A Novel Baseline-Free Damage Detection Method Based on Path Scanning of Lamb Waves Using Mobile Transducers

Abstract

:1. Introduction

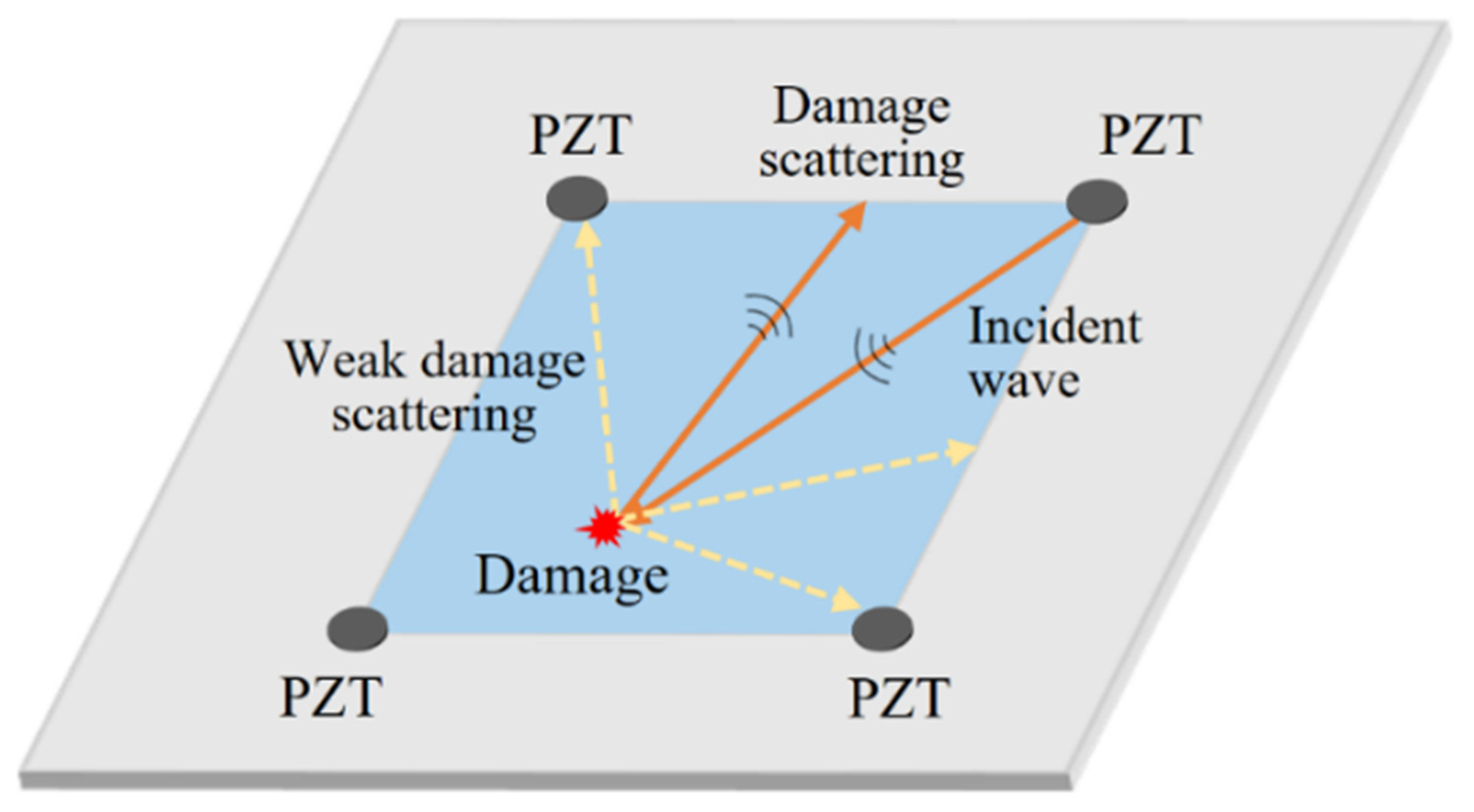

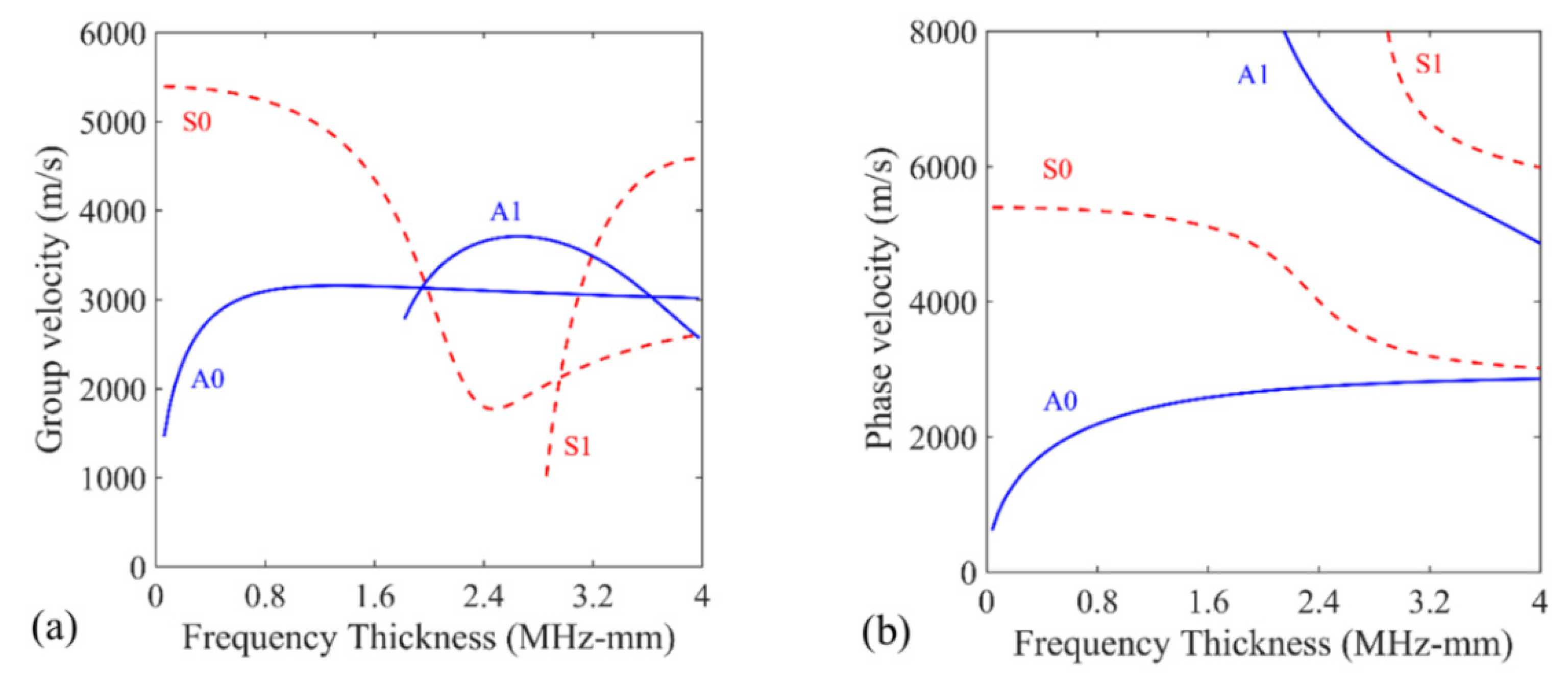

2. Angular Scattering Characteristic of Lamb Wave

3. Baseline-Free Damage Detection Method Based on Path Scanning

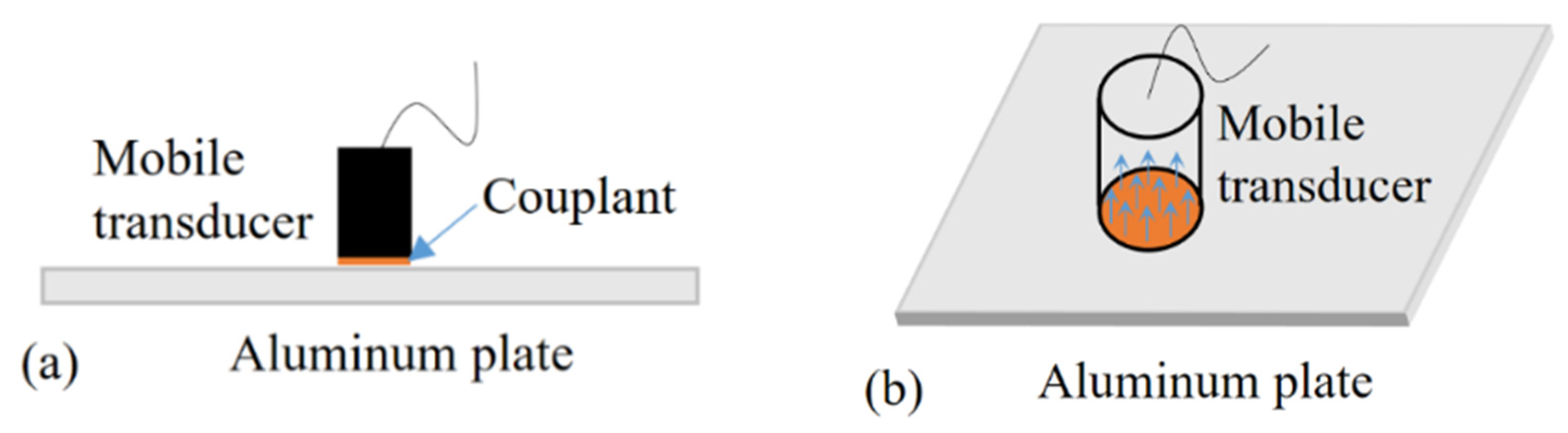

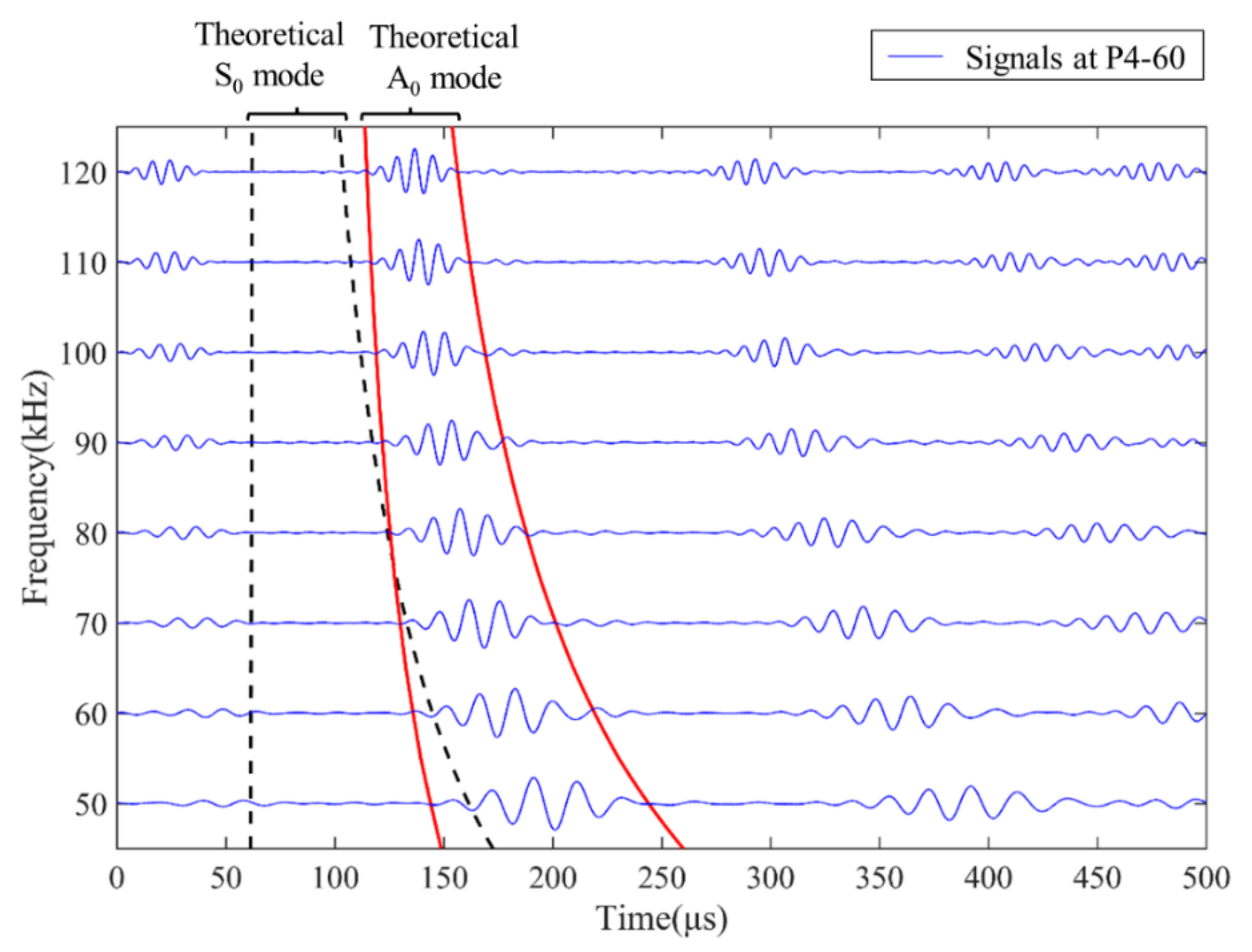

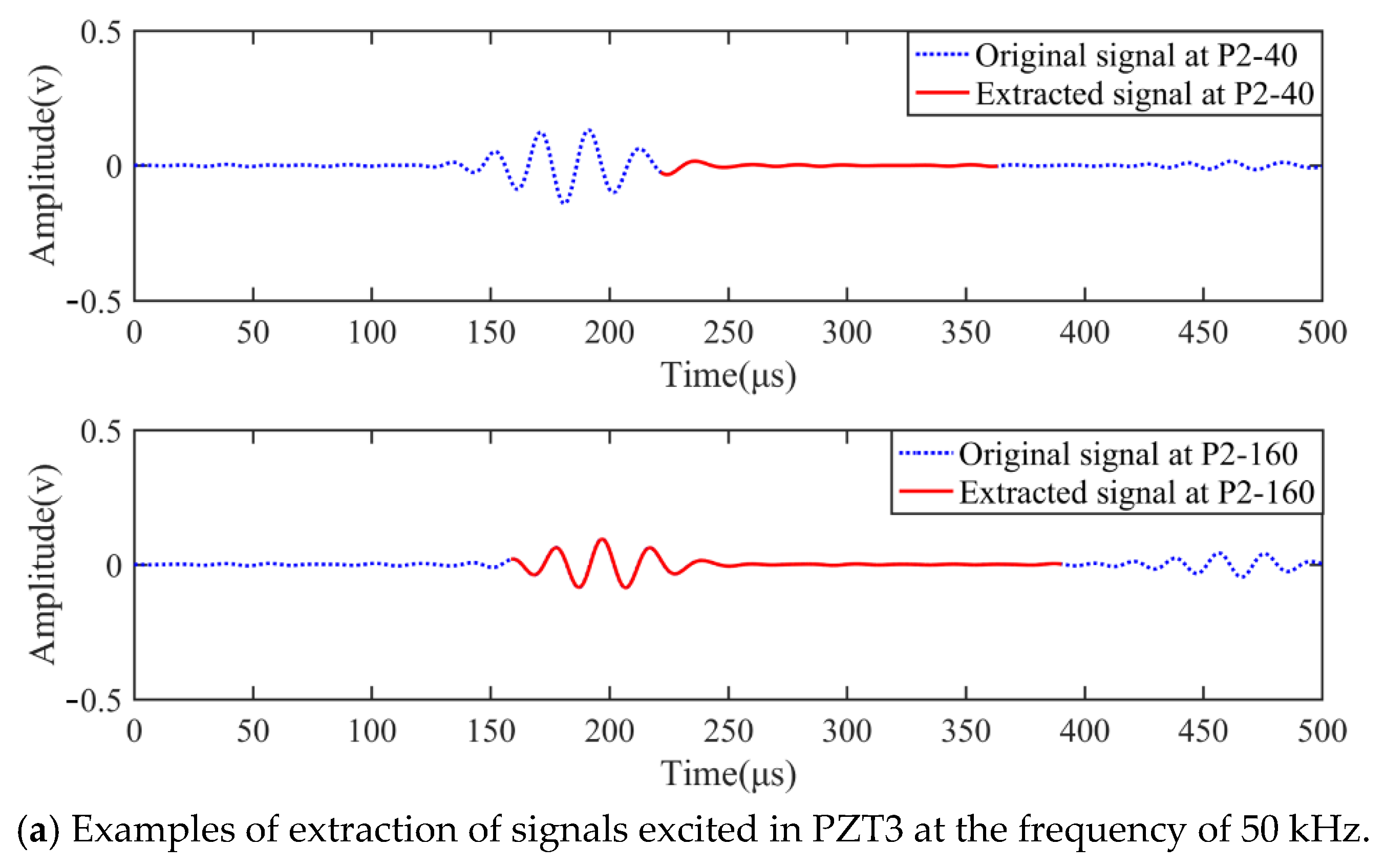

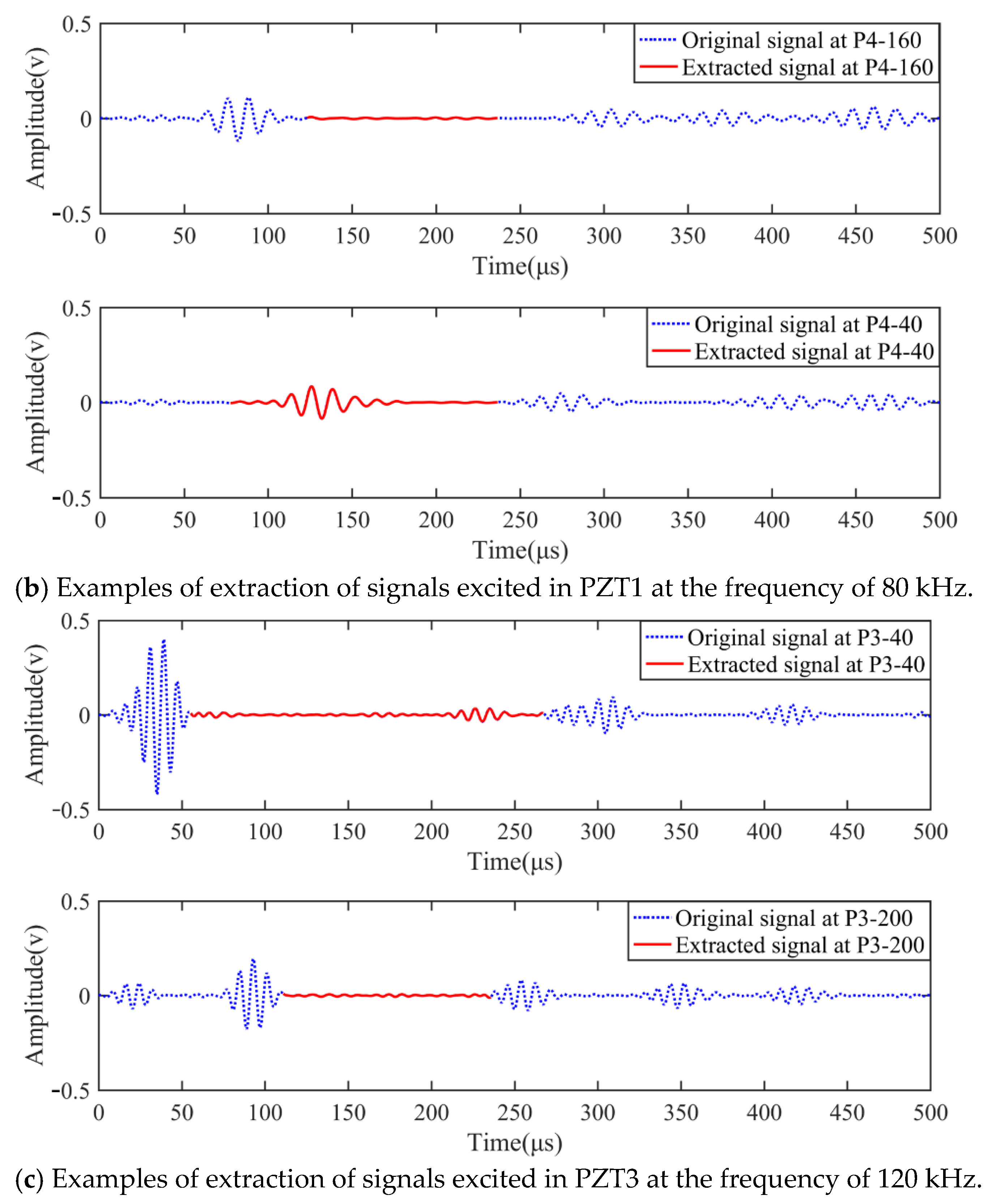

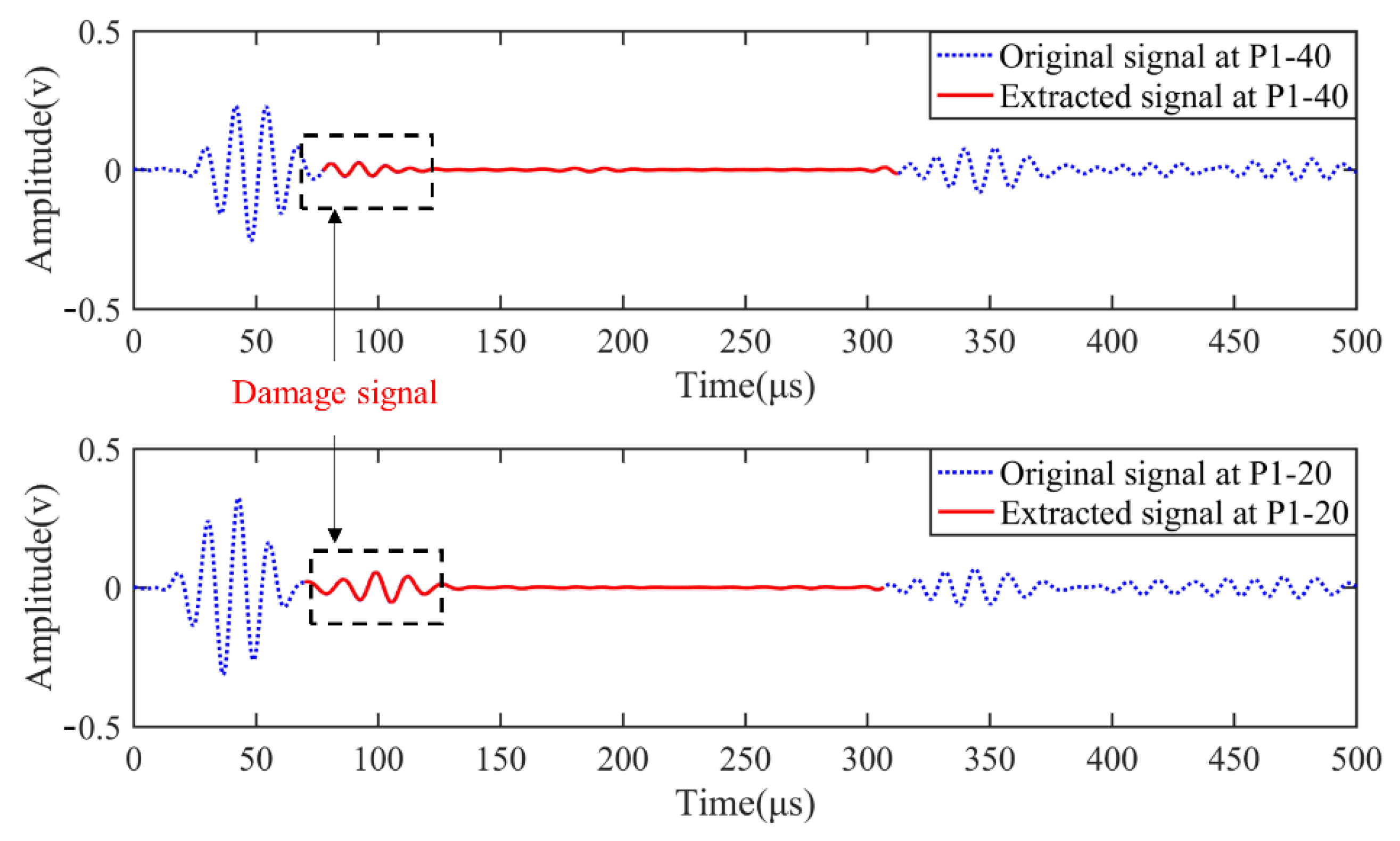

3.1. Pure A0 Mode Signal Collection

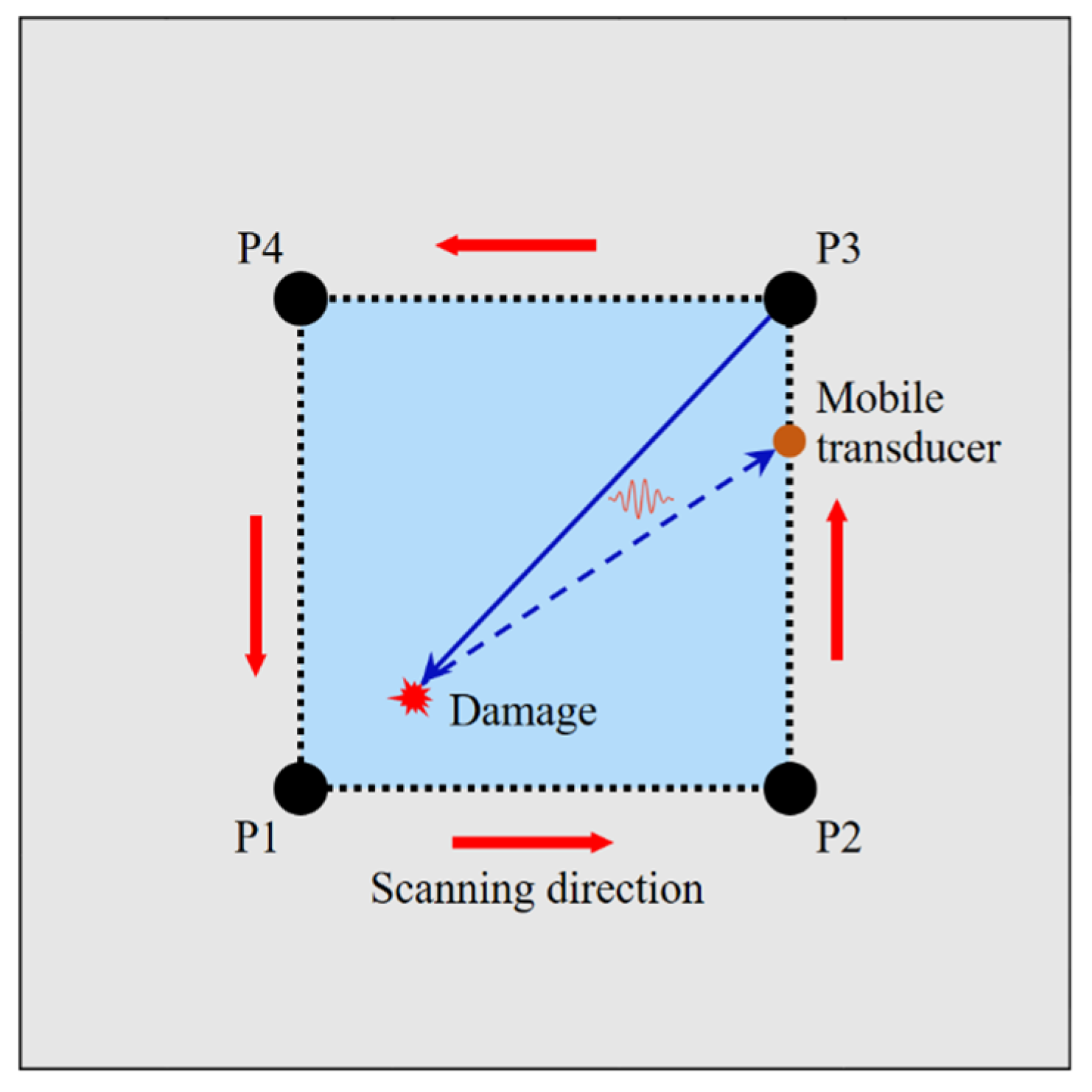

3.2. Path Scanning Using a Mobile Transducer

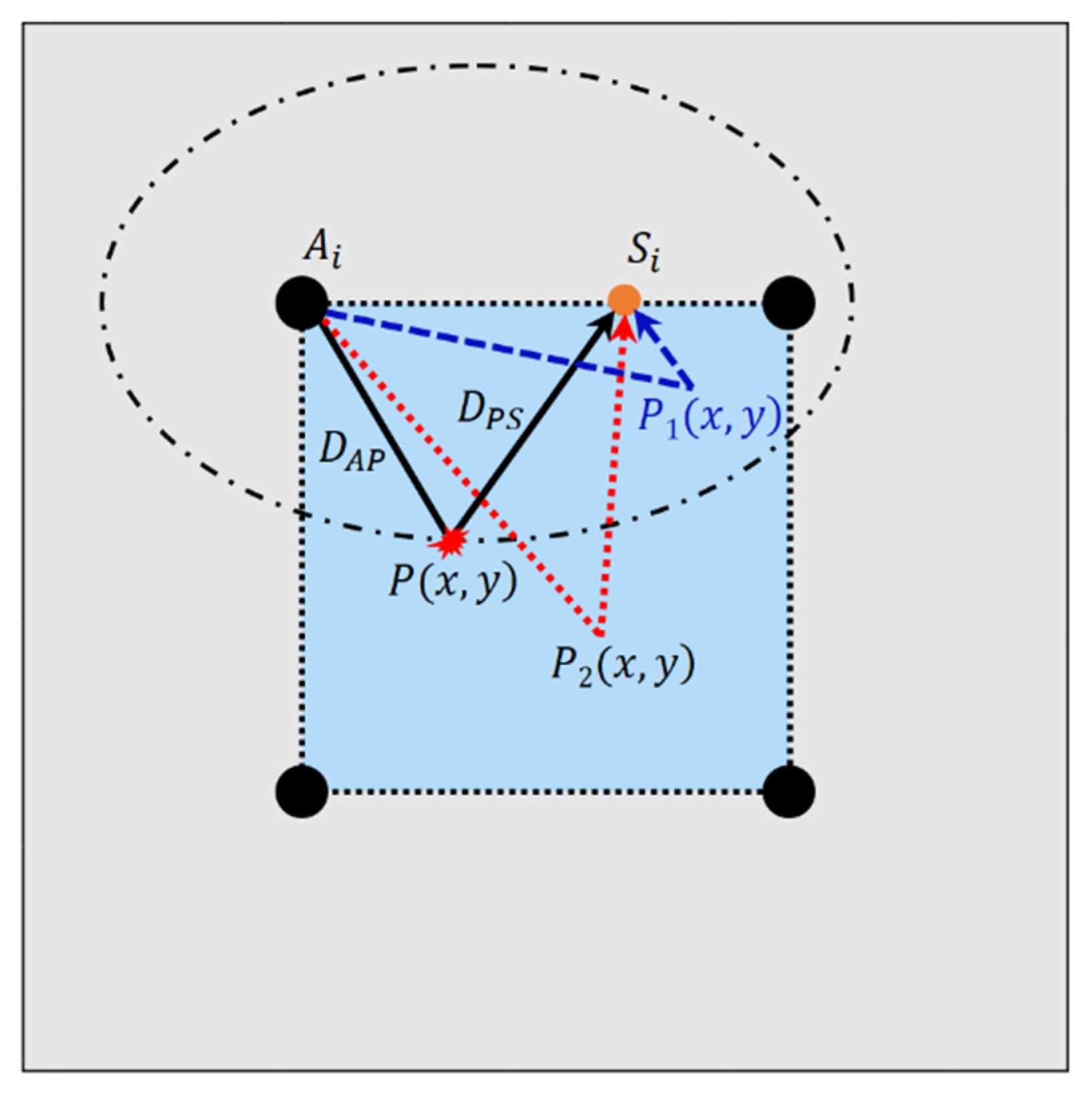

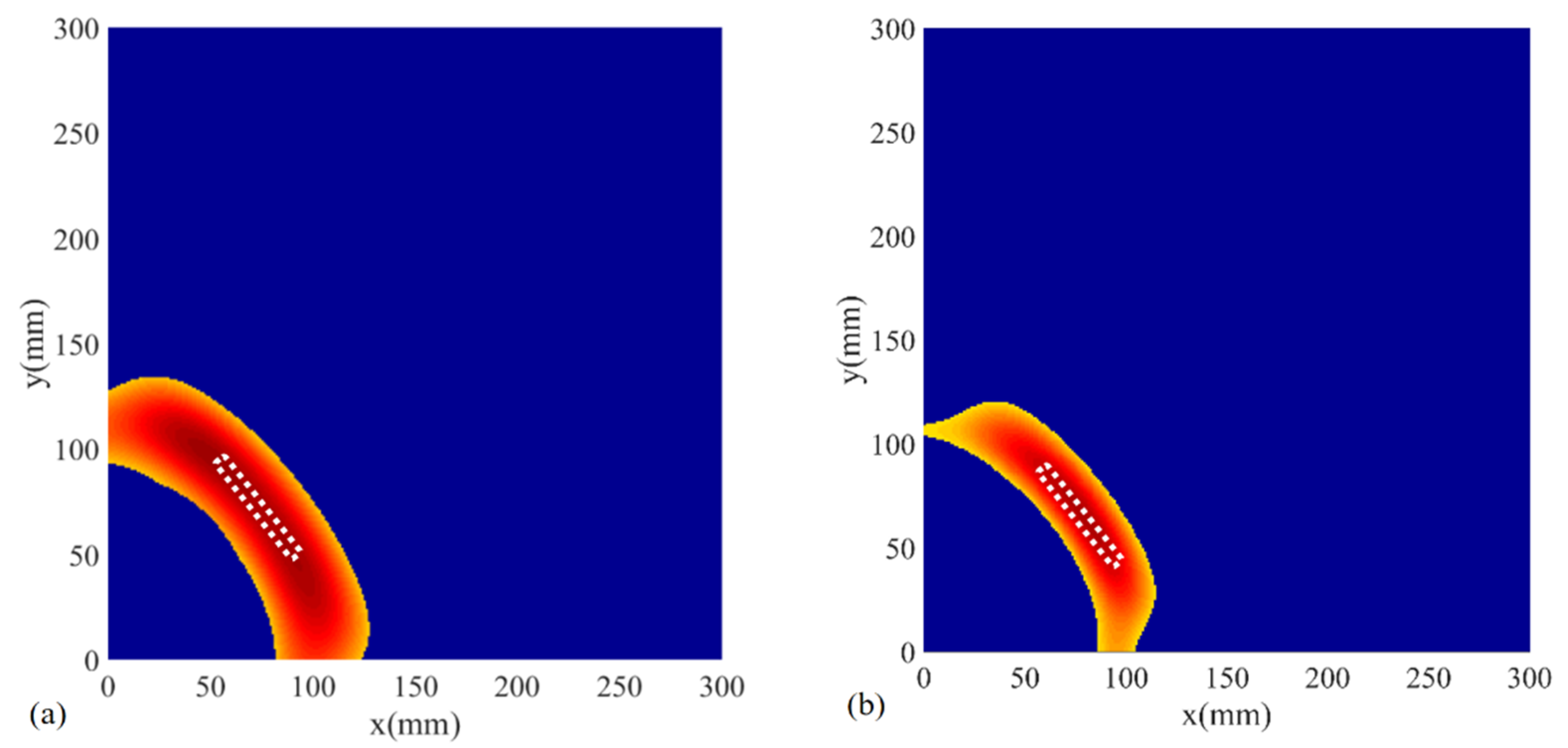

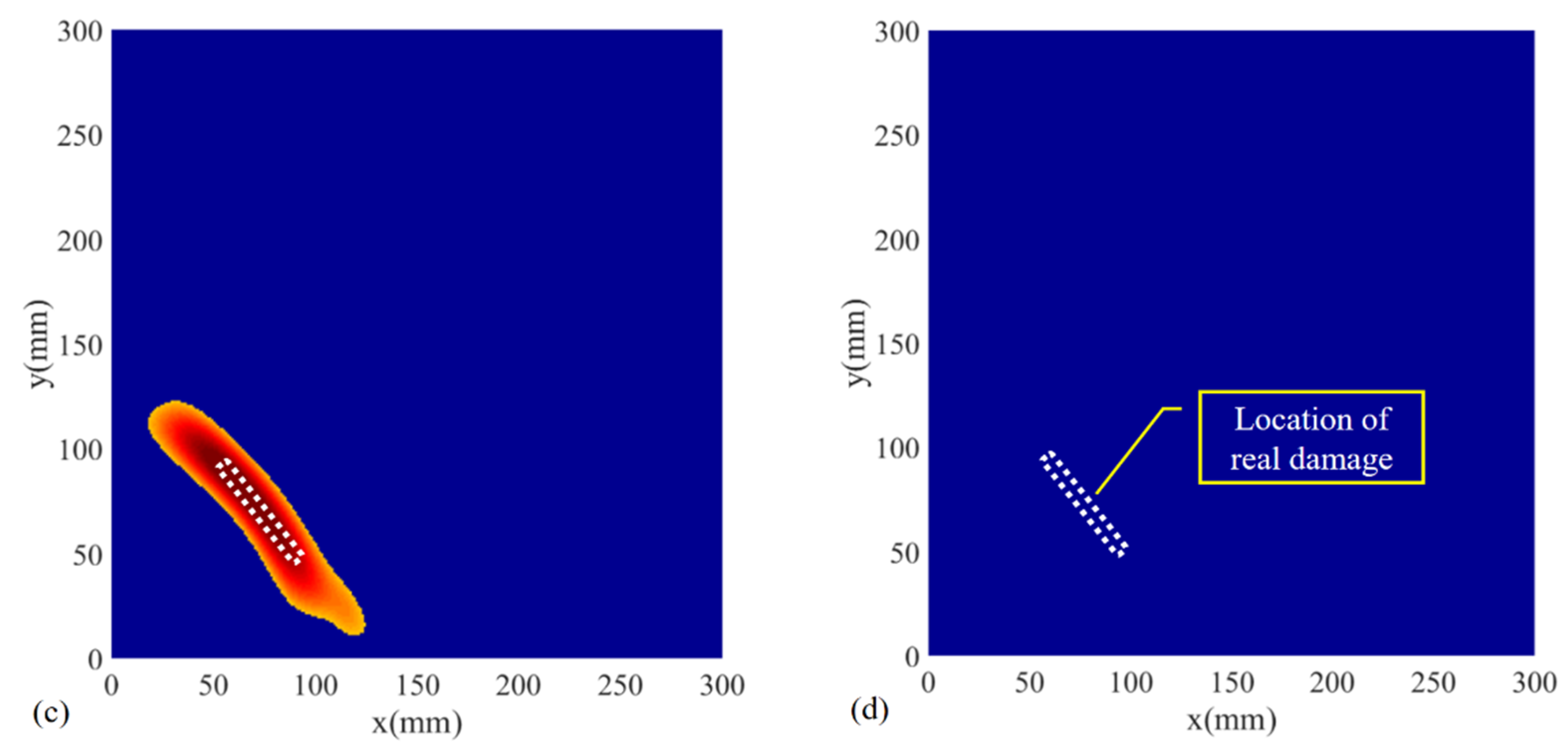

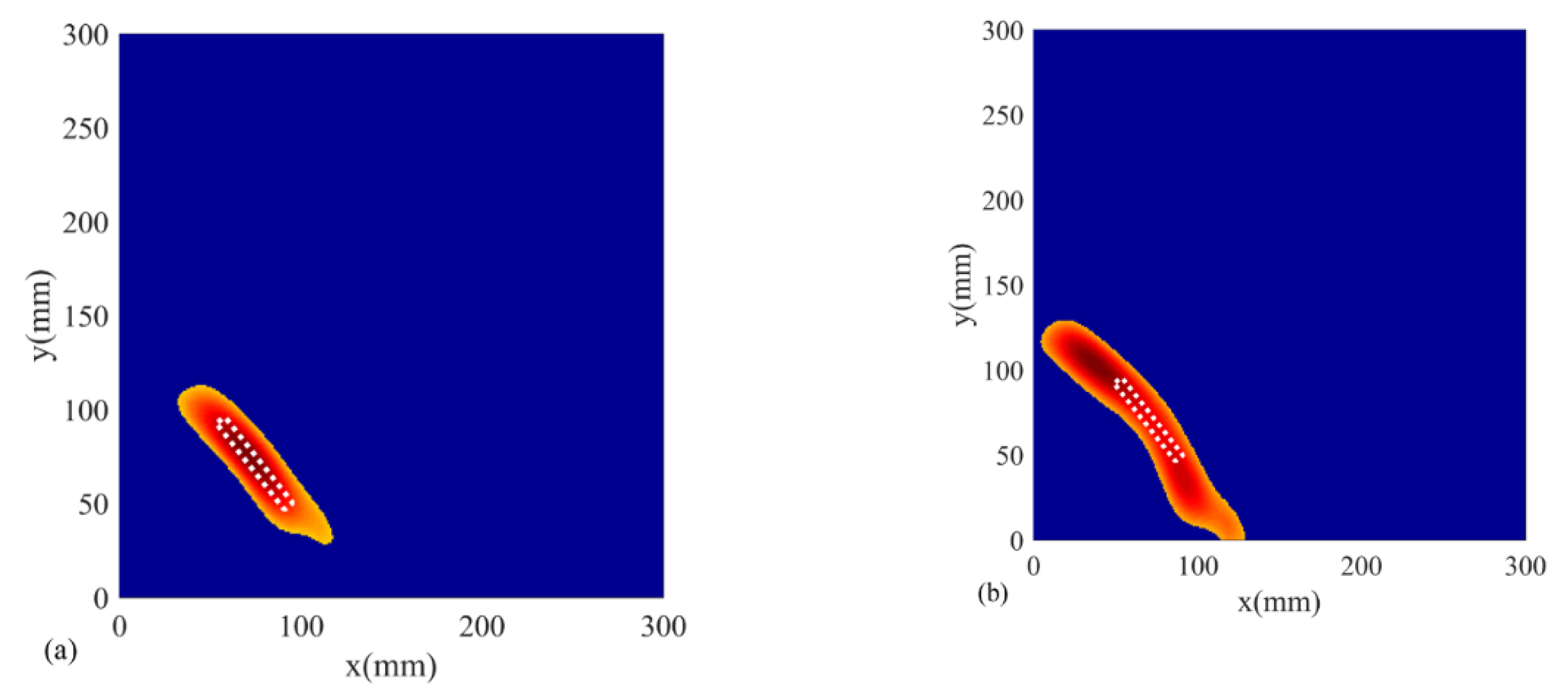

3.3. Damage Localization and Imaging Method

4. Damage Localization and Imaging Experiment

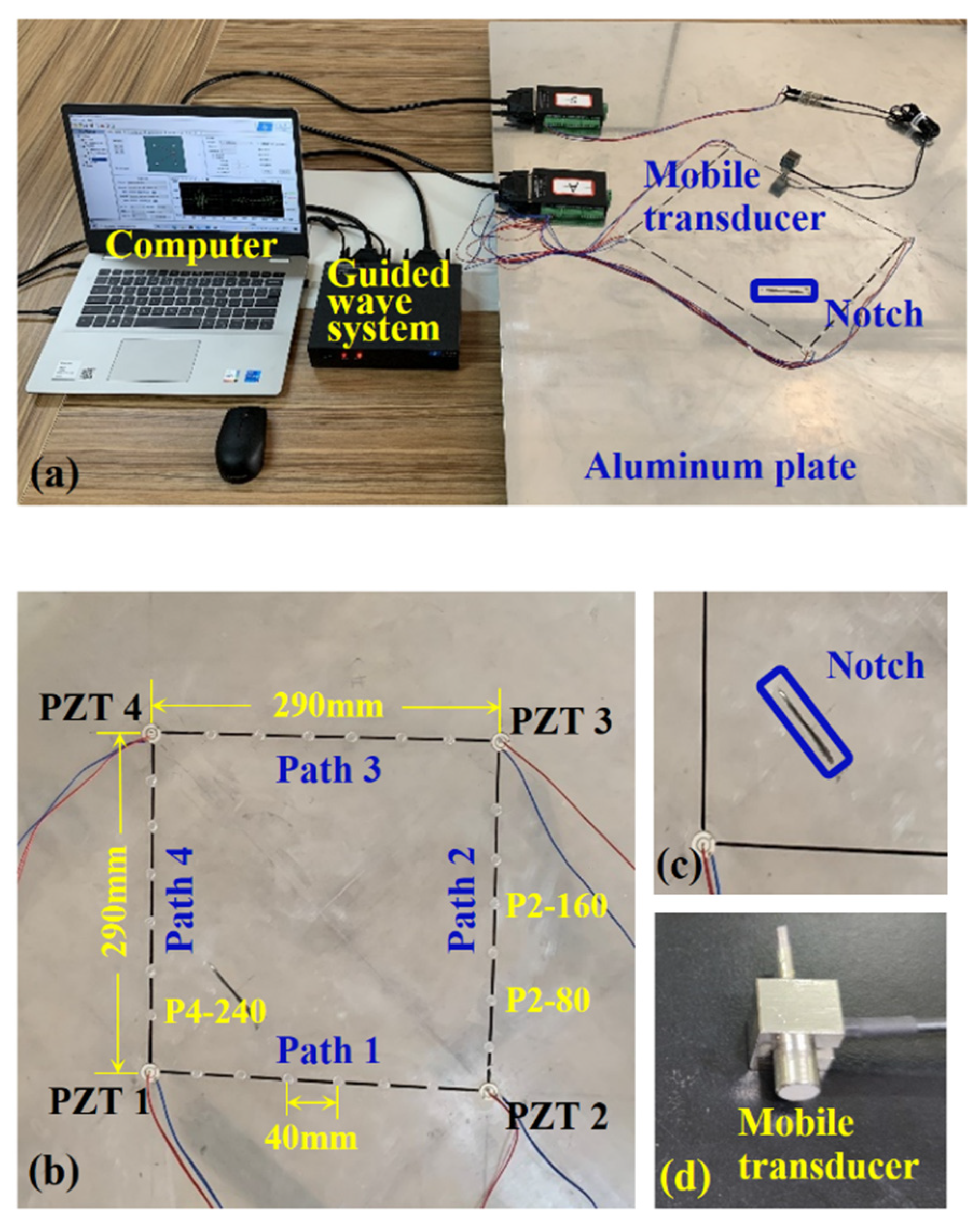

4.1. Experimental Setup and Procedure

4.2. Results and Discussion

