Abstract

The purpose of this study is to propose guidelines for sensor installation in different types of underground space smart sensing platforms. Firstly, we classify the underground space, analyze the scene requirements according to the classification of underground space, and sort out the requirements for sensors in various types of underground space. Secondly, according to the requirements of underground space scenes for sensors, the types of sensors and corresponding parameters are clarified. After that, the system design and sensor installation guidelines of the underground space smart sensing platform are proposed by sorting out the data acquired by the sensor.

1. Introduction

This paper clarifies the sensor types and corresponding parameters for smart sensing scenes by analyzing the needs of different types of underground space scenes. Based on the sensor parameters and acquired data required by the underground space smart sensing platform system, the sensor installation guidelines are formed accordingly.

This study needs to clarify types of underground spaces, and we can refer to the laws and regulations of underground spaces in each country. Japan has a perfect legal and management mechanism for underground spaces [1,2,3,4], such as the “Act on Special Measures concerning Public Use of Deep Underground”, which clarifies the specific problems and technical measures for underground space utilization. Meanwhile, for different types of underground spaces, there are different technical standards and construction regulations [5], such as “Standard Specification for Tunneling” and so on. The “State Lands Act” and “Land Acquisition Act” clarify the classification basis and ownership of underground spaces, and the “Common Services Tunnels Act” and others have introduced new technical requirements for different underground spaces. There are also different technical standards and construction procedures in different underground space classifications such as “Railway applications Fixed installations Electric traction overhead contact lines”. In the United States, there is also a relatively complete legal and management mechanism for underground space [6], and state laws such as “Laws of Minnesota for 1985 Mined Underground Space” and “Oklahoma Statutes Property” have clarified the technical measures in the development and use of underground space according to the characteristics of each state. There are also different technical standards and construction procedures in different underground space types, such as “Underground Electric Distribution Standards Manual” and “Underground Construction (Tunneling)”. Similar to the United States, the United Kingdom also has a comprehensive legal and regulatory mechanism [6], such as the “London Underground Act 1992”, which proposes measures to deal with various problems in different areas of London’s underground space. The United Kingdom also has different technical standards and construction regulations in different underground space types, such as “The Road Tunnel Safety (Amendment) Regulations”. Through these laws and regulations, the classification of underground space can be clarified [7,8].

From the location of the underground space, it requires arterial energy from facilities such as water, electricity, transportation and data flow [9,10,11,12,13], and waste water and waste disposal through veins [13,14,15,16,17], while the underground space contains the infrastructure that ensures the function and operation of urban infrastructure and is the “lifeline” that combines the arteries and veins of the city [16,17,18,19,20,21,22] in addition to the services and facilities that bring benefits and taxes from commercial operations and provide commercial value to the city [23,24]. Therefore, the planning of underground spaces also emphasizes the actual equipment [25], and smart sensing of underground spaces can improve the responsiveness of equipment and thus the efficiency of the city’s arteries and veins [26,27]. As a basic component of smart construction, the installation of sensors (including model selection, location selection, combination mode, etc.) is an important part of smart work [28,29,30,31,32].

Based on the existing design guidelines in Japan, such as “Facility Construction Safety Construction Technical Guidelines” and “Civil Engineering Work Safety Construction Technical Guidelines”, it is clear in Table 1 that the requirements for equipment in underground spaces in the traditional Japanese design guidelines are mainly reflected in the types of equipment, the general location of equipment and the occasions of use of equipment. The existing regulations and guidelines basically do not involve smart devices, sensors and other new equipment content. This problem is common in the design guidelines for underground spaces in all countries. From the devices used in the current underground space in Japan, we can also see in Table 1 that these devices consume more energy and have a lower degree of smartness, and most of them are universal and do not select devices for the characteristics of different types of underground spaces.

Table 1.

Summary of the requirements of the existing guidelines for underground space devices and the devices commonly used in the current underground space.

