Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies

Abstract

:1. Introduction

2. Acoustic Emission Monitoring System

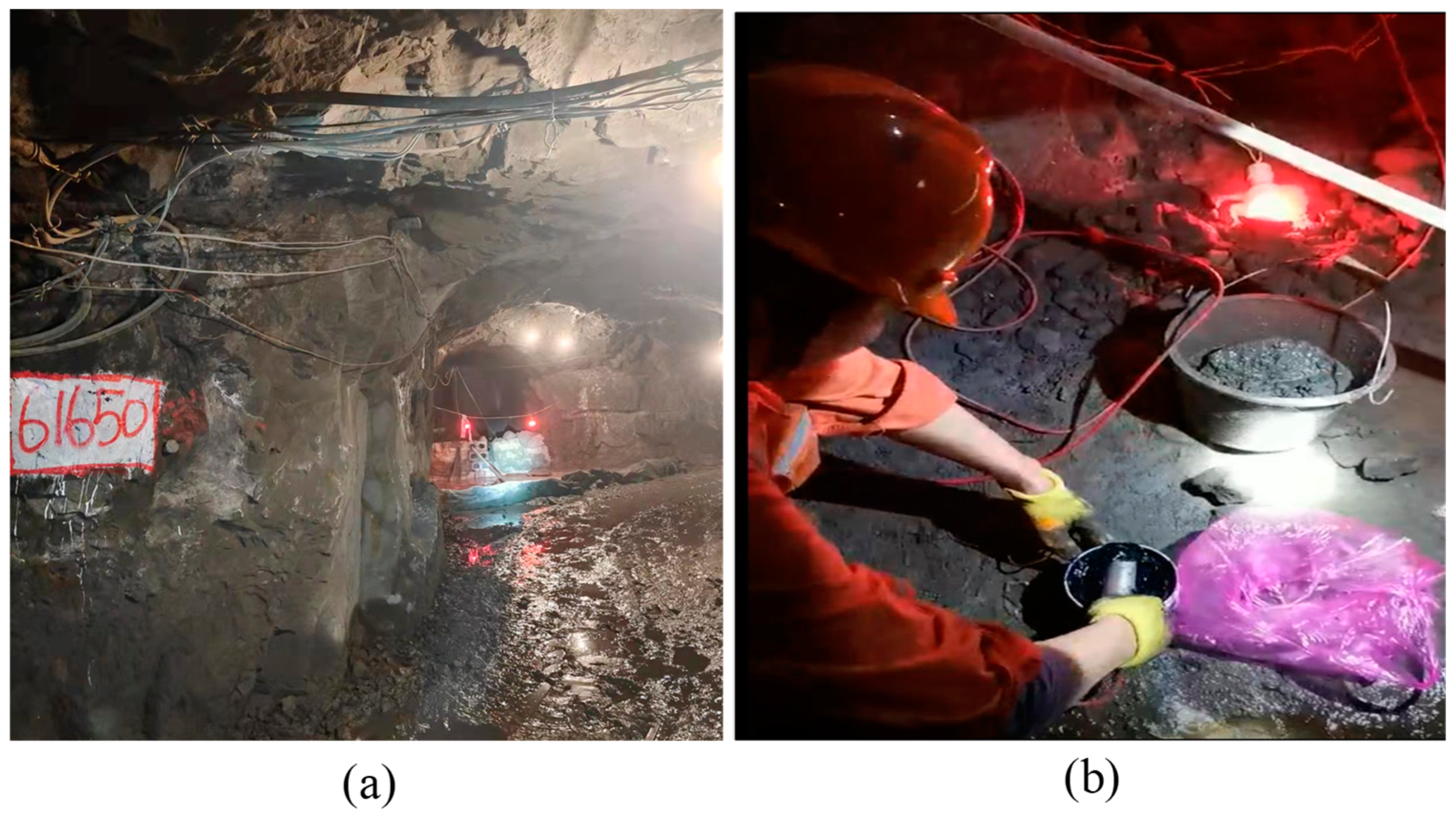

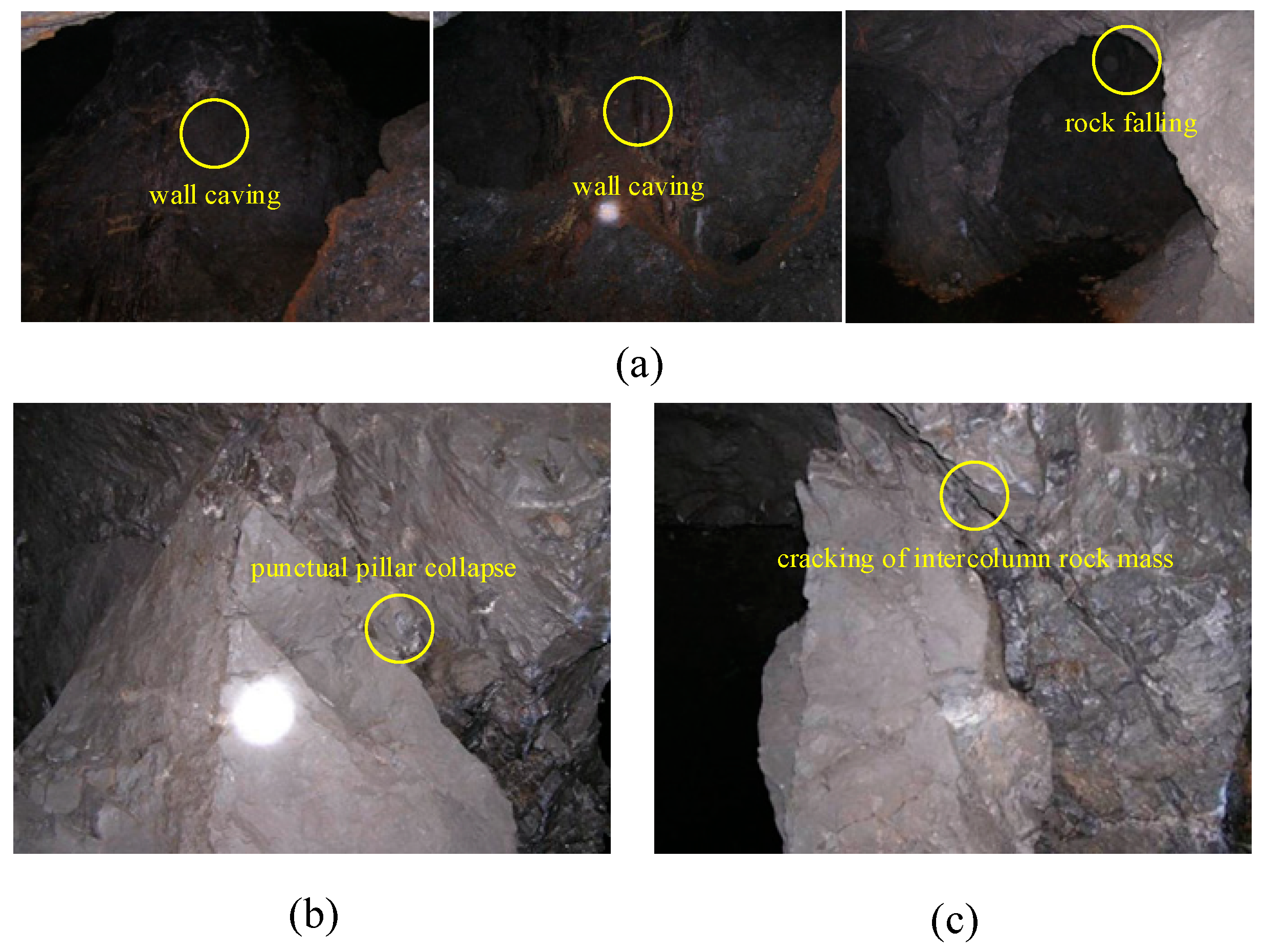

2.1. Engineering Background