5. Strategy for Practical Inspections

6. Conclusions

- The path scanning-based damage detection method introduced herein can locate the crack in a plate without baseline data and maintains effectiveness under the influence of measurement errors;

- A mobile transducer is effective and reliable in collecting pure A0 mode, which is beneficial for judging the damage location with high accuracy;

- A phenomenon where the damage-scattered signals are mixed with other wave components or are weak in certain directions due to the angular scattering characteristic of Lamb waves is verified by the proposed path scanning strategy;

- In comparison with the conventional method without using mobile transducers, the path scanning strategy can accurately obtain the necessary damage information to markedly improve the credibility of damage detection results;

- A strategy for practical inspections is proposed to provide solutions for applying the baseline-free method in damage detection of plate structures with various geometry.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Sun, K.; Song, G.; He, C.; Wu, B. Damage localization in aluminum plate with compact rectangular phased piezoelectric transducer array. Mech. Syst. Signal Process. 2016, 70–71, 625–636. [Google Scholar] [CrossRef]

- Yao, P.; Kong, Q.Z.; Xu, K.; Jiang, T.Y.; Huo, L.S.; Song, G.B. Structural health monitoring of multi-spot welded joints using a lead zirconate titanate based active sensing approach. Smart Mater. Struct. 2016, 25, 015031. [Google Scholar] [CrossRef]

- Xu, L.; Yuan, S.F.; Chen, J.; Ren, Y.Q. Guided Wave-Convolutional Neural Network Based Fatigue Crack Diagnosis of Aircraft Structures. Sensors 2019, 19, 3567. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural Health Monitoring in Composite Structures: A Comprehensive Review. Sensors 2022, 22, 153. [Google Scholar] [CrossRef] [PubMed]

- Sony, S.; Laventure, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control Health Monit. 2019, 26, e2321.1–e2321.22. [Google Scholar] [CrossRef]