In summary, countries have more complete laws and regulations for the infrastructure construction of underground space [33], but there is a lack of design guidelines for setting up smart sensing devices in the whole underground space [33]. Therefore, this study starts from the design phase of underground space, and after clarifying the classification of underground space, according to the functional requirements of different scenes for sensors in underground space, the type parameters of sensors in each scene are clarified. According to the type and parameters of sensors, the attributes of the collected data are clarified. Finally, based on the classification of underground space, the basic framework of underground space intelligent sensing system design, the properties of sensors, and the properties of data, we propose the guidelines of sensor installation for smart scenes in underground space.

2. Theoretical Concept and Methodology

To meet the monitoring and early warning needs of maintenance management, this study considers that the guidelines for setting up sensors in underground spaces need to clarify the classification of underground spaces and also the properties of sensors such as communication methods, the properties of data and the basic framework of the sensing system, thus taking the following research steps to propose guidelines for setting up sensors for smart scenes in underground spaces:

- Classify the underground space according to the classification standard of Japanese underground space and the functional characteristics of each type of underground space, and by clarifying the functional requirements of each type of underground space for sensors on the basis of the classification of underground space;

- Based on the above-mentioned requirements for sensors in the underground space, the sensors are screened on the basis of the temperature and humidity applicable to the underground space, and the sensor types and parameters are selected to meet the smart scene and functional requirements of the underground space;

- Based on the functional requirements met by the above sensors as well as the sensor types and parameters, the types of data acquired by each type of sensor and the data attributes are clarified;

- Based on the classification of underground space, sensor attributes and data attributes in I, II and III above, clarify the data transmission methods and data flow between sensors of various types of data, propose the basic framework of smart sensing system in underground space and form the guidelines for setting up sensors for smart scenes in underground space.

3. Underground Space Classification and Scene Requirements Analysis

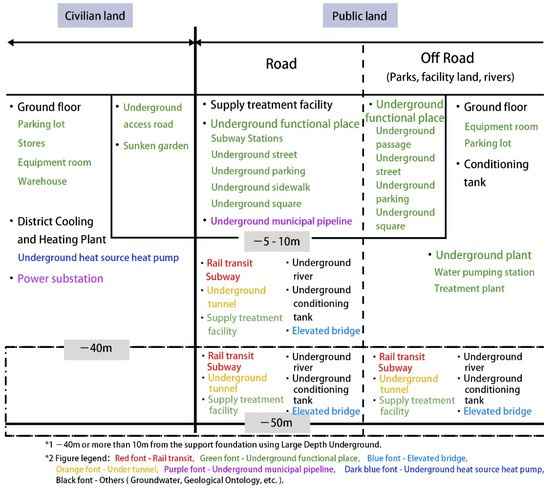

Various types of underground spaces have different needs for sensors. Since the planning and construction of underground spaces in Japan is at an advanced level internationally, this study refers to the Japanese classification standard for underground space, which distinguishes between civilian land and public land, and classifies underground spaces according to the depth of various underground facilities in Figure 1.

Figure 1.

Classification of underground space in Japan.

Based on the Japanese classification standard for underground space, underground space can be divided into six types of underground infrastructure: rail transit, underground functional places (underground stores, parking lots, subway stations, etc.), elevated bridges, underground tunnels, underground municipal pipelines, and underground heat source heat pumps in Table 2.

Table 2.

Classification of underground space and monitoring priorities.

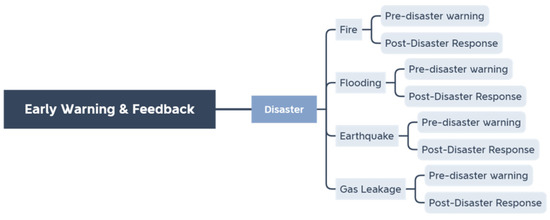

Different functions of the underground space are monitored differently during maintenance. Therefore, there are also differences in the requirements for sensors. In order to meet the operational requirements (Figure 2), the discussion needs to be based on the classification of the underground space in question.

Figure 2.

Maintenance phase monitoring content classification diagram.

Underground spaces have different requirements for various types of sensors in different types of spaces, which are organized according to the Table 3 below.

Table 3.

Summary of underground space requirements.