2.2. Layout of Monitoring System

2.3. Data Acquisition

3. Theory and Method

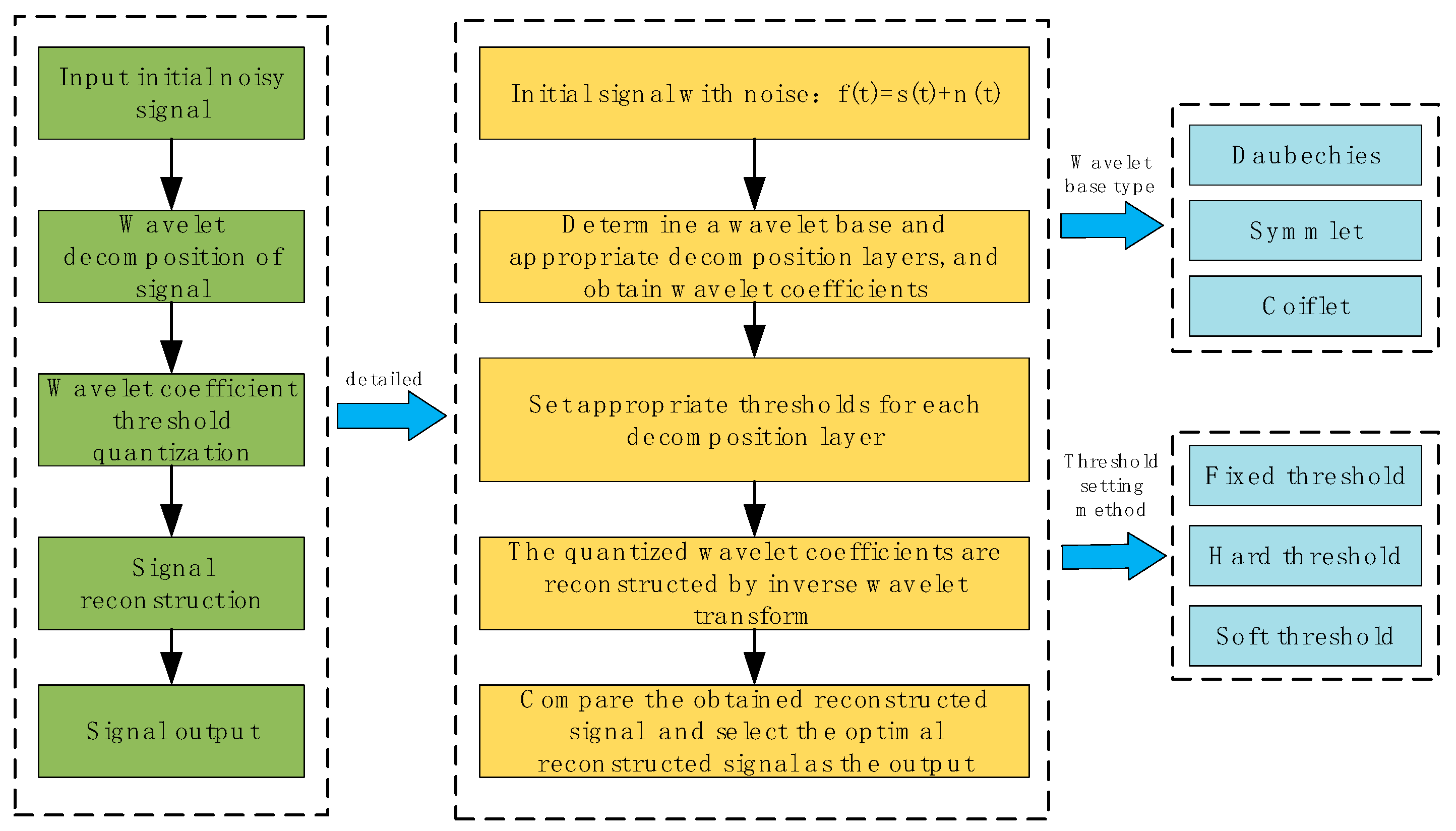

3.1. Wavelet Denoising

3.2. Waveform Recognition

3.2.1. Method of Hausdorff Dimension

3.2.2. Box Counting Dimension Method