- Pandey, P.; Rai, A.; Mitra, M. Explainable 1-D convolutional neural network for damage detection using Lamb wave. Mech. Syst. Signal Process. 2022, 164, 108220. [Google Scholar] [CrossRef]

- Malekloo, A.; Ozer, E.; AlHamaydeh, M.; Girolami, M. Machine learning and structural health monitoring overview with emerging technology and high-dimensional data source highlights. Struct. Health Monit. 2021. [Google Scholar] [CrossRef]

- Yu, X.D.; Ratassepp, M.; Fan, Z. Damage detection in quasi-isotropic composite bends using ultrasonic feature guided waves. Compos. Sci. Technol. 2017, 141, 120–129. [Google Scholar] [CrossRef]

- Wang, W.T.; Zhang, H.; Lynch, J.P.; Cesnik, C.E.S.; Li, H. Experimental and numerical validation of guided wave phased arrays integrated within standard data acquisition systems for structural health monitoring. Struct. Control Health Monit. 2018, 25, e2171. [Google Scholar] [CrossRef]

- Song, G.B.; Li, W.J.; Wang, B.; Ho, S.C.M. A Review of Rock Bolt Monitoring Using Smart Sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef] [Green Version]

- He, S.; Ng, C.T. Modelling and analysis of nonlinear guided waves interaction at a breathing crack using time-domain spectral finite element method. Smart Mater. Struct. 2017, 26, 085002. [Google Scholar] [CrossRef]

- Zhu, J.X.; Ho, S.C.M.; Patil, D.; Wang, N.; Hirsch, R.; Song, G.B. Underwater pipeline impact localization using piezoceramic transducers. Smart Mater. Struct. 2017, 26, 107002. [Google Scholar] [CrossRef] [Green Version]

- Luo, G.S.; Tan, J.P.; Wang, L.; Xu, Y. Defects detection in typical positions of bend pipes using low-frequency ultrasonic guided wave. J. Cent. South Univ. 2015, 22, 3860–3867. [Google Scholar] [CrossRef]

- Nandyala, A.R.; Darpe, A.K.; Singh, S.P. Damage localization in cross-ply laminated composite plates under varying temperature conditions using Lamb waves. Meas. Sci. Technol. 2020, 31, 064003. [Google Scholar] [CrossRef]

