A Fast Electrical Resistivity-Based Algorithm to Measure and Visualize Two-Phase Swirling Flows

Abstract

:1. Introduction

- The algorithm should be able to give all the relevant information about the light phase core (e.g., size and position).

- If the visualization is needed, the algorithm should allow parametric reconstructions from the data. This also can open another dimension of innovative visualizations, for example, introducing Augmented Reality (AR) tools to inject process results in their real region of appearance.

- The algorithm should be able to calculate the required parameter online and should also be able to send the input to multiple streams, such as an input to the controller or the visualization tool mentioned above as fast as possible.

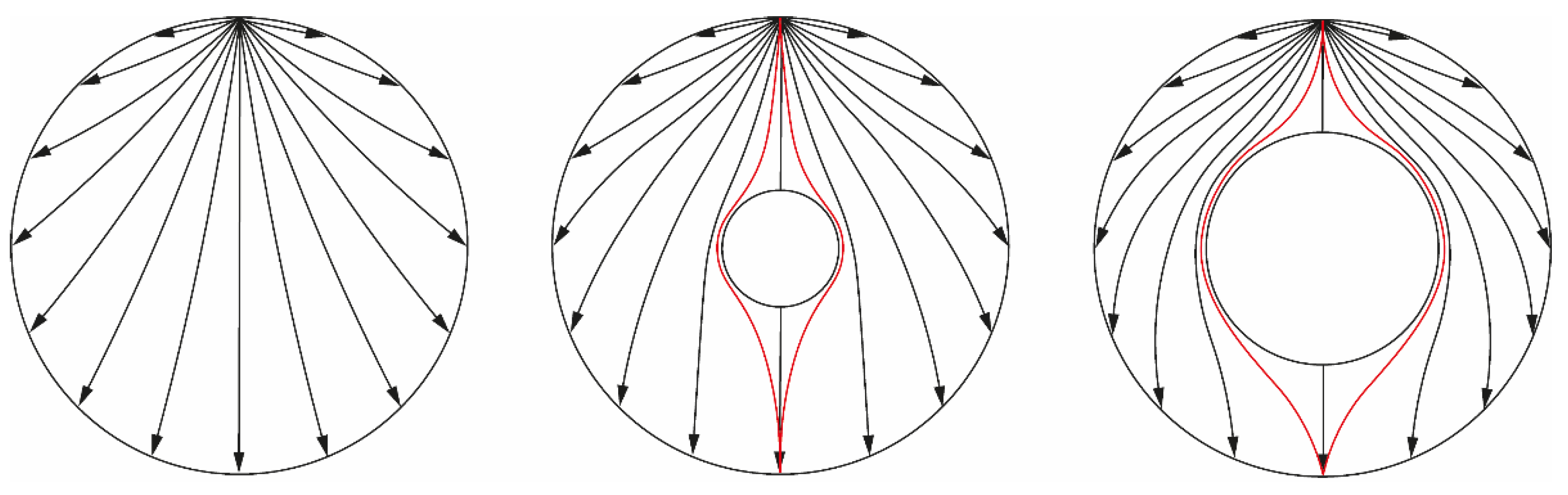

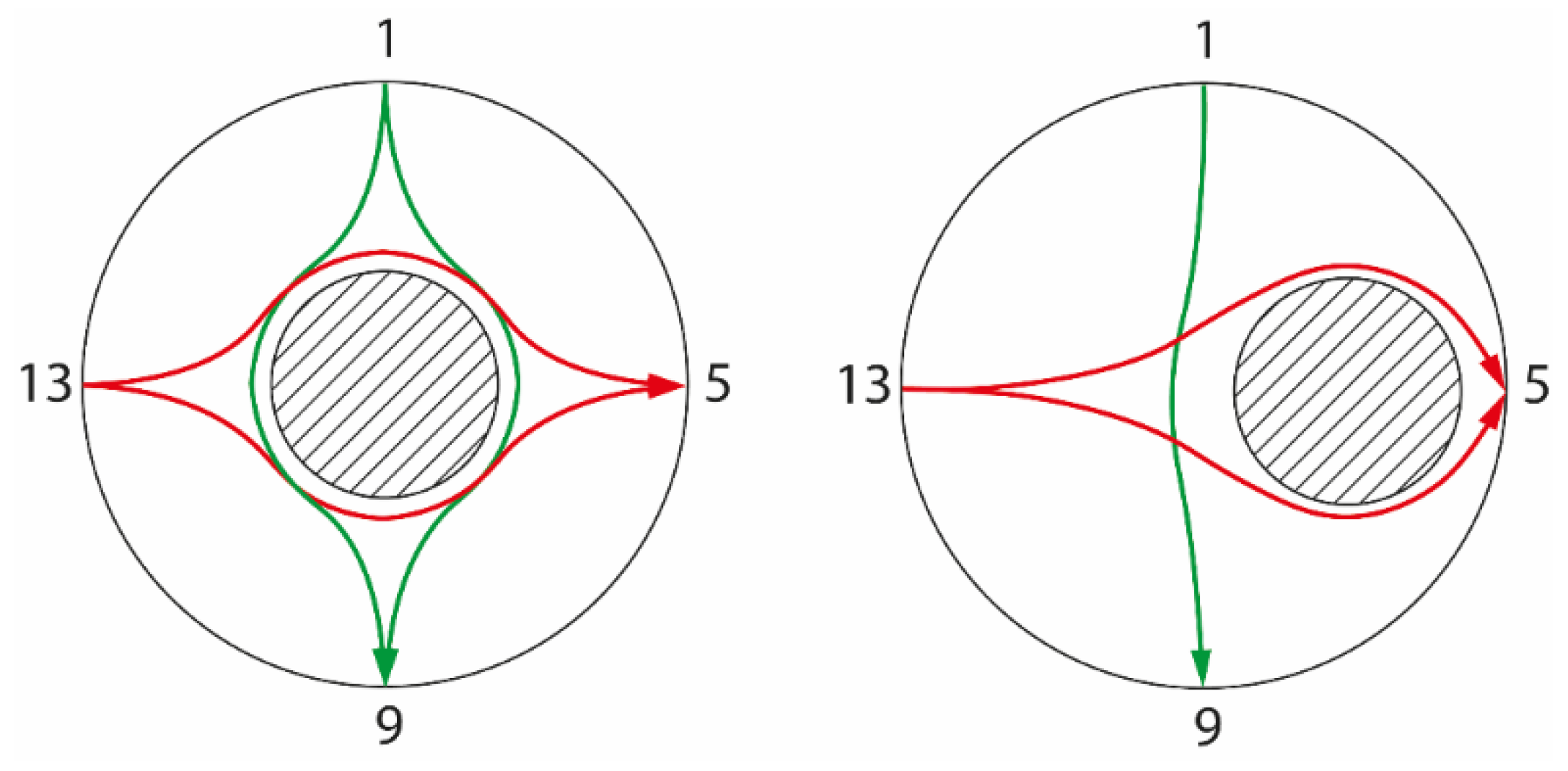

2. Algorithm Background