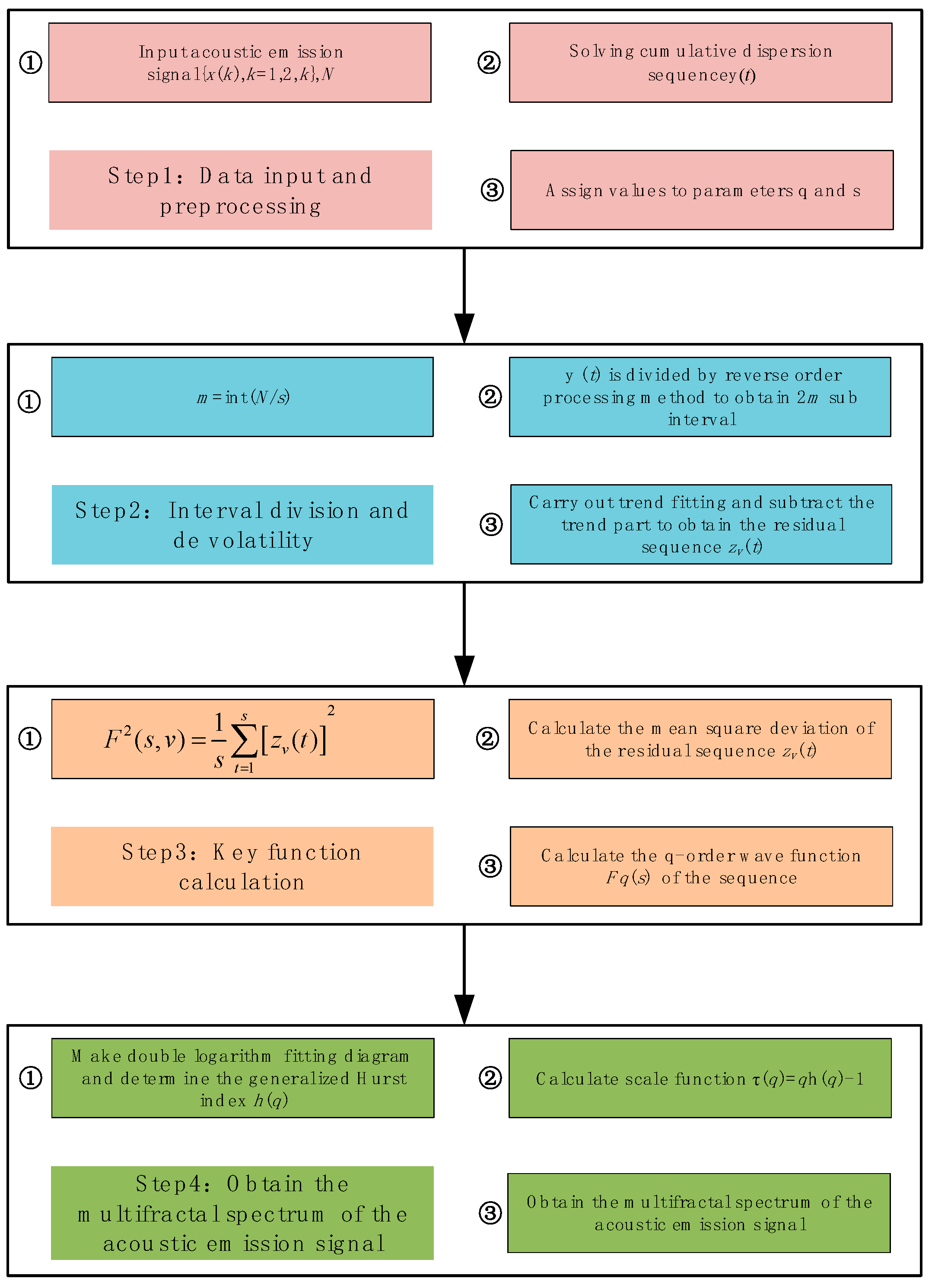

3.3. Multifractal Analysis

4. Results

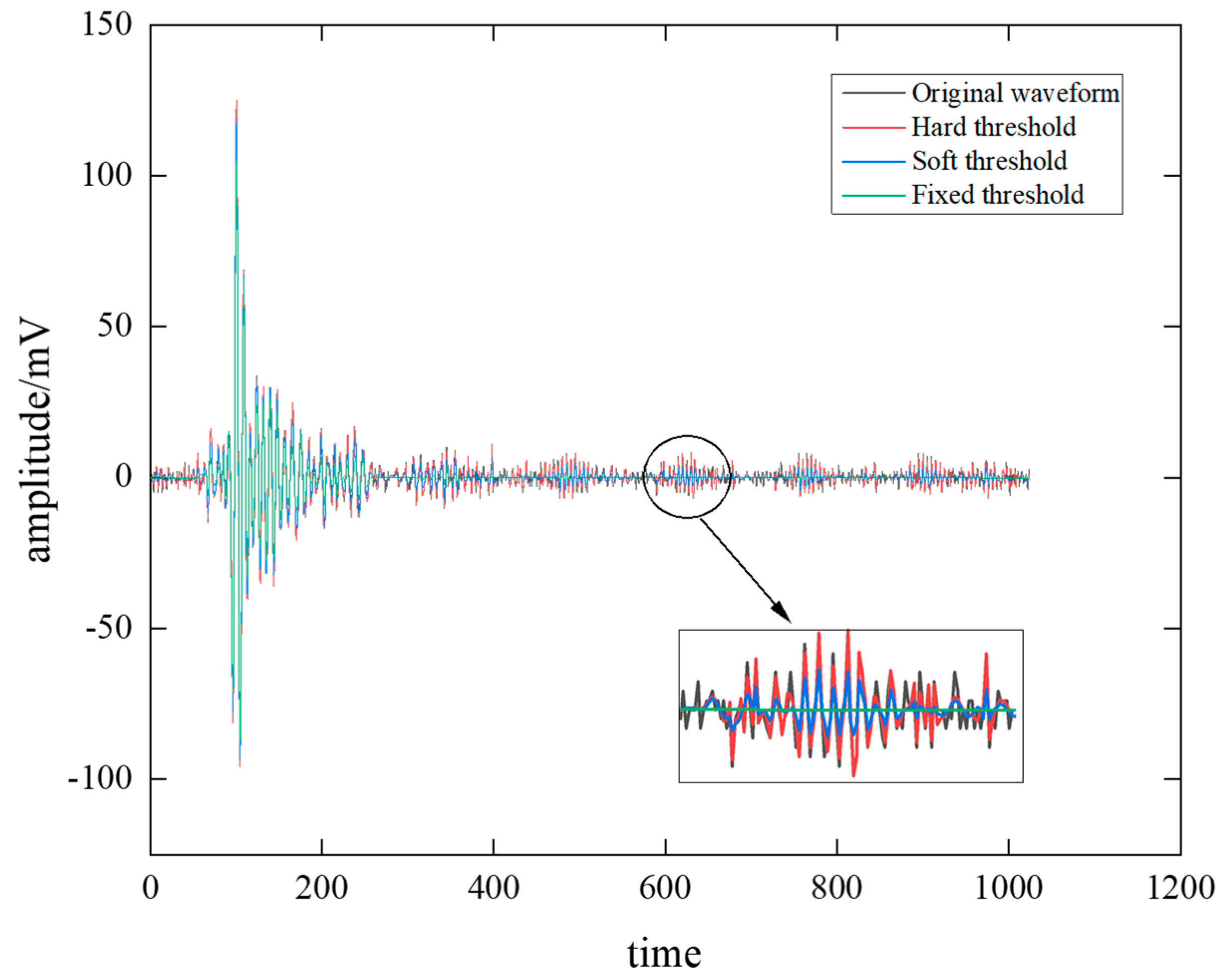

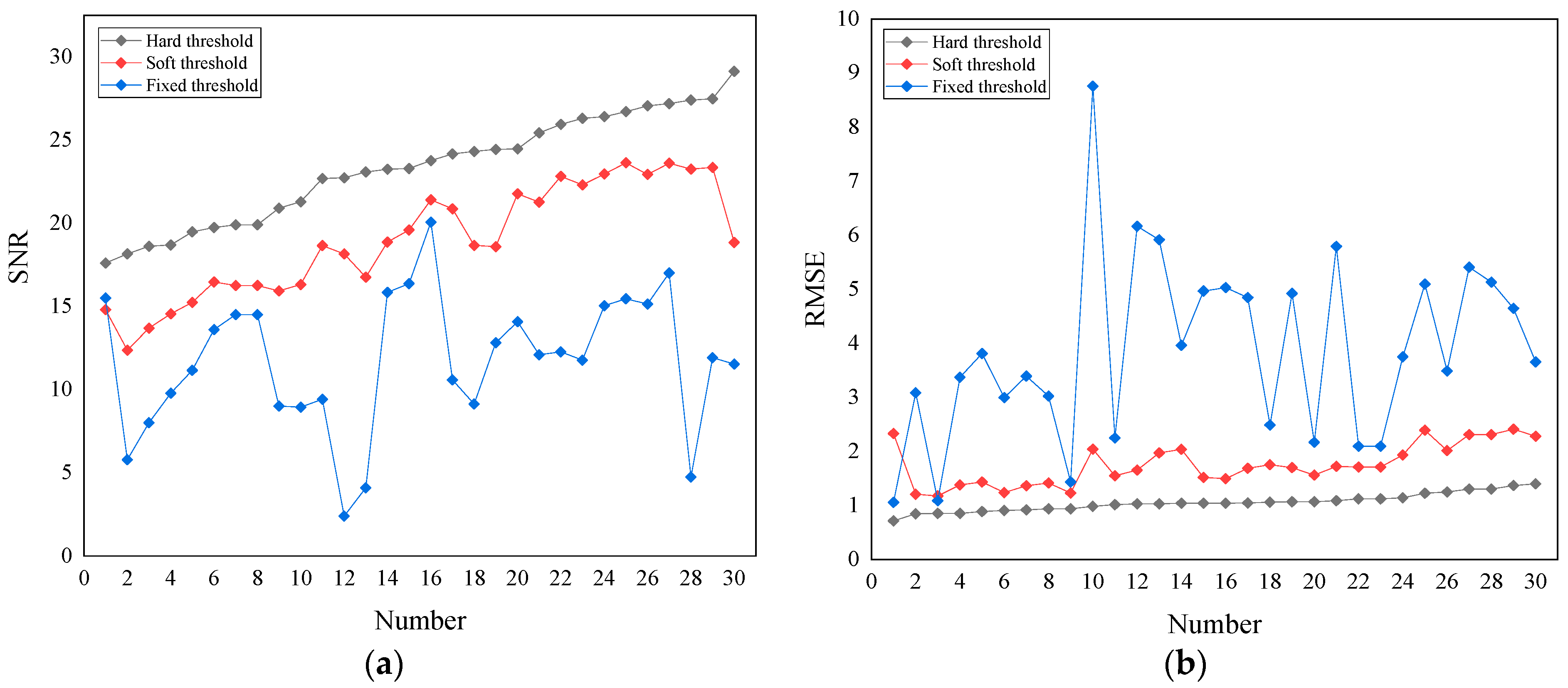

4.1. Wavelet Threshold Denoising

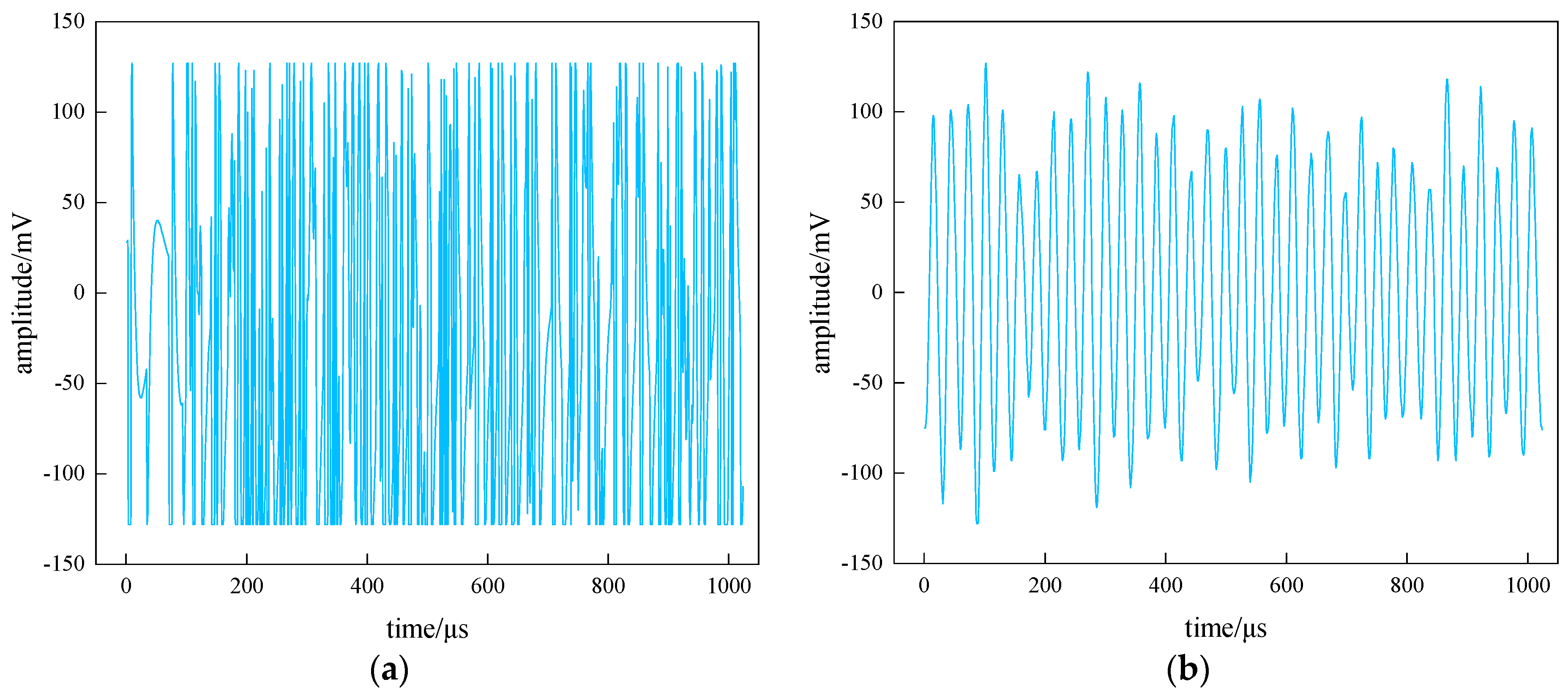