- Salmanpour, M.S.; Khodaei, Z.S.; Aliabadi, M.H.F. Impact Damage Localisation with Piezoelectric Sensors under Operational and Environmental Conditions. Sensors 2017, 17, 1178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Cho, Y. Using Lamb Waves to Monitor Moisture Absorption in Thermally Fatigued Composite Laminates. J. Korean Soc. Nondestruct. Test. 2016, 36, 175–180. [Google Scholar] [CrossRef] [Green Version]

- Schubert, K.J.; Herrmann, A.S. On the influence of moisture absorption on Lamb wave propagation and measurements in viscoelastic CFRP using surface applied piezoelectric sensors. Compos. Struct. 2012, 94, 3635–3643. [Google Scholar] [CrossRef]

- Mohabuth, M.; Kotousov, A.; Ng, C.T.; Rose, L.R.F. Implication of changing loading conditions on structural health monitoring utilising guided waves. Smart Mater. Struct. 2018, 27, 025003. [Google Scholar] [CrossRef] [Green Version]

- Roy, S.; Ladpli, P.; Chang, F.K. Load monitoring and compensation strategies for guided-waves based structural health monitoring using piezoelectric transducers. J. Sound Vib. 2015, 351, 206–220. [Google Scholar] [CrossRef]

- Lu, X.; Soh, C.K.; Avvari, P.V. Lamb wave propagation in vibrating structures for effective health monitoring. In Proceedings of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 8–12 March 2015; p. 9438. [Google Scholar]

- Krajcinovic, D.; Silva, M.A.G. Statistical aspects of the continuous damage theory. Int. J. Solids Struct. 1982, 18, 551–562. [Google Scholar] [CrossRef]

- Sony, S.; Sadhu, A. Identification of progressive damage in structures using time-frequency analysis. In Proceedings of the CSCE Annual Conference, Montreal, BC, Canada, 12–15 June 2019; pp. 12–15. [Google Scholar]

- Anton, S.R.; Inman, D.J.; Park, G. Reference-Free Damage Detection Using Instantaneous Baseline Measurements. AIAA J. 2009, 47, 1952–1964. [Google Scholar] [CrossRef]

- Kim, S.B.; Lee, C.G.; Hong, J.-W.; Park, H.W.; Sohn, H. Applications of an Instantaneous Damage Detection Technique to Plates with Additional Complexities. J. Nondestruct. Eval. 2010, 29, 189–205. [Google Scholar] [CrossRef]