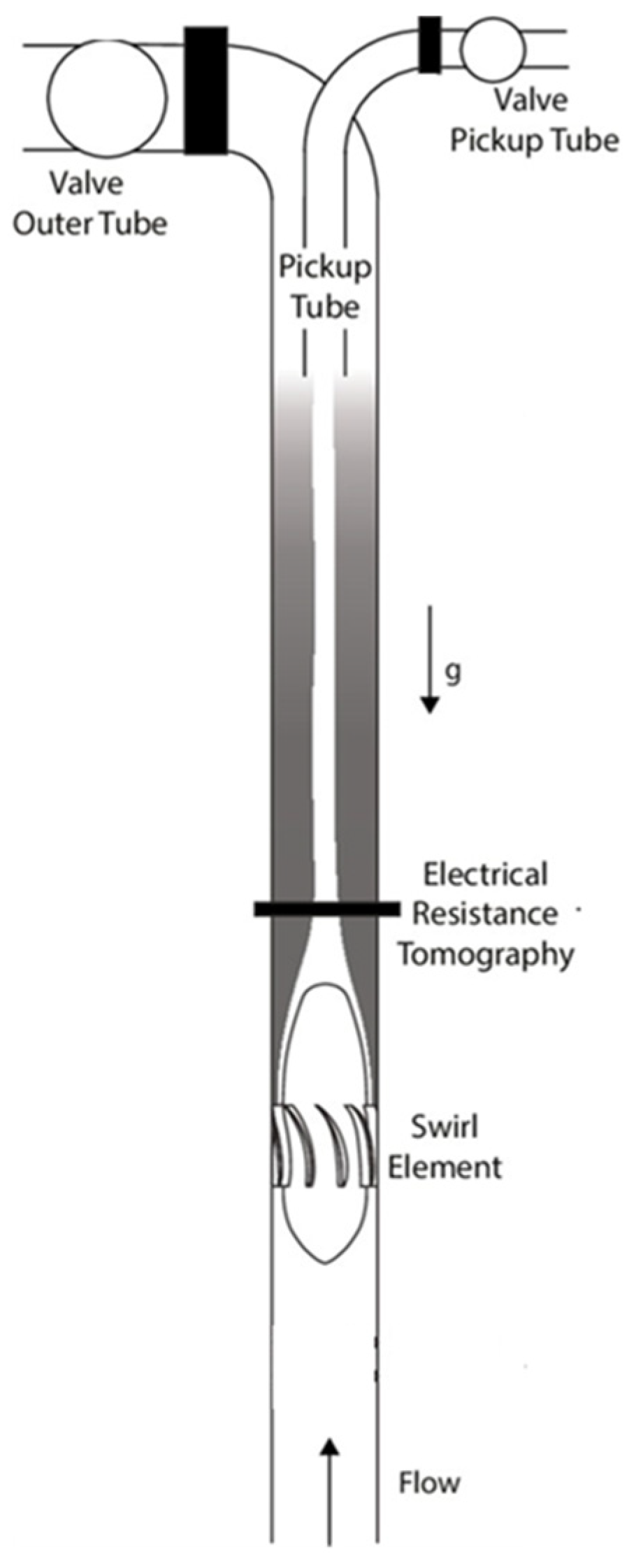

3. Materials and Methods

3.1. ERT Sensor and Measurement Electronics

3.2. Calibration Measurement

3.3. Dynamic Measurements

4. Results and Discussions

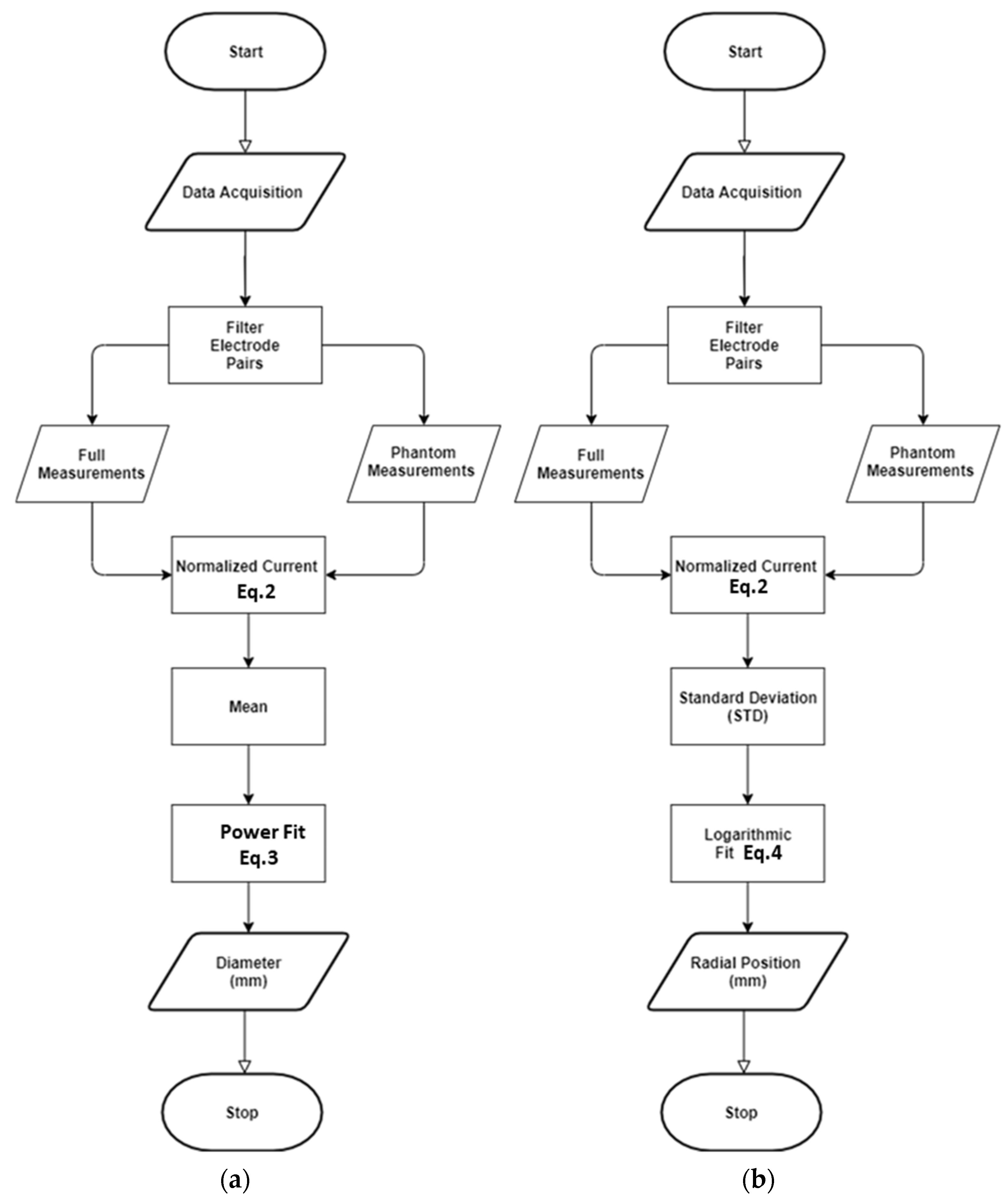

4.1. Core Size and Tracking Algorithm

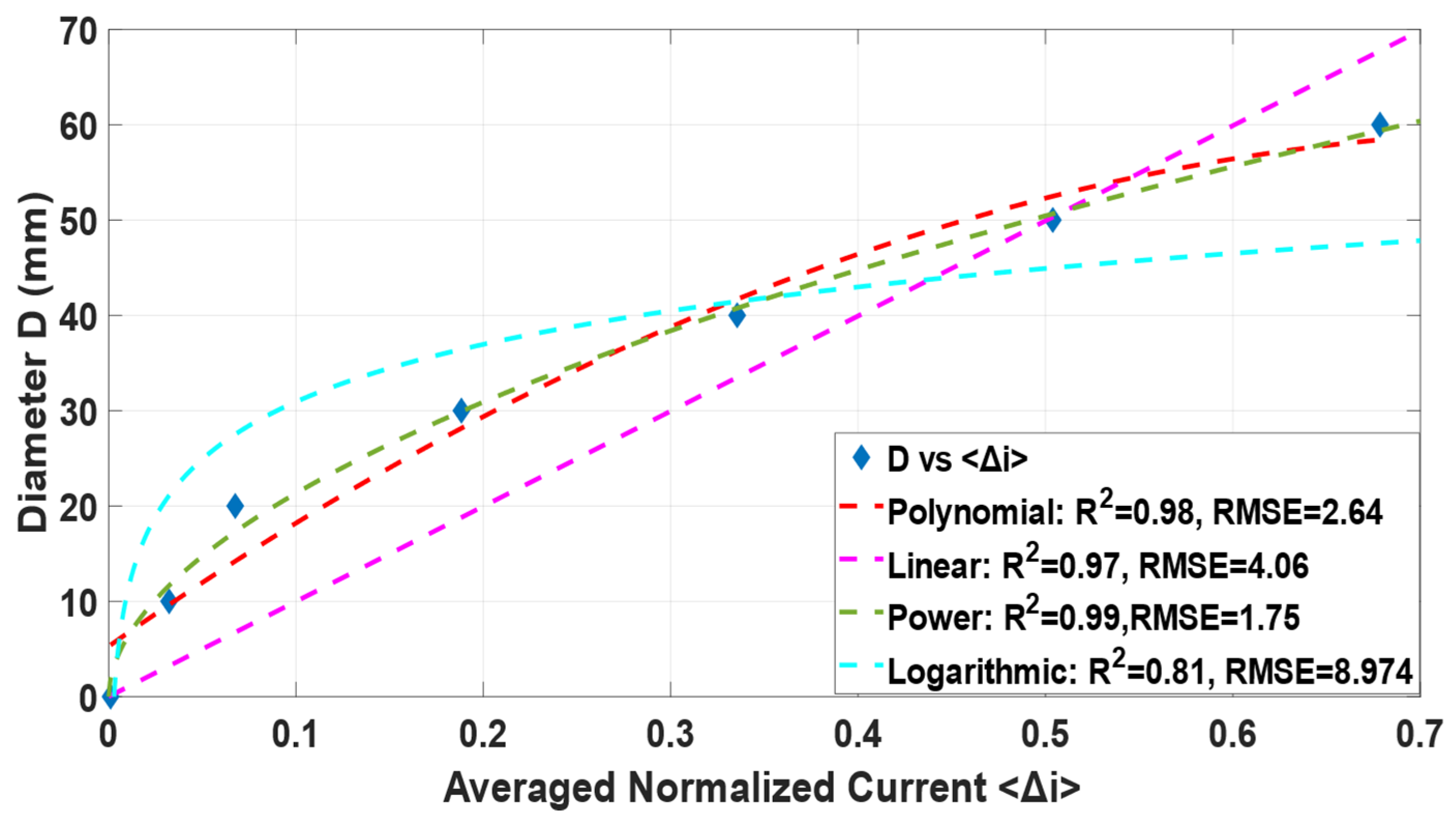

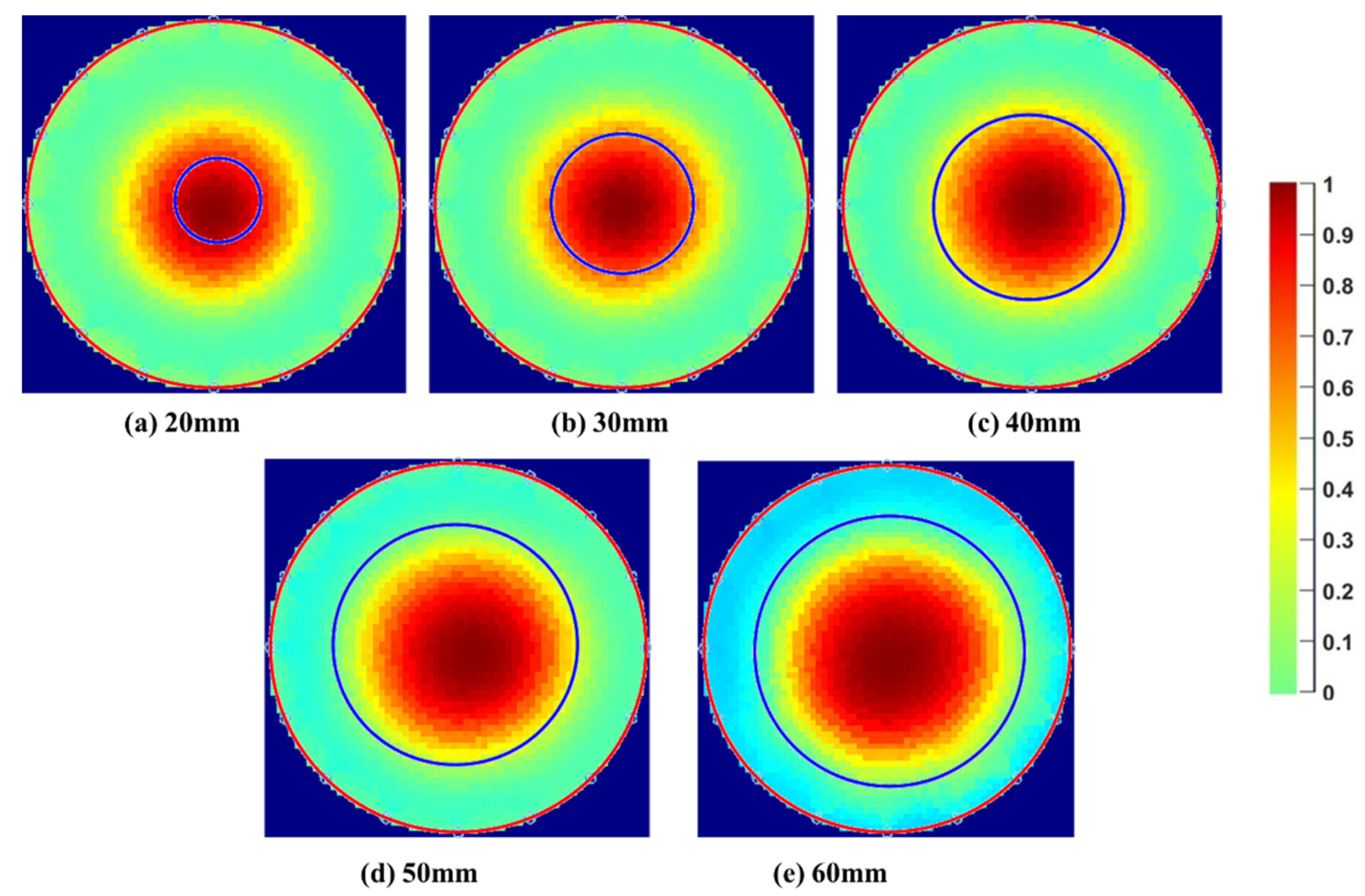

4.1.1. Core Size

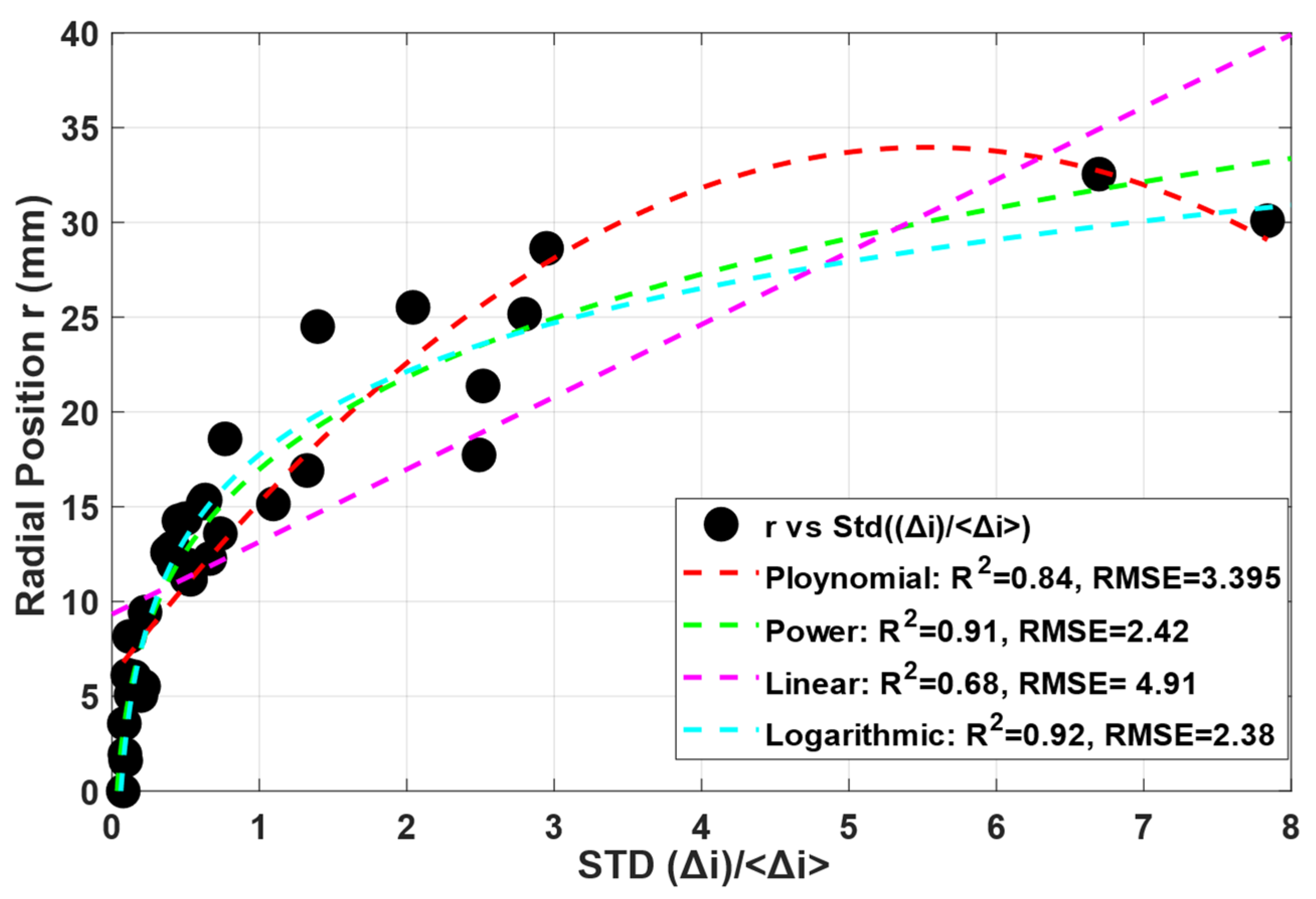

4.1.2. Radial Position

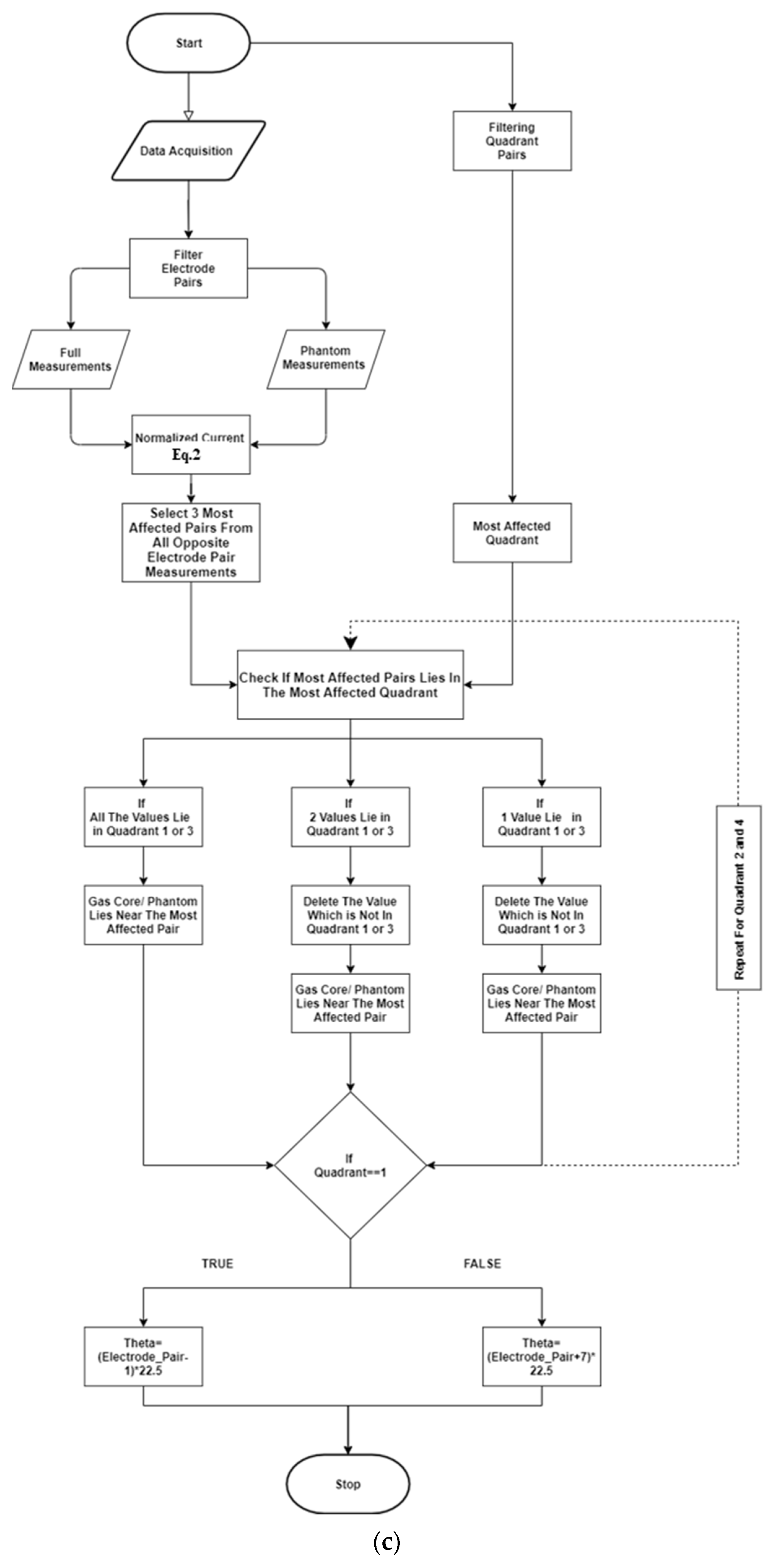

4.1.3. Angular Position

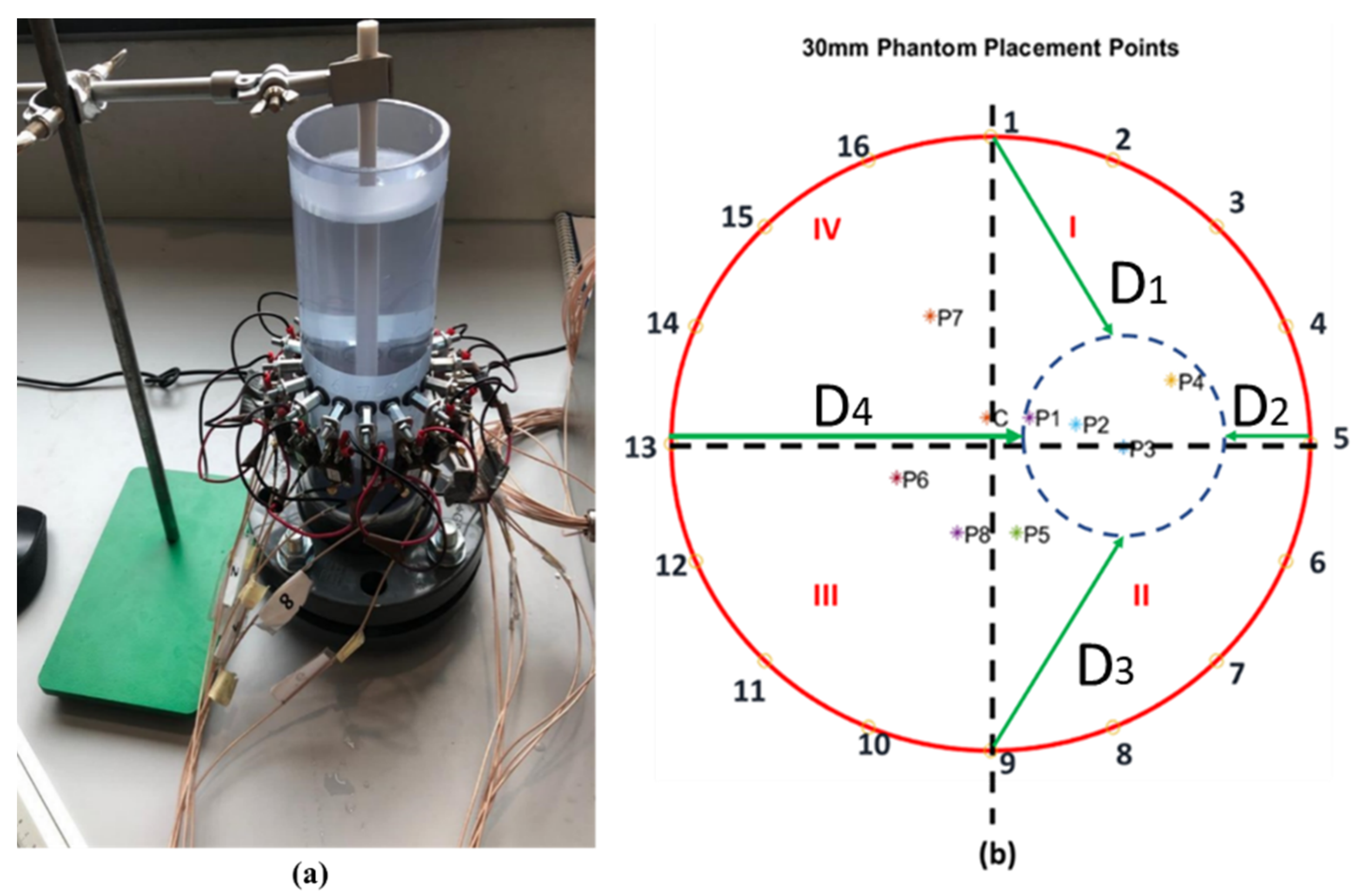

4.2. Static Tests

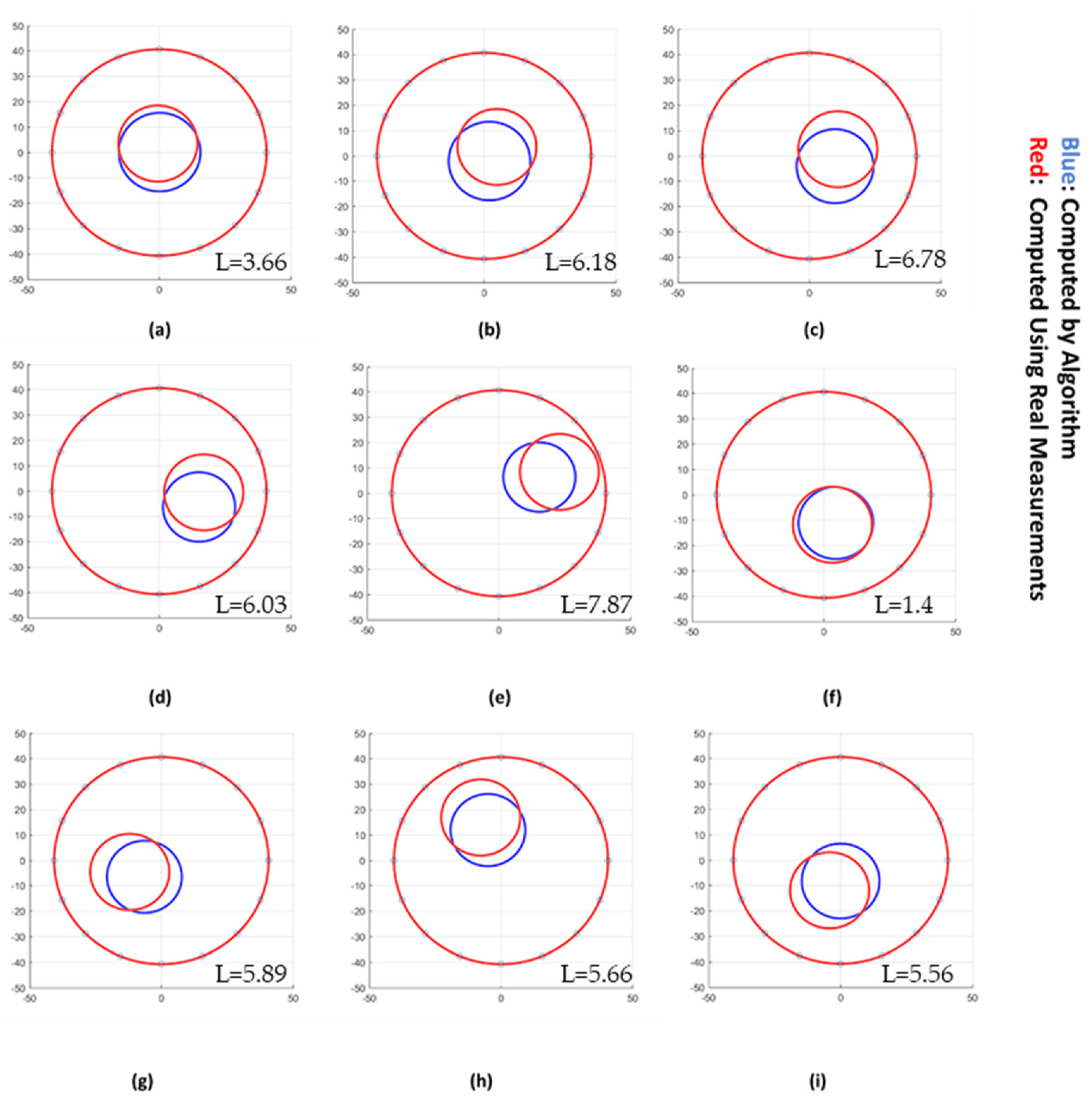

4.2.1. Algorithm Validation

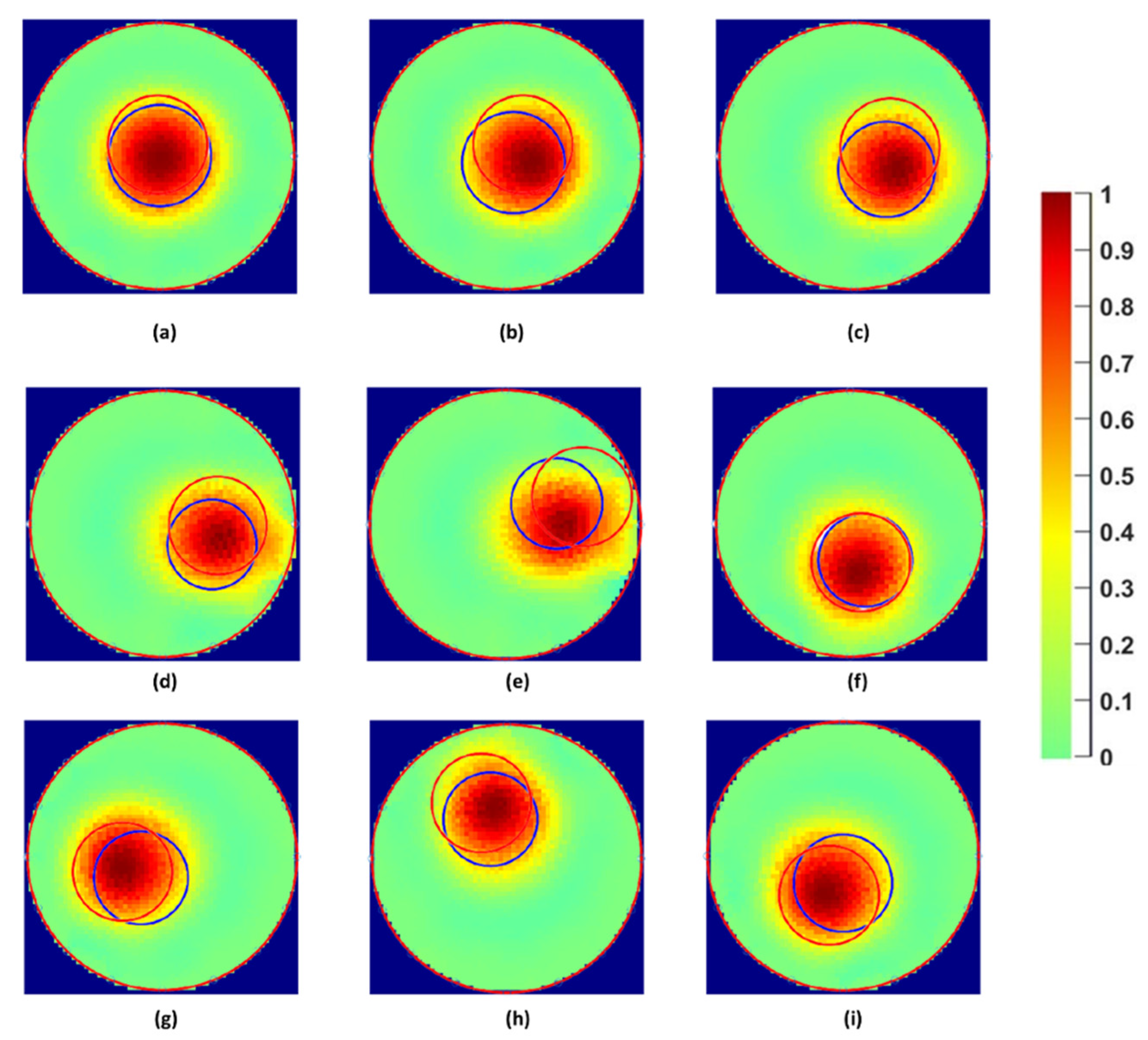

4.2.2. Comparison with Image Reconstruction

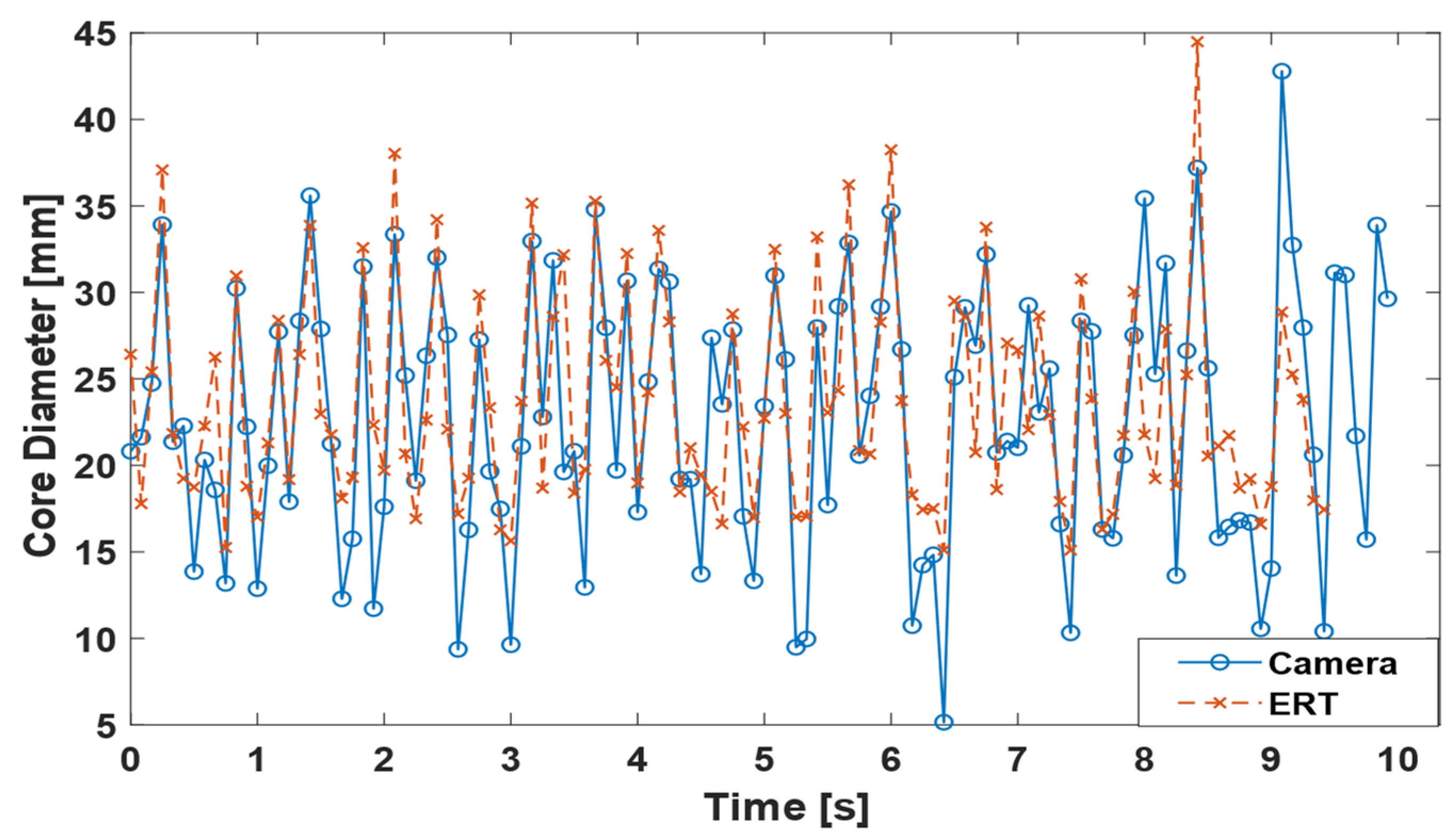

4.2.3. Dynamic Tests

4.2.4. Vision towards Smart Visualization

