A Multi-Flow Production Line for Sorting of Eggs Using Image Processing

Abstract

1. Introduction

2. Related Studies

3. Materials and Methods

3.1. Experimental Setup

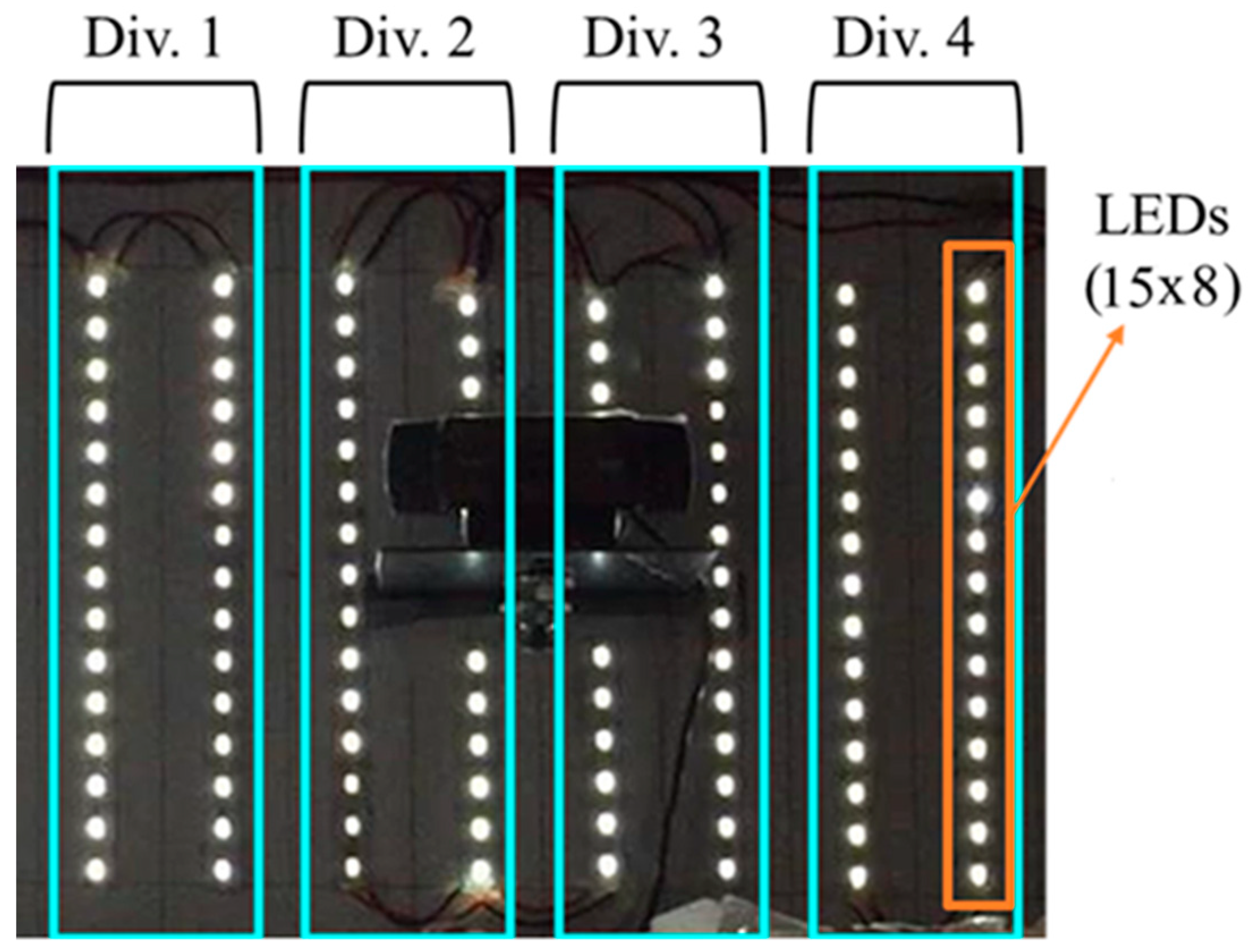

3.2. The Illumination Cabinet

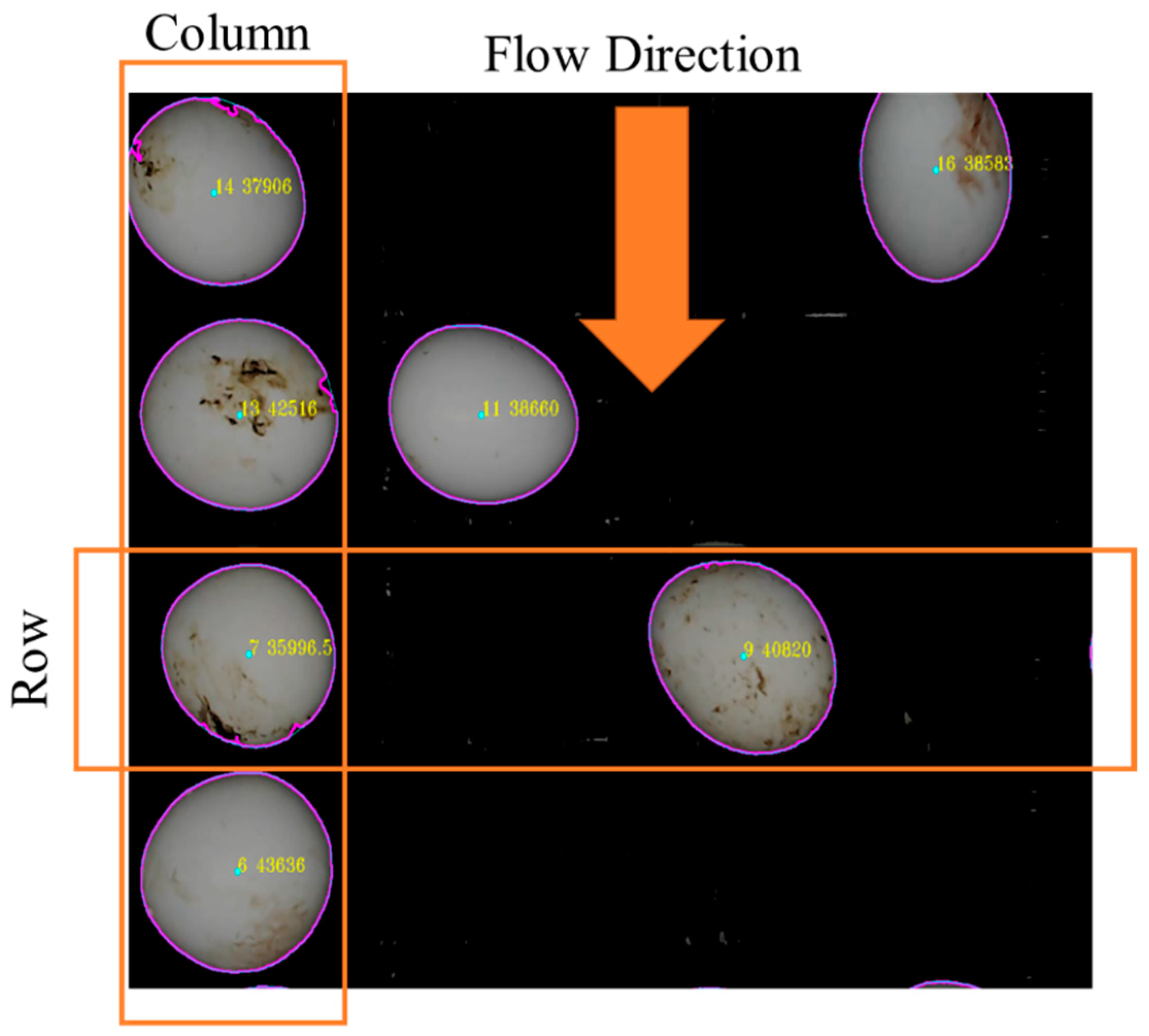

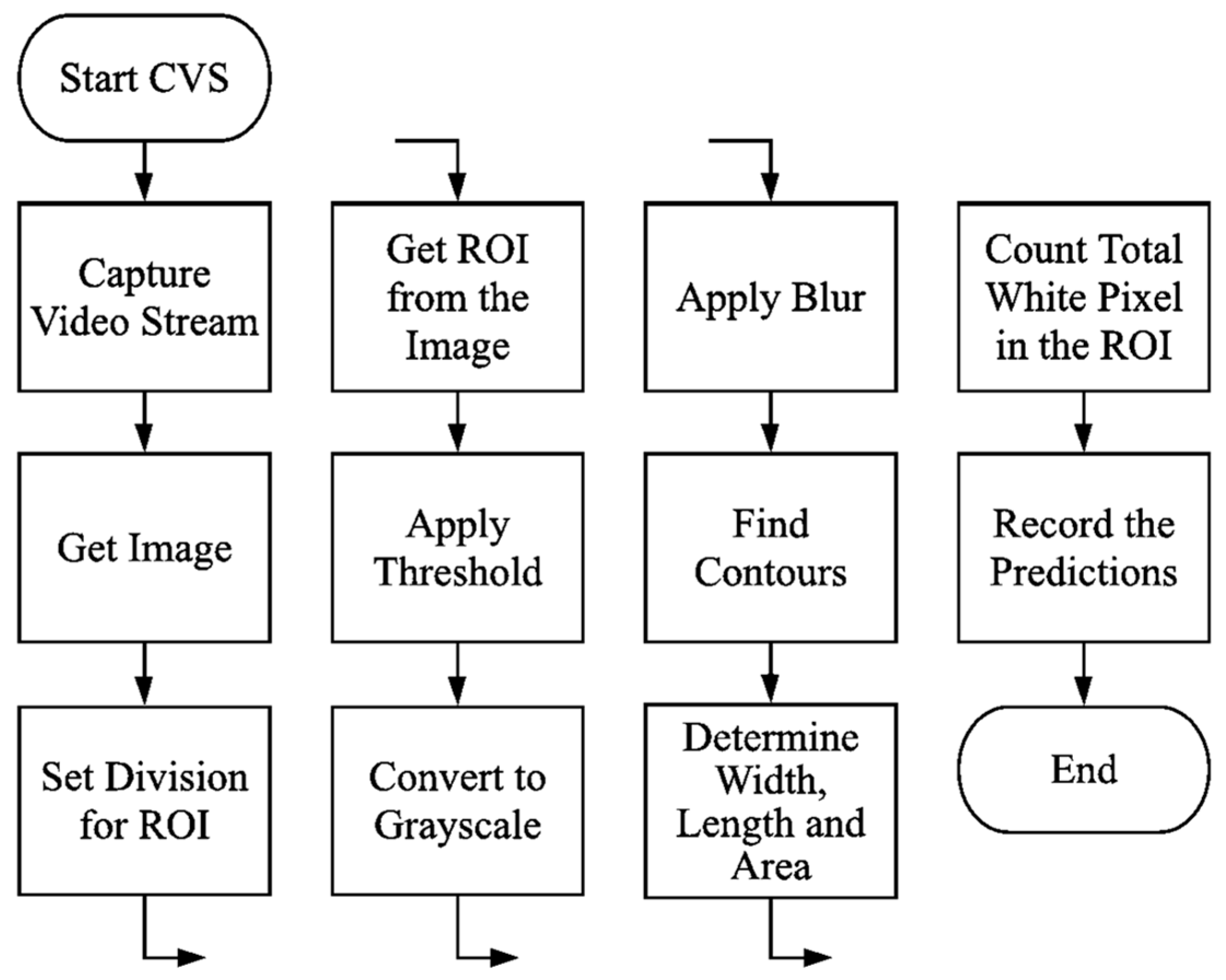

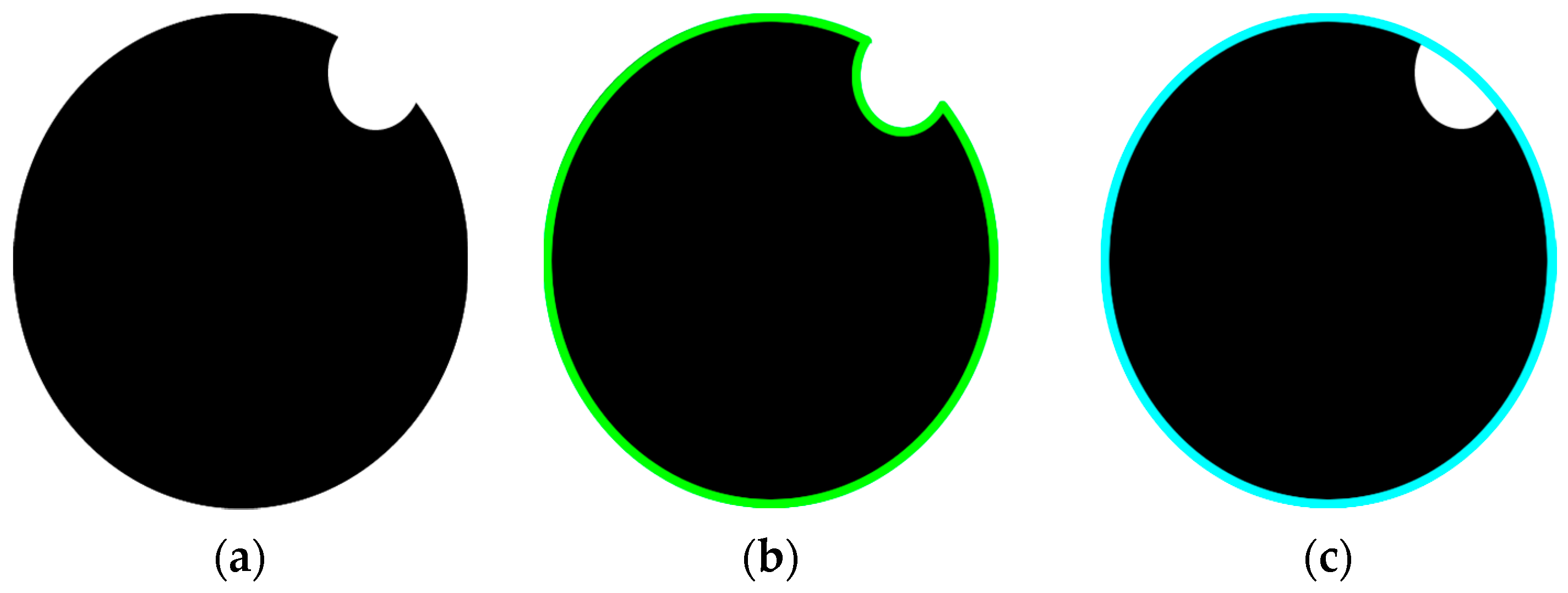

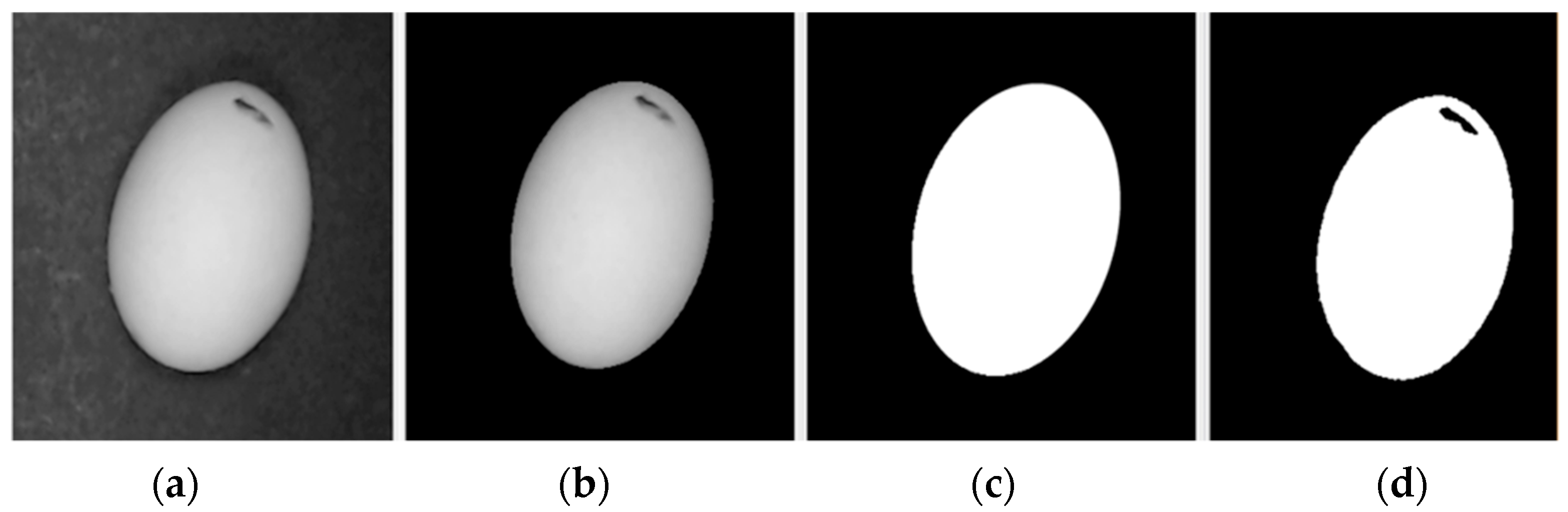

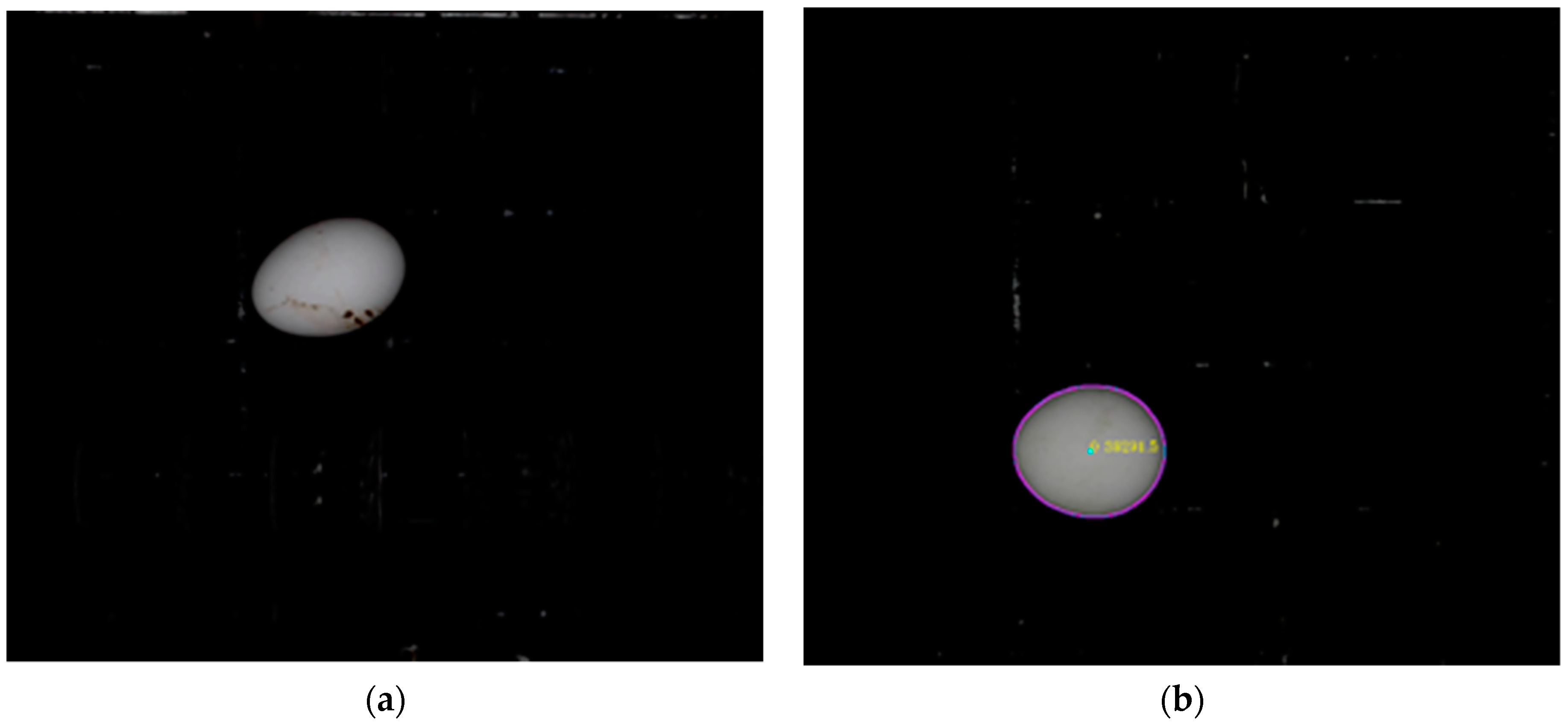

