Numerical Model Driving Multi-Domain Information Transfer Method for Bearing Fault Diagnosis

Abstract

1. Introduction

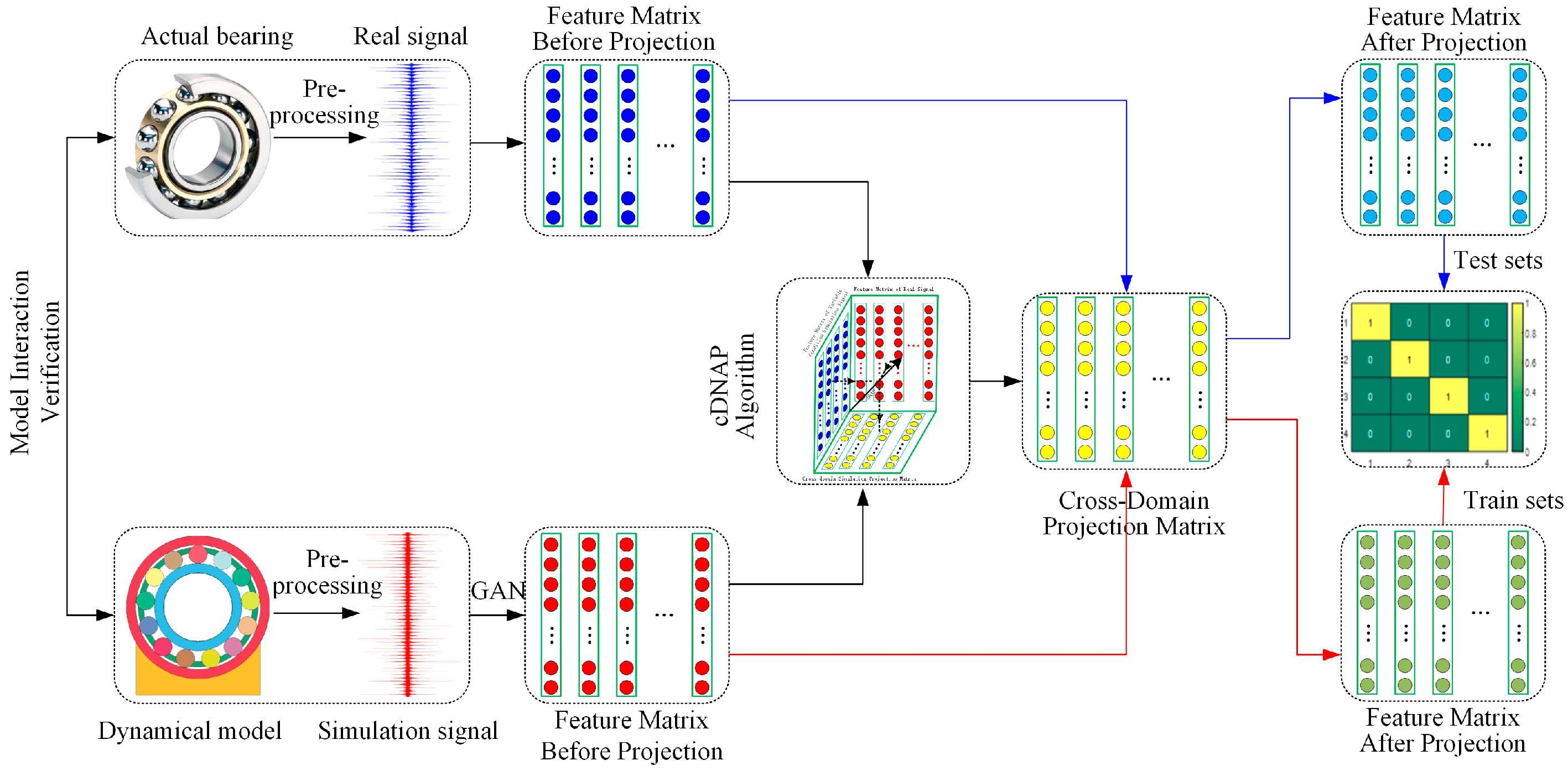

2. Framework of cDNAP Model

2.1. Explicit Dynamic Method

2.2. Generative Adversarial Net

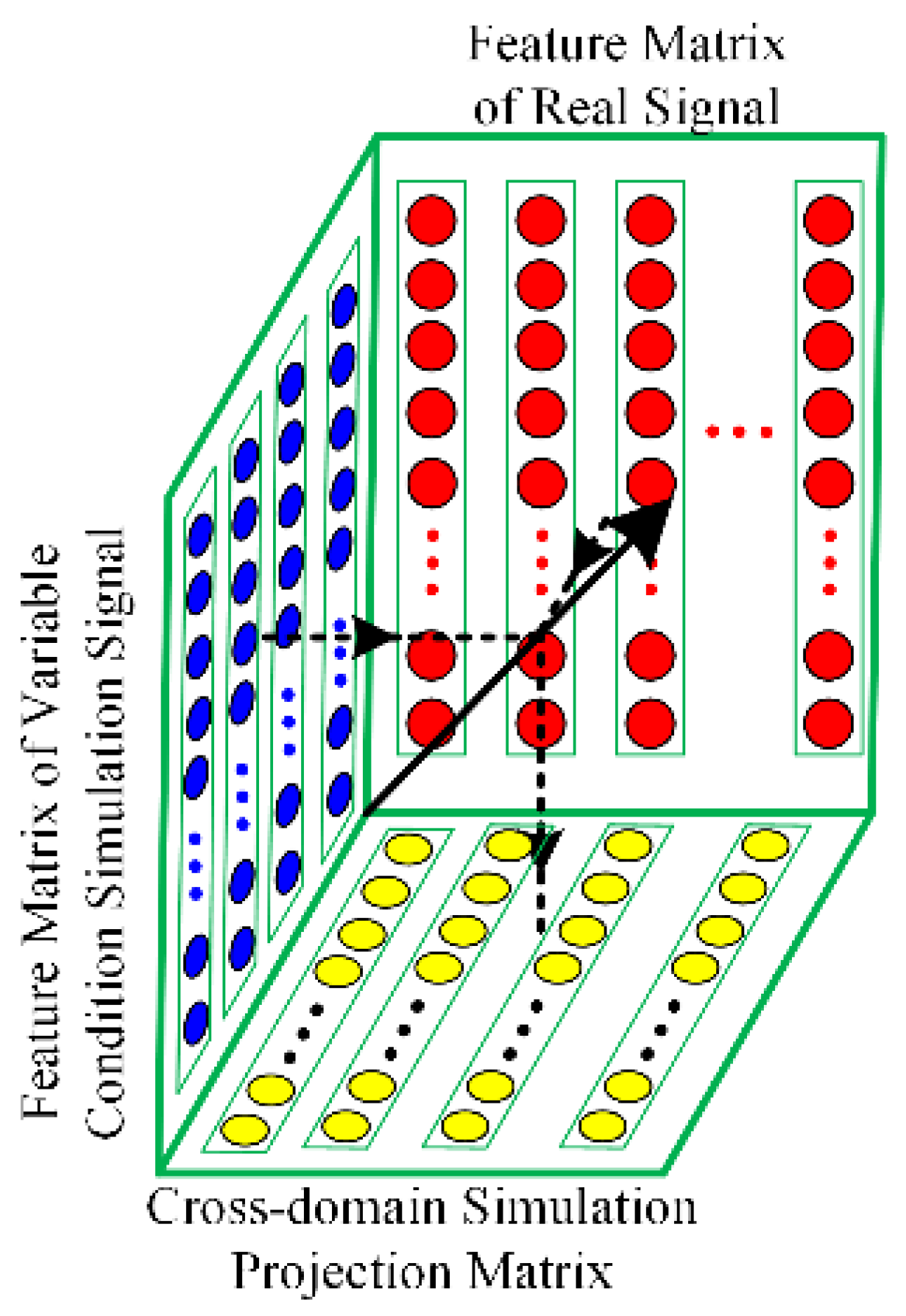