4. Underground Space Sensor Sorting

Based on the classification of the underground space, and the requirements of sensors for different underground space scenarios, the sensors on the market are screened on the basis of the temperature and humidity applicable to underground space, and the types of sensors and the corresponding parameters of sensors that can meet the needs of the scenario are obtained in Table 4.

Table 4.

Summary of underground space sensors.

5. Underground Space Data Sorting

Based on the functional requirements of the underground space for sensors, sensor types and parameters, the attributes of the data acquired by various types of sensors are clarified, including data transmission methods and data monitoring scopes. The final results will be classified based on data types and attributes to form a data summary table (Table 5).

Table 5.

Sensor-based data summarization in underground spaces.

6. Basic Framework of Underground Space Smart Sensing Platform

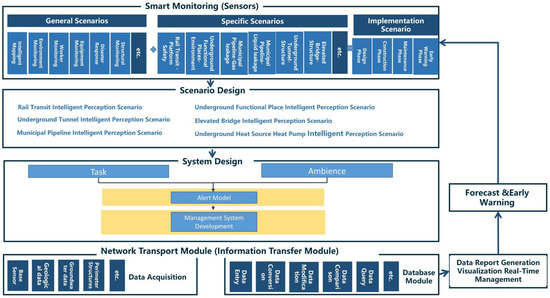

Based on the analysis of underground space classification and scene requirements, sensor attributes and data attributes, the framework of underground space smart sensing platform (smart sensing system control) is proposed in Figure 3.

Figure 3.

Basic framework of underground space smart sensing platform.

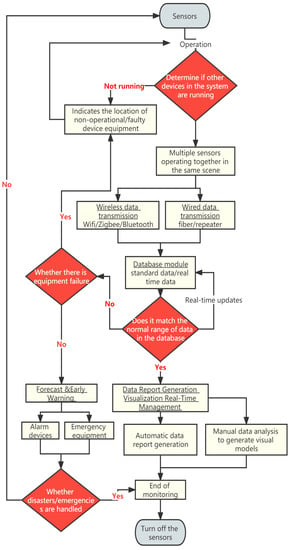

Based on the data transmission methods and data flow between sensors in the underground space, the data flow of the sensing platform is clarified in Figure 4: smart monitoring devices (sensors) acquire data Multiple sensors are combined to form smart scenarios The data acquired by each sensor is integrated as task (or the data acquired by each scene as Ambience), through the central processor and the database data for comparison, through the network transport module to the database module (update data without problems) or data report generation visualization real-time management module (problem data for feedback) feedback to smart monitoring equipment (alarm device) through forecast and early warning module with problematic data.

Figure 4.

Smart perception platform UML.

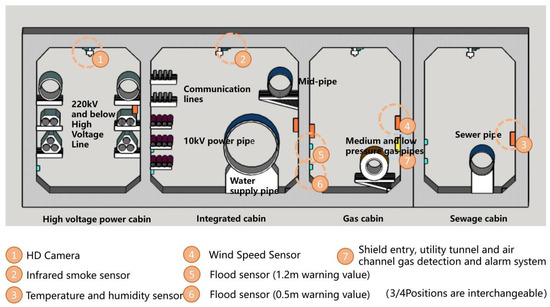

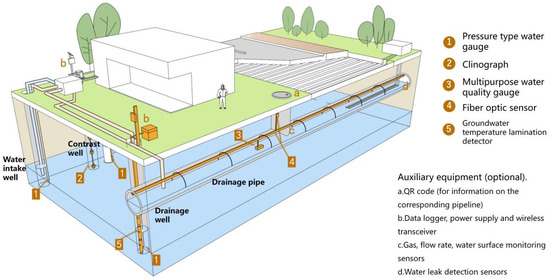

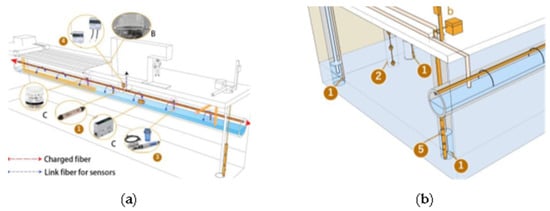

7. Production of Sensor Installation Guidelines for Underground Space

In this paper, we make a summary analysis of the requirements of different underground space types to clarify the types of underground space sensor requirements as well as the parameters of the sensors and the monitoring data of the underground space to form the sensor installation guidelines in the underground space smart sensing platform. To facilitate the designers to carry out the design work related to the underground space smart, we will finally form the sensor design and installation guidelines table (Table 6) and the installation location schematic according to the characteristics of the sensors used in different scenarios (Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16).

