Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material

Abstract

1. Introduction

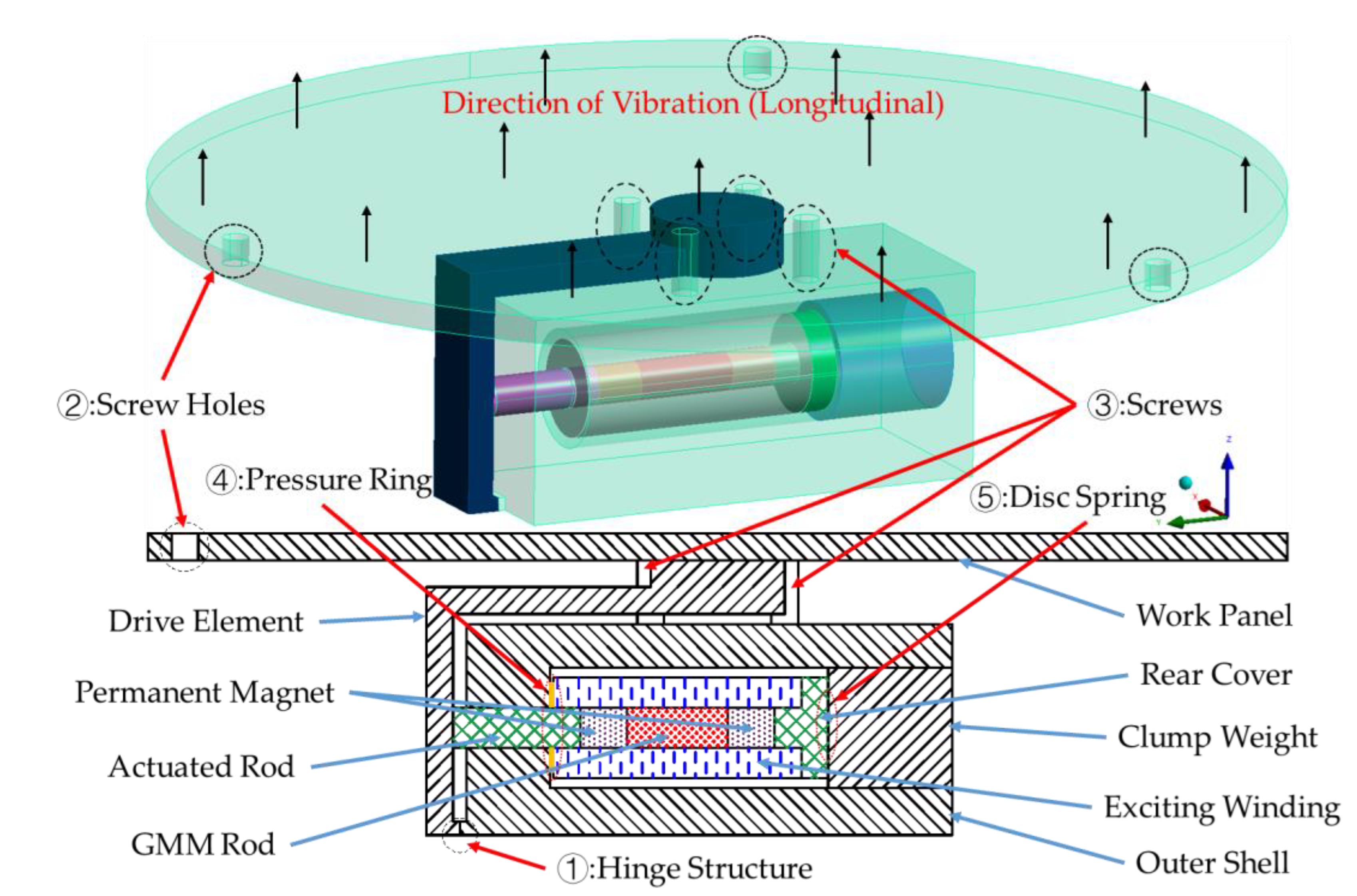

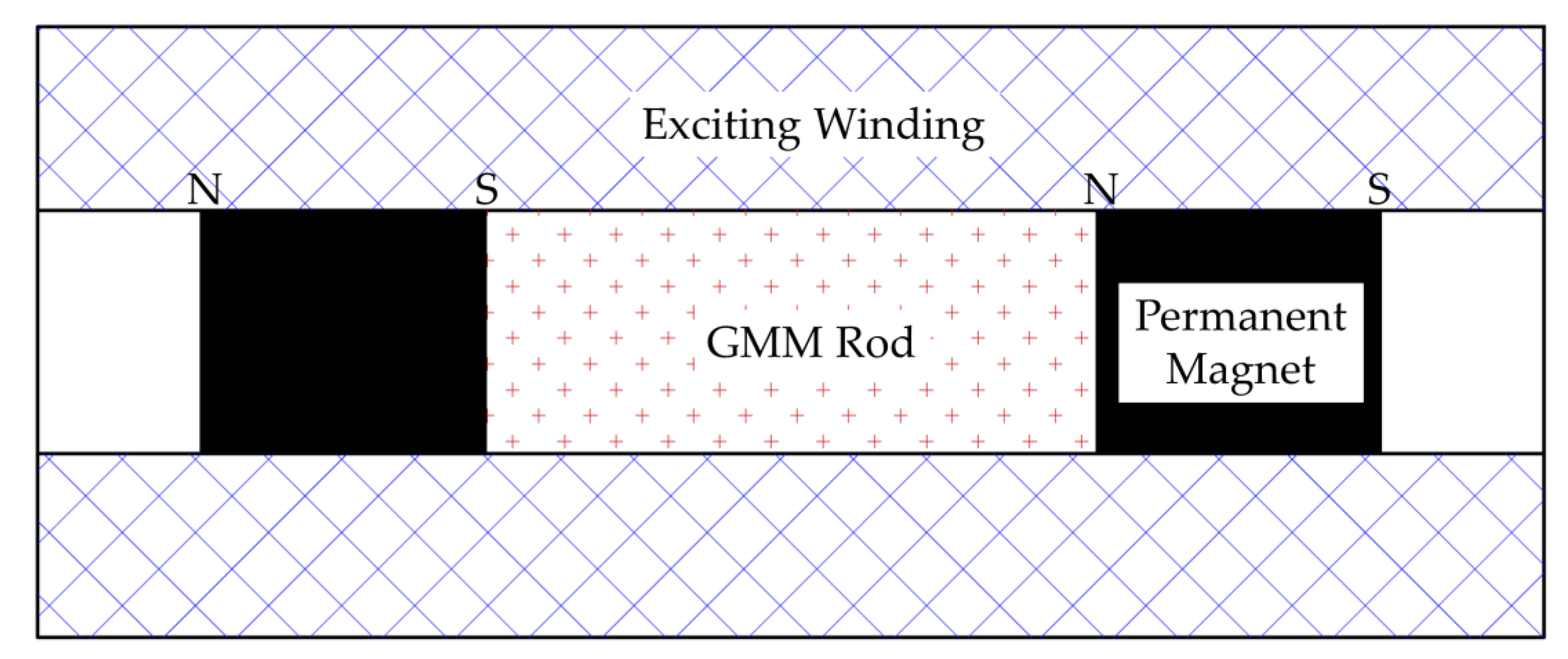

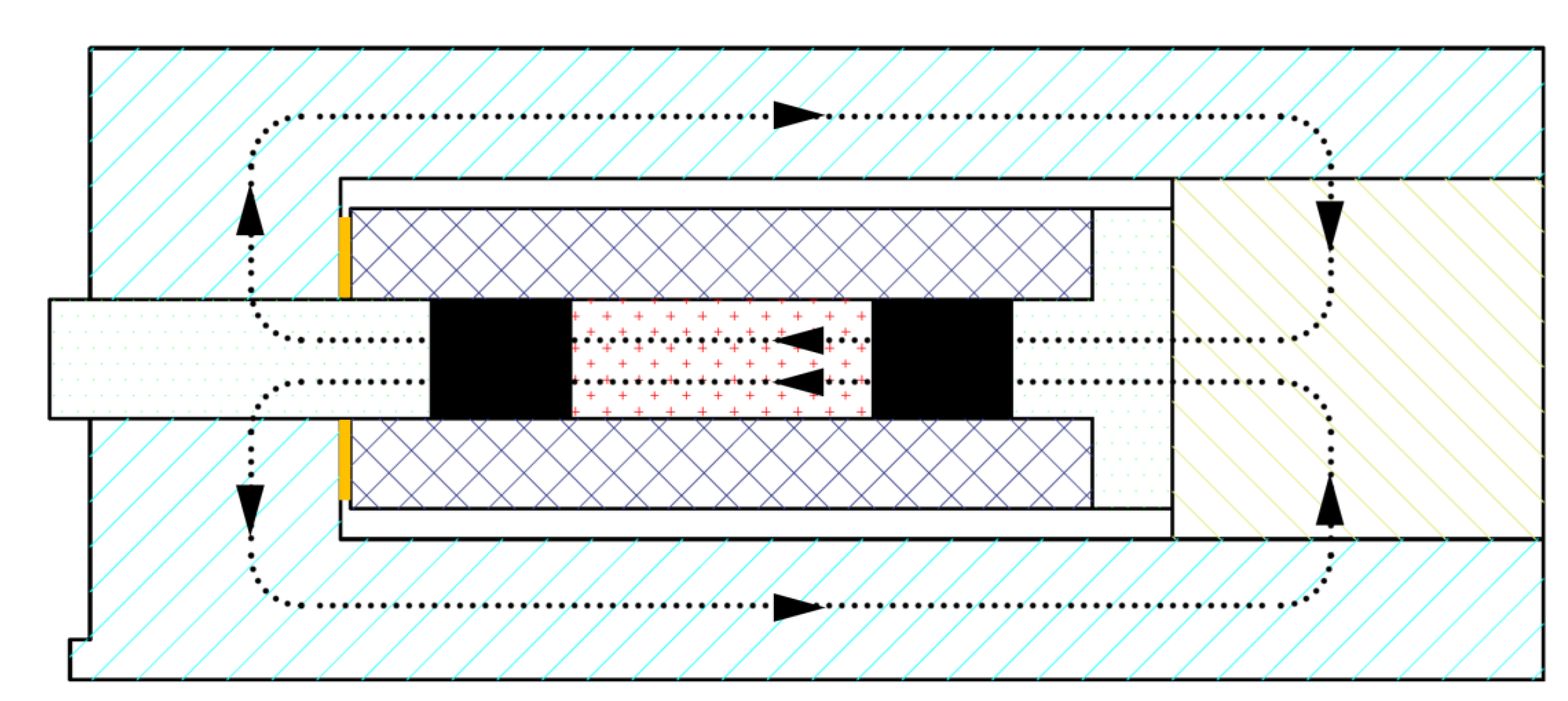

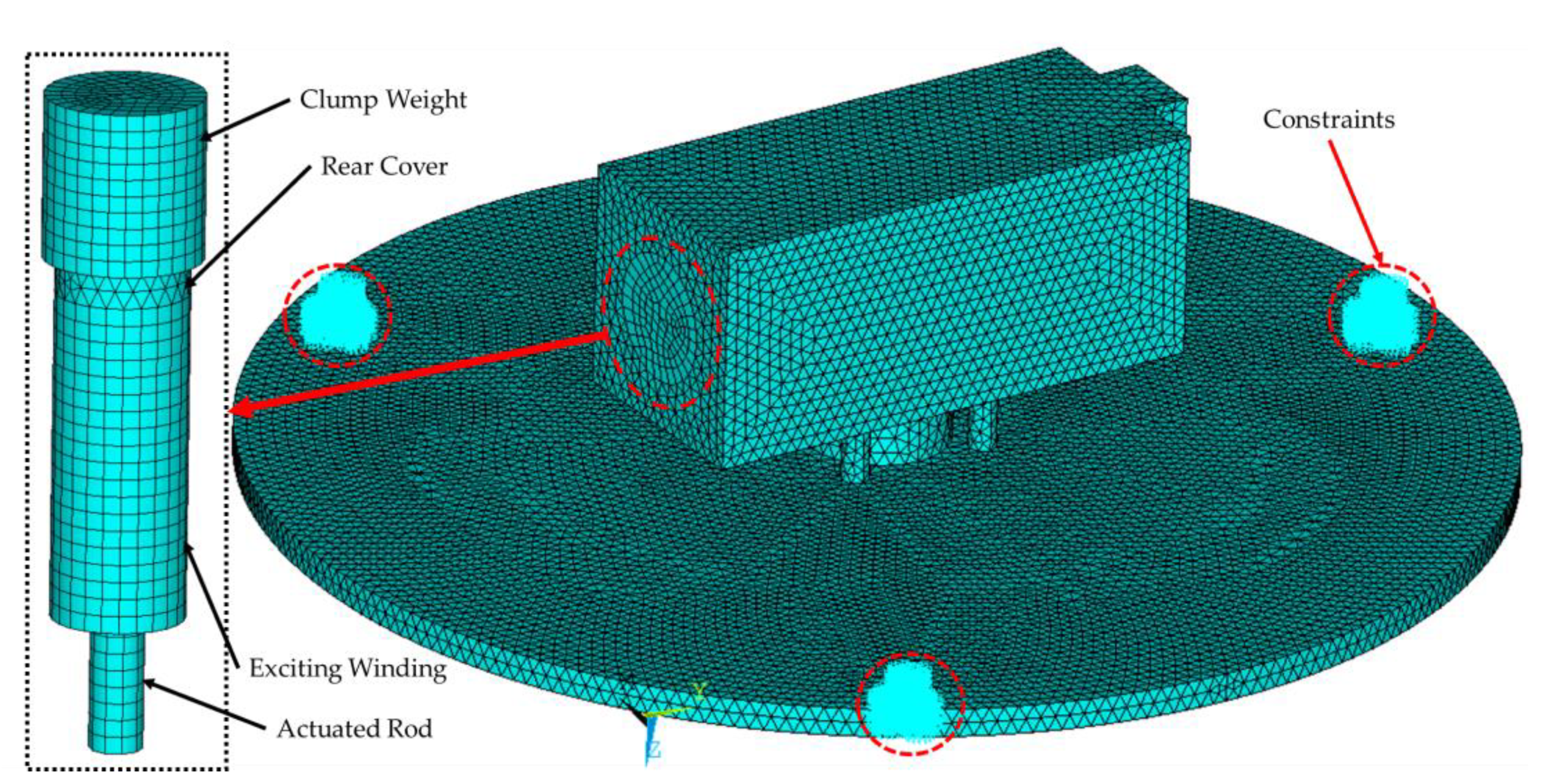

2. Original Configuration of GMM Transducer

2.1. Basic Structure and Principle

2.2. Structural Parameter Design

2.2.1. Excitation Circuit Design

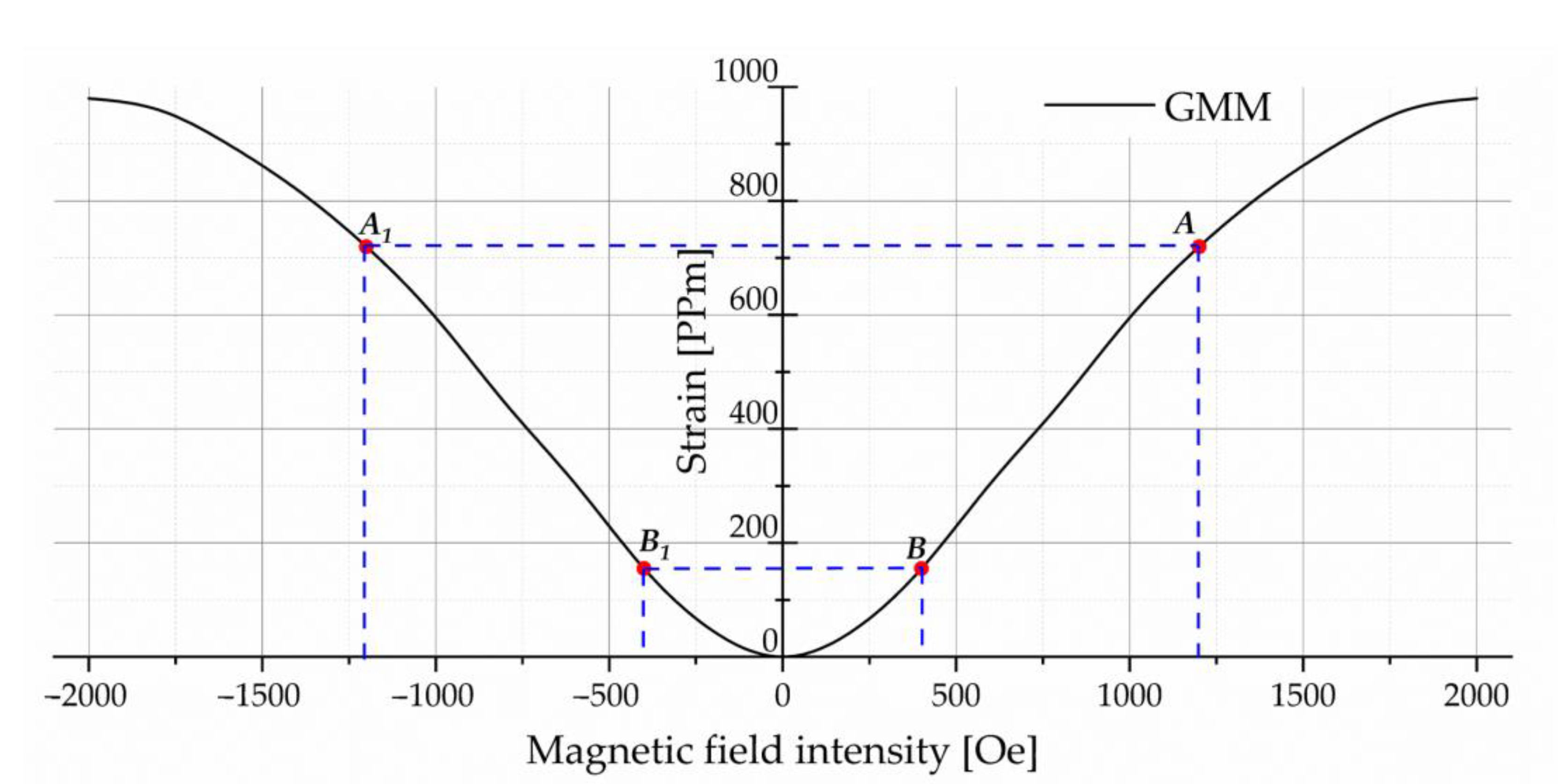

2.2.2. Determine the Bias Magnetic Field

2.2.3. Work Panel Design

3. FEM Simulation Analysis

3.1. FEM Theory of GMM