3.3. Image Processing Procedure

3.4. The Measurement Cabinet

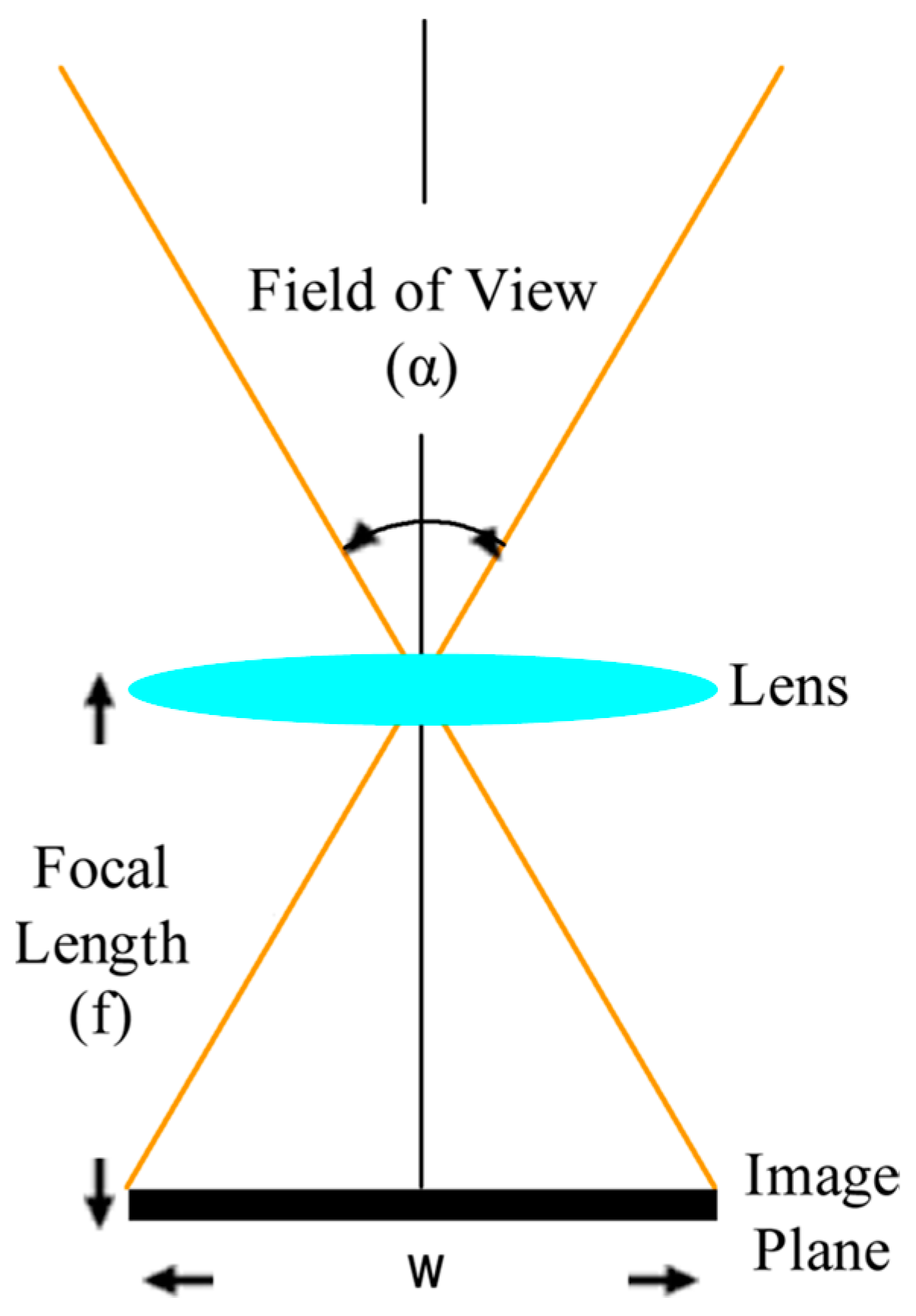

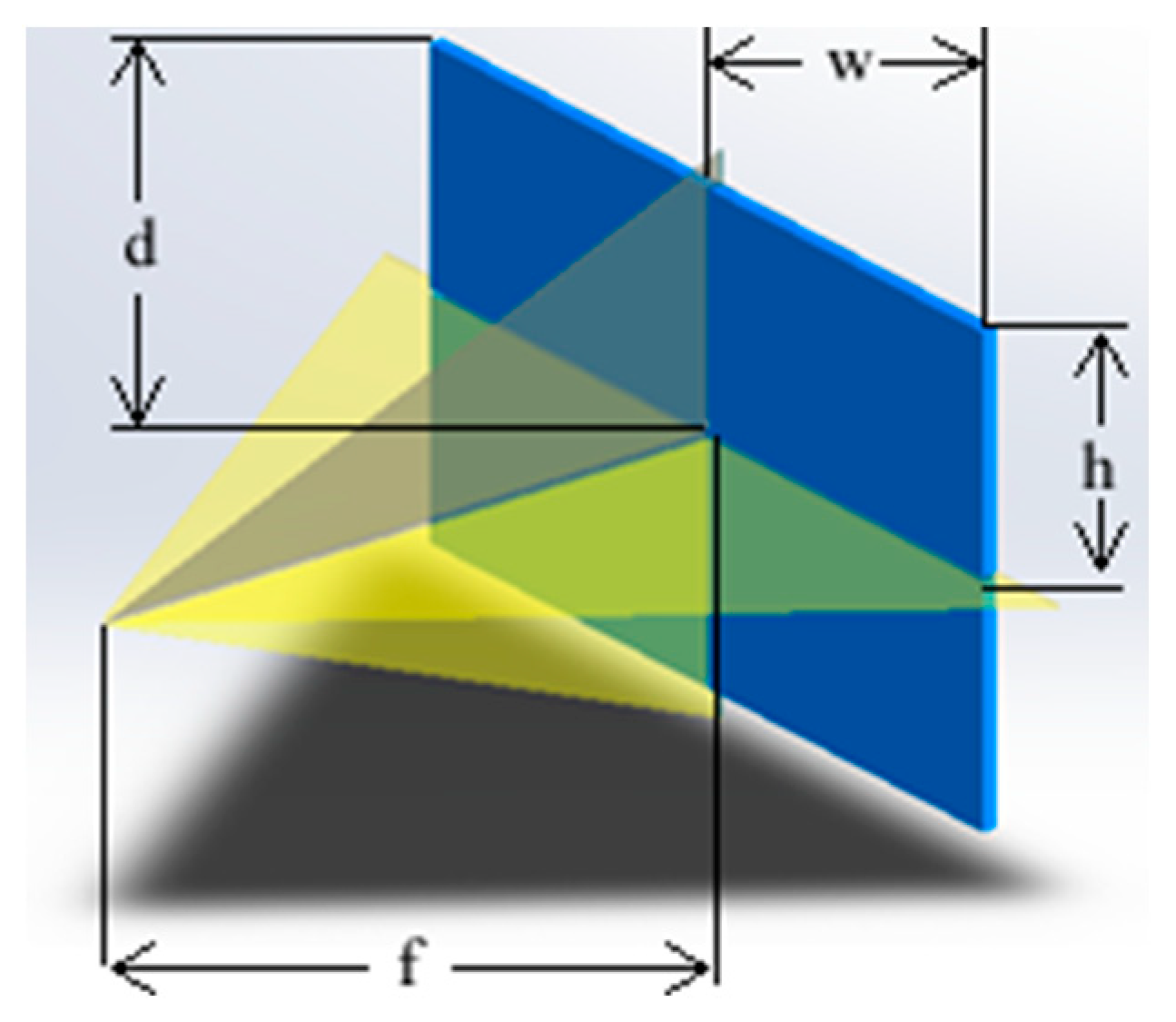

3.5. Determining the Field of View (FoV)

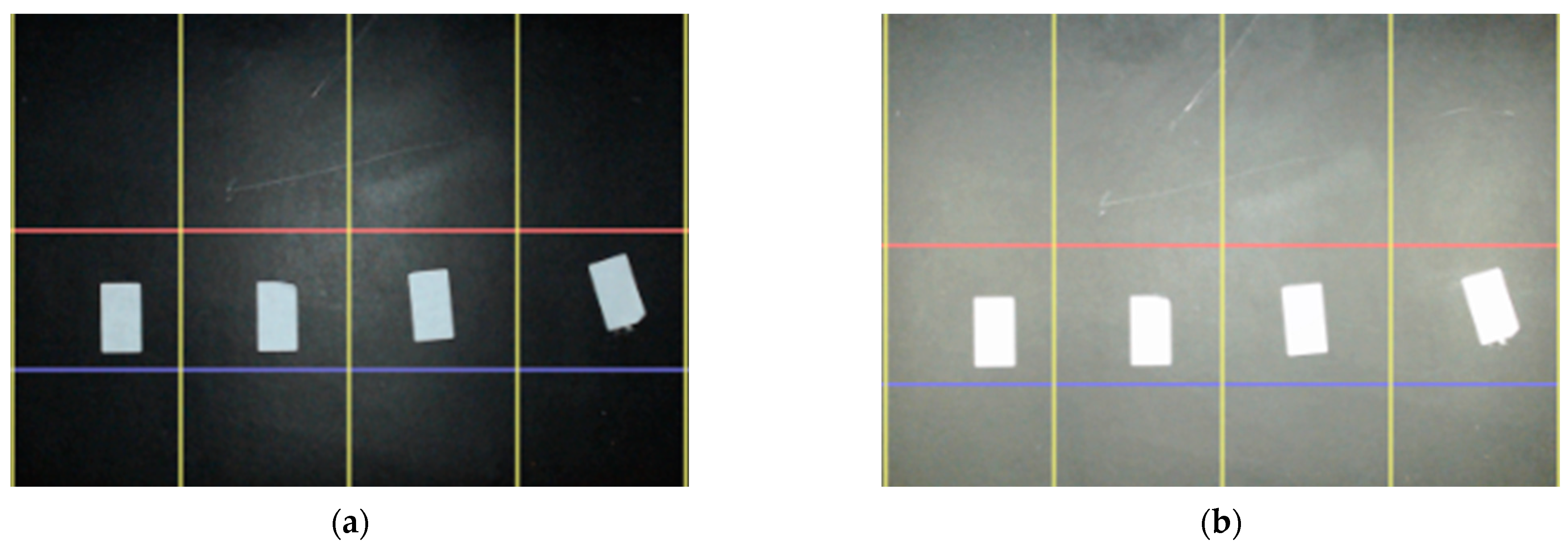

3.6. Evaluating the Accuracy of the Measurement System in Real-Time

3.7. Experimental Procedure in the Multi-Line Flow Egg Production Line

4. Results and Discussion

4.1. The Accuracy of the Measurement System