Table 6.

Sensor installation guidelines.

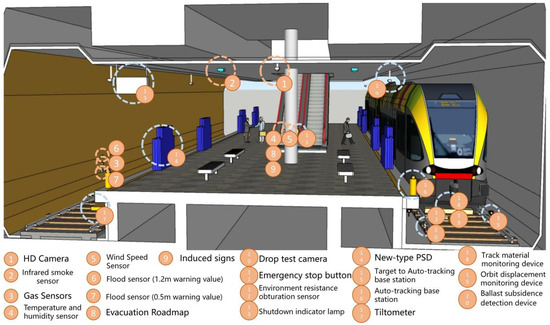

Figure 5.

Rail transit sensor installation schematic.

Figure 6.

Smart interaction function for rail transit. (a): Various types of devices in smart interaction scenarios. Including environmental monitoring devices and accident response devices. (b): User access to the detection range of new-type PSD. (c): The door opens automatically after entering the detection range of new-type PSD, after which drop test camera opens and the user enters the detection range of drop test camera. (d): When the user falls off the track, environment resistance obturation sensor will sound an alarm. He or she will remain in the detection range of drop test camera. At this time, drop test camera will determine the location of the fall accident and upload it.

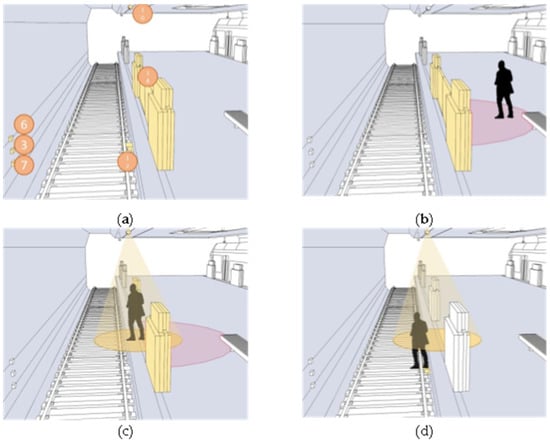

Figure 7.

Underground functional place sensor installation schematic.

Figure 8.

Smart interaction function for underground functional place. (a): Various types of devices in smart interaction scenarios. Environmental monitoring equipment is the main focus. Users can read basic environmental information at temperature and humidity sensor. (b): When a user is detected to be in the monitoring range, the devices mainly in HD camera are automatically turned on.

Figure 9.

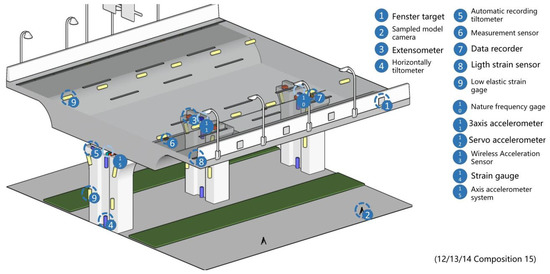

Elevated bridge sensor installation schematic.

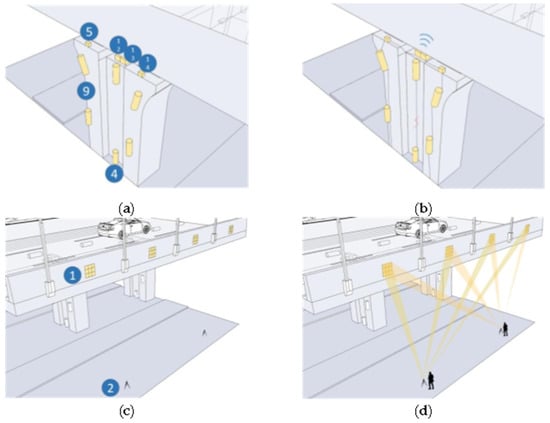

Figure 10.