3.2. Finite Element Modeling

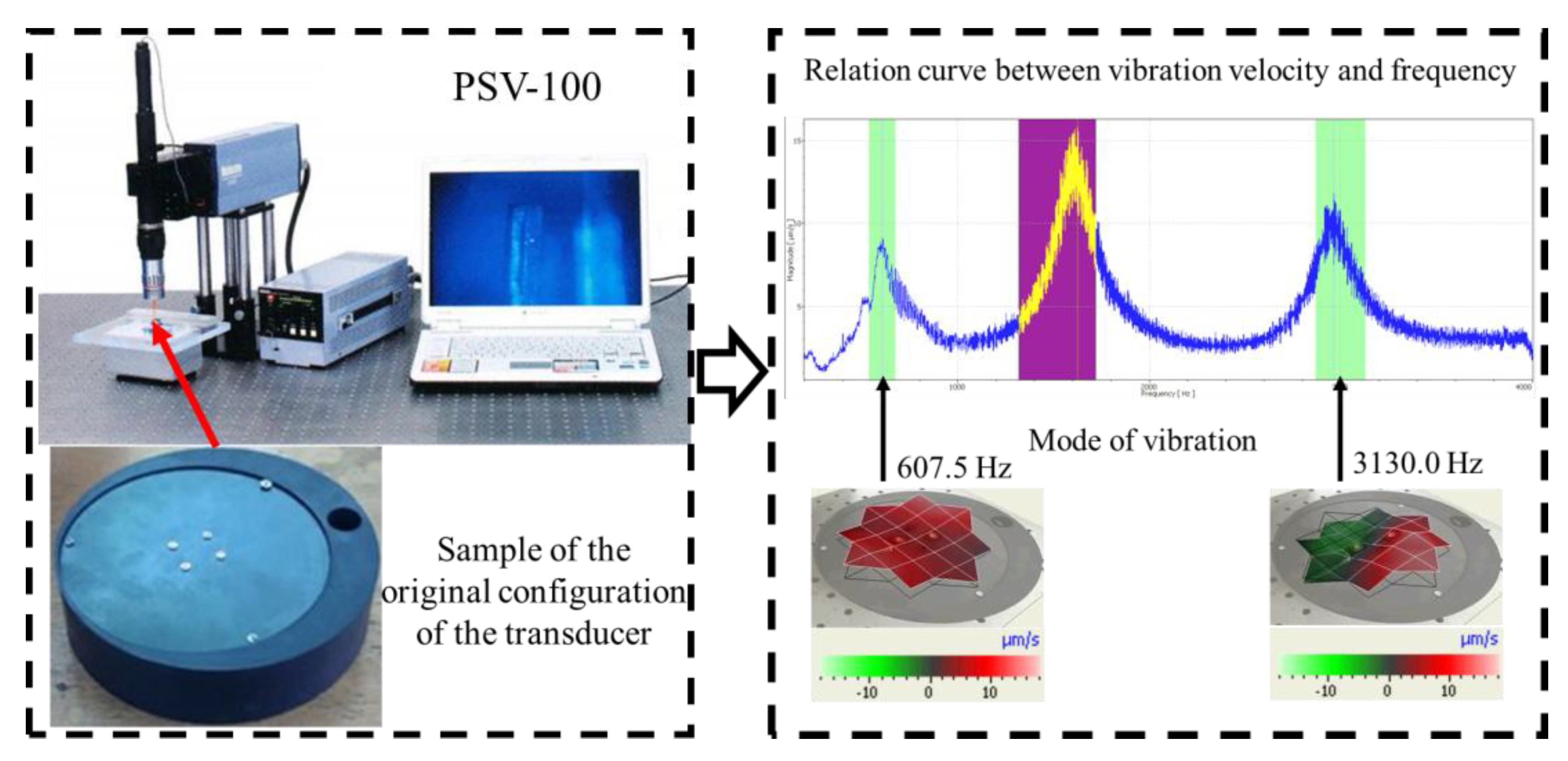

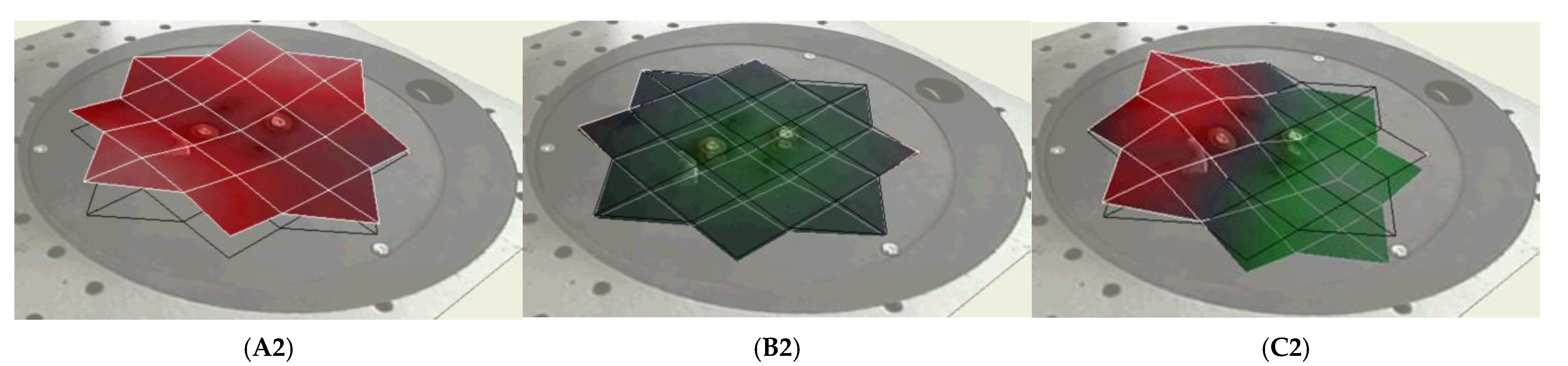

3.3. FEM Validation

- (1)

- Due to the limitation of the test instrument, all the surface of the work panel is not divided into grids for the post-test, and only the part on the opposite side, namely the rectangular part, is tested. As a result, the number of measurement points is not enough, resulting in test errors. At the same time, some modes obtained in the simulation analysis may not be reflected in the test results of the modal test.

- (2)

- In the modal test, the sample needs to constrain the boundary, so it is fixed to the rubber shell, but the rubber shell is not added in the simulation, resulting in a large error.

- (3)

- The material parameters of simulation and test cannot be completely consistent, and the process defects of the sample during processing will also affect the results, and the difference between these parameters has a greater impact on the higher order modes.

- (4)

- The error of the finite element simulation results will increase when calculating the higher-order modes [38].

