Smartphone-Based Refractive Index Optosensing Platform Using a DVD Grating

Abstract

:1. Introduction

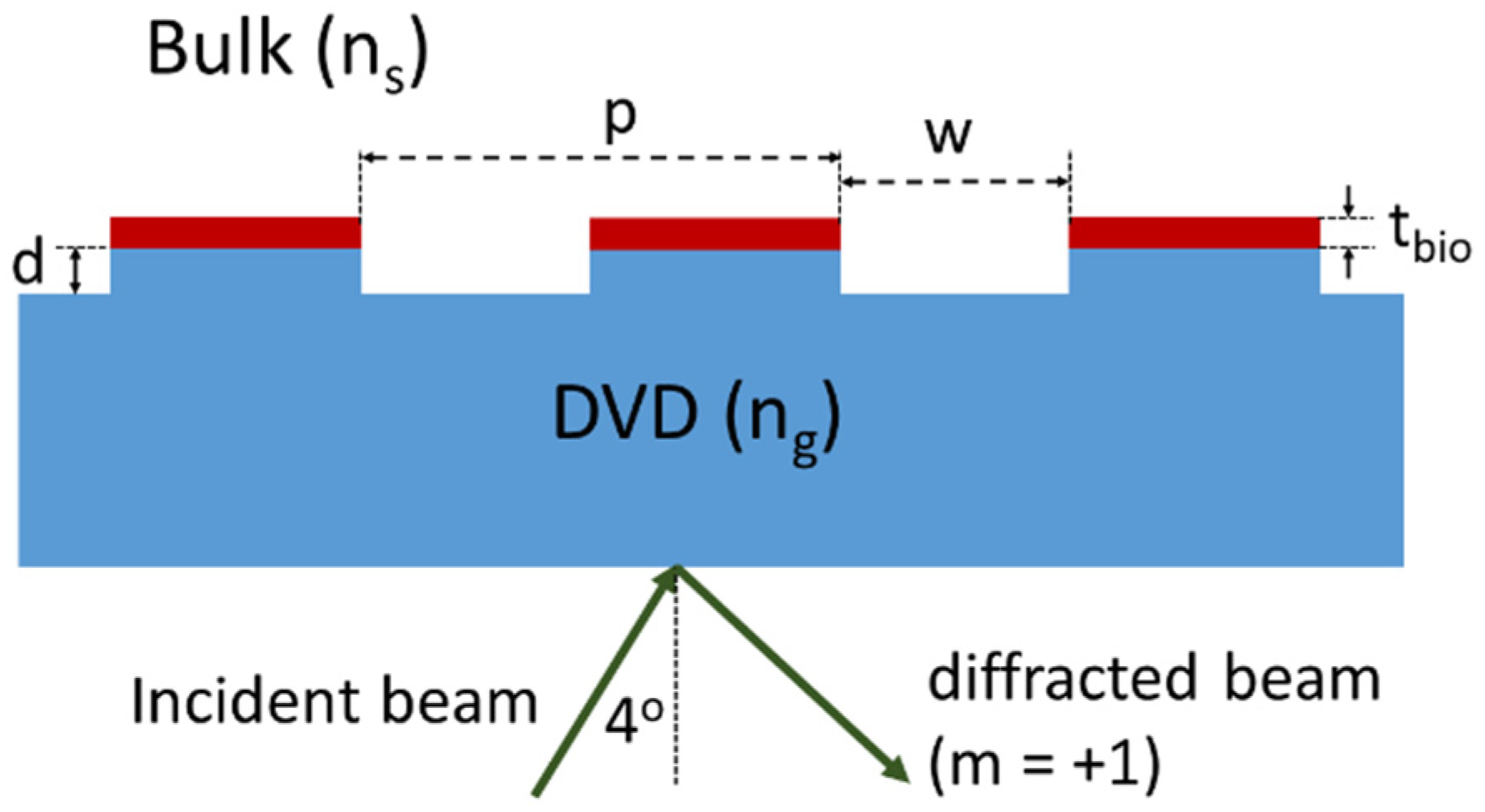

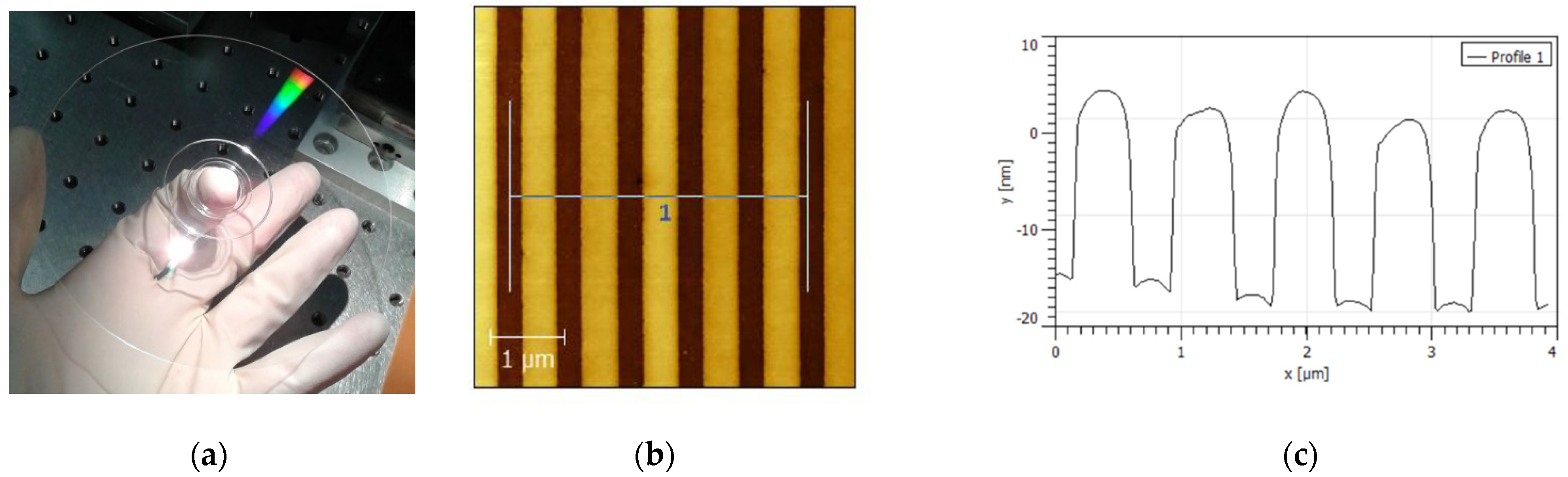

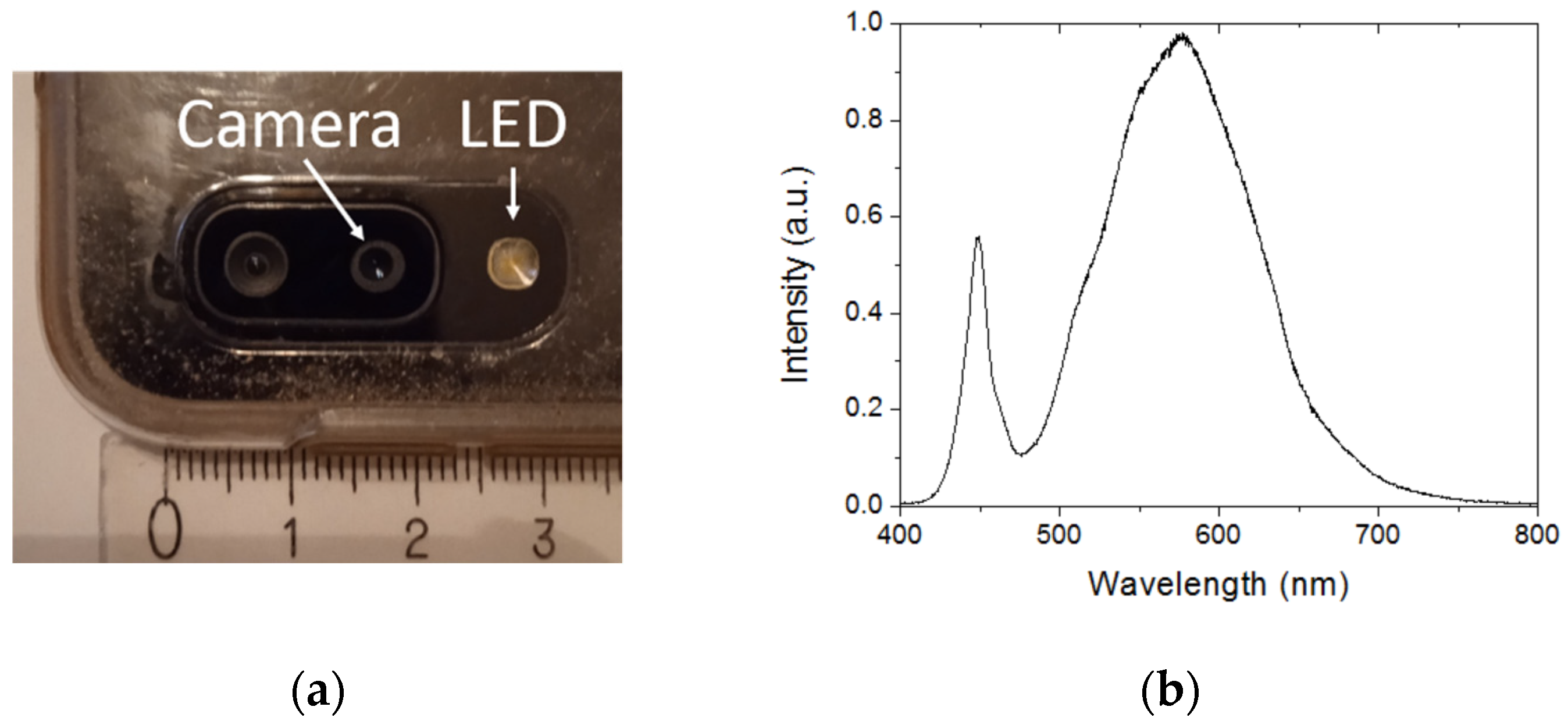

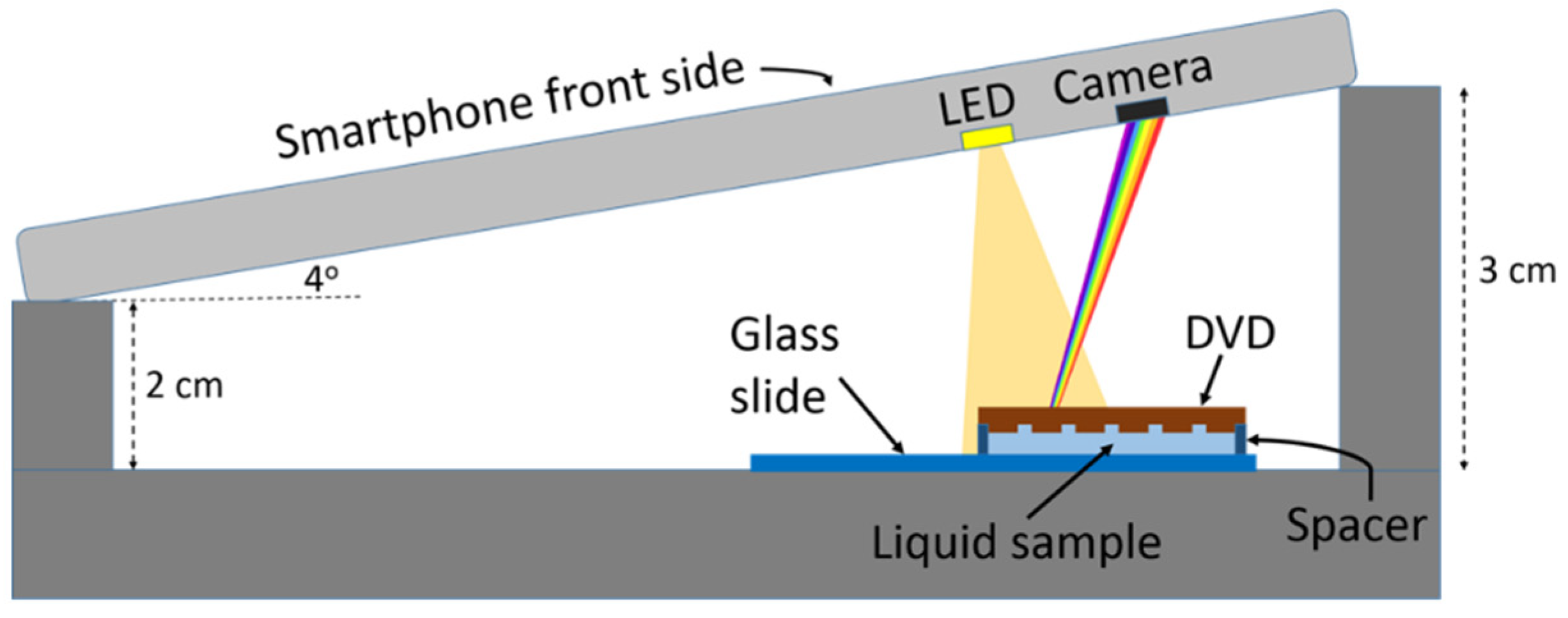

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Malardé, D.; Wu, Z.Y.; Grosso, P.; de Bougrenet de la Tocnaye, J.-L.; Le Menn, M. High resolution and compact refractometer for salinity measurements. Meas. Sci. Technol. 2008, 20, 015204. [Google Scholar] [CrossRef]