Smart interaction function for elevated bridge. (a): The monitoring devices are mainly column structure monitoring devices. (b): The various devices are linked by optical fibers, and when cracks appear/structure damage, electrical signals are conducted from measurement sensors/horizontally tiltometer to 3-axis accelerometer system and uploaded by 3-axis accelerometer system via optical fibers. (c): Bridge structure monitoring equipment is the main focus. (d): The user captures the location of multiple fenster target’s by sampled model camera and determines if the bridge is deformed by comparing it to the indicator.

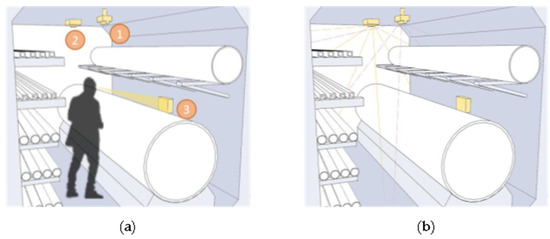

Figure 11.

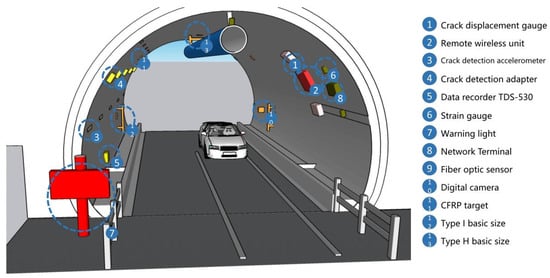

Underground tunnel sensor installation schematic.

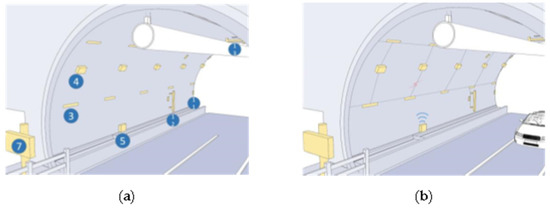

Figure 12.

Smart interaction function for underground tunnel. (a): The smart devices are mainly tunnel support structure monitoring devices. (b): Various devices are linked by fiber optics. When a crack/structure breakage occurs in the support, the electrical signal from the sensor is stored to data recorder via optical fiber and uploaded by data recorder.

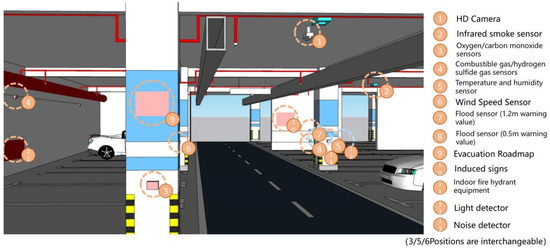

Figure 13.

Underground municipal pipeline sensor installation schematic.

Figure 14.

Smart interaction function for underground municipal pipeline. (a): The smart devices are divided into environmental monitoring devices and pipe corridor structure monitoring devices. Users can read basic environmental information from temperature and humidity sensor on the walls of the corridor. (b): The monitoring range of environmental monitoring devices covers the entire corridor space.

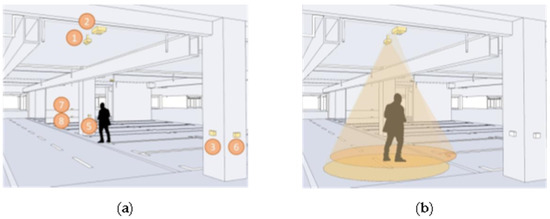

Figure 15.

Underground heat source heat pump sensor installation schematic.

Figure 16.

Smart interaction function for underground heat source heat pump. (a): Smart devices in drainage pipes. Water monitoring devices and pipeline structure monitoring devices are the main focus. All kinds of devices are linked by optical fiber, and the electrical signal is transmitted to the data recorder and wireless transceiver after water quality problems or structural problems, and uploaded by the wireless transceiver. (b): Smart devices in comparison wells, intake wells and drainage wells. Water quality monitoring devices and well structure monitoring devices are the main focus.