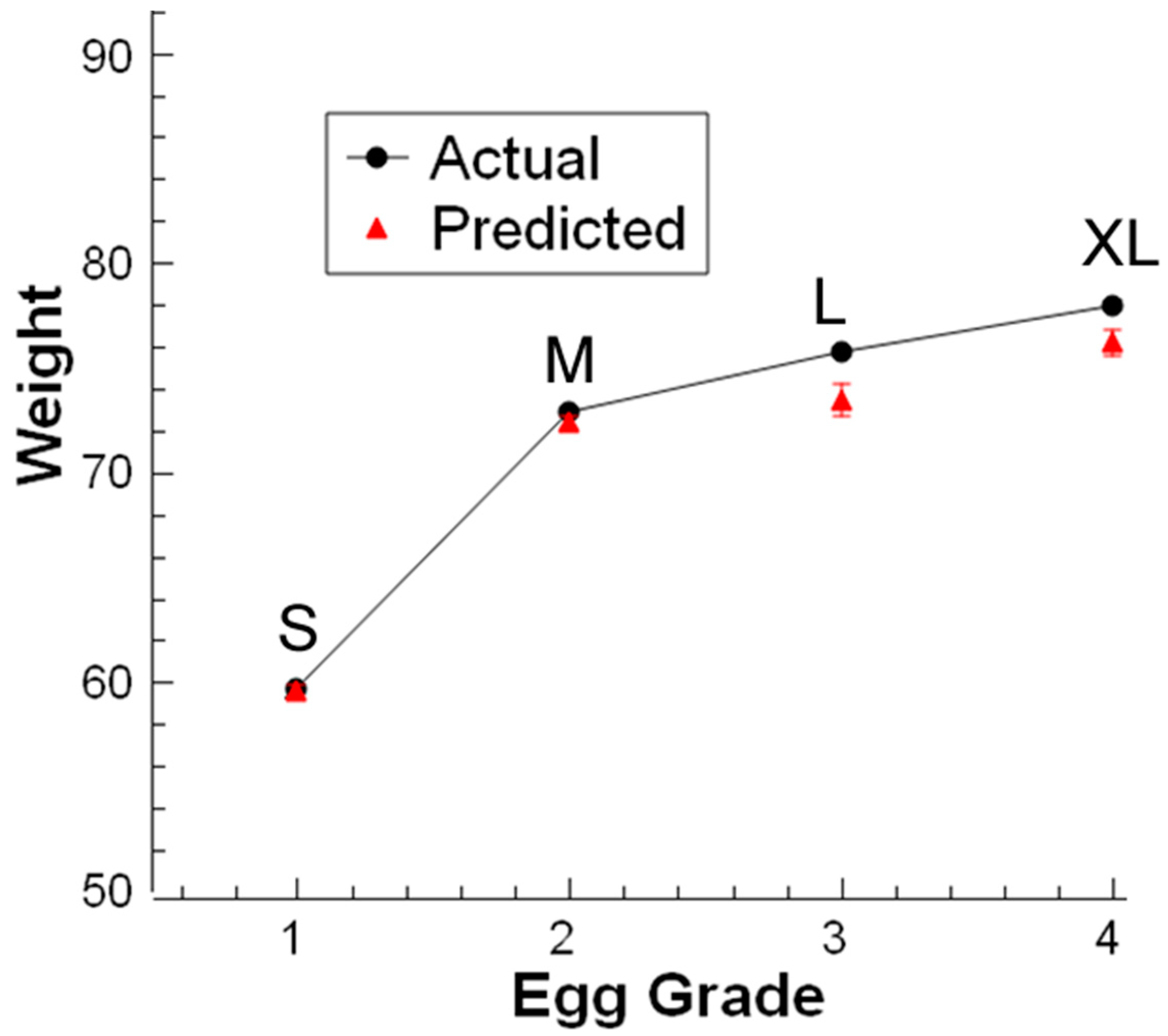

4.2. Measurements of Graded Eggs for Single Line Flow in Real-Time

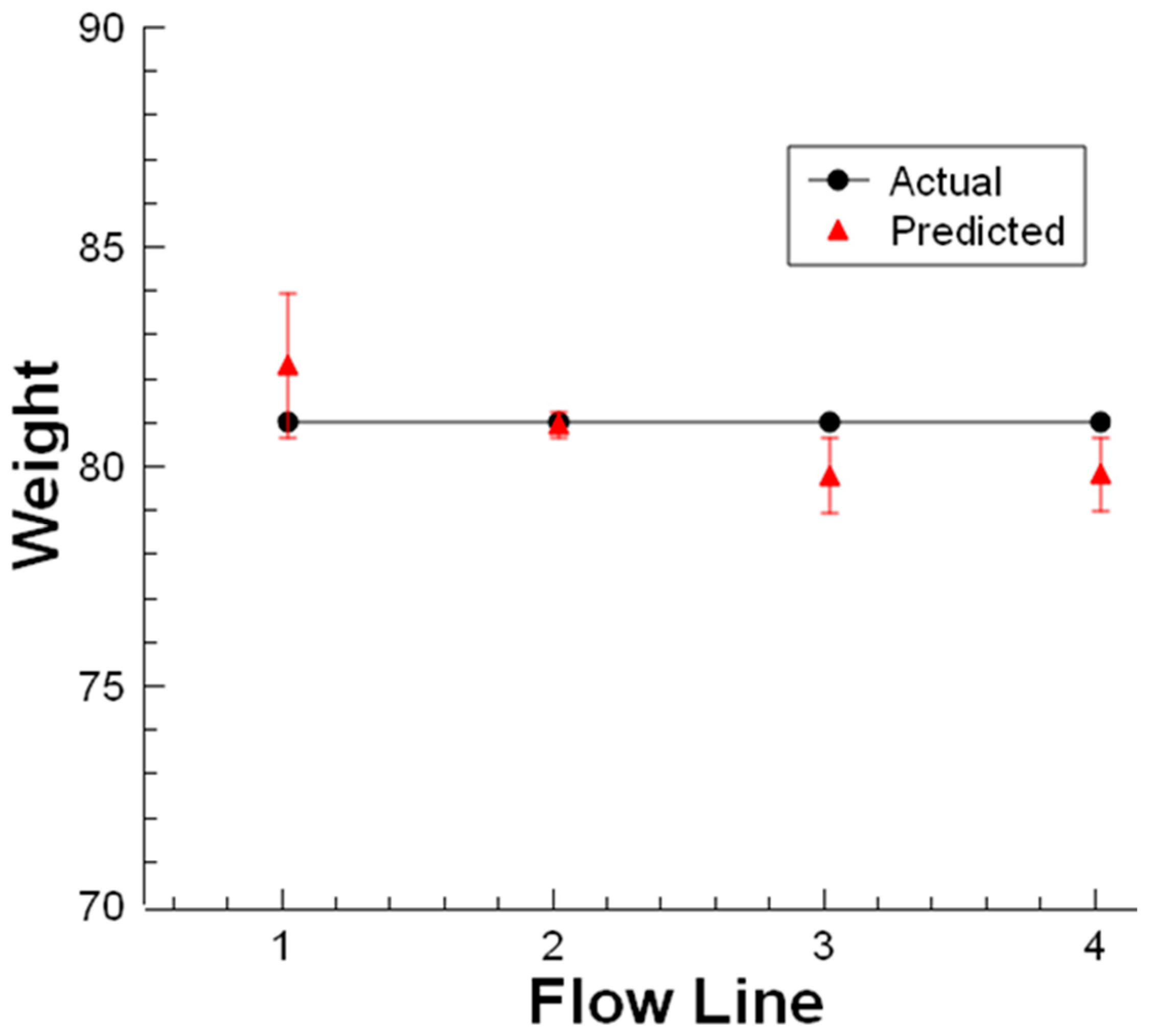

4.3. Measurements of One Egg for Multi-Line Flow in Real-Time

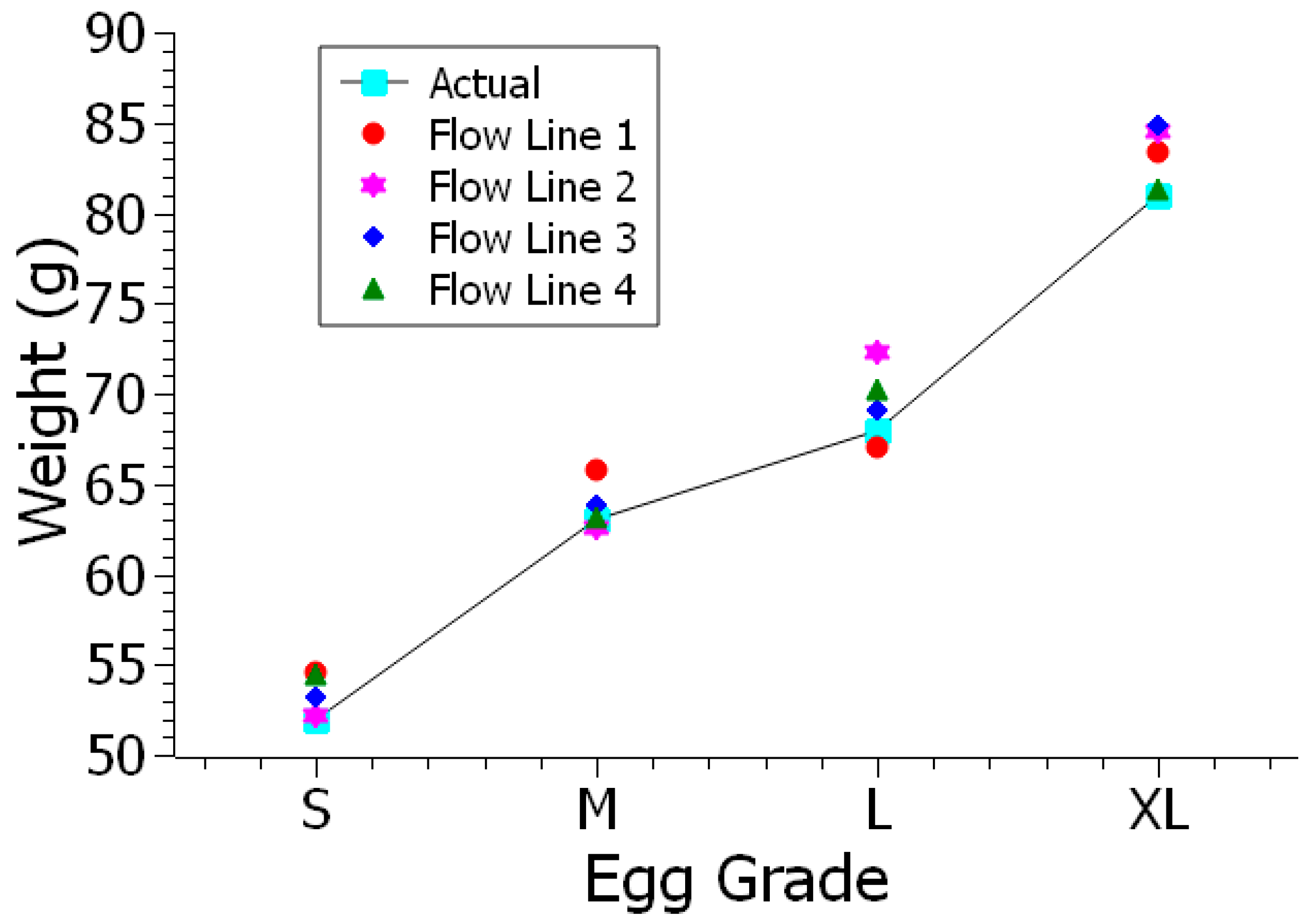

4.4. Measurements of Four Graded Eggs for Multi-Line Flow in Real-Time

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CPU | Central Processing Unit |

| CVS | Computer Vision System |