- Swatland, H.J. Refractometry of pork muscle and beef connective and adipose tissue. Meat Sci. 2002, 62, 225–228. [Google Scholar] [CrossRef]

- Jin, Y.L.; Chen, J.Y.; Xu, L.; Wang, P.N. Refractive index measurement for biomaterial samples by total internal reflection. Phys. Med. Biol. 2006, 51, N371–N379. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.; Li, Z.; Wang, C.; He, A. Experimental measurement of the refractive index of biological tissues by total internal reflection. Appl. Opt. 2005, 44, 1845–1849. [Google Scholar] [CrossRef]

- Jääskeläinen, A.J.; Peiponen, K.-E.; Räty, J.A. On reflectometric measurement of a refractive index of milk. J. Dairy Sci. 2001, 84, 38–43. [Google Scholar] [CrossRef]

- Calhoun, W.R.; Maeta, H.; Roy, S.; Bali, L.M.; Bali, S. Sensitive real-time measurement of refractive index and attenuation coefficient of milk and milkcream mixtures. J. Dairy Sci. 2010, 93, 3497–3504. [Google Scholar] [CrossRef]

- Anderson, R.E.; Lightman, A.J. Measurements of the refractive-index variations with temperature of a photomonomer. Appl. Opt. 1991, 30, 3792–3793. [Google Scholar] [CrossRef]

- Song, Q.W.; Ku, C.-Y.; Zhang, C.; Gross, R.B.; Birge, R.R.; Michalak, R. Modified critical angle method for measuring the refractive index of bio-optical materials and its application to bacteriorhodopsin. J. Opt. Soc. Am. B 1995, 12, 797–803. [Google Scholar] [CrossRef] [Green Version]