8. Conclusions

In this paper, we analyze the requirements of different types of underground space scenes and clearly establish the sensor types and corresponding parameters for smart sensing scenes. Based on the sensor parameters and the acquired data, we propose a system design for smart sensing platform in underground space and form the sensor installation guidelines accordingly. The guidelines are mainly divided into two parts: installation guideline table and installation schematic, and the purpose of setting the guidelines is to guide the work related to the construction of smart scenes in underground space.

The study of requirements in this paper focuses largely on maintenance management. The next step will be to refine the process of developing and constructing smart scenes in underground spaces, and to propose different development proposals and guidelines at different phases according to the refined process.

Author Contributions

Conceptualization, X.T. and Z.S.; methodology, X.T.; software, Z.S.; validation, Z.S. and X.T.; formal analysis, X.T.; investigation, Y.Z. and W.X.; resources, X.T.; data curation, Y.Z.; writing—original draft preparation, Y.Z. and X.T.; writing—review and editing, X.T. and Y.Z.; visualization, Z.S.; supervision, Z.S.; project administration, Z.S.; funding acquisition, Z.S. and G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by Key Research Project of Philosophy and Social Science Research of the Ministry of Education Research on the Basic Theory of Land and Space Planning in the New Era, grant number: 20JD058. This research is supported by Fujian Science & Technology Innovation Laboratory for Optoelectronic Information of China ⟪Application of virtual reality technology in smart urban planning⟫, grant number: 2021ZR139. This research is supported by External Cooperation Project of China Land Surveying and Planning Institute Depth Research on The Reference Rules of Territorial Spatial Use Control in Japan (2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in [Automatic Fire Alarm System General Catalog] [Gas detection unit KD-5A/KD-5B Specifications] [Gas detection unit KD-5D/KD-5O Specifications] [Noise and Vibration Level Indicator RTK-27R Specifications] [Catalog: Wireless Mini Logger LR8512, LR8513, LR8514, LR8515, LR8520] [Gas detection and alarm system for shield tunneling works, ditches and tunnels TDL-1/MDL-700 Specifications] [Oxygen and Carbon Monoxide Meter XOC-353II/XOC-353IIBT Specifications] [Digital dust meter (dust meter) LD-5 Specifications] [KYOSAN-Safeguards for Passenger Transfer Area] [NSG-Catalog of Track equipment monitoring-Track material monitoring device/ Orbit displacement monitoring device] [SAKATA DENKI-Catalog of Line equipment monitoring device] [Catalog: Extensometer Z4D-C01] [Catalog: KB-AB/KB-AC (Horizontally tiltometer)] [Catalog: FAC series (Crack gauge)] [Optical Fiber Measurement Solution FBG Sensing] [Kyowa-Measuring Components General Catalog 2021] [Catalog: Crack detection sensor KZCB-A] [Cloud-based IoT Remote Leakage Monitoring System Leaknets Cellular LNL-C Materials].

Acknowledgments

Any support not covered by the author contributions or funding sections.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lin, Y.; Shen, Z.; Teng, X. Review on Data Sharing in Smart City Planning Based on Mobile Phone Signaling Big Data: From the Perspective of China Experience: Anonymization Vs De-Anonymization. Int. Rev. Spat. Plan. Sustain. Dev. 2021, 9, 76–93. [Google Scholar] [CrossRef]

- Zhao, L.; Shen, Z.; Zhang, Y.; Ma, Y. The impact of the community built environment on the walking times of residents in a community in the downtown area of Fuzhou. Sustainability 2019, 11, 691. [Google Scholar] [CrossRef]

- Chen, H.; Shen, Z. Building form regulation visualisation in Japan: Automatic building volume legality verification via procedural modelling. Int. J. Sustain. Soc. 2018, 10, 313–340. [Google Scholar] [CrossRef]

- Guo, X.; Shen, Z.; Zhang, Y.; Wu, T. Review on the application of artificial intelligence in smart homes. Smart Cities 2019, 2, 402–420. [Google Scholar] [CrossRef]