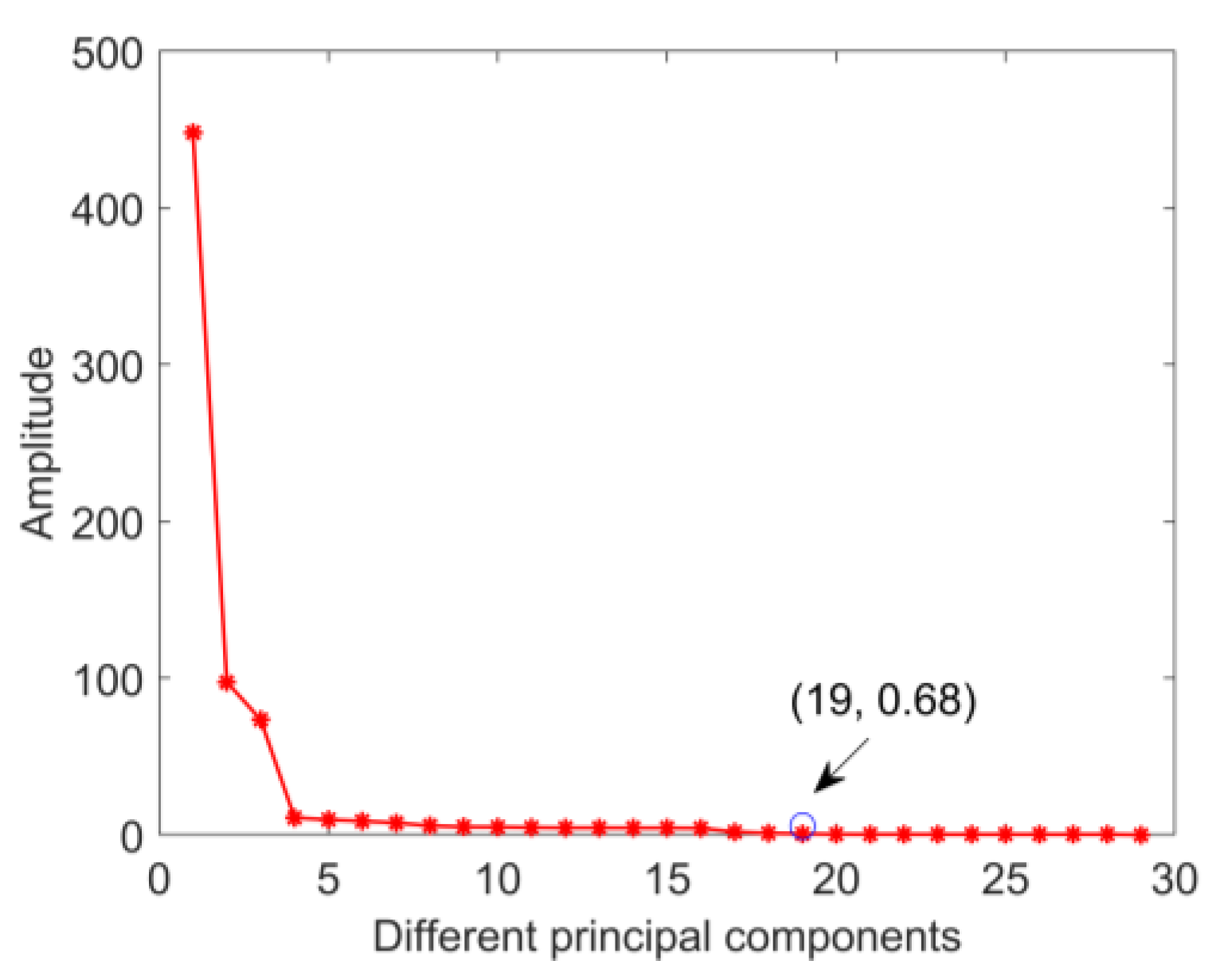

2.3. Cross-Domain Simulation Projection Matrix

2.4. Flow Chart of Fault Diagnosis Method

3. Validation of Bearing Dynamic Model and cDNAP

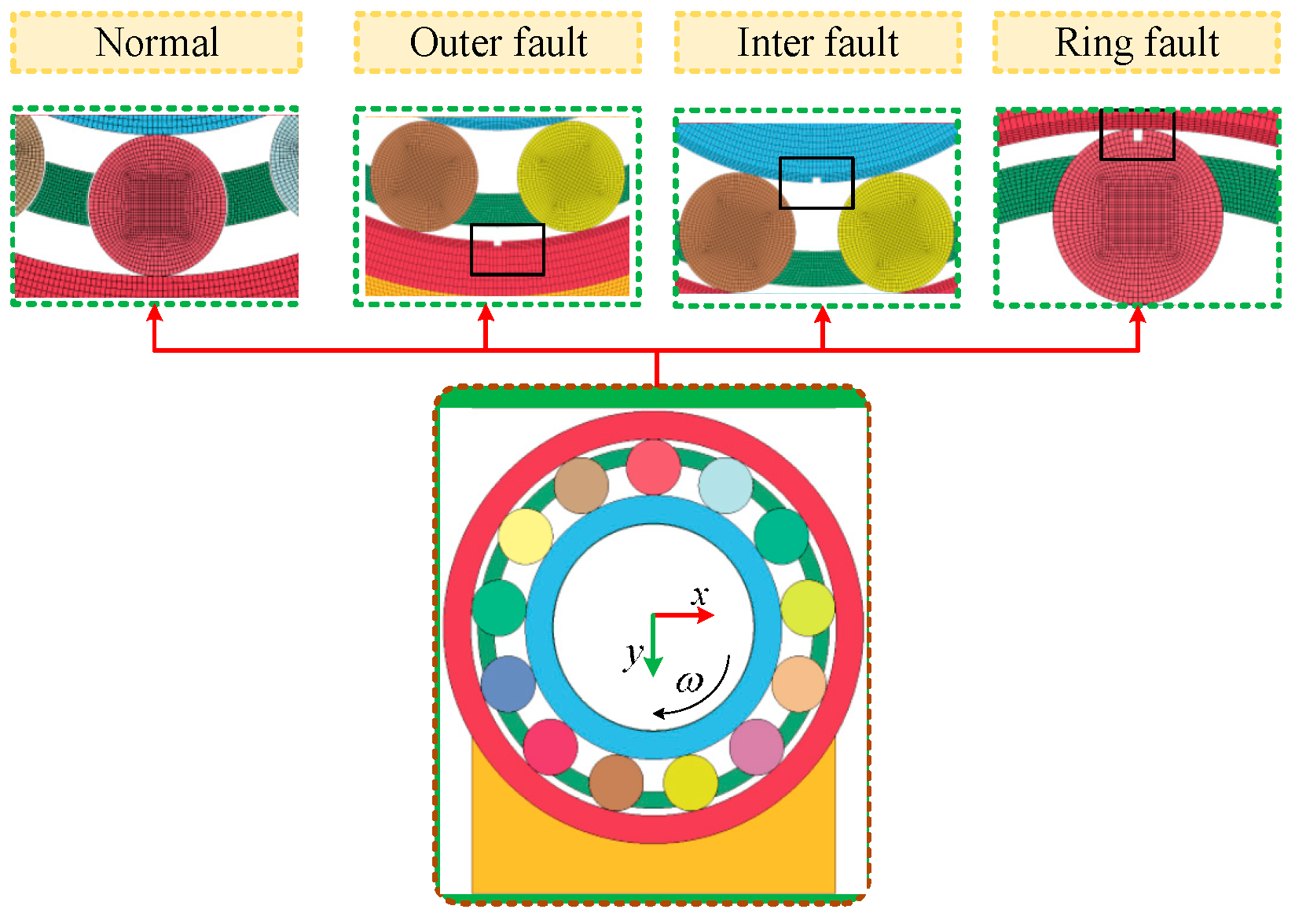

3.1. Establishment and Verification of Bearing Dynamic Model

- (1)

- Establishment of the dynamic model

- (2)

