Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings

Abstract

1. Introduction

2. Experimental Procedures for Tribocorrosion Tests

2.1. Tribocorrosion Tests under Different Configurations

2.2. Tribocorrosion Tests under Different Electrochemical Conditions

2.3. Nanoindentation

2.4. Dynamic Mechanical Analysis (DMA)

2.5. Micro/Nano-Scratch Test

2.6. Lateral Force Microscopy Using AFM

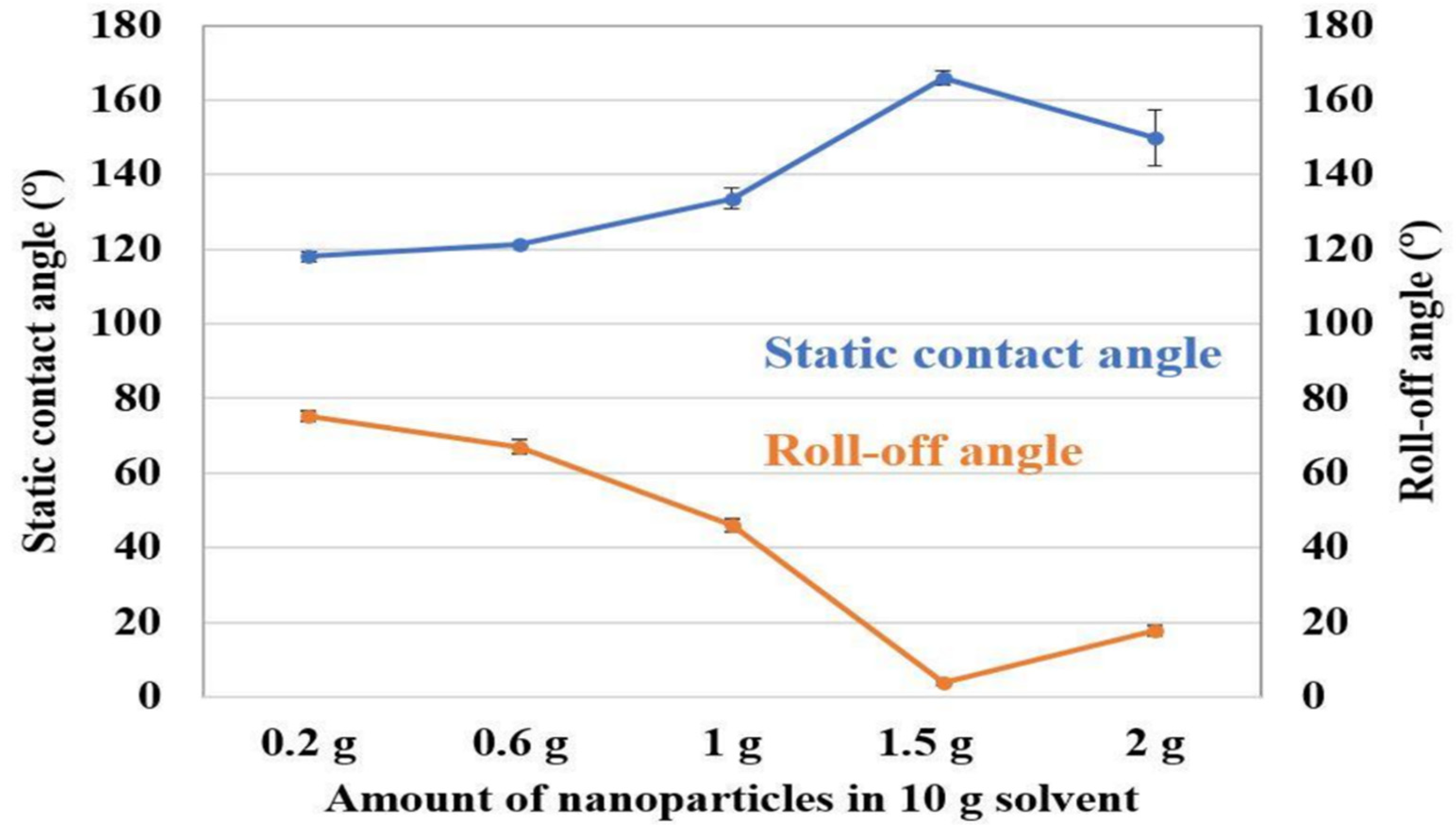

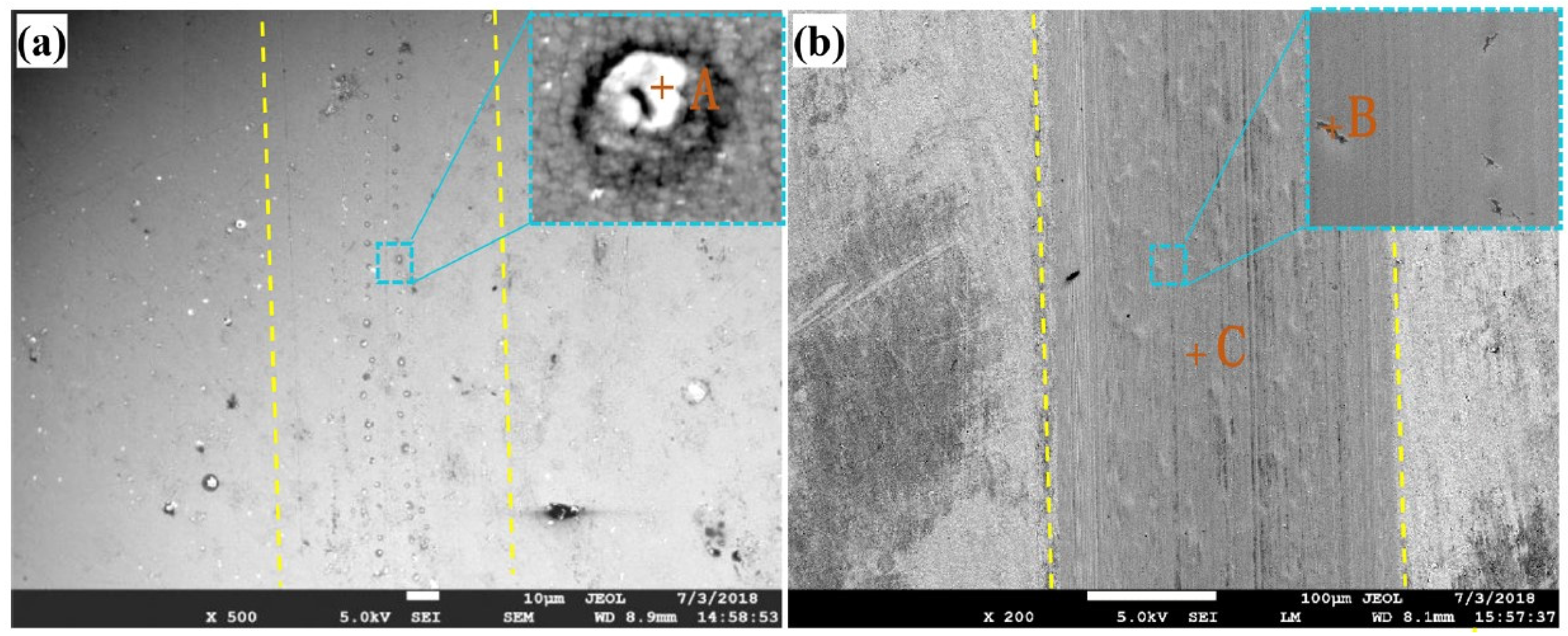

2.7. Surface Roughness, Morphology, and Wettability Tests

3. Tribocorrosion Behavior of Nanocomposite/Nanoparticle Coatings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Uhlig, H.H. Mechanism of Fretting Corrosion. J. Appl. Mech. 1954, 21, 401–407. [Google Scholar] [CrossRef]