- Fitriaty, P.; Shen, Z.; Sugihara, K. How Green Is Your Smart House: Looking Back to the Original Concept of the Smart House. In Green City Planning and Practices in Asian Cities, 1st ed.; Shen, Z., Huang, L., Peng, K., Pai, J., Eds.; Springer: Cham, Switzerland, 2018; Part 1, pp. 39–76. [Google Scholar]

- Nishigaki, M.; Kankam-Yeboah, K.; Komatsu, M. Underground dam technology in some parts of the world. J. Groundw. Hydrol. 2014, 46, 113–130. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, J.; Shen, Z.; Liu, S.; Teng, X.; Kawakami, M. Study on the construction of energy-saving evaluation index system for the development of low-carbon industrial—A case study in Pingtan of Fujian Province, China. Energy Rep. 2021, 7, 86–92. [Google Scholar] [CrossRef]

- Dan, Y.; Shen, Z.; Zhu, Y.; Huang, L. Using mixed reality (MR) to improve on-site design experience in community planning. Appl. Sci. 2021, 11, 3071. [Google Scholar] [CrossRef]

- Shen, Z.; Fitriaty, P.; Cao, Z.; Dan, Y. The Evolution and Evaluation Index of Smart House Based on the Comparison with Green House. Shanghai Urban Plan. Rev. 2018, 1, 1–11. [Google Scholar]

- Shen, Z.; Lei, Z.; Li, X.; Sugihara, K. Design Coordination Regarding Urban Design Guidelines Using Google Earth. Int. Rev. Spat. Plan. Sustain. Dev. 2013, 1, 53–68. [Google Scholar] [CrossRef]

- Nguyen, D.-T.; Shen, Z.; Honda, K.; Sugihara, K.; Nishino, T.; Truong, M.-H. A GIS-Based Model for Integrating Risk Estimations of Residential Building Damage and Shelter Capacity in the Case of Earthquakes. Nat. Hazards Rev. 2020, 21, 04019016. [Google Scholar] [CrossRef]

- Tanaka, H.; Kawakami, M.; Shen, Z.; Sekiguchi, T.; Toyoshima, Y. A study on measures for disaster prevention in historically dense Urban areas from the viewpoint of fire spread risk. AIJ J. Technol. Des. 2020, 26, 978–983. [Google Scholar] [CrossRef]

- Teng, X.; Shen, Z. Design of a smart visiting service management system for personal information collection in order to integrate tourism management into an isolated island. Appl. Sci.-Basel 2020, 10, 6442. [Google Scholar] [CrossRef]

- Huang, G.; Shen, Z.; Mardin, R. Overview of Urban Planning and Water-Related Disaster Management. In Urban Planning and Water-related Disaster Management, 1st ed.; Huang, G., Shen, Z., Eds.; Springer: Cham, Switzerland, 2019; Chapter 1; pp. 1–10. [Google Scholar]

- Huang, G.; Shen, Z. Special issue on Environment management and spatial planning. Int. Rev. Spat. Plan. Sustain. Dev. 2017, 5, 1–3. [Google Scholar]

- Li, M.; Dong, L.; Shen, Z.; Lang, W.; Ye, X. Examining the interaction of taxi and subway ridership for sustainable urbanization. Sustainability 2017, 9, 242. [Google Scholar] [CrossRef]

- Çorman, M.E.; Ozcelikay, G.; Cetinkaya, A.; Kaya, S.I.; Armutcu, C.; Özgür, E.; Uzun, L.; Ozkan, S.A. Metal-organic frameworks as an alternative smart sensing platform for designing molecularly imprinted electrochemical sensors. TrAC Trends Anal. Chem. 2022, 150, 116573. [Google Scholar] [CrossRef]

- Park, J.H.; Rathore, S.; Singh, S.K.; Salim, M.M.; Azzaoui, A.E.; Kim, T.W.; Pan, Y.; Park, J.H. A Comprehensive Survey on Core Technologies and Services for 5G Security: Taxonomies, Issues, and Solutions. Hum.-Cent. Comput. Inf. Sci. 2021, 11, 1–22. [Google Scholar]