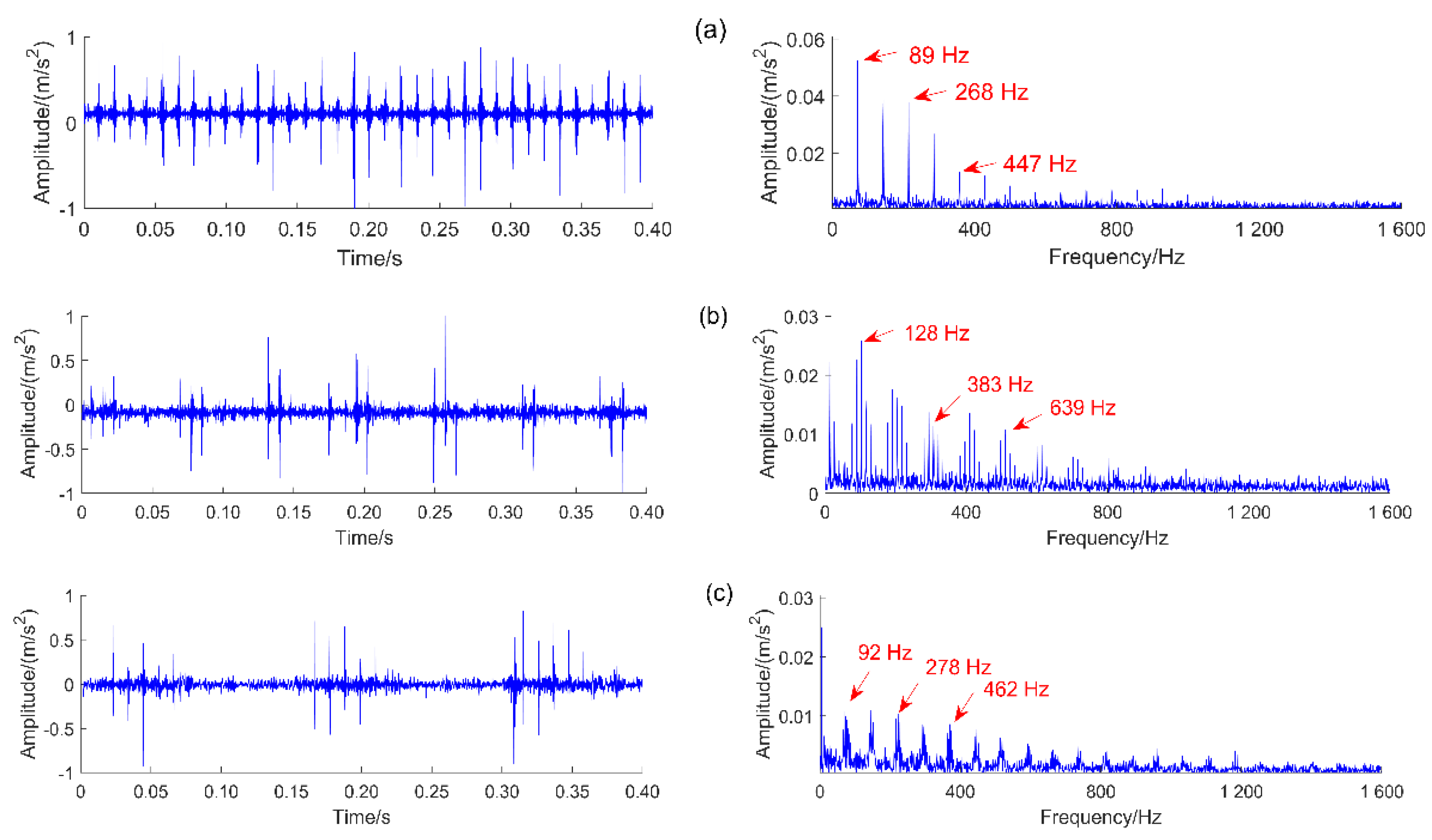

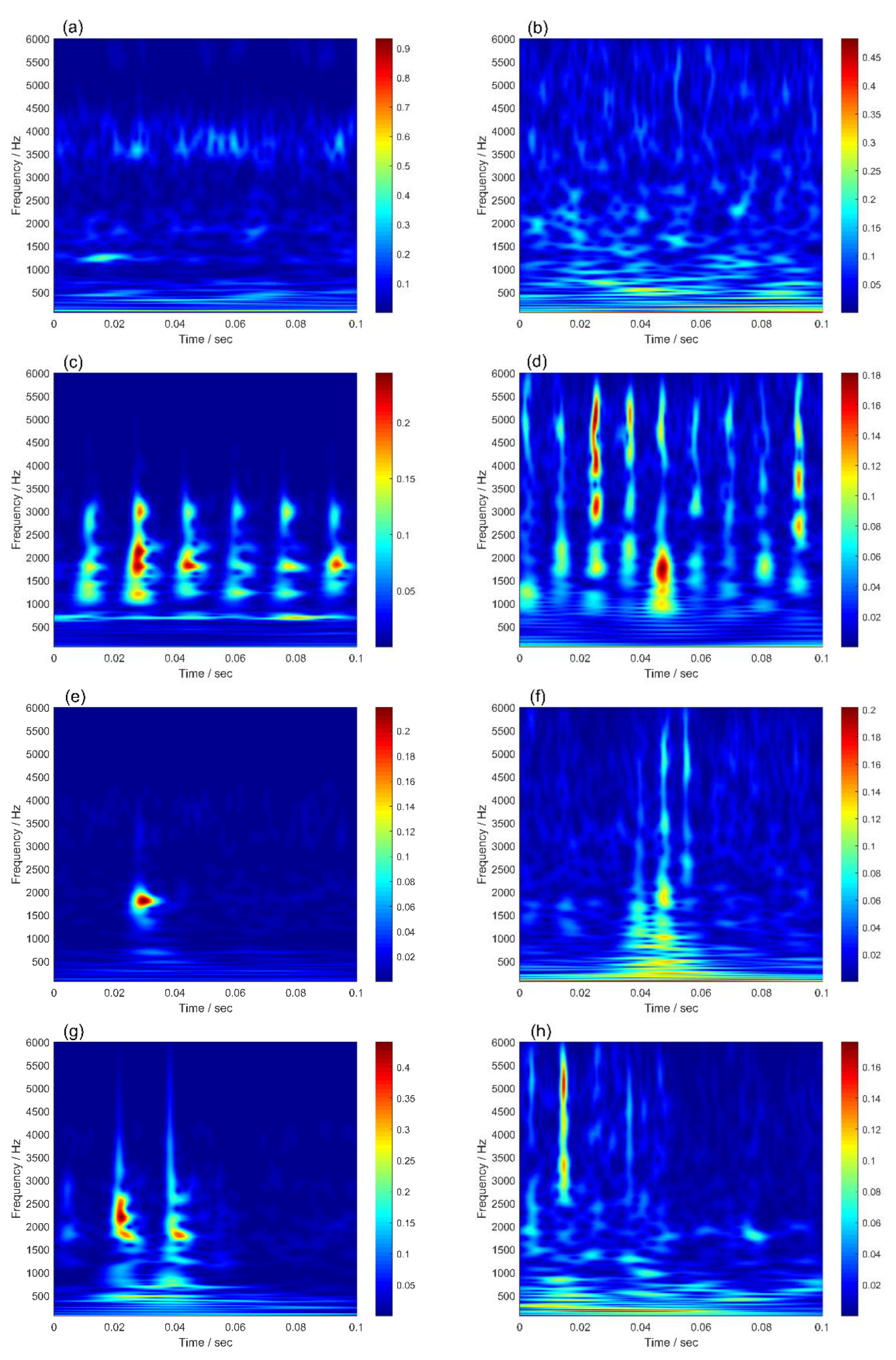

- Verification of the bearing dynamic model

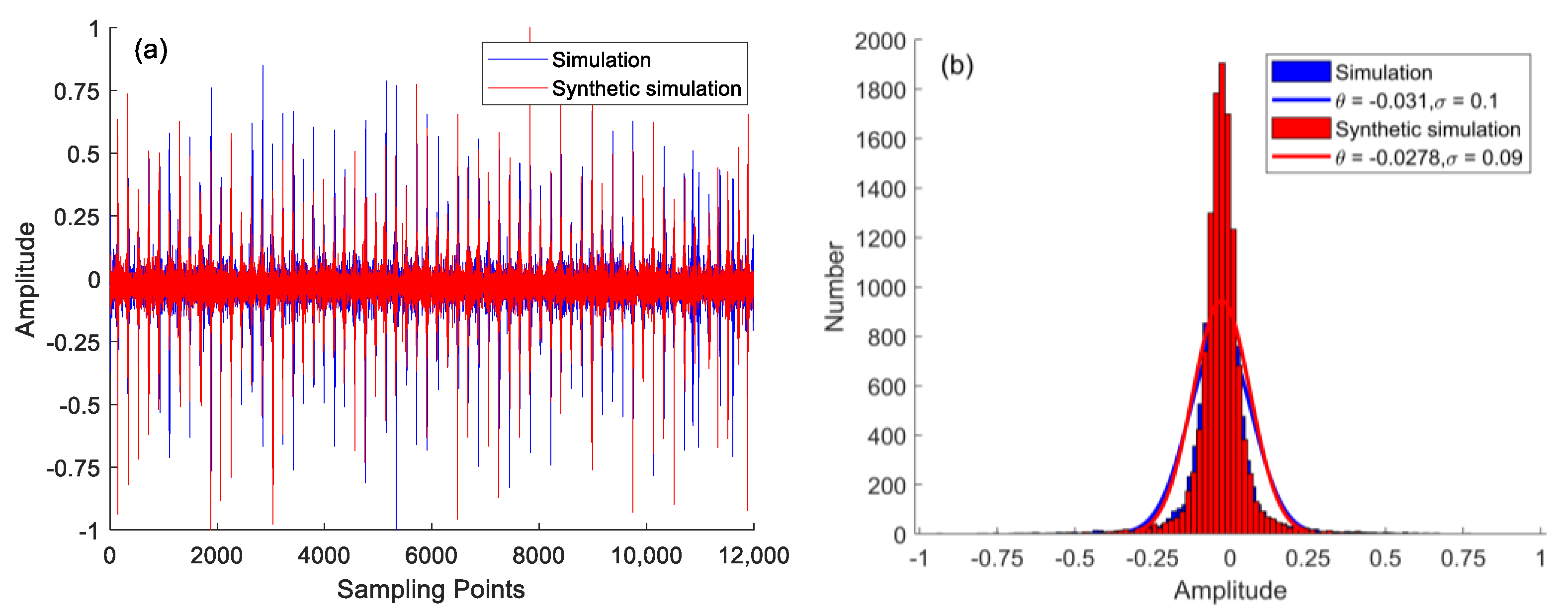

3.2. Verification of WGAN-cDNAP

4. Application Verification

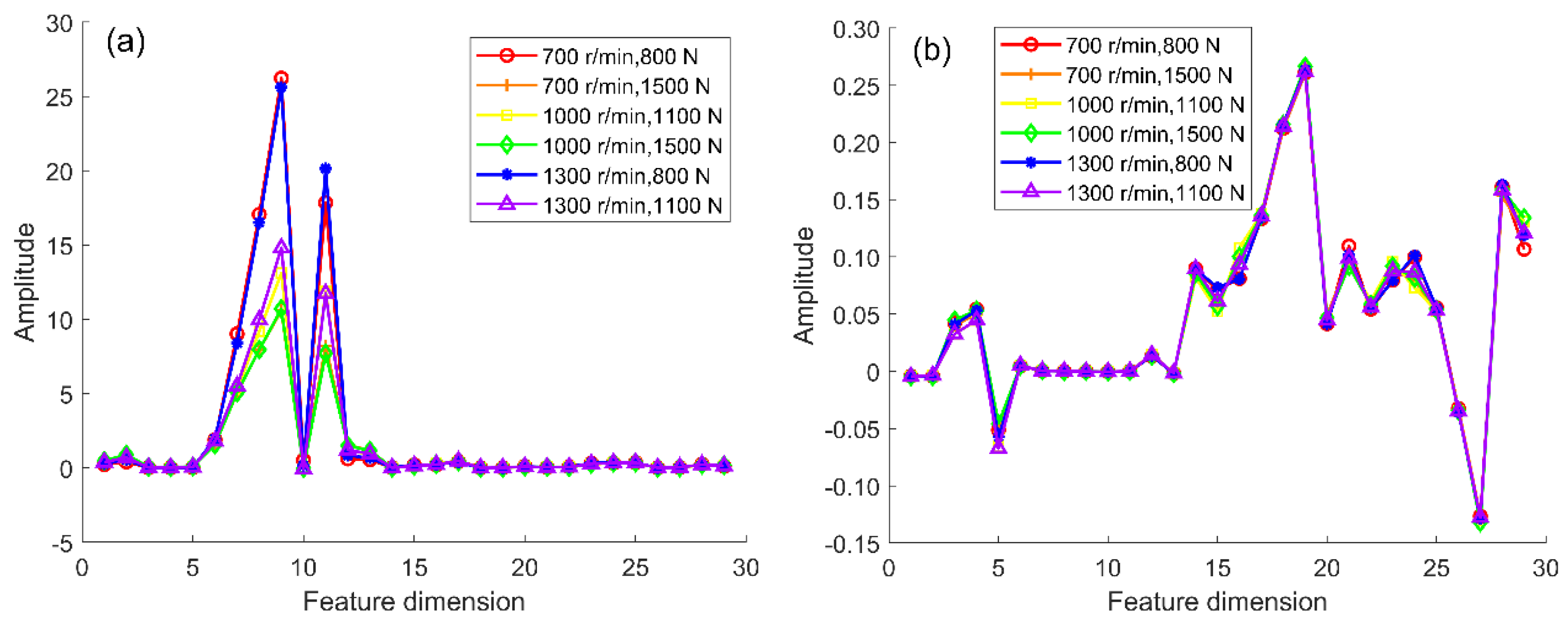

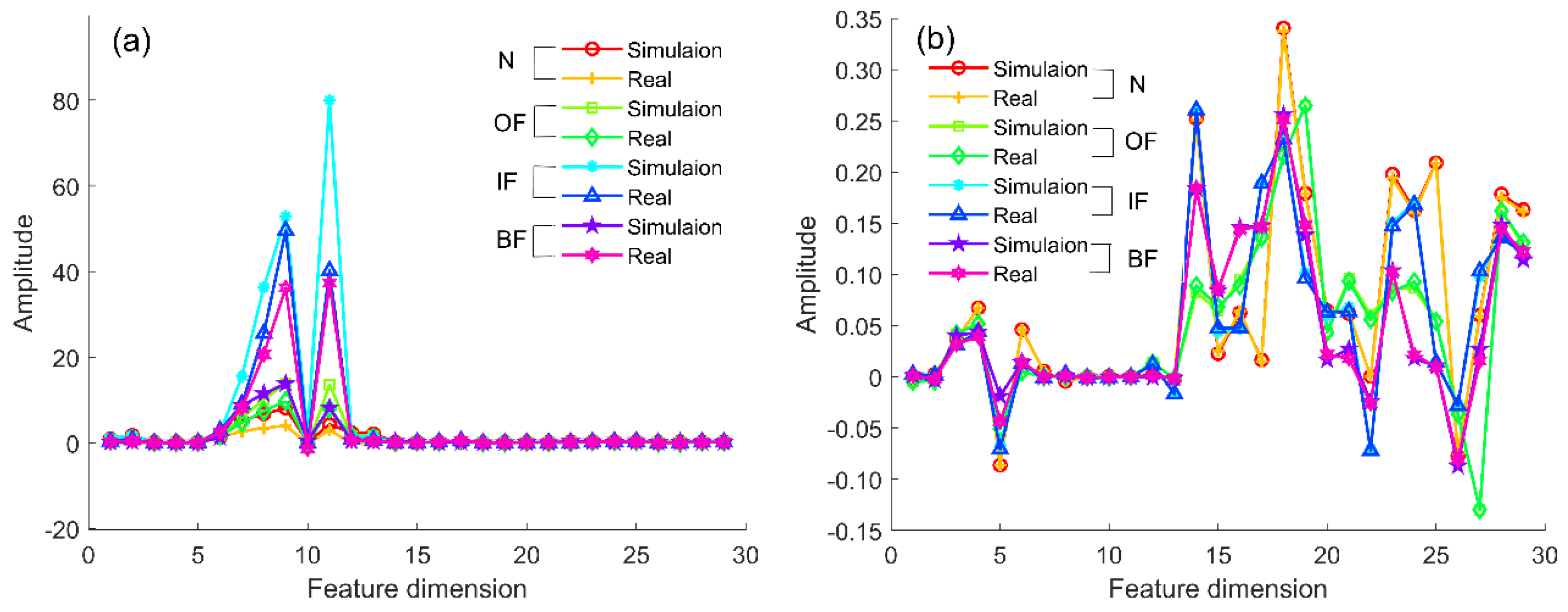

4.1. Bearing Fault Diagnosis of Single Working Condition

4.2. Bearing Fault Diagnosis of Compound Working Condition

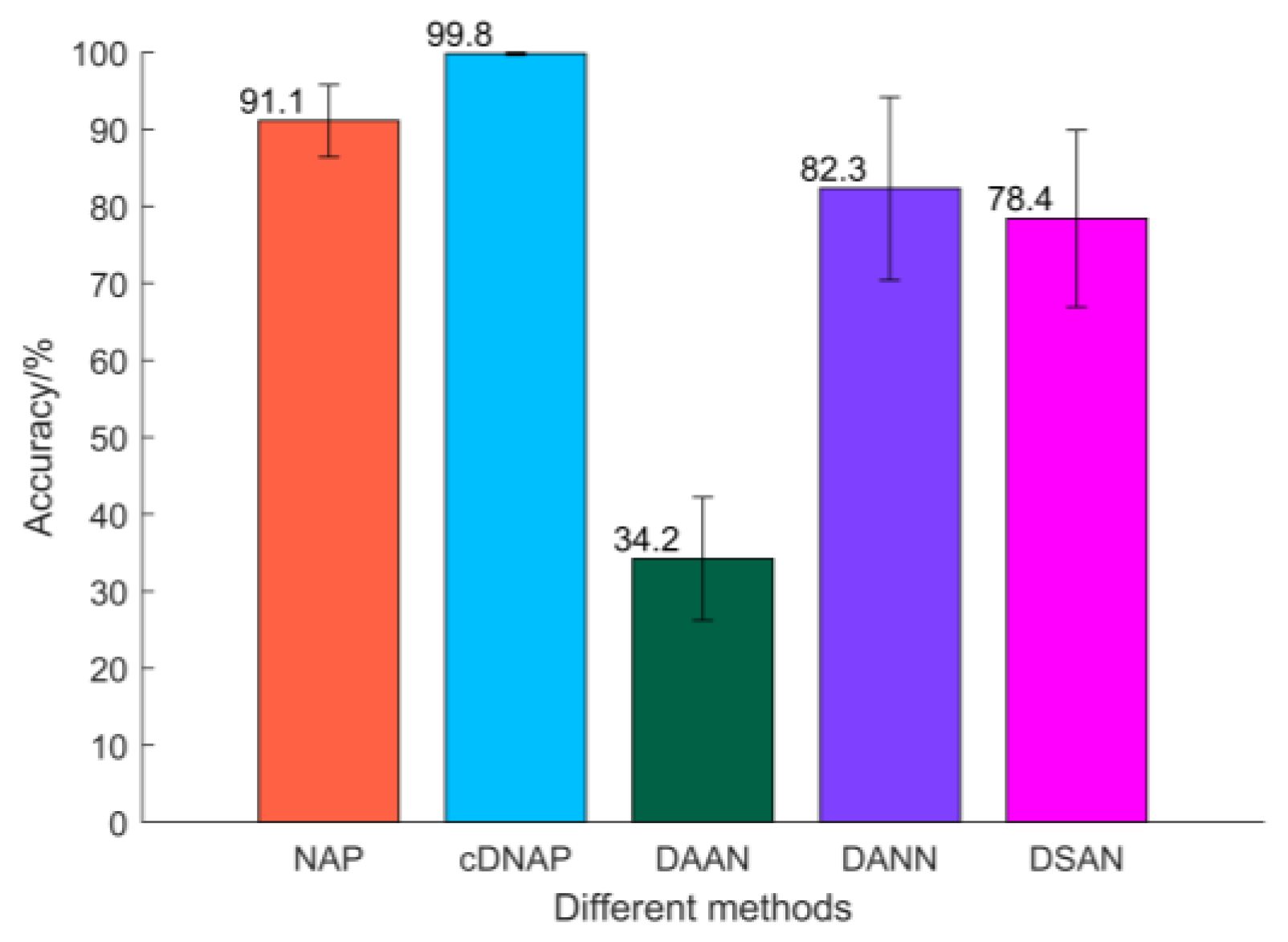

4.3. Comparative Experimental Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, B.; Weng, Y.; Zhang, N. A feature extraction and machine learning framework for bearing fault diagnosis. Renew. Energ. 2022, 191, 987–997. [Google Scholar] [CrossRef]

- Wang, Q.; Taal, C.; Fink, O. Integrating expert knowledge with domain adaptation for unsupervised fault diagnosis. IEEE Trans. Instrum. Meas. 2021, 71, 1–12. [Google Scholar] [CrossRef]