- Taufiqurrakhman, M.; Neville, A.; Bryant, M.G. The Effect of Protein Structure and Concentration on Tribocorrosion and Film Formation on CoCrMo Alloys. J. Bio-Tribo-Corros. 2021, 7, 147. [Google Scholar] [CrossRef]

- Toh, W.Q.; Tan, X.; Bhowmik, A.; Liu, E.; Tor, S.B. Tribochemical Characterization and Tribocorrosive Behavior of CoCrMo Alloys: A Review. Materials 2017, 11, 30. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, A.I.; Espallargas, N. Tribocorrosion mechanisms in sliding contacts. In Tribocorrosion of Passive Metals and Coatings; Woodhead Publishing: Cambridge, UK, 2011; pp. 118–152. [Google Scholar]

- Stack, M.; Mathew, M.; Hodge, C. Micro-abrasion–corrosion interactions of Ni–Cr/WC based coatings: Approaches to construction of tribo-corrosion maps for the abrasion–corrosion synergism. Electrochim. Acta 2011, 56, 8249–8259. [Google Scholar] [CrossRef]

- Li, L.; Liu, L.-L.; Li, X.; Guo, P.; Ke, P.; Wang, A. Enhanced Tribocorrosion Performance of Cr/GLC Multilayered Films for Marine Protective Application. ACS Appl. Mater. Interfaces 2018, 10, 13187–13198. [Google Scholar] [CrossRef]

- López-Ortega, A.; Arana, J.L.; Bayón, R. Tribocorrosion of Passive Materials: A Review on Test Procedures and Standards. Int. J. Corros. 2018, 2018, 7345346. [Google Scholar] [CrossRef]

- Wood, R.J.; Herd, S.; Thakare, M.R. A critical review of the tribocorrosion of cemented and thermal sprayed tungsten carbide. Tribol. Int. 2018, 119, 491–509. [Google Scholar] [CrossRef]

- Barona-Osorio, G.M.; Teran, L.A.; Rodríguez, S.A.; Coronado, J.J. On the Tribocorrosion Behavior of Fe-Mn-Al-C Alloys in Ringer’s Solution. Metals 2022, 12, 1339. [Google Scholar] [CrossRef]

- Huang, P.-C.; Chou, C.-C.; Wang, H.-T.; Cheng, C.-H.; Hou, K.-H.; Ger, M.-D. Tribocorrosion study of electrodeposited Ni W alloy/BN(h) composited coatings for piston rings. Surf. Coat. Technol. 2022, 436, 128289. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Heino, V.; Isotahdon, E.; Kilpi, L.; Ronkainen, H. Tribocorrosion behaviour of thermally sprayed cermet coatings in paper machine environment. Tribol. Int. 2019, 142, 106006. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, L.; Luan, J.; Wan, Y.; Li, R. Effect of carbon nanotubes additive on tribocorrosion performance of micro-arc oxidized coatings on Ti6Al4V alloy. Surf. Interfaces 2022, 28, 101626. [Google Scholar] [CrossRef]

- Sousa, L.; Mendes, A.R.; Pinto, A.M.P.; Toptan, F.; Alves, A.C. Influence of Calcium Acetate Concentration in Electrolyte on Tribocorrosion Behaviour of MAO Treated Titanium. Metals 2021, 11, 1985. [Google Scholar] [CrossRef]

- Meghwal, A.; Anupam, A.; Luzin, V.; Schulz, C.; Hall, C.; Murty, B.; Kottada, R.S.; Berndt, C.C.; Ang, A.S.M. Multiscale mechanical performance and corrosion behaviour of plasma sprayed AlCoCrFeNi high-entropy alloy coatings. J. Alloys Compd. 2021, 854, 157140. [Google Scholar] [CrossRef]

- Meghwal, A.; Singh, S.; Anupam, A.; King, H.J.; Schulz, C.; Hall, C.; Munroe, P.; Berndt, C.C.; Ang, A.S.M. Nano- and micro-mechanical properties and corrosion performance of a HVOF sprayed AlCoCrFeNi high-entropy alloy coating. J. Alloys Compd. 2022, 912, 165000. [Google Scholar] [CrossRef]

- Ma, X.; Ma, J.; Bian, X.; Tong, X.; Han, D.; Jia, Y.; Wu, S.; Zhang, N.; Geng, C.; Li, P.; et al. The role of nano-scale elastic heterogeneity in mechanical and tribological behaviors of a Cu–Zr based metallic glass thin film. Intermetallics 2021, 133, 107159. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Han, R.; Ren, J.; Li, L.; Han, N.; Xing, F.; Zhu, J. A review on the mechanical properties for thin film and block structure characterised by using nanoscratch test. Nanotechnol. Rev. 2019, 8, 628–644. [Google Scholar] [CrossRef]

- Beake, B.D.; Harris, A.J.; Liskiewicz, T.W. Review of recent progress in nanoscratch testing. Tribol. Mater. Surfaces Interfaces 2013, 7, 87–96. [Google Scholar] [CrossRef]

- Hassan, M.; Bushroa, A.; Mahmoodian, R. Identification of critical load for scratch adhesion strength of nitride-based thin films using wavelet analysis and a proposed analytical model. Surf. Coat. Technol. 2015, 277, 216–221. [Google Scholar] [CrossRef]

- Zekonyte, J.; Polcar, T. Friction Force Microscopy Analysis of Self-Adaptive W–S–C Coatings: Nanoscale Friction and Wear. ACS Appl. Mater. Interfaces 2015, 7, 21056–21064. [Google Scholar] [CrossRef]

- Pandey, M.K.; Kar, A.K. Effect of annealing temperature on the magnetic domain structure and surface mechanical properties of Ni-C composite thin films: Magnetic and lateral force microscopy, and force-distance spectroscopy. Mater. Lett. 2021, 301, 130295. [Google Scholar] [CrossRef]

- Ponthiaux, P.; Wenger, F.; Drees, D.; Celis, J. Electrochemical techniques for studying tribocorrosion processes. Wear 2004, 256, 459–468. [Google Scholar] [CrossRef]

- Shittu, J.; Sadeghilaridjani, M.; Pole, M.; Muskeri, S.; Ren, J.; Liu, Y.; Tahoun, I.; Arora, H.; Chen, W.; Dahotre, N.; et al. Tribo-corrosion response of additively manufactured high-entropy alloy. npj Mater. Degrad. 2021, 5, 31. [Google Scholar] [CrossRef]

- Da, B.; Yaxuan, L.; Vasu, A.T.; Yongxin, G.; Hao, T.; Yongwu, Z.; Yongguang, W. Improving tribocorrosion performance of chemically bonded ceramic phosphate coating reinforced by GO-ZnO. Ceram. Int. 2021, 47, 15722–15731. [Google Scholar] [CrossRef]

- Gonçalves, V.R.M.; Çaha, I.; Alves, A.C.; Toptan, F.; Rocha, L.A. Improved Tribocorrosion Behavior Obtained by In-Situ Precipitation of Ti2C in Ti-Nb Alloy. Metals 2022, 12, 908. [Google Scholar] [CrossRef]

- Gao, Z.; Ji, G.; Shi, Z.; Wang, X. The tribocorrosion behaviour of YSZ coating deposited on stainless steel substrate in 3.5 wt% NaCl solution. Ceram. Int. 2021, 47, 21051–21060. [Google Scholar] [CrossRef]

- Zhu, X.; Dang, B.; Li, F.; Wei, D.; Zhang, P.; Li, S. Tribocorrosion behavior of Nb coating deposited by double-glow plasma alloying. Mater. Res. Express 2021, 8, 016411. [Google Scholar] [CrossRef]

- Hebbar, R.S.; Isloor, A.M.; Ismail, A.F. Contact Angle Measurements. In Membrane Characterization, 1st ed.; Hilal, N., Ismail, A., Matsuura, T., Oatley-Radcliffe, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 219–255. [Google Scholar] [CrossRef]