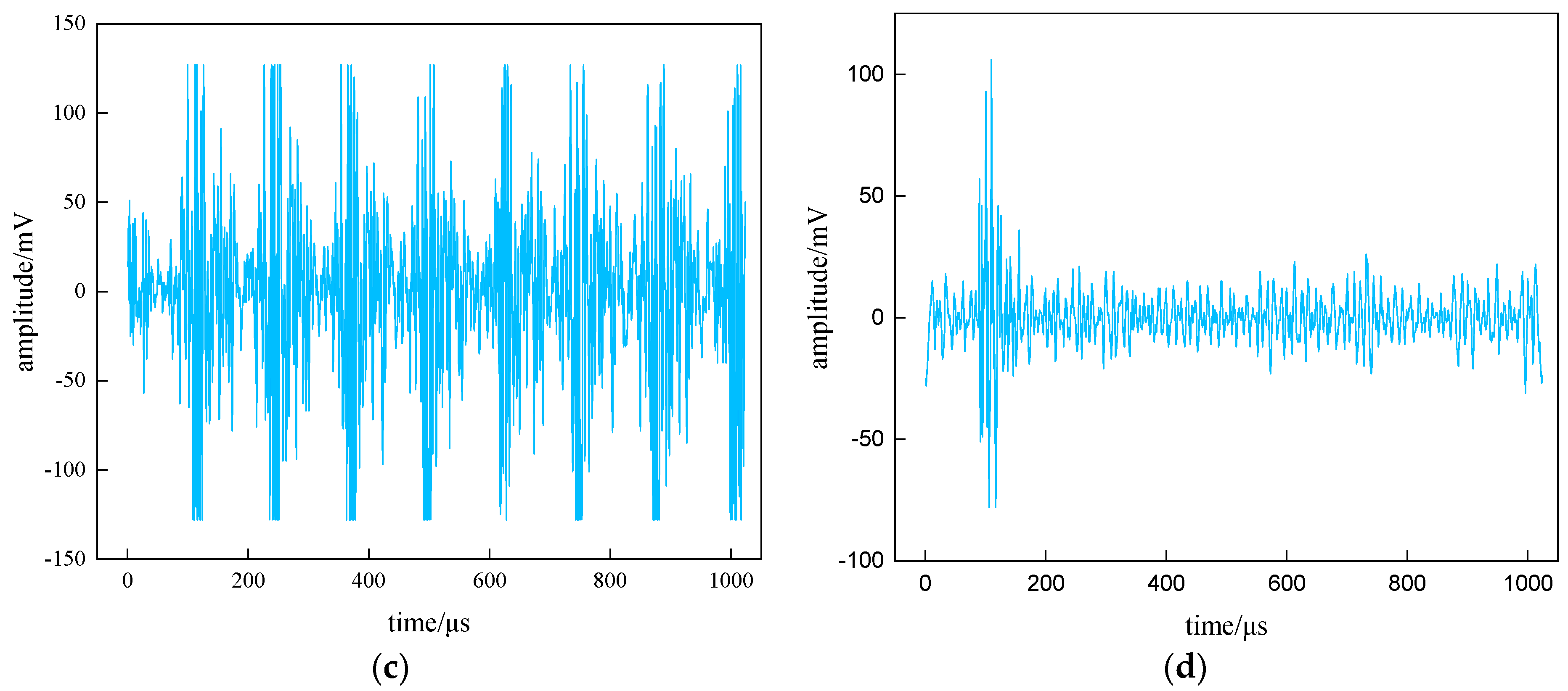

4.2. Waveform Classification

4.3. Fractal Dimension Calculation

4.4. Multifractal Analysis

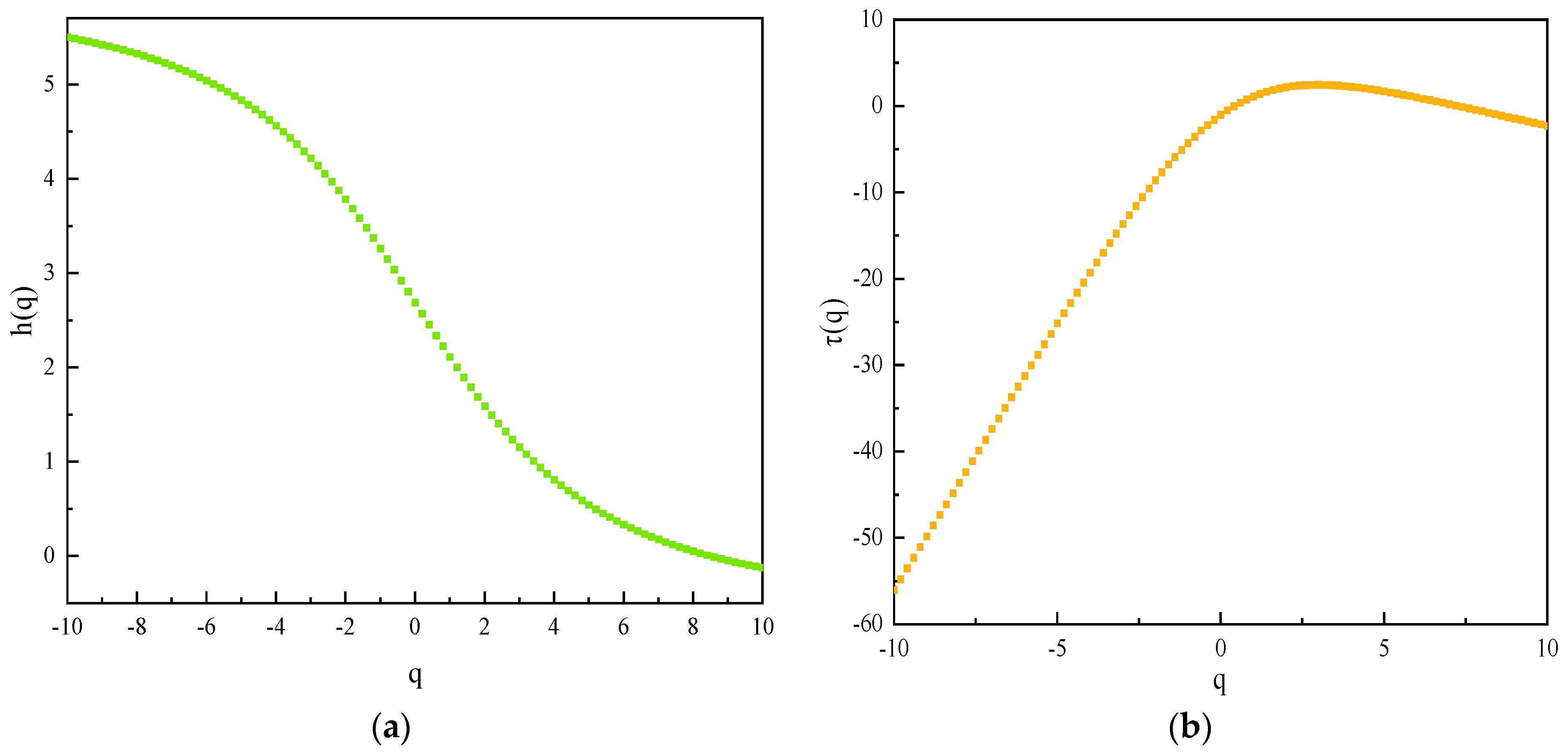

4.4.1. Key Parameter Setting

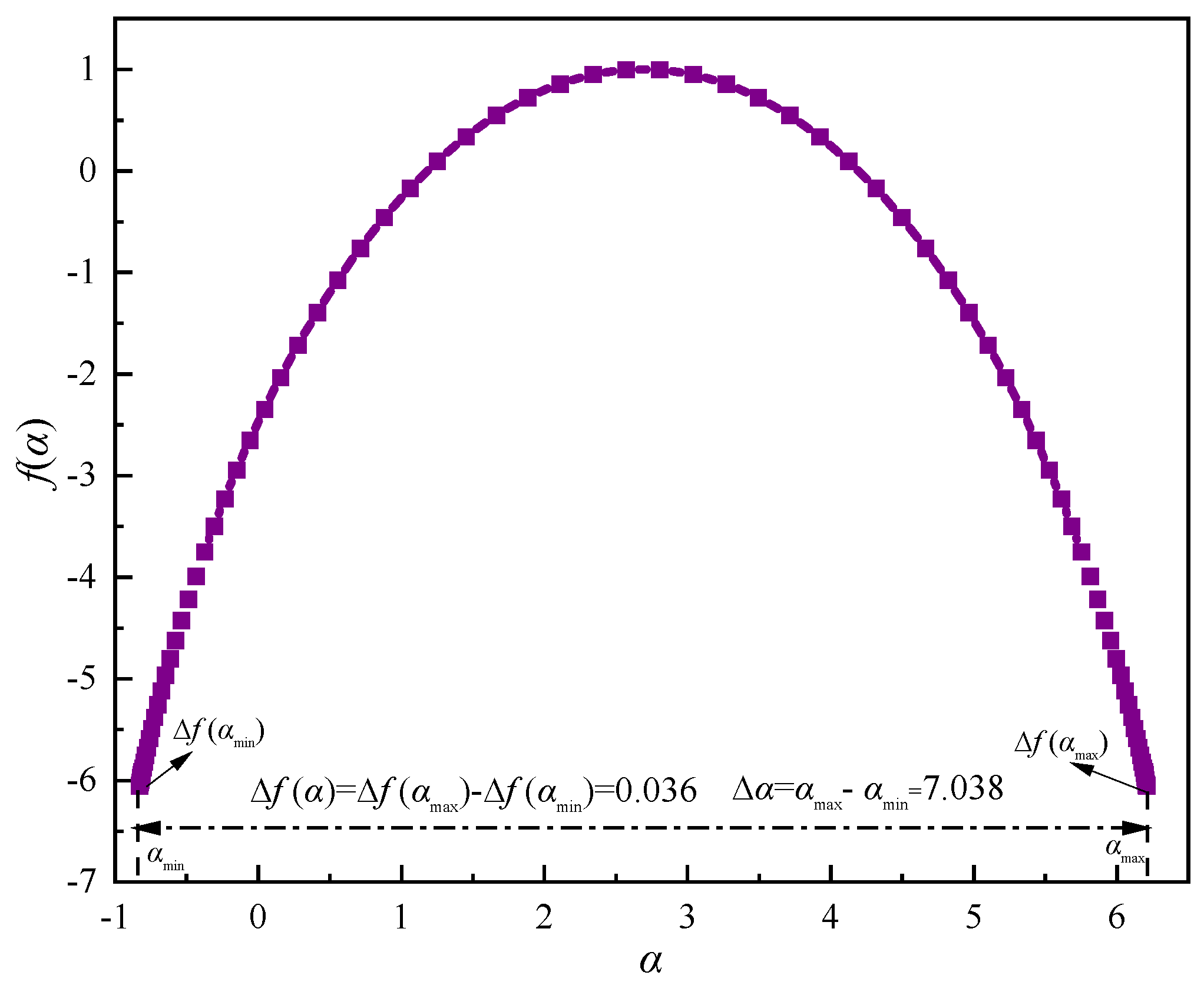