- The object was created using the AutoCAD software. The main object consists of a virtual pipe and two circular objects where the outer circle represents the pipe, and the inner circle represents the phantom or gas core.

- The object was transferred using a python script to Apple’s Reality Composer application. Reality Composer application contains various inbuilt libraries to manipulate and customize virtual objects sizes, shapes, and textures.

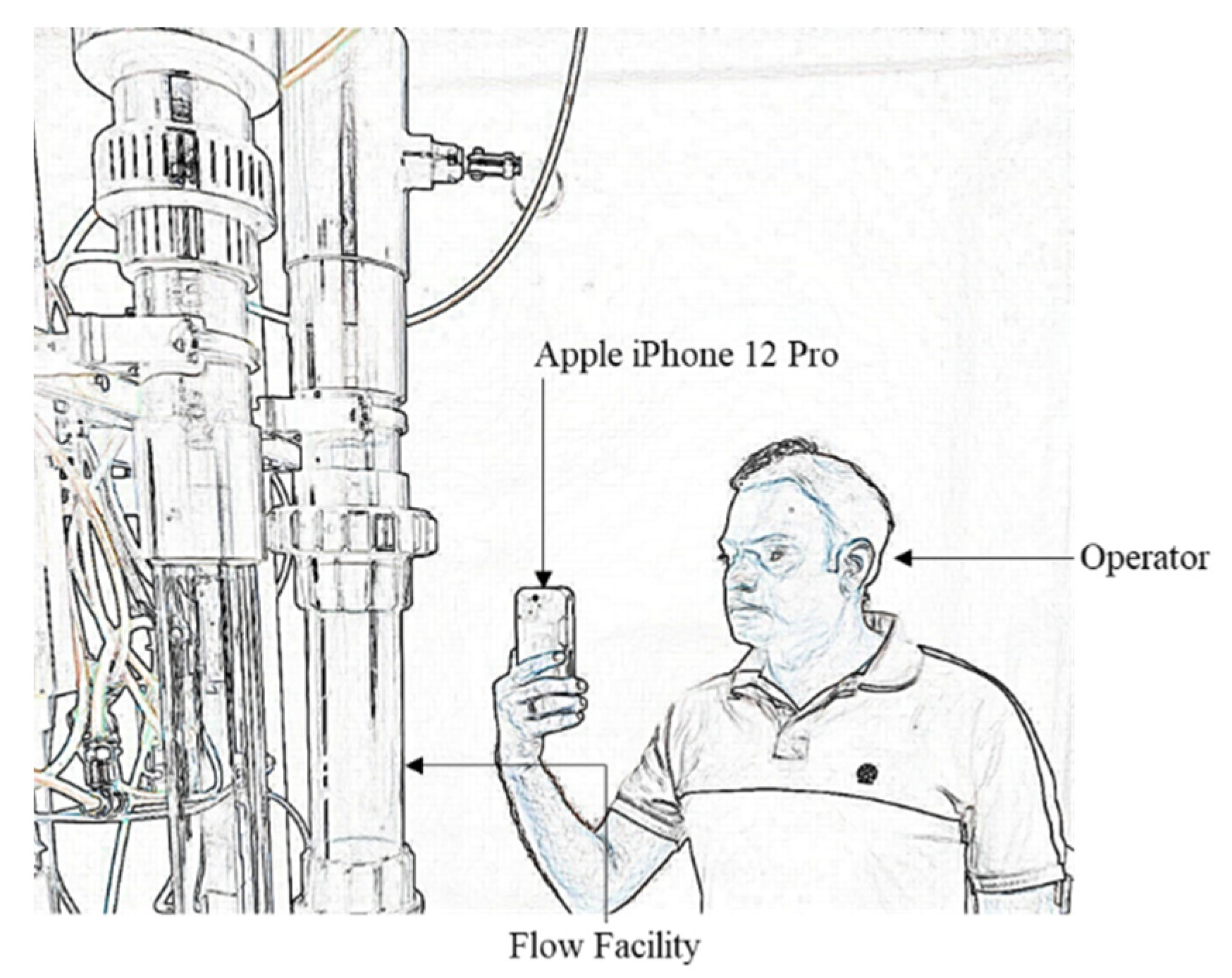

- The main aim is to superimpose the object on the pipeline, so the anchor type ‘Object’ was chosen. This particular scanning type uses the LiDAR scanner to scan the pipeline where the user wants to see the object. The object is shown in Figure 16.

- The transform parameters such as positions and size of the object were accessed in an Xcode11 IDE to manipulate the object parameters in real time.

5. Conclusions