| DFoV | Diagonal FoV |

| FoV | Field of View |

| FPGA | Field Programmable Gate Array |

| GPU | Graphical Processing Unit |

| HFoV | Horizontal FoV |

| IPC | Industrial PC |

| MCU | Microcontroller Unit |

| MV | Machine Vision |

| MVS | Machine Vision System |

| OpenCV | Open-Source Computer Vision Library |

| PC | Personal Computer |

| RGB | Red Green Blue |

| ROI | Region of Interest |

| Symbols | |

| r | coefficient of linear correlation |

| W | Watt |

| α | FoV angle |

| w | image plane dimension |

| ƒ | focal length |

References

- Yaqoob, M.; Sharma, S.; Aggarwal, P. Imaging Techniques in Agro-Industry and Their Applications, a Review. J. Food Meas. Charact. 2021, 15, 2329–2343. [Google Scholar] [CrossRef]

- Dupuis, E.M. Civic Agriculture: Reconnecting Farm, Food, and Community. Contemp. Sociol. A J. Rev. 2005, 34, 521–522. [Google Scholar] [CrossRef]

- Meredith, J. The Strategic Advantages of New Manufacturing Technologies for Small Firms. Strateg. Manag. J. 1987, 8, 249–258. [Google Scholar] [CrossRef]

- Banakar, A.; Zareiforoush, H.; Baigvand, M.; Montazeri, M.; Khodaei, J.; Behroozi-Khazaei, N. Combined Application of Decision Tree and Fuzzy Logic Techniques for Intelligent Grading of Dried Figs. J. Food Process Eng. 2017, 40, e12456. [Google Scholar] [CrossRef]