- Visentin, F.; Galenda, A.; Fabrizio, M.; Battiston, S.; Brianese, N.; Gerbasi, R.; Zin, V.; EL Habra, N. Assessment of synergistic effects of LP-MOCVD TiO2 and Ti surface finish for dental implant purposes. Appl. Surf. Sci. 2019, 490, 568–579. [Google Scholar] [CrossRef]

- Acar, M.; Kovacı, H.; Çelik, A. Investigation of corrosion and tribocorrosion behavior of boron doped and graphene oxide doped TiO2 nanotubes produced on Cp-Ti. Mater. Today Commun. 2022, 32, 104182. [Google Scholar] [CrossRef]

- Çaha, I.; Alves, A.C.; Chirico, C.; Pinto, A.M.; Tsipas, S.; Gordo, E.; Toptan, F. Improved tribocorrosion behavior on bio-functionalized β-type titanium alloy by the pillar effect given by TiN reinforcements. Surf. Coat. Technol. 2021, 415, 127122. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zhou, S.; Wang, Y.; Wang, C.; Wang, Y.; Sui, Y.; Lan, J.; Xue, Q. Improvement in the tribocorrosion performance of CrCN coating by multilayered design for marine protective application. Appl. Surf. Sci. 2020, 528, 147061. [Google Scholar] [CrossRef]

- Sui, X.; Xu, R.; Liu, J.; Zhang, S.; Wu, Y.; Yang, J.; Hao, J. Tailoring the Tribocorrosion and Antifouling Performance of (Cr, Cu)-GLC Coatings for Marine Application. ACS Appl. Mater. Interfaces 2018, 10, 36531–36539. [Google Scholar] [CrossRef] [PubMed]

- Alkan, S.; Gök, M.S. Effect of sliding wear and electrochemical potential on tribocorrosion behaviour of AISI 316 stainless steel in seawater. Eng. Sci. Technol. Int. J. 2021, 24, 524–532. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, E.; Du, S.; Zhang, J.; Wang, L.; Du, H.; Cai, H. Tribocorrosion Behavior of Typical Austenitic, Martensitic, and Ferritic Stainless Steels in 3.5% NaCl Solution. J. Mater. Eng. Perform. 2021, 30, 6284–6296. [Google Scholar] [CrossRef]

- Buciumeanu, M.; Bagheri, A.; Silva, F.S.; Henriques, B.; Lasagni, A.F.; Shamsaei, N. Tribocorrosion Behavior of NiTi Biomedical Alloy Processed by an Additive Manufacturing Laser Beam Directed Energy Deposition Technique. Materials 2022, 15, 691. [Google Scholar] [CrossRef] [PubMed]

- Grabarczyk, J.; Gaj, J.; Pazik, B.; Kaczorowski, W.; Januszewicz, B. Tribocorrosion behavior of Ti6Al4V alloy after thermo-chemical treatment and DLC deposition for biomedical applications. Tribol. Int. 2021, 153, 106560. [Google Scholar] [CrossRef]

- Ma, F.; Li, J.; Zeng, Z.; Gao, Y. Tribocorrosion behavior in artificial seawater and anti-microbiologically influenced corrosion properties of TiSiN-Cu coating on F690 steel. J. Mater. Sci. Technol. 2019, 35, 448–459. [Google Scholar] [CrossRef]

- Wang, K.; Cai, W. Modeling the effects of individual layer thickness and orientation on the tribocorrosion behavior of Al/Cu nanostructured metallic multilayers. Wear 2021, 477, 203849. [Google Scholar] [CrossRef]

- Chen, S.; Cai, Z.; Lu, Z.; Pu, J.; Chen, R.; Zheng, S.; Mao, C.; Chen, S. Tribo-corrosion behavior of VAlTiCrCu high-entropy alloy film. Mater. Charact. 2019, 157, 109887. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Nair, R.B.; Arora, H.S.; Ayyagari, A.; Mukherjee, S.; Grewal, H.S. High Entropy Alloys: Prospective Materials for Tribo-Corrosion Applications. Adv. Eng. Mater. 2018, 20, 1700946. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.W.; Ranganathan, S.; Bhattacharjee, P.P. High-Entropy Alloys; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Lu, Z.; Mao, Y.; Ren, S.; Pu, J.; Fu, Z.; Fan, X.; Gao, S.; Fan, J. A novel design of VAlTiCrCu/WC alternate multilayer structure to enhance the mechanical and tribo-corrosion properties of the high-entropy alloy coating. Mater. Charact. 2021, 176, 111115. [Google Scholar] [CrossRef]

- Hua, N.; Wang, W.; Wang, Q.; Ye, Y.; Lin, S.; Zhang, L.; Guo, Q.; Brechtl, J.; Liaw, P.K. Mechanical, corrosion, and wear properties of biomedical Ti–Zr–Nb–Ta–Mo high entropy alloys. J. Alloys Compd. 2021, 861, 157997. [Google Scholar] [CrossRef]

- Muangtong, P.; Namus, R.M.; Goodall, R. Improved Tribocorrosion Resistance by Addition of Sn to CrFeCoNi High Entropy Alloy. Metals 2020, 11, 13. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.-Z. Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding. Mater. Des. 2011, 32, 1910–1915. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Zhao, Y.-L.; Hsu, Y.-C.; Li, C.-L.; Kai, J.-J.; Liu, C.-T.; Hsueh, C.-H. High hardness and fatigue resistance of CoCrFeMnNi high entropy alloy films with ultrahigh-density nanotwins. Int. J. Plast. 2020, 131, 102726. [Google Scholar] [CrossRef]

- Huang, P.-K.; Yeh, J.-W.; Shun, T.-T.; Chen, S.-K. Multi-Principal-Element Alloys with Improved Oxidation and Wear Resistance for Thermal Spray Coating. Adv. Eng. Mater. 2004, 6, 74–78. [Google Scholar] [CrossRef]

- Yoosefan, F.; Ashrafi, A.; Vaghefi, S.M.M. Characterization of Co–Cr–Fe–Mn–Ni High-Entropy Alloy Thin Films Synthesized by Pulse Electrodeposition: Part 2: Effect of Pulse Electrodeposition Parameters on the Wettability and Corrosion Resistance. Met. Mater. Int. 2020, 27, 106–117. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of High Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Liaw, P.K. Microstructures and properties of high-entropy alloy films and coatings: A review. Mater. Res. Lett. 2018, 6, 199–229. [Google Scholar] [CrossRef]

- Sikdar, S.; Menezes, P.; Maccione, R.; Jacob, T.; Menezes, P. Plasma Electrolytic Oxidation (PEO) Process—Processing, Properties, and Applications. Nanomaterials 2021, 11, 1375. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, Z.; He, W.; Pang, Z.; Ning, Z.; Chen, R.; Zheng, C.; Yao, C.; Guo, L. Improved Tribocorrosion Properties of Ti6al4v Alloy by Anodic Plasma Electrolytic Oxidation. Available online: https://papers.ssrn.com/abstract=4213484 (accessed on 8 October 2022).