- The core size is well represented by the average current measured by electrodes installed opposite to each other in the pipeline. Moreover, using the equation proposed in this paper, a root means squared difference below 4.03 mm is observed when computing the phantom size.

- The core eccentricity (radial position) is well represented by the standard deviation of the current measured between opposite electrodes for one frame divided by its mean value. The equation considered in this paper results in a root means squared difference of ~4.3 mm when estimating the radial position of the phantom.

- The angular position of the insulating core can be successfully obtained from four additional 90° current measurements in addition to the opposite measurements, fully characterizing the core in 12 measurements using the 16 electrode system used in this paper.

- The position of the phantom using the algorithm of this paper results in an average error of the distance between the real and the estimated positions of ~6 mm in the worst case occurring for the two smaller tested phantoms.

- The proposed algorithm for core size and position estimation is suitable for dynamic monitoring of the inline separation, showing a potential measurement speed in the order of 10 kHz when measuring the core, in comparison to the speed in the order of Hz of the image reconstruction approaches.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rutqvist, J.; Wu, Y.S.; Tsang, C.F.; Bodvarsson, G. A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 429–442. [Google Scholar] [CrossRef]

- De Lillo, L.; Empringham, L.; Wheeler, P.W.; Khwan-On, S.; Gerada, C.; Othman, M.N.; Huang, X. Multiphase power converter drive for fault-tolerant machine development in aerospace applications. IEEE Trans. Ind. Electron. 2010, 57, 575–583. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, Y.; Zhang, M.; Yu, P.; Li, Y. Experimental measurement of oil-water two-phase flow by data fusion of electrical tomography sensors and venturi tube. Meas. Sci. Technol. 2017, 28, 095301. [Google Scholar] [CrossRef]

- Khatib, Z.; Paul, V. Water to Value—Produced Water Management for Sustainable Field Development of Mature and Green Fields. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Kuala Lumpur, Malaysia, 20–22 March 2002. [Google Scholar]

- Sahovic, B.; Atmani, H.; Sattar, M.A.; Garcia, M.M.; Schleicher, E.; Legendre, D.; Climent, E.; Zamansky, R.; Pedrono, A.; Babout, L.; et al. Controlled Inline Fluid Separation Based on Smart Process Tomography Sensors. Chem. Ing. Tech. 2020, 92, 554–563. [Google Scholar] [CrossRef] [Green Version]