- Ercetin, A.; Akkoyun, F.; Şimşir, E.; Pimenov, D.Y.; Giasin, K.; Gowdru Chandrashekarappa, M.P.; Lakshmikanthan, A.; Wojciechowski, S. Image Processing of Mg-Al-Sn Alloy Microstructures for Determining Phase Ratios and Grain Size and Correction with Manual Measurement. Materials 2021, 14, 5095. [Google Scholar] [CrossRef]

- Akkoyun, F.; Ercetin, A.; Aslantas, K.; Pimenov, D.Y.; Giasin, K.; Lakshmikanthan, A.; Aamir, M. Measurement of Micro Burr and Slot Widths through Image Processing: Comparison of Manual and Automated Measurements in Micro-Milling. Sensors 2021, 21, 4432. [Google Scholar] [CrossRef]

- Olaniyi, E.O.; Oyedotun, O.K.; Adnan, K. Intelligent Grading System for Banana Fruit Using Neural Network Arbitration. J. Food Process Eng. 2017, 40, e12335. [Google Scholar] [CrossRef]

- Jadhav, T.; Singh, K.; Abhyankar, A. Volumetric Estimation Using 3D Reconstruction Method for Grading of Fruits. Multimed. Tools Appl. 2019, 78, 1613–1634. [Google Scholar] [CrossRef]

- Huang, X.; Pan, S.; Sun, Z.; Ye, W.; Aheto, J.H. Evaluating Quality of Tomato during Storage Using Fusion Information of Computer Vision and Electronic Nose. J. Food Process Eng. 2018, 41, e12832. [Google Scholar] [CrossRef]

- Bell, D.D. Egg Production and Egg Weight Standards for Table-Egg Layers. In Commercial Chicken Meat and Egg Production; Springer: Boston, MA, USA, 2002; pp. 1079–1090. [Google Scholar] [CrossRef]

- Jasper, A.W. Some Highlights from Consumer Egg Studies; US Department of Agriculture, Production and Marketing Administration: Washington, DC, USA, 1953; p. 6. [Google Scholar]

- Egg-Grading Manual. Available online: https://naldc.nal.usda.gov/download/CAT11094176/PDF (accessed on 25 November 2022).

- Yao, K.; Sun, J.; Zhou, X.; Nirere, A.; Tian, Y.; Wu, X. Nondestructive Detection for Egg Freshness Grade Based on Hyperspectral Imaging Technology. J. Food Process Eng. 2020, 43, e13422. [Google Scholar] [CrossRef]

- American Egg Board Why Size Matters When It Comes To Eggs And Baking. Available online: https://www.incredibleegg.org (accessed on 27 February 2020).

- Cetin, E.; Temelli, S.; Eyigor, A. Effect of Rearing Systems and Shell Color on Some Egg Quality Parameters. Uludag Univ. J. Fac. Vet. Med. 2016, 35, 11–16. [Google Scholar] [CrossRef][Green Version]

- Cen, Y.; Ying, Y.; Rao, X. Egg Weight Detection on Machine Vision System. Opt. Nat. Resour. Agric. Foods 2006, 6381, 638114. [Google Scholar] [CrossRef]

- Liming, X.; Yanchao, Z. Automated Strawberry Grading System Based on Image Processing. Comput. Electron. Agric. 2010, 71, S32–S39. [Google Scholar] [CrossRef]

- Anbarjafari, G.; Jafari, A.; Sabet Jahromi, M.N.; Ozcinar, C.; Demirel, H. Image Illumination Enhancement with an Objective No-Reference Measure of Illumination Assessment Based on Gaussian Distribution Mapping. Eng. Sci. Technol. Int. J. 2015, 18, 696–703. [Google Scholar] [CrossRef]

- Chen, Z.; He, L.; Ye, Y.; Chen, J.; Sun, L.; Wu, C.; Chen, L.; Wang, R. Automatic Sorting of Fresh Tea Leaves Using Vision-based Recognition Method. J. Food Process Eng. 2020, 43, e13474. [Google Scholar] [CrossRef]

- Masood, H.; Trujillo, F.J. Engineering Properties of Foods. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Kurtulmus, F.; Gurbuz, O.; Degirmencioğlu, N. Discriminating Drying Method of Tarhana Using Computer Vision. J. Food Process Eng. 2014, 37, 362–374. [Google Scholar] [CrossRef]

- Akkoyun, F.; Baş, M.N.; Şimşek, S.; Uysal, D.E.; Güçlüer, S.; Özçelik, A. A Computer Vision System for Chain Link Sorting Application. Turk. J. Electromech. Energy 2021, 60, 55–60. [Google Scholar]

- Sadrnia, H.; Rajabipour, A.; Jafary, A.; Javadi, A.; Mostofi, Y. Classification and Analysis of Fruit Shapes in Long Type Watermelon Using Image Processing. Int. J. Agric. Biol. 2007, 1, 68–70. [Google Scholar]

- Patel, V.C.; McClendon, R.W.; Goodrum, J.W. Development and Evaluation of an Expert System for Egg Sorting. Comput. Electron. Agric. 1998, 20, 97–116. [Google Scholar] [CrossRef]

- Alikhanov, J.; Penchev, S.M.; Georgieva, T.D.; Moldazhanov, A.; Shynybay, Z.; Daskalov, P.I. An Indirect Approach for Egg Weight Sorting Using Image Processing. J. Food Meas. Charact. 2018, 12, 87–93. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 2002; pp. 1–793. [Google Scholar]

- Hawkins, S.A.; Jones, D.R. Prediction Modelling of Storage Time and Quality Measurements Using Visible-near Infrared Spectra of Pasteurized Shell Eggs. J. Food Meas. Charact. 2013, 7, 101–106. [Google Scholar] [CrossRef]

- Lawrence, K.C.; Yoon, S.C.; Heitschmidt, G.W.; Jones, D.R.; Park, B. Imaging System with Modified-Pressure Chamber for Crack Detection in Shell Eggs. Sens. Instrum. Food Qual. Saf. 2008, 2, 116–122. [Google Scholar] [CrossRef]

- Altuntaş, E.; Şekeroğlu, A. Effect of Egg Shape Index on Mechanical Properties of Chicken Eggs. J. Food Eng. 2008, 85, 606–612. [Google Scholar] [CrossRef]

- Wang, P.C.; Lee, R.J.; Chen, C.Y.; Chou, C.C.; Lee, M.R. Determination of Cyromazine and Melamine in Chicken Eggs Using Quick, Easy, Cheap, Effective, Rugged and Safe (QuEChERS) Extraction Coupled with Liquid Chromatography-Tandem Mass Spectrometry. Anal. Chim. Acta 2012, 752, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Poornima, R.; Iswarya, R.J. An overview of digital image steganography. Int. J. Comput. Sci. Eng. Surv. 2013, 4, 23–31. [Google Scholar] [CrossRef]

- Akkoyun, F.; Ozcelik, A. Rapid Characterization of Cell and Bacteria Counts Using Computer Vision. Turk. J. Nature Sci. 2021, 10, 269–274. [Google Scholar] [CrossRef]

- Stemmer Imaging Illumination Techniques for Industrial Image Processing. Available online: https://www.stemmer-imaging.com/en-dk/technical-tips/illumination-techniques/ (accessed on 29 February 2020).