- Costa, N.A.; Rossi, A.L.; Alves, A.C.; Pinto, A.M.P.; Toptan, F.; Rocha, L.A. Growth Mechanisms and Tribocorrosion Behavior of Bio-Functionalized ZrO2 Nanoparticles-Containing MAO Coatings Formed on Ti-40Nb Alloy. J. Bio-Tribo-Corros. 2021, 7, 53. [Google Scholar] [CrossRef]

- Fallqvist, M.; Olsson, M. The influence of surface defects on the mechanical and tribological properties of VN-based arc-evaporated coatings. Wear 2013, 297, 1111–1119. [Google Scholar] [CrossRef]

- Ge, F.; Zhu, P.; Meng, F.; Huang, F. Enhancing the wear resistance of magnetron sputtered VN coating by Si addition. Wear 2016, 354–355, 32–40. [Google Scholar] [CrossRef]

- Caicedo, J.; Zambrano, G.; Aperador, W.; Escobar-Alarcon, L.; Camps, E. Mechanical and electrochemical characterization of vanadium nitride (VN) thin films. Appl. Surf. Sci. 2011, 258, 312–320. [Google Scholar] [CrossRef]

- Marchin, N.; Ashrafizadeh, F. Effect of carbon addition on tribological performance of TiSiN coatings produced by cathodic arc physical vapour deposition. Surf. Coat. Technol. 2021, 407, 126781. [Google Scholar] [CrossRef]

- Çomaklı, O. Improved structural, mechanical, corrosion and tribocorrosion properties of Ti45Nb alloys by TiN, TiAlN monolayers, and TiAlN/TiN multilayer ceramic films. Ceram. Int. 2021, 47, 4149–4156. [Google Scholar] [CrossRef]

- Viswanathan, S.; Loganathan, M.; Bera, P.; Shanthiswaroop, S.; Muniprakash, M.; Barshilia, H.C.; Anandan, C. Corrosion and wear resistance properties of multilayered diamond-like carbon nanocomposite coating. Surf. Interface Anal. 2018, 50, 265–276. [Google Scholar] [CrossRef]

- Tyagi, A.; Walia, R.; Murtaza, Q.; Pandey, S.M.; Tyagi, P.K.; Bajaj, B. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Met. Hard Mater. 2019, 78, 107–122. [Google Scholar] [CrossRef]

- Peng, Y.; Peng, J.; Wang, Z.; Xiao, Y.; Qiu, X. Diamond-like Carbon Coatings in the Biomedical Field: Properties, Applications and Future Development. Coatings 2022, 12, 1088. [Google Scholar] [CrossRef]

- Kang, Y.; Ren, X.; Li, Y.; Yu, Z. Ni-Coated Diamond-like Carbon-Modified TiO2 Nanotube Composite Electrode for Electrocatalytic Glucose Oxidation. Molecules 2022, 27, 5815. [Google Scholar] [CrossRef]

- Nathanael, A.J.; Oh, T.H. Biopolymer Coatings for Biomedical Applications. Polymers 2020, 12, 3061. [Google Scholar] [CrossRef] [PubMed]

- Taşdemir, M.; Senaslan, F.; Çelik, A. Investigation of corrosion and thermal behavior of PU-PDMS-coated AISI 316L. e-Polymers 2021, 21, 355–365. [Google Scholar] [CrossRef]

- Taşdemir, M. Wear, Corrosion and Tribocorrosion Behavior of Polyurethane and Polyvinylpyrrolidone Blends as Coating for Corrosion Protection of AISI 316L Stainless Steel. Int. J. Electrochem. Sci. 2021, 16, 210510. [Google Scholar] [CrossRef]

- Wang, W.; Tamakloe, S.; Deng, Z.; Li, L.; Cai, W.; Lu, K. Effects of processing temperature on the corrosion and tribocorrosion resistance of perhydropolysilazane-derived coatings on AISI 304 steel. Surf. Coat. Technol. 2022, 439, 128463. [Google Scholar] [CrossRef]

- Zhao, Z.; Guo, L.; Feng, L.; Lu, H.; Xu, Y.; Wang, J.; Xiang, B.; Zou, X. Polydopamine functionalized graphene oxide nanocomposites reinforced the corrosion protection and adhesion properties of waterborne polyurethane coatings. Eur. Polym. J. 2019, 120, 109249. [Google Scholar] [CrossRef]

- Islam, M.; Azhar, M.R.; Fredj, N.; Burleigh, T.D.; Oloyede, O.R.; Almajid, A.A.; Shah, S.I. Influence of SiO2 nanoparticles on hardness and corrosion resistance of electroless Ni–P coatings. Surf. Coat. Technol. 2015, 261, 141–148. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, L.; Li, C. Highly transparent and scratch resistant polysiloxane coatings containing silica nanoparticles. J. Colloid Interface Sci. 2020, 559, 273–281. [Google Scholar] [CrossRef]

- Çaha, I.; Alves, A.C.; Chirico, C.; Pinto, A.M.; Tsipas, S.; Gordo, E.; Toptan, F. A promising method to develop TiO2-based nanotubular surfaces on Ti-40Nb alloy with enhanced adhesion and improved tribocorrosion resistance. Appl. Surf. Sci. 2021, 542, 148658. [Google Scholar] [CrossRef]

- Cheng, J.; Ge, Y.; Wang, B.; Zhang, L.; Hu, X.; Hong, S.; Liang, X.; Zhang, X. Microstructure and Tribocorrosion Behavior of Al2O3/Al Composite Coatings: Role of Al2O3 Addition. J. Therm. Spray Technol. 2020, 29, 1741–1751. [Google Scholar] [CrossRef]

- Yan, H.; Cai, M.; Song, S.; Huang, Y.; Fan, X.; Zhu, M. Expounding the interaction of ultraviolet irradiation and tribocorrosion on soap fiber enhanced epoxy coating. Prog. Org. Coat. 2022, 163, 106604. [Google Scholar] [CrossRef]

- Xu, L.; Fu, X.; Su, H.; Sun, H.; Li, R.; Wan, Y. Corrosion and tribocorrosion protection of AZ31B Mg alloy by a hydrothermally treated PEO/chitosan composite coating. Prog. Org. Coat. 2022, 170, 107002. [Google Scholar] [CrossRef]

- da Costa Aichholz, S.A.; Meruvia, M.S.; Júnior, P.C.S.; Torres, R.D. Tribocorrosion behavior of boronized AISI 4140 steel. Surf. Coat. Technol. 2018, 352, 265–272. [Google Scholar] [CrossRef]

- Kaleli, H. Tribology in Industry New Universal Tribometer as Pin or Ball-on-Disc and Reciprocating Pin-on-Plate Types. Tribol. Ind. 2016, 38, 235–240. [Google Scholar]

- Gnanavelbabu, A.; Amul, X.J.; Surendran, K.T.S. Investigation on the tribocorrosion and electrochemical corrosion behaviour of AA2014/Al2O3 nanocomposites fabricated through ultrasonication coupled stir-squeeze casting method. J. Appl. Electrochem. 2022, 52, 765–791. [Google Scholar] [CrossRef]