- Sahovic, B.; Atmani, H.; Wiedemann, P.; Schleicher, E.; Legendre, D.; Climent, E. Investigation of upstream and downstream flow conditions in a swirling inline fluid separator—Experiments with a wire-mesh sensor and CFD studies. In Proceedings of the 9th World Congress on Industrial Process Tomography, Bath, UK, 2–6 September 2018; pp. 1–10. [Google Scholar]

- Garcia, M.M.; Sahovic, B.; Sattar, M.A.; Atmani, H.; Schleicher, E.; Hampel, U.; Babout, L.; Legendre, D.; Portela, L.M. Control of a gas-liquid inline swirl separator based on tomographic measurements. IFAC-PapersOnLine 2020, 53, 11483–11490. [Google Scholar] [CrossRef]

- Sattar, M.A.; Wrasse, A.D.N.; Morales, R.E.M.; Pipa, D.R.; Banasiak, R.; Da Silva, M.J.; Babout, L. Multichannel Capacitive Imaging of Gas Vortex in Swirling Two-Phase Flows Using Parametric Reconstruction. IEEE Access 2020, 8, 69557–69565. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Niu, P.; Liu, M.; Wang, S. Gas-liquid two-phase flow measurements by the electromagnetic flowmeter combined with a phase-isolation method. Flow Meas. Instrum. 2018, 60, 78–87. [Google Scholar] [CrossRef]

- Liu, L.; Bai, B. Flow regime identification of swirling gas-liquid flow with image processing technique and neural networks. Chem. Eng. Sci. 2019, 199, 588–601. [Google Scholar] [CrossRef]

- Ofuchi, C.Y.; Eidt, H.K.; Bertoldi, D.; Da Silva, M.J.; Morales, R.E.M.; Neves, F. Void Fraction Measurement in a Gas-Liquid Swirling Flow Using an Ultrasonic Sensor. IEEE Access 2020, 8, 194477–194484. [Google Scholar] [CrossRef]

- Rakesh, A.; Kumar Reddy, V.T.S.R.; Narasimha, M. Air-core size measurement of operating hydrocyclone by electrical resistance tomography. Chem. Eng. Technol. 2014, 37, 795–805. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Sikora, J. Applying industrial tomography to control and optimization flow systems. Open Phys. 2018, 16, 332–345. [Google Scholar] [CrossRef]

- Hosseini, M.; Kaasinen, A.; Shoorehdeli, M.A.; Link, G.; Lähivaara, T. System Identification of Conveyor Belt Microwave Drying Process of Polymer Foams Using Electrical Capacitance Tomography. Sensors 2021, 21, 7170. [Google Scholar] [CrossRef] [PubMed]

- Yadav, R.; Omrani, A.; Link, G.; Vauhkonen, M. Microwave Tomography Using Neural Networks for Its Application in an Industrial Microwave Drying System. Sensors 2021, 21, 6919. [Google Scholar] [CrossRef] [PubMed]

- Koulountzios, P.; Aghajanian, S.; Rymarczyk, T.; Koiranen, T.; Soleimani, M. An Ultrasound Tomography Method for Monitoring CO2 Capture Process Involving Stirring and CaCO3 Precipitation. Sensors 2021, 21, 6995. [Google Scholar] [CrossRef] [PubMed]

- Hampel, U.; Barthel, F.; Bieberle, A.; Bieberle, M.; Boden, S.; Franz, R.; Neumann-kipping, M. Tomographic imaging of two-phase flow. Int. J. Adv. Nucl. React. Des. Technol. 2020, 2, 86–92. [Google Scholar] [CrossRef]

- Babout, L.; Grudzie, K.; Waktola, S.; Mi, K.; Adrien, J.; Maire, E. Quantitative analysis of fl ow dynamics of organic granular materials inside a versatile silo model during time-lapse X-ray tomography experiments. Comput. Electron. Agric. 2020, 172, 105346. [Google Scholar] [CrossRef]

- Liu, S.; Jia, J.; Zhang, Y.D.; Yang, Y. Image Reconstruction in Electrical Impedance Tomography Based on Structure-Aware Sparse Bayesian Learning. IEEE Trans. Med. Imaging 2018, 37, 2090–2102. [Google Scholar] [CrossRef] [Green Version]

- Ren, Z.; Kowalski, A.; Rodgers, T.L. Measuring inline velocity profile of shampoo by electrical resistance tomography (ERT). Flow Meas. Instrum. 2017, 58, 31–37. [Google Scholar] [CrossRef] [Green Version]

- Torrese, P.; Pozzobon, R.; Rossi, A.P.; Unnithan, V.; Sauro, F.; Borrmann, D.; Lauterbach, H.; Santagata, T. Detection, imaging and analysis of lava tubes for planetary analogue studies using electric methods (ERT). Icarus 2020, 357, 114244. [Google Scholar] [CrossRef]

- Rao, G.; Aghajanian, S.; Koiranen, T.; Wajman, R.; Jackowska-Strumiłło, L. Process monitoring of antisolvent based crystallization in low conductivity solutions using electrical impedance spectroscopy and 2-D electrical resistance tomography. Appl. Sci. 2020, 10, 3903. [Google Scholar] [CrossRef]

- Karhunen, K.; Seppänen, A.; Lehikoinen, A.; Monteiro, P.J.M.; Kaipio, J.P. Electrical Resistance Tomography imaging of concrete. Cem. Concr. Res. 2010, 40, 137–145. [Google Scholar] [CrossRef]

- Sharifi, M.; Young, B. Electrical resistance tomography (ert) applications to chemical engineering. Chem. Eng. Res. Des. 2013, 91, 1625–1645. [Google Scholar] [CrossRef]

- Frias, M.A.R.; Yang, W. Electrical resistance tomography with voltage excitation. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Taipei, Taiwan, 23–26 May 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Fan, W.R.; Wang, H.X. Maximum entropy regularization method for electrical impedance tomography combined with a normalized sensitivity map. Flow Meas. Instrum. 2010, 21, 277–283. [Google Scholar] [CrossRef]

- Boyle, A.; Aristovich, K.; Adler, A. Beneficial techniques for spatio-temporal imaging in electrical impedance tomography. Physiol. Meas. 2020, 41, 064003. [Google Scholar] [CrossRef]

- Shi, Y.; Rao, Z.; Wang, C.; Fan, Y.; Zhang, X.; Wang, M. Total Variation Regularization Based on Iteratively Reweighted Least-Squares Method for Electrical Resistance Tomography. IEEE Trans. Instrum. Meas. 2020, 69, 3576–3586. [Google Scholar] [CrossRef]

- Hernandez-Alvarado, F.; Kleinbart, S.; Kalaga, D.V.; Banerjee, S.; Joshi, J.B.; Kawaji, M. Comparison of void fraction measurements using different techniques in two-phase flow bubble column reactors. Int. J. Multiph. Flow 2018, 102, 119–129. [Google Scholar] [CrossRef]

- Sattar, M.A.; Garcia, M.M.; Banasiak, R.; Portela, L.M.; Babout, L. Electrical Resistance Tomography for Control Applications: Quantitative Study of the Gas-Liquid Distribution inside A Cyclone. Sensors 2020, 20, 6069. [Google Scholar] [CrossRef]

- Rao, G.; Sattar, M.A.; Wajman, R.; Jackowska-Strumiłło, L. Quantitative Evaluations with 2d Electrical Resistance Tomography in the Low-Conductivity Solutions Using 3d-Printed Phantoms and Sucrose Crystal Agglomerate Assessments. Sensors 2021, 21, 564. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Klosowski, G.; Kozlowski, E.; Tchórzewski, P. Comparison of selected machine learning algorithms for industrial electrical tomography. Sensors 2019, 19, 1521. [Google Scholar] [CrossRef] [Green Version]

- Da Mota, F.R.M.; Pagano, D.J.; Stasiak, M.E. Water Volume Fraction Estimation in Two-Phase Flow Based on Electrical Capacitance Tomometry. IEEE Sens. J. 2018, 18, 6822–6835. [Google Scholar] [CrossRef]

- Thorn, R.; Johansen, G.A.; Hjertaker, B.T. Three-phase flow measurement in the petroleum industry. Meas. Sci. Technol. 2013, 24, 012003. [Google Scholar] [CrossRef]

- Romanowski, A.; Grudzien, K.; Williams, R.A. Analysis and Interpretation of Hopper Flow Behaviour Using Electrical Capacitance Tomography. Part. Part. Syst. Charact. 2006, 23, 297–305. [Google Scholar] [CrossRef]