4.4.2. Multiple Fractal Spectrum

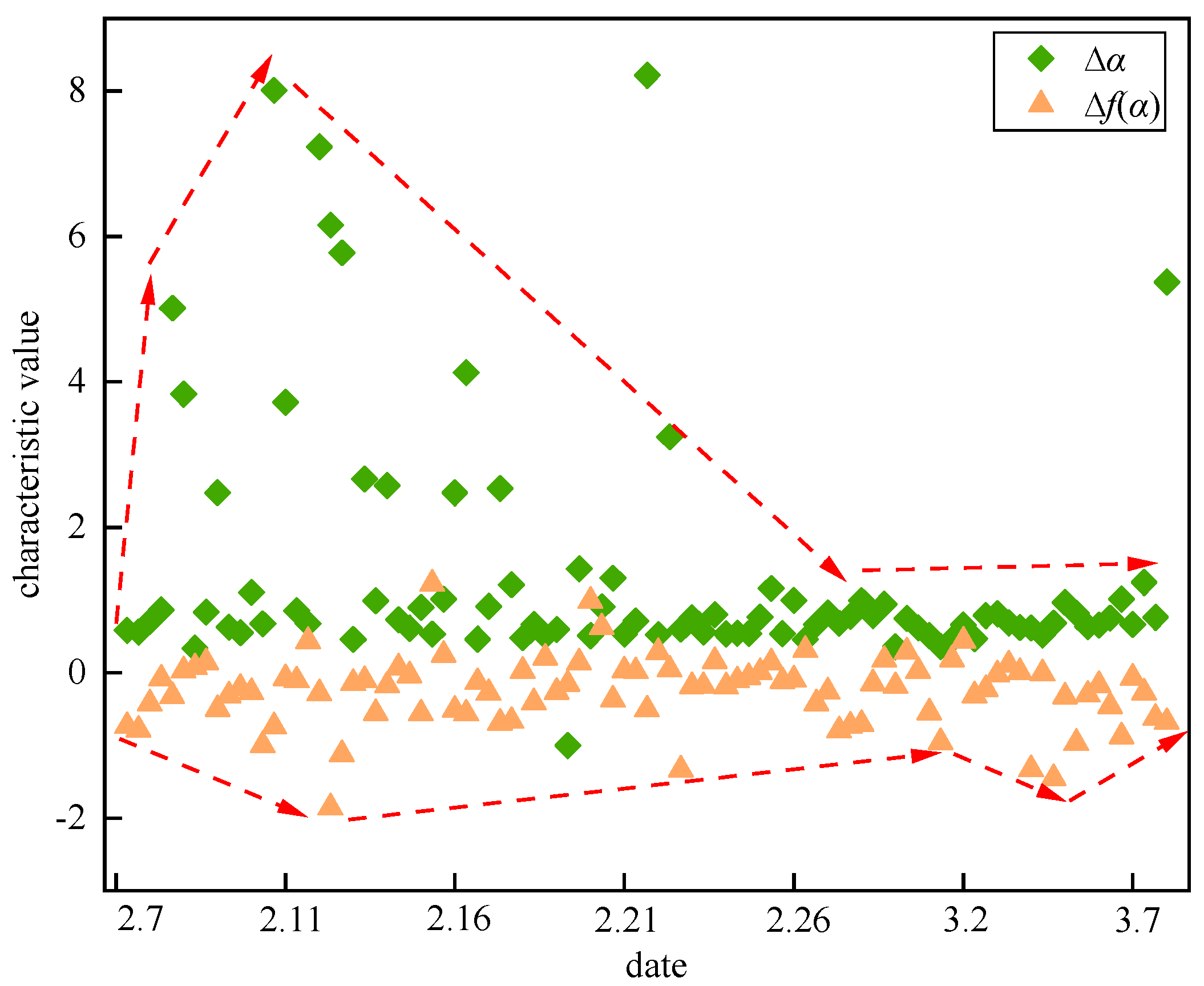

4.5. Multifractal Time-Varying Response Characteristics of Waveform

5. Conclusions

- (1)

- The wavelet threshold noise reduction method was used to reduce the noise of the obtained acoustic emission waveform. The analysis results show that the waveform obtained by the wavelet hard threshold noise reduction method has the highest SNR, the lowest RMSE and the best noise reduction performance.