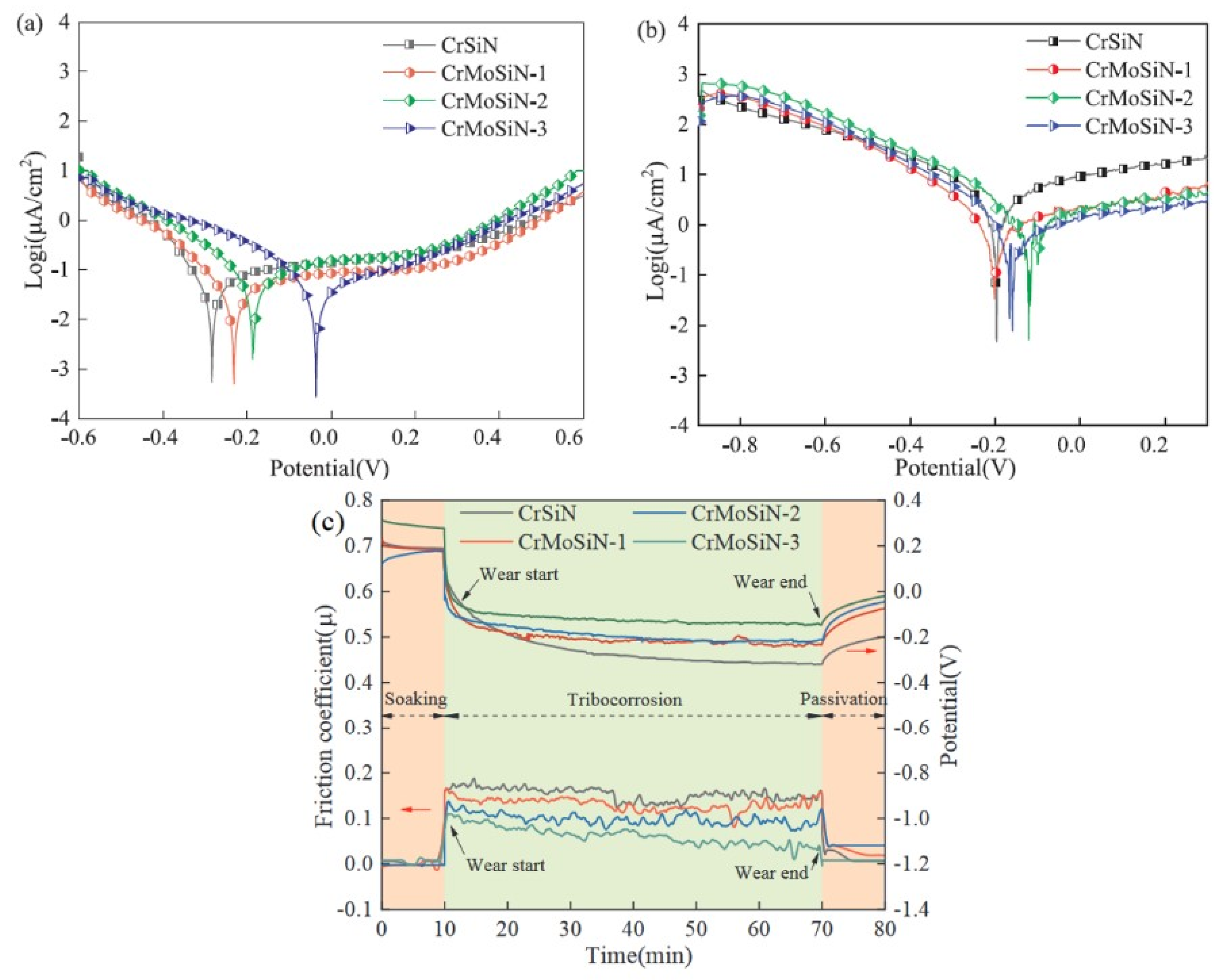

- Fu, Y.; Zhou, F.; Zhang, M.; Wang, Q.; Zhou, Z. Structural, mechanical and tribocorrosion performances of CrMoSiN coatings with various Mo contents in artificial seawater. Appl. Surf. Sci. 2020, 525, 146629. [Google Scholar] [CrossRef]

- Paul, G.; Hirani, H.; Kuila, T.; Murmu, N.C. Nanolubricants dispersed with graphene and its derivatives: An assessment and review of the tribological performance. Nanoscale 2019, 11, 3458–3483. [Google Scholar] [CrossRef]

- Ling, Z.; Fu, Z.; Yang, X.; Lu, T.; Chen, W. A new Fe-Cr-Mo-B-Al steel with outstanding tribo-corrosion resistance in liquid aluminium. Corros. Sci. 2022, 206, 110484. [Google Scholar] [CrossRef]

- Chun-Ying, L.; Wei-Ti, M.; Ming-Der, G.; Hung-Bin, L. A study on the corrosion and wear behavior of nanocrystalline Ni Mo electrodeposited coatings. Surf. Coat. Technol. 2019, 366, 286–295. [Google Scholar] [CrossRef]

- Bin Lee, H.; Wu, M.Y. A Study on the Corrosion and Wear Behavior of Electrodeposited Ni-W-P Coating. Met. Mater. Trans. A 2017, 48, 4667–4680. [Google Scholar] [CrossRef]

- Jellesen, M.; Hansen, M.; Hilbert, L.; Møller, P. A block-on-ring tribocorrosion setup for combined electrochemical and friction testing. Tribotest 2007, 13, 115–127. [Google Scholar] [CrossRef]

- He, A.; Huang, S.; Yun, J.-H.; Jiang, Z.; Stokes, J.; Jiao, S.; Wang, L.; Huang, H. The pH-dependent structural and tribological behaviour of aqueous graphene oxide suspensions. Tribol. Int. 2017, 116, 460–469. [Google Scholar] [CrossRef]

- Schlüter, B.; Mülhaupt, R.; Kailer, A. Synthesis and Tribological Characterization of Stable Dispersions of Thermally Reduced Graphite Oxide. Tribol. Lett. 2013, 53, 353–363. [Google Scholar] [CrossRef]

- Cui, W.; Cheng, J.; Liu, Z. Bio-tribocorrosion behavior of a nanocrystalline TiZrN coating on biomedical titanium alloy. Surf. Coat. Technol. 2019, 369, 79–86. [Google Scholar] [CrossRef]

- Fellah, M.; Hezil, N.; Hussein, M.; Samad, M.A.; Touhami, M.Z.; Montagne, A.; Iost, A.; Obrosov, A.; Weiss, S. Preliminary investigation on the bio-tribocorrosion behavior of porous nanostructured β-type titanium based biomedical alloys. Mater. Lett. 2019, 257, 126755. [Google Scholar] [CrossRef]

- Mischler, S. Triboelectrochemical techniques and interpretation methods in tribocorrosion: A comparative evaluation. Tribol. Int. 2008, 41, 573–583. [Google Scholar] [CrossRef]

- Shivaram, M.J.; Arya, S.B.; Nayak, J.; Panigrahi, B.B. Tribocorrosion Behaviour of Biomedical Porous Ti–20Nb–5Ag Alloy in Simulated Body Fluid. J. Bio-Tribo-Corros. 2021, 7, 59. [Google Scholar] [CrossRef]