- Fiderek, P.; Kucharski, J.; Wajman, R. Fuzzy inference for two-phase gas-liquid fl ow type evaluation based on raw 3D ECT measurement data. Flow Meas. Instrum. 2017, 54, 88–96. [Google Scholar] [CrossRef]

- Dong, F.; Jiang, Z.X.; Qiao, X.T.; Xu, L.A. Application of electrical resistance tomography to two-phase pipe flow parameters measurement. Flow Meas. Instrum. 2003, 14, 183–192. [Google Scholar] [CrossRef]

- Banasiak, R.; Wajman, R.; Tomasz, J.; Fiderek, P.; Kapusta, P.; Sankowski, D. Two-Phase Flow Regime Three-Dimensonal Visualization Using Electrical Capacitance Tomography—Algorithms and Software. Inform. Control Meas. Econ. Environ. Prot. 2017, 7, 11–16. [Google Scholar] [CrossRef]

- Evans, G.; Miller, J.; Iglesias Pena, M.; MacAllister, A.; Winer, E. Evaluating the Microsoft HoloLens through an augmented reality assembly application. Degrad. Environ. Sens. Process. Disp. 2017, 10197, 101970V. [Google Scholar] [CrossRef] [Green Version]

- Rajesh Desai, P.; Nikhil Desai, P.; Deepak Ajmera, K.; Mehta, K. A Review Paper on Oculus Rift-A Virtual Reality Headset. Int. J. Eng. Trends Technol. 2014, 13, 175–179. [Google Scholar] [CrossRef] [Green Version]

- Moro, C.; Stromberga, Z.; Stirling, A. Virtualisation devices for student learning: Comparison between desktop-based (Oculus Rift) and mobile-based (Gear VR) virtual reality in medical and health science education. Australas. J. Educ. Technol. 2017, 33, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Müller, J.; Zagermann, J.; Wieland, J.; Pfeil, U.; Reiterer, H. A Qualitative Comparison between Augmented and Virtual Reality Collaboration with Handheld Devices. In Proceedings of the MuC’19: Proceedings of Mensch und Computer , New York, NY, USA, 2019 8–11 September 2019; pp. 399–410. [Google Scholar]

- Augmented Reality—Apple Developer. Available online: https://developer.apple.com/augmented-reality/ (accessed on 2 June 2021).

| Solution | Electrical Conductivity | Temperature |

|---|---|---|

| 100% Tap Water | 474 µS/cm | 16.5 °C |

| 20% Demin Water | 369 µS/cm | 16.5 °C |

| 40% Demin Water | 269 µS/cm | 17.1 °C |

| 60% Demin Water | 180 µS/cm | 18.1 °C |

| 80% Demin Water | 100 µS/cm | 18.7 °C |

| Phantom Diameter (mm) | Reference | 10 (mm) | 20 (mm) | 30 (mm) | 40 (mm) | 50 (mm) | 60 (mm) |

| Position | |||||||

| C | 9.75 | 21.32 | 32.88 | 43.80 | 53.67 | 62.75 | |

| P1 | 9.29 | 20.11 | 31.97 | 43.15 | 54.02 | 63.91 | |

| P2 | 8.36 | 18.81 | 30.46 | 42.43 | 54.73 | ||

| P3 | 6.27 | 16.43 | 28.97 | 42.24 | |||

| P4 | 5.90 | 16.40 | 28.86 | 42.35 | |||

| P5 | 7.95 | 18.14 | 29.78 | 42.84 | |||

| P6 | 7.53 | 19.84 | 30.78 | 41.83 | |||

| P7 | 6.33 | 15.75 | 28.97 | 41.81 | |||

| P8 | 5.25 | 17.25 | 30.51 | 43.57 | |||

| Average Absolute Difference | 2.60 | 2.10 | 1.11 | 2.66 | 4.14 | 3.33 | |

| RMSD | 2.76 | 2.15 | 1.87 | 4.03 |

| Radial Position (mm) | Reference | 20 (mm) | 30 (mm) | 40 (mm) | 50 (mm) | 60 (mm) | |||||

| Position | rr | ra | rr | ra | rr | ra | rr | ra | rr | ra | |

| C | 1.61 | 1.27 | 3.56 | 0.20 | 1.93 | 0.93 | 1.06 | 0.90 | 1.39 | 1.24 | |

| P1 | 5.03 | 4.56 | 6.03 | 2.58 | 5.52 | 4.61 | 3.99 | 1.13 | 2.68 | 0.77 | |

| P2 | 11.24 | 10.51 | 11.17 | 10.59 | 5.53 | 4.61 | 2.68 | 6.10 | |||

| P3 | 25.16 | 21.20 | 16.91 | 16.36 | 15.35 | 11.57 | |||||

| P4 | 28.63 | 21.52 | 24.50 | 16.67 | 9.44 | 4.82 | |||||

| P5 | 13.58 | 12.75 | 12.26 | 12.06 | 14.26 | 10.00 | |||||

| P6 | 8.15 | 1.71 | 12.83 | 9.10 | 14.26 | 9.50 | |||||

| P7 | 25.52 | 19.16 | 18.58 | 12.95 | 12.82 | 8.81 | |||||

| P8 | 15.15 | 15.08 | 12.59 | 8.21 | 6.11 | 0.50 | |||||

| Average Absolute Difference | 2.93 | 3.30 | 3.31 | 2.14 | 0.68 | ||||||

| RMSD | 4.28 | 4.08 | 3.75 | ||||||||

| Angular Position (°) | Reference | 20 (mm) | 30 (mm) | 40 (mm) | 50 (mm) | 60 (mm) | |||||

| Position | θr | θa | θr | θa | θr | θa | θr | θa | θr | θa | |

| C | 270 | 225 | 351.67 | 225 | 346.13 | 45 | 334.84 | 135 | 222.87 | 135 | |

| P1 | 119.05 | 135 | 54 | 135 | 79.57 | 112.5 | 40.96 | 0 | 134.3 | 135 | |

| P2 | 72.55 | 112.5 | 76.3 | 112.5 | 98.55 | 112.5 | 79.99 | 112.5 | |||

| P3 | 79.5 | 112.5 | 91.7 | 112.5 | 97.96 | 112.5 | |||||

| P4 | 71.3 | 67.5 | 69.9 | 67.5 | 93.62 | 112.5 | |||||

| P5 | 147.12 | 157.5 | 164.39 | 157.5 | 170.31 | 157.5 | |||||

| P6 | 235.06 | 225 | 249.33 | 225 | 265.69 | 247.5 | |||||

| P7 | 331.05 | 337.5 | 335.5 | 337.5 | 336.24 | 315 | |||||

| P8 | 156.77 | 157.5 | 199.42 | 180 | 207.14 | 225 | |||||

| Average Absolute Difference | 13.36 | 21.06 | 16.71 | 24.50 | 0.7 | ||||||

| RMSD | 20.02 | 19.89 | 19.72 | ||||||||

| Points | L1 (mm) | L2 (mm) | L3 (mm) |

|---|---|---|---|

| C | 3.68 | 2.83 | 0.87 |

| P1 | 6.18 | 3.84 | 3.65 |

| P2 | 6.78 | 5.28 | 0.95 |

| P3 | 6.03 | 2.06 | 4.65 |

| P4 | 7.87 | 9.82 | 8.33 |

| P5 | 1.4 | 2.54 | 2.31 |

| P6 | 5.89 | 3.73 | 4.47 |

| P7 | 5.66 | 4.74 | 2.90 |

| P8 | 5.56 | 4.95 | 4.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sattar, M.A.; Garcia, M.M.; Portela, L.M.; Babout, L. A Fast Electrical Resistivity-Based Algorithm to Measure and Visualize Two-Phase Swirling Flows. Sensors 2022, 22, 1834. https://doi.org/10.3390/s22051834

Sattar MA, Garcia MM, Portela LM, Babout L. A Fast Electrical Resistivity-Based Algorithm to Measure and Visualize Two-Phase Swirling Flows. Sensors. 2022; 22(5):1834. https://doi.org/10.3390/s22051834

Chicago/Turabian StyleSattar, Muhammad Awais, Matheus Martinez Garcia, Luis M. Portela, and Laurent Babout. 2022. "A Fast Electrical Resistivity-Based Algorithm to Measure and Visualize Two-Phase Swirling Flows" Sensors 22, no. 5: 1834. https://doi.org/10.3390/s22051834

APA StyleSattar, M. A., Garcia, M. M., Portela, L. M., & Babout, L. (2022). A Fast Electrical Resistivity-Based Algorithm to Measure and Visualize Two-Phase Swirling Flows. Sensors, 22(5), 1834. https://doi.org/10.3390/s22051834