- (2)

- The fractal dimensional characteristics of the waveforms were quantified using Hausdorff dimension and box counting dimension, respectively. The results show that the acoustic emission signals generated from different operations downhole had different fractal dimensional performances. In the Hausdorff dimension, the average value of the surrounding rock body waveform was the highest, followed by shovel operation waveform, rock drilling operation waveform and the blasting operation waveform. In the box counting dimension, the fractal dimension of the rock drilling operation waveform was the largest, followed by the surrounding rock body waveform, blasting operation waveform and rock drilling operation waveform. The calculated results obtained by using box counting dimension were clearer and more recognizable, and the box counting dimension could be used as one of the important bases for waveform classification and identification.

- (3)

- The key parameters of the multifractal analysis model were determined, and the multifractal characteristics of the rock microfracture waveform time series were characterized based on the parameters Δα and Δf(α), when the time length s took the values: smin = 870, and smax = 934, and the weight factor q ∈ [–10, 10].

- (4)

- There was a close relationship between the time-varying response characteristics of the multiple fractal spectral parameters of the acoustic emission waveform of the rock body in the quarry area and the sprouting and development of microfracture of the rock body. Before deformation and damage, Δα increased and then decreased, and Δf(α) decreased and then increased. At the time of damage, Δα decreased and then stabilized, while Δf(α) decreased until its lowest point, then increased and reached a stable state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Ma, S.Q.; Cao, Q.J. Extraction of the remnant coal pillar in regular and irregular shapes: A case study. J. Loss Prev. Process Ind. 2018, 55, 191–203. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, M.; Xu, X.; Li, X.; Ma, Y.; Ma, Z. Research on Catastrophic Pillar Instability in Room and Pillar Gypsum Mining. Sustainability 2018, 10, 3773. [Google Scholar] [CrossRef] [Green Version]

- Chai, J.; Ouyang, Y.B.; Liu, J.X.; Zhang, D.D.; Du, W.G.; Lei, W.L. Experimental study on a new method to forecasting goaf pressure based key strata deformation detected using optic fiber sensors. Opt. Fiber Technol. 2021, 67, 12. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.-P.; Xu, S.-D.; Wei, J.; Huang, W.-B.; Dong, L.-B. Experimental studies on pillar failure characteristics based on acoustic emission location technique. Trans. Nonferrous Met. Soc. China 2012, 22, 2792–2798. [Google Scholar] [CrossRef]

- Luan, H.; Lin, H.; Jiang, Y.; Wang, Y.; Liu, J.; Wang, P. Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area. Sustainability 2018, 10, 631. [Google Scholar] [CrossRef] [Green Version]

- Gogotsi, G.A.; Drozdov, A.V. Acoustic emission in the deformation and failure of corundum refractories. Refractories 1986, 27, 200–204. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Z.; Li, X.; Gong, F.; Du, K. Experimental study on the effect of strain rate on rock acoustic emission characteristics. Int. J. Rock Mech. Min. Sci. 2020, 133, 104420. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, M.; Han, L.; Pu, H.; Nie, T. Effects of Acoustic Emission and Energy Evolution of Rock Specimens Under the Uniaxial Cyclic Loading and Unloading Compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J.; Wang, H.C.; Liu, K.; Zhang, Q.B. Fracturing behaviours and AE signatures of anisotropic coal in dynamic Brazilian tests. Eng. Fract. Mech. 2021, 252, 107817. [Google Scholar] [CrossRef]

- Li, J.; Hu, Q.; Yu, M.; Li, X.; Hu, J.; Yang, H. Acoustic emission monitoring technology for coal and gas outburst. Energy Sci. Eng. 2019, 7, 443–456. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Li, Z.; Wang, E.; Liang, Y.; Li, B.; Chen, P.; Liu, Y. Pattern Recognition of Mine Microseismic and Blasting Events Based on Wave Fractal Features. Fractals 2018, 26, 1850029. [Google Scholar] [CrossRef]

- Jiang, C.B.; Duan, M.K.; Yin, G.Z.; Wang, J.G.; Lu, T.Y.; Xu, J.; Zhang, D.M.; Huang, G. Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 2017, 221, 114–123. [Google Scholar] [CrossRef]

- Xie, H.P.; Wang, J.A.; Kwasniewski, M.A. Multifractal characterization of rock fracture surfaces. Int. J. Rock Mech. Min. Sci. 1999, 36, 19–27. [Google Scholar] [CrossRef]

- Xie, H.P.; Wang, J.A. Direct fractal measurement of fracture surfaces. Int. J. Solids Struct. 1999, 36, 3073–3084. [Google Scholar] [CrossRef]

- Yuan, R.F.; Li, Y.H. Fractal analysis on the spatial distribution of acoustic emission in the failure process of rock specimens. Int. J. Miner. Metall. Mater. 2009, 16, 19–24. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, J.; Sa, Z.; Wang, Z.; Lu, S.; Lv, Z. Fractal characteristics of acoustic emission of gas-bearing coal subjected to true triaxial loading. Measurement 2021, 169, 108349. [Google Scholar] [CrossRef]

- Dexing, L.; Enyuan, W.; Xiangguo, K.; Xiaoran, W.; Chong, Z.; Haishan, J.; Hao, W.; Jifa, Q. Fractal characteristics of acoustic emissions from coal under multi-stage true-triaxial compression. J. Geophys. Eng. 2018, 15, 2021–2032. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Wang, E.; Li, N. Analysis of rupture mode and acoustic emission characteristic of rock and coal samples with holes. J. Geophys. Eng. 2019, 16, 811–820. [Google Scholar] [CrossRef]

- Grassberger, P. Generalized dimensions of strange attractors. Phys. Lett. A 1983, 18, 241–244. [Google Scholar] [CrossRef]

- Kantelhardt, J.W.; Zschiegner, S.A.; Koscielny-Bunde, E.; Havlin, S.; Bunde, A.; Stanley, H.E. Multifractal detrended fluctuation analysis of nonstationary time series. Phys. A 2002, 316, 87–114. [Google Scholar] [CrossRef] [Green Version]