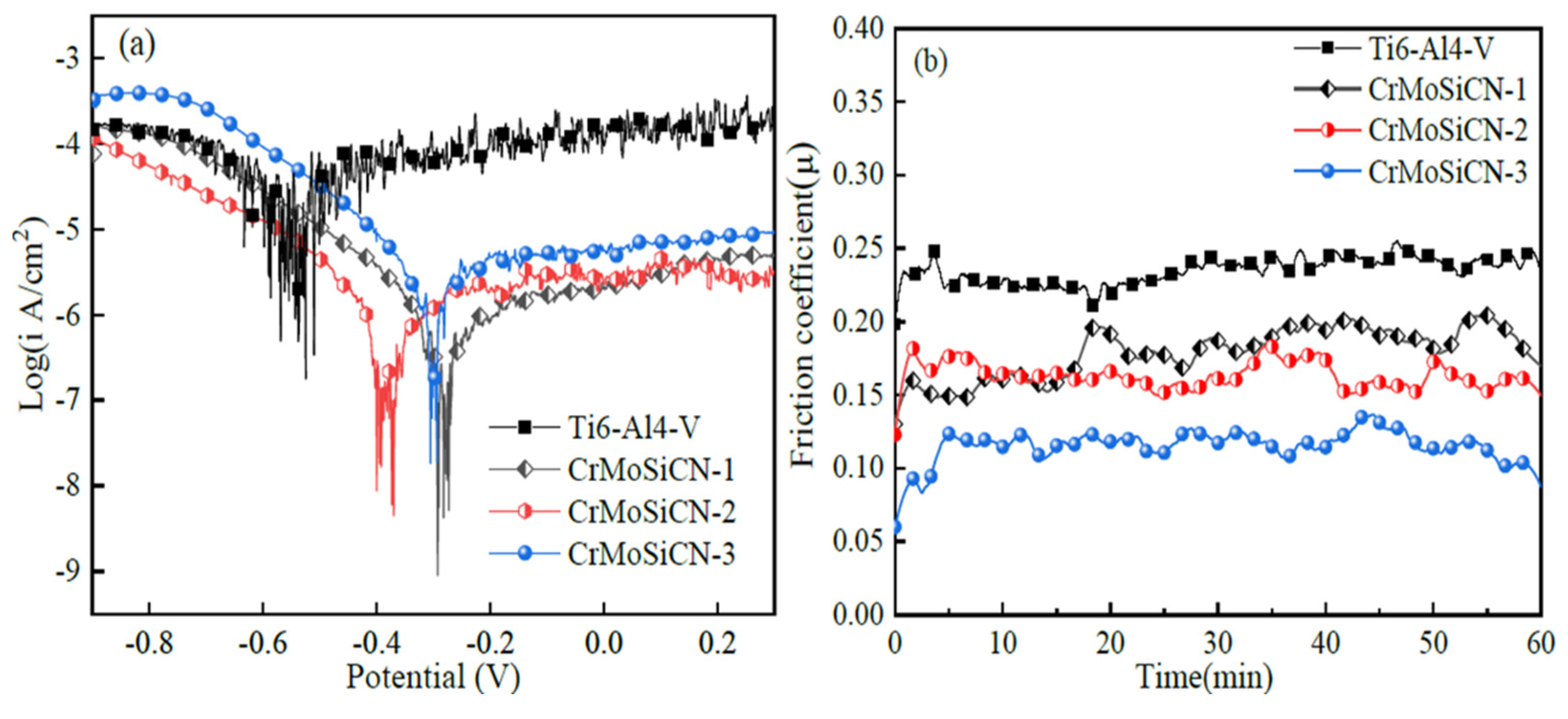

- Fu, Y.; Zhou, F.; Wang, Q.; Zhang, M.; Zhou, Z. Electrochemical and tribocorrosion performances of CrMoSiCN coating on Ti-6Al-4V titanium alloy in artificial seawater. Corros. Sci. 2020, 165, 108385. [Google Scholar] [CrossRef]

- Bayón, R.; Igartua, A.; González, J.; de Gopegui, U.R. Influence of the carbon content on the corrosion and tribocorrosion performance of Ti-DLC coatings for biomedical alloys. Tribol. Int. 2015, 88, 115–125. [Google Scholar] [CrossRef]

- Verma, G.; Dhoke, S.; Khanna, A. Polyester based-siloxane modified waterborne anticorrosive hydrophobic coating on copper. Surf. Coat. Technol. 2012, 212, 101–108. [Google Scholar] [CrossRef]

- Dey, S.; Chatterjee, S.; Singh, B.P.; Bhattacharjee, S.; Rout, T.K.; Sengupta, D.K.; Besra, L. Development of superhydrophobic corrosion resistance coating on mild steel by electrophoretic deposition. Surf. Coat. Technol. 2018, 341, 24–30. [Google Scholar] [CrossRef]

- Xiao, H.; Arsecularatne, J.A.; Zheng, J.; Hoffman, M.J.; Zhou, Z. Effect of HAP crystallite orientation upon corrosion and tribocorrosion behavior of bovine and human dental enamel. Corros. Sci. 2021, 190, 109670. [Google Scholar] [CrossRef]

- Karakaş, M.S.; Günen, A.; Çarboğa, C.; Karaca, Y.; Demir, M.; Altınay, Y.; Erdoğan, A. Microstructure, some mechanical properties and tribocorrosion wear behavior of boronized Al0.07Co1.26Cr1.80Fe1.42Mn1.35Ni1.10 high entropy alloy. J. Alloys Compd. 2021, 886, 161222. [Google Scholar] [CrossRef]

- Yan, C.; Zeng, Q.; He, W.; Zhu, J. Enhanced surface hardness and tribocorrosion performance of 60NiTi by boron ion implantation and post-annealing. Tribol. Int. 2021, 155, 106816. [Google Scholar] [CrossRef]

- Li, H.; Zhang, C.; Liu, C.; Huang, M. Improvement in corrosion resistance of CrN coatings. Surf. Coat. Technol. 2019, 365, 158–163. [Google Scholar] [CrossRef]

- Jia, Y.; Ba, Z.; Chen, X.; Zhou, B.; Zhou, W.; Liu, H.; Dong, Q. Controlled surface mechanical property and corrosion resistance of ZK60 magnesium alloy treated by zirconium ion implantation. Surf. Topogr. Metrol. Prop. 2020, 8, 025015. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, W. Coupling hybrid of HBN nanosheets and TiO2 to enhance the mechanical and tribological properties of composite coatings. Prog. Org. Coat. 2020, 148, 105881. [Google Scholar] [CrossRef]

- Di Maro, M.; Duraccio, D.; Malucelli, G.; Faga, M. High density polyethylene composites containing alumina-toughened zirconia particles: Mechanical and tribological behavior. Compos. Part B Eng. 2021, 217, 108892. [Google Scholar] [CrossRef]

- Rath, A.; Mathesan, S.; Ghosh, P. Nanomechanical characterization and molecular mechanism study of nanoparticle reinforced and cross-linked chitosan biopolymer. J. Mech. Behav. Biomed. Mater. 2016, 55, 42–52. [Google Scholar] [CrossRef]

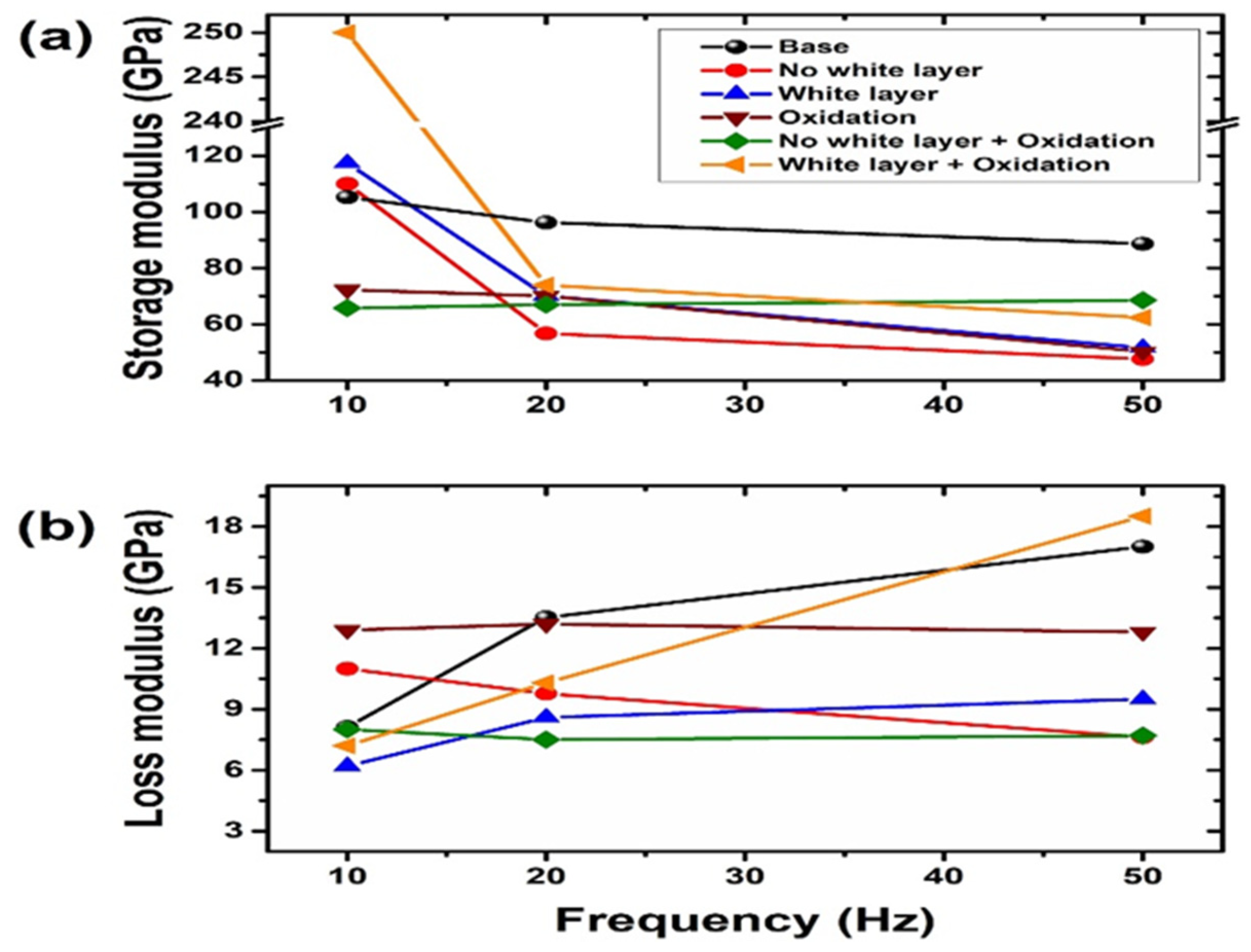

- Díaz-Guillén, J.; Naeem, M.; Hdz-García, H.; Acevedo-Davila, J.; Díaz-Guillén, M.; Khan, M.; Iqbal, J.; Mtz-Enriquez, A. Duplex plasma treatment of AISI D2 tool steel by combining plasma nitriding (with and without white layer) and post-oxidation. Surf. Coat. Technol. 2020, 385, 125420. [Google Scholar] [CrossRef]