- Castrejón-Pita, J.R.; Morales, A.; Castrejón-García, R. Critical angle laser refractometer. Rev. Sci. Instrum. 2006, 77, 035101. [Google Scholar] [CrossRef]

- Zylstra, S. Assessments of Seven Refractometers for Evaluating Wildland Fire Retardants; TE52P13—WFCS Technical Services; USDA Forest Service Technology and Development Program: Missoula, MT, USA, 2005. [Google Scholar]

- Hand-Held Refractometer MASTER Series. ATAGO. Available online: https://www.atago.net/en/products-master-top.php (accessed on 16 November 2021).

- Chen, J.Y.; Xie, Z.H.; Li, W.N.; Lin, S.B.; Zhang, L.L.; Liu, C.X. Construction and investigation of a planar waveguide in photo-thermal-refractive glass by proton implantation. Optik 2020, 207, 164461. [Google Scholar] [CrossRef]

- Revathi, V.; Rajendran, V. Investigation about nonlinear optics and antibacterial activity of pyrrolidine-2-carboxylic acid cadmium chloride hydrate single crystal. Optik 2018, 154, 234–241. [Google Scholar] [CrossRef]

- Liu, C.X.; Shen, X.L.; Guo, H.T.; Li, W.N.; Wei, W. Proton-implanted optical waveguides fabricated in Er3+-doped phosphate glasses. Optik 2017, 131, 132–137. [Google Scholar] [CrossRef]

- Pocket Refractometer PAL Series. ATAGO. Available online: https://www.atago.net/en/products-pal-top.php (accessed on 16 November 2021).

- Hussain, I.; Bowden, A.K. Smartphone-based optical spectroscopic platforms for biomedical applications: A review. Biomed. Opt. Express 2021, 12, 1974–1998. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, X.; Chen, P.; Tran, N.T.; Zhang, J.; Chia, W.S.; Boujday, S.; Liedberg, B. Smartphone spectrometer for colorimetric biosensing. Analyst 2016, 141, 3233–3238. [Google Scholar] [CrossRef]

- Wang, L.-J.; Chang, Y.-C.; Ge, X.; Osmanson, A.T.; Du, D.; Lin, Y.; Li, L. Smartphone Optosensing Platform Using a DVD Grating to Detect Neurotoxins. ACS Sens. 2016, 1, 366–373. [Google Scholar] [CrossRef]

- Liu, Q.; Yuan, H.; Liu, Y.; Wang, J.; Jing, Z.; Peng, W. Real-time biodetection using a smartphone-based dual-color surface plasmon resonance sensor. J. Biomed. Opt. 2018, 23, 1–6. [Google Scholar] [CrossRef]

- Lertvachirapaiboon, C.; Baba, A.; Shinbo, K.; Kato, K. A smartphone-based surface plasmon resonance platform. Anal. Methods 2018, 10, 4732–4740. [Google Scholar] [CrossRef]

- Amloy, S.; Preechaburana, P. Smartphone-based critical angle refractometer for real-time monitoring of Brix value. IEEE Photon. Technol. Lett. 2019, 31, 307–310. [Google Scholar] [CrossRef]

- ImageJ User Guide. Available online: https://imagej.nih.gov/ij/docs/guide/146.html (accessed on 5 November 2021).

- Magnusson, R.; Gaylord, T.K. Diffraction efficiencies of thin phase gratings with arbitrary grating shape. J. Opt. Soc. Am. 1978, 68, 806–809. [Google Scholar] [CrossRef]

- Burggraaff, O.; Schmidt, N.; Zamorano, J.; Pauly, K.; Pascual, S.; Tapia, C.; Spyrakos, E.; Snik, F. Standardized spectral and radiometric calibration of consumer cameras. Opt. Express 2019, 27, 19075–19101. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Zhang, D.; Xu, Y.; Sun, S.; Sun, X. Refractive Index Sensor Based on Double Side-Polished U-Shaped Plastic Optical Fiber. Sensors 2020, 20, 5253. [Google Scholar] [CrossRef] [PubMed]