- Alem, B.; Abedian, A.; Nasrollahi-Nasab, K. Reference-Free Damage Identification in Plate-Like Structures Using Lamb-Wave Propagation with Embedded Piezoelectric Sensors. J. Aerosp. Eng. 2016, 29, 04016062. [Google Scholar] [CrossRef]

- Qiu, J.; Li, F.; Abbas, S.; Zhu, Y. A baseline-free damage detection approach based on distance compensation of guided waves. J. Low Freq. Noise Vib. Act. Control 2018, 38, 1132–1148. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, K.; Wu, Z.; Gao, D.; Gorgin, R.; Ma, S.; Lei, Z. Lamb waves and electro-mechanical impedance based damage detection using a mobile PZT transducer set. Ultrasonics 2019, 92, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Jia, H.; Liu, H.; Zhang, Z.; Dai, F.; Liu, Y.; Leng, J. A baseline-free approach of locating defect based on mode conversion and the reciprocity principle of Lamb waves. Ultrasonics 2020, 102, 106063. [Google Scholar] [CrossRef] [PubMed]

- He, T.H.; Xing, G.L.; Li, Y.; Li, Q.F.; Zhou, S.P. A novel baseline-free defect detection and localization method of welded steel plate based on reciprocity loss. Meas. Sci. Technol. 2021, 32, 025602. [Google Scholar] [CrossRef]

- Huang, L.; Zeng, L.; Lin, J. Baseline-free damage detection in composite plates based on the reciprocity principle. Smart Mater. Struct. 2018, 27, 015026. [Google Scholar] [CrossRef]

- Agrahari, J.K.; Kapuria, S. A refined Lamb wave time-reversal method with enhanced sensitivity for damage detection in isotropic plates. J. Intell. Mater. Syst. Struct. 2015, 27, 1283–1305. [Google Scholar] [CrossRef]

- Kannusamy, M.; Kapuria, S.; Sasmal, S. Accurate baseline-free damage localization in plates using refined Lamb wave time-reversal method. Smart Mater. Struct. 2020, 29, 055044. [Google Scholar] [CrossRef]

- Bagheri, A.; Li, K.; Rizzo, P. Reference-free damage detection by means of wavelet transform and empirical mode decomposition applied to Lamb waves. J. Intell. Mater. Syst. Struct. 2012, 24, 194–208. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, M.; Li, Q.; Png, M. Baseline-free defect evaluation of complex-microstructure composites using frequency-dependent ultrasound reflections. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106090. [Google Scholar] [CrossRef]

- He, J.; Leser, P.E.; Leser, W.P.; Yuan, F.-G. IWSHM 2017: Damage-scattered wave extraction in an integral stiffened isotropic plate: A baseline-subtraction-free approach. Struct. Health Monit. 2018, 17, 1365–1376. [Google Scholar] [CrossRef]

- Villalobos, A.; Ruiz, R.O.; Meruane, V. Generalized Gaussian smoothing for baseline-free debonding assessment of sandwich panels. Struct. Control Health Monit. 2021, 28, e2727. [Google Scholar] [CrossRef]

- Cao, S.; Ouyang, H.; Cheng, L. Baseline-free adaptive damage localization of plate-type structures by using robust PCA and Gaussian smoothing. Mech. Syst. Signal Process. 2019, 122, 232–246. [Google Scholar] [CrossRef]

- Alguri, K.S.; Chia, C.C.; Harley, J.B. Sim-to-Real: Employing ultrasonic guided wave digital surrogates and transfer learning for damage visualization. Ultrasonics 2021, 111, 106338. [Google Scholar] [CrossRef] [PubMed]

- Alguri, K.S.; Melville, J.; Harley, J.B. Baseline-free guided wave damage detection with surrogate data and dictionary learning. J. Acoust. Soc. Am. 2018, 143, 3807. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Zheng, Y.; Zhang, J.; Xu, X.; Ma, S.; Wu, Z. A reconstruction-based mode separation method of Lamb wave for damage detection in plate structures. Smart Mater. Struct. 2019, 28, 035033. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, H.; Zhou, K.; Yang, Z.; Liu, K.; Zheng, Y.; Ma, S.; Wu, Z. Baseline-Free Damage Diagnostic Imaging Approach Relying on the Extraction of Converted Modes of Ultrasonic Guided Waves. J. Aerosp. Eng. 2021, 34, 04021071. [Google Scholar] [CrossRef]

- Cegla, F.B.; Rohde, A.; Veidt, M. Analytical prediction and experimental measurement for mode conversion and scattering of plate waves at non-symmetric circular blind holes in isotropic plates. Wave Motion 2008, 45, 162–177. [Google Scholar] [CrossRef] [Green Version]

- Fromme, P. Guided wave sensitivity prediction for part and through-thickness crack-like defects. Struct. Health Monit. 2019, 19, 953–963. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X.; Michaels, J.E.; Michaels, T.E.; He, C. Incremental scattering of the A0 Lamb wave mode from a notch emanating from a through-hole. Ultrasonics 2019, 91, 220–230. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Cheng, L.; Su, Z. Correlative sensor array and its applications to identification of damage in plate-like structures. Struct. Control Health Monit. 2012, 19, 650–671. [Google Scholar] [CrossRef]

- Rajagopal, P.; Lowe, M. Angular influence on the scattering of fundamental shear horizontal guided waves by a through-thickness crack in an isotropic plate. J. Acoust. Soc. Am. 2007, 122, 2021. [Google Scholar] [CrossRef]

- Quaegebeur, N.; Bouslama, N.; Bilodeau, M.; Guitel, R.; Masson, P.; Maslouhi, A.; Micheau, P. Guided wave scattering by geometrical change or damage: Application to characterization of fatigue crack and machined notch. Ultrasonics 2017, 73, 187–195. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media: Plates; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- Michaels, J.E. Detection, localization and characterization of damage in plates with an in situ array of spatially distributed ultrasonic sensors. Smart Mater. Struct. 2008, 17, 035035. [Google Scholar] [CrossRef] [Green Version]

- Sharif-Khodaei, Z.; Aliabadi, M.H. Assessment of delay-and-sum algorithms for damage detection in aluminium and composite plates. Smart Mater. Struct. 2014, 23, 075007. [Google Scholar] [CrossRef]

| Young’s Modulus | Poisson Ratio | Density | Thickness |

|---|---|---|---|

| 70 GPa | 0.33 | 2700 kg/m3 | 4 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, H.; Zhou, K.; Li, X.; Wei, X.; Yu, Z.; Ma, Q.; Du, G. A Novel Baseline-Free Damage Detection Method Based on Path Scanning of Lamb Waves Using Mobile Transducers. Sensors 2022, 22, 2076. https://doi.org/10.3390/s22062076

Yuan H, Zhou K, Li X, Wei X, Yu Z, Ma Q, Du G. A Novel Baseline-Free Damage Detection Method Based on Path Scanning of Lamb Waves Using Mobile Transducers. Sensors. 2022; 22(6):2076. https://doi.org/10.3390/s22062076

Chicago/Turabian StyleYuan, Hongqiang, Kai Zhou, Xiuquan Li, Xiaolong Wei, Zeyu Yu, Qi Ma, and Guofeng Du. 2022. "A Novel Baseline-Free Damage Detection Method Based on Path Scanning of Lamb Waves Using Mobile Transducers" Sensors 22, no. 6: 2076. https://doi.org/10.3390/s22062076

APA StyleYuan, H., Zhou, K., Li, X., Wei, X., Yu, Z., Ma, Q., & Du, G. (2022). A Novel Baseline-Free Damage Detection Method Based on Path Scanning of Lamb Waves Using Mobile Transducers. Sensors, 22(6), 2076. https://doi.org/10.3390/s22062076