- Deng, G.; Tieu, A.K.; Su, L.; Wang, P.; Wang, L.; Lan, X.; Cui, S.; Zhu, H. Investigation into reciprocating dry sliding friction and wear properties of bulk CoCrFeNiMo high entropy alloys fabricated by spark plasma sintering and subsequent cold rolling processes: Role of Mo element concentration. Wear 2020, 460–461, 203440. [Google Scholar] [CrossRef]

- Hoque, A.; Yao, C.-W.; Lian, I.; Zhou, J.; Jao, M.; Huang, Y.-C. Enhancement of corrosion resistance of a hot-dip galvanized steel by superhydrophobic top coating. MRS Commun. 2022, 12, 415–421. [Google Scholar] [CrossRef]

- Kumar, G.S.P.; Keshavamurthy, R.; Umesh, V.; Tambrallimath, V.; Yadav, Y.; Toufeeq, T.; Arun, S. Dry Sliding Friction and Wear Performance of HVOF Sprayed WC–Co Coatings Deposited on Aluminium Alloy. J. Inst. Eng. Ser. D 2021, 102, 331–344. [Google Scholar] [CrossRef]

- Shi, J.; Ge, Y.; Kong, D. Microstructure, dry sliding friction performances and wear mechanism of laser cladded WC–10Co4Cr coating with different Al2O3 mass fractions. Surf. Coat. Technol. 2021, 406, 126749. [Google Scholar] [CrossRef]

- Al-Abboodi, H.; Fan, H.; Mhmood, I.A.; Al-Bahrani, M. The dry sliding wear rate of a Fe-based amorphous coating prepared on mild steel by HVOF thermal spraying. J. Mater. Res. Technol. 2022, 18, 1682–1691. [Google Scholar] [CrossRef]

- Cao, L.; Wan, Y.; Li, Y.; Yang, S. Corrosion-resistant and friction-reducing performance of super-hydrophobic coating on hot-dip galvanised steel in a 3.5% NaCl solution. Lubr. Sci. 2021, 33, 325–334. [Google Scholar] [CrossRef]

- Satheesan, B.; Mohammed, A.S. Tribological characterization of epoxy hybrid nanocomposite coatings reinforced with graphene oxide and titania. Wear 2021, 466–467, 203560. [Google Scholar] [CrossRef]

- Kharanzhevskiy, E.V.; Ipatov, A.G.; Krivilyov, M.D.; Makarov, A.; Gil’Mutdinov, F.Z.; Volkova, E.G. Ultralow friction behaviour of B4C-BN-MeO composite ceramic coatings deposited on steel. Surf. Coat. Technol. 2020, 390, 125664. [Google Scholar] [CrossRef]

- Song, W.; Wang, S.; Lu, Y.; Zhang, X.; Xia, Z.; Sun, K.; Xin, G. Effect of MoS2/PTFE coatings on performance of Si3N4/TiC ceramics in dry sliding against WC/Co. Ceram. Int. 2021, 47, 12631–12640. [Google Scholar] [CrossRef]

- Torkashvand, K.; Joshi, S.; Testa, V.; Ghisoni, F.; Morelli, S.; Bolelli, G.; Lusvarghi, L.; Marra, F.; Gupta, M. Tribological behavior of HVAF-sprayed WC-based coatings with alternative binders. Surf. Coat. Technol. 2022, 436, 128296. [Google Scholar] [CrossRef]

- Akhter, R.; Zhou, Z.; Xie, Z.; Munroe, P. Enhancing the adhesion strength and wear resistance of nanostructured NiCrN coatings. Appl. Surf. Sci. 2020, 541, 148533. [Google Scholar] [CrossRef]

- Farhan, M.S. A review on adhesion strength of single and multilayer coatings and the evaluation method. Wasit J. Eng. Sci. 2016, 4, 1–27. [Google Scholar]

- Zhang, Z.-Q.; Zeng, R.-C.; Yan, W.; Lin, C.-G.; Wang, L.; Wang, Z.-L.; Chen, D.-C. Corrosion resistance of one-step superhydrophobic polypropylene coating on magnesium hydroxide-pretreated magnesium alloy AZ31. J. Alloys Compd. 2020, 821, 153515. [Google Scholar] [CrossRef]

- Lei, F.; Wu, B.; Sun, H.; Jiang, F.; Yang, J.; Sun, D. Simultaneously Improving the Anticorrosion and Antiscratch Performance of Epoxy Coatings with Graphite Fluoride via Large-Scale Preparation. Ind. Eng. Chem. Res. 2018, 57, 16709–16717. [Google Scholar] [CrossRef]

- Samani, M.A.; Ghasemi, B.; Khodaei, M. Nano-scratch and nano-indentation study of diamond-like car-bon/NiP-SiC nanocomposite bilayer. Mater. Sci. Technol. 2021, 37, 663–671. [Google Scholar] [CrossRef]

- Echeverrigaray, F.G.; de Mello, S.R.S.; Boeira, C.D.; Leidens, L.M.; da Costa, M.E.H.M.; Freire, F.L.; Alvarez, F.; Michels, A.F.; Figueroa, C.A. Nanoindentation unidirectional sliding and lateral force microscopy: Evaluation of experimental techniques to measure friction at the nanoscale. AIP Adv. 2018, 8, 125013. [Google Scholar] [CrossRef]

- Wood, J.; Hayles, A.; Bright, R.; Palms, D.; Vasilev, K.; Hasan, J. Nanomechanical tribological characterisation of nanostructured titanium alloy surfaces using AFM: A friction vs velocity study. Colloids Surfaces B Biointerfaces 2022, 217, 112600. [Google Scholar] [CrossRef]

- Elam, F.M.; Hsia, F.-C.; van Vliet, S.; Bliem, R.; Yang, L.; Weber, B.; Franklin, S.E. The influence of corrosion on diamond-like carbon topography and friction at the nanoscale. Carbon 2021, 179, 590–599. [Google Scholar] [CrossRef]