- Huo, Z.; Zhang, Y.; Jombo, G.; Shu, L. Adaptive multiscale weighted permutation entropy for rolling bearing fault diagnosis. IEEE Access 2020, 8, 87529–87540. [Google Scholar] [CrossRef]

- Hou, J.; Wu, Y.; Ahmad, A.S.; Gong, H.; Liu, L. A novel rolling bearing fault diagnosis method based on adaptive feature selection and clustering. IEEE Access 2021, 9, 99756–99767. [Google Scholar] [CrossRef]

- Chen, L.; Xu, G.; Tao, T.; Wu, Q. Deep residual network for identifying bearing fault location and fault severity concurrently. IEEE Access 2020, 8, 168026–168035. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, X.; Wang, T. Time-varying demodulation analysis for rolling bearing fault diagnosis under variable speed conditions. J. Sound Vib. 2017, 400, 71–85. [Google Scholar] [CrossRef]

- Liu, D.; Cheng, W.; Wen, W. An online bearing fault diagnosis technique via improved demodulation spectrum analysis under variable speed conditions. IEEE Syst. J. 2019, 14, 2323–2334. [Google Scholar] [CrossRef]

- Shi, J.; Hua, Z.; Huang, W.; Dumond, P.; Shen, C.; Zhu, Z. Instantaneous Frequency Synchronized Generalized Stepwise Demodulation Transform for Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2022, 71, 1–15. [Google Scholar] [CrossRef]

- Zhang, B.; Li, W.; Li, X.L.; Ng, S.K. Intelligent fault diagnosis under varying working conditions based on domain adaptive convolutional neural networks. IEEE Access 2018, 6, 66367–66384. [Google Scholar] [CrossRef]

- Du, Y.; Wang, A.; Wang, S.; He, B.; Meng, G. Fault diagnosis under variable working conditions based on STFT and transfer deep residual network. Shock Vib. 2020, 2020, 1274380. [Google Scholar] [CrossRef]

- She, B.; Wang, X. A hidden feature label propagation method based on deep convolution variational autoencoder for fault diagnosis. Meas. Sci. Technol. 2022, 33, 055107. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Q.; Chen, H.; Chu, X. A deformable CNN-DLSTM based transfer learning method for fault diagnosis of rolling bearing under multiple working conditions. Int. J. Prod. Res. 2021, 59, 4811–4825. [Google Scholar] [CrossRef]

- Su, H.; Xiang, L.; Hu, A.; Xu, Y.; Yang, X. A novel method based on meta-learning for bearing fault diagnosis with small sample learning under different working conditions. Mech. Syst. Signal Process. 2022, 169, 108765. [Google Scholar] [CrossRef]

- Huan, M.; Yin, J.; Yan, S.; Xue, P. A fault diagnosis method of bearings based on deep transfer learning simulation modelling. Simul. Model. Pract. Theory 2023, 122, 102659. [Google Scholar] [CrossRef]