4. Work Panel Optimization

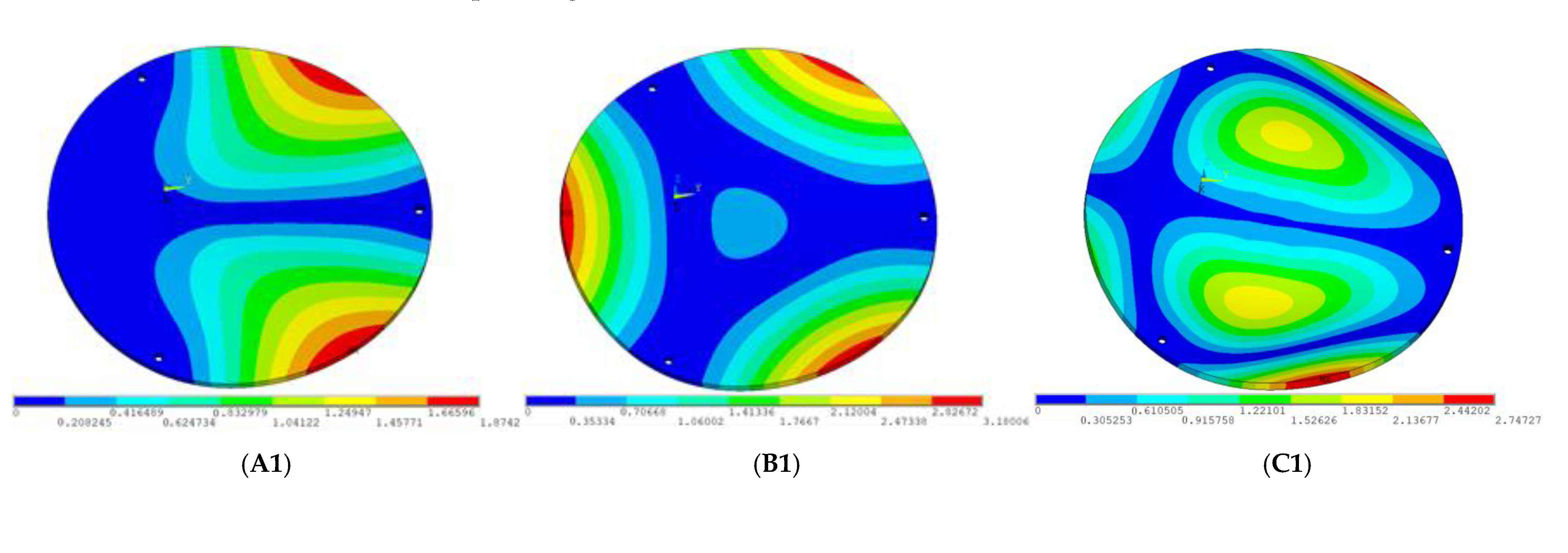

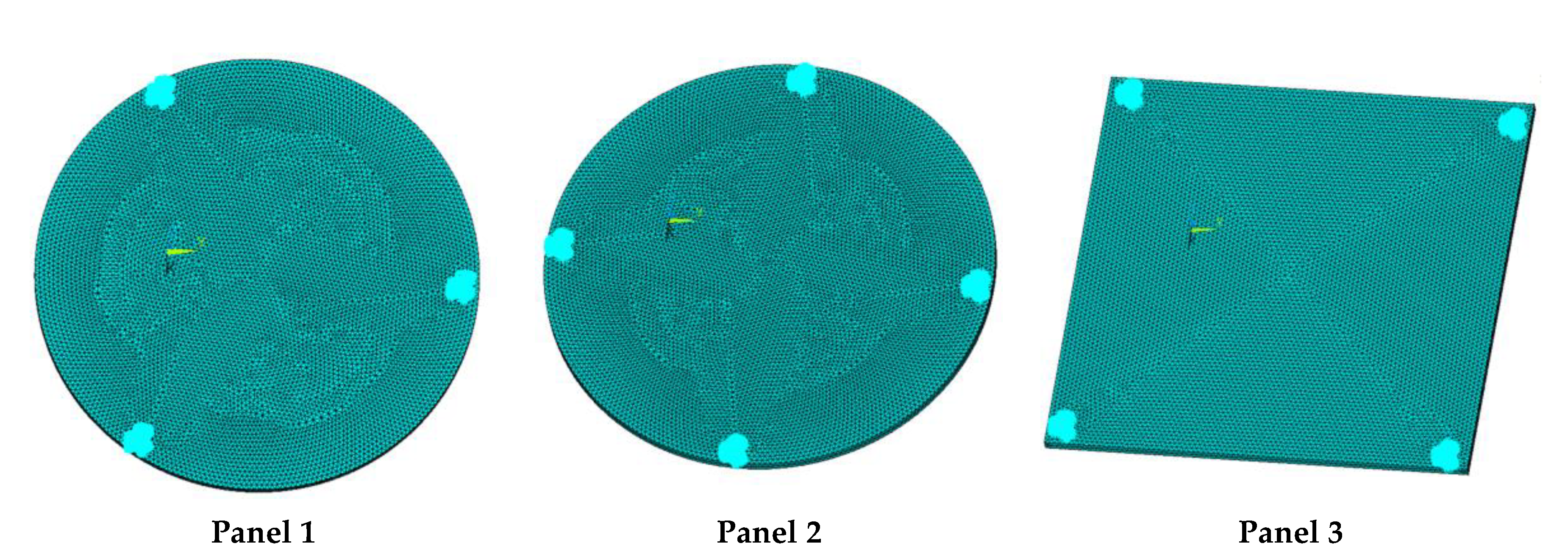

4.1. Comparison of Basic Configurations

4.1.1. Resonance Frequency Analysis

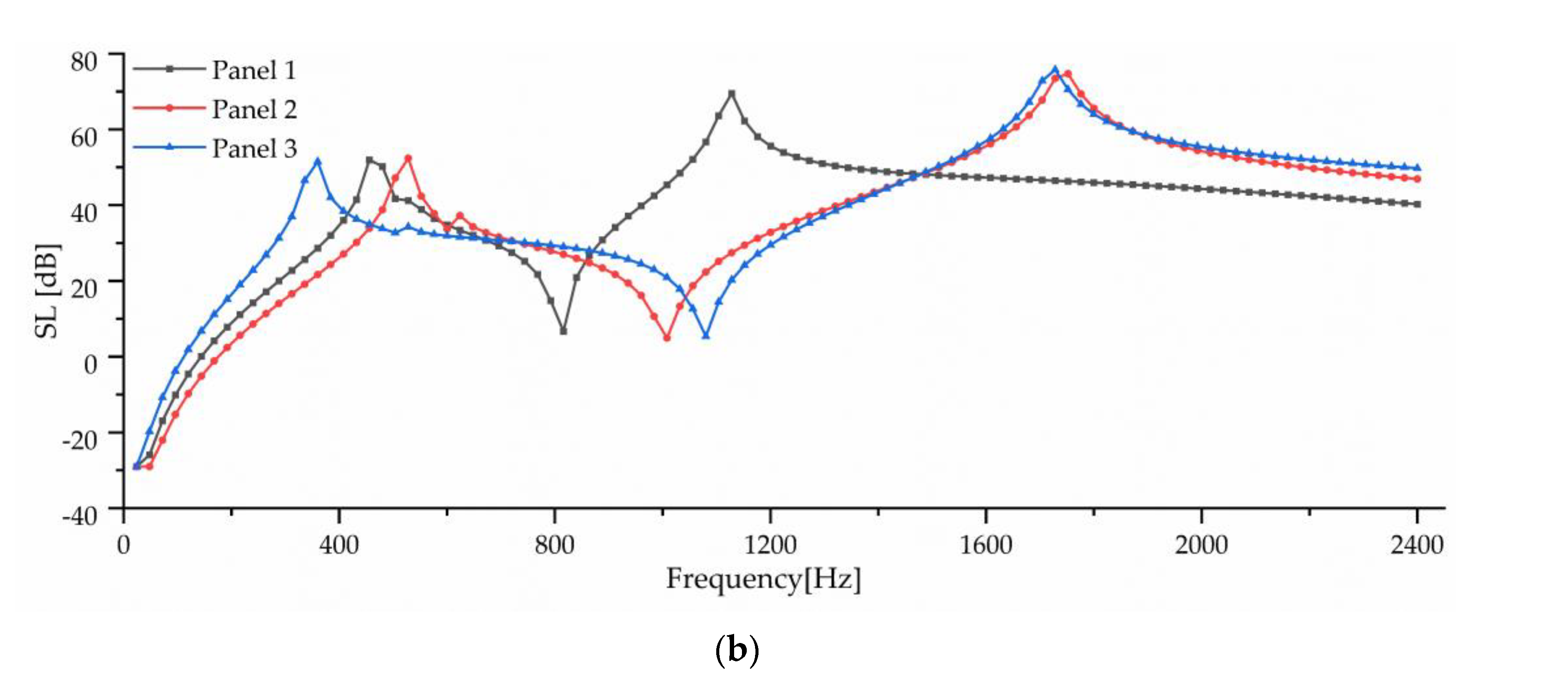

4.1.2. Vibration Velocity and Sound Source Level Analysis

4.2. Honeycomb Panel Design

4.2.1. Performance Analysis of Honeycomb Panels

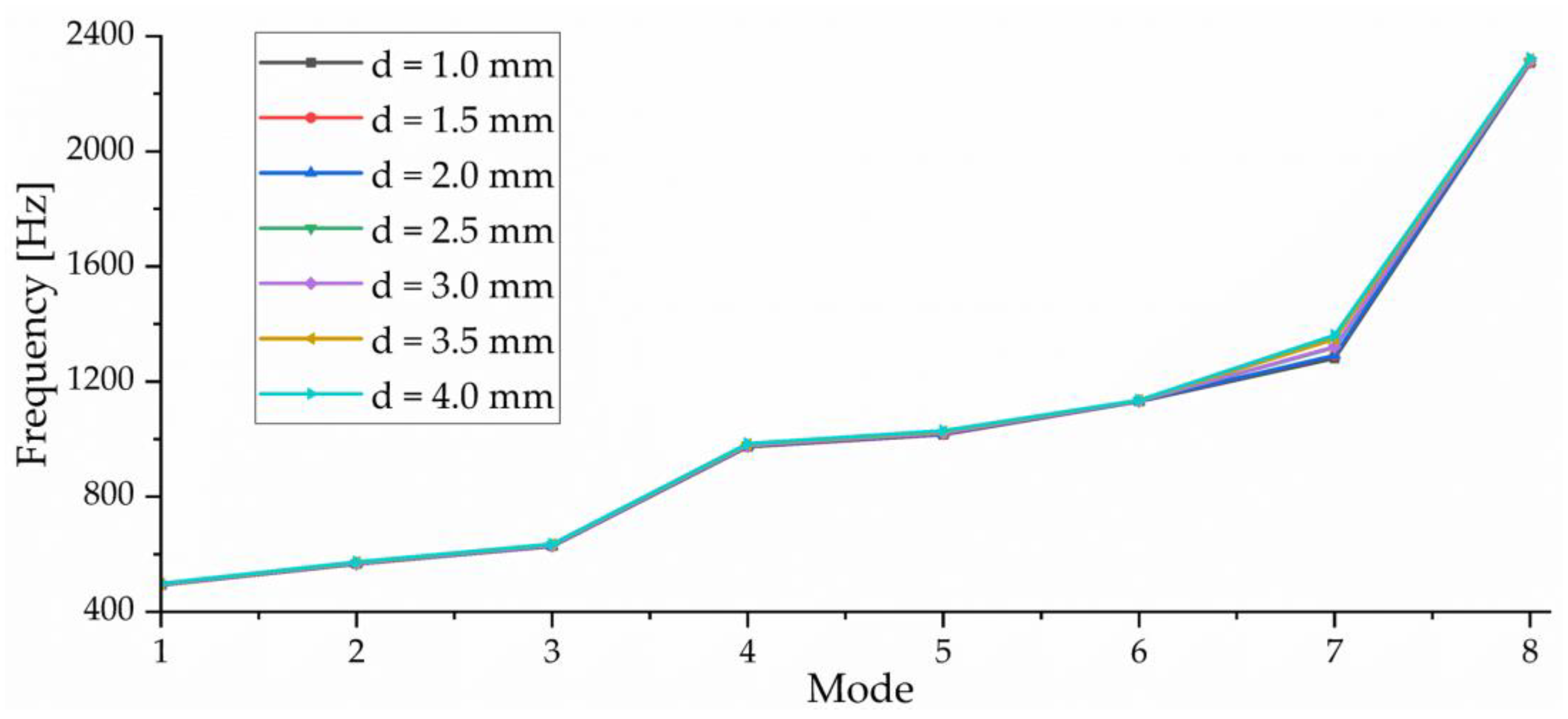

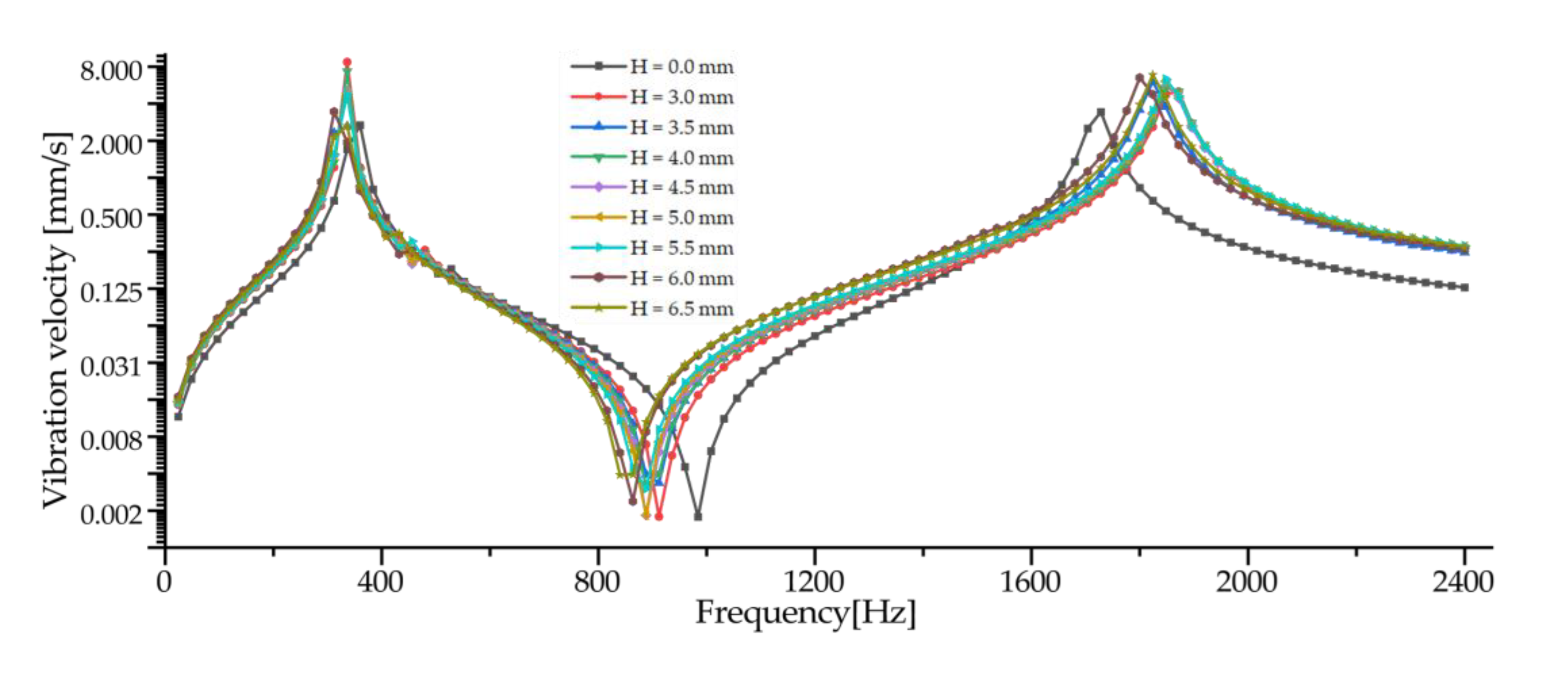

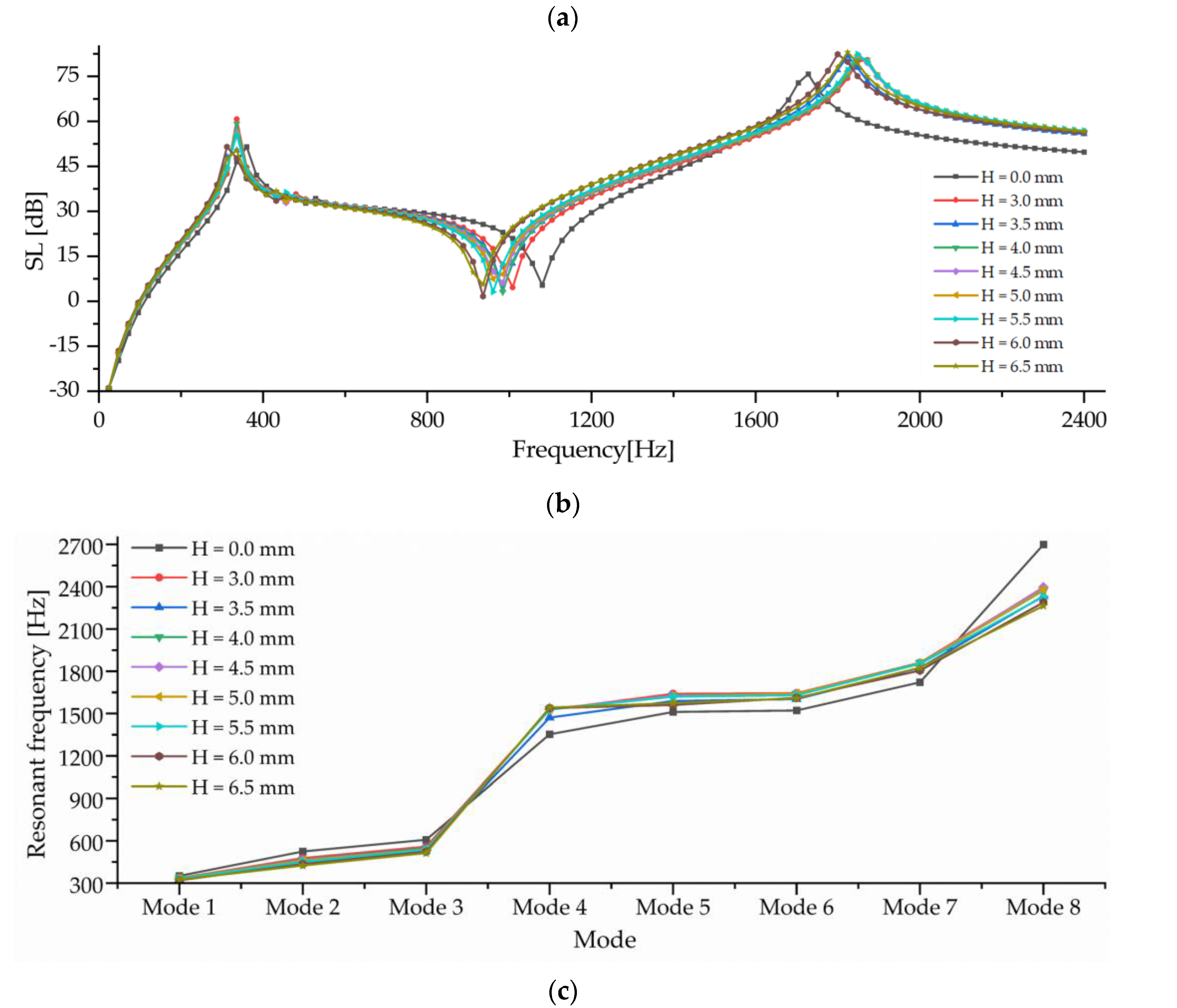

4.2.2. Optimization of Honeycomb Structure Parameters

5. Conclusions

- (1)

- The original configuration of the GMM transducer is proposed. The actual working conditions and material properties of each part are considered in the finite element modeling and numerical simulation, and the effectiveness of the finite element simulation is verified by comparing it with the modal test. The original configuration preliminarily realizes the functions of low frequency, high efficiency, light weight, and high power, which provides a reference for the subsequent structural optimization.

- (2)

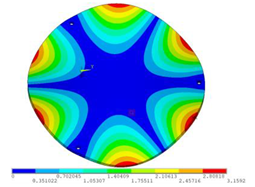

- Three basic configurations of the work panel are proposed and developed, and the optimal panel, Panel 3, is selected as the configuration of the work panel through modal, acoustic, and vibration coupling analysis and comparison. The resonant frequency of mode 1 of Panel 3 is 372.47 Hz, which is 24.6% lower than the original configuration. At the same time, the highest resonant frequency of Panel 3 within 2000 Hz is 1744.9 Hz, which greatly improves the working bandwidth and vibration power of the panel.