- Lopes, R.; Betrouni, N. Fractal and multifractal analysis: A review. Med. Image Anal. 2009, 13, 634–649. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Chen, Y.; Zhang, D. Study on the Feature of Acoustic Emission of Rock under Compression Experiment Based on Multi-fractal Theory. Chin. J. Undergr. Space Eng. 2012, 8, 963–968. [Google Scholar]

- Kong, B.; Wang, E.; Li, Z.; Lu, W.E.I. Study on the Feature of Electromagnetic Radiation under Coal Oxidation and Temperature Rise Based on Multifractal Theory. Fractals 2019, 27, 1950038. [Google Scholar] [CrossRef]

- Kong, X.; Wang, E.; He, X.; Li, Z.; Li, D.; Liu, Q. Multifractal Characteristics and Acoustic Emission of Coal with Joints under Uniaxial Loading. Fractals 2017, 25, 1750045. [Google Scholar] [CrossRef]

- Dong, X.J.; Wang, C.J.; Liu, X.S. Application of Filling Mining Method in Pillar Recovery of Panlong Lead-zine Mine. Min. Res. Dev. 2015, 35, 19–22. [Google Scholar] [CrossRef]

- Zhang, K.-F.; Yuan, H.-Q.; Nie, P. A method for tool condition monitoring based on sensor fusion. J. Intell. Manuf. 2015, 26, 1011–1026. [Google Scholar] [CrossRef]

- Akin, M. Comparison of wavelet transform and FFT methods in the analysis of EEG signals. J. Med. Syst. 2002, 26, 241–247. [Google Scholar] [CrossRef]

- Song, C.M.; Havlin, S.; Makse, H.A. Origins of fractality in the growth of complex networks. Nat. Phys. 2006, 2, 275–281. [Google Scholar] [CrossRef] [Green Version]

- Li, L.C.; Wu, W.B.; El Naggar, M.H.; Mei, G.X.; Liang, R.Z. Characterization of a jointed rock mass based on fractal geometry theory. Bull. Eng. Geol. Environ. 2019, 78, 6101–6110. [Google Scholar] [CrossRef]

- Kong, X.; Wang, E.; Hu, S.; Shen, R.; Li, X.; Zhan, T. Fractal characteristics and acoustic emission of coal containing methane in triaxial compression failure. J. Appl. Geophys. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Wu, M.; Wang, W.; Shi, D.; Song, Z.; Li, M.; Luo, Y. Improved box-counting methods to directly estimate the fractal dimension of a rough surface. Measurement 2021, 177, 109303. [Google Scholar] [CrossRef]

- Husain, A.; Reddy, J.; Bisht, D.; Sajid, M. Fractal dimension of coastline of Australia. Sci. Rep. 2021, 11, 10. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Li, L.; Dai, H.Z.; Jia, M.M. Effect of fractal dimension in concrete meso-structure on its axial mechanical behavior: A numerical case study. Fractals-Complex Geom. Patterns Scaling Nat. Soc. 2021, 29, 11. [Google Scholar] [CrossRef]

- Wen, T.; Cheong, K.H. The fractal dimension of complex networks: A review. Inf. Fusion 2021, 73, 87–102. [Google Scholar] [CrossRef]

- Fernandez-Martinez, M. Theoretical properties of fractal dimensions for fractal structures. Discret. Contin. Dyn. Syst.-Ser. S 2015, 8, 1113–1128. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Du, Q.; Sun, C.X. An improved box-counting method for image fractal dimension estimation. Pattern Recognit. 2009, 42, 2460–2469. [Google Scholar] [CrossRef]

- Yun, C.; Ri, M. Box-counting dimension and analytic properties of hidden variable fractal interpolation functions with function contractivity factors. Chaos Solitons Fractals 2020, 134, 10. [Google Scholar] [CrossRef] [Green Version]

- Ning, J.G.; Liu, X.S.; Tan, Y.L.; Wang, J.; Tian, C.L. Relationship of box counting of fractured rock mass with Hoek-Brown parameters using particle flow simulation. Geomech. Eng. 2015, 9, 619–629. [Google Scholar] [CrossRef]

- Li, N.; Li, B.L.; Chen, D.; Sun, W.C. Multi-fractaland time-varying response characteristics of micro seismic waves during the rock burst process. J. China Univ. Min. Technol. 2017, 46, 1007–1013. [Google Scholar] [CrossRef]

- Zhou, L.T.; Liu, Z.K. Multifractal feature analysis method for measured data of dam deformation. Adv. Sci. Technol. Water Resour. 2021, 41, 18–24. [Google Scholar] [CrossRef]

- Mao, H.Y.; Zhang, M.; Jiang, R.C.; Li, B.; Xu, J.; Xu, N.W. Study on deformation pre-warning of rock slopes based on multi-fractal characteristics of microseismical signals. Chin. J. Rock Mech. Eng. 2020, 39, 560–571. [Google Scholar] [CrossRef]

- Xie, X.B.; Wang, X.P.; Liu, T. Recognition and classification methods of mine acoustic emission signals based on ICEEMDAN and MC-CNN. J. Saf. Sci. Technol. 2022, 18, 113–118. [Google Scholar] [CrossRef]

- Zhu, Q.J.; Jiang, F.X.; Yin, Y.M.; Yu, X.Z.; Wen, J.L. Classification of mine microseismical events based on wavelet-fractal method and pattern recognition. Chin. J. Geotech. Eng. 2012, 34, 2036–2042. [Google Scholar]

- Telesca, L.; Lapenna, V. Measuring multifractality in seismic sequences. Tectonophysics 2006, 423, 115–123. [Google Scholar] [CrossRef]

| Methods | Strength | Weakness |

|---|---|---|

| Short time Fourier transform | Good locality in time domain | Susceptible to analysis window functions |

| Wigner-Ville distribution | High time-frequency resolution and good time-frequency aggregation performance | Problem of cross interference |

| Wavelet transform theory | Ensure the authenticity of the signal | Wavelet basis function limited selection |

| EMD methods | Adaptive time-frequency decomposition | Mode aliasing and endpoint effect |

| Signal Type | Attenuation | Frequency/Hz | Energy |

|---|---|---|---|

| Surrounding rock body waveform | Slow | 20~80 | 50~128 |

| Rock drilling waveform | Relatively fast | 70~200 | 120~128 |

| Shovel operation waveform | Relatively fast | 100~150 | 80~110 |

| Blasting operation waveform | Fast | 10~300 | 60~128 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Li, S.; Guo, J. Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies. Sensors 2022, 22, 2746. https://doi.org/10.3390/s22072746

Xie X, Li S, Guo J. Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies. Sensors. 2022; 22(7):2746. https://doi.org/10.3390/s22072746

Chicago/Turabian StyleXie, Xuebin, Shaoqian Li, and Jiang Guo. 2022. "Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies" Sensors 22, no. 7: 2746. https://doi.org/10.3390/s22072746

APA StyleXie, X., Li, S., & Guo, J. (2022). Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies. Sensors, 22(7), 2746. https://doi.org/10.3390/s22072746