- Choudhury, M.D.; Hong, L.; Dhupia, J.S. A novel tacholess order analysis method for bearings operating under time-varying speed conditions. Measurement 2021, 186, 110127. [Google Scholar] [CrossRef]

- Hu, Y.; Tu, X.; Li, F.; Li, H.; Meng, G. An adaptive and tacholess order analysis method based on enhanced empirical wavelet transform for fault detection of bearings with varying speeds. J. Sound Vib. 2017, 409, 241–255. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, J.; Shi, H.; Zhang, X.; Tang, Y. A fault diagnosis method based on improved convolutional neural network for bearings under variable working conditions. Measurement 2021, 182, 109749. [Google Scholar] [CrossRef]

- Han, B.; Ji, S.; Wang, J.; Bao, H.; Jiang, X. An intelligent diagnosis framework for roller bearing fault under speed fluctuation condition. Neurocomputing 2021, 420, 171–180. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. A survey on deep learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Guo, Q.; Li, Y.; Song, Y.; Wang, D.; Chen, W. Intelligent fault diagnosis method based on full 1-D convolutional generative adversarial network. IEEE Trans. Instrum. Meas. 2019, 16, 2044–2053. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, G.; Cheng, C. Data fusion generative adversarial network for multi-class imbalanced fault diagnosis of rotating machinery. IEEE Access 2020, 8, 70111–70124. [Google Scholar] [CrossRef]

- Pham, M.T.; Kim, J.M.; Kim, C.H. Rolling bearing fault diagnosis based on improved GAN and 2-D representation of acoustic emission signals. IEEE Access 2022, 10, 78056–78069. [Google Scholar] [CrossRef]

- Tong, Q.; Lu, F.; Feng, Z.; Wan, Q.; An, G.; Cao, J.; Guo, T. A novel method for fault diagnosis of bearings with small and imbalanced data based on generative adversarial networks. Appl. Sci. 2022, 12, 7346. [Google Scholar] [CrossRef]

- Pei, X.; Su, S.; Jiang, L.; Chu, C.; Gong, L.; Yuan, Y. Research on Rolling Bearing Fault Diagnosis Method Based on Generative Adversarial and Transfer Learning. Processes 2022, 10, 1443. [Google Scholar] [CrossRef]

- Yang, X.; Chi, F.; Shao, S.; Zhang, Q. Bearing Fault Diagnosis under Variable Working Conditions Based on Deep Residual Shrinkage Networks and Transfer Learning. J. Sens. 2021, 2021, 5714240. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Li, Y.; Li, Y. A new transfer learning fault diagnosis method using TSC and JGSA under variable condition. IEEE Access 2020, 8, 177287–177295. [Google Scholar] [CrossRef]

- Wu, H.; Li, J.; Zhang, Q.; Tao, J.; Meng, Z. Intelligent fault diagnosis of rolling bearings under varying operating conditions based on domain-adversarial neural network and attention mechanism. ISA Trans. 2022, 130, 477–489. [Google Scholar] [CrossRef]

- Yang, B.; Lei, Y.; Jia, F.; Xing, S. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mech. Syst. Signal Process. 2019, 122, 692–706. [Google Scholar] [CrossRef]

- Yu, K.; Fu, Q.; Ma, H.; Lin, T.R.; Li, X. Simulation data driven weakly supervised adversarial domain adaptation approach for intelligent cross-machine fault diagnosis. Struct. Health Monit. 2021, 20, 2182–2198. [Google Scholar] [CrossRef]

- Liu, C.; Gryllias, K. Simulation-driven domain adaptation for rolling element bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2021, 18, 5760–5770. [Google Scholar] [CrossRef]

- Ruan, D.; Chen, Y.; Gühmann, C.; Yan, J.; Li, Z. Dynamics Modeling of Bearing with Defect in Modelica and Application in Direct Transfer Learning from Simulation to Test Bench for Bearing Fault Diagnosis. Electronics 2022, 11, 622. [Google Scholar] [CrossRef]

- Solomonoff, A.; Campbell, W.M.; Quillen, C. Nuisance attribute projection. Speech Commun. 2007, 1–73. [Google Scholar]

- Štruc, V.; Vesnicer, B.; Mihelič, F.; Pavešić, N. Removing illumination artifacts from face images using the nuisance attribute projection. In Proceedings of the IEEE International Conference on Acoustics, Speech and Signal Processing, Dallas, TX, USA, 14–19 March 2010; pp. 846–849. [Google Scholar]

- Vesnicer, B.; Mihelič, F. The likelihood ratio decision criterion for nuisance attribute projection in GMM speaker verification. EURASIP J. Adv. Sig. Pr. 2008, 2008, 786431. [Google Scholar] [CrossRef]

- Jiang, H.; Chen, J.; Dong, G. Hidden Markov model and nuisance attribute projection based bearing performance degradation assessment. Mech. Syst. Signal Process. 2016, 72, 184–205. [Google Scholar] [CrossRef]

- Zhu, P.; Dong, S.; Pan, X.; Hu, X.; Zhu, S. A simulation-data-driven subdomain adaptation adversarial transfer learning network for rolling element bearing fault diagnosis. Meas. Sci. Technol. 2022, 33, 075101. [Google Scholar] [CrossRef]

- Creswell, A.; White, T.; Dumoulin, V.; Arulkumaran, K.; Sengupta, B.; Bharath, A.A. Generative adversarial networks: An overview. IEEE signal Proc. Mag. 2018, 35, 53–65. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, H.; Wu, Z.; Li, X. Rolling bearing fault diagnosis using variational autoencoding generative adversarial networks with deep regret analysis. Measurement 2021, 168, 108371. [Google Scholar] [CrossRef]

- Peng, C.; Zhang, S.; Li, C. A Rolling Bearing Fault Diagnosis Based on Conditional Depth Convolution Countermeasure Generation Networks under Small Samples. Sensors 2022, 22, 5658. [Google Scholar] [CrossRef]

- Luo, M.; Guo, Y.; Andre, H.; Wu, X.; Na, J. Dynamic modeling and quantitative diagnosis for dual-impulse behavior of rolling element bearing with a spall on inner race. Mech. Syst. Signal Process. 2021, 158, 107711. [Google Scholar] [CrossRef]

- Singh, S.; Howard, C.Q.; Hansen, C.H.; Köpke, U.G. Analytical validation of an explicit finite element model of a rolling element bearing with a localised line spall. J. Sound Vib. 2018, 416, 94–110. [Google Scholar] [CrossRef]