- Delbracio, M.; Kelly, D.; Brown, M.S.; Milanfar, P. Mobile Computational Photography: A Tour. Annu. Rev. Vis. Sci. 2021, 7, 571–604. [Google Scholar] [CrossRef] [PubMed]

- Calixto, S.; Piazza, V.; Gonzalez-Suarez, A.M.; Garcia-Cordero, J.L.; Bruce, N.C.; Rosete-Aguilar, M.; Garnica, G. Liquid refractive index measured through a refractometer based on diffraction gratings. Opt. Express 2019, 27, 34705–34720. [Google Scholar] [CrossRef] [PubMed]

- Goh, B.; Loo, R.W.; McAloney, R.A.; Goh, M.C. Diffraction-based assay for detecting multiple analytes. Anal. Bioanal. Chem. 2002, 374, 54–56. [Google Scholar] [CrossRef] [PubMed]

- Pak, B.J.; Vasquez-Camargo, F.; Kalinichenko, E.; Chiodini, P.L.; Nutman, T.B.; Tanowitz, H.B.; McAuliffe, I.; Wilkins, P.; Smith, P.T.; Ward, B.J.; et al. Development of a rapid serological assay for the diagnosis of strongyloidiasis using a novel diffraction-based biosensor technology. PLoS Negl. Trop. Dis. 2014, 7, e3002. [Google Scholar] [CrossRef]

- Dahlin, A.B. Plasmonic Sensors: An Integrated View of Refractometric Detection; IOS Press: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Lin, V.S.-Y.; Motesharei, K.; Dancil, K.-P.S.; Sailor, M.J.; Ghadiri, M.R. A porous silicon-based optical interferometric biosensor. Science 1997, 278, 840–843. [Google Scholar] [CrossRef] [PubMed]

- Weisser, M.; Tovar, G.; Mittler-Neher, S.; Knoll, W.; Brosinger, F.; Freimuth, H.; Lacher, M.; Ehrfeld, W. Specific bio-recognition reactions observed with an integrated Mach–Zehnder interferometer. Biosens. Bioelectron. 1999, 14, 405–411. [Google Scholar] [CrossRef]

- Angulo Barrios, C. An Analysis of a Compact Label-Free Guiding-Wave Biosensor Based on a Semiconductor-Clad Dielectric Strip Waveguide. Sensors 2020, 20, 3368. [Google Scholar] [CrossRef]

- Synopsis. DiffractMOD Product Overview. Available online: https://www.synopsys.com/photonic-solutions/rsoft-photonic-device-tools/passive-device-diffractmod.html (accessed on 15 November 2021).

- Špačková, B.; Scott Lynn, N., Jr.; Slabý, J.; Šípová, H.; Homola, J. A Route to Superior Performance of a Nanoplasmonic Biosensor: Consideration of both Photonic and Mass Transport Aspects. ACS Photonics 2018, 5, 1019–1025. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angulo Barrios, C. Smartphone-Based Refractive Index Optosensing Platform Using a DVD Grating. Sensors 2022, 22, 903. https://doi.org/10.3390/s22030903

Angulo Barrios C. Smartphone-Based Refractive Index Optosensing Platform Using a DVD Grating. Sensors. 2022; 22(3):903. https://doi.org/10.3390/s22030903

Chicago/Turabian StyleAngulo Barrios, Carlos. 2022. "Smartphone-Based Refractive Index Optosensing Platform Using a DVD Grating" Sensors 22, no. 3: 903. https://doi.org/10.3390/s22030903

APA StyleAngulo Barrios, C. (2022). Smartphone-Based Refractive Index Optosensing Platform Using a DVD Grating. Sensors, 22(3), 903. https://doi.org/10.3390/s22030903