- Mardin, R.; Shen, Z. Integrated Criteria for Flood Disaster Mitigation in Indonesian Urban Masterplan; Housing and Settlement Suitability Case in Palu Urban Masterplan. In Urban Planning and Water-Related Disaster Management; Springer: Cham, Switzerland, 2019; pp. 127–153. [Google Scholar]

- Sugihara, K.; Shen, Z. Automatic generation of 3D building models by rectification of building polygons. Adv. Sci. Lett. 2015, 21, 3649–3654. [Google Scholar] [CrossRef]

- Long, Y.; Shen, Z. Population Spatialization and Synthesis with Open Data. Geospat. Anal. Support Urban Plan. Beijing 2015, 116, 115–131. [Google Scholar]

- Li, M.; Deng, J.; Liu, L.; Long, Y.; Shen, Z. Evacuation simulation and evaluation of different scenarios based on traffic grid model and high performance computing. Int. Rev. Spat. Plan. Sustain. Dev. 2015, 3, 4–15. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Shen, Z.; Nishino, T.; Chen, X. 3D laser scanning technology-based historic building mapping for historic preservation A case study of Shang Shu Di in Fujian Province, China. Int. Rev. Spat. Plan. Sustain. Dev. 2015, 3, 53–67. [Google Scholar]

- Guo, X.; Shen, Z.; Teng, X.; Lin, Y. Using Web Data Scraping to Reveal the Relationship between AI Product and Room Layout. In Design and Technological Applications in Sustainable Architecture, 1st ed.; Lau, S.S.Y., Li, J., Hao, S., Lu, S., Eds.; Springer: Cham, Switzerland, 2021; Part 5, pp. 147–158. [Google Scholar]

- Shen, Z.; Ma, Y.; Sugihara, K.; Lei, Z.; Shi, E. Technical possibilities of cloud-based virtual reality implementing software as a service for online collaboration in urban planning. Int’l J. Commun. Netw. Syst. Sci. 2015, 7, 463. [Google Scholar] [CrossRef][Green Version]

- Gong, S.; Liu, Z.; Guan, S.; Jiao, J.; Shen, Z.; Yang, D.; Sun, S.; Chen, C. Lidar study on the parameter relations of gravity waves in the mesopause region at Beijing. Infrared Laser Eng. 2015, 44, 1134–1140. [Google Scholar]

- Li, M.; Shen, Z.; Yang, T.; Wang, J.; Kobayashi, F.; Li, M. Application of spatial and temporal entropy based on multivariate data for measuring the degree of urban function mix. China City Plan. Rev. 2015, 24, 40–48. [Google Scholar]

- Shen, Z. Overview: Big data support for urban planning and management in China. In Big Data Support of Urban Planning and Management, 1st ed.; Shen, Z., Li, M., Eds.; Springer: Cham, Switzerland, 2018; Chapter 1; pp. 1–15. [Google Scholar]

- Shen, Z.; Kawakami, M. Overview: Spatial Planning for Achieving Sustainable Urban Forms. In Spatial Planning and Sustainable Development, 1st ed.; Kawakami, M., Shen, Z., Gao, X., Zhang, M., Eds.; Springer: Cham, Switzerland, 2013; Chapter 1; pp. 1–11. [Google Scholar]

- Li, M.; Shen, Z.; Sheng, Q.; Duan, B.; Li, L. A study on the correlation between spatial configuration and rail passenger volume in different scales-take Fuxia region as an example. Int. J. Soc. Syst. Sci. 2016, 8, 114–130. [Google Scholar] [CrossRef]

- Alsalemi, A.; Himeur, Y.; Bensaali, F.; Amira, A. Smart Sensing and End-Users’ Behavioral Change in Residential Buildings: An Edge-Based Internet of Energy Perspective. IEEE Sens. J. 2021, 21, 27623–27631. [Google Scholar] [CrossRef]

- Singh, S.K.; Tanwar, S. Analysis of software testing techniques: Theory to practical approach. Indian J. Sci. Technol. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Z.; Cui, B.; Lin, Y. Construction of Urban Planning Supporting System Using Genetic Algorithm Responding to Urban Decentralization: Case of Kanazawa City. J. Urban Plan. Dev. 2020, 146, 04020044. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).