- Lv, Z.; Wang, F. Improved morphological skeleton extraction algorithm. Comput. Eng. 2009, 35, 23–25. [Google Scholar]

- Chang, Q.; Wu, M. Handwritten Chinese Character Skeleton Extraction Based on Improved ZS Refinement Algorithm. Comput. Appl. Softw. 2020, 37, 107–113+164. [Google Scholar]

- Naseri, M.; Heidari, S.; Gheibi, R.; Gong, L.-H.; Ahmadzadeh Rajii, M.; Sadri, A. A novel quantum binary images thinning algorithm: A quantum version of the Hilditch’s algorithm. Optik 2017, 131, 678–686. [Google Scholar] [CrossRef]

- Liu, H. The Research of Image Detection System of Fiber Tape Laying Based on Machine Vision. Ph.D. Thesis, Wuhan University Of Technology, Wuhan, China, 2008. [Google Scholar]

- Abdi, H. The Method of Least Squares. Encycl. Meas. Stat. 2007, 1, 530–532. [Google Scholar]

- Lang, M.C. An iterative reweighted least squares algorithm for constrained design of nonlinear phase FIR filters. In Proceedings of the 1998 IEEE International Symposium on Circuits and Systems (Cat. No. 98CH36187) (ISCAS’98), Monterey, CA, USA, 31 May–3 June 1998; IEEE: Washington, DC, USA, 1998; Volume 5, pp. 367–370. [Google Scholar]

- Hough, P. Method and Means for Recognizing Complex Patterns. U.S. Patent 3,069,654, 18 December 1962. [Google Scholar]

- Duda, R.; Hart, P. Use of the Hough transformation to detect lines and curves in pictures. Commun. ACM 1972, 15, 11–15. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Ma, M.; Chen, Z.; Yue, S.; He, T.; Xu, X. A High Precision Quality Inspection System for Steel Bars Based on Machine Vision. Sensors 2018, 18, 2732. [Google Scholar] [CrossRef]

| Physical Appearance | Parameter | |

|---|---|---|

| Industrial Camera | |

| Model | MER2-1220-32U3C | |

| Pixel resolution | 4024 × 3036 | |

| Pixel size | 1.85 μm × 1.85 μm | |

| Frame rate | 32.3 fps | |

| Lens | |

| Model | HN-1226-20M-C1/1X | |

| Focal length | 12 mm | |

| Maximum supported pixels | 20 million | |

| Distortion factor | 0.0 | |

| Improved Interval Rotation Projection Method | Quadratic Iterative Least Squares Method | Hough Transform Linear Detection Method | Angle Measuring Tape | |||||

|---|---|---|---|---|---|---|---|---|

| Angle (°) | Time (s) | Angle (°) | Time (s) | Angle (°) | Time (s) | Angle (°) | Time (s) | |

| Group 1 | 1.1 | 6.68 | 1.03 | 0.14 | 1.00 | 0.003 | 0.95 | 9.30 |

| Group 2 | 0.6 | 5.64 | 0.94 | 0.13 | 0.78 | 0.003 | 0.75 | 8.70 |

| Group 3 | −0.8 | 6.95 | −0.93 | 0.16 | −0.93 | 0.002 | −1.05 | 8.80 |

| Group 4 | 1.1 | 7.78 | 1.29 | 0.19 | 0.987 | 0.002 | 0.96 | 7.50 |

| Group 5 | −1.1 | 8.85 | −1.14 | 0.15 | −0.987 | 0.002 | −1.00 | 5.30 |

| Group 6 | −1.2 | 5.93 | −1.23 | 0.19 | −1.19 | 0.002 | −1.20 | 8.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zheng, S.; Sun, K.; Song, P. Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision. Sensors 2023, 23, 4755. https://doi.org/10.3390/s23104755

Xu J, Zheng S, Sun K, Song P. Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision. Sensors. 2023; 23(10):4755. https://doi.org/10.3390/s23104755

Chicago/Turabian StyleXu, Jiazhong, Shiyi Zheng, Kewei Sun, and Pengfei Song. 2023. "Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision" Sensors 23, no. 10: 4755. https://doi.org/10.3390/s23104755

APA StyleXu, J., Zheng, S., Sun, K., & Song, P. (2023). Research and Application of Contactless Measurement of Transformer Winding Tilt Angle Based on Machine Vision. Sensors, 23(10), 4755. https://doi.org/10.3390/s23104755