- Sun, X.; Jia, X. A fault diagnosis method of industrial robot rolling bearing based on data driven and random intuitive fuzzy decision. IEEE Access 2019, 7, 148764–148770. [Google Scholar] [CrossRef]

| Health States | Working Condition Types | ||

|---|---|---|---|

| N; OF; IF; BF | 800 N/700 rpm | 800 N/1000 rpm | 800 N/1300 rpm |

| 1100 N/700 rpm | 1100 N/1000 rpm | 1100 N/1300 rpm | |

| 1500 N/700 rpm | 1500 N/1000 rpm | 1500 N/1300 rpm | |

| Conditions | Source Domain | Target Domain | Accuracy/% | |||||

|---|---|---|---|---|---|---|---|---|

| Speed/(Rad/s) | Load/N | Speed/(Rad/s) | Load/N | SVM | ELM | ELM+NAP | ELM+cDNAP | |

| Variable load | 700 | 800/1100 | 700 | 1500 | 25 | 33.2 | 85.2 | 100 |

| 700 | 800/1500 | 700 | 1100 | 25 | 37.8 | 88.9 | 100 | |

| 700 | 1100/1500 | 700 | 800 | 24.5 | 36.2 | 89.7 | 99.9 | |

| 1000 | 800/1100 | 1000 | 1500 | 25 | 34.2 | 92.9 | 99.9 | |

| 1000 | 800/1500 | 1000 | 1100 | 25 | 39.4 | 89.2 | 100 | |

| 1000 | 1100/1500 | 1000 | 800 | 28 | 36.5 | 98.9 | 99.3 | |

| 1300 | 800/1100 | 1300 | 1500 | 25 | 35.1 | 94.5 | 99.9 | |

| 1300 | 800/1500 | 1300 | 1100 | 25 | 41.2 | 96.7 | 99.8 | |

| 1300 | 1100/1500 | 1300 | 800 | 25 | 38.8 | 94.5 | 99.6 | |

| Variable speed | 700/1000 | 800 | 1300 | 800 | 25 | 33.4 | 97.7 | 99.3 |

| 700/1300 | 800 | 1000 | 800 | 25 | 35.2 | 99.2 | 99.3 | |

| 1000/1300 | 800 | 700 | 800 | 25 | 36.2 | 91.8 | 99.9 | |

| 700/1000 | 1100 | 1300 | 1100 | 27 | 34.7 | 95.7 | 99.9 | |

| 700/1300 | 1100 | 1000 | 1100 | 20.5 | 35.4 | 84.9 | 100 | |

| 1000/1300 | 1100 | 700 | 1100 | 25 | 32.5 | 88.3 | 100 | |

| 700/1000 | 1500 | 1300 | 1500 | 24.5 | 36.2 | 93.5 | 99.9 | |

| 700/1300 | 1500 | 1000 | 1500 | 25 | 31.8 | 93.4 | 99.9 | |

| 1000/1300 | 1500 | 700 | 1500 | 25 | 32.8 | 83.6 | 99.9 | |

| Conditions | Source Domain | Target Domain | Accuracy/% | |||||

|---|---|---|---|---|---|---|---|---|

| Speed/(rad/s) | Load/N | Speed/(rad/s) | Load/N | SVM | ELM | ELM+NAP | ELM+cDNAP | |

| 1 | 700/1000 | 800/1100 | 1300 | 1500 | 25 | 37.1 | 96.3 | 99.9 |

| 2 | 700/1000 | 800/1500 | 1300 | 1100 | 25 | 43.4 | 93.9 | 99.8 |

| 3 | 700/1000 | 1100/1500 | 1300 | 800 | 25 | 41.3 | 92.5 | 99.7 |

| 4 | 700/1300 | 800/1100 | 1000 | 1500 | 25 | 34.6 | 89.1 | 99.9 |

| 5 | 700/1300 | 800/1500 | 1000 | 1100 | 25 | 40.4 | 81.7 | 100 |

| 6 | 700/1300 | 1100/1500 | 1000 | 800 | 25 | 42.4 | 95.7 | 99.6 |

| 7 | 1000/1300 | 800/1100 | 700 | 1500 | 25 | 33.2 | 82.3 | 100 |

| 8 | 1000/1300 | 800/1500 | 700 | 1100 | 25 | 37.2 | 81.5 | 100 |

| 9 | 1000/1300 | 1100/1500 | 700 | 800 | 25 | 38.5 | 84.9 | 99.9 |

| Conditions | Source Domain | Target Domain | Accuracy/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Speed /(rad/s) | Load/N | Speed /(rad/s) | Load/N | ELM+NAP | ELM+cDNAP | DAAN | DANN | DSAN | |

| 1 | 700 | 800/1500 | 700 | 1100 | 88.9 | 100 | 42.2 | 77.3 | 67.8 |

| 2 | 1000 | 800/1500 | 1000 | 1100 | 89.2 | 100 | 37.0 | 69.7 | 70.5 |

| 3 | 1300 | 800/1500 | 1300 | 1100 | 96.7 | 99.8 | 31.5 | 98.8 | 92.3 |

| 4 | 700/1300 | 800 | 1000 | 800 | 99.2 | 99.3 | 29.2 | 75.0 | 67.8 |

| 5 | 700/1300 | 1100 | 1000 | 1100 | 84.9 | 100 | 39.0 | 75.0 | 77.8 |

| 6 | 700/1300 | 1500 | 1000 | 1500 | 93.4 | 99.9 | 25.0 | 90.7 | 90.2 |

| 7 | 700/1000 | 800/1500 | 1300 | 1100 | 93.9 | 99.8 | 28.7 | 99.0 | 94.2 |

| 8 | 700/1300 | 800/1100 | 1000 | 1500 | 89.1 | 99.9 | 50.0 | 90.0 | 83.7 |

| 9 | 1000/1300 | 1100/1500 | 700 | 800 | 84.9 | 99.9 | 25.0 | 64.8 | 61.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhang, H.; Xiao, Q.; Zhao, L.; Hu, Y.; Liu, H.; Qiao, Y. Numerical Model Driving Multi-Domain Information Transfer Method for Bearing Fault Diagnosis. Sensors 2022, 22, 9759. https://doi.org/10.3390/s22249759

Zhang L, Zhang H, Xiao Q, Zhao L, Hu Y, Liu H, Qiao Y. Numerical Model Driving Multi-Domain Information Transfer Method for Bearing Fault Diagnosis. Sensors. 2022; 22(24):9759. https://doi.org/10.3390/s22249759

Chicago/Turabian StyleZhang, Long, Hao Zhang, Qian Xiao, Lijuan Zhao, Yanqing Hu, Haoyang Liu, and Yu Qiao. 2022. "Numerical Model Driving Multi-Domain Information Transfer Method for Bearing Fault Diagnosis" Sensors 22, no. 24: 9759. https://doi.org/10.3390/s22249759

APA StyleZhang, L., Zhang, H., Xiao, Q., Zhao, L., Hu, Y., Liu, H., & Qiao, Y. (2022). Numerical Model Driving Multi-Domain Information Transfer Method for Bearing Fault Diagnosis. Sensors, 22(24), 9759. https://doi.org/10.3390/s22249759