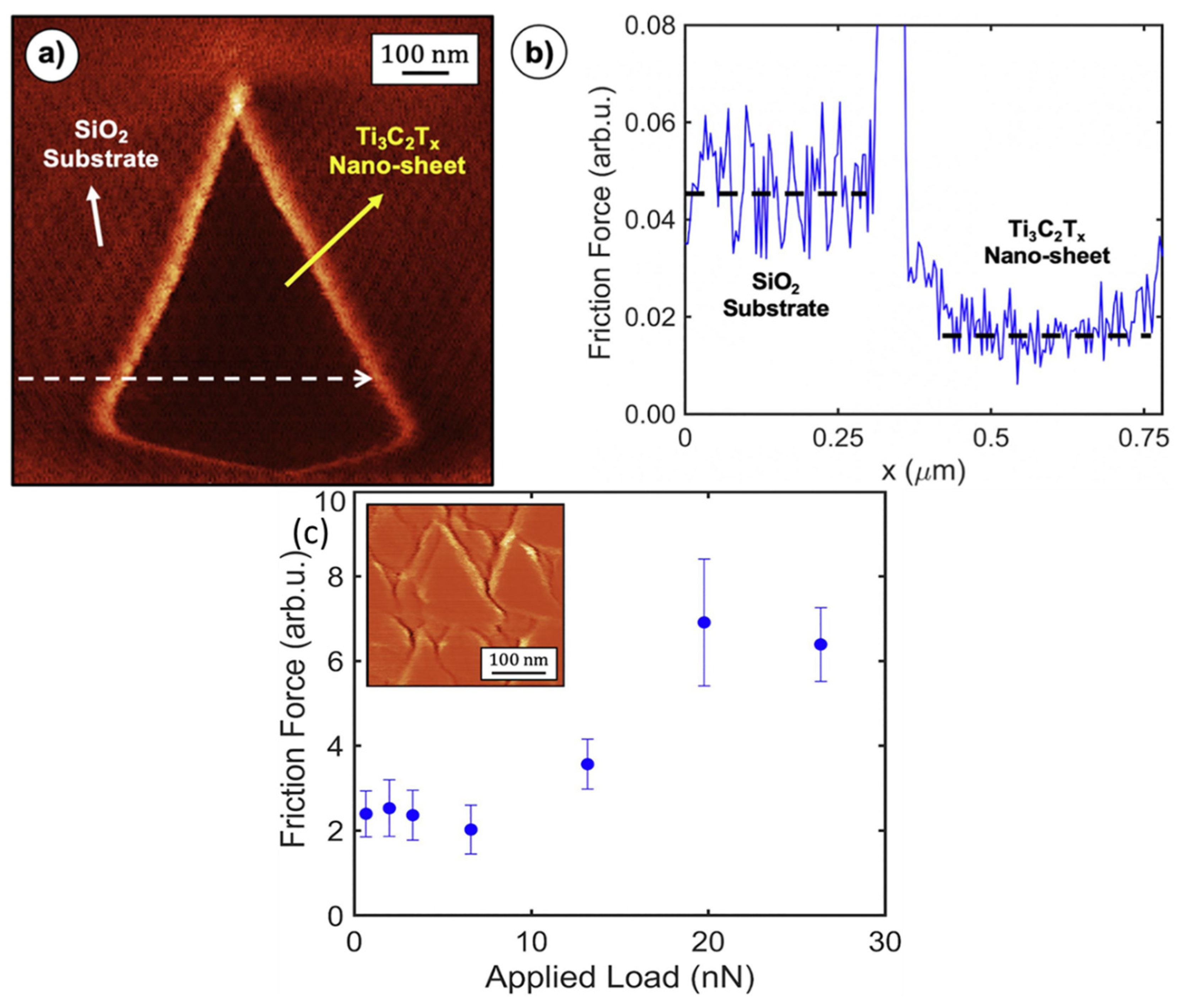

- Rodriguez, A.; Jaman, M.; Acikgoz, O.; Wang, B.; Yu, J.; Grützmacher, P.; Rosenkranz, A.; Baykara, M. The potential of Ti3C2TX nano-sheets (MXenes) for nanoscale solid lubrication revealed by friction force microscopy. Appl. Surf. Sci. 2021, 535, 147664. [Google Scholar] [CrossRef]

- Freyman, C.; Zhao, B.; Chung, Y.-W. Suppression of Moisture Sensitivity of Friction in Carbon-Based Coatings. Superlubricity 2007, 295–310. [Google Scholar] [CrossRef]

- Siddaiah, A.; Mao, B.; Kasar, A.K.; Liao, Y.; Menezes, P.L. Influence of laser shock peening on the surface energy and tribocorrosion properties of an AZ31B Mg alloy. Wear 2020, 462–463, 203490. [Google Scholar] [CrossRef]

- Sebastian, D.; Yao, C.-W. Effect of poly(dimethylsiloxane) binder in a silica-based superhydrophobic coating on mechanical properties, surface roughness, and wettability. MRS Commun. 2020, 10, 512–518. [Google Scholar] [CrossRef]

- Mukherjee, S.; Dhara, S.; Saha, P. Enhanced corrosion, tribocorrosion resistance and controllable osteogenic potential of stem cells on micro-rippled Ti6Al4V surfaces produced by pulsed laser remelting. J. Manuf. Process. 2021, 65, 119–133. [Google Scholar] [CrossRef]

- Sebastian, D.; Yao, C.-W.; Lian, I. Abrasion Resistance of Superhydrophobic Coatings on Aluminum Using PDMS/SiO2. Coatings 2018, 8, 414. [Google Scholar] [CrossRef]

- Dai, Y.; Jiang, X.; Ou, G.M.; Li, M.K.; Xiang, Q.; Yang, F.; Liu, J. Study of Tribocorrosion Behaviour of Ti–25nb–3zr–2sn–3mo Alloy Induction Nitride Layer in a Simulated Body Fluidsolution. Available online: https://papers.ssrn.com/abstract=4239576 (accessed on 3 November 2022).

- Wang, H.; Zhou, Q.; Ou, Y.; Liao, B.; Zhang, X.; Hua, Q.; Ouyang, X.; Luo, C. Tribocorrosion behaviors of nc-TiC/a-C:H nanocomposite coatings: In-situ electrochemical response. Thin Solid Films 2021, 730, 138719. [Google Scholar] [CrossRef]

- Hatem, A.; Lin, J.; Wei, R.; Torres, R.D.; Laurindo, C.; de Souza, G.B.; Soares, P. Tribocorrosion behavior of low friction TiSiCN nanocomposite coatings deposited on titanium alloy for biomedical applications. Surf. Coat. Technol. 2018, 347, 1–12. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, F.; Zhang, M.; Wang, Q.; Zhou, Z. Structure and tribocorrosion behavior of CrMoSiCN nanocomposite coating with low C content in artificial seawater. Friction 2020, 9, 1599–1615. [Google Scholar] [CrossRef]

- Feng, J.; Xiao, H. Tribocorrosion Behavior of Laser Cladded Ti-Al-(C, N) Composite Coatings in Artificial Seawater. Coatings 2022, 12, 187. [Google Scholar] [CrossRef]

- Shi, T.; Liang, J.; Li, X.; Zhang, C.; Yang, H. Improving the Corrosion Resistance of Aluminum Alloy by Creating a Superhydrophobic Surface Structure through a Two-Step Process of Etching followed by Polymer Modi-fication. Polymers 2022, 14, 4509. [Google Scholar] [CrossRef]

- Yildiz, R.A.; Genel, K.; Gulmez, T. Effect of electroless Ni-B and Ni-WB coatings on the corrosion-fatigue behaviour of 7075 Al alloy. Int. J. Fatigue 2021, 144, 106040. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, H.; Shao, Y.; Zhang, H.; Zhu, J. Recent Progresses of Superhydrophobic Coatings in Different Application Fields: An Overview. Coatings 2021, 11, 116. [Google Scholar] [CrossRef]

- Boinovich, L.B.; Emelyanenko, A.M.; Modestov, A.D.; Domantovsky, A.G.; Emelyanenko, K.A. Synergistic Effect of Superhydrophobicity and Oxidized Layers on Corrosion Resistance of Aluminum Alloy Surface Textured by Nanosecond Laser Treatment. ACS Appl. Mater. Interfaces 2015, 7, 19500–19508. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoque, M.A.; Yao, C.-W.; Khanal, M.; Lian, I. Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings. Sensors 2022, 22, 9974. https://doi.org/10.3390/s22249974

Hoque MA, Yao C-W, Khanal M, Lian I. Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings. Sensors. 2022; 22(24):9974. https://doi.org/10.3390/s22249974

Chicago/Turabian StyleHoque, Md Ashraful, Chun-Wei Yao, Mukunda Khanal, and Ian Lian. 2022. "Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings" Sensors 22, no. 24: 9974. https://doi.org/10.3390/s22249974

APA StyleHoque, M. A., Yao, C.-W., Khanal, M., & Lian, I. (2022). Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings. Sensors, 22(24), 9974. https://doi.org/10.3390/s22249974