- Brosnan, T.; Sun, D.-W. Inspection and Grading of Agricultural and Food Products by Computer Vision Systems—A Review. Comput. Electron. Agric. 2002, 36, 193–213. [Google Scholar] [CrossRef]

- Akkoyun, F. Inexpensive Multispectral Imaging Device. Instrum. Sci. Technol. 2022, 50, 543–559. [Google Scholar] [CrossRef]

- Pulli, K.; Baksheev, A.; Kornyakov, K.; Eruhimov, V. Real-Time Computer Vision with OpenCV. Commun. ACM 2012, 55, 61. [Google Scholar] [CrossRef]

- Kilic, K.; Boyaci, I.H.; Koksel, H.; Kusmenoglu, I.; Kılıç, K.; Boyacı, İ.H.; Köksel, H.; Küsmenoğlu, İ.; Kiliç, K.; Boyaci, I.H.; et al. A Classification System for Beans Using Computer Vision System and Artificial Neural Networks. J. Food Eng. 2007, 78, 897–904. [Google Scholar] [CrossRef]

- Milovanovic, B.; Tomovic, V.; Djekic, I.; Solowiej, B.G.; Lorenzo, J.M.; Barba, F.J.; Tomasevic, I. Color Assessment of the Eggs Using Computer Vision System and Minolta Colorimeter. J. Food Meas. Charact. 2021, 15, 5097–5112. [Google Scholar] [CrossRef]

- Nyalala, I.; Okinda, C.; Kunjie, C.; Korohou, T.; Nyalala, L.; Chao, Q. Weight and volume estimation of poultry and products based on computer vision systems: A review. Poult. Sci. 2021, 100, 101072. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.; Lin, T.; Ying, Y.; Chowdhary, G.; Ting, K.C. Agricultural robotics research applicable to poultry production: A review. Comput. Electron. Agric. 2020, 169, 105216. [Google Scholar] [CrossRef]

- Omid, M.; Soltani, M.; Dehrouyeh, M.H.; Mohtasebi, S.S.; Ahmadi, H. An expert egg grading system based on machine vision and artificial intelligence techniques. J. Food Eng. 2013, 118, 70–77. [Google Scholar] [CrossRef]

- Nasiri, A.; Omid, M.; Taheri-Garavand, A. An automatic sorting system for unwashed eggs using deep learning. J. Food Eng. 2020, 283, 110036. [Google Scholar] [CrossRef]

- Valdez, M.A.T.; Watt, P.A.S.T.; Mappatao, G.P. Automated fertilized duck egg sorting system using image processing. Adv. Sci. Lett. 2017, 23, 5191–5194. [Google Scholar] [CrossRef]

- Alikhanov, J.; Penchev, S.M.; Georgieva, T.D.; Moldazhanov, A.; Kulmakhambetova, A.; Shynybay, Z.; Stefanov, E.; Daskalov, P.I. Design and performance of an automatic egg sorting system based on computer vision. TEM J. 2019, 8, 1319–1325. [Google Scholar] [CrossRef]

- Priyadumkol, J.; Kittichaikarn, C.; Thainimit, S. Crack detection on unwashed eggs using image processing. J. Food Eng. 2017, 209, 76–82. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Q.; Jie, D.; Wang, S.; Zhu, Z.; Xiong, L. Detection of crack eggs by image processing and soft-margin support vector machine. J. Comput. Methods Sci. Eng. 2018, 18, 21–31. [Google Scholar] [CrossRef]

- Alikhanov, D.; Penchec, S.; Georgieva, T.; Moldajanov, A.; Shynybaj, Z.; Daskalov, P. Indirect method for egg weight measurement using image processing. Int. J. Emerg. Technol. Adv. Eng. 2015, 5, 30–34. [Google Scholar]

- Soltani, M.; Omid, M.; Alimardani, R. Egg Volume Prediction Using Machine Vision Technique Based on Pappus Theorem and Artificial Neural Network. J. Food Sci. Technol. 2015, 52, 3065–3071. [Google Scholar] [CrossRef] [PubMed]

- Thipakorn, J.; Waranusast, R.; Riyamongkol, P. Egg Weight Prediction and Egg Size Classification Using Image Processing and Machine Learning. In Proceedings of the 2017 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 27–30 June 2017; pp. 477–480. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.-W. Colour Measurements by Computer Vision for Food Quality Control—A Review. Trends Food Sci. Technol. 2013, 29, 5–20. [Google Scholar] [CrossRef]

- Bradski, G.; Kaehler, A. Learning OpenCV: Computer Vision with OpenCV Library, 1st ed.; O’Reilly Media: Sebastopol, CA, USA, 2008; p. 543. ISBN 9780596516130. [Google Scholar]

- Dos Reis, G.; Stroustrup, B. A Principled, Complete, and Efficient Representation of C++. Math. Comput. Sci. 2011, 5, 335–356. [Google Scholar] [CrossRef]

- Stroustrup, B. The C++ Programming Language, 4th ed.; Addison-Wesley: Boston, MA, USA, 2013; ISBN 0201889544. [Google Scholar]

- Murray, A.T. Complexities in Spatial Center Derivation. Trans. GIS 2018, 22, 1335–1350. [Google Scholar] [CrossRef]

- Joni, H.H.; Alwan, I.A.; Naji, G. Utilizing Artificial Intelligence to Collect Pavement Surface Condition Data. Eng. Technol. J. 2020, 38, 74–82. [Google Scholar] [CrossRef]

- Lin, C.-S.; Yeh, P.T.; Chen, D.-C.; Chiou, Y.-C.; Lee, C.-H. The Identification and Filtering of Fertilized Eggs with a Thermal Imaging System. Comput. Electron. Agric. 2013, 91, 94–105. [Google Scholar] [CrossRef]

- Phate, V.R.; Malmathanraj, R.; Palanisamy, P. Classification and Weighing of Sweet Lime (Citrus Limetta) for Packaging Using Computer Vision System. J. Food Meas. Charact. 2019, 13, 1451–1468. [Google Scholar] [CrossRef]

- Golnabi, H.; Asadpour, A. Design and Application of Industrial Machine Vision Systems. Robot. Comput. Integr. Manuf. 2007, 23, 630–637. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Ji, G.; Phillips, P. Fruit Classification Using Computer Vision and Feedforward Neural Network. J. Food Eng. 2014, 143, 167–177. [Google Scholar] [CrossRef]

| Grade | Weight | Classification |

|---|---|---|

| 1 | >73 | XL—Extra |

| 2 | >63 and ≤73 | L—Large |

| 3 | >53 and ≤63 | M—Medium |

| 4 | <53 | Small |

| Process | Time (sec) |

|---|---|

| Frame capture | 0.0025324 |

| +Select ROI +GrayScale +Blur +Gaussian Filter | 0.0035324 |

| +Find Contors | 0.0045324 |

| +Predict Egg Weights | 0.0055324 |

| One Cycle | 0.092 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkoyun, F.; Ozcelik, A.; Arpaci, I.; Erçetin, A.; Gucluer, S. A Multi-Flow Production Line for Sorting of Eggs Using Image Processing. Sensors 2023, 23, 117. https://doi.org/10.3390/s23010117

Akkoyun F, Ozcelik A, Arpaci I, Erçetin A, Gucluer S. A Multi-Flow Production Line for Sorting of Eggs Using Image Processing. Sensors. 2023; 23(1):117. https://doi.org/10.3390/s23010117

Chicago/Turabian StyleAkkoyun, Fatih, Adem Ozcelik, Ibrahim Arpaci, Ali Erçetin, and Sinan Gucluer. 2023. "A Multi-Flow Production Line for Sorting of Eggs Using Image Processing" Sensors 23, no. 1: 117. https://doi.org/10.3390/s23010117

APA StyleAkkoyun, F., Ozcelik, A., Arpaci, I., Erçetin, A., & Gucluer, S. (2023). A Multi-Flow Production Line for Sorting of Eggs Using Image Processing. Sensors, 23(1), 117. https://doi.org/10.3390/s23010117