- (3)

- The honeycomb structure is innovatively applied to the work panel, which verifies that the honeycomb structure has a good effect on the vibration power of the work panel. The dimensional parameters of the honeycomb structure are optimized by considering the surface vibration velocity, sound source level, and resonance frequency. It is obtained that the honeycomb structure with the half opposite sides of a hexagon (H = 3.5 mm) has the highest performance improvement on the work panel. Comparing with Panel 3, the lowest resonance frequency was reduced by 12.8%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Benjeddou, A. Preface: Smart composites. Mech. Adv. Mater. Struct. 2006, 13, 355. [Google Scholar] [CrossRef]

- De Simone, M.E.; Ciampa, F.; Boccardi, S.; Meo, M. Impact source localisation in aerospace composite structures. Smart Mater. Struct. 2017, 26, 125026. [Google Scholar] [CrossRef]

- Sobczyk, M.; Wiesenhütter, S.; Noennig, J.R.; Wallmersperger, T. Smart materials in architecture for actuator and sensor applications: A review. J. Intell. Mater. Syst. Struct. 2021, 33, 379–399. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, Y.; Thomas, P.J. Structural Design and Physical Mechanism of Axial and Radial Sandwich Resonators with Piezoelectric Ceramics: A Review. Sensors 2021, 21, 1112. [Google Scholar] [CrossRef] [PubMed]

- Bani-Hani, M.A.; Almomani, A.M.; Aljanaideh, K.F.; Kouritem, S.A. Mechanical Modeling and Numerical Investigation of Earthquake-Induced Structural Vibration Self-Powered Sensing Device. IEEE Sens. J. 2022, 22, 19237–19248. [Google Scholar] [CrossRef]

- Aridogan, U.; Basdogan, I. A review of active vibration and noise suppression of plate-like structures with piezoelectric transducers. J. Intell. Mater. Syst. Struct. 2015, 26, 1455–1476. [Google Scholar] [CrossRef]

- Shi, Y.; Piao, C.; El Fadlaoui, D.; Al-Saadi, A.; Jia, Y. Integration and Characterisation of Piezoelectric Macro-Fibre Composite on Carbon Fibre Composite for Vibration Energy Harvesting. J. Phys. Conf. Ser. 2019, 1407, 012080. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, Y.; Chen, K. Development of a High-precision Digital Display Torque Wrench. J. Phys. Conf. Ser. 2020, 1626, 012138. [Google Scholar] [CrossRef]

- Srinivasaraghavan Govindarajan, R.; Rojas-Nastrucci, E.; Kim, D. Surface Acoustic Wave-Based Flexible Piezocomposite Strain Sensor. Crystals 2021, 11, 1576. [Google Scholar] [CrossRef]

- Köhler, B.; Kim, Y.; Chwelatiuk, K.; Tschöke, K.; Schubert, F.; Schubert, L. A Mode-Switchable Guided Elastic Wave Transducer. J. Nondestruct. Eval. 2020, 39, 45. [Google Scholar] [CrossRef]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric Transducer-Based Structural Health Monitoring for Aircraft Applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Chen, J.; Yang, W.; Qiu, L. On-line crack prognosis in attachment lug using Lamb wave-deterministic resampling particle filter-based method. Smart Mater. Struct. 2017, 26, 085016. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, W.; Han, L.; Liu, X.; Hu, W. Application of Sensor Path Weighting RAPID Algorithm on Pitting Corrosion Monitoring of Aluminum Plate. Materials 2022, 15, 3887. [Google Scholar] [CrossRef] [PubMed]

- Kouritem, S.A.; Altabey, W.A. Ultra-broadband natural frequency using automatic resonance tuning of energy harvester and deep learning algorithms. Energy Convers. Manag. 2022, 272, 116332. [Google Scholar] [CrossRef]

- Tian, F.; Liu, Y.; Ma, R.; Li, F.; Xu, Z.; Yang, Y. Properties of PMN-PT single crystal piezoelectric material and its application in underwater acoustic transducer. Appl. Acoust. 2021, 175, 107827. [Google Scholar] [CrossRef]

- Zhao, N.; Huo, L.; Song, G. A nonlinear ultrasonic method for real-time bolt looseness monitoring using PZT transducer–enabled vibro-acoustic modulation. J. Intell. Mater. Syst. Struct. 2019, 31, 364–376. [Google Scholar] [CrossRef]

- Li, H.; Lu, J.; Myjak, M.J.; Liss, S.A.; Brown, R.S.; Tian, C.; Deng, Z.D. An implantable biomechanical energy harvester for animal monitoring devices. Nano Energy 2022, 98, 107290. [Google Scholar] [CrossRef]

- Yan, S.; Wang, W.; Yan, X.; Zhou, J.; Liu, Y. Temperature characterization of magnetic and elastic parameters of TFD giant magnetostrictive materials. J. Magn. Magn. Mater. 2022, 563, 169979. [Google Scholar] [CrossRef]

- Yu, C.; Wang, C.; Deng, H.; He, T.; Mao, P. Hysteresis nonlinearity modeling and position control for a precision positioning stage based on a giant magnetostrictive actuator. RSC Adv. 2016, 6, 59468–59476. [Google Scholar] [CrossRef]

- Li, P.; Chen, Y.; Li, W.; Sun, J.; Li, J.; Wang, K. Design of Longitudinal-Bending Coupled Horn of a Giant Magnetostriction Transducer. Actuators 2022, 11, 110. [Google Scholar] [CrossRef]

- Zhao, T.; Yuan, H.; Pan, H.; Li, B. Study on the rare-earth giant magnetostrictive actuator based on experimental and theoretical analysis. J. Magn. Magn. Mater. 2018, 460, 509–524. [Google Scholar] [CrossRef]

- Ghorbanpour Arani, A.; Khani Arani, H.; Khoddami Maraghi, Z. Size-dependent in vibration analysis of magnetostrictive sandwich composite micro-plate in magnetic field using modified couple stress theory. J. Sandw. Struct. Mater. 2017, 21, 580–603. [Google Scholar] [CrossRef]

- Backman, G.; Lawton, B.; Morley, N.A. Magnetostrictive Energy Harvesting: Materials and Design Study. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Toutsop, B.; Ducharne, B.; Lallart, M.; Morel, L.; Tsafack, P. Characterization of Tensile Stress-Dependent Directional Magnetic Incremental Permeability in Iron-Cobalt Magnetic Sheet: Towards Internal Stress Estimation through Non-Destructive Testing. Sensors 2022, 22, 6296. [Google Scholar] [CrossRef]

- Liu, K.; Yang, L.; Wang, M.; Yang, S. Optimization of High Precision Magnetostrictive Linear Displacement Sensor. IEEE Sens. J. 2021, 21, 18535–18543. [Google Scholar] [CrossRef]

- Xie, C.; Liu, T.; Pei, C.; Chen, Z. A Flexible Thin-Film Magnetostrictive Patch Guided-Wave Transducer for Structural Health Monitoring. IEEE Sens. J. 2022, 22, 12237–12244. [Google Scholar] [CrossRef]

- Leong, Z.; Holmes, W.; Clarke, J.; Padki, A.; Hayes, S.; Morley, N.A. Magnetostrictive Sensors for Composite Damage Detection and Wireless Structural Health Monitoring. IEEE Trans. Magn. 2019, 55, 1–6. [Google Scholar] [CrossRef]

- Al-Taher, A.; Reiss, R.W.; Lafferty, A.D.; Hayes, S.A.; Lupu, N.; Murgulescu, I.; Morley, N.A. Magnetostrictive Materials for aerospace applications. J. Phys. Conf. Ser. 2017, 903, 012010. [Google Scholar] [CrossRef]

- Wang, W.; Shi, W.; Thomas, P.; Yang, M. Design and Analysis of Two Piezoelectric Cymbal Transducers with Metal Ring and Add Mass. Sensors 2019, 19, 137. [Google Scholar] [CrossRef]

- Coatney, M.; Hall, A.; Haile, M.; Bradley, N.; Yoo, J.H.; Williams, B.; Myers, O. Nondestructive damage detection of a magentostricive composite structure. In Conference Proceedings of the Society for Experimental Mechanics Series; Springer New York LLC: New York, NY, USA, 2019; pp. 85–87. [Google Scholar]

- Daniel, L.; Domenjoud, M. Anhysteretic Magneto-Elastic Behaviour of Terfenol-D: Experiments, Multiscale Modelling and Analytical Formulas. Materials 2021, 14, 5165. [Google Scholar] [CrossRef]

- Milyutin, V.A.; Bureš, R.; Fáberová, M.; Molčanová, Z.; Csanádi, T. Structure, magnetostriction and elastic properties of an Fe3Ga0.7Cu0.3 alloy. Mater. Lett. 2022, 327, 133063. [Google Scholar] [CrossRef]

- Han, J.; Zhang, J.; Gao, Y. A nonlinear magneto-mechanical-thermal-electric coupling model of Terfenol-D/PZT/Terfenol-D and Ni/PZT/Ni laminates. J. Magn. Magn. Mater. 2018, 466, 200–211. [Google Scholar] [CrossRef]

- Hashi, S.; Sora, D.; Ishiyama, K. Strain and Vibration Sensor Based on Inverse Magnetostriction of Amorphous Magnetostrictive Films. IEEE Magn. Lett. 2019, 10, 1–4. [Google Scholar] [CrossRef]

- Zhou, J.; He, Z.; Rong, C.; Xue, G. A giant magnetostrictive rotary actuator: Design, analysis and experimentation. Sens. Actuators A: Phys. 2019, 287, 150–157. [Google Scholar] [CrossRef]

- Dai, B.; He, Z.; Yang, Z.; Zhou, J.; Xue, G.; Liu, G. Modeling and analysis of the piezomagnetic, electromagnetic, and magnetostrictive effects in a magnetostrictive transducer. Aip Adv. 2021, 11, 125213. [Google Scholar] [CrossRef]

- Mohamed, K.; Elgamal, H.; Kouritem, S.A. An experimental validation of a new shape optimization technique for piezoelectric harvesting cantilever beams. Alex. Eng. J. 2021, 60, 1751–1766. [Google Scholar] [CrossRef]

- Yang, M.; Hu, Y.; Zhang, J.; Ding, G.; Song, C. Analytical model for flexural damping responses of CFRP cantilever beams in the low-frequency vibration. J. Low Freq. Noise Vib. Act. Control. 2018, 37, 669–681. [Google Scholar] [CrossRef]

- Wang, L.; Dai, L. Vibro-acoustical responses of a sandwich panel consist of aluminum honeycomb core and fabric-reinforced graphite facings. J. Sandw. Struct. Mater. 2022, 24, 1407–1428. [Google Scholar] [CrossRef]

- Razgordanisharahi, A.; Alipour Ghassabi, A.; Hellmich, C. Free vibration analysis of cylindrical honeycomb sandwich panels using state-space Levy method. Thin-Walled Struct. 2023, 182, 110308. [Google Scholar] [CrossRef]

| Structure Name | Size/mm |

|---|---|

| work panel | |

| GMM rod | |

| permanent magnet | |

| clump weight | |

| exciting winding | |

| outer shell | section side length: 31.5, axial length: 72.5 |

| Materials | Elasticity Modulus E/GPa | Density ρ/kg·m−3 | Poisson’s Ratio μ |

|---|---|---|---|

| steel | 209 | 7890 | 0.269 |

| GMM | 23 | 9250 | 0.210 |

| iron | 194 | 7930 | 0.280 |

| copper | 90 | 8500 | 0.300 |

| magnet | 113 | 3800 | 0.230 |

| Structures | clump weight | actuated rod | permanent magnet | GMM rod | exciting winding | rear cover |

| Materials | steel | iron | magnet | GMM | copper | iron |

| Mode | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Frequency f/Hz | 494.06 | 567.56 | 629.15 | 975.65 | 1018.7 | 1131.9 | 2310.0 | 2441.0 | 2448.0 | 2758.7 | 3530.6 |

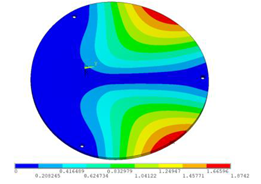

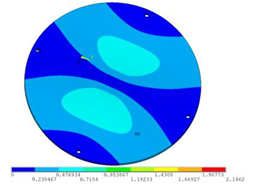

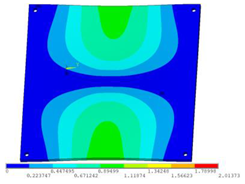

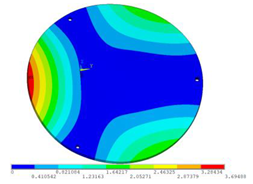

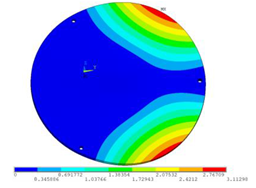

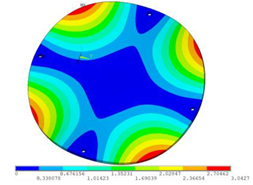

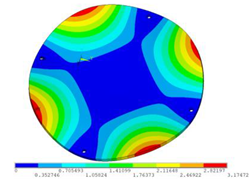

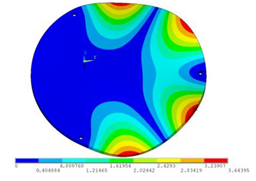

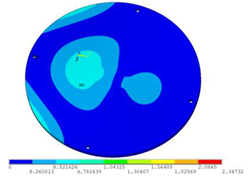

| Resonant Mode | Panel 1 | Panel 2 | Panel 3 |

|---|---|---|---|

| mode 1 |  |  |  |

| 494.06 Hz | 551.41 Hz | 372.47 Hz | |

| mode 2 |  |  |  |

| 567.56 Hz | 651.86 Hz | 563.60 Hz | |

| mode 3 |  |  |  |

| 629.15 Hz | 744.26 Hz | 645.18 Hz | |

| mode 4 |  |  |  |

| 975.65 Hz | 1380.0 Hz | 1352.1 Hz | |

| mode 5 |  |  |  |

| 1018.7 Hz | 1566.4 Hz | 1521.7 Hz | |

| mode 6 |  |  |  |

| 1131.9 Hz | 1572.2 Hz | 1540.9 Hz | |

| mode 7 |  |  |  |

| 2310.0 Hz | 1745.3 Hz | 1744.9 Hz | |

| mode 8 |  |  |  |

| 2441.0 Hz | 2776.5 Hz | 2705.1 Hz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Wang, W.; Zhao, X.; Li, H.; Xiang, Y. Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material. Sensors 2023, 23, 108. https://doi.org/10.3390/s23010108

Yang L, Wang W, Zhao X, Li H, Xiang Y. Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material. Sensors. 2023; 23(1):108. https://doi.org/10.3390/s23010108

Chicago/Turabian StyleYang, Long, Wenjie Wang, Xu Zhao, Haojun Li, and Yue Xiang. 2023. "Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material" Sensors 23, no. 1: 108. https://doi.org/10.3390/s23010108

APA StyleYang, L., Wang, W., Zhao, X., Li, H., & Xiang, Y. (2023). Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material. Sensors, 23(1), 108. https://doi.org/10.3390/s23010108